Effect of Glue Spreads on the Structural Properties of Laminated Veneer Lumber from Spindleless Rotary Veneers Recovered from Short Rotation Hevea Plantation Logs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of LVL

2.2. Evaluation

2.2.1. Determine the Moisture Content

2.2.2. Determine the Density

2.2.3. Determine the Specific Gravity

2.2.4. Determining the Water Absorption and Radial, Tangential, Longitudinal and Volumetric Swelling

2.2.5. Determining the Modulus of Rupture (MOR) and Modulus of Elasticity (MOE)

2.2.6. Determining the Compressive Strength Parallel to the Longitudinal Axis

2.2.7. Determining the Tensile Strength Parallel to the Longitudinal Axis

2.2.8. Determining the Gluebond Shear Strength

2.2.9. Scanning Electron Microscopy (SEM)

2.3. Statistical Analysis

3. Results and Discussion

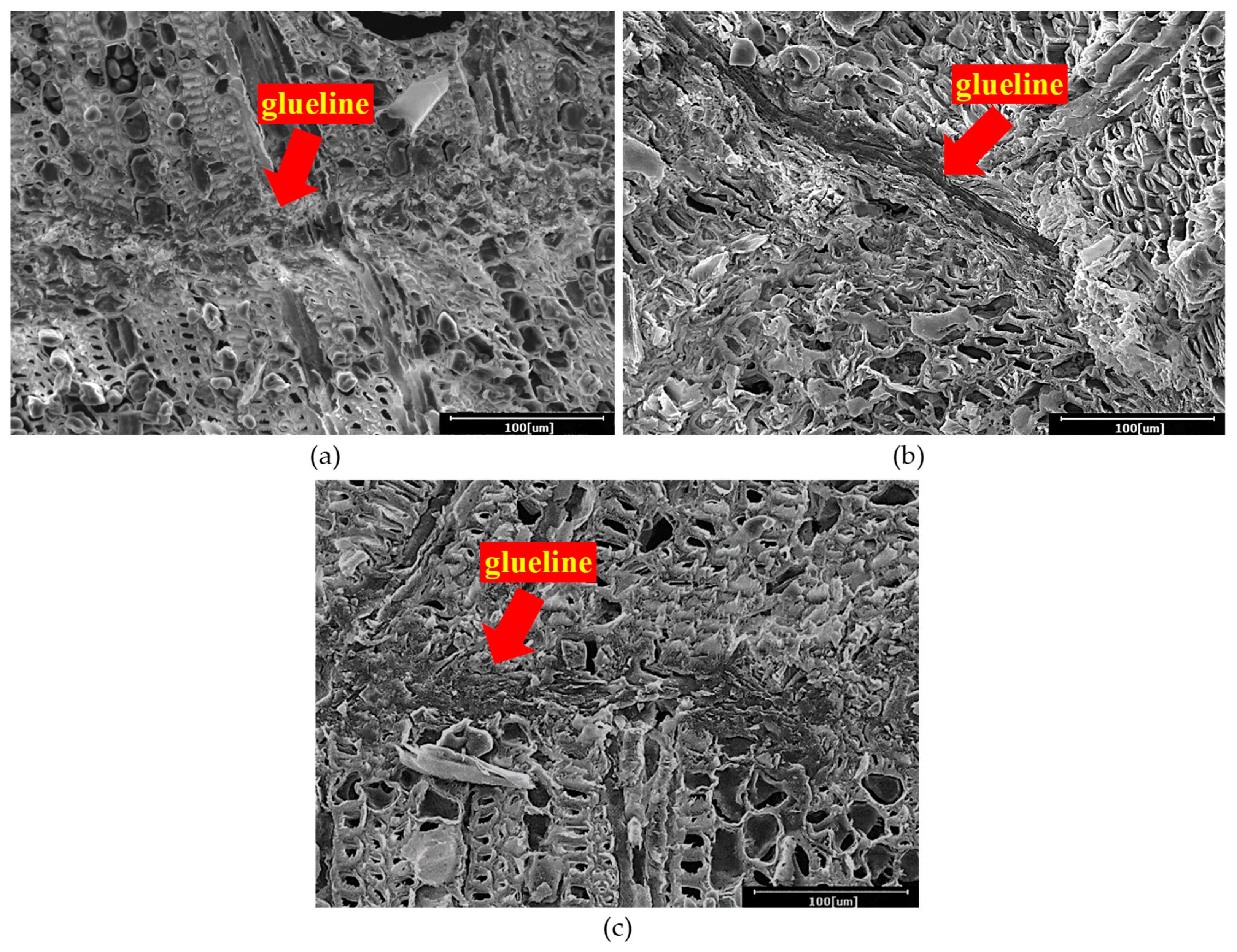

3.1. Morphological Properties

3.2. Physical Properties

3.2.1. Moisture Content, Density and Specific Gravity

3.2.2. Water Absorption

3.2.3. Dimensional Stability

3.3. Mechanical Properties

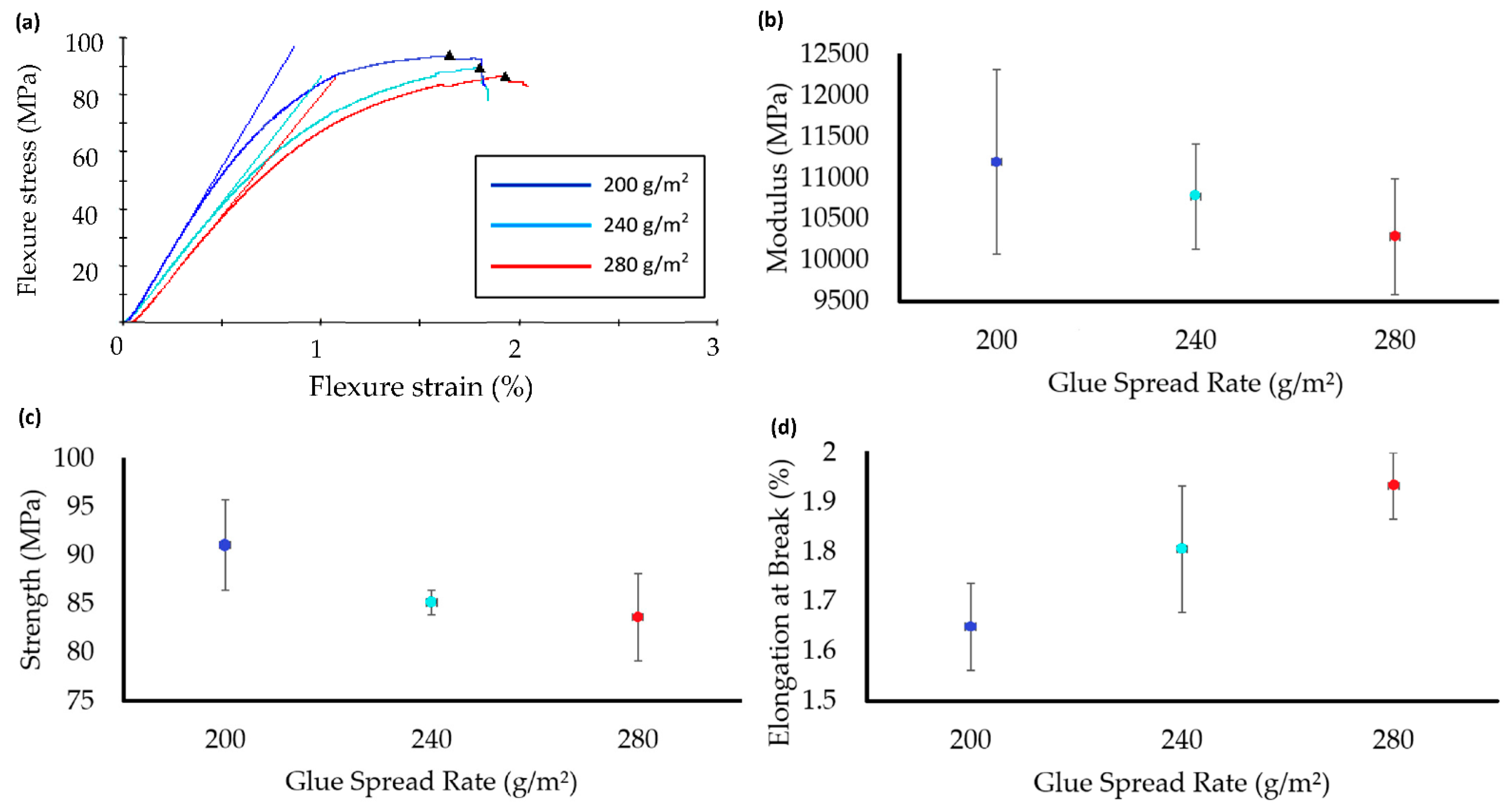

3.3.1. Modulus of Rupture (MOR) and Modulus of Elasticity (MOE)

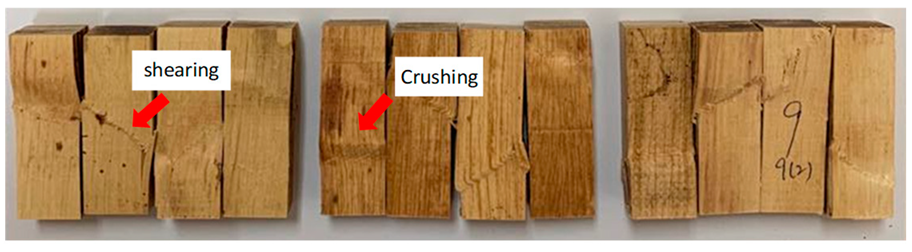

3.3.2. Compressive Strength Parallel to the Longitudinal Axis

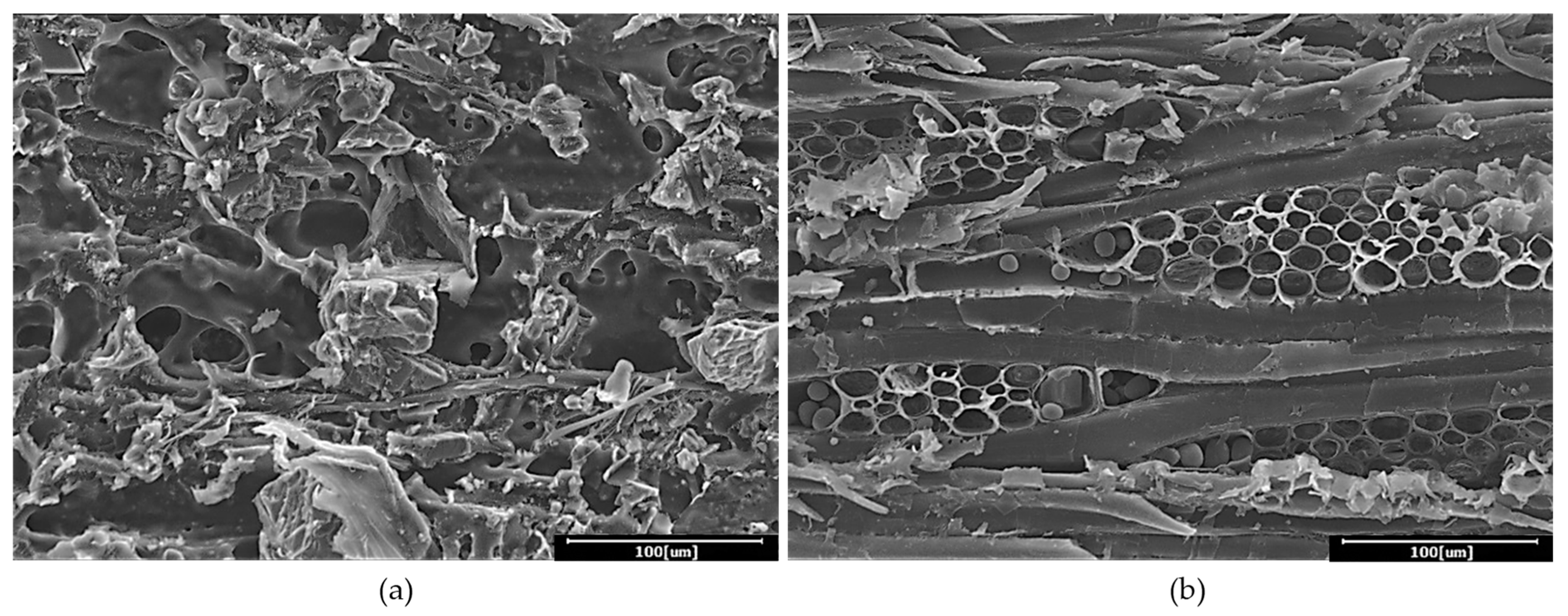

3.3.3. Tensile Strength Parallel to the Longitudinal Axis

3.3.4. Gluebond Shear Strength and Percentage of Wood Failure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khoo, P.S.; H’ng, P.S.; Chin, K.L.; Bakar, E.S.; Maminski, M.; Raja-Ahmad, R.N.; Lee, C.L.; Ashikin, S.N.; Saharudin, M.H. Peeling of small diameter rubber log using spindleless lathe technology: Evaluation of veneer properties from outer to inner radial section of log at different veneer thicknesses. Eur. J. Wood Wood Prod. 2018, 76, 1335–1346. [Google Scholar] [CrossRef]

- Ulker, O. Wood Adhesives and Bonding Theory. In Adhesives—Applications and Properties; Rudawska, A., Ed.; IntechOpen: London, UK, 2016; pp. 271–288. ISBN 978-953-51-2784-0. [Google Scholar]

- Frihart, C.R. Wood Adhesion and Adhesives. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 215–278. ISBN 0849315883. [Google Scholar]

- Kurt, R.; Cil, M. Effects of press pressures on glueline thickness and properties of laminated veneer lumber glued with phenol formaldehyde adhesive. BioResources 2012, 7, 5346–5354. [Google Scholar] [CrossRef] [Green Version]

- Vick, C.B. Adhesive Bonding of Wood Materials. In Wood Handbook: Wood as an Engineering Material; General Technical Report FPL; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; pp. 9-1–9-24. [Google Scholar]

- Daoui, A.; Descamps, C.; Marchal, R.; Zerizer, A. Influence of veneer quality on beech LVL mechanical properties. Maderas Cienc. y Tecnol. 2011, 13, 69–83. [Google Scholar] [CrossRef] [Green Version]

- Loh, Y.F.; Paridah, M.T.; Yeoh, B.H. Density distribution of oil palm stem veneer and its influence on plywood mechanical properties. J. Appl. Sci. 2011, 11, 824–831. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Adhesives with Wood Materials—Bond Formation and Performance. In Wood Handbook: Wood as an Engineering Material; Centennial, Ed.; U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 9-1–9-24. [Google Scholar]

- Mohd Yusof, N.; Md Tahir, P.; Muhammad Roseley, A.S.; Lee, S.H.; Abdul Halip, J.; Mohammad Suffian James, R.; Ashaari, Z. Bond integrity of cross laminated timber from Acacia mangium wood as affected by adhesive types, pressing pressures and loading direction. Int. J. Adhes. Adhes. 2019, 94, 24–28. [Google Scholar] [CrossRef]

- Darmawan, W.; Nandika, D.; Massijaya, Y.; Kabe, A.; Rahayu, I.; Denaud, L.; Ozarska, B. Lathe check characteristics of fast growing sengon veneers and their effect on LVL glue-bond and bending strength. J. Mater. Process. Technol. 2015, 215, 181–188. [Google Scholar] [CrossRef] [Green Version]

- Khoo, P.S.; Chin, K.L.; H’ng, P.S.; Lee, C.L.; Bakar, E.S.; Ashaari, Z.; Abdullah, L.C.; Gandaseca, S. Laminated veneer lumber from spindleless rotary-peeled veneers produced from short rotation, small hevea plantation logs: Effects of lamination pressure. BioResources 2020, 15, 6735–6751. [Google Scholar] [CrossRef]

- ASTM D4442-07: Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D2395-14: Standard Test Methods for Specific Gravity of Wood-based Materials; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D1037-12: Standard Test Methods for Evaluating Properties of Wood-Based Fiber and Particle Panel Materials; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D5456-10: Standard Test Methods for Evaluation of Structural Composite Lumber Products; ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D906-11: Standard Test Method for Strength Properties of Adhesives in Plywood Type Construction in Shear by Tension Loading; ASTM International: West Conshohocken, PA, USA, 2011.

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology, 3rd ed.; Pizzi, A., Mittal, K.L., Eds.; CRC Press: New York, NY, USA, 2017; ISBN 9781498736442. [Google Scholar]

- Wang, X.; Huang, L.; Zhang, C.; Deng, Y.; Xie, P.; Liu, L.; Cheng, J. Research advances in chemical modifications of starch for hydrophobicity and its applications: A review. Carbohydr. Polym. 2020, 240, 116292. [Google Scholar] [CrossRef]

- Din, Z.; Chen, L.; Xiong, H.; Wang, Z.; Ullah, I.; Lei, W.; Shi, D.; Alam, M.; Ullah, H.; Khan, S.A. Starch: An Undisputed Potential Candidate and Sustainable Resource for the Development of Wood Adhesive. Starch/Staerke 2020, 72, 1900276. [Google Scholar] [CrossRef]

- Teoh, Y.P.; Don, M.M.; Ujang, S. Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): A case study in Malaysia. J. Wood Sci. 2011, 57, 255–266. [Google Scholar] [CrossRef]

- Wei, B.; Sun, B.; Zhang, B.; Long, J.; Chen, L.; Tian, Y. Synthesis, characterization and hydrophobicity of silylated starch nanocrystal. Carbohydr. Polym. 2016, 136, 1203–1208. [Google Scholar] [CrossRef]

- Jiang, S.; Dai, L.; Qin, Y.; Xiong, L.; Sun, Q. Preparation and characterization of octenyl succinic anhydride modified taro starch nanoparticles. PLoS ONE 2016, 11, e0150043. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Sagir, M.; Tahir, M.S.; Ullah, S. Phenol Formaldehyde Resin for Hydrophilic Cellulose Paper. In Advances in Sustainable and Environmental Hydrology, Hydrogeology, Hydrochemistry and Water Resources; Charminé, H., Ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 89–92. ISBN 9783030015725. [Google Scholar]

- De Oliveira, R.G.E.; Gonçalves, F.G.; de Segundinho, P.G.A.; da Oliveira, J.T.S.; Paes, J.B.; Chaves, I.L.S.; Brito, A.S. Analysis of glueline and correlations between density and anatomical characteristics of Eucalyptus grandis x Eucalyptus urophylla glulam. Maderas Cienc. Tecnol. 2020, 22, 495–504. [Google Scholar] [CrossRef]

- Tienne, D.L.C.; Nascimento, A.M.; Garcia, R.A.; Silva, D.B. Adhesion quality of pine wood glued joints under internal and external service conditions. Floresta Ambient. 2011, 18, 16–29. [Google Scholar] [CrossRef]

- APA. PRL-501: Performance Standard for Laminated Veneer Lumber; APA—The Engineered Wood Association: Tacoma, WA, USA, 2000. [Google Scholar]

- Sulastiningsih, I.M.; Trisatya, D.R.; Balfas, J. Some properties of laminated veneer lumber manufactured from oil palm trunk. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 012019. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Nurul Fazita, M.R.; Bhat, A.H.; Jawaid, M.; Nik Fuad, N.A. Development and material properties of new hybrid plywood from oil palm biomass. Mater. Des. 2010, 31, 417–424. [Google Scholar] [CrossRef]

- Hashim, R.; Sarmin, S.N.; Sulaiman, O.; Yusof, L.H.M. Effects of cold setting adhesives on properties of laminated veneer lumber from oil palm trunks in comparison with rubberwood. Eur. J. Wood Wood Prod. 2011, 69, 53–61. [Google Scholar] [CrossRef]

- Sulaiman, O.; Salim, N.; Hashim, R.; Yusof, L.H.M.; Razak, W.; Yunus, N.Y.M.; Hashim, W.S.; Azmy, M.H. Evaluation on the suitability of some adhesives for laminated veneer lumber from oil palm trunks. Mater. Des. 2009, 30, 3572–3580. [Google Scholar] [CrossRef]

- He, M.; Xu, D.; Li, C.; Ma, Y.; Dai, X.; Pan, X.; Fan, J.; He, Z.; Gui, S.; Dong, X.; et al. Cell wall bulking by maleic anhydride for wood durability improvement. Forests 2020, 11, 367. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Deng, Y.; Li, Y.; Kjoller, K.; Roy, A.; Wang, S. In situ identification of the molecular-scale interactions of phenol-formaldehyde resin and wood cell walls using infrared nanospectroscopy. RSC Adv. 2016, 6, 76318–76324. [Google Scholar] [CrossRef]

- Furuno, T.; Imamura, Y.; Kajita, H. The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: A properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci. Technol. 2004, 37, 349–361. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Alwani, M.S.; Ridzuan, R.; Kamarudin, H.; Khairul, A.; Khalil, H.P.S.A.; Alwani, M.S.; Ridzuan, R.; Kamarudin, H.; Khairul, A. Chemical Composition, Morphological Characteristics, and Cell Wall Structure of Malaysian Oil Palm Fibers. Polym. Plast. Technol. Eng. 2008, 47, 273–280. [Google Scholar] [CrossRef]

- Khalid, I.; Sulaiman, O.; Hashim, R.; Razak, W.; Jumhuri, N.; Rasat, M.S.M. Evaluation on layering effects and adhesive rates of laminated compressed composite panels made from oil palm (Elaeis guineensis) fronds. Mater. Des. 2015, 68, 24–28. [Google Scholar] [CrossRef]

- Shukla, S.R.; Kamdem, D.P. Properties of laboratory made yellow poplar (Liriodendron tulipifera) laminated veneer lumber: Effect of the adhesives. Eur. J. Wood Wood Prod. 2009, 67, 397–405. [Google Scholar] [CrossRef]

- Rowell, R.M.; Youngs, R.L. Dimensional Stabilization of Wood in Use; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1981. [Google Scholar]

- Augustina, S.; Wahyudi, I.; Darmawan, I.W.; Malik, J.; Basri, E.; Kojima, Y. Specific gravity and dimensional stability of boron-densified wood on three lesser-used species from Indonesia. J. Korean Wood Sci. Technol. 2020, 48, 458–471. [Google Scholar] [CrossRef]

- Chai, L.Y.; H’Ng, P.S.; Lim, C.G.; Chin, K.L.; Jusoh, M.Z.; Bakar, E.S. Production of oil palm trunk core board with wood veneer lamination. J. Oil Palm Res. 2011, 23, 1166–1171. [Google Scholar]

- Nuryawan, A.; Abdullah, C.K.; Hazwan, C.M.; Olaiya, N.G.; Yahya, E.B.; Risnasari, I.; Masruchin, N.; Baharudin, M.S.; Khalid, H.; Abdul Khalil, H.P.S. Enhancement of Oil Palm Waste Nanoparticles on the Properties and Characterization of Hybrid. Polymers 2020, 12, 1007. [Google Scholar] [CrossRef]

- Khoo, P.S.; Chin, K.L.; Hng, P.S.; Bakar, E.S.; Lee, C.L.; Go, W.Z.; Dahali, R. Physical properties and bonding quality of laminated veneer lumber produced with veneers peeled from small-diameter rubberwood logs. R. Soc. Open Sci. 2019, 6. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Hu, X.; Huang, Z.; Chen, Y.; Han, H.; Xiao, C. Effect of several modifiers on the mechanical and tribological properties of phenol formaldehyde resin. High Perform. Polym. 2018, 30, 580–590. [Google Scholar] [CrossRef]

- De Boever, L.; Vansteenkiste, D.; Van Acker, J.; Stevens, M. End-use related physical and mechanical properties of selected fast-growing poplar hybrids (Populus trichocarpa x P. deltoides). Ann. For. Sci. 2007, 64, 621–630. [Google Scholar] [CrossRef] [Green Version]

- Bekhta, P.; Sedliačik, J.; Bekhta, N. Effects of selected parameters on the bonding quality and temperature evolution inside plywood during pressing. Polymers 2020, 12, 1035. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.J.; Dai, C. Hot-pressing stress graded aspen veneer for laminated veneer lumber (LVL). Holzforschung 2005, 59, 10–17. [Google Scholar] [CrossRef]

- López, L.F.; Correal, J.F. Exploratory study of the glued laminated bamboo Guadua angustifolia as a structural material. Maderas Cienc. Technol. 2009, 11, 171–182. [Google Scholar]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Trociński, A. Flour fillers with urea-formaldehyde resin in plywood. BioResources 2019, 14, 6727–6735. [Google Scholar] [CrossRef]

- NIST. PS 2-04: Performance Standard for Wood-Based Structural-Use Panels; United States Department of Commerce: Washington, DC, USA, 2004.

| Lathe Check Properties | Contact Angle (°C) after 10 s | |

|---|---|---|

| Depth (%) | Frequency per 5 cm | |

| 50 ± 15 | 30 ± 10 | 6 |

| Test | Size of Specimen (mm) | Number of Specimen Tested per Board |

|---|---|---|

| Moisture content | 50 × 50 × 12 | 6 |

| Density; specific gravity | 50 × 50 × 12 | 6 |

| Water absorption | 50 × 50 × 12 | 6 |

| Radial; tangential; longitudinal; volumetric swelling | 50 × 50 × 12 | 6 |

| Static bending in the flatwise direction | 316 × 50 × 12 | 6 |

| Compression parallel to the longitudinal axis | 60 ×20 × 12 | 3 |

| Tension parallel to the longitudinal axis | 250 × 25 × 12 | 3 |

| Gluebond shear test | 81 × 25 × 12 | 3 |

| Physical Properties | Glue Spread Rate (g/m2) | Pr > F | ||

|---|---|---|---|---|

| 200 | 240 | 280 | ||

| Moisture content (%) | 12.68 a (2.66) | 12.91 a (4.92) | 13.13 a (6.32) | n.s |

| Density (kg/m3) | 864.11 a (2.44) | 874.73 ab (2.82) | 893.02 b (3.18) | ** |

| Specific gravity | 0.8261 a (2.66) | 0.8611 b (2.56) | 0.8793 c (2.42) | ** |

| Water absorption after 2 h (%) | 9.67 b (6.53) | 9.14 b (8.89) | 7.98 a (11.22) | ** |

| Water absorption after 24 h (%) | 28.56 b (3.89) | 26.01 a (5.93) | 25.48 a (5.46) | ** |

| Radial swelling after 2 h (%) | 2.59 b (16.21) | 2.35 b (12.44) | 2.00 a (16.52) | ** |

| Radial swelling after 24 h (%) | 4.93 b (11.98) | 4.82 b (13.09) | 4.00 a (16.39) | ** |

| Tangential swelling after 2 h (%) | 0.566 b (6.99) | 0.570 b (10.39) | 0.518 a (3.67) | ** |

| Tangential swelling after 24 h (%) | 1.342 b (10.21) | 1.192 a (12.21) | 1.154 a (12.71) | ** |

| Longitudinal swelling after 2 h (%) | 0.122 b (17.05) | 0.090 a (19.62) | 0.076 a (19.46) | ** |

| Longitudinal swelling after 24 h (%) | 0.146 b (13.27) | 0.153 b (15.91) | 0.118 a (18.67) | ** |

| Volumetric swelling after 2 h (%) | 3.51 b (12.47) | 3.17 a (10.04) | 2.88 a (13.86) | ** |

| Volumetric swelling after 24 h (%) | 6.72 b (15.10) | 6.45 b (9.99) | 5.44 a (14.57) | ** |

| Mechanical Properties | Glue Spread Rate (g/m2) | Pr > F | ||

|---|---|---|---|---|

| 200 | 240 | 280 | ||

| MOR in flatwise direction (MPa) | 91.0518 a (5.15) | 85.1048 b (1.53) | 83.5965 b (5.44) | ** |

| MOE in flatwise direction (MPa) | 11189.55 a (10.04) | 10767.51 a (5.99) | 10278.66 a (6.88) | n.s |

| Compressive strength parallel to the longitudinal axis (MPa) | 50.2340 a (5.74) | 48.0382 b (4.38) | 46.9340 b (4.47) | ** |

| Tensile strength parallel to the longitudinal axis (MPa) | 50.3791 a (5.17) | 51.1458 a (6.11) | 50.3899 a (2.43) | n.s |

| Gluebond shear strength (MPa) | 6.46 a (4.64) | 6.44 a (8.88) | 5.84 a (12.33) | n.s |

| Glue Spread Rate (g/m2) | Compression Failure Characteristics | Percentage of Specimens with Failure Modes (%) | Percentage of Specimens with Total Delamination (%) | |

|---|---|---|---|---|

| Crushing | Shearing | |||

| 200 |  | 50 | 50 | 0 |

| 240 |  | 33 | 67 | 18 |

| 280 |  | 25 | 75 | 33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoo, P.S.; Chin, K.L.; Lee, C.L.; H’ng, P.S.; Hafizuddin, M.S. Effect of Glue Spreads on the Structural Properties of Laminated Veneer Lumber from Spindleless Rotary Veneers Recovered from Short Rotation Hevea Plantation Logs. Polymers 2021, 13, 3799. https://doi.org/10.3390/polym13213799

Khoo PS, Chin KL, Lee CL, H’ng PS, Hafizuddin MS. Effect of Glue Spreads on the Structural Properties of Laminated Veneer Lumber from Spindleless Rotary Veneers Recovered from Short Rotation Hevea Plantation Logs. Polymers. 2021; 13(21):3799. https://doi.org/10.3390/polym13213799

Chicago/Turabian StyleKhoo, Pui San, Kit Ling Chin, Chuan Li Lee, Paik San H’ng, and Mohd Sahfani Hafizuddin. 2021. "Effect of Glue Spreads on the Structural Properties of Laminated Veneer Lumber from Spindleless Rotary Veneers Recovered from Short Rotation Hevea Plantation Logs" Polymers 13, no. 21: 3799. https://doi.org/10.3390/polym13213799

APA StyleKhoo, P. S., Chin, K. L., Lee, C. L., H’ng, P. S., & Hafizuddin, M. S. (2021). Effect of Glue Spreads on the Structural Properties of Laminated Veneer Lumber from Spindleless Rotary Veneers Recovered from Short Rotation Hevea Plantation Logs. Polymers, 13(21), 3799. https://doi.org/10.3390/polym13213799