Effect of Processing Temperature and the Content of Carbon Nanotubes on the Properties of Nanocomposites Based on Polyphenylene Sulfide

Abstract

1. Introduction

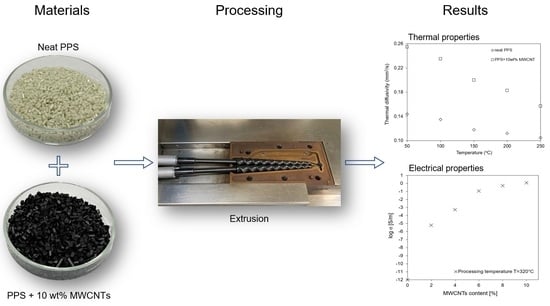

2. Materials and Methods

2.1. Materials

2.2. Measurement Methods

3. Results and Discussion

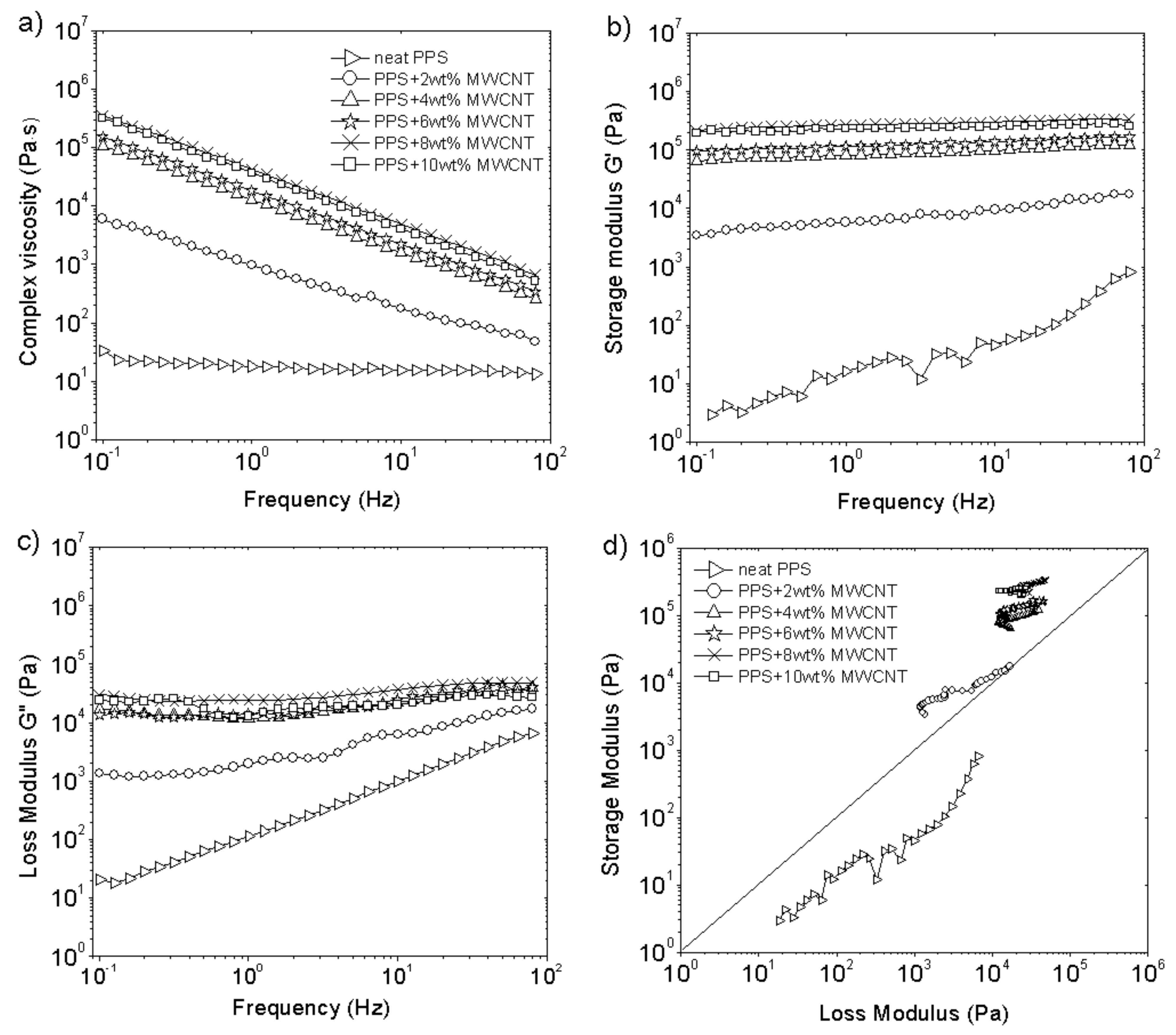

3.1. Rheological Properties

3.2. Microscope Observations

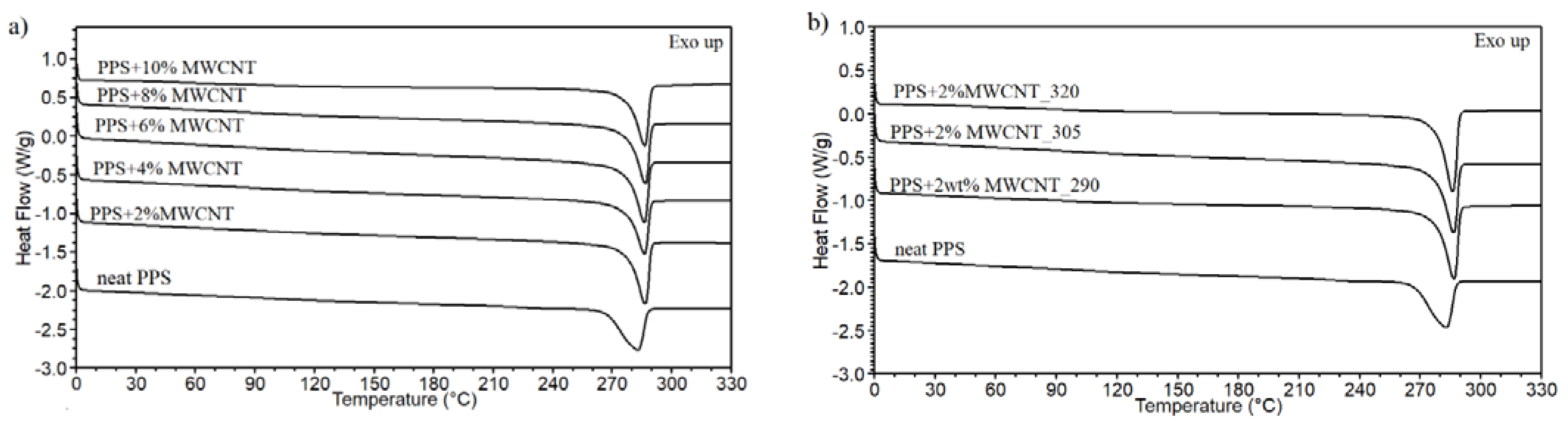

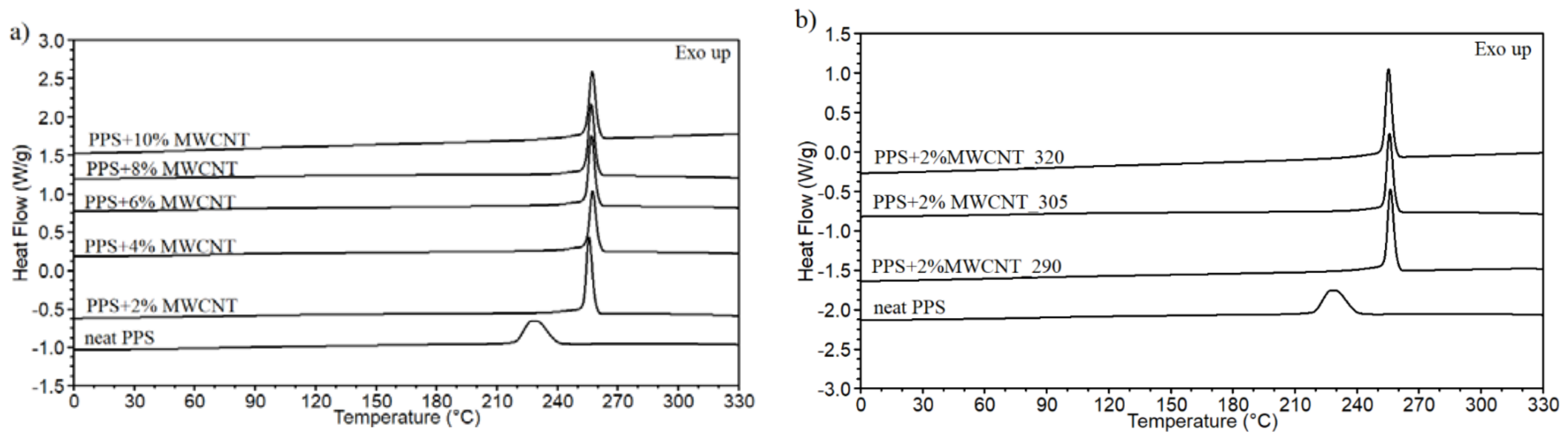

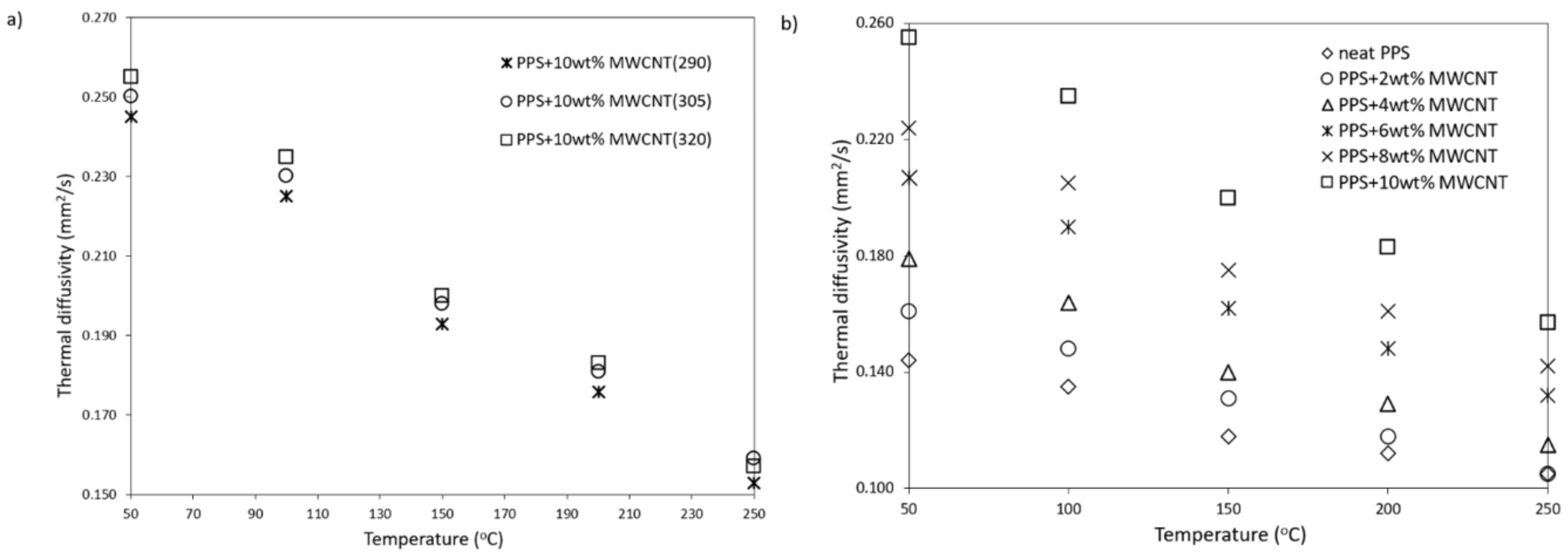

3.3. Thermal Properties

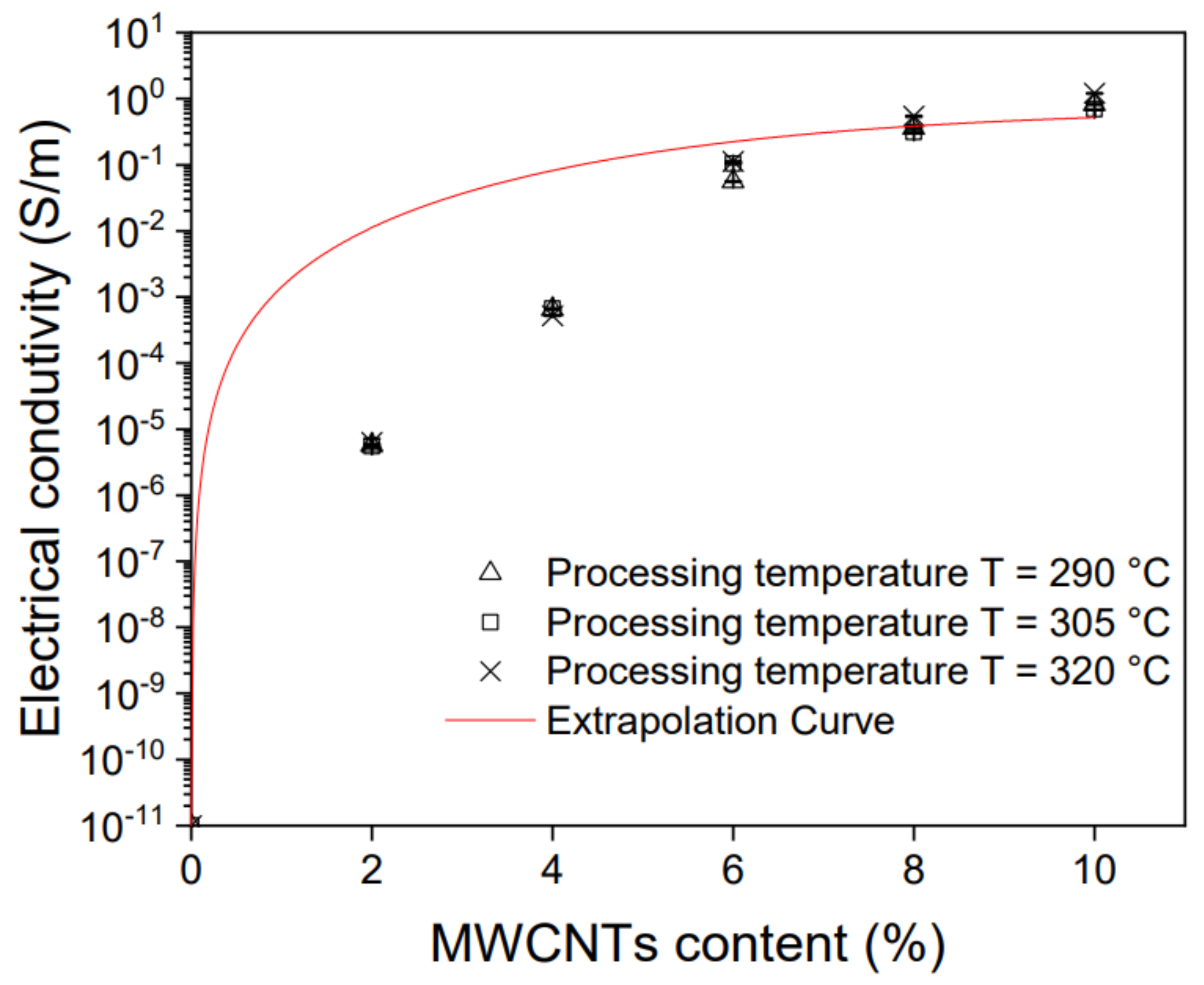

3.4. Electrical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Corea, J.R.; Flynn, A.M.; Lechêne, B.; Scott, G.; Reed, G.D.; Shin, P.J.; Lustig, M.; Arias, A.C. Screen-printed flexible MRI receive coils. Nat. Commun. 2016, 7, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, C.J.; Bahadur, S. The role of filler deformability, filler-polymer bonding, and counterface material on the tribological behavior of polyphenylene sulfide (PPS). Wear 2001, 250, 1532–1540. [Google Scholar] [CrossRef]

- Menzel, F.; Klein, T.; Ziegler, T.; Neumaier, J.M. 3D-printed PEEK reactors and development of a complete continuous flow system for chemical synthesis. React. Chem. Eng. 2020, 5, 1300–1310. [Google Scholar] [CrossRef]

- Yu, L.; Yang, S.; Liu, W.; Xue, Q. Investigation of the friction and wear behaviors of polyphenylene sulfide filled with solid lubricants. Polym. Eng. Sci. 2000, 40, 1825–1832. [Google Scholar] [CrossRef]

- Deng, Y.; Yang, Y.; Ma, Y.; Fan, K.; Yang, W.; Yin, G. Nano-hydroxyapatite reinforced polyphenylene sulfide biocomposite with superior cytocompatibility and in vivo osteogenesis as a novel orthopedic implant. RSC Adv. 2017, 7, 559–573. [Google Scholar] [CrossRef]

- Kulpinski, P.; Czarnecki, P.; Niekraszewicz, B.; Jeszka, J.K. Functional nanocomposite poly(phenylene sulphide) fibres—Preliminary studies. Fibres Text. East. Eur. 2016, 24, 20–26. [Google Scholar] [CrossRef][Green Version]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Overall Investigation of Poly (Phenylene Sulfide) from Synthesis and Process to Applications—A Review. Macromol. Mater. Eng. 2019, 304, 1–27. [Google Scholar] [CrossRef]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Polyphenylene sulfide (PPS): State of the art and applications. Rev. Chem. Eng. 2013, 29, 471–489. [Google Scholar] [CrossRef]

- Lv, C.; Wang, H.; Liu, Z.; Wang, C.; Li, H.; Zhao, Y.; Zhu, Y. A fluorine-free superhydrophobic PPS composite coating with high thermal stability, wear resistance, corrosion resistance. Prog. Org. Coatings 2017, 110, 47–54. [Google Scholar] [CrossRef]

- Chen, G.; Mohanty, A.K.; Misra, M. Progress in research and applications of Polyphenylene Sulfide blends and composites with carbons. Compos. Part B Eng. 2021, 209, 108553. [Google Scholar] [CrossRef]

- Yu, Y.; Xiong, S.; Huang, H.; Zhao, L.; Nie, K.; Chen, S.; Xu, J.; Yin, X.; Wang, H.; Wang, L. Fabrication and application of poly (phenylene sulfide) ultrafine fiber. React. Funct. Polym. 2020, 150, 104539. [Google Scholar] [CrossRef]

- Liang, J.Z. Heat distortion temperature of PPS/PC blend, PPS/PC nanocomposite and PPS/PC/GF hybrid nanocomposite. J. Polym. Eng. 2013, 33, 483–488. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, G.; Yang, Q.; Shi, X.; Li, J.; Zhang, H.; Qin, J. Tailored morphologies and properties of high-performance microcellular poly(phenylene sulfide)/poly(ether ether ketone) (PPS/PEEK) blends. J. Supercrit. Fluids 2018, 140, 116–128. [Google Scholar] [CrossRef]

- Jiang, Z.; Gyurova, L.A.; Schlarb, A.K.; Friedrich, K.; Zhang, Z. Study on friction and wear behavior of polyphenylene sulfide composites reinforced by short carbon fibers and sub-micro TiO2 particles. Compos. Sci. Technol. 2008, 68, 734–742. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, W.; Li, Y.; Yan, C. Isothermal crystallization kinetics of poly(phenylene sulfide)/ZnO composites. Adv. Mater. Res. 2012, 535–537, 243–246. [Google Scholar] [CrossRef]

- Goyal, R.K.; Kambale, K.R.; Nene, S.S.; Selukar, B.S.; Arbuj, S.; Mulik, U.P. Fabrication, thermal and electrical properties of polyphenylene sulphide/copper composites. Mater. Chem. Phys. 2011, 128, 114–120. [Google Scholar] [CrossRef]

- Yang, J.; Xu, T.; Lu, A.; Zhang, Q.; Tan, H.; Fu, Q. Preparation and properties of poly (p-phenylene sulfide)/multiwall carbon nanotube composites obtained by melt compounding. Compos. Sci. Technol. 2009, 69, 147–153. [Google Scholar] [CrossRef]

- Park, M.; Park, J.H.; Yang, B.J.; Cho, J.; Kim, S.Y.; Jung, I. Enhanced interfacial, electrical, and flexural properties of polyphenylene sulfide composites filled with carbon fibers modified by electrophoretic surface deposition of multi-walled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2018, 109, 124–130. [Google Scholar] [CrossRef]

- Seki, Y.; Kizilkan, E.; İşbilir, A.; Sarikanat, M.; Altay, L. Enhanced in-plane and through-plane thermal conductivity and mechanical properties of polyamide 4.6 composites loaded with hybrid carbon fiber, synthetic graphite and graphene. Polym. Compos. 2021, 42, 4630–4642. [Google Scholar] [CrossRef]

- Deng, S.; Lin, Z.; Xu, B.; Qiu, W.; Liang, K.; Li, W. Isothermal crystallization kinetics, morphology, and thermal conductivity of graphene nanoplatelets/polyphenylene sulfide composites. J. Therm. Anal. Calorim. 2014, 118, 197–203. [Google Scholar] [CrossRef]

- Gu, J.; Xie, C.; Li, H.; Dang, J.; Geng, W.; Zhang, Q. Thermal Percolation Behavior of Graphene Nanoplatelets/Polyphenylene Sulfide Thermal Conductivity Composites Junwei. Polym. Compos. 2014, 35, 1087–1092. [Google Scholar] [CrossRef]

- Xing, J.; Xu, Z.; Ni, Q.Q.; Ke, H. Preparation and characterization of polyphenylene sulfide/graphene nanoplatelets composite fibers with enhanced oxidation resistance. High Perform. Polym. 2020, 32, 394–405. [Google Scholar] [CrossRef]

- Retolaza, J.; Ansola, R.; Gómez, J.L.; Díez, G. Identifying elastic constants for pps technical material when designing and printing parts using fdm technology. Materials 2021, 14, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Parans Paranthaman, M.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive manufacturing of isotropic NdFeB PPS bonded permanent magnets. Materials 2020, 13, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Boczkowska, A.; Latko, P. Sposób Wytwarzania Włókien i Włókniny z Nanorurkami Węglowymi. Polish Patent Pl 221848 B1, 30 June 2016. [Google Scholar]

- Dydek, K.; Latko-Durałek, P.; Boczkowska, A.; Sałaciński, M.; Kozera, R. Carbon Fiber Reinforced Polymers Modified with Thermoplastic Nonwovens Containing Multi-Walled Carbon Nanotubes. Compos. Sci. Technol. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Dydek, K.; Golonko, E.; Boczkowska, A. Mechanical properties of PETG fibres and their usage in carbon fibres/epoxy composite laminates. Fibres Text. East. Eur. 2018, 26. [Google Scholar] [CrossRef]

- Latko-Duralek, P.; Dydek, K.; Bolimowski, P.; Golonko, E.; Duralek, P.; Kozera, R.; Boczkowska, A. Nonwoven fabrics with carbon nanotubes used as interleaves in CFRP. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012033. [Google Scholar] [CrossRef]

- Quan, D.; Mischo, C.; Binsfeld, L.; Ivankovic, A.; Murphy, N. Fracture behaviour of carbon fibre/epoxy composites interleaved by MWCNT- and graphene nanoplatelet-doped thermoplastic veils. Compos. Struct. 2020, 235, 111767. [Google Scholar] [CrossRef]

- Dydek, K.; Boczkowska, A.; Latko-Durałek, P.; Wilk, M.; Padykuła, K.; Kozera, R. Effect of the areal weight of CNT-doped veils on CFRP electrical properties. J. Compos. Mater. 2020, 54, 2677–2685. [Google Scholar] [CrossRef]

- Kasaliwal, G.R.; Pegel, S.; Göldel, A.; Pötschke, P.; Heinrich, G. Analysis of agglomerate dispersion mechanisms of multiwalled carbon nanotubes during melt mixing in polycarbonate. Polymer 2010, 51, 2708–2720. [Google Scholar] [CrossRef]

- Nohara, L.B.; Nohara, E.L.; Moura, A.; Gonçalves, J.M.R.P.; Costa, M.L.; Rezende, M.C. Study of crystallization behavior of poly(phenylene sulfide). Polimeros 2006, 16, 104–110. [Google Scholar] [CrossRef]

- Nobile, M.R. Rheology of Polymer-Carbon Nanotube Composites Melts; Woodhead Publishing Limited: Sawstln, UK, 2011; ISBN 9781845697617. [Google Scholar]

- Jin, S.H.; Choi, D.K.; Lee, D.S. Electrical and rheological properties of polycarbonate/multiwalled carbon nanotube nanocomposites. Colloids Surf. Physicochem. Eng. Asp. 2008, 313–314, 242–245. [Google Scholar] [CrossRef]

- Bangarusampath, D.S.; Ruckdäschel, H.; Altstädt, V.; Sandler, J.K.W.; Garray, D.; Shaffer, M.S.P. Rheological and electrical percolation in melt-processed poly(ether ether ketone)/multi-wall carbon nanotube composites. Chem. Phys. Lett. 2009, 482, 105–109. [Google Scholar] [CrossRef]

- Pegel, S.; Pötschke, P.; Petzold, G.; Alig, I.; Dudkin, S.M.; Lellinger, D. Dispersion, agglomeration, and network formation of multiwalled carbon nanotubes in polycarbonate melts. Polymer 2008, 49, 974–984. [Google Scholar] [CrossRef]

- Villmow, T.; Kretzschmar, B.; Pötschke, P. Influence of screw configuration, residence time, and specific mechanical energy in twin-screw extrusion of polycaprolactone/multi-walled carbon nanotube composites. Compos. Sci. Technol. 2010, 70, 2045–2055. [Google Scholar] [CrossRef]

- Noll, A.; Burkhart, T. Morphological characterization and modelling of electrical conductivity of multi-walled carbon nanotube/poly(p-phenylene sulfide) nanocomposites obtained by twin screw extrusion. Compos. Sci. Technol. 2011, 71, 499–505. [Google Scholar] [CrossRef]

- Villmow, T.; Pötschke, P.; Pegel, S.; Häussler, L.; Kretzschmar, B. Influence of twin-screw extrusion conditions on the dispersion of multi-walled carbon nanotubes in a poly(lactic acid) matrix. Polymer 2008, 49, 3500–3509. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Crystallization behavior of nylon 6 nanocomposites. Polymer 2003, 44, 3945–3961. [Google Scholar] [CrossRef]

- Krause, B.; Villmow, T.; Boldt, R.; Mende, M.; Petzold, G.; Pötschke, P. Influence of dry grinding in a ball mill on the length of multiwalled carbon nanotubes and their dispersion and percolation behaviour in melt mixed polycarbonate composites. Compos. Sci. Technol. 2011, 71, 1145–1153. [Google Scholar] [CrossRef]

- Socher, R.; Krause, B.; Hermasch, S.; Wursche, R.; Pötschke, P. Electrical and thermal properties of polyamide 12 composites with hybrid fillers systems of multiwalled carbon nanotubes and carbon black. Compos. Sci. Technol. 2011, 71, 1053–1059. [Google Scholar] [CrossRef]

| Material | Extrusion Temp. (°C) | TGA | DSC | ||||

|---|---|---|---|---|---|---|---|

| T2% (°C) | T5% (°C) | Td (°C) | Tm (°C) | Xc (%) | Tc (°C) | ||

| neat PPS | 453 | 481 | 521 | 283 | 54.5 | 228 | |

| PPS + 10% masterbatch | 467 | 493 | 535 | 286 | 59.3 | 257 | |

| PPS + 2% MWCNT | 290 | 456 | 486 | 531 | 287 | 66.5 | 256 |

| PPS + 4% MWCNT | 452 | 484 | 532 | 287 | 53.2 | 257 | |

| PPS + 6% MWCNT | 451 | 483 | 535 | 286 | 61.8 | 257 | |

| PPS + 8% MWCNT | 453 | 484 | 533 | 286 | 58.7 | 257 | |

| PPS + 10% MWCNT | 451 | 482 | 530 | 287 | 65.3 | 257 | |

| PPS + 2% MWCNT | 305 | 454 | 487 | 535 | 287 | 57.3 | 256 |

| PPS + 4% MWCNT | 453 | 484 | 531 | 286 | 53.3 | 258 | |

| PPS + 6% MWCNT | 454 | 485 | 534 | 287 | 58.9 | 257 | |

| PPS + 8% MWCNT | 454 | 484 | 534 | 286 | 73.1 | 257 | |

| PPS + 10% MWCNT | 457 | 486 | 535 | 286 | 61.1 | 257 | |

| PPS + 2% MWCNT | 320 | 452 | 484 | 533 | 286 | 60.6 | 255 |

| PPS + 4% MWCNT | 457 | 487 | 532 | 287 | 67.5 | 257 | |

| PPS + 6% MWCNT | 454 | 484 | 534 | 287 | 65.7 | 257 | |

| PPS + 8% MWCNT | 456 | 486 | 538 | 287 | 64.1 | 257 | |

| PPS + 10% MWCNT | 453 | 483 | 534 | 286 | 54.1 | 257 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dydek, K.; Latko-Durałek, P.; Sulowska, A.; Kubiś, M.; Demski, S.; Kozera, P.; Sztorch, B.; Boczkowska, A. Effect of Processing Temperature and the Content of Carbon Nanotubes on the Properties of Nanocomposites Based on Polyphenylene Sulfide. Polymers 2021, 13, 3816. https://doi.org/10.3390/polym13213816

Dydek K, Latko-Durałek P, Sulowska A, Kubiś M, Demski S, Kozera P, Sztorch B, Boczkowska A. Effect of Processing Temperature and the Content of Carbon Nanotubes on the Properties of Nanocomposites Based on Polyphenylene Sulfide. Polymers. 2021; 13(21):3816. https://doi.org/10.3390/polym13213816

Chicago/Turabian StyleDydek, Kamil, Paulina Latko-Durałek, Agata Sulowska, Michał Kubiś, Szymon Demski, Paulina Kozera, Bogna Sztorch, and Anna Boczkowska. 2021. "Effect of Processing Temperature and the Content of Carbon Nanotubes on the Properties of Nanocomposites Based on Polyphenylene Sulfide" Polymers 13, no. 21: 3816. https://doi.org/10.3390/polym13213816

APA StyleDydek, K., Latko-Durałek, P., Sulowska, A., Kubiś, M., Demski, S., Kozera, P., Sztorch, B., & Boczkowska, A. (2021). Effect of Processing Temperature and the Content of Carbon Nanotubes on the Properties of Nanocomposites Based on Polyphenylene Sulfide. Polymers, 13(21), 3816. https://doi.org/10.3390/polym13213816