Abstract

The exposure to extreme temperatures in workplaces involves physical hazards for workers. A poorly acclimated worker may have lower performance and vigilance and therefore may be more exposed to accidents and injuries. Due to the incompatibility of the existing standards implemented in some workplaces and the lack of thermoregulation in many types of protective equipment that are commonly fabricated using various types of polymeric materials, thermal stress remains one of the most frequent physical hazards in many work sectors. However, many of these problems can be overcome with the use of smart textile technologies that enable intelligent thermoregulation in personal protective equipment. Being based on conductive and functional polymeric materials, smart textiles can detect many external stimuli and react to them. Interconnected sensors and actuators that interact and react to existing risks can provide the wearer with increased safety, protection, and comfort. Thus, the skills of smart protective equipment can contribute to the reduction of errors and the number and severity of accidents in the workplace and thus promote improved performance, efficiency, and productivity. This review provides an overview and opinions of authors on the current state of knowledge on these types of technologies by reviewing and discussing the state of the art of commercially available systems and the advances made in previous research works.

1. Introduction

1.1. Thermal Stress in the Workplace

Thermal stress is among the most common physical hazards in various work sectors. In fact, any worker exposed to a high heat load through a combination of his or her metabolic heat during work, environmental factors (air temperature, humidity, air movement, heat transfer by radiation), and the clothing requirements of his or her job can suffer health problems [1]. In addition, exposure to extreme temperatures in workplaces involves physical hazards for workers. Workers in firefighting, construction, mining, smelting and primary metal processing, metal product manufacturing, forestry, agricultural, food manufacturing, and police services are among the most exposed sectors to heat-related hazards. Workers in construction, agriculture, fishing, logging, forestry, and other outdoor activities are at risk of cold stress [2].

Indeed, the exposure to extreme temperatures can lead the worker to a state of heat stress, which occurs when the body is unable to maintain its temperature between 36 and 37 °C [3]. Heat syncope, heat exhaustion, heat stroke, dehydration, heat cramps, miliary eruptions, hyponatremia, and rhabdomyolysis are among the diseases or health disorders due to heat exposure. Hypothermia, immersion feet, and frostbite are the most significant injuries and illnesses caused by exposure to extreme cold [2]. Therefore, the prevention of thermal stress risks should be a priority in order to avoid any negative effects on workers’ health and safety [4]. Adequate prevention of heat stress risks not only provides a sense of comfort for the worker toward his work environment, but it can also have a positive impact on the productivity rate and result in a decrease in the employer’s number of injuries [5].

In addition to being a direct cause of serious injuries in the workplace, thermal stress can indirectly lead to accidents and other types of injuries. A poorly acclimated worker may have reduced performance and alertness and therefore may be at greater risk of accidents and injuries [6,7,8]. One of the main risks indirectly related to working in extreme cold is the decreased manual function, which can quickly impair task performance and increase the risk of accidents or intensify a hazardous situation [9]. Research has shown that manual dexterity is impaired during work in cold storage warehouses [10]. Cold can also reduce alertness and impair cognitive performance, increasing the risk of inappropriate mental actions leading to accidents. Indeed, one study was able to demonstrate that reaction time and signal detection decreased in workers exposed to a temperature of -20 °C for more than 45 min [11].

Exposure to extreme temperatures can also temporarily reduce work capacity and affect productivity [2]. As a result, thermal stress can directly alter operational capacity, both by decreasing work tolerance and by requiring changes in work schedules, such as longer rest and recovery breaks [2]. For some professions, such as firefighters, the interaction between high physical exertion and heat is the main cause of death [12]. According to studies conducted in the United States, thermal and physiological stress during interventions is associated with an increased risk of cardiovascular accidents, which are the most common cause of death among firefighters [13]. In addition to the impact of heat on cardiovascular behavior, the thermoregulatory mechanisms of the human body under thermal stress and the physiological changes they imply can alter the functions of several organs related to the absorption and chemical metabolism. Heat exposure has been shown to be associated with increased pulmonary and dermal absorption of xenobiotics [14].

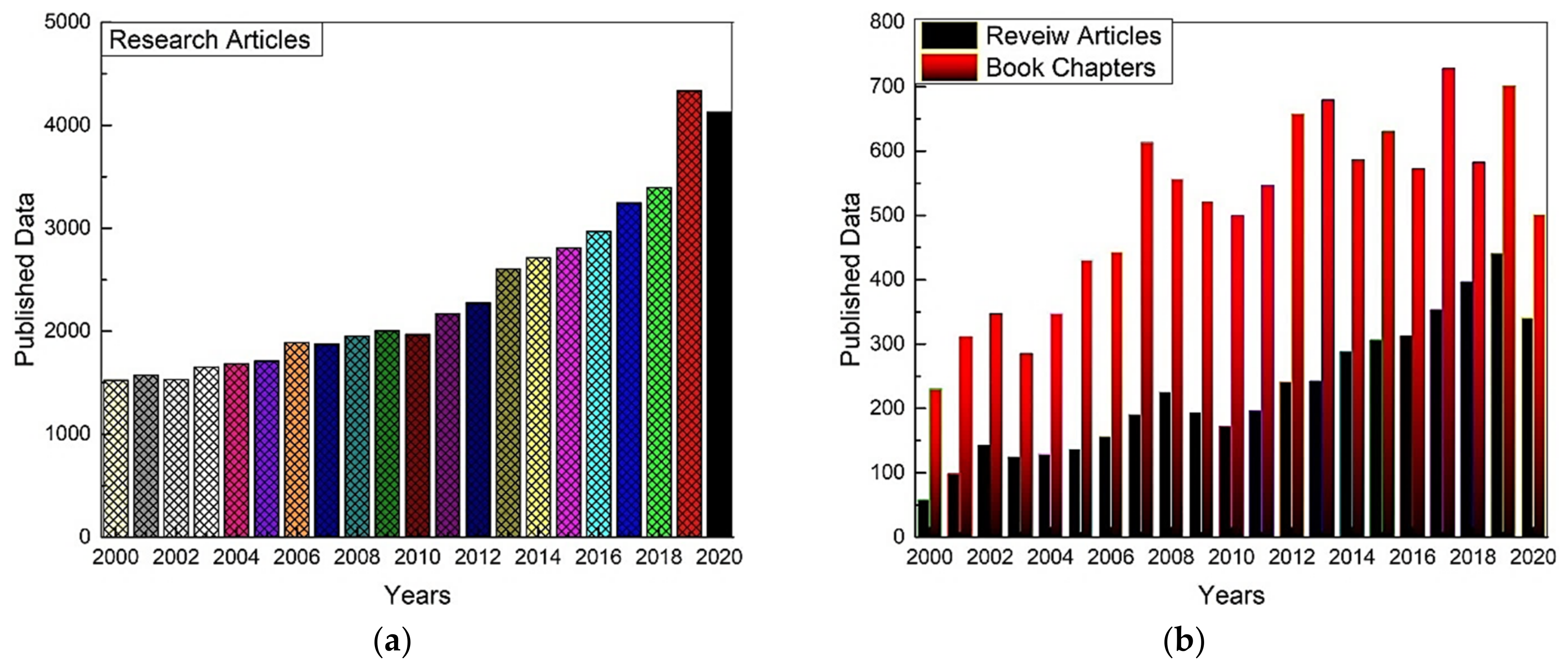

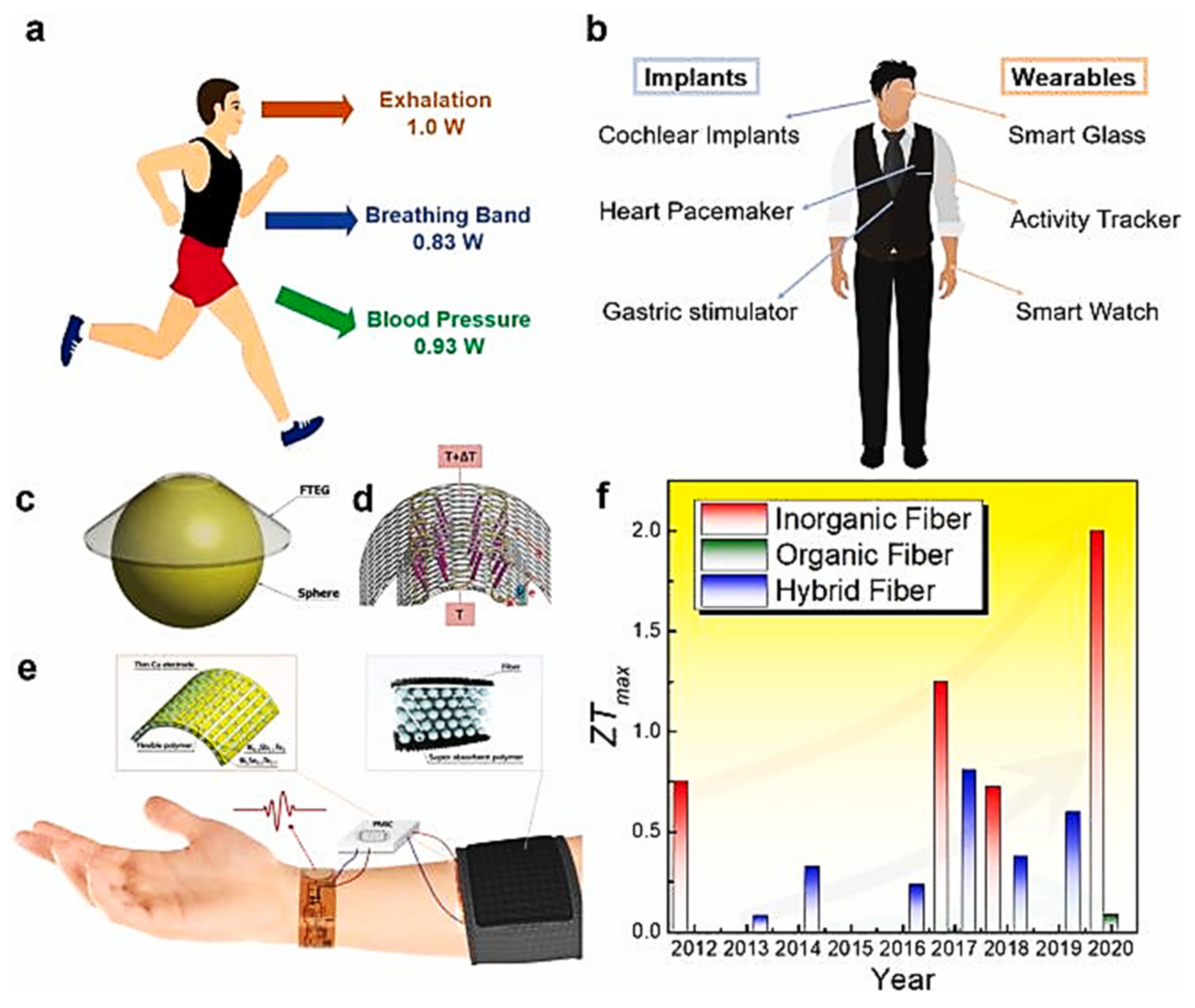

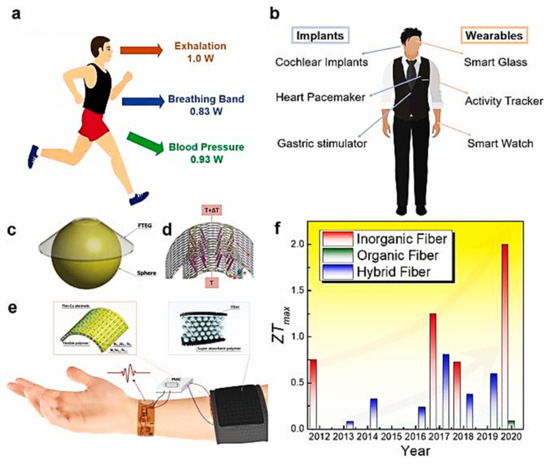

The protection of workers against thermal risks becomes even more important since, according to experts, the current climate change context will contribute to emphasizing the impact of thermal constraints in the workplace [15,16,17]. Over the past few decades, many research studies related to thermal management have been witnessed, as shown in Figure 1.

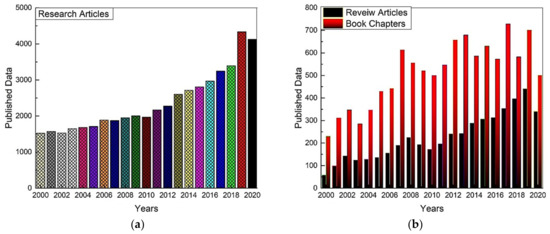

Figure 1.

Published data for personal thermal management from 2000 to 20 June 2020. (a) Research articles published during the last two decades. (b) Review articles and book chapters published during the last two decades. Reproduced with permission [3]. Copyright 2020, Elsevier.

As a result of the importance of preventing the risks of thermal stress, recommendations and measures have been planned by the authorities. These regulations recommend redesigning the workstation, reducing the workload, and wearing appropriate personal protective equipment (PPE) to ensure that thermal stress thresholds are not exceeded. However, some studies have shown that despite compliance with these regulations, some workers may be subject to thermophysiological constraints depending on their age, sex, physical fitness, or state of health [12]. Moreover, these types of measures against thermal stress are sometimes far from being applicable in certain environments such as agriculture [18,19]. Regulations are sometimes very cautious and sometimes overestimate the level of thermal stress, while for heavy work in indoor workplaces, they may underestimate exposure [20]. Prevention measures remain unclear and sometimes unrealistic in the face of reality [21].

1.2. Personal Protective Equipment Design Challenges

In addition to several gaps in the established regulations to counter the risks of thermal stress in the workplace, PPE can accentuate the impact of thermal stress, as many of these items of equipment lack comfort [22]. PPE is designed primarily to protect workers against external hazards such as chemical, biological, thermal, and mechanical. Various polymeric materials are commonly used for the fabrication of PPE [23]. For instance, protective gloves can be made with polymers (nitrile, latex, neoprene, poly(vinylacetate), polyvinyl chloride (PVC)), with woven or knitted textiles materials (aramid fibers (Kevlar®), high-performance polyethylene (HPPE)), coated or not with polymers, in single or multiple layers [24,25,26,27]. Depending on the protection required, different synthetic materials can be used also in the fabrication of protective clothing, such as meta-aramide (Nomex®), para-aramide (Kevlar®), polybenzimidazole (PBI), melamine (Basofil®), polyphenylene benzobisoxazole (Zylon®), and polyimide for heat and flame hazard, polyurethane (PU), chlorinated polyethylene (CPE), polytetrafluoroethylene (PTFE), PVC, and polyvinylidene chloride (PVDC) as impermeable layers and moisture barriers [26,28], or activated carbon impregnated foam, fluoro-polymer coatings, polyurethane nonporous membrane, or elastomers for chemical protection [23,29,30,31]. Being a multidisciplinary field calling for several technological knowledge, the materials used in the design of protective equipment has been the subject of several technical reviews. While some of these studies have been devoted to a global state of the art of materials used and the evolution of associated needs [23,26,32,33], others analyzed specific developments and needs to counter a particular type of risk, for example, reviews specifically dedicated to advances and applications of materials for chemical protective clothing [25,30]. Some contemporary research studies have even evoked a potential application of nanofiber materials in protective clothing. These materials obtained from nanoparticles mixed with polymer solutions can offer greater breathability, a selective filtration potential along with an improved liquid chemical and aerosol particle retention capability compared with current commercially available membranes [25,34,35].

However, the materials used in the design of several types of PPE tend to avoid the adequate dissipation of body heat [36]. Thus, workers such as firefighters or metal fabricators may be exposed to more thermal and physiological stresses due to their type of protective equipment [37]. As reported by occupational health and safety experts, workers often find protective equipment uncomfortable, too hot, or too bulky, which does not encourage them to wear it regularly, thus accentuating potential risk situations [38].

Given the existing shortcomings in the prevention of thermal stress in workplaces due to conventional conception in the design of protective equipment and the inefficiency of the established standards and recommendations, it is essential to develop new tools and equipment to ensure thermal risk management adapted to the individual situation of the worker and his or her work environment. In such a context, smart textile technologies integrated into personal protective equipment have a very great potential to respond to many issues related to thermal risks. Thus, using them in the development of PPE presents great potential for the field of occupational health and safety [22,39,40,41].

Being based on textronic (e-textiles), conductive textiles, functional textiles, and flexible and extensible electronics, smart textiles can contribute to the development of thermal regulation systems [42,43] to better protect workers against the risks of thermal stress while offering them greater comfort. They can also be used in the development of tools for measuring external and internal garment temperatures, as well as body temperature [39,40]. In addition to being the basic textile material, polymeric materials are also widely used in the production of smart textiles whether in the design of sensors or actuators, their methods of integration into textiles, conductive yarns fabrication, conductive polymers coating, functional coating, or embedding conductive fillers [44,45,46].

Recent technical reviews often report on knowledge in the area of smart textiles [44,45,47], including a number of studies that mention their potential use in PPE design [40,48,49]. Although some other studies have made reviews of the heat stress state in conventional PPE [50,51], to our knowledge, no reviews are specifically related to the analysis of smart textile technologies for the prevention of thermal stress risks while wearing PPE. In fact, despite the studies that have separately reviewed heating, cooling, or thermal sensor technologies integrated into clothing [44,45,48], no study exists on a complete analysis of all the technologies that facilitate intelligent thermal management in PPE. Furthermore, the continuous evolution of smart textile technologies in an increasingly connected world, both at the societal and industrial levels, requires an update of knowledge to better support the adaptation of such technologies to occupational health and safety applications.

In spite of the recent technological progress, a preliminary analysis has shown that most of the current commercial solutions are dedicated to the fields of sport and leisure, and very few are related to occupational protective equipment [52,53]. Indeed, heating systems integrated into different types of clothing and accessories have emerged in recent years [54]. However, these systems suffer from a lack of comfort and are difficult to use in a work context.

While some integrated systems have presented risks of overheating [55], others suffer from a lack of temperature control [56]. Integrated cooling systems are usually based on passive devices composed of multilayer structures or functional coatings, which limits their reactivity to temperature variations [57]. Moreover, active integrated cooling systems remain cumbersome and energy consuming [43] and sometimes not very efficient in extreme climatic conditions [58]. The development of self-regulating temperature systems using functional materials of phase change materials types [59,60] has attracted the attention of many research groups [59]. However, these materials in their current state remain limited by their overall enthalpy of phase change or thermal window. They are active during their phase change period but cease to function when the phase change is completed [61]. Despite the emergence of commercial products incorporating smart textile technologies, garments with integrated sensors capable of detecting thermal stressors in order to mitigate the risk of contact and prolonged exposure to extreme temperatures in workplaces are also rare. Although isolated cases have been developed for some trades in a few countries [62], most work remains limited to research [63].

Using the potential of advanced materials both in the design of conductive textiles and in the development of thermal sensors and actuators to be integrated in protective equipment can provide a reliable solution to fill current lacks in the design of intelligent thermal management tools in the context of occupational health and safety. Therefore, the present study aims to present a review of current knowledge of these technologies facilitating smart thermoregulation in personal protective equipment.

2. Temperature Sensor

This part of the study focuses on systems that provide data on the body temperature of an active person. It also discusses the sensors that can be integrated into PPE in order to facilitate the acquisition of the temperature of the microclimate under the clothing or the outside temperature with the objective of warning the worker in case of prolonged exposure to extreme temperatures.

Real-time monitoring of body temperature is very important in order to prevent in time the occurrence of disorder in many organs during exposure to high thermal stress [64]. The calculation of body temperature is commonly based on the measurements of the core body temperature (Tc) and the skin temperature (Ts). While Tc is adjusted by thermoregulatory mechanisms of the body, Ts is affected by blood circulation and is related to heart rate (HR) and metabolic rate [64]. Therefore, temperature sensors used for body temperatures (Ts and Tc) must operate efficiently over a temperature range of 35 to 40 °C and ideally offer a measurement accuracy of 0.1 °C [65].

2.1. Methods to Measure Body Temperature

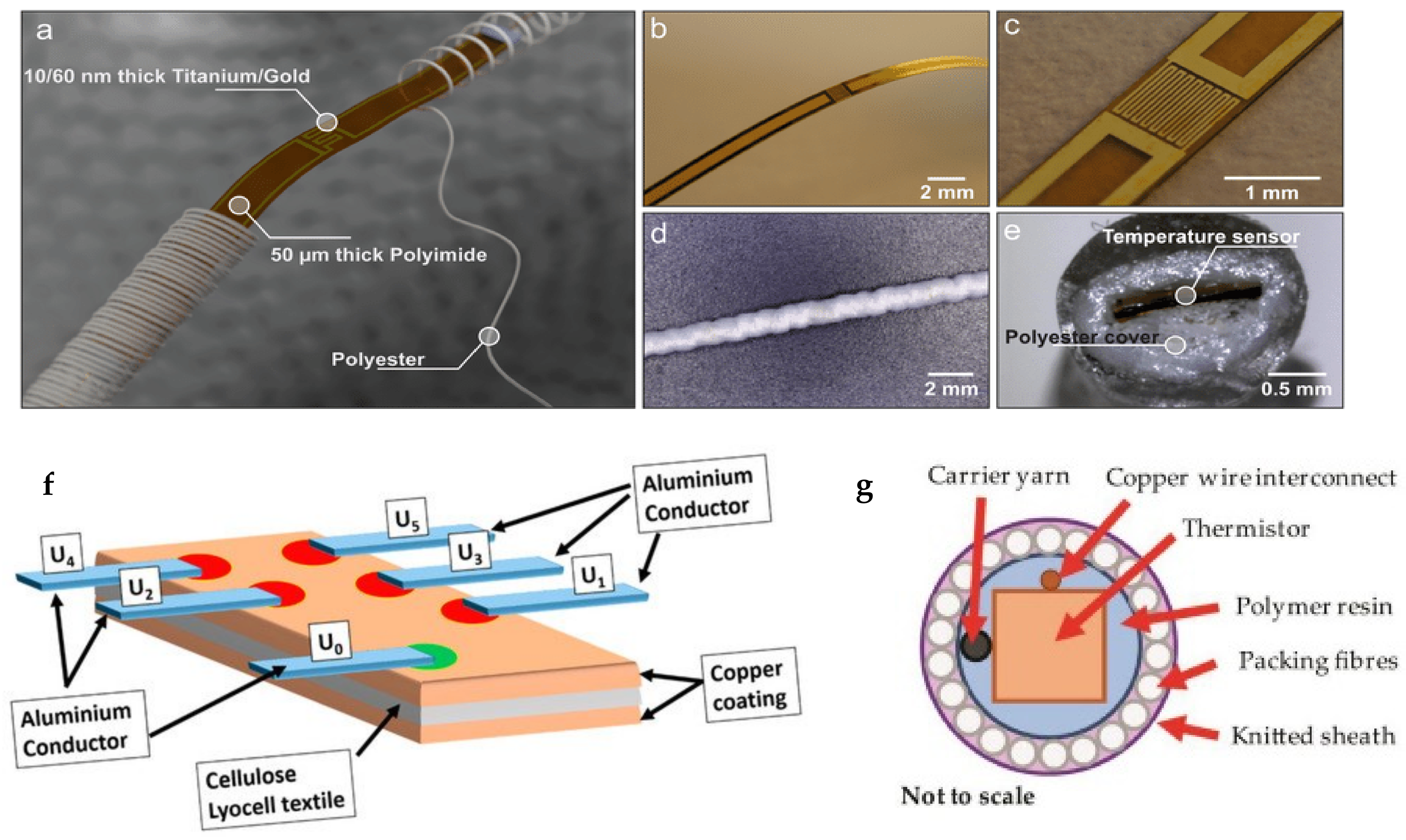

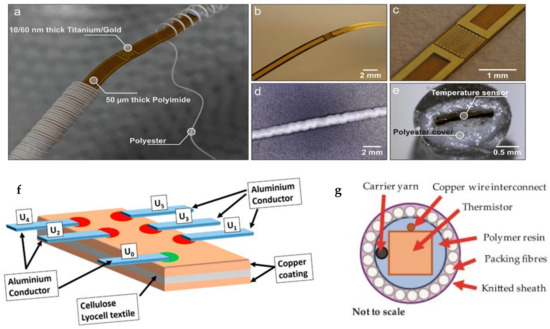

Various types of analog electrical sensors have been deployed in recent years to measure body temperature (Ts and Tc). These sensors are generally based on thermistors, resistance temperature detectors (RTDs) [66] (Figure 2a–e), or thermocouples [64] (Figure 2f,g).

Figure 2.

Temperature sensors: (a) Concept of the flexible temperature sensor embedded within the fibers of a textile yarn; (b) Bending of the uncovered flexible resistance temperature detectors RTD; (c) RTD Close-up sensing area. (d) Resistance temperature detectors embedded within a braided polyester yarn; (e) Cross-section of the braided temperature-sensing yarn ((a–e) [7]); (f) Lightweight and flexible conductor materials in a thermocouple array with copper-coated cellulose textiles [8]; (g) A cross-sectional schematic of encapsulation for a thermistor within a yarn. The standard encapsulation is composed of three layers: a polymer resin, packing fibers, and a knitted sheath [9].

Rectal thermometry is the most accurate method for measuring body temperature, and its value is recognized as the most representative of core body temperature [64]. It has been widely used as the standard measurement in many heat stress studies, including work on the development of heat stress indices [67,68,69,70]. However, rectal thermometry is an intrusive method that requires private arrangements and is therefore unsuitable for the continuous monitoring of workers with high physical activity [65]. Although heart rate can be used for indirect inference of Tc [71,72], some other studies have also proposed an estimation of Tc from Ts [73,74].

Thus, in order to contribute to the protection of individuals against thermal aggressors, the scientific community has been interested in the development of temperature sensors that can be integrated into personal protective equipment [75]. These sensors could measure Ts and monitor the microclimate temperature between the body and the clothing or the outside temperature during exposure to thermal aggressors. While much work has been dedicated to the development of temperature sensors based on smart textile technologies and flexible electronics, a very limited number of studies have been devoted to the systems integrated into clothing.

In fact, the main motivation for the development of textile or flexible sensors has been to overcome the obstacles that hinder portable temperature detection despite the progress made [76]. Most thermistors or thermocouples used in wearable technologies [77] are sensitive to deformation, which can impair temperature sensing with bending or twisting of the sensor [76]. To counter the strain dependence of this type of sensor, some researchers have proposed a hybrid approach based on the integration of a small rigid thermistor embedded in a flexible and extensible matrix [78]. In one of these selected works, an NTC-type thermistor (having a negative temperature coefficient) in association with conductive textile threads was integrated in a bamboo belt to monitor the body temperature of newborns. Despite an encouraging detection accuracy of 0.1 °C of the prototype tested in a hospital setting, the concept lacked mechanical strength due to the use of knots to ensure the connection between the sensor and the signal-transmitting conductive textile threads [79]. In more recent work, the aspect of mechanical strength could be improved by encapsulating a standard thermistor in a polymer resin microcapsule, then embedding it in the fibers of a yarn, and then incorporating it into a textile structure [78,80,81,82,83]. As part of this work, ongoing optimizations have been made, including encapsulating the commercial thermistor in a microcapsule of thermally conductive resin to improve the sensitivity of the sensor [82] or connecting the sensor leads to a microcontroller and a Bluetooth module for wireless transmission of the collected data [78,80]. However, the proposed concepts still require further optimization, particularly in terms of detection accuracy, as differences of 0.5 to 1 °C were observed between the reading and the actual temperature of the sample surfaces [80,82].

Temperature sensors can also be manufactured from textile materials composed of conductive fibers or yarns using conventional textile manufacturing technologies such as weaving, knitting, or embroidery [65]. Depending on their operating principles, these types of sensors can be classified as thermocouples or RTD-type detectors [84].

Textile thermocouples: They exploit the Seebeck effect, which is based on the development of a corresponding potential difference between the junctions of two different metal structures due to the temperature difference between the junctions [65]. Structures with textile electrode pairs consisting of graphite fiber/antistatic fibers, non-woven graphite/silver-coated yarns, or hybrid knitted steel/alloy constantan wire composition have been used to design textile thermocouples [85,86]. However, these thermocouples exhibit a non-linear relationship between potential change and temperature and are characterized by low accuracy and sensitivity compared to conventional wire thermocouples [65]. In addition, they are also sensitive to changes in environmental relative humidity [86].

Textile RTDs: They use the temperature dependence of materials with electrical resistivity to determine temperature. These sensors can be developed by incorporating wires or conductors with a high temperature resistance coefficient into the fabric [65].

Therefore, fibrous sensors of RTD types could be developed by inserting metal wires (copper, nickel, and tungsten) in a knitted structure [87], by integrating metallic filaments in the middle of a double-knitted structure with different densities of metallic wire incorporation [88], by using cotton yarns coated with a PEDOT-PSS conductive polymer solution and a polystyrene encapsulation layer embeddable in a textile structure by weaving or stitching [89], by embroidering chromium–nickel austenitic stainless steel threads on a textile substrate [90], or by embroidering a hybrid thread composed of polyester fibers and a stainless steel micro thread on a fabric [91], which could be inserted in the outer layer of firefighters’ clothing [92]. This last work was able to demonstrate that textile RTDs offer increased accuracy and sensitivity, shorter response time, and better linearity with temperature compared to thermocouples [65]. However, these sensors could not provide localized temperature measurements, as the measurement is instead performed over the entire area of the textile [78,92].

Some studies, on the other hand, have reported an optical sensing approach for measuring body temperature by integrating optical fibers into the textile structure [93]. As a result, a distributed Bragg reflector with the ability to reflect light of specific wavelengths and transmit it to other wavelengths has been used [94]. The Bragg reflector was encapsulated with a polymeric substance and then woven into the fabric structure [95]. The authors have also analyzed mathematically the transmission of heat from the skin to the environment via the Bragg reflector and used a weighted coefficient model to estimate body temperature considering the wavelength shift as a function of temperature. They have also reported a high accuracy of ±0.18 °C in a range of 33 to 42 °C [95]. A new method of integrating optical fibers constituting a Bragg reflector into a hollow double-walled fabric structure has also been proposed in a recent study [96]. Despite the high accuracy provided by Bragg reflectors, the concept is far from being applicable to the design of a wearable device, as it requires connection to at least one amplified broad-spectrum light source and an optical spectrum analyzer [96]. The design of a textile heat flux sensor has also been proposed by investigating a method of inserting a constantan yarn into three different textile structures (polyamide-based knitted fabric, non-woven aramid, and aramid-based woven fabric), which is followed by several treatment and post-treatment steps including the electrochemical deposition of copper on the constantan yarn to obtain a thermoelectric yarn [97]. Figure 3 shows some examples of integrated flexible sensors in textiles and yarns.

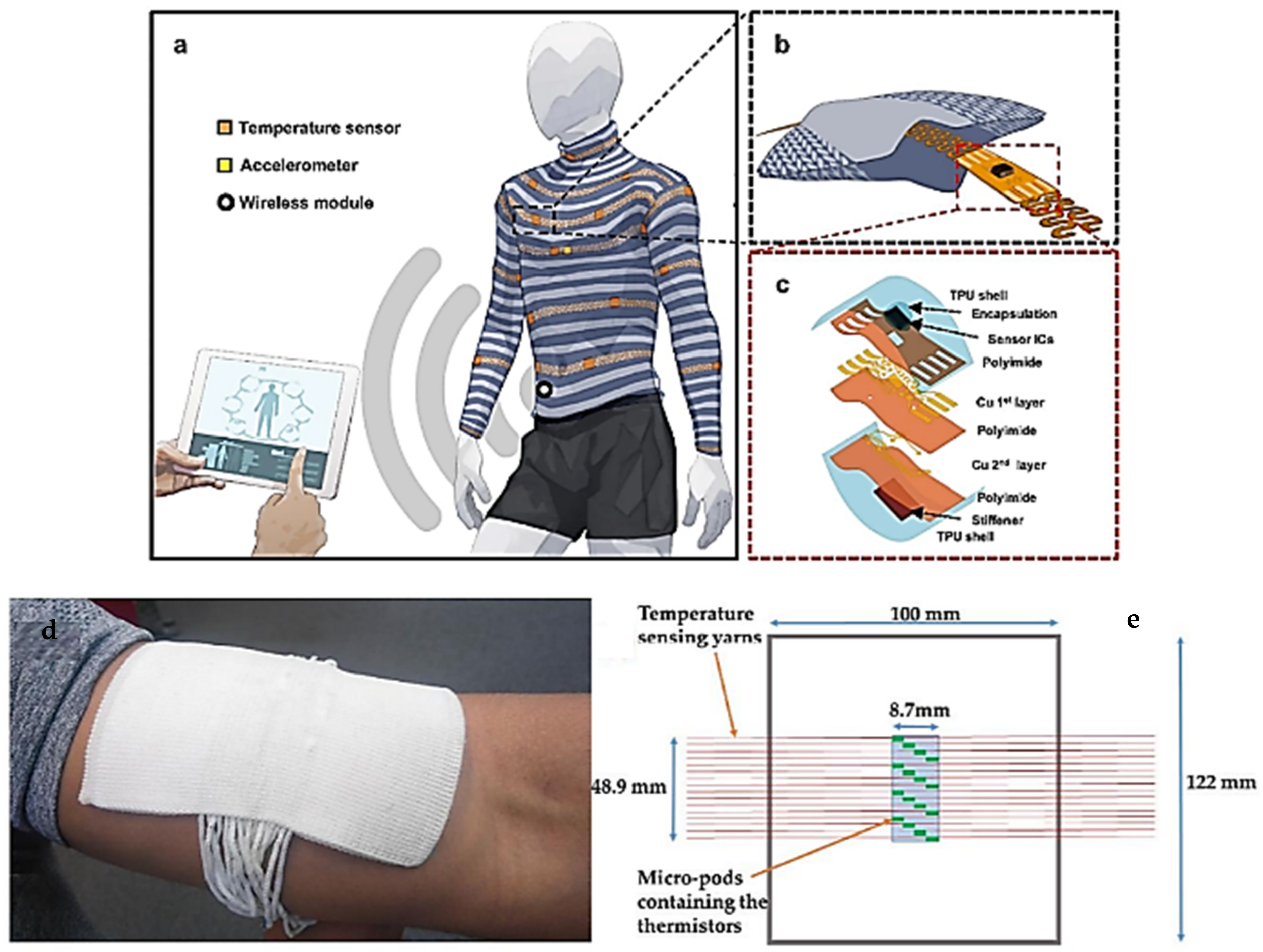

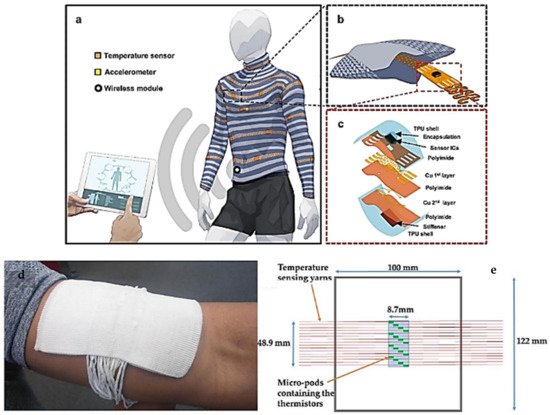

Figure 3.

Thermal detection of smart textiles. (a) Illustration of spatiotemporal sensor mapping of the body with temperature and accelerometer (heart beat and respiration); (b) Wearable textile with embedding stretchable–flexible electronic strips; (c) Exploded view of a sensor island. Reproduced with permission [98]. Copyright © 2021, Wicaksono et al. (d) Health monitoring textile with temperature-sensing yarns; (e) A schematic of the textile thermograph (d,e) [78].

2.2. Flexible Temperature Sensors

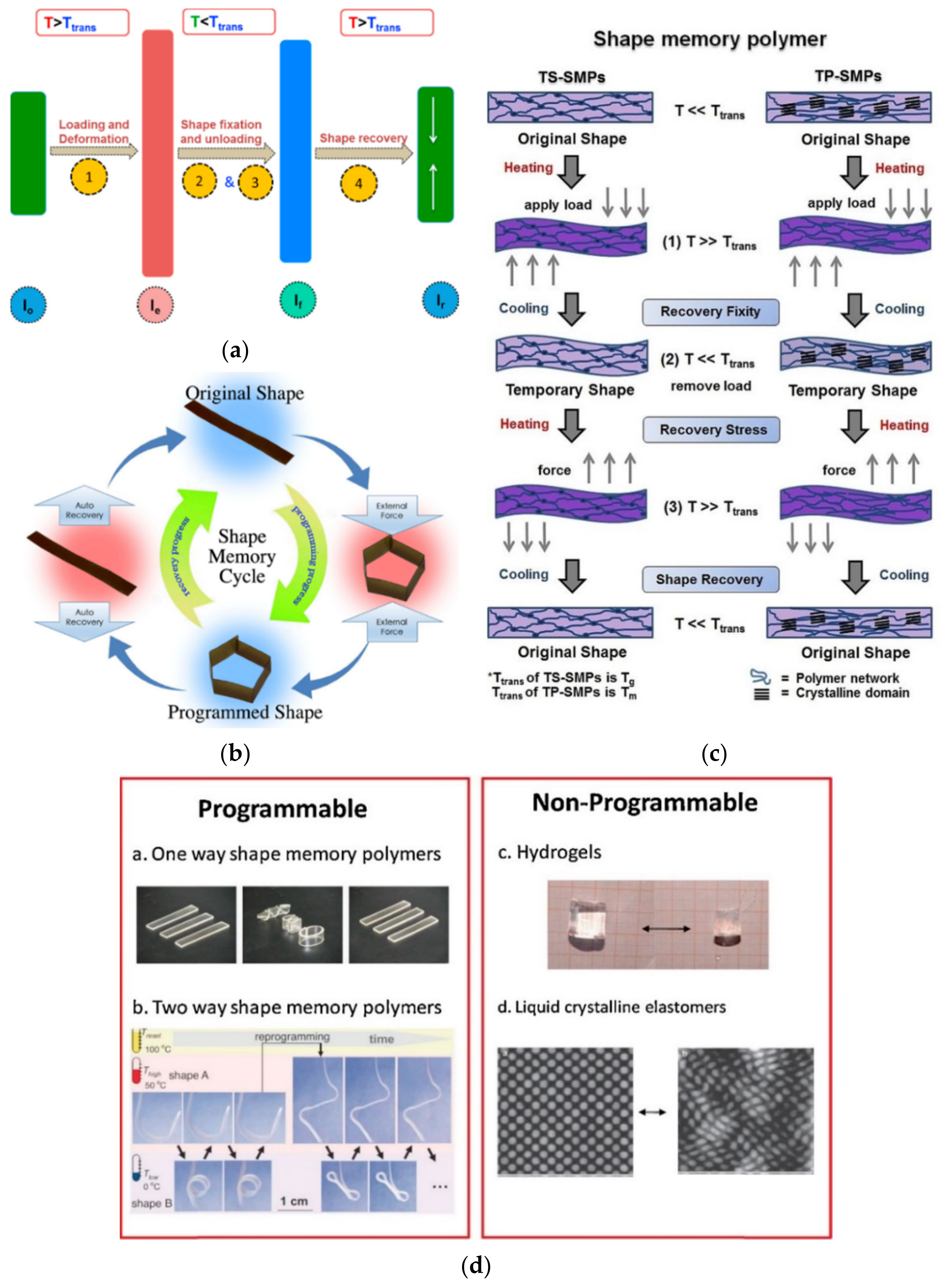

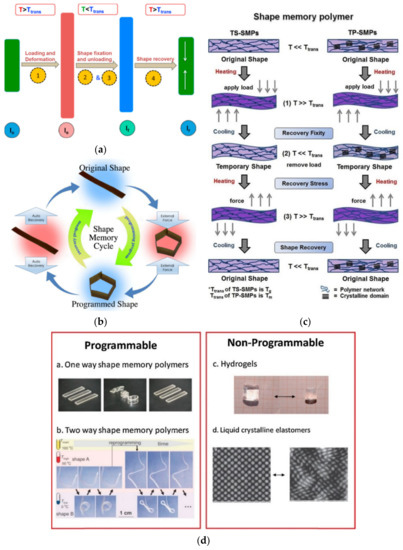

Although these studies are still at a very preliminary stage, some research groups have attempted to develop shape memory textile sensors. The concept is based on the use of shape memory polymers sensitive to external stimuli such as light or temperature. Recently, the innovation of sol gels, conductive polymers, and copolymers as biomaterials enabled the miniaturization of biological analyses in an integrated chip with new generation sensors using a Si light source with a wide visible wavelength range as an optical biosensor [99].

Temperature sensing functionality can be obtained by spinning shape memory polymer fibers, such as polyurethane fibers, with other types of fibers to make textile fabrics, or by coating shape memory polymer emulsions on a woven or knitted fabric [100]. Other configurations of shape memory materials applicable to fabrics include silicon [101], nanofibers, and shape memory foams. In order to facilitate the characterization of the thermal sensitivity of textile shape memory sensors, a shape memory coefficient based on the change of deformation angle with temperature variation was suggested [102].

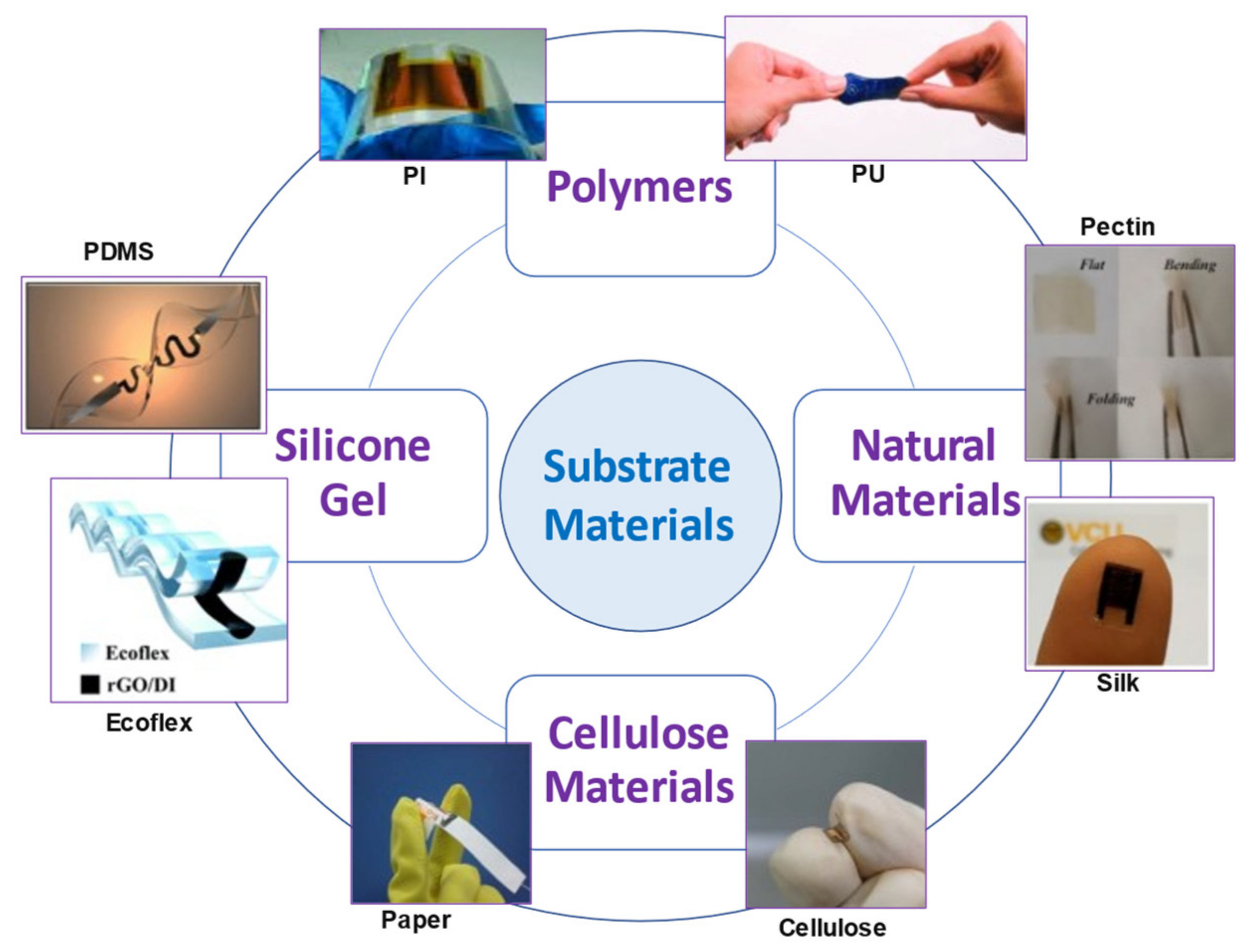

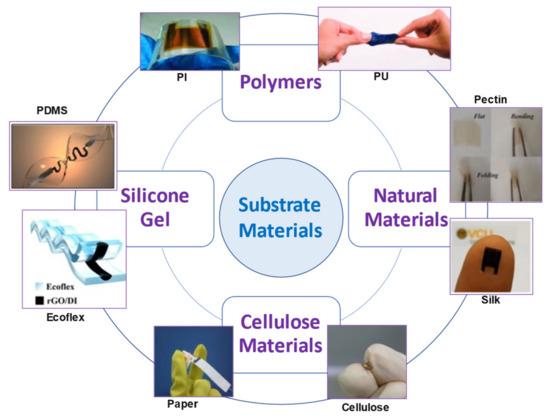

Many researchers have also worked on the development of flexible temperature sensors with the deposition of materials that facilitate temperature detection on flexible polymeric substrates using printing, coating, and lamination techniques [65] (Figure 4).

Figure 4.

Schematic illustration of flexible sensors materials. Clockwise from the right top: polyimide (PI) [103], polyurethane (PU) [104], pectin [105], silk [106], cellulose [107], paper [108], ecoflex [109], polydimethylsiloxane (PDMS) [110].

If they maintain their mechanical strength, these types of sensors can then be attached to fabrics or integrated into textile structures [100]. In this context, several studies investigated the development of flexible temperature sensors based on graphene as a highly conductive material from an electrical and thermal point of view [111,112]. Therefore, electrical resistance temperature-sensing layers have been developed by printing a graphene oxide formulation on polyimide and polyethylene terephthalate substrates, which is followed by infrared firing to obtain a material with a negative temperature coefficient [113]. A layer with an RTD property having a positive temperature coefficient (PTC) was also developed by deploying the plasma-assisted chemical vapor deposition method of graphene nanosheets on a polydimethylsiloxane (PDMS) substrate [114]. In addition, a stretchable thermistor was designed by integrating a graphene-based dispersion in a PDMS-based matrix as a detection channel, which was associated with electrodes formed from silver nanofilaments in polycarbonate membranes [111]. Thanks to the use of graphene, temperature sensitivities very close to those of metal oxide materials used in classical sensors have been obtained in a flexible structure [113]. However, the stretchable structure based on graphene has shown strong variations in its thermal behavior as a function of mechanical deformation [114], which may constitute a limitation for their integration in textile structures.

Printing techniques were also used to design flexible temperature sensors [115]. The most notable works include the screen printing of a carbon-based ink on a polyimide sheet to obtain a PTC thermistor-type structure [43], the screen printing of various resistive inks on polyethylene naphthalene being protected by a passivation layer of dielectric ink and plasma post-treatment to improve the temperature resistance coefficient of the printed layer [116], the ink-jet printing of a dispersion based on nanoparticles of nickel oxide in the space between two silver-printed electrodes using a polyimide substrate to develop an NTC thermistor [117], a 100 × 100 pixel array all-CMOS (Complementary metal–oxide–semiconductor) monolithic microdisplay system has proven possible to create a high-optical power efficiency all-CMOS microdisplay [118], and the ink-jet printing of a silver complex dispersion on a polyimide substrate to obtain a layer with PTC thermistor behavior [119]. Overall, the printed thermosensitive structures were able to offer high temperature sensitivity, while having very low hysteresis during heating and cooling cycles [116,117,119]. Screen printing of PEDOT-PSS conductive polymer and carbon nanotubes dispersion on polyimide substrates and the use of silver-based printed electrodes has also allowed the development of RTD layers. Then, the printed RTD layers were combined with radio signal transmittances to design a label [120] or bandage [121] to be placed on an individual’s skin to communicate with an external reader device [120]. Printed temperature sensors have also been developed on paper substrates [122,123]. In their current state, these types of development are rather intended for the packaging field and require work to reformulate the inks used to make them compatible with non-porous polymeric substrates with surface properties different from those of paper [64].

The formation of composite layers on flexible substrates has also been another method for the design of flexible temperature sensors. In this register, a composite film with RTD properties could be obtained by coating a mixture of poly o-methylaniline and manganese oxide (Mn3O4) on a solid substrate [124]. In addition, a composite film based on tellurium nanofilaments in a poly-3-hexylthiophene matrix deposited on a flexible substrate was used to obtain RTD behavior [125]. The deposition of graphite particles dispersed in a PDMS matrix on inter-digitalized copper electrodes prefabricated on a polyimide substrate was also deployed to obtain a composite film demonstrating RTD properties [126]. The dispersion of multiwall carbon nanotubes in a toluene solution of polystyrene–ethylene–butylene–styrene (SEBS) deposited on gold electrodes fabricated on a polyimide substrate resulted in a composite film showing NTC-type thermoelectric characteristic of a sensitivity comparable to the highest values for metals [127]. In a similar study, a mixture of multiwall carbon nanotubes and a polyvinyl benzyl derivative with trimethylamine coated on a pair of gold electrodes fabricated on a polyimide film led to the formation of a composite film with RTD behavior and a sensitivity comparable to that of metals [128]. The combination of a binary composite film of polyethylene and polyethylene oxide loaded with nickel microparticles with a passive RFID antenna has led to the design of a portable RTD temperature sensor. Despite the portability of this prototype sensor, it had three times the sensitivity of similar commercial sensors and a significant measurement error of ±2.7 °C [85]. In this framework, an array of 16 RTD-type temperature sensors was also fabricated with narrow serpentine gold traces using a microlithography technique on thin layers of polyimide to design an electronic skin to be fixed to the skin by the action of Van der Waals forces [129].

2.3. Radio-Frequency Identification (RFID)

As part of the development of flexible temperature sensors, other work has opted for radio-frequency identification (RFID) tags to be placed on the skin to measure Ts. For example, these studies have contributed to the development of a passive ultra-high frequency (UHF) RFID tag, which is based on the temperature dependence of the ring oscillator frequency and allows data to be sent to a reader at 868 MHz with a range of 2 m [130]. Similar work has developed a flexible RFID tag comprising a commercial microchip providing direct thermal reading and an antenna designed with copper adhesive transferred onto a polycaprolactone membrane to be attached to the individual’s arm or abdomen with hypoallergenic cosmetic glue. The label allowed the data collected to be sent in a band of 780–950 MHz and a range of 30–80 cm to a nearby reading device [131]. According to the analyses of this study, the label placed on the skin requires that the label itself does not alter the locally measured Ts and must allow the natural perspiration of the skin to be preserved [131]. In a similar work, a modular patch with two detachable components, including a reusable inner part housing electronic element (the antenna, the integrated circuit, and the battery) and a disposable cover encapsulating the sensor associated with a medical-grade adhesive ensuring adhesion to the skin surface, made it possible to develop a real-time epidermal temperature sensor using UHF-type RFID communication [132]. In addition to a deviation of 0.6 °C from reference measurement methods, the influence of human variability and environmental conditions on the sensitivity of this sensor remains to be clarified [132].

Advanced materials have also been applied to the optimization of certain types of portable devices such as portable in-ear devices, which is a new technological trend in recent years to measure body temperature and other physiological parameters through sensors that hold. A dispersion based on graphene, as a highly conductive material known for its strong optical absorption in the infrared range, has been coated on the silicon substrate of the lens of IR thermopiles used in portable in-ear devices with the aim of increasing the accuracy of measurements in such a thermopile [133].

2.4. Textile Prototypes with Flexible Temperature Sensors

The overall analysis of the research on temperature sensors integrated in textile structures, textile sensors, and flexible temperature sensors has shown that the vast majority of these studies remain at the level of proof-of-concept of components that are still to be integrated in clothing, although some work is dedicated to temperature sensors integrated in work clothing. In one of these studies, the ambient temperature and heat flux through the garment could be measured by a modified PTC grade sensor network integrated in the outer and inner side of the firefighters’ protective clothing with the transmission of the collected data to an external reader device using the Zigbee communication protocol. The prototype, tested on a thermal manikin in the laboratory, had yet to be validated in an operational environment [134]. A work jacket for oil workers operating in extreme cold was also developed using an embedded IR temperature sensor and two combined humidity/temperature sensors. The jacket consisted of one humidity/temperature sensor on the outside of the jacket, a second pair of sensors placed on the opposite side of the jacket on the inner side, and the IR sensor, which was integrated on the inside of the sleeve for non-contact measurements of Ts at the wrist [135]. This jacket equipped with temperature sensors could be optimized by, among other things, placing a layer of heat-reflecting film in the lining of the jacket on the inside to reduce the influence of the person’s heat on the outside temperature measurements and adding a layer of elastomeric material around the outside sensor to reduce the heat flow through the jacket in the vicinity of the sensor [136].

A smart glove and an armband each comprising two electrodes made of conductive textiles to measure the galvanic skin response and a sensor from a commercial digital thermometer detecting Ts were developed to assess the conditions of soldiers in real time. Both were tested on about 40 subjects, but the assembly remained cumbersome, and the main signal transmission lines were fabricated with electrical wires that could be damaged during use or maintenance [137]. A thermistor microencapsulated in a wire [78,82] has been integrated into a cuff, glove, and sock for measuring Ts [138]. The cuff contained four wires each with a thermistor, while the glove and sock were based on a set of five wires each containing a thermistor. The contact pressure on the hands was found to influence the measurements due to the deformation of the sensor wire structure in the glove. In addition, the fit of the sock can also affect the measurements, as can the wearing of a shoe or walking, which appear to strongly influence the temperature measurements. These measurement errors seem to show that monitoring the foot skin temperature by sensors integrated in the textiles could be challenging for applications where accurate measurements are required. According to this study, fabrics containing sensor yarns should be manufactured according to the contact pressure exerted at the temperature measurement emplacement [138].

2.5. Commercial Textile with Temperature Sensors

Due to the need to monitor patient health or athlete performance, more and more portable products with temperature sensors have appeared on the market in recent years. Some integrate temperature sensors into their structure and others are based on the deployment of advanced materials. Among the commercial devices for biometric sign detection in the form of portable accessories in recent years, Biofusion (by Biopeak, Ottawa, Canada) and QardioCore (by Qardio, San Francisco, US) offer integrated systems that use contact RTD-type temperature sensors to measure Ts from the chest.

Based on printable electronics techniques, flexible temperature sensors have also been produced and have entered the market to serve areas such as transportation, logistics, food supply chain, and home appliances. Thanks to their flexibility, their integration into textile structures seems conceivable. However, their adaptation to textile structures still requires a certain number of technical challenges to be taken up, especially in terms of durability in wear or maintenance, especially in washing [139]. These types of flexible sensors such as those proposed by the company PST sensors (Cape Town, South Africa) are mainly printed thermistors associated with an electronic chip. The conductive ink used in these types of development is based on a composition that, once printed, demonstrates RTD properties [113,120].

Then, circuits containing these types of printed thermistors can be combined in a hybrid system with wireless data transmission protocols [140]. According to the manufacturers of these types of flexible thermistors, the sensors developed provide measurement accuracy ranging from ±0.1 to ±0.25 °C. While providing a very low response time of 100 to 250 ms, these flexible temperature sensors have the advantage of operating with low working powers in the nano or micro watt range. Graphene conductive layers with RTD characteristics, demonstrating a very high sensitivity to temperature changes [111], have recently been successfully used in the design of a connected insole based on an integrated thermistor to continuously monitor temperature changes in patients’ feet and detect early signals of foot ulcers in diabetics (Smart Insole by Flextrapower, New York City, NY, USA). These types of products for the medical field may be of interest for knowledge transfer toward an occupational health and safety application.

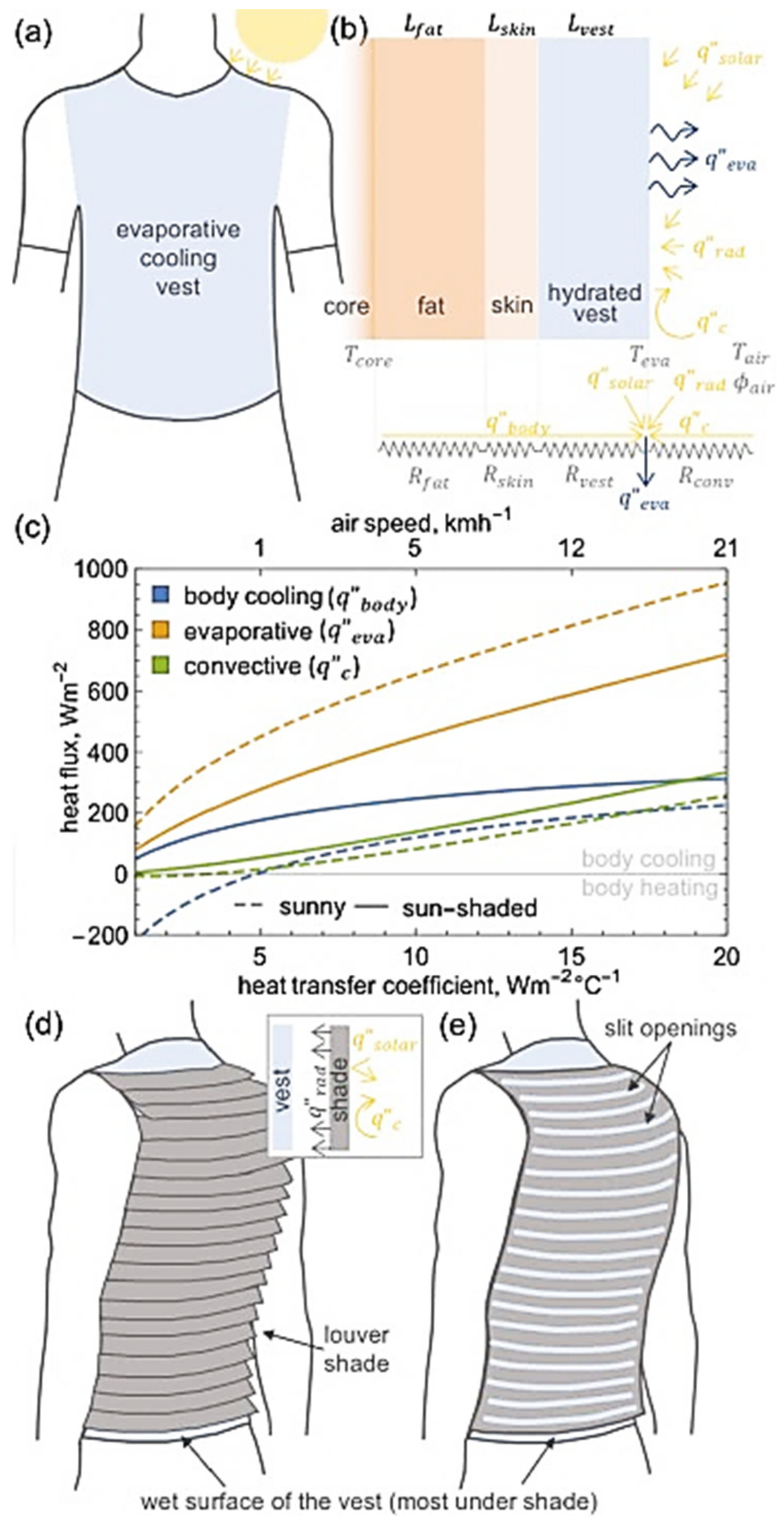

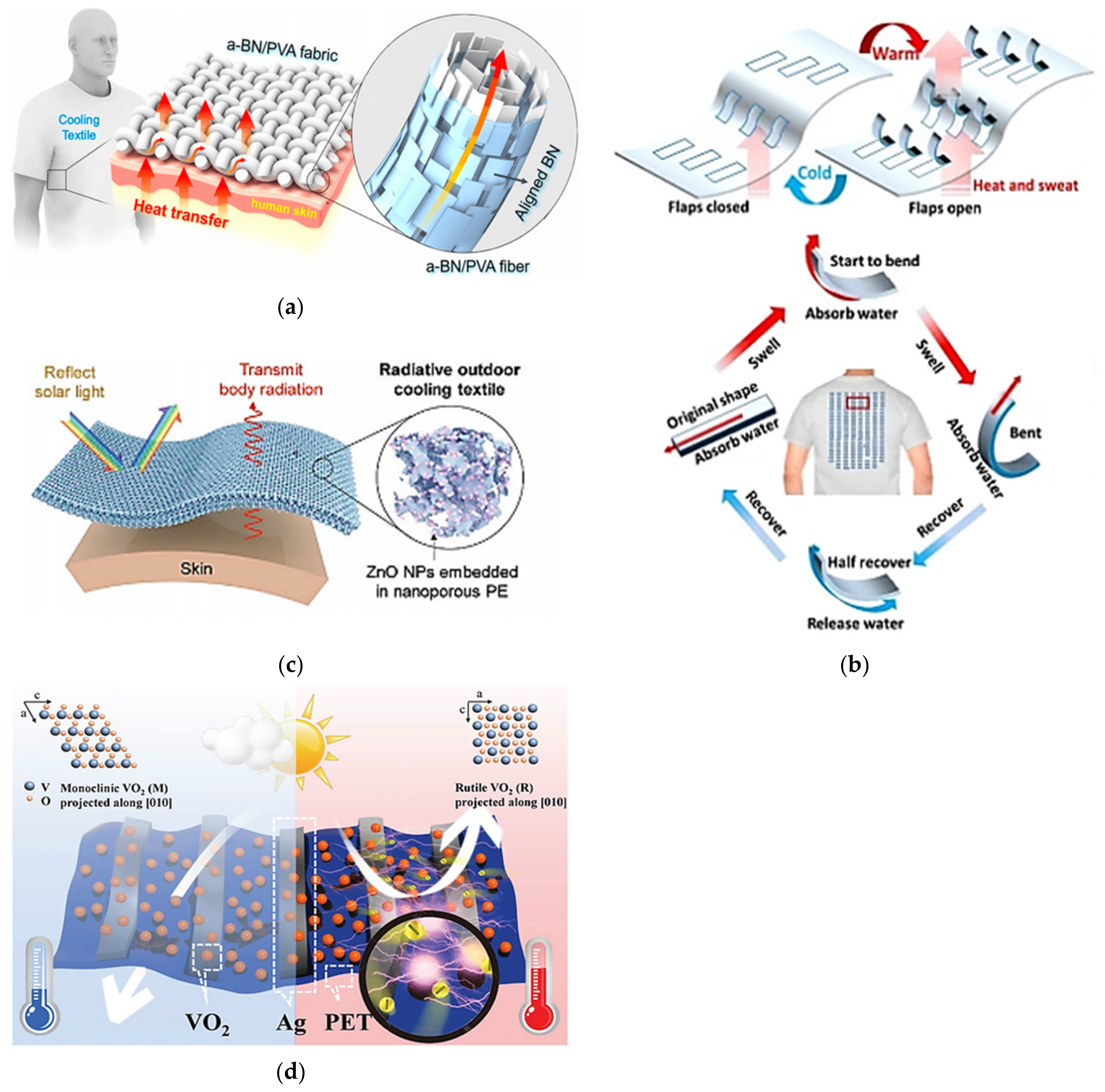

Regarding products marketed in the form of temperature sensors integrated into clothing, a very limited number of products exist on the market. These products were mainly developed to help protect firefighters [39]. In this context, the companies Ohmatex (Aarhus, Denmark) and Viking (Esbjerg, Denmark) jointly presented a firefighter suit containing thermal sensors integrated inside and outside the firefighter’s clothing to monitor environmental and near-body heat, respectively. The sensors are connected to LED displays on the sleeve and shoulder of the jacket. Above a certain temperature threshold detected on the outside or inside the jacket, the flashing of the display alerts the user. Despite the presence of an integrated electronic device, this garment had the advantage of withstanding at least 25 wash cycles.

The Balsan fire jacket (by TeckniSolar Seni, Saint-Malo, France) was also equipped with temperature and humidity sensors. A temperature sensor on the outside of the jacket measures the environmental temperature and a pair of temperature/humidity sensors on the inside of the jacket measures microclimatic conditions close to the body. When parameters exceed a certain level, an audible and visual alarm alerts the firefighter [62,141].

2.6. Apparels Measuring Thermal Stress

The review of research literature for measuring body temperature tools and sensors that can be integrated into protective equipment to assess the microclimate under the clothing or the environmental temperature in order to develop warnings in case of very high thermal stress are presented in Table 1.

Table 1.

Temperature sensors to be integrated into textile apparels.

2.7. Temperature Sensors Challenges

Concerning the studies dedicated to temperature sensors that can be integrated in textiles, the present state of the art has found that a lot of work is dedicated to the design of temperature sensors based on smart textiles and flexible electronics [53,93,157], and a very limited number of studies on sensors integrated in clothing has been identified. A hybrid approach has been proposed to integrate rigid thermistors in a flexible matrix in the textile structure. Despite several works related to integrated thermistors, some prototypes lack mechanical strength, while others require optimizations regarding detection accuracy. Another method has been to design fibrous sensors such as RTDs or thermocouples. According to the studies analyzed, fibrous thermocouples require significant optimization effort, because in addition to low sensitivity and low measurement accuracy, they have proven to be sensitive to environmental humidity. Although the textile RTDs developed in analyzed studies have provided better accuracy, higher sensitivity, and shorter response time compared to textile thermocouples, these sensors were not able to provide localized temperature measurements. Therefore, the use of textile RTDs to measure temperatures in micro or macro environments remains to be validated. The integration of Bragg reflector-type optical fibers to measure body temperature, which has provided high accuracy, is far from being applicable to a portable device, as such concepts require connection to fixed optical systems. The same observation is valid for concepts that have integrated heat flow sensors in textile structures. Being intended to be eventually integrated in clothing, textile temperature sensors need to be validated for mechanical or wash resistance in future work.

In addition, experts in flexible electronics have shown great interest in the development of temperature sensors on flexible polymeric substrates. Graphene layers deposited on flexible substrates have demonstrated RTD properties of very high temperature sensitivity. However, in an extensible configuration, the RTD graphene layers have shown thermal properties sensitive to mechanical deformations. Layers with RTD properties have also been developed on flexible substrates by depositing different types of dispersion (based on carbon, nickel oxide, silver complex, and mixing PEDOT-PSS with carbon nanotubes) using printing techniques. These heat-sensitive printed layers were able to ensure high temperature sensitivity while demonstrating low hysteresis in the heat–cooling cycles. The formation of composite layers on flexible substrates also allowed the fabrication of flexible temperature sensors. Among the various developments, composite layers based on carbon nanotubes have made it possible to obtain thermal sensitivities comparable to those of metals. However, in many studies on composite layers, electrodes based on precious metals such as gold have been used. Despite the advantages of some concepts for flexible temperature sensors, significant efforts are required to integrate them into clothing. From a general point of view, work on textile-integrated temperature sensors, textile sensors, and flexible temperature sensors seems to remain at the level of proof of concept with very few connected device demonstrators and even fewer prototypes of garments equipped with temperature sensors. In addition, the influence of various environmental parameters on the performance of these types of sensors remains unknown. Among the few studies on the design of garments with integrated temperature sensors, very few were dedicated to protective equipment, and almost all the work was carried out in the laboratory with tests on very few subjects. The effectiveness of these concepts has yet to be validated in operational environments. In addition, in most of these studies, conventional electrical wires were used for electrical connections or to ensure the transmission of collected signals. These types of structures containing electronics can be vulnerable to mechanical constraints during use and maintenance. The use of structures based on conductive textiles is to be expected in order to ensure a better mechanical resistance in use. Clothing equipped with temperature sensors that incorporate rigid thermistors embedded in textile fibers also require optimization efforts in order to reduce the impact of mechanical stresses on the quality of the sensor reading. The literature also mentions the influence of the fibrous structure surrounding the sensor on the reading [78]. Not only have few studies been carried out in this area, but an in-depth knowledge of the influence of the multilayer structures of various types of protective equipment on the performance of integrated sensors remains to be developed.

Among the commercially available products, flexible temperature sensors seem to be able to ensure high measurement accuracy and very short response times. Being mainly based on a very thin printed structure, this type of sensor requires relatively low power supplies of the order of microwatts. These products, which are currently manufactured on flexible polymeric substrates, are mainly dedicated to the fields of warehousing and logistics. In order to extend their application to clothing, research is still needed to ensure their reliability and durability in use. Very few products including garments with integrated temperature sensors currently exist on the market. These products are mainly dedicated to the protection of firefighting workers. These types of protective equipment, which include temperature sensors incorporated into their structure, can warn the firefighter when predefined temperature thresholds inside or outside the garment are exceeded.

3. Heated Actuator

In recent years, the textile industry has proposed multiple solutions to offer better protection against the cold during outdoor winter activities. The use of various types of textile materials has made it possible to reduce heat loss from the body while ensuring the transmission of moisture from sweat through a garment that must remain water and wind resistant [158].

Despite technological advances in textile materials engineering, these types of garments still need to be improved. Indeed, most garments against extreme cold remain bulky by being based on multilayer fibrous structures taking advantage of the thermal resistance of textile materials, which depends mainly on their content of air trapped inside. In addition, highly insulating garments can sometimes limit body and arm movement and reduce manual dexterity, thus affecting individual performance. A feeling of discomfort may be particularly accentuated when clothing against the cold is worn in combination with other clothing [39,159]. In addition, it has always been difficult to correctly estimate the optimal clothing or number of layers to wear for sustained physical activity under varying environmental conditions [55].

3.1. Heating Garment Technologies

During intense activities in the cold, excessive perspiration, and consequently the humidification of the inner layers of the garment, can lead to a considerable decrease in thermal insulation, thus increasing the risk of cold-related injuries [160,161]. To offer a better level of comfort and higher endurance during activities in extreme cold, warm personal clothing has been proposed by actors of the textile industry. These types of garments also aim to offer more personalized solutions to individuals, incorporating additional technologies to their basic textile structure. The development of personal warming garments is of particular interest in a work context in order to protect workers against injuries directly or indirectly related to prolonged exposure to extreme cold [161]. These garments can be presented under four main categories according to their principle of operation: (1) Electric heating garment; (2) Fluid-flow-based heating garment; (3) Phase change material heating garment; and (4) Chemical heating garment [55].

3.1.1. Electric Heating Garment

Among the different categories of personal heat garments, this study has mainly focused on electric heat garments, as they can provide heat in a sustained and durable manner throughout the performance of tasks in extreme cold, depending on the endurance of their portable power source. In addition, their structure incorporating a heating element could provide heat distribution in a space-saving, thinner cold protective garment [162,163]. The integration of electronic modules in combination with electric heating elements facilitates the creation of garments with adjustable heating levels that can even be adjusted to the individual’s personal situation [164].

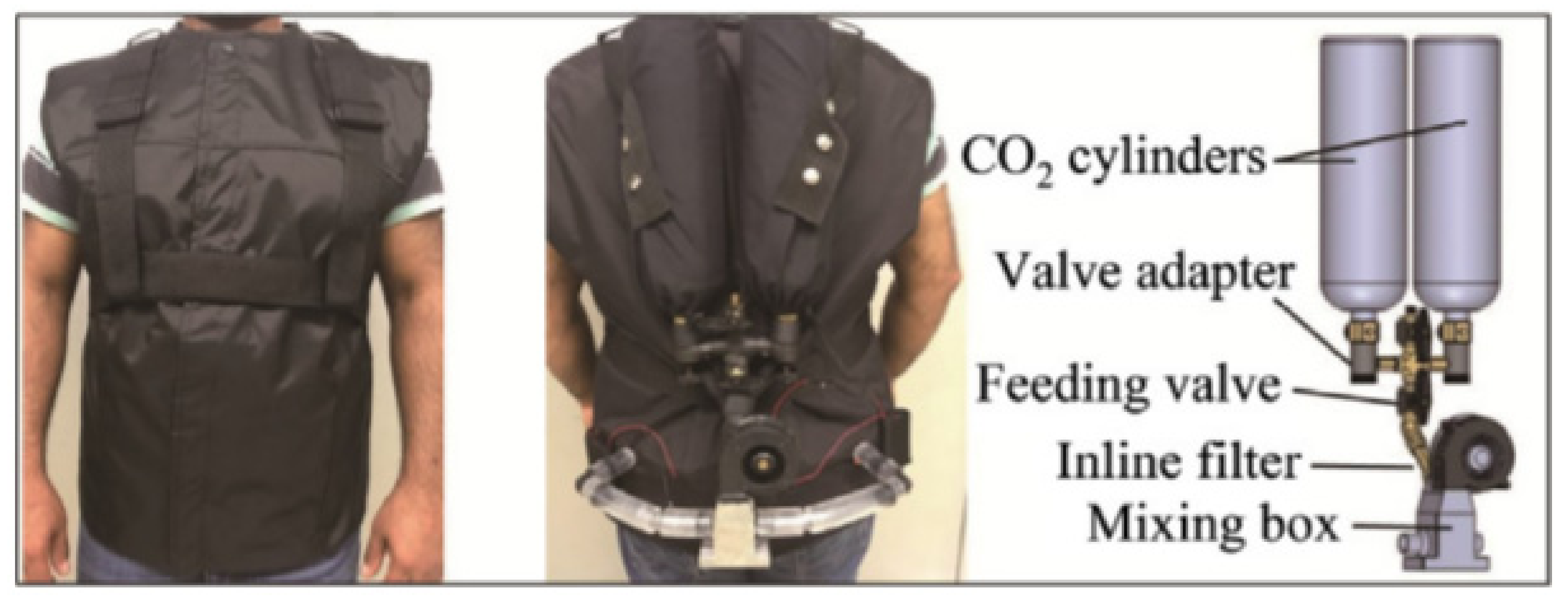

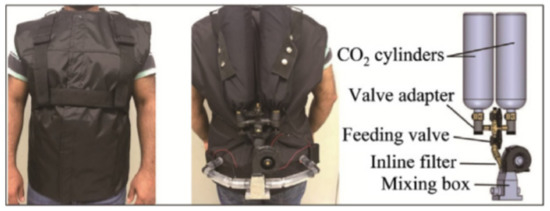

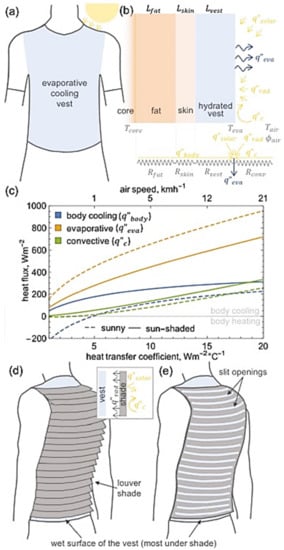

3.1.2. Fluid-Flow and Airflow Based on a Tubing System

In contrast to electric heating garments, fluid-flow-based heating garments are very bulky. Almost every example of this type of heating garment, based on a flexible tubing system for circulating liquid or hot air, requires an external energy source and fluid supply. In addition, the tubing system integrated into the garment makes it rigid, which may limit its usability during activities [55]. Nevertheless, due to their thermodynamic efficiency in heating the human body and the heat exchange capacity of specific areas, airflow-based heating garments have been successfully applied for medical surgery [165].

3.1.3. Phase Change Material Heating Garment

Heating garments based on phase change material (PCM) also have important limitations despite a very interesting potential and many dedicated efforts. The most important limitation of this technology is its temporary heating effect. Although it is active during its phase change period, the release of heat ceases when the PCM, initially in a liquid state, solidifies with exposure to cold. Thus, in order to recover its heat source based on a phase change mechanism, it is necessary for the PCM to move away from the cold environment to reach its liquid state again [59]. It has also been reported in the literature that the integration of microencapsulated PCM into garments by coating and fiber-spinning techniques shows a low heating effect due to their low mass. In addition, their effect may gradually disappear when clothes are washed several times [60].

Since the thermal regulation capacity of textiles incorporating PCM is highly dependent on the amount of material deployed, the incorporation of PCM pockets in clothing generally leads to heavy clothing and may only be suitable for people for whom, depending on the activities, the extra weight is not a problem [60]. To address these problems, a great deal of research is underway. However, significant efforts still seem necessary to optimize the global enthalpy of phase change and the thermal window of the PCMs to ensure a sustained heat release effect [59,61] to meet the requirements of continuous hours of activity in cold weather.

3.1.4. Chemical Heating Garment

Chemical heating garments are mainly based on chemical energy converted into thermal energy by oxidation during the reaction of chemical substances and are mostly used in diving suits to protect divers in cold water. The integration method remains primitive, because the reactive material placed in cushion-like packages is glued by an adhesive to the inner surface of the garment. The heat-generating chemicals are kept in separate compartments inside the cushion. When the user presses the pad, the barrier between the substance’s breaks, and the reagent mixes is generating heat. Although this system can use a mass of selected reagents to provide a highly exothermic chemical reaction free of gaseous by-products, the released temperature is difficult to control and of limited duration [166,167].

3.1.5. Power Source

Despite durable heating throughout the duration of cold work, the low capacity of the batteries to ensure the proper functioning of the integrated heating system during long exposures to cold remains one of the major drawbacks of textile structures incorporating electric heating elements [38]. The rapid development of telephones and laptops has led to the availability of powerful and durable batteries that can also be used for auxiliary heating. However, these batteries may have disadvantages in terms of weight, space requirements in the garment structure, and the danger of overheating for some types of lithium-ion batteries [38]. The problem of efficient power supply for electrical functions is a major challenge in the design of intelligent textiles. Therefore, a lot of work has been undertaken to develop new methods for integrating energy sources [168] and textile structure batteries [169], while searching for new regenerated energy sources such as solar energy, sound wave power, human movement, or even friction energy from clothing [170,171]. Since this is a topic of important scientific interest that affects the entire field of smart textiles, the analysis of advances in flexible and portable energy storage for different types of electronic textiles requires a comprehensive study separate from the present one. Thus, the review of the literature concerning heating actuators has mainly focused on techniques for the development of electric heating elements that would offer a more efficient energy consumption with current portable energy sources, as well as a better heat input while ensuring flexible structures in order to better withstand mechanical stresses during the use and maintenance of personal protective equipment.

3.2. Conductive Heated Actuator

The functioning of electric heating garments is based on the Joule heating principle also known as ohmic heating [172], according to which the passage of an electric current through a conductor generates heat by affecting the integrity of the conductive body. According to Joule’s first law, the heating power of this principle is proportional to the product of the resistance of the conductive body and the square of the electric current flowing [173]. In early versions of electric heating garments, the heating element was based on an integrated electric heating wire or a 3D heating pad composed of electric wires or graphite elements [174]. Despite their advantages in terms of increased comfort in the cold, some users have pointed out disadvantages such as clutter, restriction of movement, overheating, and problems with the durability of the electrical wiring system during use and maintenance [55]. In addition, electric wire heating had technical limitations, as by restricting heating to the path of the wire, it failed to produce uniform heat over a selected area [163].

In order to circumvent these drawbacks, the design of heating elements based on conductive textile fibers or the deposition of conductive layers on the surface of textiles has been proposed by the scientific community [166]. Based on the technology used, these types of heating elements can be divided into five categories: (i) textile substrates coated with compositions based on silver particles; (ii) textile substrates coated with conductive polymers; (iii) heating elements based on carbon fiber or carbon-based compositions; (iv) heating textiles based on yarns of metallic compositions, and (v) hybrid heating textiles using simultaneously passive heating actuators and electric heating elements.

3.2.1. Silver Coated Yarns

With the goal of solving the problems associated with the use of electrical wires as an integrated heating element in clothing, several works have attempted to apply metallic textile wires or wires made from metallic compositions [175]. In part of this work, heating elements were developed by sewing seams of metallic textile threads on the surface of various types of fabrics to simulate the embroidery process. In an analytical study, conductive yarns based on silver-coated VectranTM fibers (a type of aromatic polyester) [176] were sewn in serpentine shape on three stretchable knit fabric composed of cotton–elastane, polyester–elastane, and nylon–elastane in different variations. It was found that different levels of heat can be generated depending on the number of yarn passes, the spacing of the coil curves, and the type of knit, which also dictate the level of electrical power required [54]. Based on the knowledge developed on the spacing required between the coil curves and the number of yarn layers superimposed to obtain the best thermal response in terms of electrical power versus temperature [54], a prototype wrist heater providing a temperature range from 33 to 40 °C was developed using the same type of conductive textile yarn [177]. According to these studies, the creation of heating elements from embroidered conductive textile yarns could allow the generation of a much higher heat range than heating elements based on electric heating wires by applying the same power supply. According to the authors of this study, the influence of substrate fiber content, stitch configuration, and increased heating zone still requires further work [54]. Using the same technique, a heating element based on a silver wire was designed to provide heat close to body temperature with a power of 5 W supported by a portable 10 V battery with a capacity of 6000 mAh for 8 to 10 h of supply [178]. In addition, the power supply and saturation time for a given temperature were analyzed for a heating element designed by sewing a silver-coated nylon thread onto a polyester-based fabric to elucidate the power level required to achieve heat levels in the range of 27 to 43 °C [166]. All these results can contribute to the optimization of heating element design with embroidery techniques on an industrial scale.

As knitted fabrics offer flexible and stretchable structures, the creation of knitted heating elements has attracted particular attention from the scientific community in recent years [179,180,181,182]. In this context, the heat production of two silver-coated textile yarns with different electrical resistance, embedded in a traditional wool knitted fabric, has been studied by applying various levels of electrical tension for more than one hour. The results of this study showed that the total electrical resistance of the conductive knit fabric decreases significantly when the fabric is heated, as the linear resistance of the conductive yarns as well as the resistance of the contact points between the superimposed conductive yarns in the knit structure decreases with increasing temperature [182]. Studying the behavior of a silver-coated polyester yarn embedded in three different knit structures showed that the maximum equilibrium surface temperature of heated knit fabrics is strongly correlated with the energy consumption density. Furthermore, the maximum equilibrium surface temperature can be influenced by the knitting method, as the electrical resistance of some structures seems to remain more stable than others during the heating process [183].

Analysis of the design of weft knitted heating pads using three different types of conductive textile yarns embedded in two knitted fabrics of similar structure, but with different main yarns (acrylic and polyester respectively), showed that the electrical resistance of the conductive yarn and the composition of the knitted textile fibers surrounding the conductive textile yarn greatly influence the heat generated at a fixed supply voltage. The authors concluded that the acrylic yarn of the knitted fabric would have better heating and heat retention properties compared to polyester when using the same type of conductive yarn [184]. The influence of the design and the method of integrating the conductive yarn on the heat generated was also studied by integrating a silver-coated textile yarn into a fully knitted structure to compare it to stitches on the surface of a shoe insole. Depending on the design and the type of textile threads surrounding the conductive thread in the fabric, temperatures higher than the body temperature could be obtained with electrical powers as low as 1.7 Watt provided by portable low-voltage batteries [185].

3.2.2. Metallic Textile Heating Elements

In addition to silver or silver-coated conductive textile yarns, other types of conductive textile yarns with a metallic composition were also considered for the design of heating elements. The study of the behavior of steel wire-based heating panels using single and multilayer steel wire integrated in clothes showed that the thermal effect obtained, and the time required to reach an equilibrium temperature at a fixed voltage, depended on the number of wire folds in the cloths [186]. In addition, the criteria for selecting conductive yarns for knitting an electric heater was explored using two types of steel yarn, two types of silver-coated polyamide yarn, and one polyester/steel blend yarn, each of which was knit in two patterns: (1) wool/polyamide knit with a 1 m long conductive yarn in three rows of loops; (2) a conductive area in a multiply knit fabric [187]. While finding that the maximum equilibrium temperature of the heating elements was influenced by the method of integration of conductive yarns, the authors concluded that an optimal heating element should contain conductive yarns with low electrical resistance and minor variations in electrical resistance to elongation, providing good temperature uniformity during the heating process while being mechanically suitable for knit structure. In this work, silver-coated polyamide yarns in a three-ply configuration were able to provide the most uniform heating zones while being technically suitable for a knit structure [187]. Analysis of the method of manufacturing flexible heating fabrics by integrating a copper coil filament between two pieces of flexible interlining fabric using the thermal adhesion process has demonstrated that reducing the copper wire spacing and the applied tension, while improving the thermal conductivity of the textile structure of the fabric, not only increases the temperature and heating rate but also helps to maintain the fabric at a uniform temperature [188].

In this context, a fabric with variable insulation properties was developed with a structure consisting of three fleece layers and two interlayers comprising copper filament spirals and Nitinol as a temperature-sensitive shape memory element. The inner layers, being heated by the passage of an electric stream, made it possible to increase the thickness of this part of the fabric during the heating process, thus ensuring the increase in the insulation of the fabric due to the increase in air present in the transverse direction of the fabric. The heat-induced physical change in the conductive spirals could be electrically adjusted, providing a means to control the overall insulation level of the fabric [159]. Finally, a heated knitted fabric was developed using a conductive elastic yarn of composite structure that included an elastane filament as a core and a steel filament combined with rayon fibers as a sheath wrapped around the core. Composite yarns of varying degrees of tension were embroidered on the surface of commercial knitted fabrics to obtain heating fabrics. According to the analysis of the thermomechanical behavior of heating fabrics based on conductive elastic yarn, despite reasonable cyclic stability in tensile tests, the temperatures obtained seemed to decrease with increasing tensile stress but still reached a stable thermal equilibrium after the application of the deformation [189].

3.2.3. Mathematical Models for Metallic Heating Textiles

To facilitate the design of electric heating elements based on metallic textile wires, some research work has proposed mathematical models to better anticipate the behavior of the heating textile to be developed. In one of these studies, the thermomechanical properties of knitted structures based on silver-coated textile yarn were mathematically modeled as a function of the influence of the contact pressure at the structural bonding points on the heating level. Thus, considering the relationship of the electrothermal property of the material and the structural parameters of the knitted fabric, the resulting temperature and loop resistance of a knitted fabric of uniform width can be predicted. Practical validation of the model with a heated knitted fabric based on silver-coated polymeric yarn showed that the maximum temperature obtained at a fixed supply voltage would depend on the structure of the knitted fabric in plain, ribbed, and interlock stitches [190]. The same research group proposed a second model to predict the electrothermal behavior of a steel wire knitted structure, whose predictive accuracy was subsequently evaluated with experimental trials of integrating conductive steel wires into double-ply knitted fabrics of interlock and solid structures [191]. The results of this study showed again that the maximum temperature obtained and the reaching of a heating temperature equilibrium state at a given voltage would depend on the structure of the knitted fabric. Based on the analyses performed, steel wire-based heating elements can generate a greater amount of heat at very low power supply voltage, and therefore, its use would be recommended over silver-coated yarns when a high level of heat is required. This study also recommends an interlock structure for the design of heated knitwear due to better stability and higher temperature supplied compared to solid knitwear at the same electrical supply voltage [192].

Another theoretical model has been proposed to control the temperature of conductive knitwear of various courses and stitch yarns based on the quantitative relationship between the electrical resistance of a conductive knitwear and the temperature provided. According to this model, by knowing the initial resistance and thermal diffusivity [193] of the knitted fabric, as well as the applied voltage, it would be possible to predict the temperature provided by the knitted fabric. Experimental validation of the model with silver-coated yarns in the design of five woolen knitwear, with the same loop density but different loop arrangements, has demonstrated the dependence of the maximum temperature obtained on the type of loop arrangement [193]. Another model predicting the electrothermal properties of conductive knitwear was proposed by taking into consideration the thermal capacity of conductive and non-conductive yarns, the electrical resistance, and the thermal capacity of the heated knitwear. Experimental validation of the model, which also considered the coefficient of thermal conductivity, the mass, and the initial temperature of the fabric, showed that the coefficients of thermal conductivity and the thermal capacities of electrothermal fabrics depend on the type of conventional fiber used and the density of the loops of the knitted fabric. Experimental validation of the model using the integration of silver-coated yarns in three types of wool, acrylic, and cotton knitted fabrics with three different densities for each type of knitted fabric showed that the maximum temperature and time required to reach a stable heating temperature depend on the types of expanded textile fibers and the loop density of the knitted fabric [194].

These types of patterns have also been proposed to predict the design of heated woven fabrics. In order to express the relationship between various parameters of a heated woven fabric, an equation was proposed based on the resistance of the fabric, the heat output power, the DC voltage, the number of parallel conducting wires, the length of the single conducting wire, the resistivity of the conducting wire, and the cross-sectional area of the conducting wire. Validation experiments using the integration of silver filaments and silver-coated yarns in identical cotton fabrics concluded that the conductive yarns or filaments must be uniformly distributed in order to avoid overheating on parts of the heating fabric [195]. It was observed that silver-coated yarns would not be suitable for the design of heating fabric due to their poor thermal stability. In addition, silver filaments would be a better choice compared to steel wires in such structures to avoid wire breakage [195].

According to some of the models discussed, knowing the electrical resistance of a conductive tissue can greatly contribute to predicting its electrothermal behavior [193,195]. Therefore, theoretical models suggested by some experts to predict the overall resistance of a conductive knitted fabric can be taken into account. Studies such as the modeling of the resistance of conductive knitwear from the length-related resistance and the contact point resistance associated with the analysis of the electromechanical behavior of such knitwear [196], the modeling of the resistive network for conductive knitwear stitches [197], and the estimation of the resistance of conductive knitwear from a macroscopic view by considering the surface resistance of the conductive yarns [198], can be considered in such an approach to the design of a heated knitwear. In the same context, a derived simulation model has been developed to calculate the electrical resistance of a conductive woven fabric by considering its structure as well as the density and arrangement of the integrated conductive yarns. Once the radius of the warp yarn and the resistance of a unit of conductive yarn were known, the electrical resistance of the conductive woven fabric could be calculated. By validating the model using the integration of a silver-coated nylon wire in three woven structures with different weft density and constant warp density, the study demonstrated that for the same fabric size, the electrical resistance can be adjusted by controlling the fabric structure and the arrangement of conductive wires [199].

In order to facilitate the design of a heating element in a textile with a versatile design, and to overcome the technical challenges related to the integration of a conductive wire in a textile structure, coating techniques have been deployed to form conductive and heating zones on the surface of textile substrates. The deposition of a silver particle-based conductive ink on the surface of one polyester/cotton fabric resulted in a heating element that provided a maximum temperature of 33 °C with power supplies as low as 1.4 Watt and a time of about 10 s to reach the equilibrium heating temperature [200]. In a similar work, the deposition of a dispersion containing silver nanofilaments on a cotton woven fabric created a heating zone that could provide 50 °C heat at an applied power density as low as 0.05 W/cm2. Despite such performance, due to the relatively low environmental stability of silver nanofilaments, the developed heating fabrics lost their performance after two months of storage under ambient conditions. In addition, the created conductive layer was damaged during washing, and its thermal performance was significantly reduced [201]. In order to take advantage of the benefits of using silver nanofilaments in the design of a heating element, techniques such as the one proposed for the fabrication of heating membranes based on nanosilicon carbide and thermoplastic polyurethane covering the silver filaments [202] should be considered. Although these types of membranes may offer good thermal stability and better mechanical properties, their integration into textile structures remains to be explored.

3.2.4. Textile Substrates Coated with Conductive Polymers

The formation of polymeric conductive layers on textile substrates has also been explored for the design of electrical heating textiles. The in situ polymerization of poly (3,4-ethylene dioxythiophene) p-toluene sulfonic acid (PEDOT-PTSA) on a polyester web by coating has allowed the development of a very flexible and lightweight heating textile with a durable and high heating potential that still required high supply voltages [203]. The deposition of a polypyrrole coating on a nylon-based knitted fabric was also used to create a textile heating element. However, voltages as high as 18 volts were required to generate temperatures in excess of 45 °C. In addition, the provided temperature appears to be altered during the elongation of the fabric [191]. Vapor-phase polymerization of poly (3,4-ethylene dioxythiophene) on a cotton fabric has made it possible to develop a heating element that can reach 28 and 45 °C with voltages of 4.5 and 6 volts, respectively. By means of a vapor-phase post-treatment for the deposition of a protective layer against moisture, it was possible to achieve better protection of the polymeric heating element against abrasion and mechanical deformation. According to the analyses performed, cutting, sewing, and partial weaving would not appear to alter the electrical conductivity and electrothermal responses of the heating layer [204]. Although these types of developments are very interesting, due to the technical challenges and high cost of scaling up vapor deposition techniques to meet the high-volume production requirements of the textile industry, it is difficult to envisage soon the use of vapor deposition processes to create textile-based electronic components [205].

3.2.5. Heating Elements Based on Carbon Fiber or Carbon-Based Compositions

Carbon fibers are also very interesting candidates in the design of electric heating textiles because of their good thermal efficiency and ability to generate uniform heat quickly [206,207]. Allowing a very high rate of electricity conversion, carbon fibers can promote the design of heating elements with versatile surface temperatures depending on the desired design while providing an average lifespan of up to 100,000 h [55]. Examples of work in this context are the development of a heating element in the form of a composite layer based on recycled carbon fiber in a polyurethane resin producing heat ranging from 26 to 96 °C [208], the development of an anti-icing/de-icing device with the integration of a carbon fiber composite laminate in a multilayer structure requiring electrical currents of 2 to 4 amps to provide the desired electrical power density [209], and the evaluation of a carbon fiber-based electric blanket to warm patients during abdominal surgery, demonstrating a performance equivalent to that of forced hot air heating technologies and superior to that of hot water circulation mattresses in tests conducted in the hospital environment [210].

A few studies have also been devoted to the use of carbon fiber-based heating elements in the design of electric heating garments. The evaluation of an electric heating vest with a carbon fiber-based heating element on a thermal manikin in a cold climate chamber has shown that the application of too high temperatures can lead to a reduction in heating efficiency due to a significant loss of heat to the environment, thus demonstrating that the heating power should be adjusted according to the external temperature [211]. The influence of ambient air velocity and the influence of the suit of clothing worn on heating efficiency was also studied by testing an electric heating vest, equipped with six carbon fiber-based heating elements, on a thermal manikin. The combination of the vest with knitted underwear and a military uniform in different orders demonstrated that the order of the clothing combination can significantly influence the heating efficiency. Indeed, the best heating efficiency was obtained when the heating vest was worn as a middle layer in the middle of the other clothing. It has also been found that the heating efficiency of the heating vest decreases with increasing cold air velocity [212]. The efficiency of an electric heating garment containing seven carbon yarn-based heating pads was compared to that of a heating garment containing 14 PCM pockets during tests conducted under identical conditions using a thermal manikin operating in the thermoregulatory model control mode. According to the analyses performed, the electric heating garment can show a more efficient heating power and a significantly higher total thermal insulation compared to the PCM at low airflow velocities, whereas no significant difference was observed at high airflow velocities [162]. In addition, the analysis of different methods of applying carbon fiber in the design of an electric heating garment has shown that the use of carbon fiber can lead to a rapid temperature increase as well as a high recovery rate when disconnected from the power supply, so that such a heating element has the necessary characteristics for precise temperature control. Based on the results obtained, it was also recommended to take into consideration the human body heat dissipation principles and that of the garment surface in the design of the garment as well as a sandwich-type heating element design to promote better heat input [213]. Despite the advantages of a carbon fiber-based heating element, its integration into clothing still requires further work to optimize its resistance to washing [213] and energy consumption [208,209,211,213].

3.2.6. Efficiency of Heating Clothing Based on Yarns of Metallic Compositions