Distributed Humidity Sensing in Concrete Based on Polymer Optical Fiber

Abstract

:1. Introduction

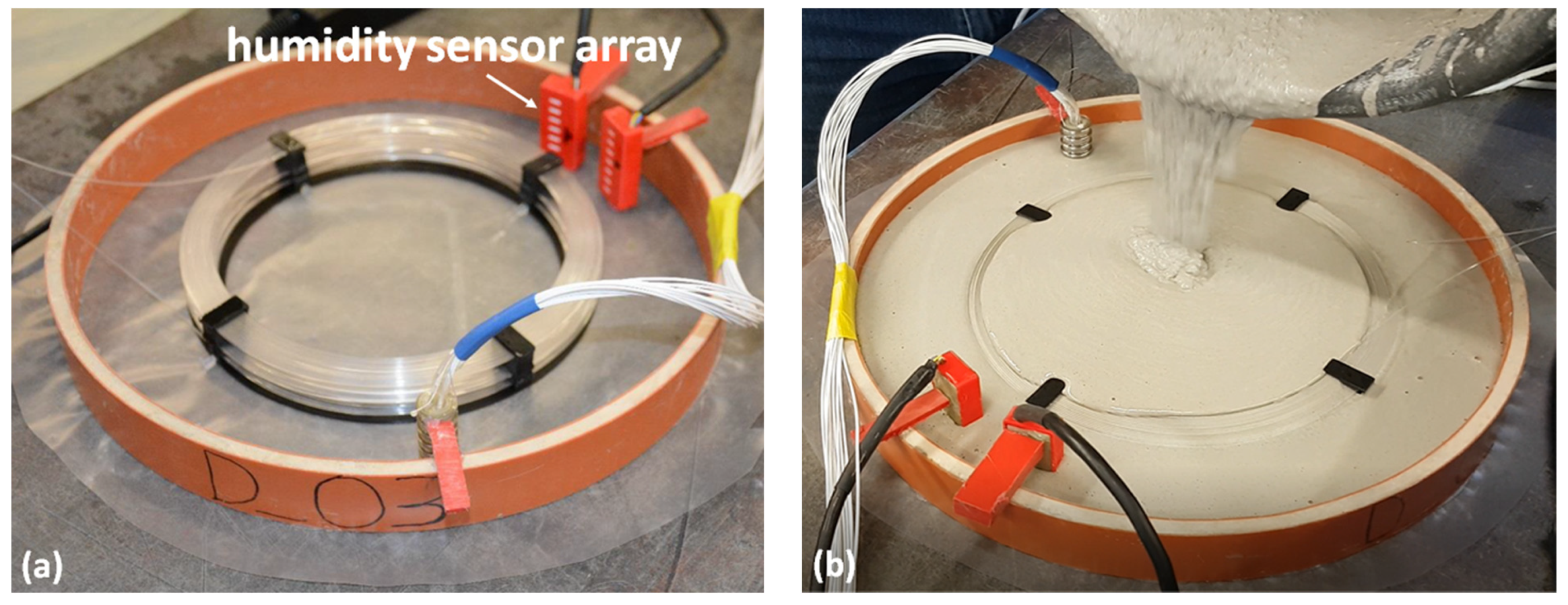

2. Materials and Methods

2.1. Materials

2.2. Impact of Water on Fiber Property

2.3. Methods

3. Results and Discussion

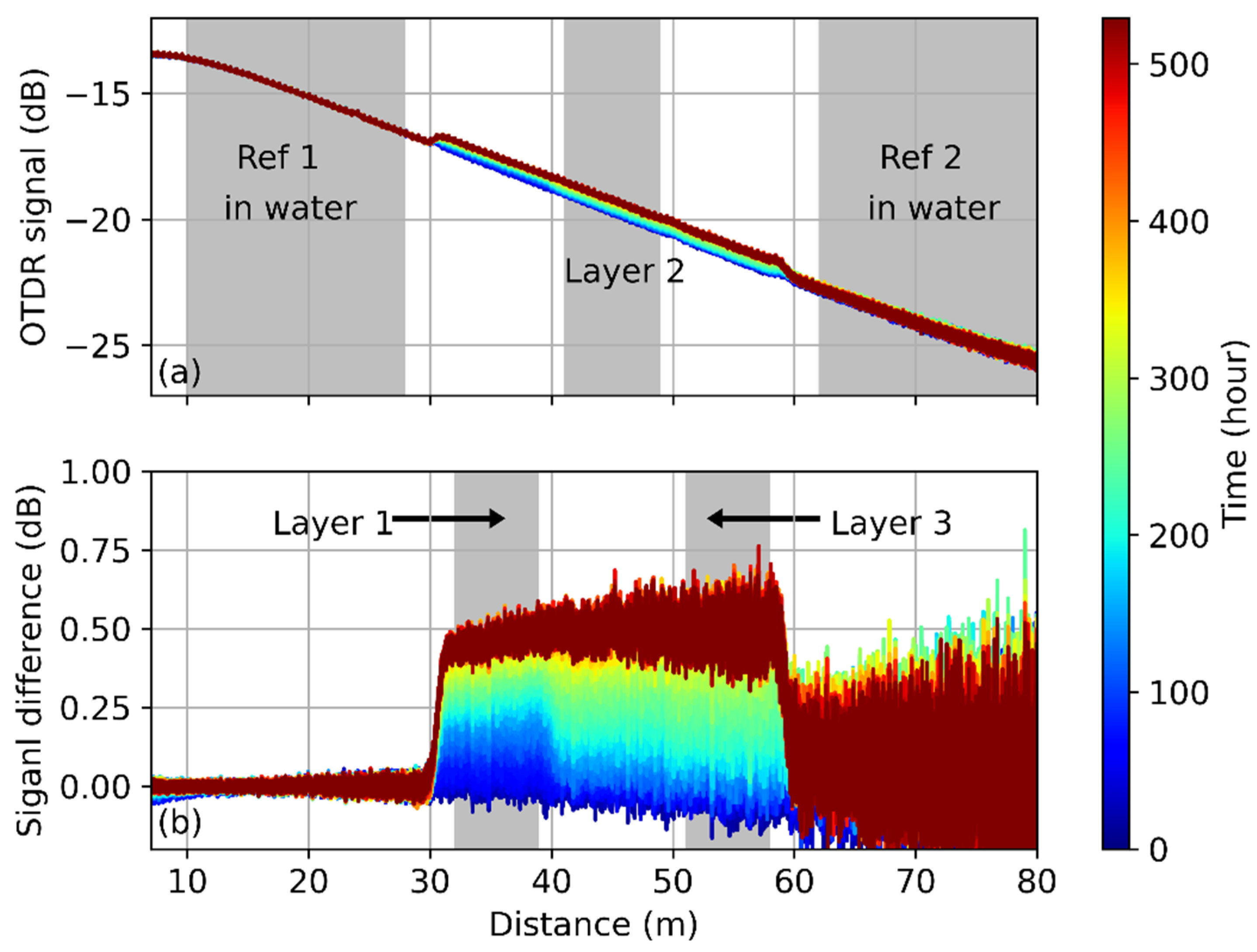

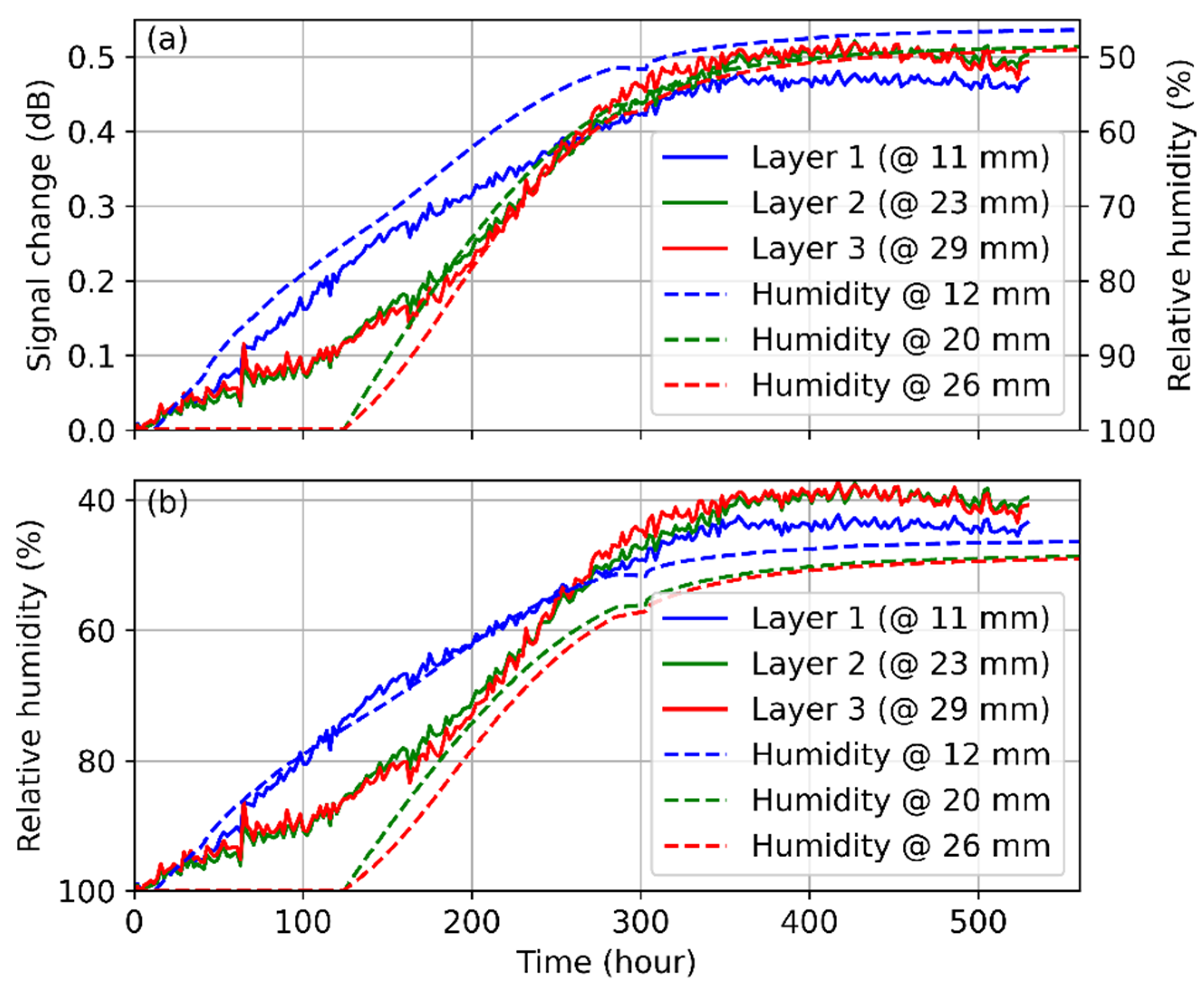

3.1. Results at 650 nm

3.2. Results at 500 nm

4. Conclusions

- The impact of the humidity on the fiber property needs to be further investigated to develop a quantifiable relationship between the RH change and changes of the backscattered light.

- The sensor should be highly selective to a particular analyte, in this case, water. A protective coating or jacket is necessary to allow the target to reach the fiber and block other elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuators A Phys. 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Lu, X.; Thomas, P.J.; Hellevang, J.O. A review of methods for fibre-optic distributed chemical sensing. Sensors 2019, 19, 2876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Michie, W.C.; Culshaw, B.; Konstantaki, M.; McKenzie, I.; Kelly, S.; Graham, N.B.; Moran, C. Distributed pH and water detection using fiber-optic sensors and hydrogels. J. Lightw. Technol. 1995, 13, 1415–1420. [Google Scholar] [CrossRef]

- Xu, K.; Li, H.; Liu, Y.; Wang, Y.; Tian, J.; Wang, L.; Du, J.; He, Z.; Song, Q. Optical fiber humidity sensor based on water absorption peak near 2-μm waveband. IEEE Photon. J. 2019, 11, 7101308. [Google Scholar] [CrossRef]

- Stajanca, P.; Hicke, K.; Krebber, K. Distributed fiberoptic sensor for simultaneous humidity and temperature monitoring based on polyimide-coated optical fibers. Sensors 2019, 19, 5279. [Google Scholar] [CrossRef] [Green Version]

- Thomas, P.J.; Hellevang, J.O. A high response polyimide fiber optic sensor for distributed humidity measurements. Sens. Actuators B Chem. 2018, 270, 417–423. [Google Scholar] [CrossRef]

- Tan, Y.; Sun, L.; Jin, L.; Li, J.; Guan, B. Temperature-insensitive humidity sensor based on a silica fiber taper interferometer. IEEE Photon. Technol. Lett. 2013, 25, 2201–2204. [Google Scholar] [CrossRef]

- Hu, P.; Dong, X.; Ni, K.; Chen, L.H.; Wong, W.C.; Chan, C.C. Sensitivity-enhanced Michelson interferometric humidity sensor with waist-enlarged fiber bitaper. Sens. Actuators B Chem. 2014, 294, 180–184. [Google Scholar] [CrossRef]

- Fu, M.Y.; Lin, G.R.; Liu, W.F.; Wu, C.W. Fiber-optic humidity sensor based on an air-gap long period fiber grating. Opt. Rev. 2011, 18, 93–95. [Google Scholar] [CrossRef]

- Strangfeld, C. Determination of the diffusion coefficient and the hydraulic conductivity of porous media based on embedded humidity sensors. Constr. Build. Mater. 2020, 263, 120092. [Google Scholar] [CrossRef]

- Thomas, P.J.; Hellevang, J.O. A distributed fibre optic approach for providing early warning of Corrosion Under Insulation (CUI). J. Loss. Prev. Process Ind. 2020, 64, 104060. [Google Scholar] [CrossRef]

- Lu, X.; Thomas, P.J. Numerical modeling of Fcy OTDR sensing using a refractive index perturbation approach. J. Lightwave Technol. 2020, 38, 974–980. [Google Scholar] [CrossRef]

- Behnood, A.; Tittelboom, K.V.; Belie, N.D. Methods for measuring pH in concrete: A review. Constr. Build. Mater. 2016, 105, 176–188. [Google Scholar] [CrossRef]

- Bartelmess, J.; Zimmek, D.; Bartholmai, M.; Strangfeld, C.; Schaferling, M. Fibre optic ratiometric fluorescence pH sensor for monitoring corrosion in concrete. Analyst 2020, 145, 2111–2117. [Google Scholar] [CrossRef]

- Simović, A.; Drljača, B.; Savović, S.; Djordjevich, A.; Min, R. Investigation of bandwidth in multimode graded-index plastic optical fibers. Opt. Express 2021, 29, 29587–29594. [Google Scholar] [CrossRef] [PubMed]

- Simović, A.; Savović, S.; Drljača, B.; Djordjevich, A. Wavelength dependent transmission in W-type plastic optical fibers with graded index core distribution. Optik 2021, 246, 167775. [Google Scholar] [CrossRef]

- Savović, S.; Djordjevich, A.; Simović, A.; Drljača, B. Spatial division multiplexing in nine-core graded index plastic optical fibers. Laser Phys. 2020, 30, 095103. [Google Scholar] [CrossRef]

- Oliverira, R.; Sequeira, F.; Bilro, L.; Nogueira, R. Polymer Optical Fiber Sensors and Devices. In Handbook of Optical Fibers, 1st ed.; Peng, G.D., Ed.; Springer: Singapore, 2018; pp. 1–41. [Google Scholar] [CrossRef]

- Liehr, S.; Breithaupt, M.; Krebber, K. Distributed humidity sensing in PMMA optical fibers at 500 nm and 650 nm wavelengths. Sensors 2017, 17, 738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schreier, A.; Wosniok, A.; Liehr, S.; Krebber, K. Humidity-induced Brillouin frequency shift in perfluorinated polymer optical fibers. Opt. Express 2018, 26, 22307–22314. [Google Scholar] [CrossRef]

- Han, P.; Li, L.; Zhang, H.; Guan, L.; Marques, C.; Savović, S.; Ortega, B.; Min, R.; Li, X. Low-cost plastic optical fiber sensor embedded in mattress for sleep performance monitoring. Opt. Fiber Technol. 2021, 64, 102541. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Quek, S.T.; Koh, C.G.; Cantwell, W.J.; Scully, P.J. Plastic optical fibre sensors for structural health monitoring: A review of recent progress. J. Sens. 2009, 2009, 312053. [Google Scholar] [CrossRef] [Green Version]

- Wong, Y.M.; Scully, P.J.; Bartlett, R.J.; Kuang, K.S.C.; Cantwell, W.J. Plastic optical fibre sensors for environmental monitoring: Biofouling and strain applications. Strain 2003, 39, 115–119. [Google Scholar] [CrossRef]

- Estrichmörtel, Estrichmassen und Estriche—Estrichmörtel und Estrichmassen—Eigenschaften und Anforderungen; DIN EN 13813:2017; German Standard; Beuth: Berlin, Germany, 2017.

- Strangfeld, C.; Kruschwitz, S. Monitoring of the absolute water content in porous materials based on embedded humidity sensors. Constr. Build. Mater. 2018, 177, 511–521. [Google Scholar] [CrossRef]

- Bueche, F. Diffusion of water in polymethyl methacrylate. J. Polym. Sci. 1954, 14, 414–416. [Google Scholar] [CrossRef]

- Turner, D.T. Polymethyl methacrylate plus water: Sorption kinetics and volumetric changes. Polymer 1982, 23, 197–202. [Google Scholar] [CrossRef]

- Watanabe, T.; Ooba, N.; Hida, Y.; Hikita, M. Influence of humidity on refractive index of polymers for optical waveguide and its temperature dependence. Appl. Phys. Lett. 1998, 72, 1533–1535. [Google Scholar] [CrossRef]

- Ioannides, N.; Chunga, E.B.; Bachmatiuk, A.; Gonzalez-Martinez, I.G.; Trzebicka, B.; Adebimpe, D.B.; Kalymnios, D.; Rümmeli, M.H. Approaches to mitigate polymer-core loss in plastic optical fibers: A review. Mater. Res. Express 2014, 1, 032002. [Google Scholar] [CrossRef]

- Kaino, T. Influence of water absorption on plastic optical fibers. Appl. Opt. 1985, 24, 4192–4195. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Hicke, K.; Breithaupt, M.; Strangfeld, C. Distributed Humidity Sensing in Concrete Based on Polymer Optical Fiber. Polymers 2021, 13, 3755. https://doi.org/10.3390/polym13213755

Lu X, Hicke K, Breithaupt M, Strangfeld C. Distributed Humidity Sensing in Concrete Based on Polymer Optical Fiber. Polymers. 2021; 13(21):3755. https://doi.org/10.3390/polym13213755

Chicago/Turabian StyleLu, Xin, Konstantin Hicke, Mathias Breithaupt, and Christoph Strangfeld. 2021. "Distributed Humidity Sensing in Concrete Based on Polymer Optical Fiber" Polymers 13, no. 21: 3755. https://doi.org/10.3390/polym13213755

APA StyleLu, X., Hicke, K., Breithaupt, M., & Strangfeld, C. (2021). Distributed Humidity Sensing in Concrete Based on Polymer Optical Fiber. Polymers, 13(21), 3755. https://doi.org/10.3390/polym13213755