Preparation of Intercalated Organic Montmorillonite DOPO-MMT by Melting Method and Its Effect on Flame Retardancy to Epoxy Resin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Intercalated DOPO-MMT

2.3. Preparation of Physical Mixed Sample DOPO+MMT

2.4. Preparation of Epoxy Resin Composites

2.5. Instrumentation and Methods for Testing Characterization

2.5.1. XRD Characterization

2.5.2. SEM Characterization

2.5.3. LOI Analysis

2.5.4. UL-94 Vertical Combustion Analysis

2.5.5. TGA Characterization

2.5.6. DSC Characterization

2.5.7. CONE Characterization

3. Results

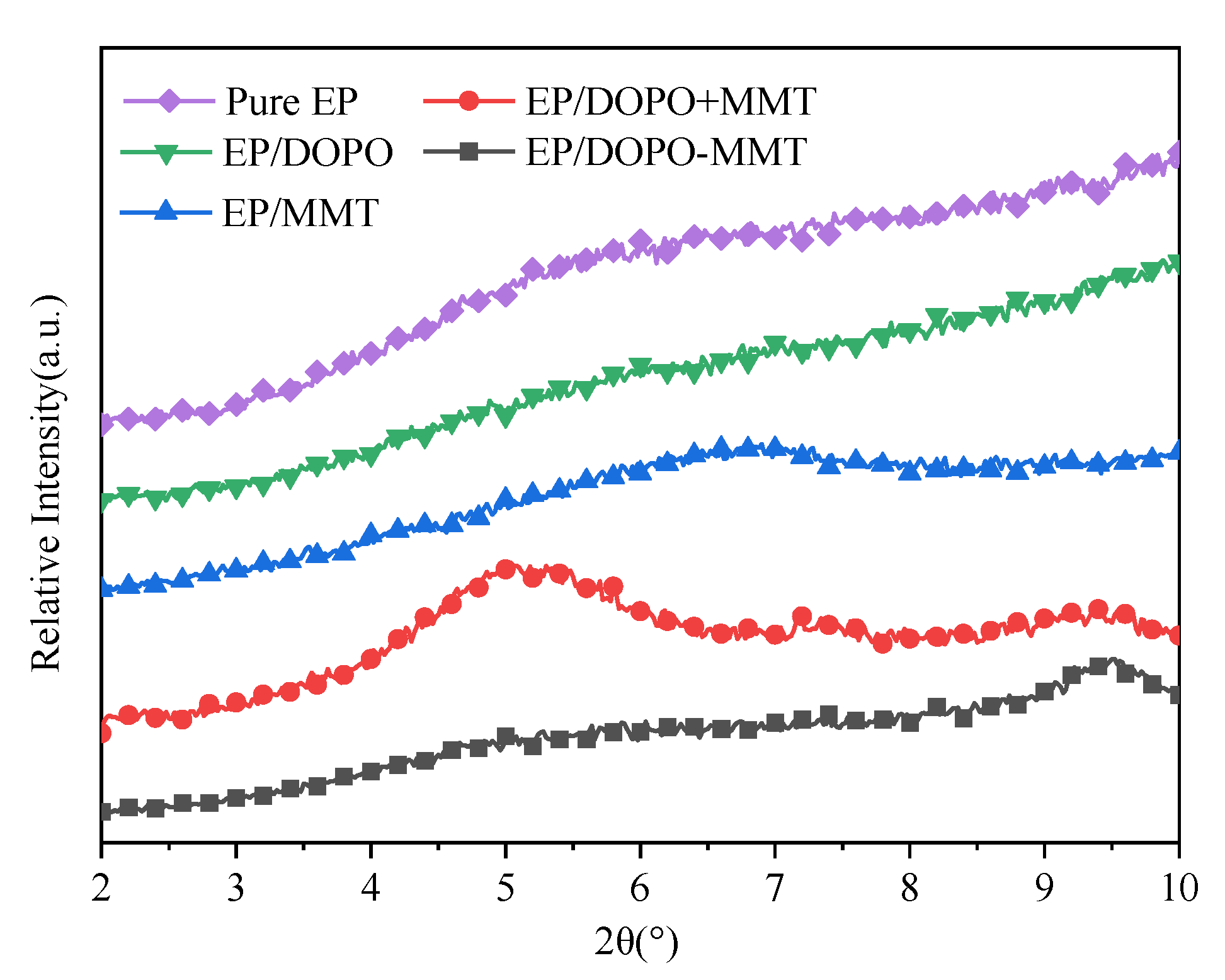

3.1. XRD Analysis of Four Flame Retardants

3.2. XRD Analysis of Epoxy Resin Composite

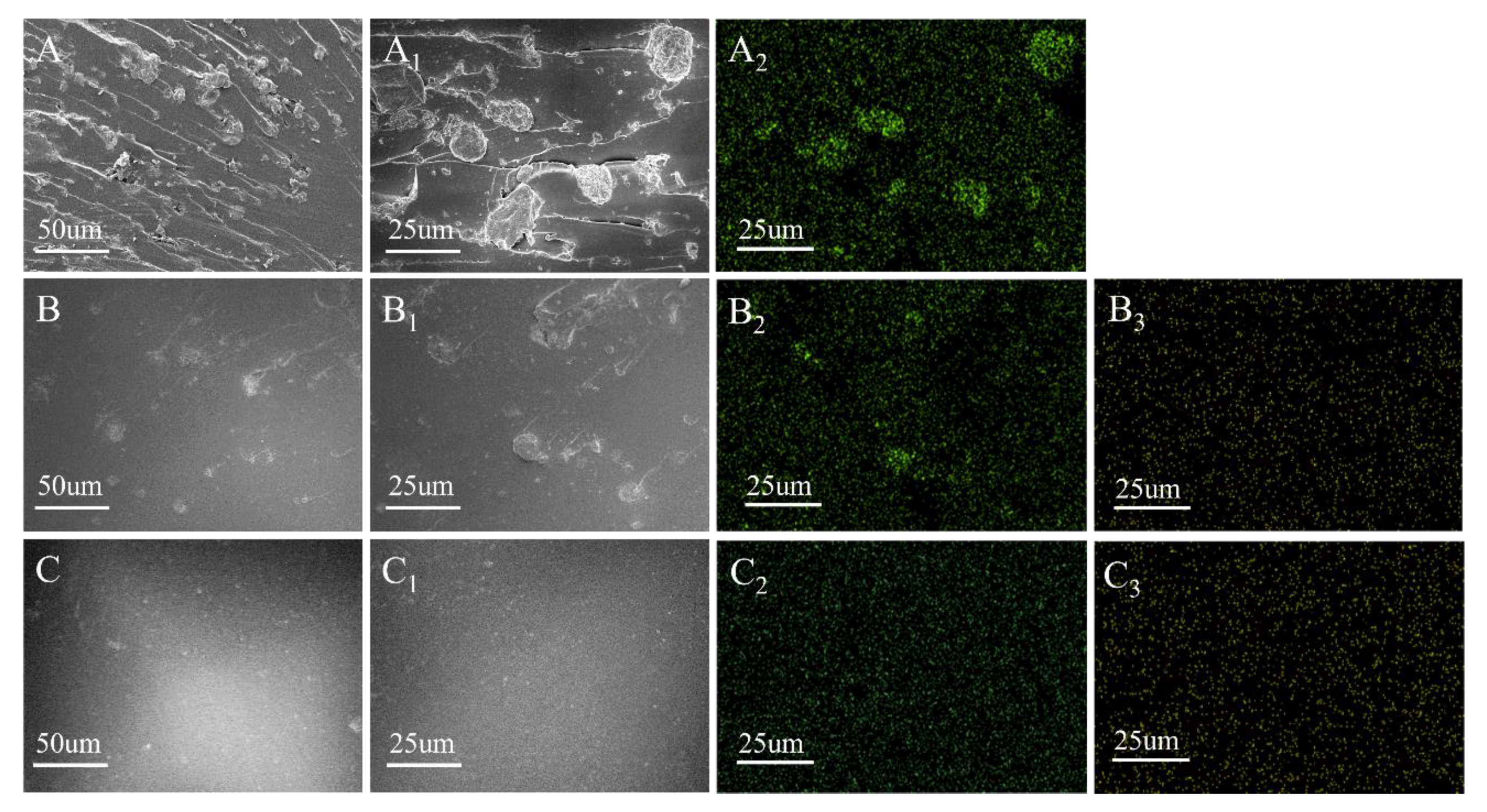

3.3. SEM Analysis of Epoxy Resin Composite

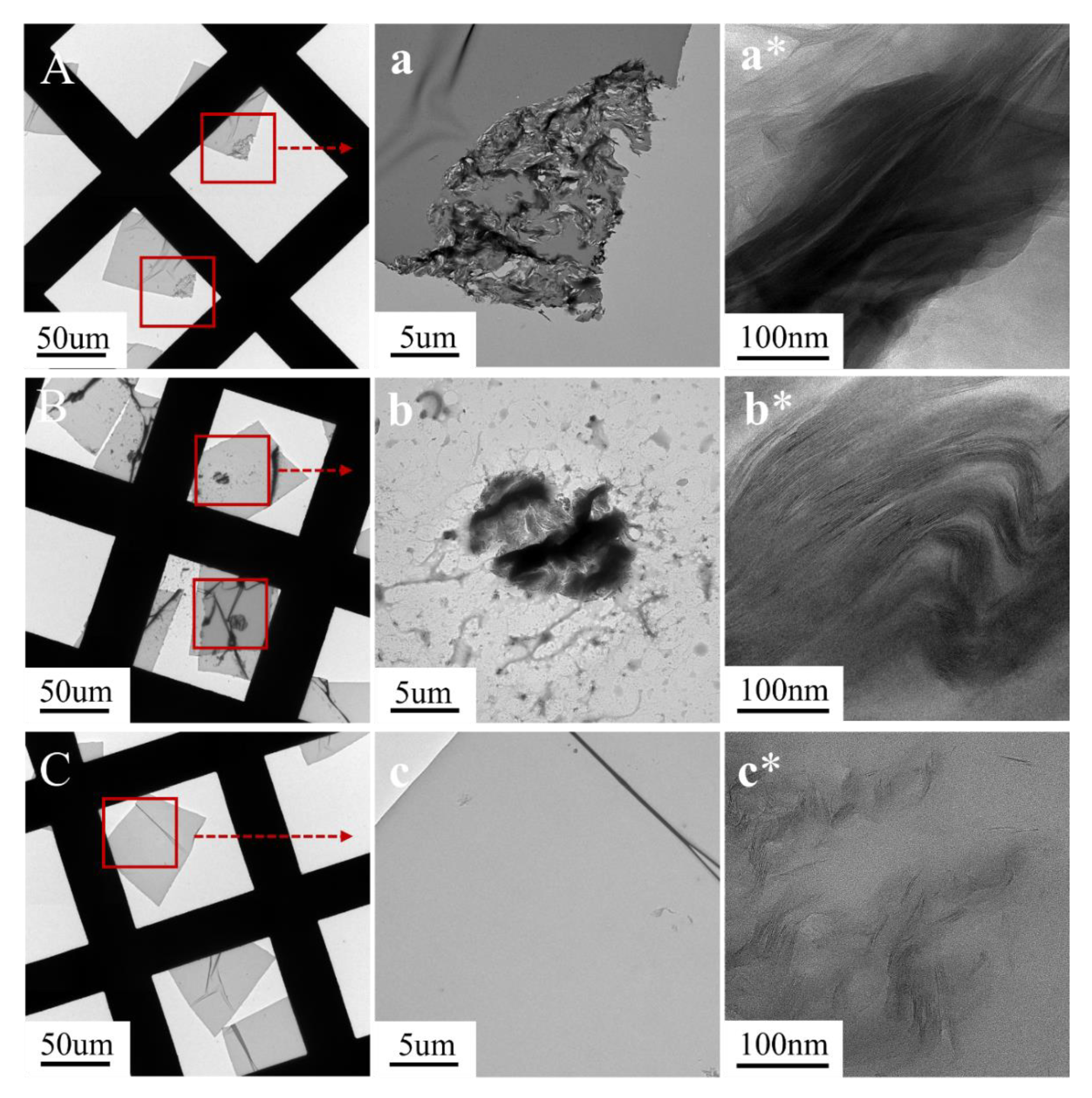

3.4. TEM Analysis of Epoxy Resin Composite

3.5. LOI and UL-94 Test of Epoxy Resin Composites

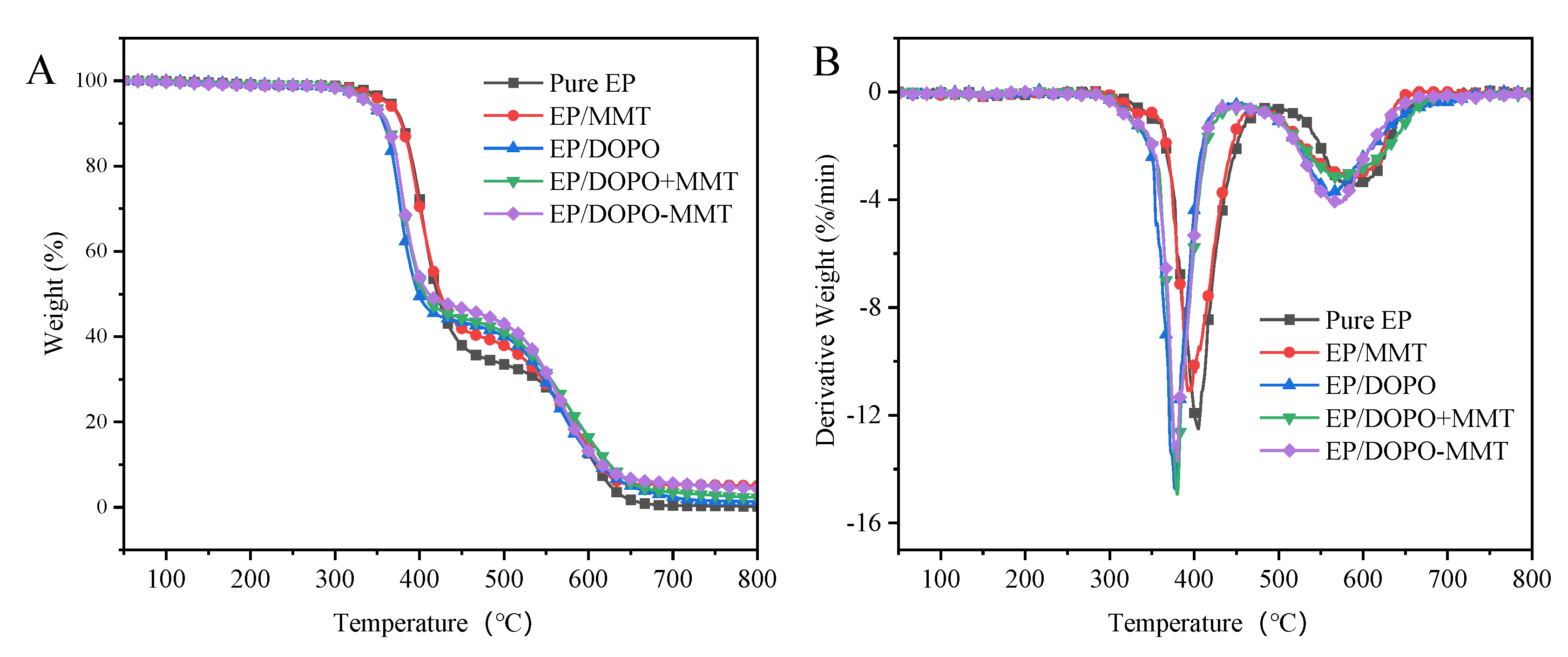

3.6. Thermal Stability of EPs

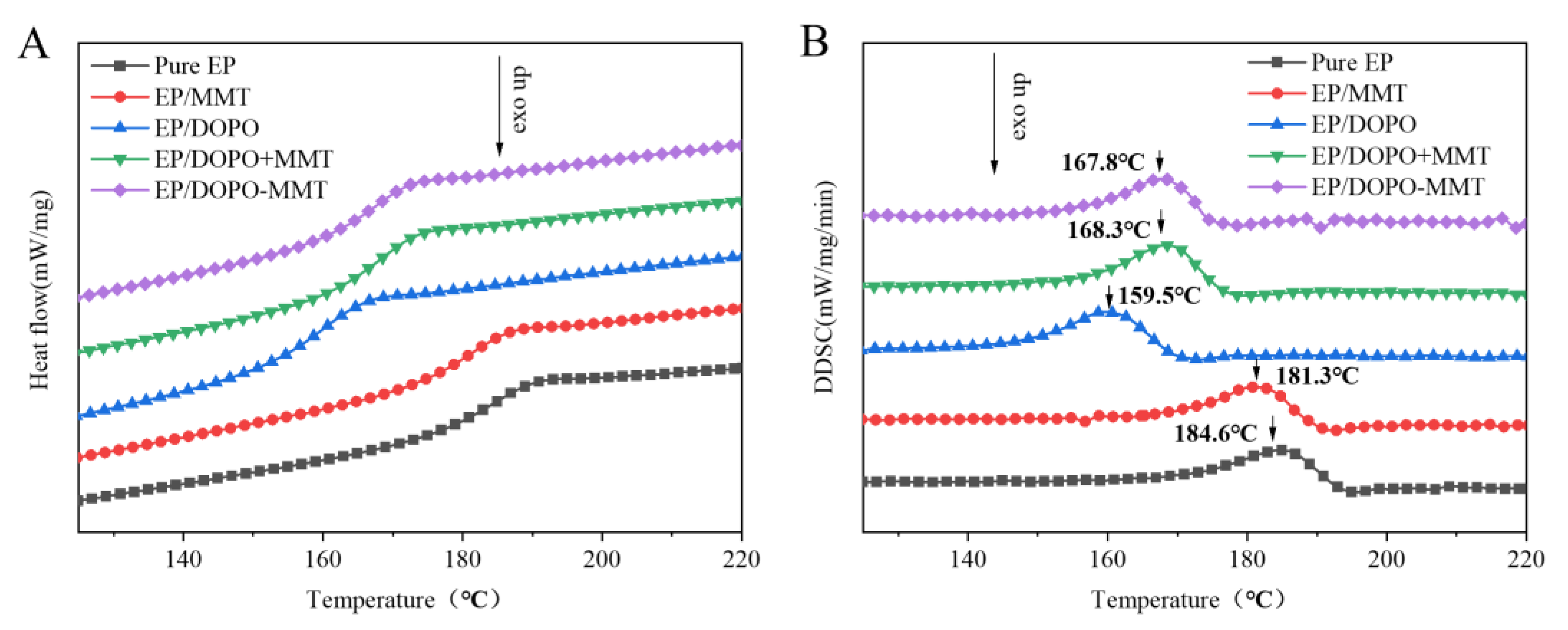

3.7. Glass Transition of EPs

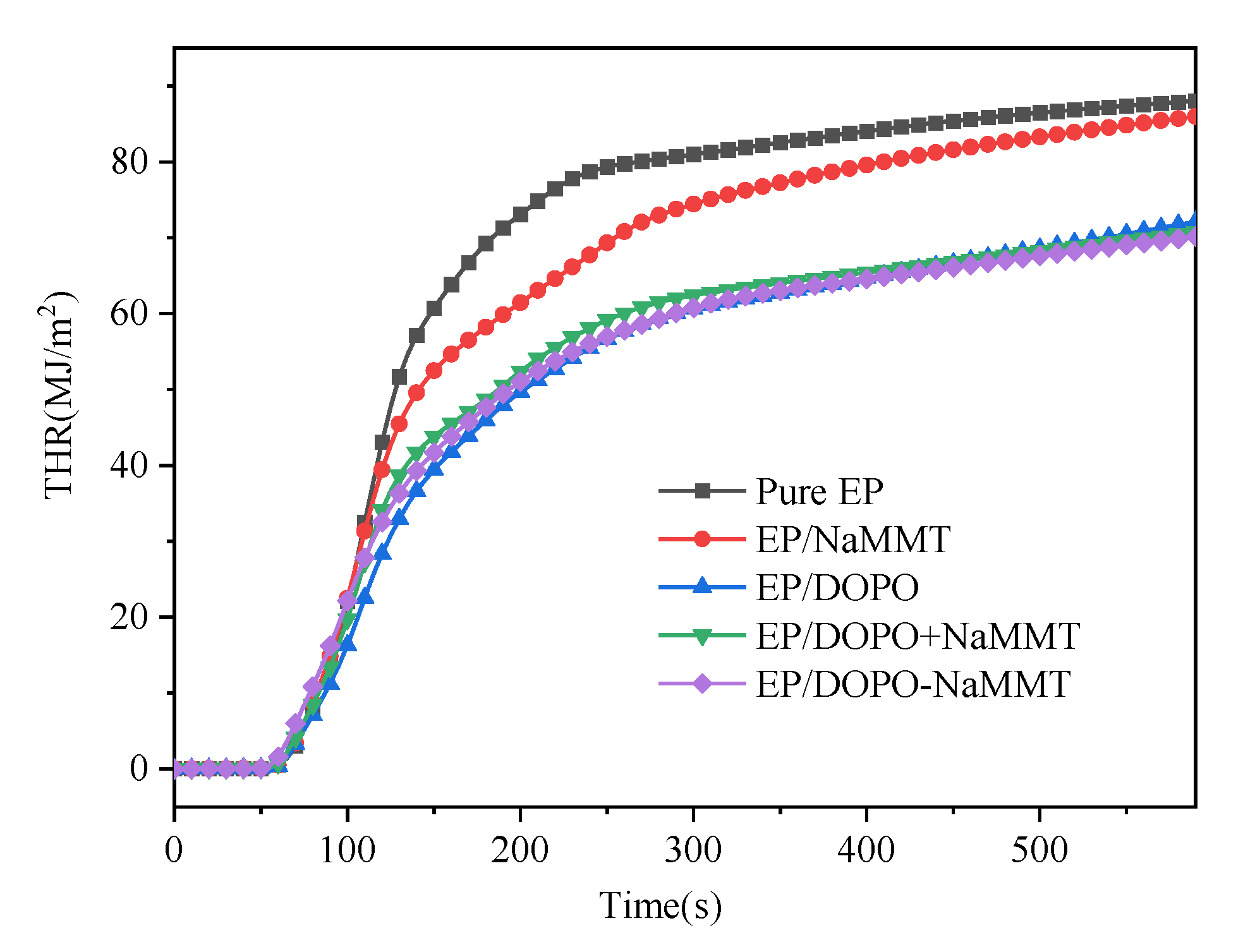

3.8. CONE Test of Epoxy Resin Composites

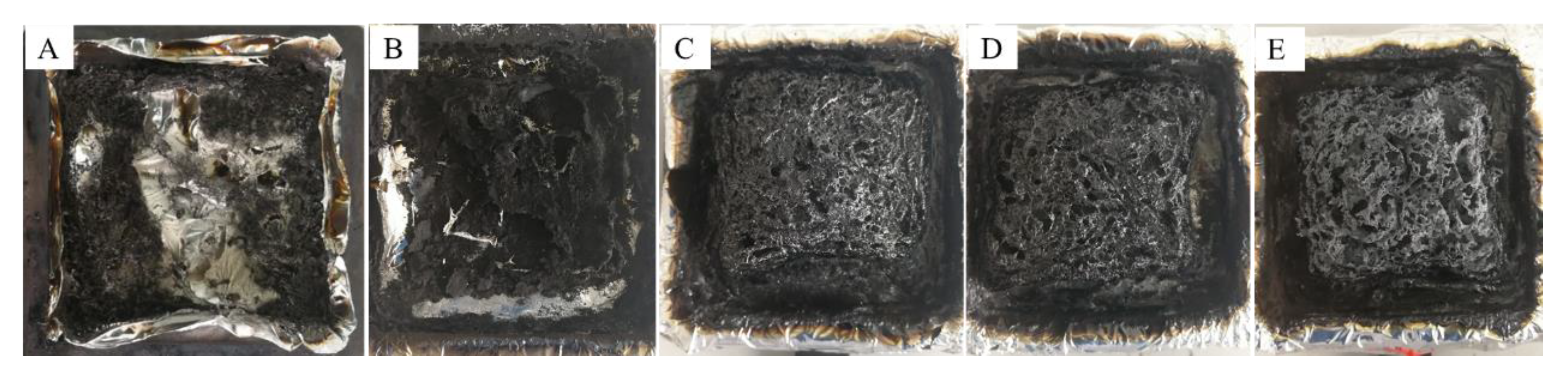

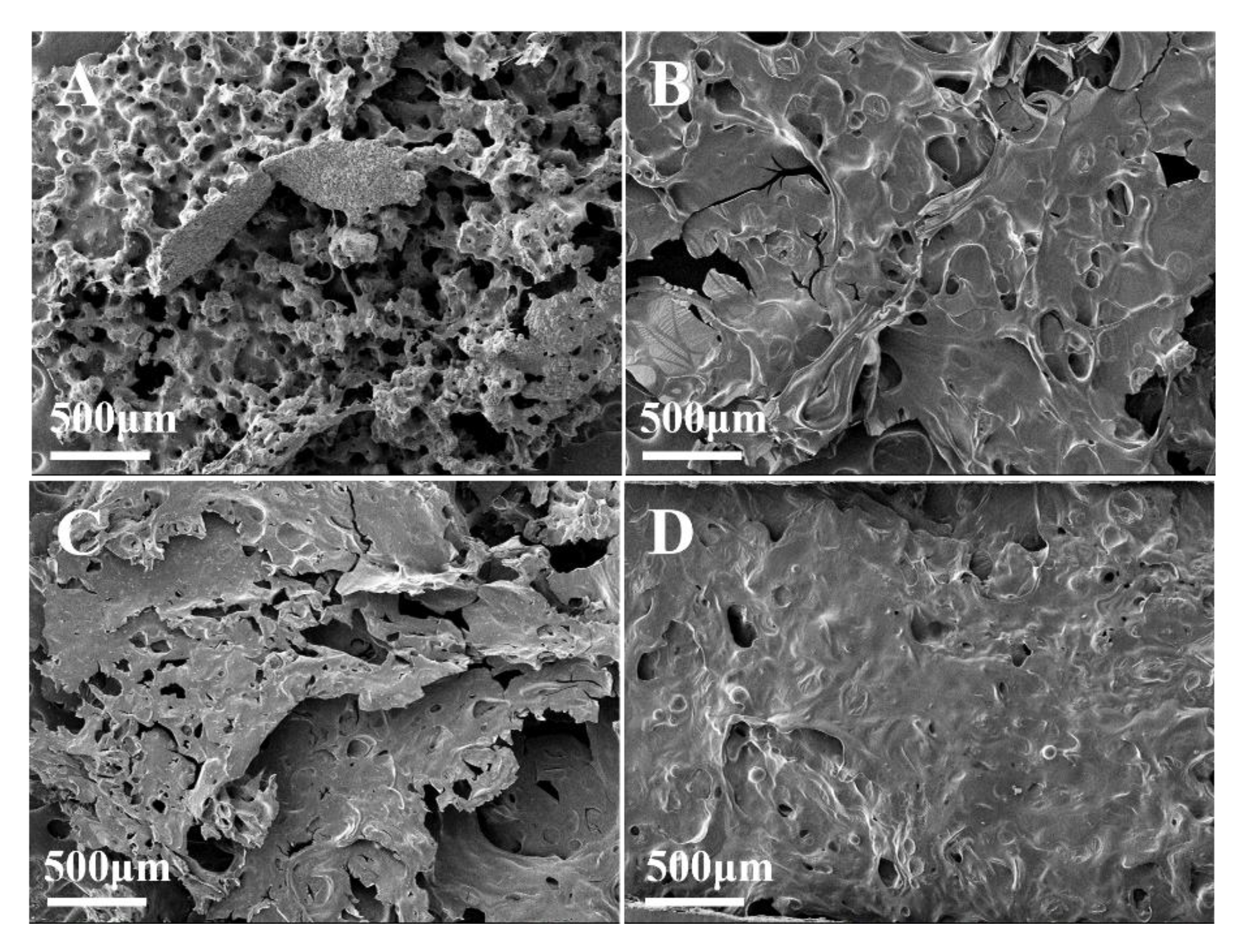

3.9. Analysis of Condensed Phase of Epoxy Resin Composites CONE of Epoxy Resin Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azeez, A.A.; Rhee, K.Y.; Park, S.J.; Hui, D. Epoxy clay nanocomposites—Processing, properties and applications: A review. Compos. Part B Eng. 2013, 45, 308–320. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C. Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy. Prog. Polym. Sci. 2010, 35, 902–958. [Google Scholar] [CrossRef]

- Köklükaya, O.; Carosio, F.; Duran, V.L.; Wågberg, L. Layer-by-layer modified low density cellulose fiber networks: A sustainable and fireproof alternative to petroleum based foams. Carbohydr. Polym. 2020, 230, 115616. [Google Scholar] [CrossRef] [PubMed]

- Hua, X.; Lia, M.; Yanga, J.; Liua, F.; Huanga, H.; Panc, H.; Yangab, H. In situ fabrication of melamine hydroxy ethylidene diphosphonate wrapped montmorillonite for reducing the fire hazards of epoxy resin. Appl. Clay Sci. 2021, 201, 105934. [Google Scholar] [CrossRef]

- Baney, R.H.; Itoh, M.; Sakakibara, A.; Suzuki, T. Silsesquioxanes. Chem. Rev. 1995, 94, 1409–1430. [Google Scholar] [CrossRef]

- Bourbigot, S.; Samyn, F.; Turf, T.; Duquesne, S. Nanomorphology and reaction to fire of polyurethane and polyamide nanocomposites containing flame retardants. Polym. Degrad. Stab. 2010, 95, 320–326. [Google Scholar] [CrossRef]

- Jang, B.N.; Costache, M.; Wilkie, C.A. The relationship between thermal degradation behavior of polymer and the fire retardancy of polymer/clay nanocomposites—ScienceDirect. Polymer 2005, 46, 10678–10687. [Google Scholar] [CrossRef]

- Samyn, F.; Bourbigot, S.; Jama, C.; Bellayer, S.; Nazare, S.; Hull, R.; Fina, A.; Castrovinci, A.; Camino, G. Characterisation of the dispersion in polymer flame retarded nanocomposites. Eur. Polym. J. 2008, 44, 1631–1641. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Hu, Y.; Song, L.; Zong, R.; Gui, Z.; Fan, W. Preparation and combustion properties of flame retarded polypropylene–polyamide-6 alloys. Polym. Degrad. Stab. 2006, 91, 234–241. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Nikafshar, S.; Preyeswary, K.C.; Naebe, M. A technical review on epoxy-clay nanocomposites: Structure, properties, and their applications in fiber reinforced composites. Compos. Part B Eng. 2018, 135, 1–24. [Google Scholar] [CrossRef]

- Zhu, J.; Morgan, A.B.; Lamelas, F.J.; Wilkie, C.A. Fire Properties of Polystyrene−Clay Nanocomposites. Chem. Mater. 2001, 13, 3774–3780. [Google Scholar] [CrossRef]

- Guo, Y.X.; Liu, J.H.; Gates, W.P.; Zhou, C.H. Organo-modification of montmorillonite. Clays Clay Miner. 2020, 68, 601–622. [Google Scholar] [CrossRef]

- Malik, N.; Kumar, P.; Ghosh, S.B.; Shrivastava, S. Organically Modified Nanoclay and Aluminum Hydroxide Incorporated Bionanocomposites towards Enhancement of Physico-mechanical and Thermal Properties of Lignocellulosic Structural Reinforcement. J. Polym. Environ. 2018, 26, 3243–3249. [Google Scholar] [CrossRef]

- Oiwa, M.; Yamaguchi, K.; Shibayama, T.; Chiou, T.-Y.; Saitoh, T. Sorption of Antibiotics, Pharmaceuticals, and Personal Care Products in Water on Didodecyldimethylammonium Bromide-Montmorillonite Organoclay. J. Chem. Eng. Jpn. 2020, 53, 608–615. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, J. Preparation of novel flame-retardant organoclay and its application to natural rubber composites. J. Phys. Chem. Solids 2018, 115, 137–147. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, L.; Xia, Z. Ultrasound-assisted preparation and characterization of anionic surfactant modified montmorillonites. Appl. Clay Sci. 2010, 50, 576–581. [Google Scholar] [CrossRef]

- Silva, I.; de Sousa, F.K.A.; Menezes, R.; Neves, G.; Santana, L.; Ferreira, H. Modification of bentonites with nonionic surfactants for use in organic-based drilling fluids. Appl. Clay Sci. 2014, 95, 371–377. [Google Scholar] [CrossRef]

- Zhuang, G.; Zhang, Z.; Wu, H.; Zhang, H.; Zhang, X.; Liao, L. Influence of the nonionic surfactants’ nature on the structures and properties of organo-montmorillonites. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 518, 116–123. [Google Scholar] [CrossRef]

- Sun, J.; Zhuang, G.; Wu, S.; Zhang, Z. Structure and performance of anionic–cationic-organo-montmorillonite in different organic solvents. RSC Adv. 2016, 6, 54747–54753. [Google Scholar] [CrossRef]

- Zhuang, G.; Zhang, Z.; Guo, J.; Liao, L.; Zhao, J. A new ball milling method to produce organo-montmorillonite from anionic and nonionic surfactants. Appl. Clay Sci. 2015, 104, 18–26. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, Z.; Tang, J.; Wang, F.; Liao, L. Applied properties of oil-based drilling fluids with montmorillonites modified by cationic and anionic surfactants. Appl. Clay Sci. 2016, 121-122, 1–8. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, Z.; Tang, J.; Zhang, M.; Liao, L. Effects of variables on the dispersion of cationic–anionic organomontmorillonites and characteristics of Pickering emulsion. RSC Adv. 2016, 6, 9678–9685. [Google Scholar] [CrossRef]

- Yin, Q.; Zhang, Z.; Wu, S.; Tan, J.; Meng, K.; Qixun, Y.; Zepeng, Z.; Sanqin, W.; Jialun, T.; Ke, M. Preparation and characterization of novel cationic–nonionic organo-montmorillonite. Mater. Express 2015, 5, 180–190. [Google Scholar] [CrossRef]

- Zhuang, G.; Zhang, Z.; Fu, M.; Ye, X.; Liao, L. Comparative study on the use of cationic–nonionic-organo-montmorillonite in oil-based drilling fluids. Appl. Clay Sci. 2015, 116-117, 257–262. [Google Scholar] [CrossRef]

- Lin, C.H.; Feng, C.C.; Hwang, T.Y. Preparation, thermal properties, morphology, and microstructure of phosphorus-containing epoxy/SiO2 and polyimide/SiO2 nanocomposites. Eur. Polym. J. 2007, 43, 725–742. [Google Scholar] [CrossRef]

- Peng, C.; Wu, Z.; Li, J.; Wang, Z.; Wang, H.; Zhao, M. Synthesis, thermal and mechanical behavior of a silicon/phosphorus containing epoxy resin. J. Appl. Polym. Sci. 2015, 132, 132. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Commercial Flame Retardancy of Unsaturated Polyester and Vinyl Resins: Review. J. Fire Sci. 2004, 22, 293–303. [Google Scholar] [CrossRef]

- He, X.; Zhang, W.; Yang, R. The characterization of DOPO/MMT nanocompound and its effect on flame retardancy of epoxy resin. Compos. Part A Appl. Sci. Manuf. 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, W.; Yang, R. Synthesis of novel phosphonium bromide-montmorillonite nanocompound and its performance in flame retardancy and dielectric properties of epoxy resins. Polym. Compos. 2020, 42, 362–374. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, W.; Yang, R. Intercalation process in the preparation of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-montmorillonite nanocompounds and their application in epoxy resins. Mater. Des. 2019, 178, 107834. [Google Scholar] [CrossRef]

- Yi, D.; Yang, R. Ammonium polyphosphate/montmorillonite nanocompounds in polypropylene. J. Appl. Polym. Sci. 2010, 118, 834–840. [Google Scholar] [CrossRef]

- Schartel, B.; Braun, U.; Balabanovich, A.; Artner, J.; Ciesielski, M.; Döring, M.; Perez, R.; Sandler, J.; Altstädt, V. Pyrolysis and fire behaviour of epoxy systems containing a novel 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-(DOPO)-based diamino hardener. Eur. Polym. J. 2008, 44, 704–715. [Google Scholar] [CrossRef]

- Lewin, M.; Zhang, J.; Pearce, E.; Zammarano, M. Polyamide 6 treated with pentabromobenzyl acrylate and layered silicates. Polym. Adv. Technol. 2010, 21, 825–834. [Google Scholar] [CrossRef]

| Samples | LOI (%) | UL-94 | |||

|---|---|---|---|---|---|

| t1 (s) | t2 (s) | Dripping | Rating | ||

| Pure EP | 23.0 | >60 | / | YES | NR |

| EP/MMT | 25.0 | >60 | / | NO | NR |

| EP/DOPO | 32.6 | 7 | 17 | NO | V-1 |

| EP/DOPO+MMT | 32.1 | 16 | 22 | NO | V-1 |

| EP/DOPO-MMT | 32.9 | 6 | 9 | NO | V-0 |

| Samples | Toneset (°C) | Tmax (°C) | Maximum Thermal Weight Loss Rate (%/min) | Mass Residue Ratio at 900 °C (%) |

|---|---|---|---|---|

| Pure EP | 372.9 | 408.5 | −16.31 | 9.4 |

| EP/MMT | 362.0 | 402.6 | −17.11 | 18.1 |

| EP/DOPO | 340.6 | 390.1 | −13.3 | 17.0 |

| EP/DOPO+MMT | 346.4 | 382.4 | −13.63 | 17.5 |

| EP/DOPO-MMT | 344.8 | 380.0 | −13.07 | 18.3 |

| Samples | Toneset (°C) | Tmax 1 (°C) | Tmax 2 (°C) | Mass Residue Ratio at 900 °C (%) |

|---|---|---|---|---|

| Pure EP | 363.8 | 404.8 | 580.5 | 0 |

| EP/MMT | 360.2 | 401.3 | 581.0 | 3.88 |

| EP/DOPO | 339.6 | 377.0 | 560.5 | 0.43 |

| EP/DOPO+MMT | 341.1 | 369.8 | 580.0 | 1.09 |

| EP/DOPO-MMT | 338.9 | 369.6 | 572.2 | 3.19 |

| Samples | TTI (s) | PHRR (kW/m2) | THR (MJ/m2) | TSR (m2/m2) | ASEA (m2/kg) | PCOP (g/s) | PCO2P (g/s) |

|---|---|---|---|---|---|---|---|

| Pure EP | 41 | 1190 | 88.0 | 3658 | 843 | 0.030 | 0.615 |

| EP/MMT | 41 | 911 | 86.0 | 3396 | 691 | 0.029 | 0.564 |

| EP/DOPO | 53 | 610 | 72.1 | 3792 | 867 | 0.035 | 0.368 |

| EP/DOPO+MMT | 45 | 749 | 70.7 | 3533 | 705 | 0.037 | 0.449 |

| EP/DOPO-MMT | 45 | 536 | 70.1 | 3346 | 668 | 0.026 | 0.361 |

| Samples | Contents | ΔPHRR (kW/m2) | SE |

|---|---|---|---|

| EP/MMT | 6% MMT | 279 | - |

| EP/DOPO | 6% DOPO | 580 | - |

| EP/DOPO+MMT | 6% DOPO+MMT (4% DOPO 2%MMT) | 441 | 0.92 |

| EP/DOPO-MMT | 6% DOPO-MMT (4% DOPO 2%MMT) | 654 | 1.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, J.; Qin, J.; He, J. Preparation of Intercalated Organic Montmorillonite DOPO-MMT by Melting Method and Its Effect on Flame Retardancy to Epoxy Resin. Polymers 2021, 13, 3496. https://doi.org/10.3390/polym13203496

Geng J, Qin J, He J. Preparation of Intercalated Organic Montmorillonite DOPO-MMT by Melting Method and Its Effect on Flame Retardancy to Epoxy Resin. Polymers. 2021; 13(20):3496. https://doi.org/10.3390/polym13203496

Chicago/Turabian StyleGeng, Junming, Jianyu Qin, and Jiyu He. 2021. "Preparation of Intercalated Organic Montmorillonite DOPO-MMT by Melting Method and Its Effect on Flame Retardancy to Epoxy Resin" Polymers 13, no. 20: 3496. https://doi.org/10.3390/polym13203496

APA StyleGeng, J., Qin, J., & He, J. (2021). Preparation of Intercalated Organic Montmorillonite DOPO-MMT by Melting Method and Its Effect on Flame Retardancy to Epoxy Resin. Polymers, 13(20), 3496. https://doi.org/10.3390/polym13203496