Valorization of Hemp Hurds as Bio-Sourced Additives in PLA-Based Biocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Hemp Hurd Powders

2.2.1. Alkaline Treatment

2.2.2. Alkaline/Peroxide Treatment

2.3. Biocomposite Fabrication

2.4. Characterization

2.4.1. Fourier-Transform Infrared Spectroscopy (FTIR)

2.4.2. Scanning Electron Microscopy (SEM)

2.4.3. X-ray Diffraction (XRD) Analysis

2.4.4. Thermo-Gravimetric Analysis (TGA)

2.4.5. Differential Scanning Calorimetry (DSC)

2.5. Mechanical Testing of Biocomposites

3. Results and Discussion

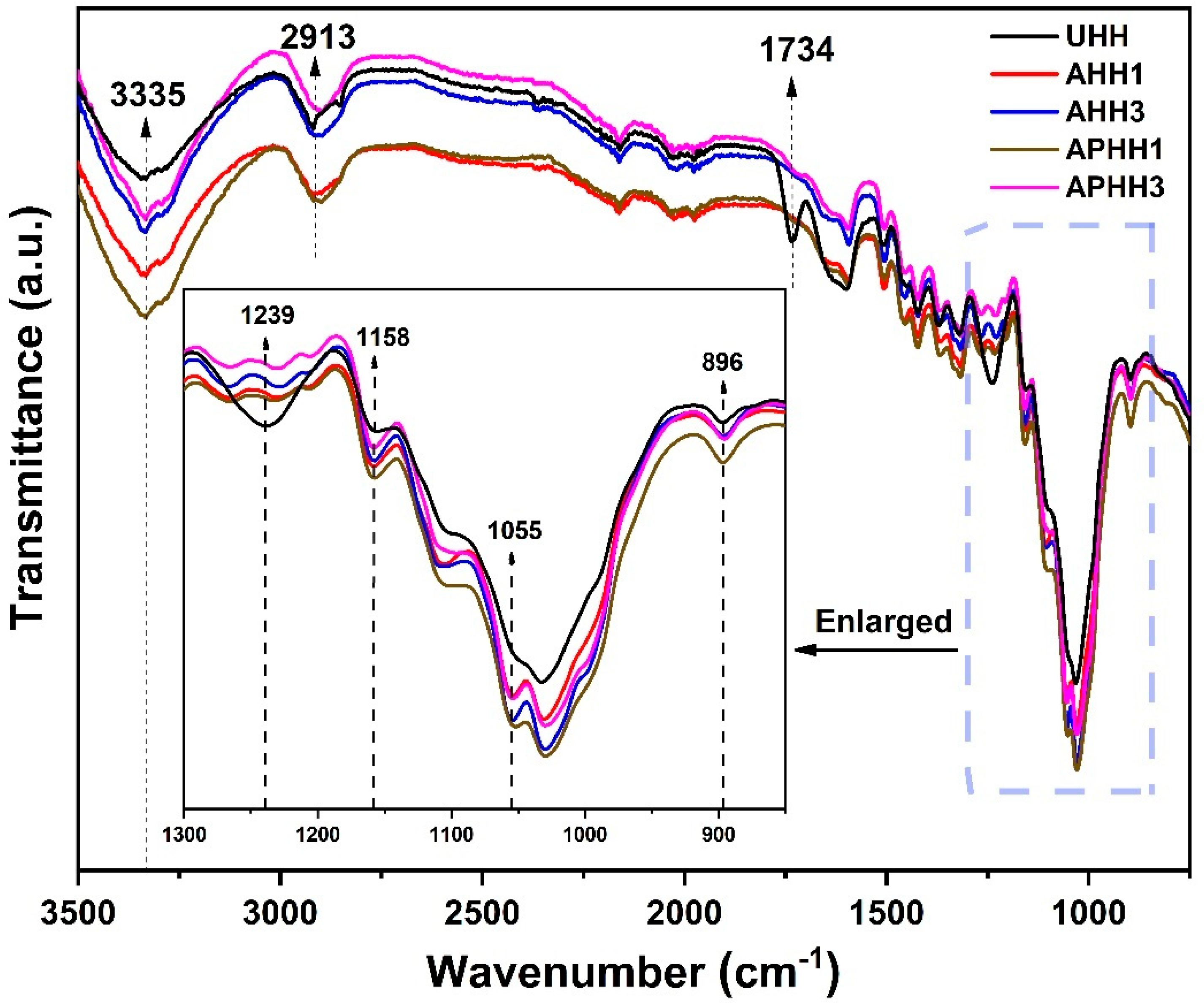

3.1. FTIR Analysis

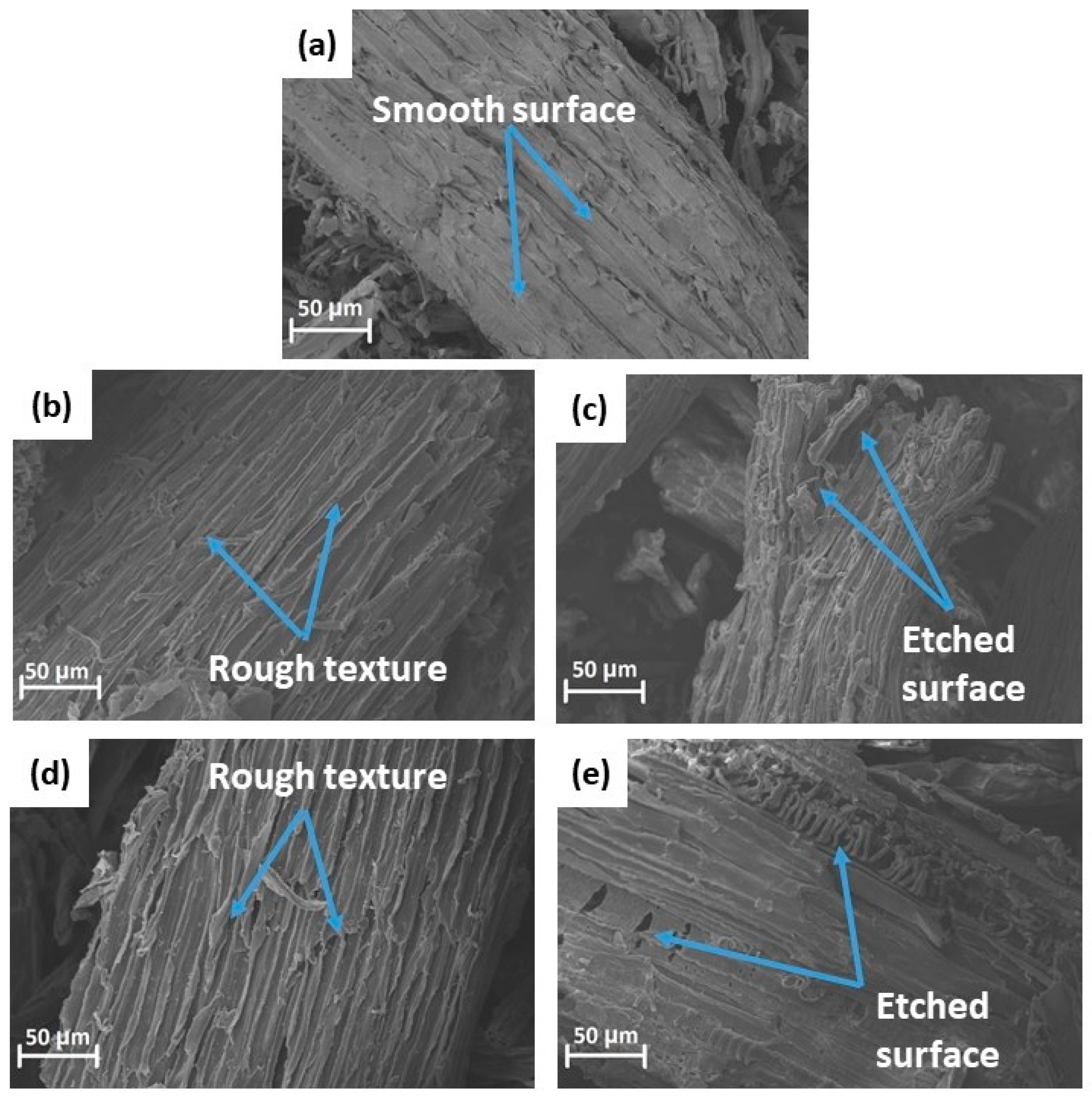

3.2. SEM Analysis

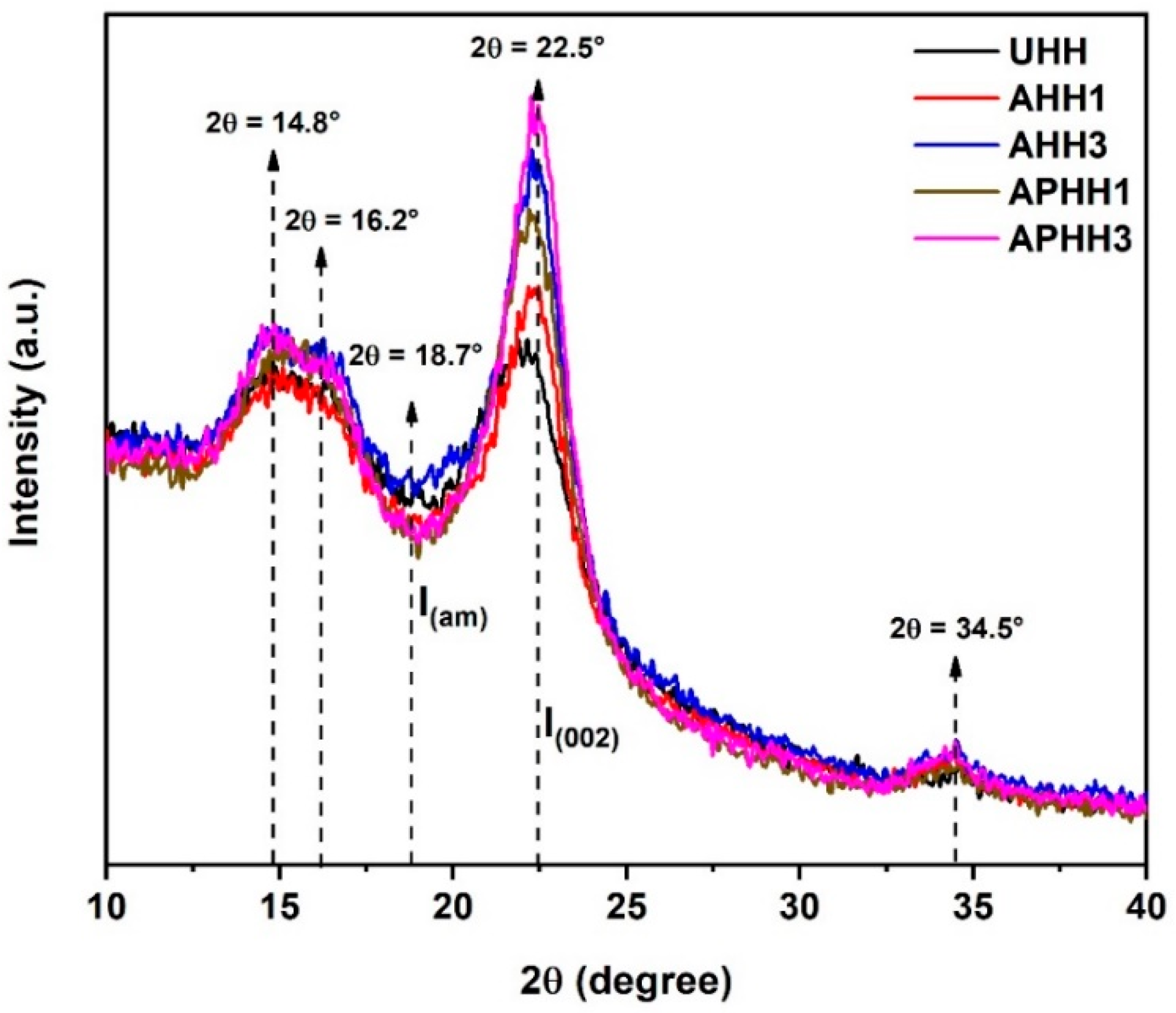

3.3. XRD

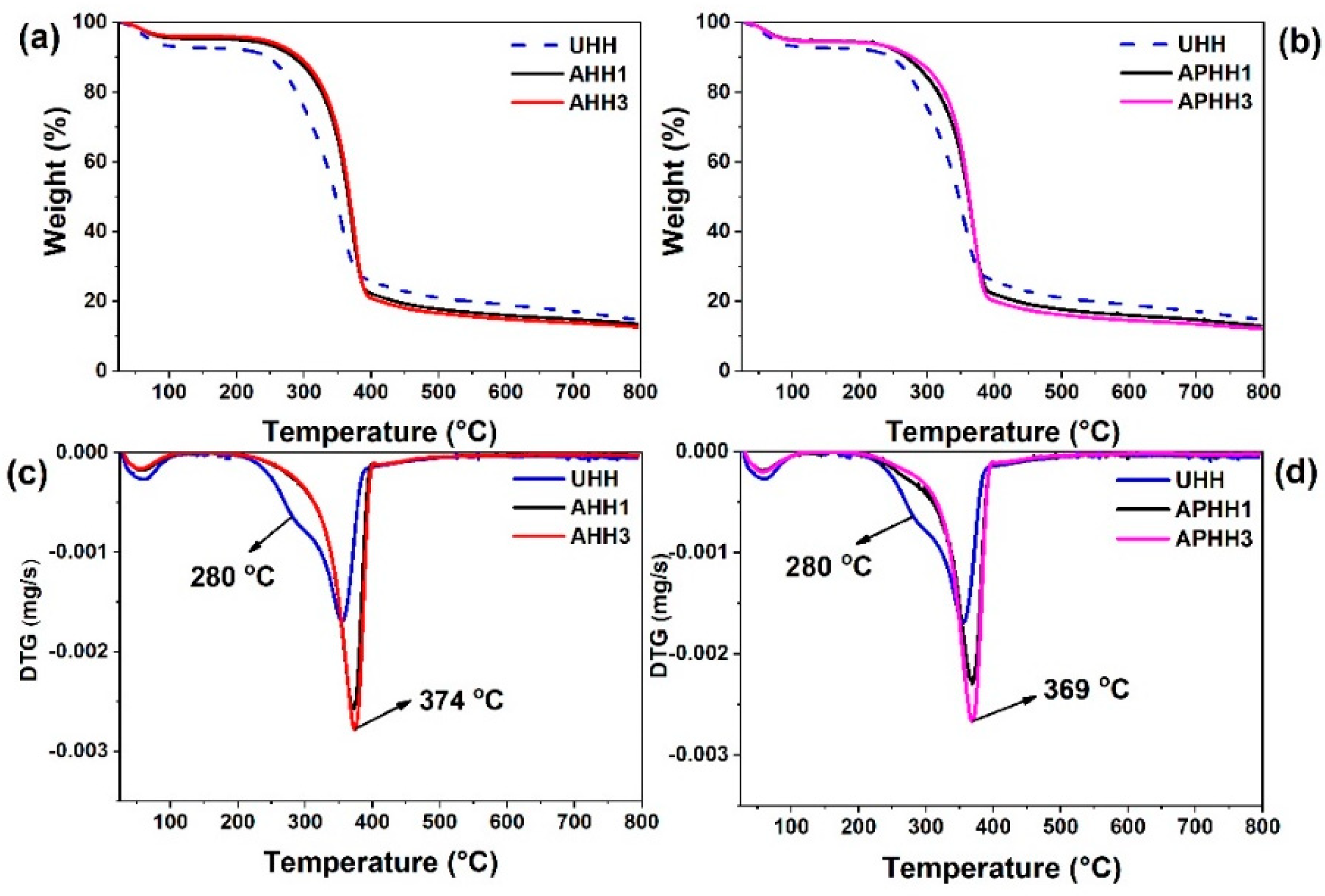

3.4. Thermal Stability of Hemp Hurd Powders

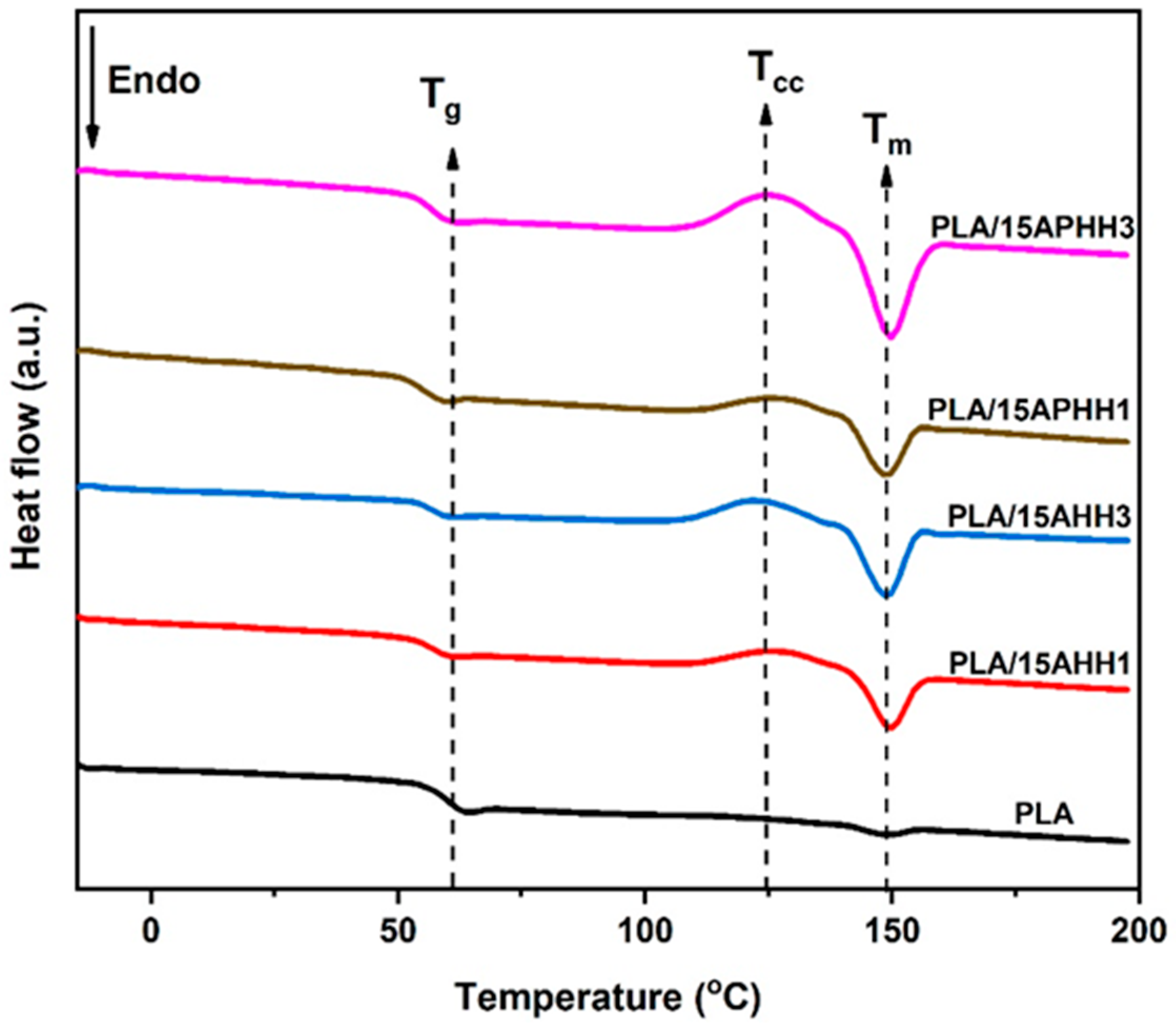

3.5. Thermal Analysis of Biocomposites

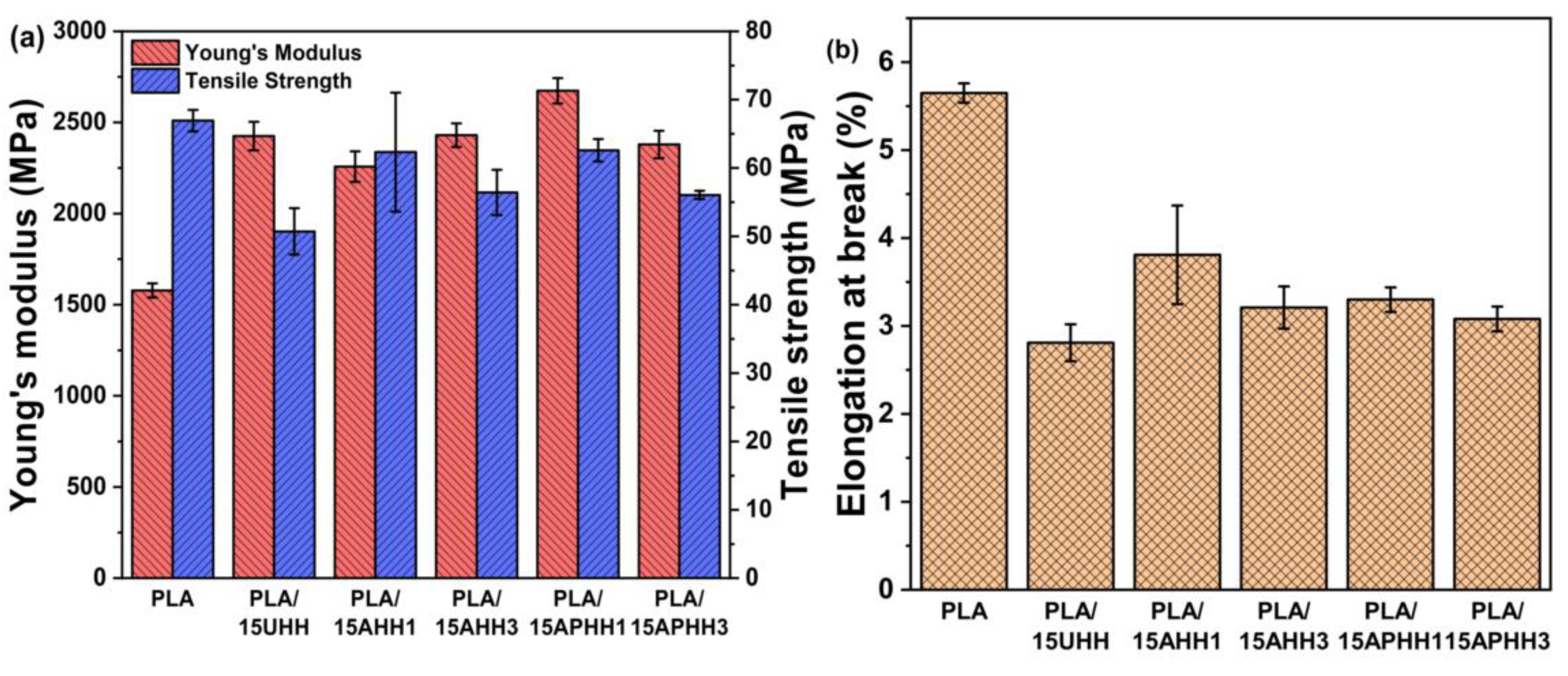

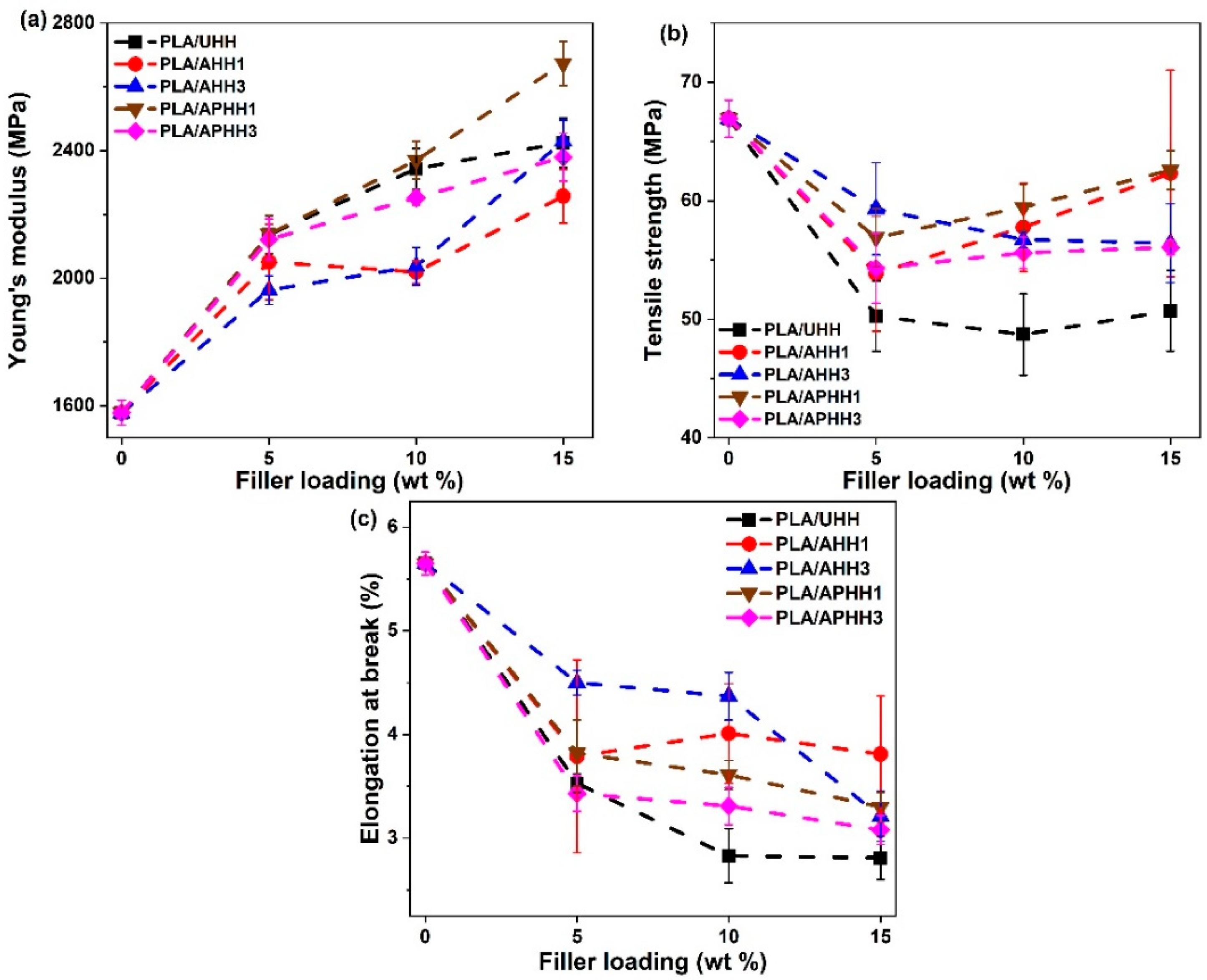

3.6. Mechanical Properties of Biocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- da Silva, D.; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Roitman, J.; Schroeder, A. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem. Eng. J. 2018, 340, 9–14. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Tang, G.; Wang, X.; Xing, W.; Zhang, P.; Wang, B.; Hong, N.; Yang, W.; Hu, Y.; Song, L. Thermal degradation and flame retardance of biobased polylactide composites based on aluminum hypophosphite. Ind. Eng. Chem. Res. 2012, 51, 12009–12016. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xuan, S.; Xing, W.; Bai, Z.; Lu, H. Flame retardancy and thermal degradation of intumescent flame retardant poly(lactic acid)/starch biocomposites. Ind. Eng. Chem. Res. 2011, 50, 713–720. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [Green Version]

- Rhim, J.W.; Park, H.M.; Ha, C.S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Singh, A.A.; Genovese, M.E.; Mancini, G.; Marini, L.; Athanassiou, A. Green Processing Route for Polylactic Acid-Cellulose Fiber Biocomposites. ACS Sustain. Chem. Eng. 2020, 8, 4128–4136. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K.; Williams, K.; Mielewski, D.F. A study on biocomposites from recycled newspaper fiber and poly(lactic acid). Ind. Eng. Chem. Res. 2005, 44, 5593–5601. [Google Scholar] [CrossRef]

- Lopera-Valle, A.; Caputo, J.V.; Leão, R.; Sauvageau, D.; Luz, S.M.; Elias, A. Influence of epoxidized Canola Oil (eCO) and Cellulose Nanocrystals (CNCs) on the mechanical and thermal properties of polyhydroxybutyrate (PHB)-Poly(lactic acid) (PLA) blends. Polymers 2019, 11, 933. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Chen, F.; Qian, J.; Huang, J.; Wolcott, M.; Liu, L.; Zhang, J. Reinforcing and toughening effects of bamboo pulp fiber on poly(3-hydroxybutyrate-C0-3-hydroxyvalerate) fiber composites. Ind. Eng. Chem. Res. 2010, 49, 572–577. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial hemp fibers: An overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef] [Green Version]

- Abraham, R.E.; Wong, C.S.; Puri, M. Enrichment of cellulosic waste hemp (Cannabis sativa) hurd into non-toxic microfibres. Materials 2016, 9, 562. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stevulova, N.; Cigasova, J.; Purcz, P.; Schwarzova, I.; Kacik, F.; Geffert, A. Water absorption behavior of hemp hurds composites. Materials 2015, 8, 2243–2257. [Google Scholar] [CrossRef] [Green Version]

- Oza, S.; Ning, H.; Ferguson, I.; Lu, N. Effect of surface treatment on thermal stability of the hemp-PLA composites: Correlation of activation energy with thermal degradation. Compos. Part B Eng. 2014, 67, 227–232. [Google Scholar] [CrossRef]

- Senthamaraikannan, P.; Kathiresan, M. Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis.L. Carbohydr. Polym. 2018, 186, 332–343. [Google Scholar] [CrossRef]

- Balaji, A.N.; Nagarajan, K.J. Characterization of alkali treated and untreated new cellulosic fiber from Saharan aloe vera cactus leaves. Carbohydr. Polym. 2017, 174, 200–208. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Martínez, M.A. Influence of plasma treatment on the adhesion between a polymeric matrix and natural fibres. Cellulose 2017, 24, 1791–1801. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of plasma treatment on the properties of Arundo Donax L. leaf fibres and its bio-based epoxy composites: A preliminary study. Compos. Part B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Boonterm, M.; Sunyadeth, S.; Dedpakdee, S.; Athichalinthorn, P.; Patcharaphun, S.; Mungkung, R.; Techapiesancharoenkij, R. Characterization and comparison of cellulose fiber extraction from rice straw by chemical treatment and thermal steam explosion. J. Clean. Prod. 2016, 134, 592–599. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L. Hemp fibre reinforced composites using chelator and enzyme treatments. Compos. Sci. Technol. 2008, 68, 3293–3298. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. Part A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos. Part B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fibre reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461–468. [Google Scholar] [CrossRef]

- Rosa, M.F.; Chiou, B.S.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imam, S.H. Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef] [Green Version]

- Razak, N.I.A.; Ibrahim, N.A.; Zainuddin, N.; Rayung, M.; Saad, W.Z. The influence of chemical surface modification of kenaf fiber using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly(Lactic Acid) composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef] [Green Version]

- Salam, M.A. Effect of hydrogen peroxide bleaching onto sulfonated jute fiber. J. Appl. Polym. Sci. 2006, 99, 3603–3607. [Google Scholar] [CrossRef]

- Zhang, Y.; Qi, J.; Zeng, W.; Huang, Y.; Yang, X. Properties of dietary fiber from citrus obtained through alkaline hydrogen peroxide treatment and homogenization treatment. Food Chem. 2020, 311, 125873. [Google Scholar] [CrossRef] [PubMed]

- Barberà, L.; Pèlach, M.A.; Pérez, I.; Puig, J.; Mutjé, P. Upgrading of hemp core for papermaking purposes by means of organosolv process. Ind. Crops. Prod. 2011, 34, 865–872. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- ASTM International. D638-14 Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Yatsenko, D.A.; Medvedeva, T.B. Estimating Crystality Index of Microcrystalline Cellulose Using Diffraction Methods. J. Struct. Chem. 2019, 60, 1430–1436. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef] [Green Version]

- Panaitescu, D.M.; Nicolae, C.A.; Vuluga, Z.; Vitelaru, C.; Sanporean, C.G.; Zaharia, C.; Florea, D.; Vasilievici, G. Influence of hemp fibers with modified surface on polypropylene composites. J. Ind. Eng. Chem. 2016, 37, 137–146. [Google Scholar] [CrossRef]

- Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Khan, A.; Parameswaranpillai, J. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int. J. Biol. Macromol. 2019, 125, 99–108. [Google Scholar] [CrossRef]

- Viscusi, G.; Barra, G.; Gorrasi, G. Modification of hemp fibers through alkaline attack assisted by mechanical milling: Effect of processing time on the morphology of the system. Cellulose 2020, 27, 8653–8665. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Schwanninger, M.; Rodrigues, J.C.; Pereira, H.; Hinterstoisser, B. Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Maréchal, Y.; Chanzy, H. The hydrogen bond network in Iβ cellulose as observed by infrared spectrometry. J. Mol. Struct. 2000, 523, 183–196. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.P.; Saravanakumar, S.S. Characterization of cellulose fibers in Thespesia populnea barks: Influence of alkali treatment. Carbohydr. Polym. 2019, 217, 178–189. [Google Scholar] [CrossRef] [PubMed]

- Wada, M.; Okano, T.; Sugiyama, J. Synchrotron-radiated X-ray and neutron diffraction study of native cellulose. Cellulose 1997, 4, 221–232. [Google Scholar] [CrossRef]

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatment of jute fibers on the interfacial adhesion in poly(lactic acid)/jute fiber biocomposites. Fibers Polym. 2016, 17, 266–274. [Google Scholar] [CrossRef]

- Ajouguim, S.; Abdelouahdi, K.; Waqif, M.; Stefanidou, M.; Saâdi, L. Modifications of Alfa fibers by alkali and hydrothermal treatment. Cellulose 2019, 26, 1503–1516. [Google Scholar] [CrossRef]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.-M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Ozyhar, T.; Baradel, F.; Zoppe, J. E ff ect of functional mineral additive on processability and material properties of wood- fi ber reinforced poly (lactic acid) (PLA) composites. Compos. Part A 2020, 132, 105827. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Fan, M.; Naughton, A. Mechanisms of thermal decomposition of natural fibre composites. Compos. Part B Eng. 2016, 88, 1–10. [Google Scholar] [CrossRef]

- Du, Y.; Wu, T.; Yan, N.; Kortschot, M.T.; Farnood, R. Fabrication and characterization of fully biodegradable natural fiber-reinforced poly(lactic acid) composites. Compos. Part B Eng. 2014, 56, 717–723. [Google Scholar] [CrossRef]

- Johari, A.P.; Mohanty, S.; Kurmvanshi, S.K.; Nayak, S.K. Influence of Different Treated Cellulose Fibers on the Mechanical and Thermal Properties of Poly(lactic acid). ACS Sustain. Chem. Eng. 2016, 4, 1619–1629. [Google Scholar] [CrossRef]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos. Sci. Technol. 2009, 69, 1187–1192. [Google Scholar] [CrossRef]

- Yusriah, L.; Sapuan, S.M.; Zainudin, E.S.; Mariatti, M. Characterization of physical, mechanical, thermal and morphological properties of agro-waste betel nut (Areca catechu) husk fibre. J. Clean. Prod. 2014, 72, 174–180. [Google Scholar] [CrossRef]

- Khan, B.A.; Na, H.; Chevali, V.; Warner, P.; Zhu, J.; Wang, H. Glycidyl methacrylate-compatibilized poly(lactic acid)/hemp hurd biocomposites: Processing, crystallization, and thermo-mechanical response. J. Mater. Sci. Technol. 2018, 34, 387–397. [Google Scholar] [CrossRef]

- Malenab, R.A.J.; Ngo, J.P.S.; Promentilla, M.A.B. Chemical Treatment of Waste Abaca for Natural Fiber-Reinforced Geopolymer Composite. Materials 2017, 10, 579. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Biocomposites | Filler Loading (wt. %) | Filler Type | Type of Treatment | Number of Cycles of Treatment |

|---|---|---|---|---|

| PLA/5UHH | 5 | UHH | Untreated | - |

| PLA/5AHH1 | 5 | AHH1 | Alkaline | 1 |

| PLA/5AHH3 | 5 | AHH3 | Alkaline | 3 |

| PLA/5APHH1 | 5 | APHH1 | Alkaline/peroxide | 1 |

| PLA/5APHH3 | 5 | APHH3 | Alkaline/peroxide | 3 |

| PLA/10UHH | 10 | UHH | Untreated | - |

| PLA/10AHH1 | 10 | AHH1 | Alkaline | 1 |

| PLA/10AHH3 | 10 | AHH3 | Alkaline | 3 |

| PLA/10APHH1 | 10 | APHH1 | Alkaline/peroxide | 1 |

| PLA/10APHH3 | 10 | APHH3 | Alkaline/peroxide | 3 |

| PLA/15UHH | 15 | UHH | Untreated | - |

| PLA/15AHH1 | 15 | AHH1 | Alkaline | 1 |

| PLA/15AHH3 | 15 | AHH3 | Alkaline | 3 |

| PLA/15APHH1 | 15 | APHH1 | Alkaline/peroxide | 1 |

| PLA/15APHH3 | 15 | APHH3 | Alkaline/peroxide | 3 |

| Sample | UHH | AHH1 | AHH3 | APHH1 | APHH3 |

|---|---|---|---|---|---|

| Crystallinity index (%) | 27.1 | 40.2 | 42.6 | 39.7 | 53.3 |

| Sample | T10 (°C) | T50 (°C) |

|---|---|---|

| UHH | 246.5 | 347.1 |

| AHH1 | 284.8 | 365.6 |

| AHH3 | 294.0 | 368.4 |

| APHH1 | 269.4 | 361.8 |

| APHH3 | 278.6 | 363.3 |

| Sample | Ti (°C) | Tf (°C) | Tpeak (°C) at DTG | Char Residue (%) at 799 °C |

|---|---|---|---|---|

| PLA | 327.0 | 378.5 | 363.4 | 0.8 |

| PLA/15AHH1 | 322.0 | 373.0 | 353.1 | 3.9 |

| PLA/15AHH3 | 320.4 | 372.2 | 352.7 | 3.2 |

| PLA/15APHH1 | 317.3 | 373.6 | 353.1 | 3.8 |

| PLA/15APHH3 | 303.5 | 365.8 | 347.3 | 4.6 |

| Sample | Tg (°C) | Tcc (°C) | Tm (°C) | ΔHm (J/g) | XC (%) |

|---|---|---|---|---|---|

| PLA | 60.4 | - | 149.1 | 1.28 | 1.3 |

| PLA/15AHH1 | 56.1 | 125.3 | 149.6 | 10.62 | 13.0 |

| PLA/15AHH3 | 56.4 | 122.3 | 148.9 | 15.13 | 18.5 |

| PLA/15APHH1 | 55.0 | 125.7 | 148.8 | 9.11 | 11.2 |

| PLA/15APHH3 | 56.5 | 124.8 | 149.7 | 15.28 | 18.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of Hemp Hurds as Bio-Sourced Additives in PLA-Based Biocomposites. Polymers 2021, 13, 3786. https://doi.org/10.3390/polym13213786

Momeni S, Safder M, Khondoker MAH, Elias AL. Valorization of Hemp Hurds as Bio-Sourced Additives in PLA-Based Biocomposites. Polymers. 2021; 13(21):3786. https://doi.org/10.3390/polym13213786

Chicago/Turabian StyleMomeni, Sina, Muhammad Safder, Mohammad Abu Hasan Khondoker, and Anastasia Leila Elias. 2021. "Valorization of Hemp Hurds as Bio-Sourced Additives in PLA-Based Biocomposites" Polymers 13, no. 21: 3786. https://doi.org/10.3390/polym13213786

APA StyleMomeni, S., Safder, M., Khondoker, M. A. H., & Elias, A. L. (2021). Valorization of Hemp Hurds as Bio-Sourced Additives in PLA-Based Biocomposites. Polymers, 13(21), 3786. https://doi.org/10.3390/polym13213786