Experimental Investigation of the Wear Behaviour of Coated Polymer Gears

Abstract

:1. Introduction

2. Materials and Methods

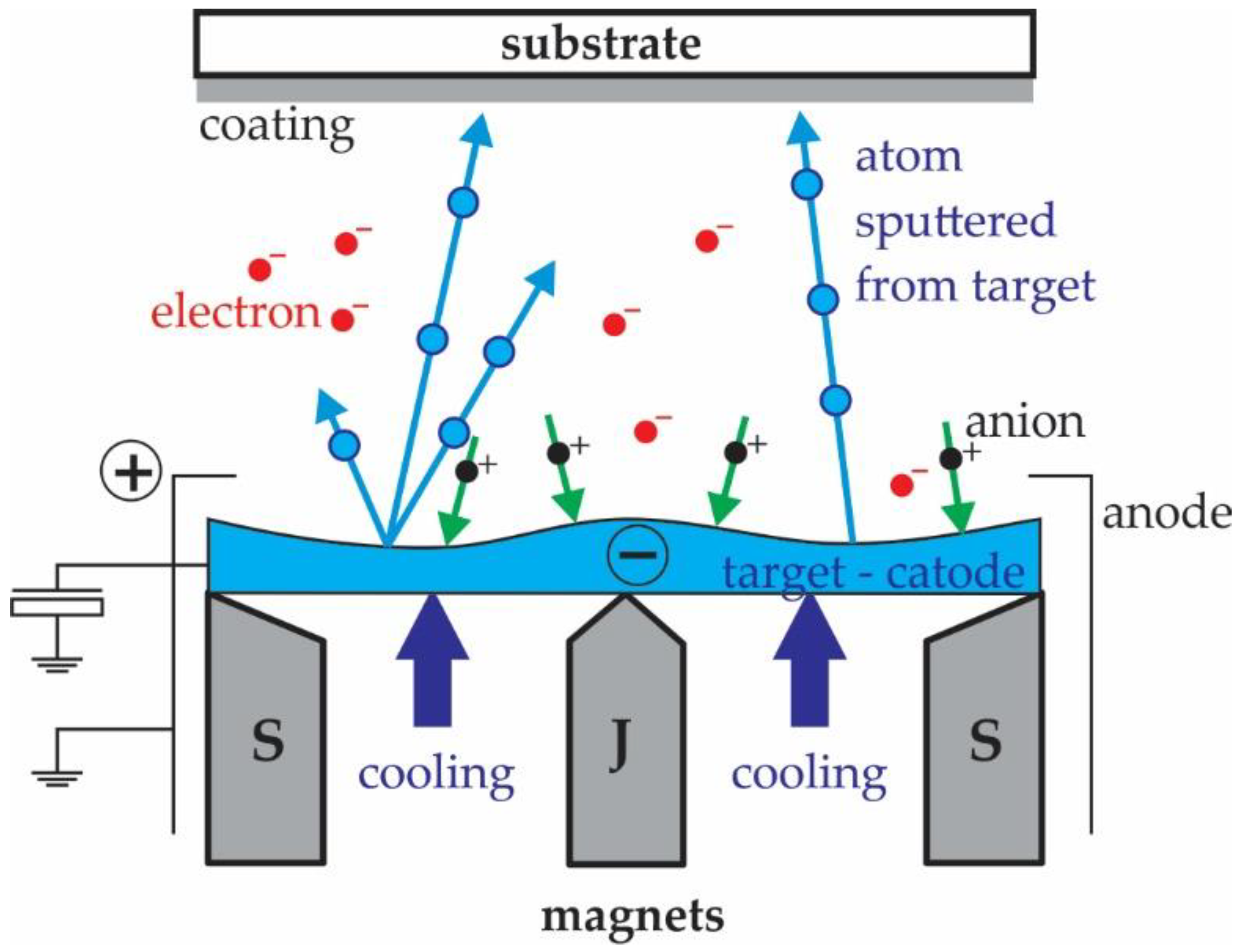

2.1. Deposition Process

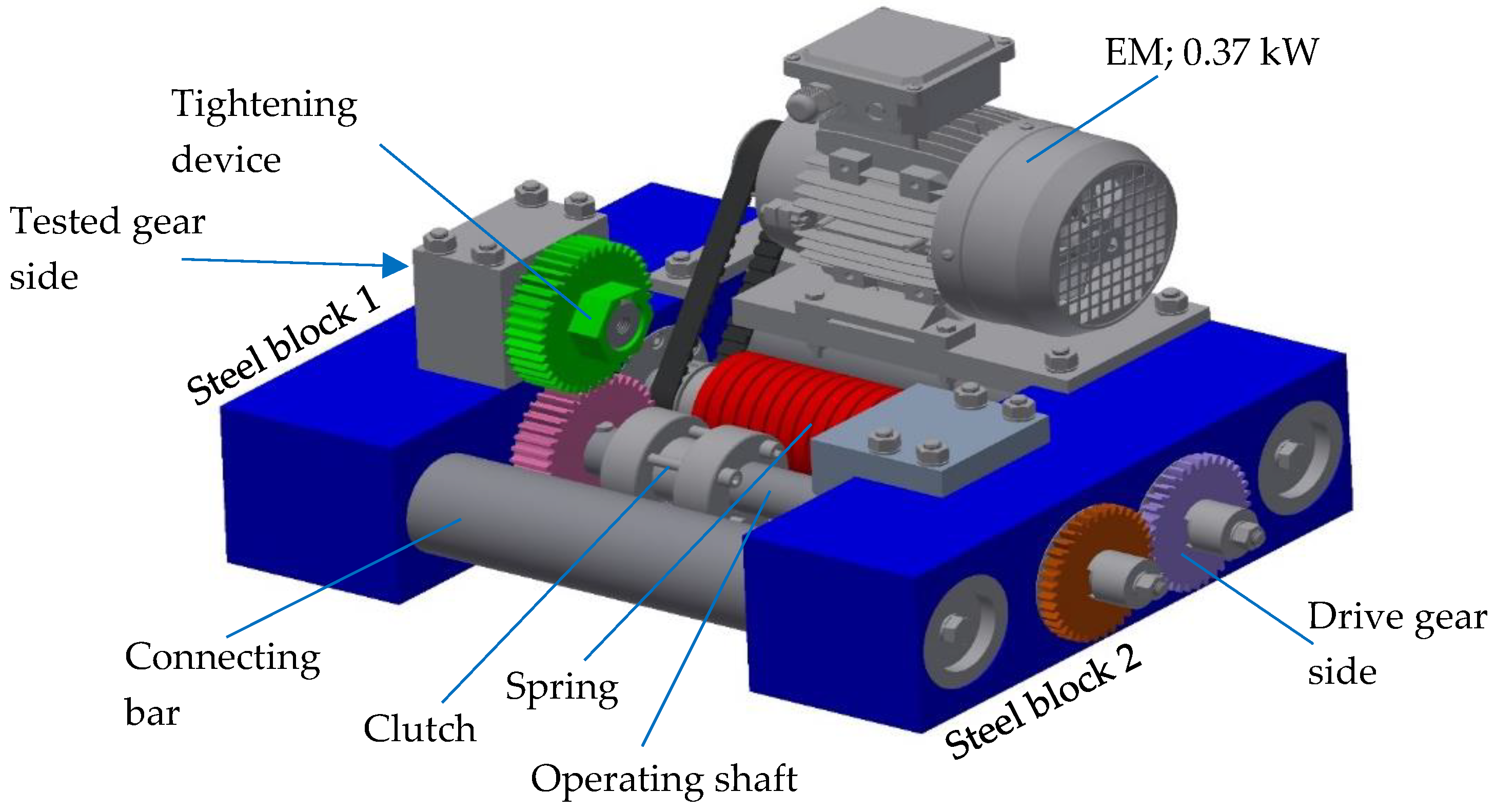

2.2. Experimental Procedure

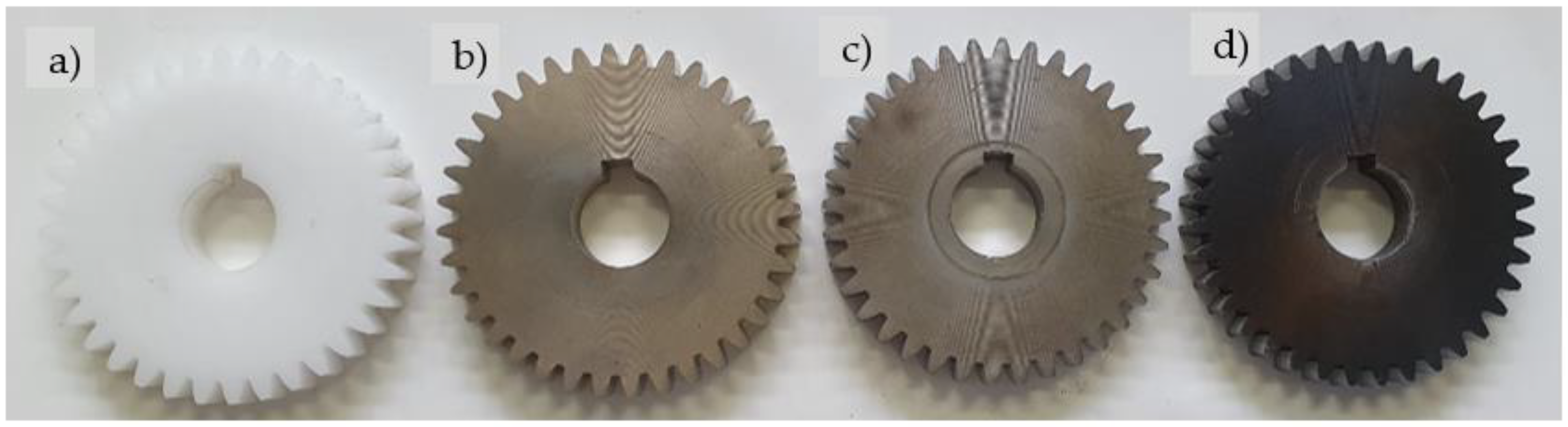

2.2.1. Sample Preparation

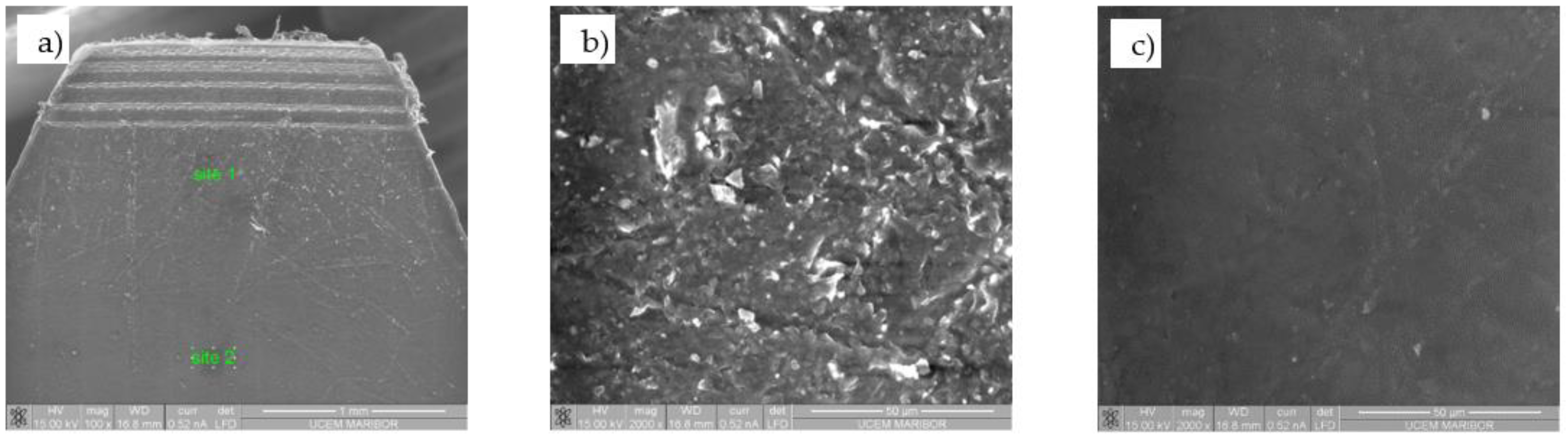

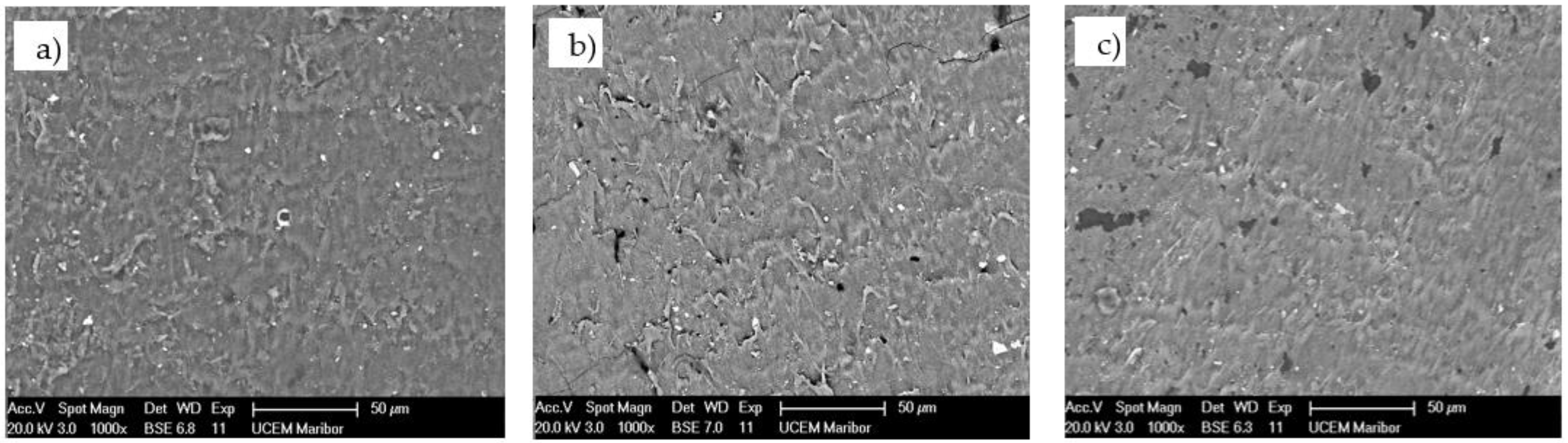

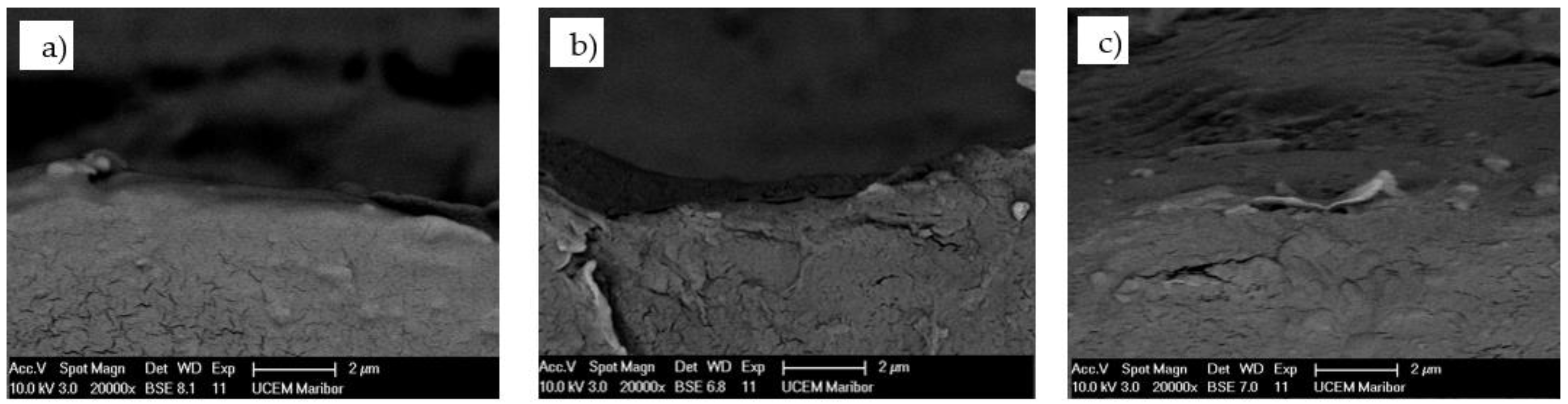

2.2.2. Characterisation of the Coatings by Scanning Electron Microscopy

2.2.3. Experimental Testing

3. Results and Discussion

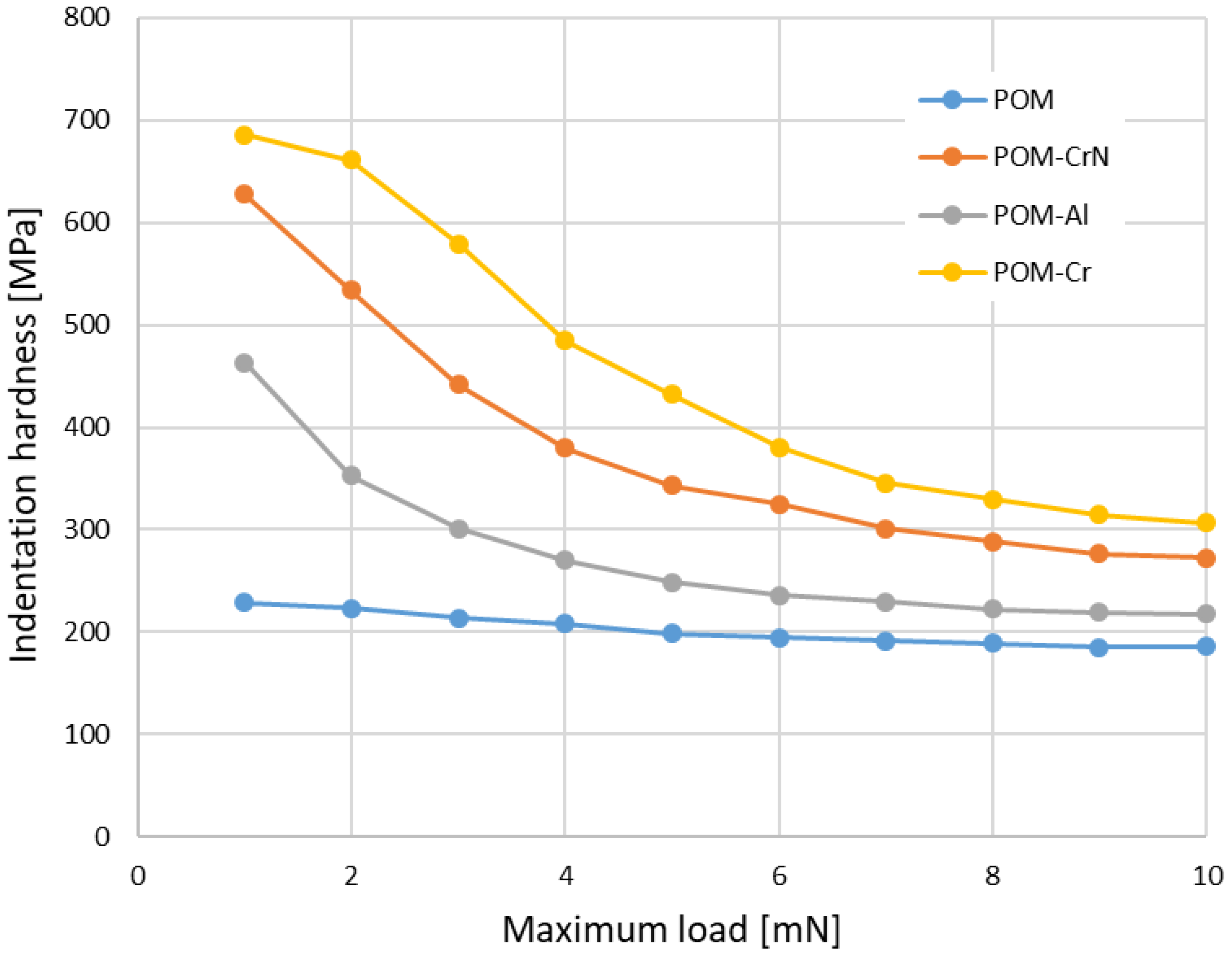

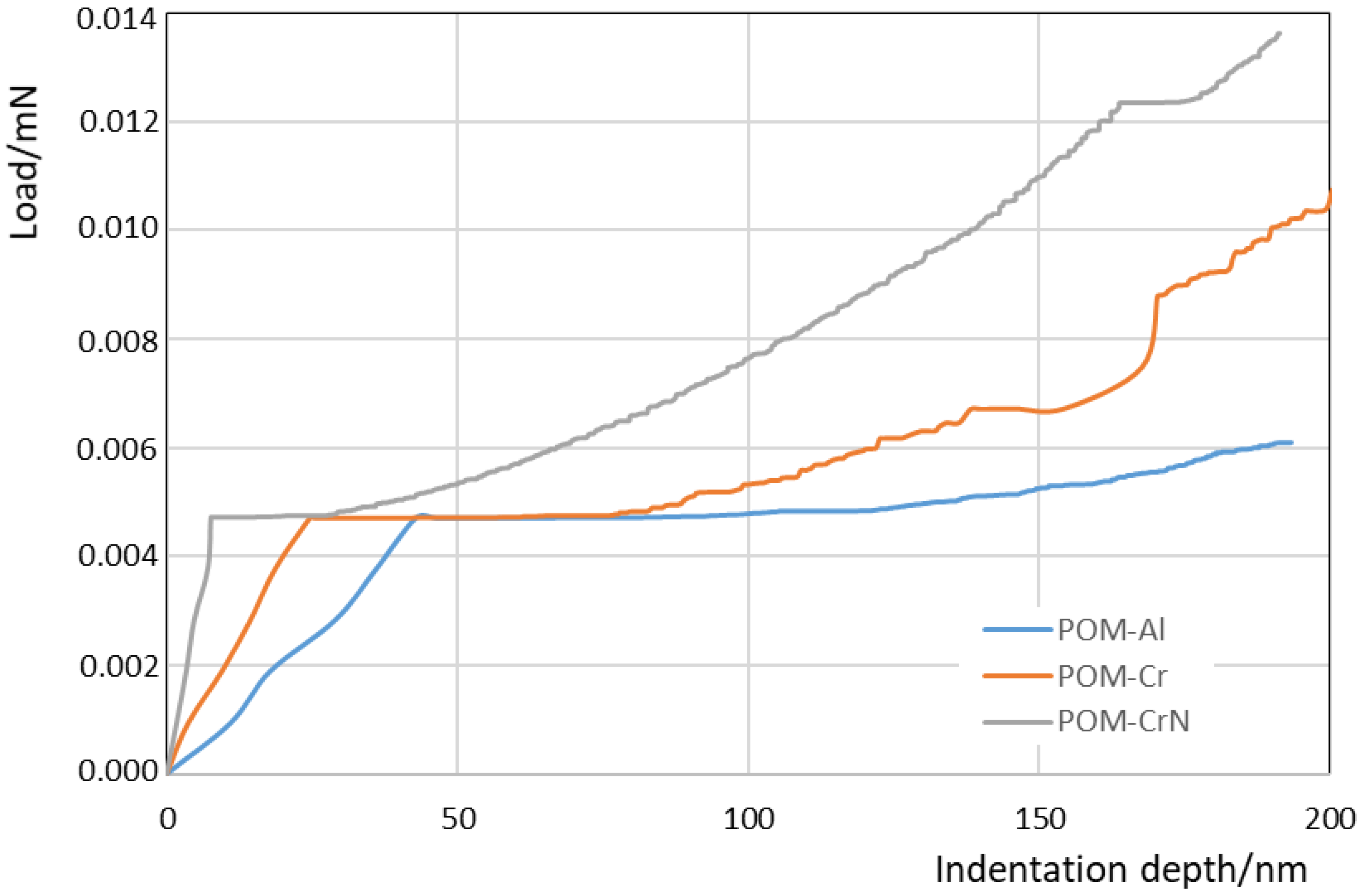

3.1. Coating Morphology and Thickness

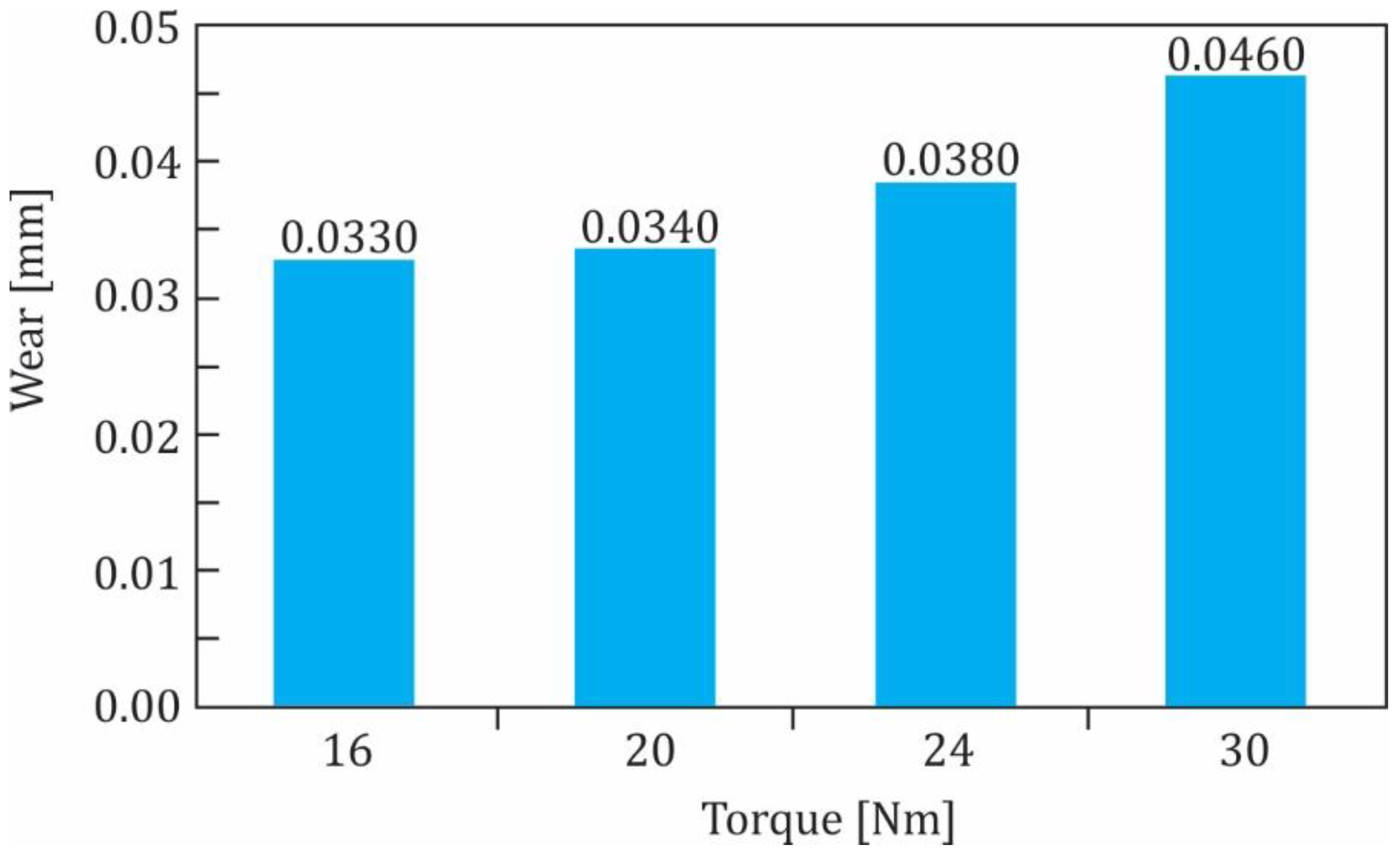

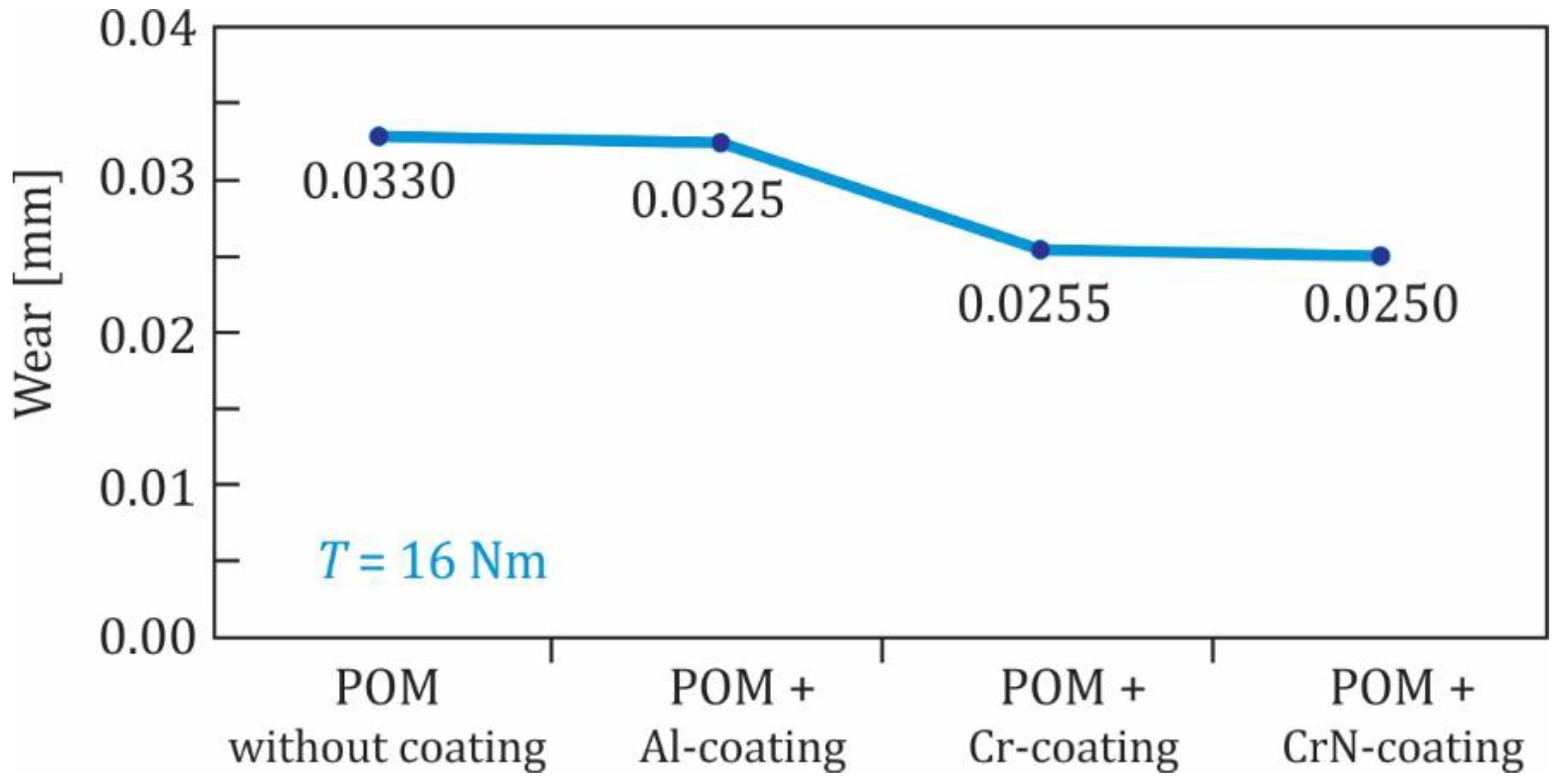

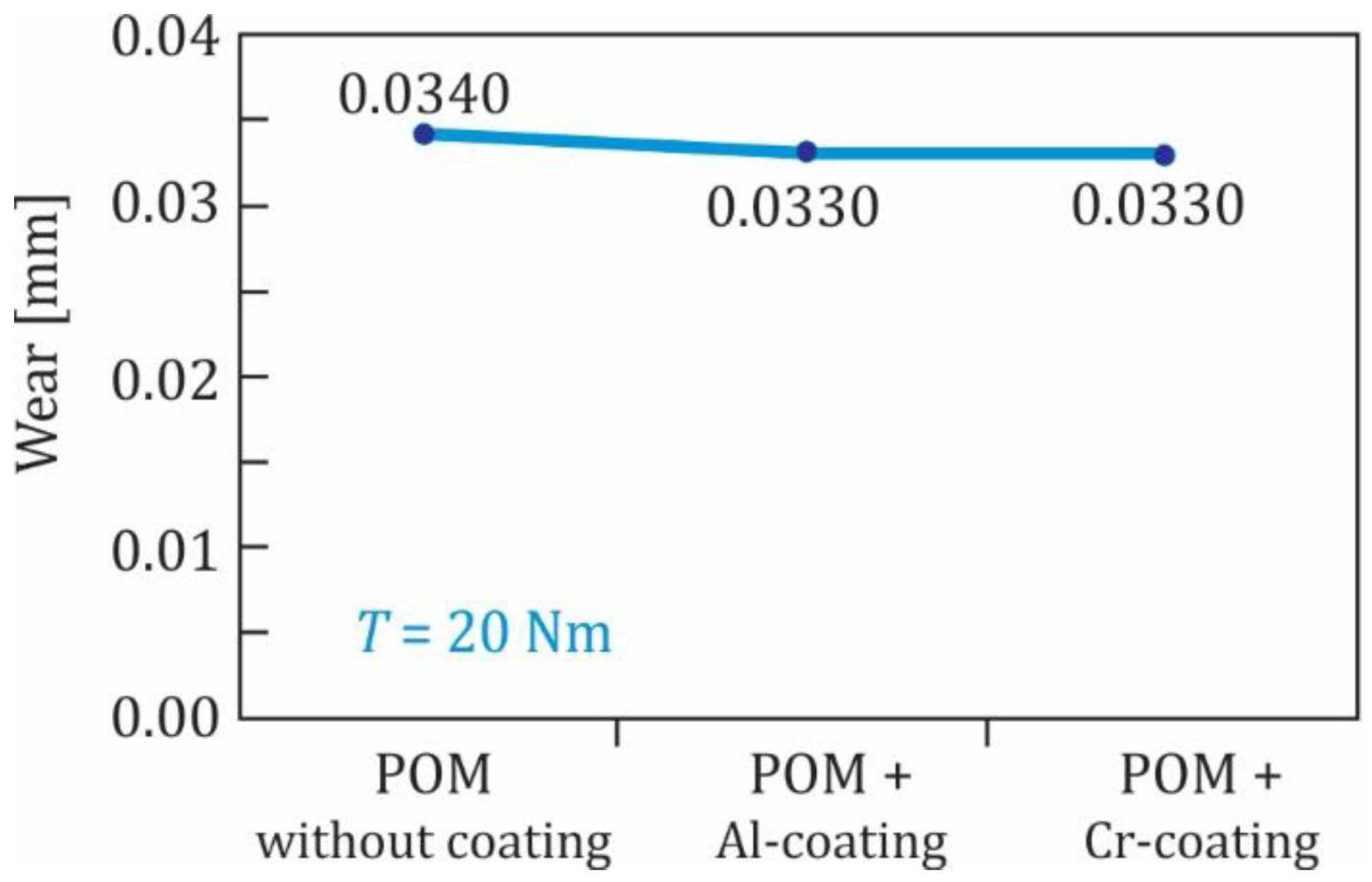

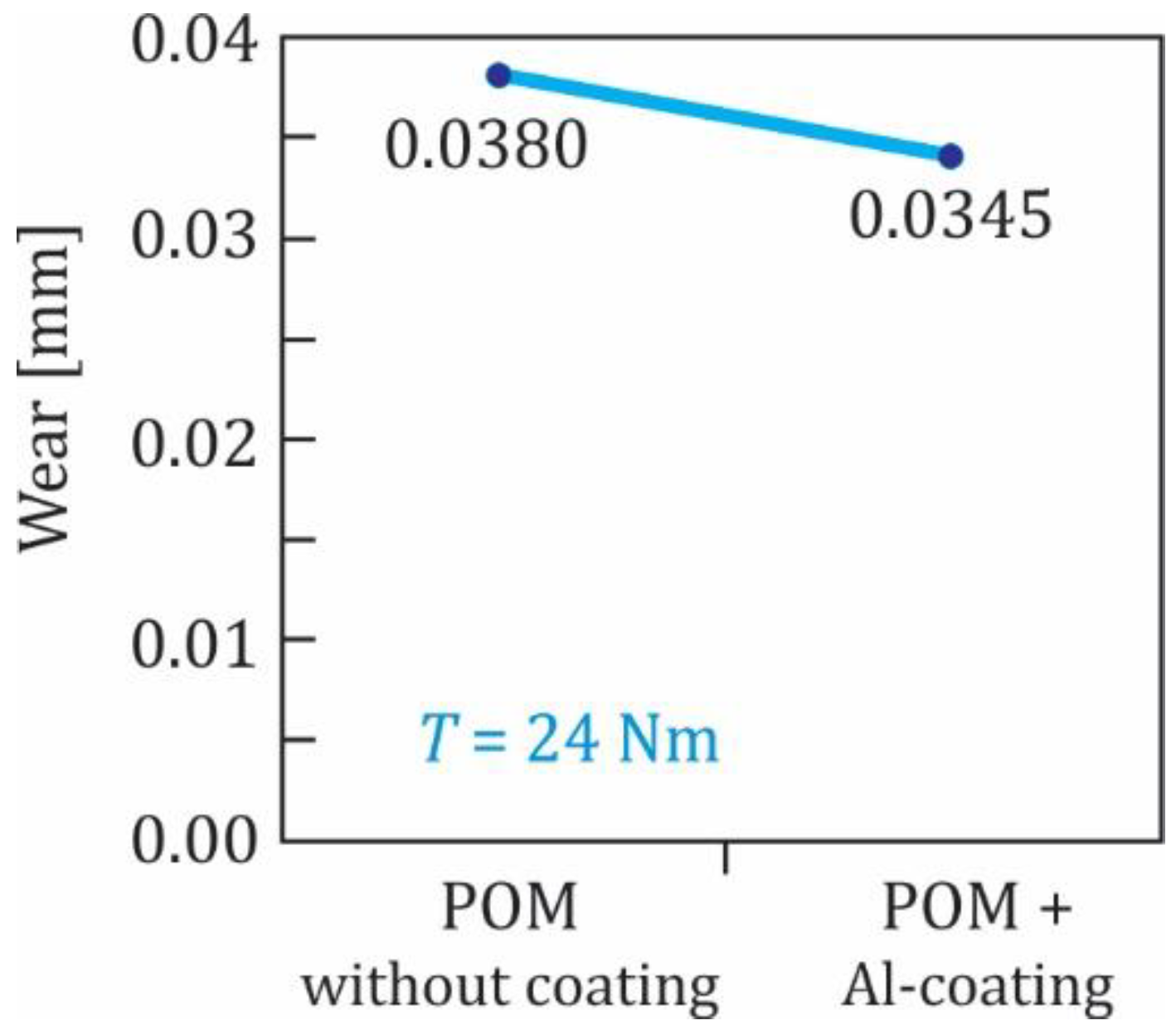

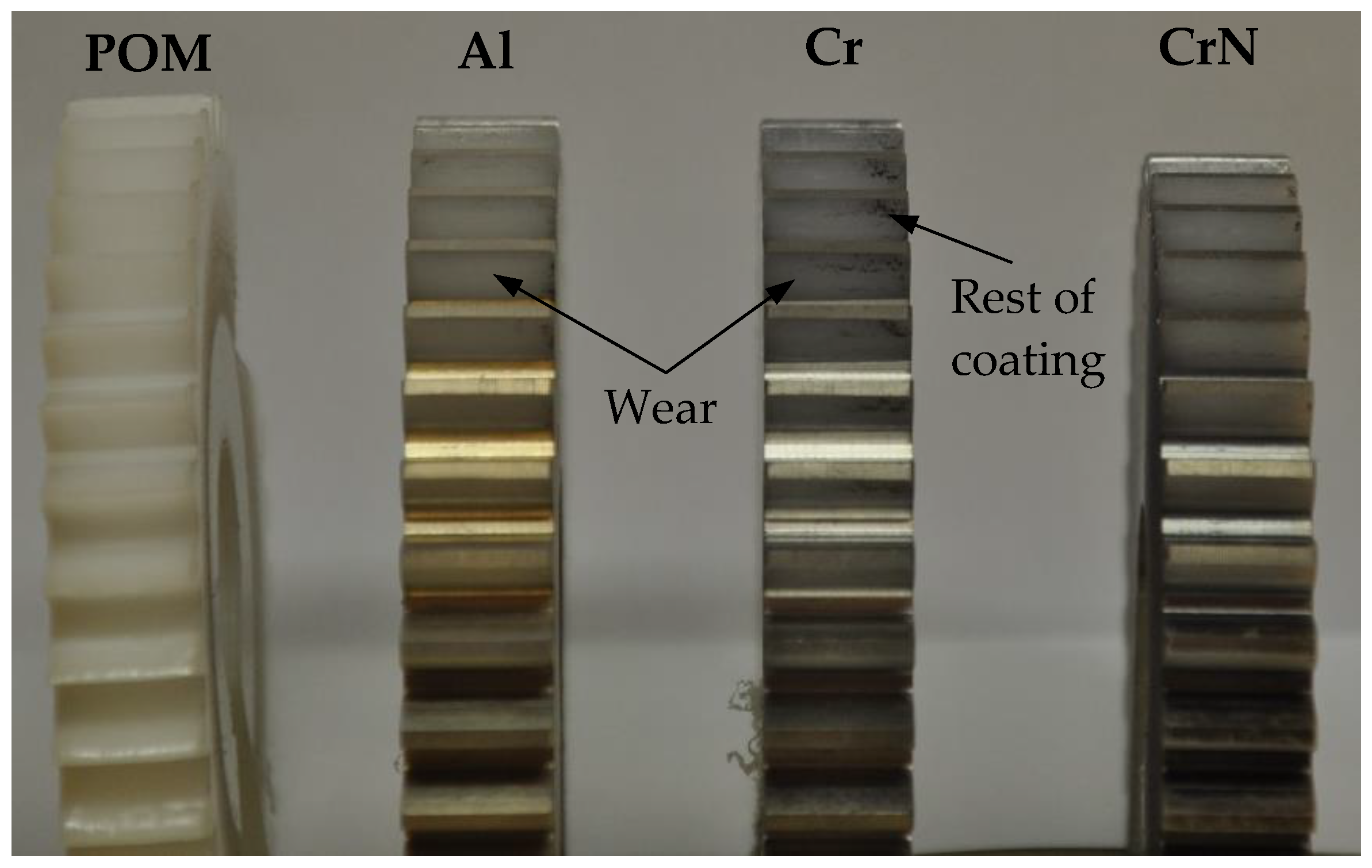

3.2. Wear Evaluation

4. Conclusions

- In general, the influence of the analysed metal coatings on the wear behaviour of POM polymer spur gears is small and does not reduce the wear significantly. Namely, the thickness of the analysed coatings was, in all cases, very thin (less than 500 nm), and did not influence the wear behaviour significantly.

- If we compare the three analysed coatings, the Cr- and CrN-coatings have a little more beneficial effect compared to the Al-coating.

- The further study should be focused on the wear evaluation of coated polymer gears, where multilayer (thicker) Al, Cr and CrN coatings will be considered. Furthermore, the additional scratch tests should be performed for the appropriate adhesion evaluation of the analysed coatings. Therefore, more accurate conclusions could be made as to whether metal coatings reduce the wear of POM gears.

- The further study should also have to consider the measurement of the coefficient of friction for all three analysed surface coatings. Based on such measurements, the tribological behaviour could be analysed and evaluated critically for both dry and lubricated contact of meshing gears.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trobentar, B.; Kulovec, S.; Hlebanja, G.; Glodež, S. Experimental failure analysis of S-polymer gears. Eng. Fail. Anal. 2020, 111, 104496. [Google Scholar] [CrossRef]

- Pisula, J.; Budzik, G.; Turek, P.; Cieplak, M. An Analysis of Polymer Gear Wear in a Spur Gear Train Made Using FDM and FFF Methods Based on Tooth Surface Topography Assessment. Polymers 2021, 13, 1649. [Google Scholar] [CrossRef] [PubMed]

- Zorko, D.; Demšar, I.; Tavčar, J. An investigation on the potential of bio-based polymers for use in polymer gear transmissions. Polym. Test. 2021, 93, 106994. [Google Scholar] [CrossRef]

- Kalin, M.; Kupec, A. The dominant effect of temperature on the fatigue behaviour of polymer gears. Wear 2017, 376–377, 1339–1346. [Google Scholar] [CrossRef]

- Gnatowski, A.; Golebski, A.; Sikora, P. Analysis of the Impact of Changes in Thermomechanical Properties of Polymer Materials on the Machining Process of Gears. Polymers 2021, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- Xiansong, H.; Wangqing, W. A Practical Numerical Approach to Characterizing Non-Linear Shrinkage and Optimizing Dimensional Deviation of Injection-Molded Small Module Plastic gears. Polymers 2021, 13, 2092. [Google Scholar] [CrossRef]

- Zorko, D.; Kulovec, S.; Duhovnik, J.; Tavčar, J. Durability and design parameters of a Steel/PEEK gear pair. Mech. Mach. Theory 2019, 140, 825–846. [Google Scholar] [CrossRef]

- Urbas, U.; Zorko, D.; Černe, B.; Tavčar, J.; Vukašinović, N. A method for enhanced polymer spur gear inspection based on 3D optical metrology. Measurement 2021, 169, 108584. [Google Scholar] [CrossRef]

- Hriberšek, M.; Erjavec, M.; Hlebanja, G.; Kulovec, S. Durability testing and characterization of POM gears. Eng. Fail. Anal. 2021, 124, 105377. [Google Scholar] [CrossRef]

- Černe, B.; Petkovšek, M.; Duhovnik, J.; Tavčar, J. Thermo-mechanical modeling of polymer spur gears with experimental validation using high-speed infrared thermography. Mech. Mach. Theory 2020, 146, 103734. [Google Scholar] [CrossRef]

- Düzcükoglu, H. Study on development of polyamide gears for improvement of load-carrying capacity. Tribol. Int. 2009, 42, 1146–1153. [Google Scholar] [CrossRef]

- Mao, K.; Chetwynd, D.G.; Milsson, M. A new method for testing polymer gear wear rate and performance. Polym. Test. 2020, 82, 106323. [Google Scholar] [CrossRef]

- Pogačnik, A.; Tavčar, J. An accelerated multilevel test and design procedure for polymer gears. Mater. Des. 2015, 65, 961–973. [Google Scholar] [CrossRef]

- Letzelter, E.; de Vaujany, J.P.; Guigand, M. Load-sharing model for polymer cylindrical gears. Gear Technol. 2011, 28–34, 154–196. [Google Scholar]

- Cathelin, J.; de Vaujany, J.P.; Guigand, M. Loaded behavior of Gears Made of Fiber-Reinforced PA6. Gear Technol. 2014, 31, 54–60. [Google Scholar]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modelling of short fiber reinforced polymer composites: A literature review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- VDI 2736, Thermoplastic Gear Wheels; Beuth Publishing: Berlin, Germany, 2014.

- Bravo, A.; Koffi, D.; Toubal, L.; Erchiqui, F. Life and damage mode modeling applied to plastic gears. Eng. Fail. Anal. 2015, 58, 113–133. [Google Scholar] [CrossRef]

- Kumar, S.P.; Suman, K.N.S.; Ramanjaneyulu, S. A review on tribological performance characteristics of plastic gears. Int. J. Mech. Eng. Technol. 2019, 10, 516–526. [Google Scholar]

- Singh, P.K.; Singh, A.K. An investigation on the thermal and wear behavior of polymer based spur gears. Tribol. Int. 2018, 118, 264–272. [Google Scholar] [CrossRef]

- Li, W.; Wood, A.; Weidig, R.; Mao, K. An investigation on the wear behaviour of dissimilar polymer gear engagements. Wear 2011, 271, 2176–2183. [Google Scholar] [CrossRef]

- Evans, S.M.; Keogh, P.S. Wear mechanisms in polyoxymethylene spur gears. Wear 2019, 428–429, 356–365. [Google Scholar] [CrossRef]

- Lin, A.D.; Kuang, J.H. Dynamic interaction between contact loads and tooth wear of engaged plastic gear pairs. Int. J. Mech. Sci. 2008, 50, 205–213. [Google Scholar] [CrossRef]

- Mao, K.; Langlois, P.; Hu, Z.; Alharbi, K.; Xu, X.; Milson, M.; Li, W.; Hooke, C.J.; Chetwynd, D. The wear and thermal mechanical contact behaviour of machine cut polymer gears. Wear 2015, 332–333, 822–826. [Google Scholar] [CrossRef]

- Hoskins, T.J.; Dearn, K.D.; Chen, Y.K.; Kukureka, S.N. The wear of PEEK in rolling-sliding contact simulation of polymer gear applications. Wear 2014, 309, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Miler, D.; Hoić, M.; Domitran, Z.; Žeželj, D. Prediction of friction coefficient in dry-lubricated polyoxymethylene spur gear pairs. Mech. Mach. Theory 2019, 138, 205–222. [Google Scholar] [CrossRef]

- Liu, H.J.; Liu, H.L.; Zhu, C.C.; Wei, P.T.; Tang, J.Y. Tribological behaviour of coated spur gear pairs with tooth surface roughness. Friction 2019, 7, 117–128. [Google Scholar] [CrossRef] [Green Version]

- Martinez, D.; Hosson, J.M.T. On the deposition and properties of DLC protective coatings on elastomers: A critical review. Surf. Coat. Technol. 2014, 258, 677–690. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Yang, H.K.; Kim, D.E. Tribology of multilayer coatings for wear reduction: A review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef] [Green Version]

- Dearn, K.D.; Hoskins, T.J.; Petrov, D.G.; Reynolds, S.C.; Banks, R. Applications of dry film lubricants for polymer gears. Wear 2013, 298–299, 99–108. [Google Scholar] [CrossRef]

- Bae, S.M.; Seo, K.J.; Kim, D.E. Effect of friction on the contact stress of a coated polymer gear. Friction 2020, 8, 1169–1177. [Google Scholar] [CrossRef]

- Petrov, D.; Dearn, K.; Walton, D.; Banks, R. Some experimental results concerning the influence of surface coatings on the wear of poly-ether-ether-ketone (PEEK) polymeric gears. Ann. Dunarea Jos Univ. Galati Fascicle VIII Tribol. 2011, XVII, 5–10. [Google Scholar]

- Babtista, A.; Silva, F.; Porteiro, J.; Miguez, J.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef] [Green Version]

- Babtista, A.; Pinto, G.; Silva, F.J.G.; Fereira, A.A.; Pinto, A.G.; Sousa, V.F.C. Wear Characterization of Chromium PVD Coatings on Polymeric Substrate for Automotive Optical Components. Coatings 2021, 11, 555. [Google Scholar] [CrossRef]

- Fereira, A.A.; Silva, F.J.G.; Pinto, A.G.; Sousa, V.F.C. Characterization of Thin Chromium Coatings Produced by PVD Sputtering for Optical Applications. Coatings 2021, 11, 215. [Google Scholar] [CrossRef]

- Abdullah, M.Z.B.; Ahmad, M.A.; Abdullah, A.N.; Othman, M.H.; Hussain, P.; Zainuddin, A. Metal release of multilayer coatings by physical vapour deposition (PVD). Procedia Eng. 2016, 148, 254–260. [Google Scholar] [CrossRef] [Green Version]

- Imbeni, V.; Martini, C.; Lanzoni, E.; Poli, G.; Hutchings, I.M. Tribological behaviour of multi-layered PVD nitride coatings. Wear 2001, 251, 997–1002. [Google Scholar] [CrossRef]

- Fallah, P.; Rajagopalan, S.; McDonald, A.; Yue, S. Development of hybrid metallic coatings on carbon fiber-reinforced polymers (CFRPs) by cold spray deposition of copper-assisted copper electroplating process. Surf. Coat. Technol. 2020, 400. [Google Scholar] [CrossRef]

- Maurer, C.; Schulz, U. Erosion resistant titanium based PVD coating on CFRP. Wear 2013, 302, 937–945. [Google Scholar] [CrossRef]

- Coto, B.; Mendizabal, L.; Pagano, F.; Kling, H.; Azpitarte, I.; Barriga, J.; Selegard, L. Role of surface finishing and interfacial lacquer layer on particle erosion mechanisms of Ti/TiN multilayer PVD coatings for carbon fibre reinforced polymer substrates protection. Mater. Lett. 2021, 285, 129187. [Google Scholar] [CrossRef]

- Stanford Advanced Materials: An Overview of Magnetron Sputtering. Available online: https://www.sputtertargets.net/blog/an-overview-of-magnetron-sputtering.html (accessed on 5 July 2021).

- Panjan, P.; Čekada, M. Magnetron sputtering of thin films. Vakuumist 2005, 25, 18–22. [Google Scholar]

- Rossnagel, S. Sputtering and Sputter Deposition. In Book Handbook of Thin-Film Deposition Processes and Technologies, 2nd ed.; Seshan, K., Ed.; Noyes Publications: Norwich, NY, USA, 2002; Volume 8, pp. 319–348. [Google Scholar]

- Panjan, P.; Kralj, T.; Mozetič, M.; Maček, M. Industrial Applications of Plasma Surface Engineering. Vakuumist 1998, 18, 4–12. [Google Scholar]

- Muralidhar Singh, M.; Vijaya, G.; Krupashankara, M.S.; Sridhara, B.K.; Shridhar, T.N. Studies on Nanostructure Aluminium Thin Film Coatings Deposited using DC magnetron Sputtering Process. Mater. Sci. Eng. 2016, 149, 012071. [Google Scholar] [CrossRef]

- Pedrosa, P.; Rodrigues, M.S.; Neto, M.A.; Oliveira, F.J.; Silva, R.F.; Borges, J.; Amaral, M.; Fereira, A.; Godinho, L.H.; Carvalho, S.; et al. Properties of CrN thin films deposited in plasma-activated ABS by reactive magnetron sputtering. Surf. Coat. Technol. 2018, 349, 937–945. [Google Scholar] [CrossRef]

| Coating | Process | Pumping Time (s) | Starting Pressure (mbar) | MFC | Regulation Pressure (mbar) | Process Time (s) | Regulation Energy (kWs) | T [°C] | |

|---|---|---|---|---|---|---|---|---|---|

| min | max | ||||||||

| Al | Plasma activation | 10 | 5 × 10−3 | 800 | 3 × 10−2 | 18 | 198 | 500 | 5000 |

| Magnetron sputtering | 150 | 4 × 10−4 | 500 | 2.2 × 10−3 | 62 | 10,500 | 30 | 90 | |

| Plasma polymerisation | 1 | 1.5 × 10−2 | 300 | 2 × 10−2 | 50 | 582 | 500 | 5000 | |

| Cr | Magnetron sputtering | 80 | 6 × 10−4 | 500 | 3 × 10−3 | 105 | 10,200 | 25 | 90 |

| CrN | Magnetron sputtering | 80 | 6 × 10−4 | 500 | 3 × 10−3 | 105 | 10,200 | 25 | 90 |

| Reactive metallisation | 90 | 9 × 10−4 | 120 (190) | 3.4 × 10−3 | 67 | 6200 | 40 | 90 | |

| Parameter | Tested Gear | Supported Gear |

|---|---|---|

| Material | POM | Steel (16 MnCr5) |

| Normal module m | 2.5 mm | 2.5 mm |

| Pressure angle αn | 20° | |

| Helix angle β | 0° | |

| Number of teeth z | 36 | 36 |

| Tooth width b | 14 mm | 14 mm |

| Profile shift coefficient x | 0 | |

| Centre distance a | 90 mm | |

| Basic rack profile | ISO 53 | |

| Lubrication | Dry (no lubricated) | |

| Indentation Hardness (MPa) | Indentation Modulus (GPa) | |

|---|---|---|

| POM | 161.22 ± 2.16 | 3.50 ± 0.16 |

| POM-Al | 269.41 ± 24.67 | 4.91 ± 0.45 |

| POM-Cr | 260.52 ± 8.91 | 4.76 ± 0.19 |

| POM-CrN | 232.67 ± 5.59 | 4.59 ± 0.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polanec, B.; Zupanič, F.; Bončina, T.; Tašner, F.; Glodež, S. Experimental Investigation of the Wear Behaviour of Coated Polymer Gears. Polymers 2021, 13, 3588. https://doi.org/10.3390/polym13203588

Polanec B, Zupanič F, Bončina T, Tašner F, Glodež S. Experimental Investigation of the Wear Behaviour of Coated Polymer Gears. Polymers. 2021; 13(20):3588. https://doi.org/10.3390/polym13203588

Chicago/Turabian StylePolanec, Brigita, Franc Zupanič, Tonica Bončina, Frančišek Tašner, and Srečko Glodež. 2021. "Experimental Investigation of the Wear Behaviour of Coated Polymer Gears" Polymers 13, no. 20: 3588. https://doi.org/10.3390/polym13203588

APA StylePolanec, B., Zupanič, F., Bončina, T., Tašner, F., & Glodež, S. (2021). Experimental Investigation of the Wear Behaviour of Coated Polymer Gears. Polymers, 13(20), 3588. https://doi.org/10.3390/polym13203588