Fused Filament Fabrication Process: A Review of Numerical Simulation Techniques

Abstract

:1. Introduction

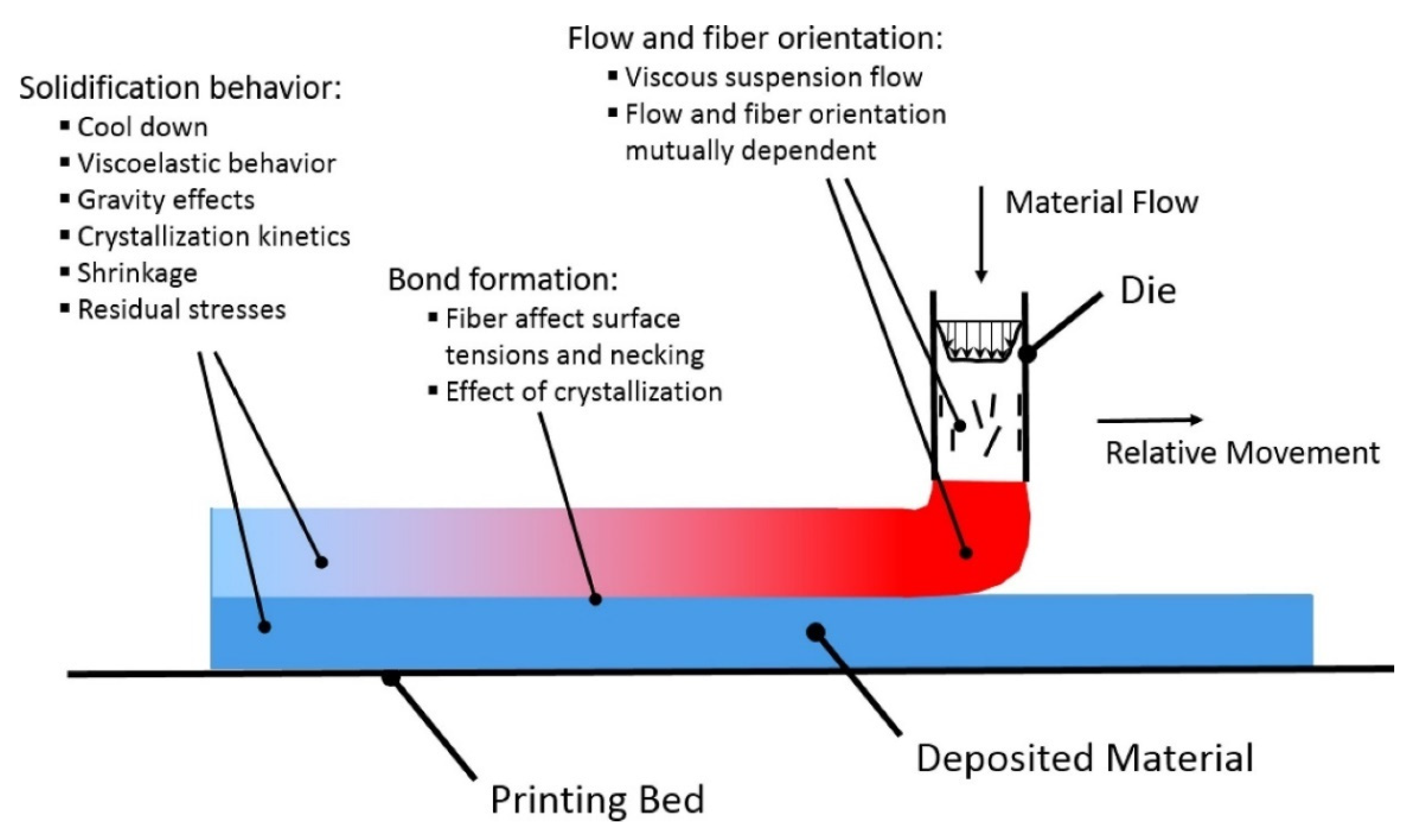

2. Physics Involved in Fused Filament Fabrication Process

3. Numerical Simulation Techniques

3.1. Melt Flow Behavior

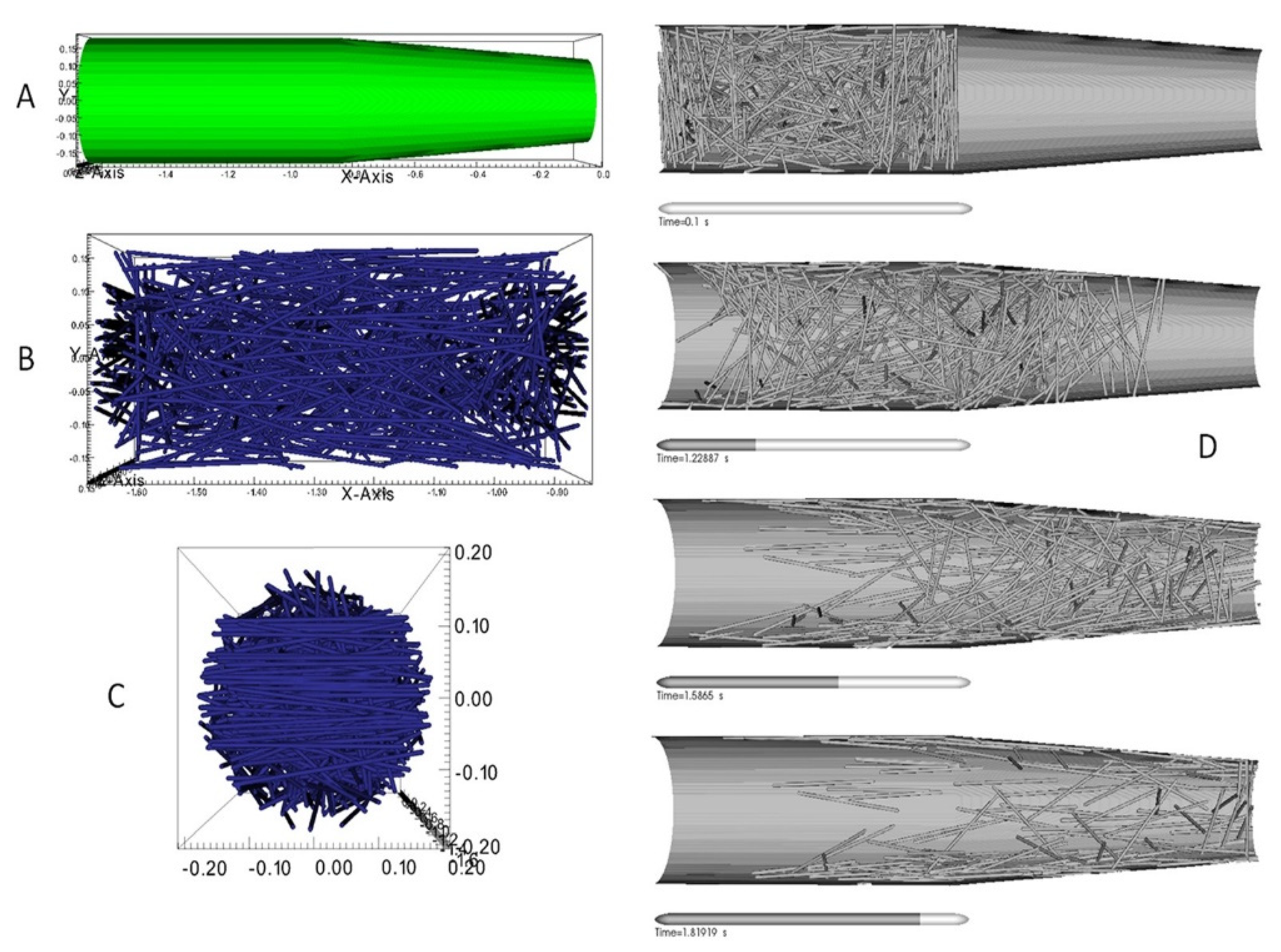

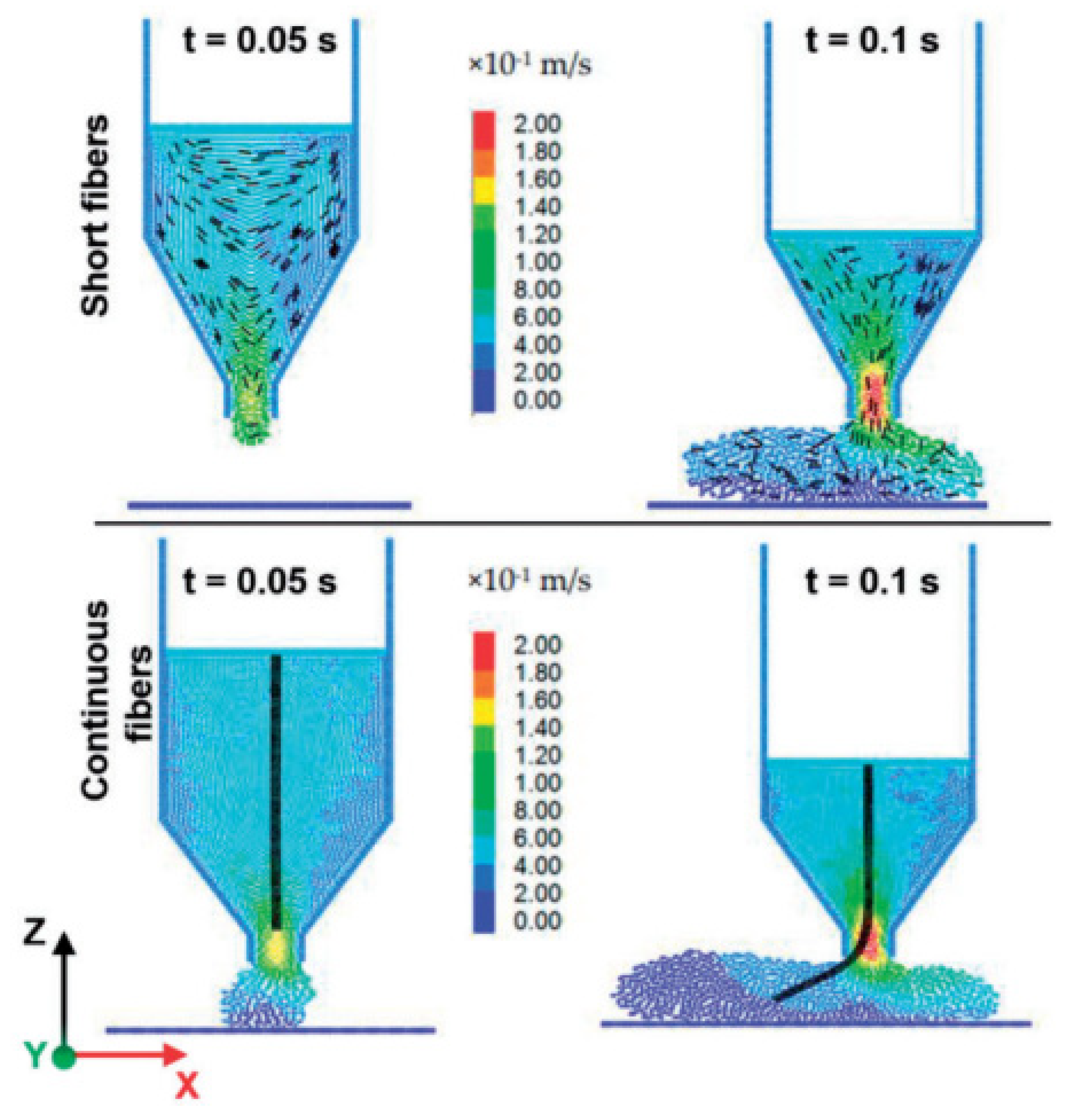

3.2. Fiber Orientation in Polymer Composites

3.3. Solidification Behavior

3.4. Residual Stresses and Warpage

4. Future Outlook

- Fiber Orientation: The fiber orientation in deposited beads depends upon the material flow through the nozzle and deposition process. Most of the literature reports the use of Newtonian isotropic fluid properties; however, these materials should be modeled under anisotropic viscous flow conditions. Current modeling software cannot solve fourth or higher-order orientation tensors and cannot consider anisotropic flow characteristics (which is the case with fiber-reinforced composites). Therefore, there is a need for better numerical simulation tools to consider realistic fiber orientation during material flow.

- Beads Deposition: Several heat transfer models have been reported in the literature to predict the cooling process of the deposited beads. However, due to the anisotropy involved in the 3DP process, interlayer conduction phenomena need to be considered as thermal conductivities of deposited beads change with the fiber orientation.

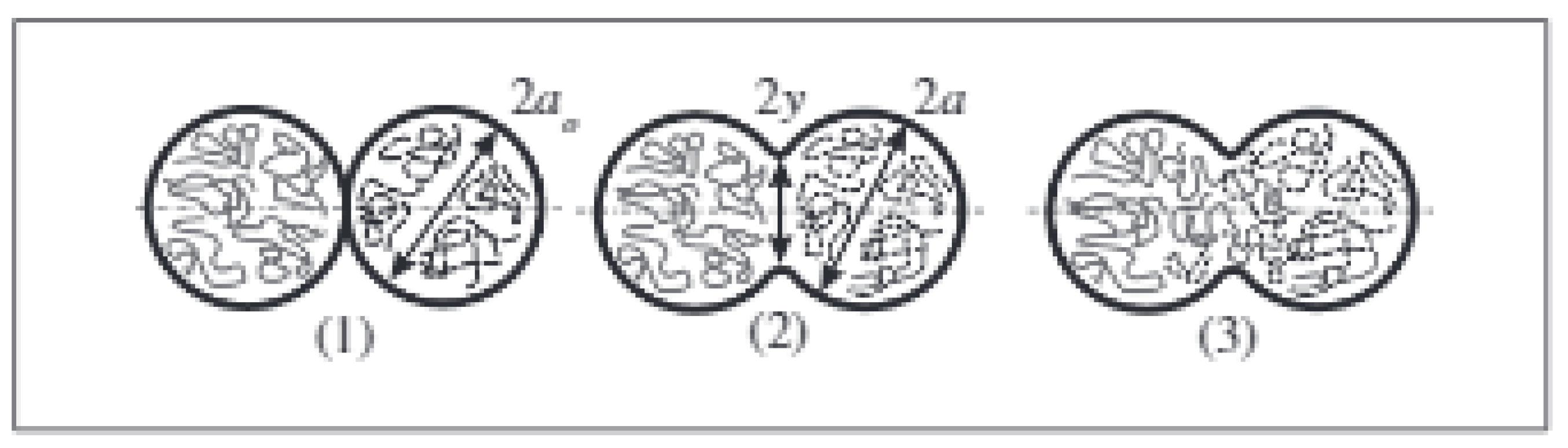

- Interface and Bonding: Bonding between the subsequent layers is highly correlated with the interface; therefore, the presence of fibers on the bead surface can affect this process. In addition, the necking phenomenon is derived by the gradients of surface tension is also influenced by the bead surface morphology. Finally, the material behavior (crystalline or amorphous) will reflect its viscosity, which ultimately affects the bonding process; therefore, it must be accounted for accurate process modeling.

- Integrated Simulation Models: The FFF process is a complex multi-stage process as described in this paper. However, most reported computational work either focused on the material flow inside the liquefier or material behavior after deposition and is not as mature as the experimental literature. Therefore, there is a need for integrated studies considering all these phases of the FFF process (i.e., melt flow behavior inside/outside the nozzle, material deposition, solidification behavior, bond formation, and warpage and residual stresses).

- Model Validation: The validation of numerical and analytical models is vital through experimental studies. Limited studies compared the numerical simulation results with experimental work, which is essential for validating and broader application of these models.

- Materials Portfolio: Materials portfolio for the FFF process is rapidly growing. However, few materials (such as PLA and ABS) are considered for numerical and analytical modeling of process or material behavior. The researchers should focus on implementing existing models to a broader range of materials or develop models for materials not yet considered in the literature.

- Polymer Composites: Two-phase materials (composites) are also barely considered for the numerical modeling of material or the FFF process. The most reported models address linear amorphous polymers. Different polymers exhibit different characteristics, such as bare PLA and ABS act as amorphous materials; however, PBT, PA12, and PEEK exhibit a semi-crystalline nature [84,85,86]. Moreover, the addition of the reinforcing phase can alter the nature of the resulting composite material, e.g., PLA acts as semi-crystalline material with tricalcium phosphate (TCP) [87]. The effect of reinforcement type and process parameters on polymer nature (amorphous or crystalline) will be worth addressing.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat Photopolymerization of Polymer and Polymer Composites: Processes and Applications. Addit. Manuf. 2021, 47, 102279. [Google Scholar]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Yilmaz, B.; Al Rashid, A.; Ait, Y.; Evis, Z.; Koç, M. Bioprinting: A review of processes, materials and applications. Bioprinting 2021, 23, e00148. [Google Scholar] [CrossRef]

- Ahangar, P.; Cooke, M.E.; Weber, M.H. Rosenzweig, D.H. Current biomedical applications of 3D printing and additive manufacturing. Appl. Sci. 2019, 9, 1713. [Google Scholar] [CrossRef] [Green Version]

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv. Manuf. 2019, 7, 155–173. [Google Scholar] [CrossRef]

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Critical Review on 3DP Concrete trends, needs and research recommendations. In Proceedings of the International Conference of Materials and Engineering Technology (TICMET’20), Gaziantep, Turkey, 5–7 November 2020; p. 553. [Google Scholar]

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5,121,329A, 9 June 1992. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin/Heidelber, Gemany, 2015. [Google Scholar] [CrossRef]

- Diegel, O.; Nordin, A.; Motte, D. Additive Manufacturing Technologies. In A Practical Guide to Design for Additive Manufacturing; Springer: Singapore, 2019; pp. 19–39. [Google Scholar]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing of Polymer Nanocomposites: Needs and Challenges in Materials, Processes, and Applications. J. Mater. Res. Technol. 2021, 14, 910–941. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koç, M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials 2020, 13, 3167. [Google Scholar] [CrossRef] [PubMed]

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdullah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Nawafleh, N.; Celik, E. Additive manufacturing of short fiber reinforced thermoset composites with unprecedented mechanical performance. Addit. Manuf. 2020, 33, 101109. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koc, M. Creep and Recovery Behavior of Continuous Fiber-Reinforced 3DP Composites. Polymers 2021, 13, 1644. [Google Scholar] [CrossRef] [PubMed]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Pocius, A.V.; Dillard, D.A. (Eds.) Adhesion Science and Engineering: Surfaces, Chemistry and Applications; Elsevier Science: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- McIlroy, C.; Graham, R.S. Modelling flow-enhanced crystallisation during fused filament fabrication of semi-crystalline polymer melts. Addit. Manuf. 2018, 24, 323–340. [Google Scholar] [CrossRef]

- Shaqour, B.; Samaro, A.; Verleije, B.; Beyers, K.; Vervaet, C.; Cos, P. Production of drug delivery systems using fused filament fabrication: A systematic review. Pharmaceutics 2020, 12, 517. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Kim, S.Y.; Song, Y.S.; Youn, J.R. Relationship between the Crystallization Behavior and the Warpage of Film-Insert-Molded Parts. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of material properties on warpage in fused deposition modeling parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Ramanath, H.S.; Chua, C.K.; Leong, K.F.; Shah, K.D. Melt flow behaviour of poly-ε-caprolactone in fused deposition modelling. J. Mater. Sci. Mater. Med. 2008, 19, 2541–2550. [Google Scholar] [CrossRef]

- Mostafa, N.; Syed, H.M.; Igor, S.; Andrew, G. A study of melt flow analysis of an ABS-Iron composite in fused deposition modelling process. Tsinghua Sci. Technol. 2009, 14, 29–37. [Google Scholar] [CrossRef]

- Monzón, M.D.; Gibson, I.; Benítez, A.N.; Lorenzo, L.; Hernandez, P.M.; Marrero, M.D. Process and material behavior modeling for a new design of micro-additive fused deposition. Int. J. Adv. Manuf. Technol. 2013, 67, 2717–2726. [Google Scholar] [CrossRef]

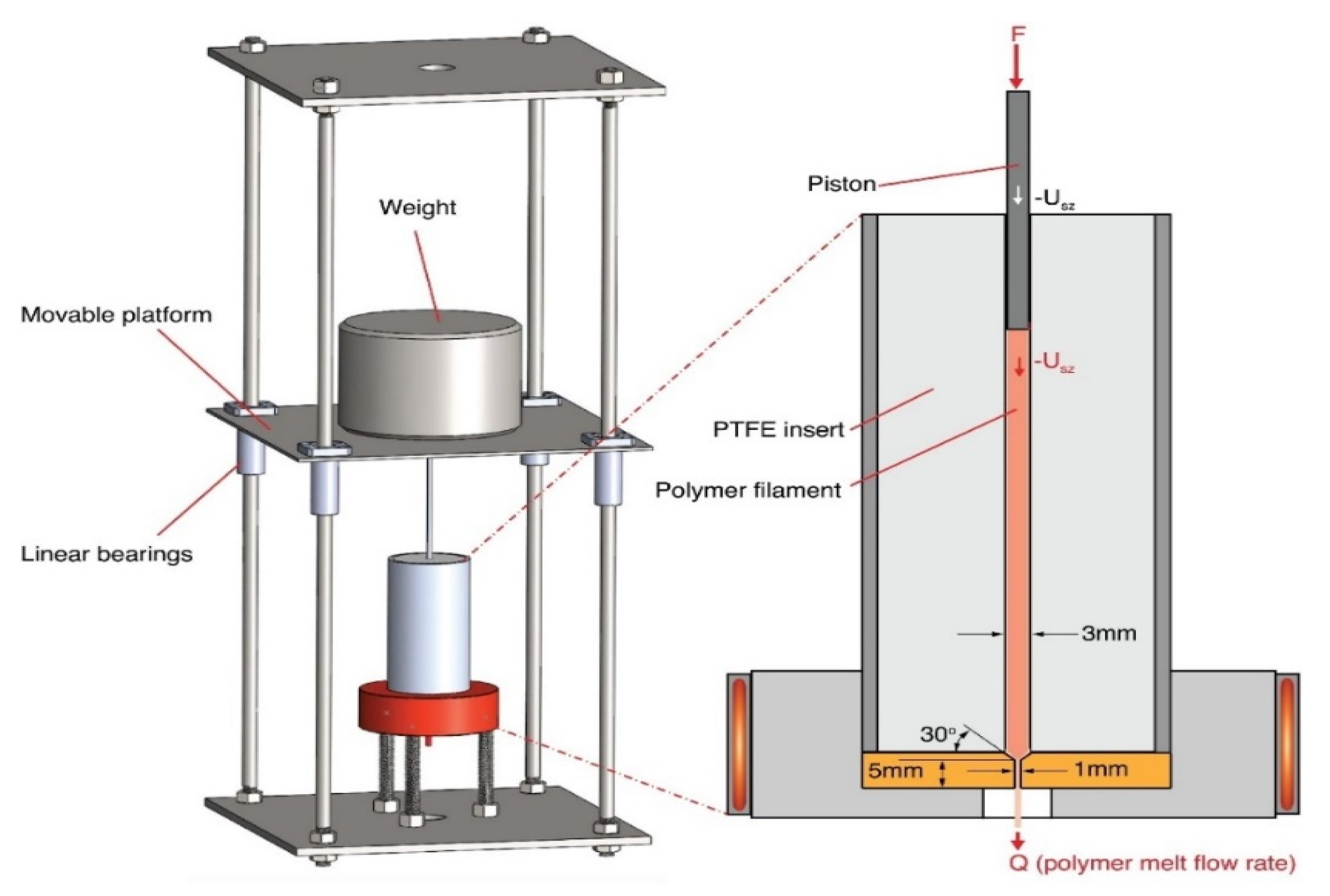

- Osswald, T.A.; Puentes, J.; Kattinger, J. Fused filament fabrication melting model. Addit. Manuf. 2018, 22, 51–59. [Google Scholar]

- Wang, T.M.; Xi, J.T.; Jin, Y. A model research for prototype warp deformation in the FDM process. Int. J. Adv. Manuf. Technol. 2007, 33, 1087–1096. [Google Scholar] [CrossRef]

- Armillotta, A.; Bellotti, M.; Cavallaro, M. Warpage of FDM parts: Experimental tests and analytic model. Robot. Comput. Integr. Manuf. 2018, 50, 140–152. [Google Scholar] [CrossRef]

- Folgar, F.; Tucker, C.L. Orientation Behavior of Fibers in Concentrated Suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L. The Use of Tensors to Describe and Predict Fiber Orientation in Short Fiber Composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Nixon, J.; Dryer, B.; Lempert, I.; Bigio, D.I. Three parameter analysis of fiber orientation in fused deposition modeling geometries. In Proceedings of the 30th International Conference of the Polymer Processing Society, Cleveland, OH, USA, 6–12 June 2014. [Google Scholar]

- Garcia, A. Nozzle Geometry Effects on Exit Orientation of Short Fiber Composites. Master’s Thesis, Wichita State University, Wichita, KS, USA, May 2017. [Google Scholar]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Effects of extrudate swell and nozzle geometry on fiber orientation in Fused Filament Fabrication nozzle flow. Addit. Manuf. 2016, 12, 252–264. [Google Scholar] [CrossRef]

- Yang, D.; Wu, K.; Wan, L.; Sheng, Y. A Particle Element Approach for Modelling the 3D Printing Process of Fibre Reinforced Polymer Composites. J. Manuf. Mater. Process. 2017, 1, 10. [Google Scholar]

- Brenken, B.; Favaloro, A.; Barocio, E.; DeNardo, N.M.; Pipes, R.B. Development of a model to predict temperature history and crystallization behavior of 3dprinted parts made from fiber-reinforced thermoplastic polymers. In Proceedings of the SAMPE Conference 2016, Long Beach, CA, USA, 23–26 May 2016. [Google Scholar]

- Zhou, Y.; Nyberg, T.; Xiong, G.; Liu, D. Temperature Analysis in the Fused Deposition Modeling Process. In Proceedings of the 2016 3rd International Conference on Information Science and Control Engineering (ICISCE), Beijing, China, 8–10 July 2016; pp. 678–682. [Google Scholar]

- Danoglidis, P.A.; Falara, M.G.; Katotriotou, M.K.; Konsta-Gdoutos, M.S.; Gdoutos, E.E. Mechanics of Composite and Multi-functional Materials. In Proceedings of the SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Costa Mesa, CA, USA, 8–11 June 2015. [Google Scholar]

- Bellehumeur, C.; Li, L.; Sun, Q.; Gu, P. Modeling of bond formation between polymer filaments in the fused deposition modeling process. J. Manuf. Process. 2004, 6, 170–178. [Google Scholar] [CrossRef]

- Stewart, S.R.; Wentz, J.E.; Allison, J.T. Experimental and Computational Fluid Dynamic Analysis of Melt Flow Behavior in Fused Deposition Modelling of Poly(lactic) Acid. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015. [Google Scholar] [CrossRef]

- Papon, M.E.A.; Haque, A.; Sharif, M.A.R. Effect of nozzle geometry on Melt flow simulation and structural property of thermoplastic nanocomposites in Fused deposition modeling. In Proceedings of the 32nd Technical Conference of the American Society for Composites 2017, West Lafayette, IN, USA, 23–25 October 2017; pp. 2167–2182. [Google Scholar]

- Xinhua, L.; Shengpeng, L.; Zhou, L.; Xianhua, Z.; Xiaohu, C.; Zhongbin, W. An investigation on distortion of PLA thin-plate part in the FDM process. Int. J. Adv. Manuf. Technol. 2015, 79, 1117–1126. [Google Scholar] [CrossRef]

- Wijnen, B.; Sanders, P.; Pearce, J.M. Improved model and experimental validation of deformation in fused filament fabrication of polylactic acid. Prog. Addit. Manuf. 2018, 3, 193–203. [Google Scholar] [CrossRef] [Green Version]

- Xia, H.; Lu, J.; Tryggvason, G. A numerical study of the effect of viscoelastic stresses in fused filament fabrication. Comput. Methods Appl. Mech. Eng. 2019, 346, 242–259. [Google Scholar] [CrossRef]

- Ortega, Z.; Alemán, M.E.; Benítez, A.N.; Monzon, M.D. Theoretical-experimental evaluation of different biomaterials for parts obtaining by fused deposition modeling. Meas. J. Int. Meas. Confed. 2016, 89, 137–144. [Google Scholar] [CrossRef]

- Watanabe, N. Computational and Experimental Investigation of Reinforced Polymers for Material Extrusion Additive Manufacturing. Master’s Thesis, Georgia Institute of Technology, Atlanta, GA, USA, December 2016. [Google Scholar]

- Kim, T.; Trangkanukulkij, R.; Kim, W.S. Nozzle Shape Guided Filler Orientation in 3D Printed Photo-curable Nanocomposites. Sci. Rep. 2018, 8, 3805. [Google Scholar] [CrossRef] [Green Version]

- Lewicki, J.P.; Rodriguez, J.N.; Zhu, C.; Worsley, M.A.; Wu, A.S.; Kanarska, Y.; Horn, J.D.; Duoss, E.B.; Ortega, J.M.; Elmer, W.; et al. 3D-Printing of Meso-structurally Ordered Carbon Fiber/Polymer Composites with Unprecedented Orthotropic Physical Properties. Sci. Rep. 2017, 7, 43401. [Google Scholar] [CrossRef] [Green Version]

- Bellini, A. Fused Deposition of Ceramics: A Comprehensive Experimental, Analytical and Computational Study of Material Behavior, Fabrication Process and Equipment Design. Ph.D. Thesis, Drexel University Philadelphia, Philadelphia, PA, USA, September 2002. [Google Scholar]

- Mellor, L.F.; Huebner, P.; Cai, S.; Mohiti-Asli, M.; Taylor, M.A.; Spang, J.; Shirwaiker, R.A.; Loboa, E.G. Fabrication and Evaluation of Electrospun, 3D-Bioplotted, and Combination of Electrospun/3D-Bioplotted Scaffolds for Tissue Engineering Applications. Biomed. Res. Int. 2017, 2017, 6956794. [Google Scholar] [CrossRef] [PubMed]

- Palmero, E.M.; Casaleiz, D.; de Vicente, J.; Hernández-Vicen, J.; López-Vidal, S.; Ramiro, E.; Bollero, A. Composites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105497. [Google Scholar] [CrossRef]

- Kulich, D.M.; Gaggar, S.K.; Lowry, V.; Stepien, R. Acrylonitrile–Butadiene–Styrene (ABS) Polymers. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar] [CrossRef]

- Cress, A.K.; Huynh, J.; Anderson, E.H.; O’neill, R.; Keles, O. Effect of recycling on the mechanical behavior and structure of additively manufactured acrylonitrile butadiene styrene (ABS). J. Clean. Prod. 2021, 279, 123689. [Google Scholar] [CrossRef]

- Bellini, A.; Guceri, S.; Bertoldi, M. Liquefier Dynamics in Fused Deposition. J. Manuf. Sci. Eng. 2004, 126, 237–246. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of poly(lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Zhang, Q.; Lei, H.; Cai, H.; Han, X.; Lin, X.; Qian, M.; Zhao, Y.; Huo, E.; Villota, E.M.; Mateo, W. Improvement on the properties of microcrystalline cellulose/polylactic acid composites by using activated biochar. J. Clean. Prod. 2020, 252, 119898. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Yunus, D.E.; Shi, W.; Sohrabi, S.; Liu, Y. Shear induced alignment of short nanofibers in 3D printed polymer composites. Nanotechnology 2016, 27, 495302. [Google Scholar] [CrossRef]

- Yunus, D.E.; He, R.; Shi, W.; Kaya, O.; Liu, Y. Short fiber reinforced 3d printed ceramic composite with shear induced alignment. Ceram. Int. 2017, 43, 11766–11772. [Google Scholar] [CrossRef]

- Mulholland, T.; Goris, S.; Boxleitner, J.; Osswald, T.A.; Rudolph, N. Process-Induced Fiber Orientation in Fused Filament Fabrication. J. Compos. Sci. 2018, 2, 45. [Google Scholar] [CrossRef] [Green Version]

- Russell, T.; Heller, B.; Jack, D.A.; Smith, D.E. Prediction of the Fiber Orientation State and the Resulting Structural and Thermal Properties of Fiber Reinforced Additive Manufactured Composites Fabricated Using the Big Area Additive Manufacturing Process. J. Compos. Sci. 2018, 2, 26. [Google Scholar] [CrossRef] [Green Version]

- Bertevas, E.; Férec, J.; Khoo, B.C.; Ausias, G.; Phan-Thien, N. Smoothed particle hydrodynamics (SPH) modeling of fiber orientation in a 3D printing process. Phys. Fluids 2018, 30, 103103. [Google Scholar] [CrossRef]

- Shahriar, B.B.; France, C.; Valerie, N.; Arthur, C.; Christian, G. Toward improvement of the properties of parts manufactured by FFF (fused filament fabrication) through understanding the influence of temperature and rheological behaviour on the coalescence phenomenon. AIP Conf. Proc. 2017, 1896, 040008. [Google Scholar]

- Yardimci, M.A.; Hattori, T.; Guceri, S.I.; Danforth, S.C. Thermal analysis of Fused Deposition. In Proceedings of the 1997 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–13 August 1997; pp. 689–698. [Google Scholar]

- Liu, J.; Anderson, K.L.; Sridhar, N. Direct Simulation of Polymer Fused Deposition Modeling (FDM)—An Implementation of the Multi-Phase Viscoelastic Solver in OpenFOAM. Int. J. Comput. Methods 2020, 17, 1844002. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q. Bond Formation between Polymer Filaments in Fused Deposition Modeling Process. Master’s Thesis, University of Calgary, Calgary, AB, Canada, August 2005. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid. Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Gurrala, P.K.; Regalla, S.P. Part strength evolution with bonding between filaments in fused deposition modelling. Virtual Phys. Prototyp. 2014, 9, 141–149. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Towards modelling of Free Form Extrusion: Analytical solution of transient heat transfer. Int. J. Mater. Form. 2008, 1, 703–706. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Estimation of filament temperature and adhesion development in fused deposition techniques. J. Mater. Process. Technol. 2017, 245, 167–179. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

- McIlroy, C.; Olmsted, P.D. Deformation of an amorphous polymer during the fused-filament-fabrication method for additive manufacturing. J. Rheol. 2017, 61, 379–397. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chou, K. A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 959–968. [Google Scholar] [CrossRef]

- Xia, H.; Lu, J.; Tryggvason, G. Fully resolved numerical simulations of fused deposition modeling. Part II–solidification, residual stresses and modeling of the nozzle. Rapid Prototyp. J. 2018, 24, 973–987. [Google Scholar] [CrossRef] [Green Version]

- Xia, H.; Lu, J.; Tryggvason, G. Simulations of fused filament fabrication using a front tracking method. Int. J. Heat. Mass. Transf. 2019, 138, 1310–1319. [Google Scholar] [CrossRef]

- Cattenone, A.; Morganti, S.; Alaimo, G.; Auricchio, F. Finite Element Analysis of Additive Manufacturing Based on Fused Deposition Modeling: Distortions Prediction and Comparison with Experimental Data. J. Manuf. Sci. Eng. 2019, 141, 011010. [Google Scholar] [CrossRef]

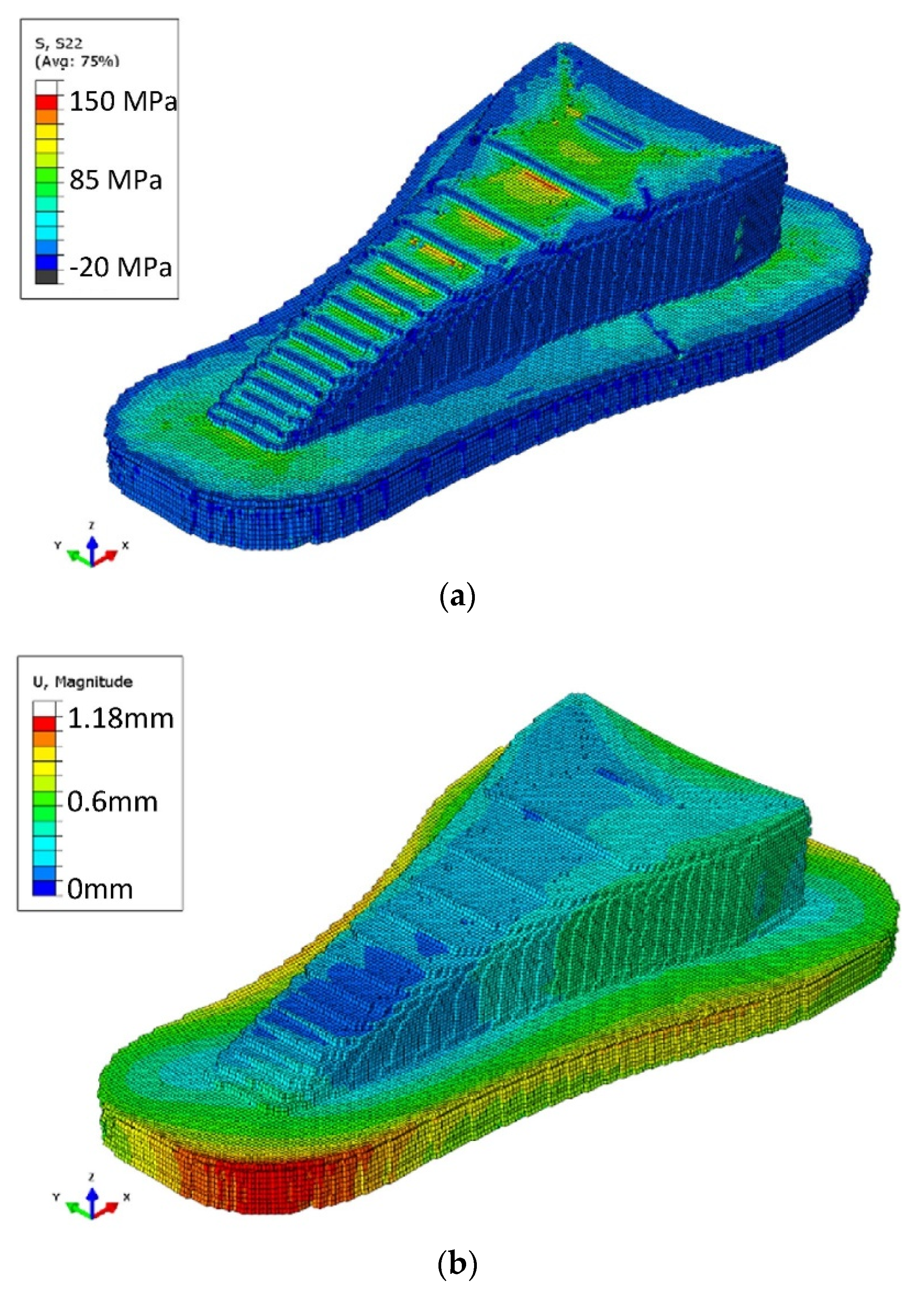

- Favaloro, A.J.; Barocio, E.; Brenken, B.; Pipes, R.B. Simulation of Polymeric Composites Additive Manufacturing using Abaqus. In Proceedings of the Dassault Systemes’ Science in the Age of Experience, Chicago, IL, USA, 15–18 May 2017; pp. 103–114. [Google Scholar]

- Talagani, M.R.; Dormohammadi, S.; Dutton, R.; Godines, C.; Baid, H.; Abdi, F.; Kunc, V.; Compton, B.; Simunovic, S.; Duty, C. Numerical Simulation of Big Area Additive Manufacturing (3D Printing) of a Full Size Car. SAMPE J. 2015, 51, 27–36. [Google Scholar]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT-and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Li, H.; Zhang, S.; Yi, Z.; Li, J.; Sun, A.; Guo, J.; Xu, G. Bonding quality and fracture analysis of polyamide 12 parts fabricated by fused deposition modeling. Rapid Prototyp. J. 2017, 23, 973–982. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Drummer, D.; Cifuentes-Cuéllar, S.; Rietzel, D. Suitability of PLA/TCP for fused deposition modeling. Rapid Prototyp. J. 2012, 18, 500–507. [Google Scholar] [CrossRef]

| Material | Additives | Analysis | Tools | Highlights | Ref. |

|---|---|---|---|---|---|

| PCL | - | Melt Flow Behavior | ANSYS© | Observation of velocity, pressure, and thermal variations. Filament velocity at the inlet of the channel was varied. Variation in nozzle shape and the angle at the exit. Material liquified within 35% of the channel length. | [29] |

| ABS | Iron Particles (10%) | Melt Flow Behavior | ANSYS© | Study of velocity, temperature, and pressure variations. Fabrication and characterization of composites. Promising simulation results for melt flow behavior and process optimization. | [30] |

| ABS | - | Swelling and Filament Cooling | Dieplast© and EFD Lab | Potential for using fine nozzle diameters for MAFD. Nozzle temperature regarded as primary contributor to die swelling. Temperature variations along the nozzle length. Volume of flow 215 times lower than conventional nozzles. | [31] |

| ABS | - | Melting Inside Nozzle | Mathematical Model | Analytical model for melting inside the nozzle. Material flow was controlled by applied force. Experimental validation of proposed model. Good prediction of material behavior for force up to 40 N. | [32] |

| ABS | - | Warpage | Mathematical Model | Simple model for warpage deformation was developed. All influencing parameters (layer number, chamber temperature, material shrinkage rate) were quantitatively analyzed. Recommendations to avoid warp deformation. | [33] |

| ABS | - | Warpage | Mathematical Model | Analytical model based on experimental observations was developed. Model can predict multi-layer deformation of 3D printed parts. Strong effect of layer thickness on warpage was observed. | [34] |

| ABS | CF | Fiber Orientation | COMSOL© MATLAB© | Effect of nozzle geometry and extrudate swell. Used Floger-Tucker [35] and Advani and Tucker [36] models. Comparable results to previously reported studies [37,38]. | [39] |

| ABS | CF | Fiber Orientation | SPH-DEM | Both short and continuous fiber composites. Highly aligned short fibers with material flow over time. Lower printing speeds recommended for continuous fiber composites to avoid nozzle wear and fiber breakage. | [40] |

| ABS | - | Solidification | ANSYS© | Rectangular cross-section of deposited beads. 3D model to investigate thermal behavior. Similar stepwise activation, as reported by [41]. Thermal properties of the material were found to have a significant effect on the solidification process. | [42] |

| ABS | - | Solidification | Mathematical Model | Both convective and radiative heat transfer phenomena were considered to develop a 3D model. The numerical model results found sound agreement with experimental results. | [43] |

| ABS | - | Bond Formation | Mathematical Model | First model to predict the bond formation mechanism. 1D lumped heat transfer model was used. The model also considered the effect of printing parameters. Concluded better control of the cooling process to control mechanical properties of FFF parts. | [44] |

| PLA | - | Melt Flow Behavior | ANSYS© | Experimentally obtained liquefier temperature profile and heating element power output. Detailed 3D model with all assemblies. External heat transfer mechanisms were found more significant. | [45] |

| PLA | CNF (0–1%) | Melt Flow Behavior | ANSYS© | Rheological and mechanical properties obtained experimentally. Simulation of non-Newtonian fluid flow using 3D model. Results agreed well with existing numerical models. | [46] |

| PLA | - | Warpage | Mathematical Model Statistical Analysis | 2D analytical model based on theory of thin plates. Taguchi’s method was used for design of experiments. ANOVA and S/N ratio were used to optimize the process parameters. Proposed model was found efficient but thermal stresses were ignored. | [47] |

| PLA | - | Warpage | Mathematical Model | Successful prediction of distortion for PLA thin walls. Limitation in terms of warpage magnitude. | [48] |

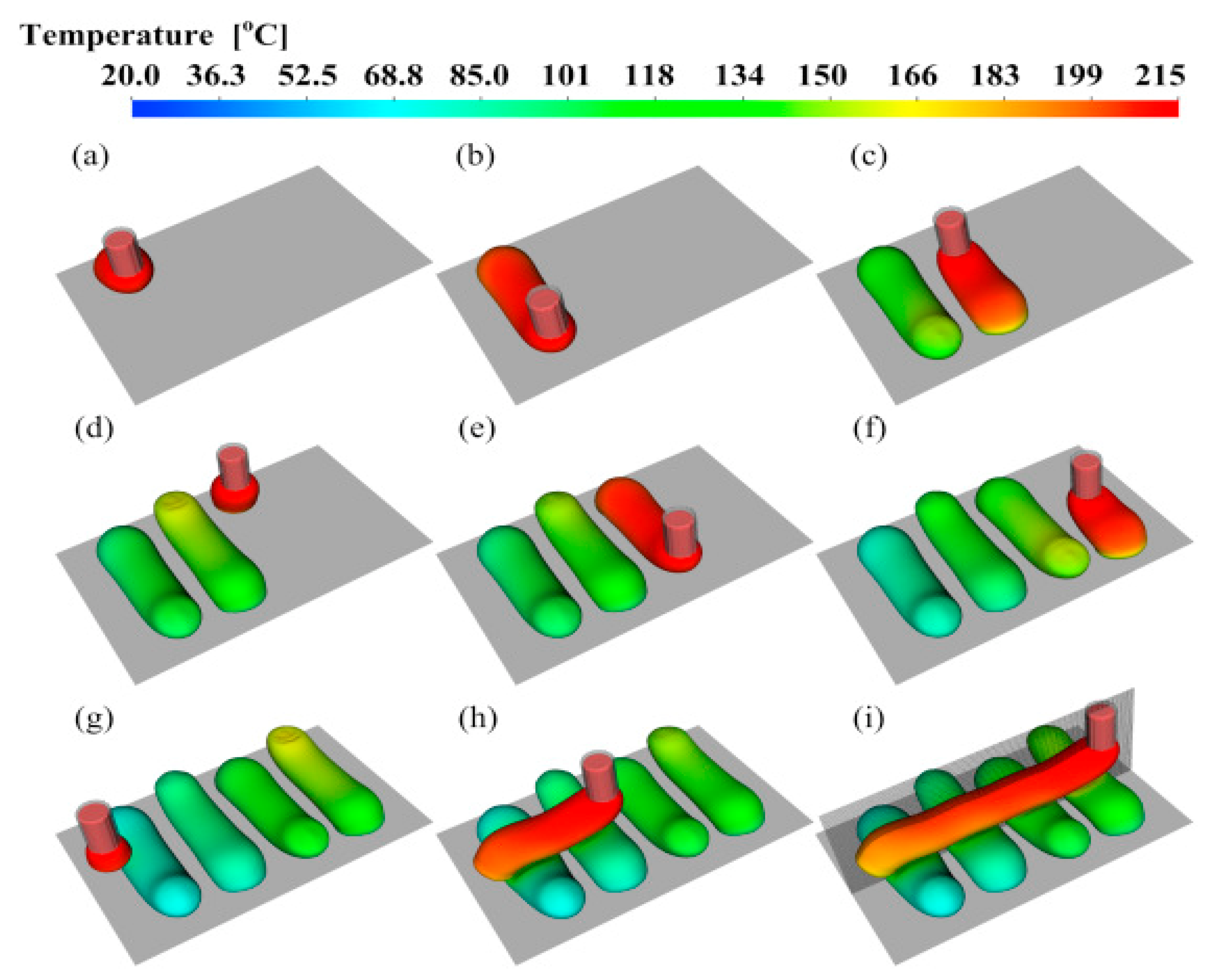

| PLA | - | Bead Deposition and Solidification | Mathematical Model | A model for viscoelastic materials The front-tracking/finite volume method was used. Three extruded filaments built vertically were simulated considering viscoelastic stresses. The model was also employed to larger objects. | [49] |

| ABS, PCL, PLA | - | Swelling and Process Conditions | SolidWorks© | Nozzle equipped with pressure and temperature sensors. High shear rates resulted in a higher swell. Viscosity models were obtained from experimental analysis. Simulations agreed well with experimental data. | [50] |

| PP | - | Melt Flow Bead Shape Residual Stresses Warpage | ANSYS© | Experimental and numerical investigation. Special focus on warpage and mechanical properties. Good agreement of numerical simulation results with experimental observations. | [51] |

| PPS | AIN | Warpage | ANSYS© | Extended work from Watanable [51]. Analysis of most significant material parameter. CTE concluded most significant for part warpage. Composite materials with lower CTE can reduce warpage. | [28] |

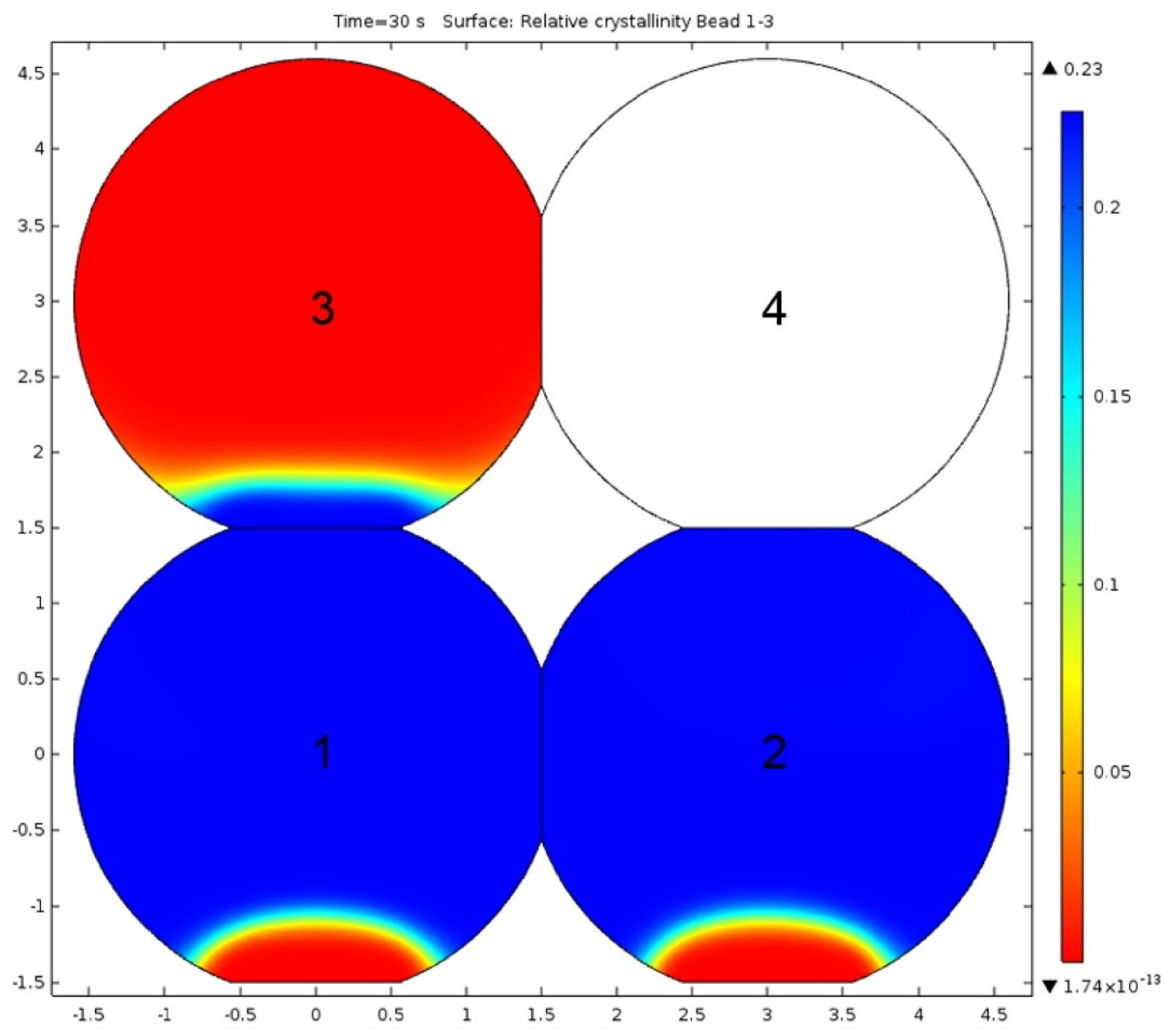

| PPS | CF | Solidification Crystallization | COMSOL© | 2D model for thermal history and crystallization behavior. Used non-isothermal dual crystallization kinetics model. Individual activation of beads. Thermal variations of the beads in the printing direction were not considered. | [41] |

| Photo Polymer | AgNWs (1.6 vol%) | Nanofiller orientation | ANSYS© | Nozzle geometry effect on fiber orientation. Aligned nanowires for circular nozzle. Different velocity profiles at nozzle exits. | [52] |

| Epoxy | CF (8 vol%) | Fiber Orientation | STARCCM+ | Melt flow within the nozzle. Fibers interactions with other fibers, epoxy, and wall. Higher fiber orientation near to the wall. | [53] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, A.A.; Koç, M. Fused Filament Fabrication Process: A Review of Numerical Simulation Techniques. Polymers 2021, 13, 3534. https://doi.org/10.3390/polym13203534

Rashid AA, Koç M. Fused Filament Fabrication Process: A Review of Numerical Simulation Techniques. Polymers. 2021; 13(20):3534. https://doi.org/10.3390/polym13203534

Chicago/Turabian StyleRashid, Ans Al, and Muammer Koç. 2021. "Fused Filament Fabrication Process: A Review of Numerical Simulation Techniques" Polymers 13, no. 20: 3534. https://doi.org/10.3390/polym13203534

APA StyleRashid, A. A., & Koç, M. (2021). Fused Filament Fabrication Process: A Review of Numerical Simulation Techniques. Polymers, 13(20), 3534. https://doi.org/10.3390/polym13203534