United-Atom Molecular Dynamics Study of the Mechanical and Thermomechanical Properties of an Industrial Epoxy

Abstract

1. Introduction

2. Experimental Methods

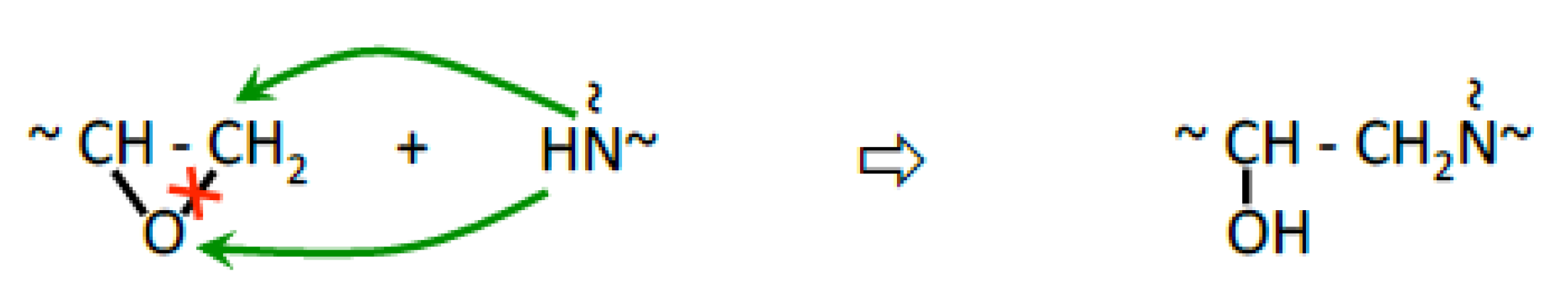

3. Molecular Model

4. Results and Discussion

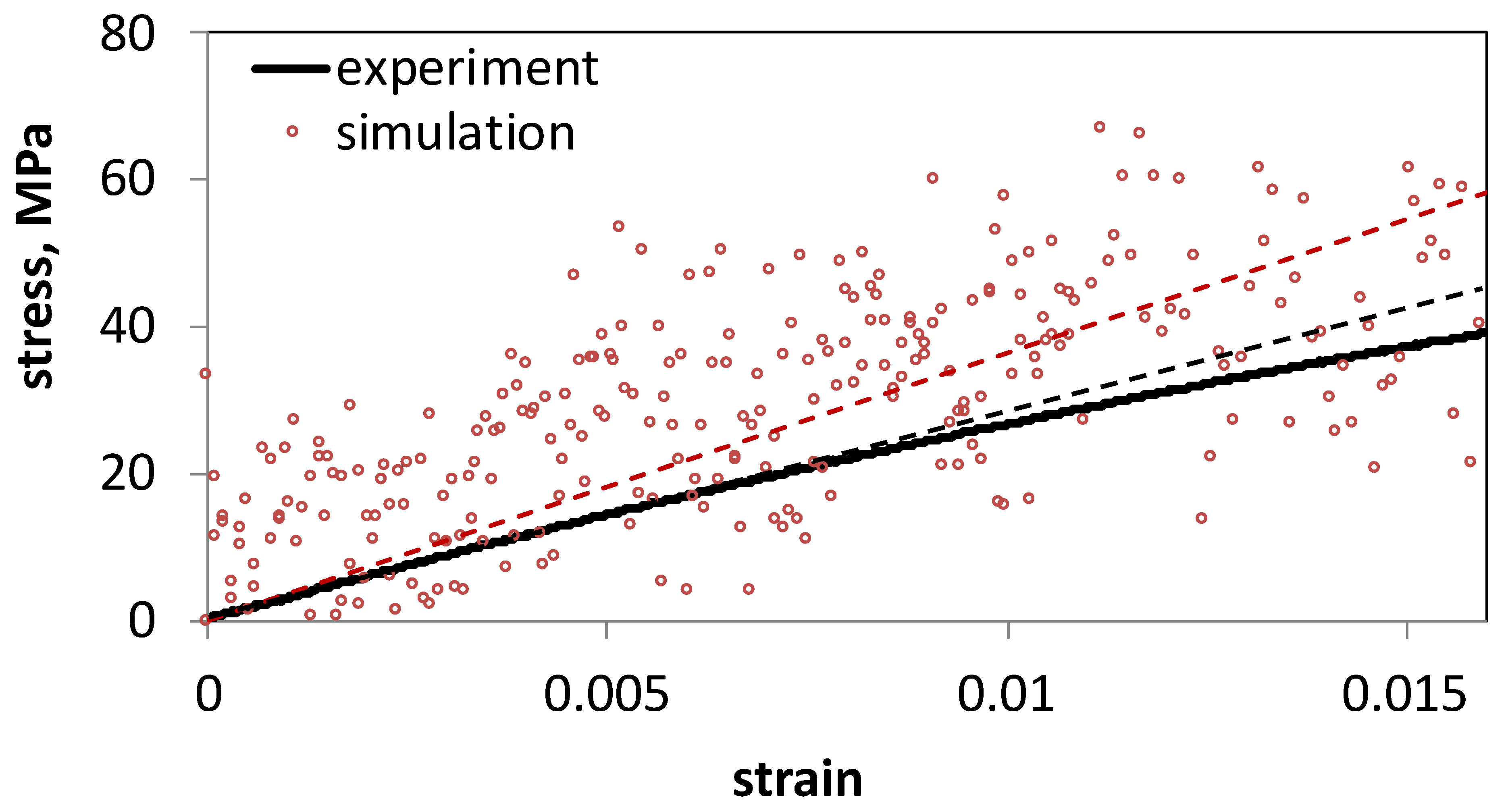

4.1. Experimental

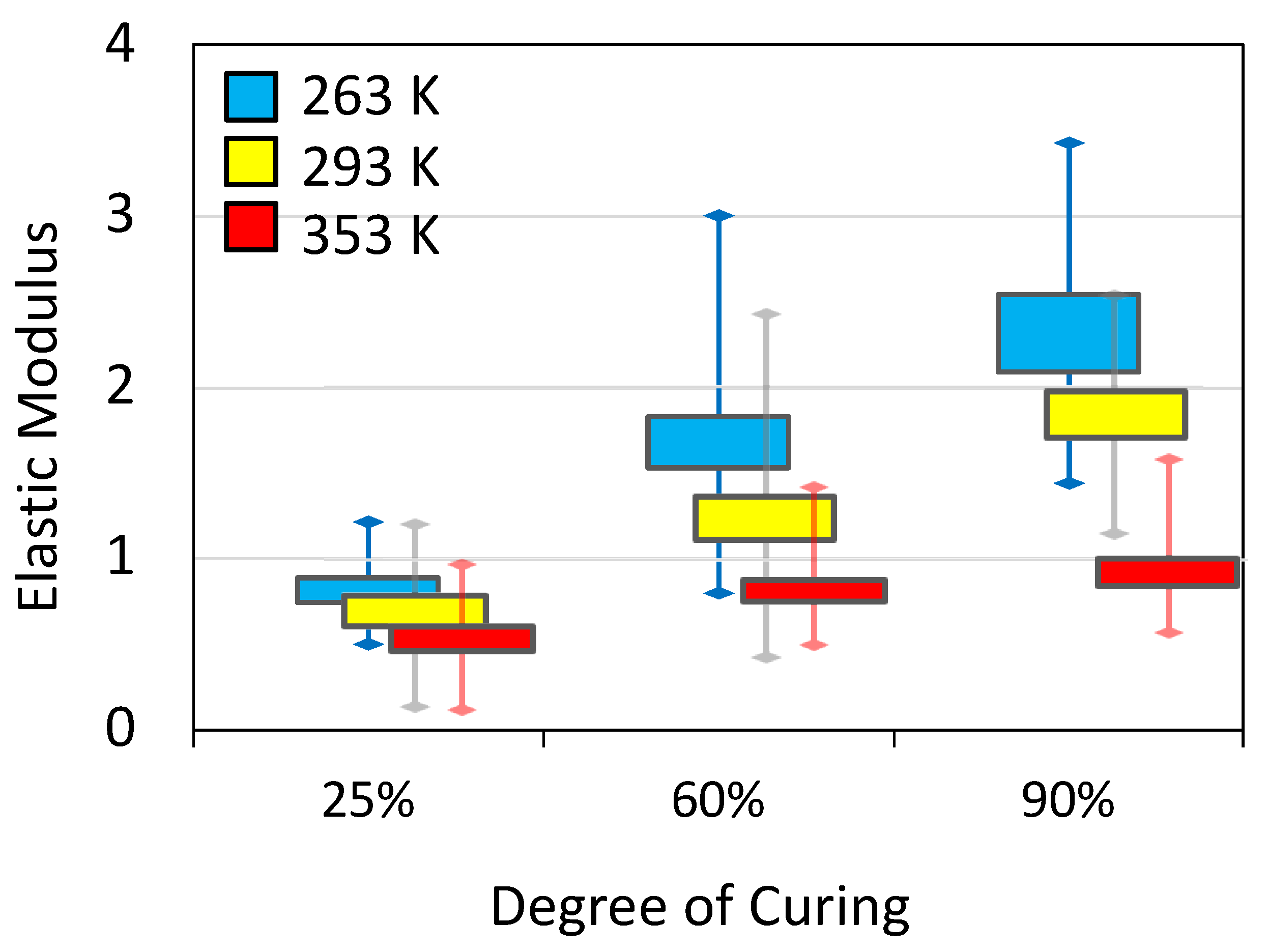

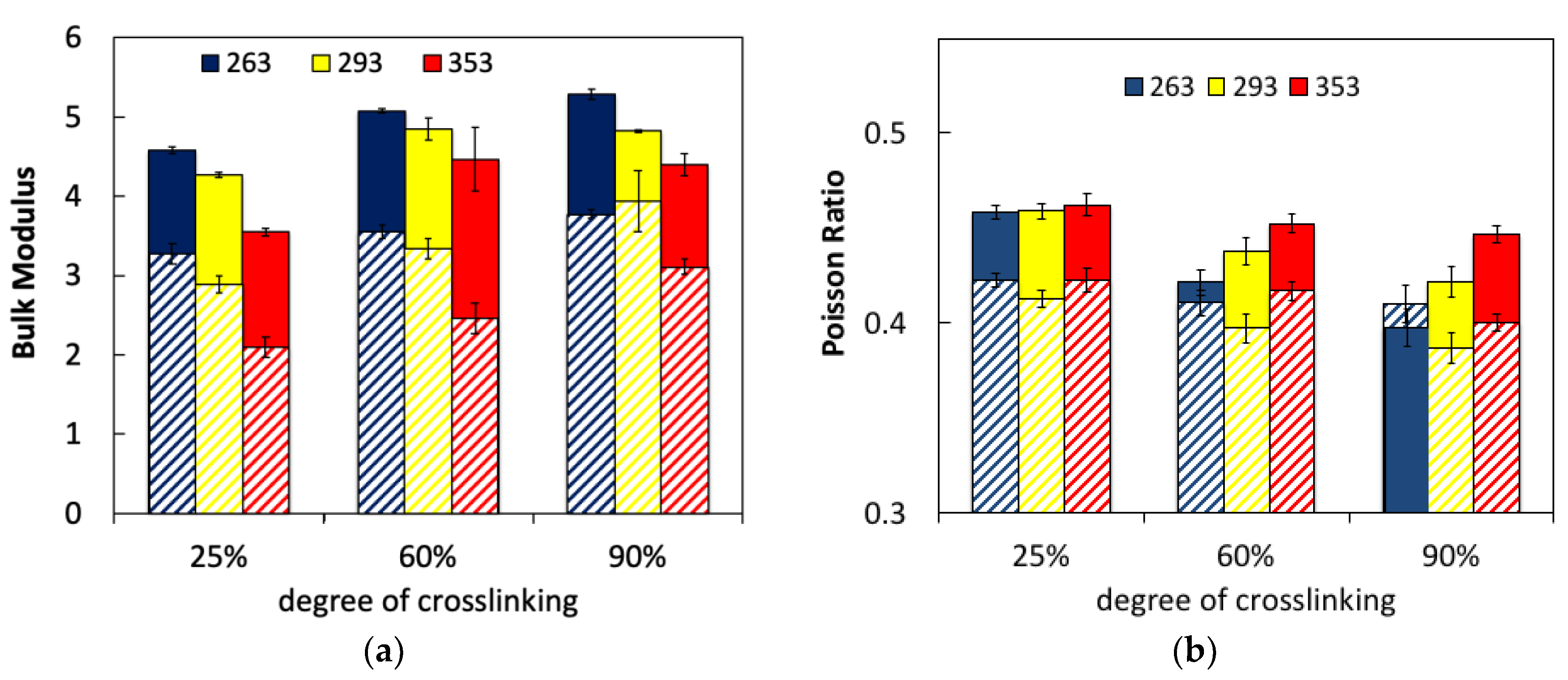

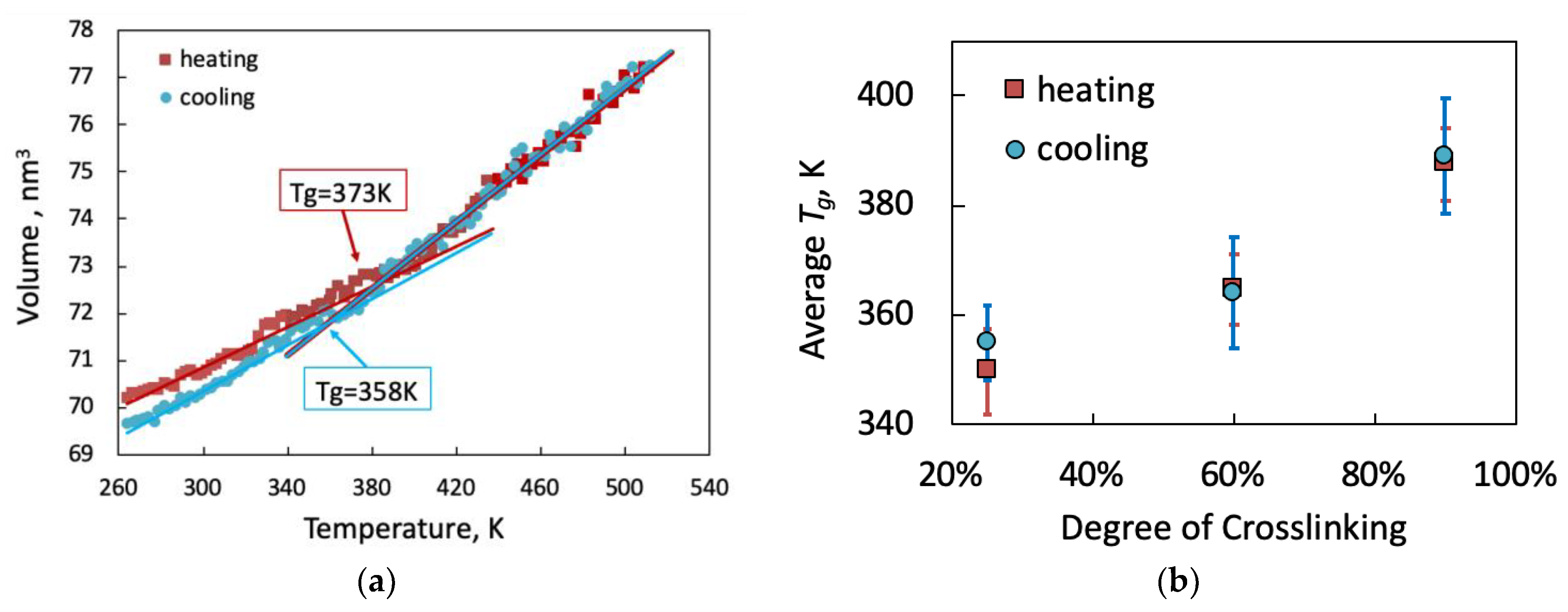

4.2. Computational

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pascault, J.P.; Williams, R. Epoxy Polymers New Materials and Innovations; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and Application of Epoxy Resins: A Review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Lapique, F.; Redford, K. Curing Effects on Viscosity and Mechanical Properties of a Commercial Epoxy Resin Adhesive. Int. J. Adhes. Adhes. 2002, 22, 337–346. [Google Scholar] [CrossRef]

- Havlíček, I.; Dušek, K. Crosslinked Epoxies. In Proceedings of the 9th Discussion Conference, Prague, Czech Republic, 14–17 July 1986; pp. 417–424. [Google Scholar] [CrossRef]

- Vella, D.; Mahadevan, L. A Simple Microscopic Model for the Dynamics of Adhesive Failure. Langmuir 2006, 22, 163–168. [Google Scholar] [CrossRef][Green Version]

- Yarovsky, I.; Evans, E. Computer Simulation of Structure and Properties of Crosslinked Polymers: Application to Epoxy Resins. Polymer 2002, 43, 963–969. [Google Scholar] [CrossRef]

- Odegard, G.M.; Jensen, B.D.; Gowtham, S.; Wu, J.; He, J. Predicting Mechanical Response of Crosslinked Epoxy Using ReaxFF. Chem. Phys. Lett. 2014, 591, 175–178. [Google Scholar] [CrossRef]

- Unger, R.; Braun, U.; Fankhänel, J.; Daum, B.; Arash, B.; Rolfes, R. Molecular Modelling of Epoxy Resin Crosslinking Experimentally Validated by Near-Infrared Spectroscopy. Comput. Mater. Sci. 2019, 161, 223–235. [Google Scholar] [CrossRef]

- Shokuhfar, A.; Arab, B. The Effect of Cross Linking Density on the Mechanical Properties and Structure of the Epoxy Polymers: Molecular Dynamics Simulation. J. Mol. Modeling 2013, 19, 3719–3731. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Odegard, G.M. Molecular Modeling of Crosslink Distribution in Epoxy Polymers. Model. Simul. Mater. Sci. Eng. 2012, 20, 045018. [Google Scholar] [CrossRef]

- Wu, C.; Xu, W. Atomistic Molecular Modelling of Crosslinked Epoxy Resin. Polymer 2006, 47, 6004–6009. [Google Scholar] [CrossRef]

- Tack, J.L.; Ford, D.M. Thermodynamic and Mechanical Properties of Epoxy Resin DGEBF Crosslinked with DETDA by Molecular Dynamics. J. Mol. Graph. Model. 2008, 26, 1269–1275. [Google Scholar] [CrossRef]

- Arab, B.; Shokuhfar, A. Molecular Dynamics Simulation of Cross-Linked Epoxy Polymers: The Effect of Force Field on the Estimation of Properties. J. Nano-Electron. Phys. 2013, 5, 01013. [Google Scholar]

- Fu, Y.; Michopoulos, J.G.; Song, J.H. On Investigating the Thermomechanical Properties of Cross-Linked Epoxy via Molecular Dynamics Analysis. Nanoscale Microscale Thermophys. Eng. 2017, 21, 8–25. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Valavala, P.K.; Clancy, T.C.; Wise, K.E.; Odegard, G.M. Molecular Modeling of Crosslinked Epoxy Polymers: The Effect of Crosslink Density on Thermomechanical Properties. Polymer 2011, 52, 2445–2452. [Google Scholar] [CrossRef]

- Fan, H.B.; Yuen, M.M.F. Material Properties of the Cross-Linked Epoxy Resin Compound Predicted by Molecular Dynamics Simulation. Polymer 2007, 48, 2174–2178. [Google Scholar] [CrossRef]

- Kallivokas, S.V.; Sgouros, A.P.; Theodorou, D.N. Molecular Dynamics Simulations of EPON-862/DETDA Epoxy Networks: Structure, Topology, Elastic Constants, and Local Dynamics. Soft Matter 2019, 15, 721–733. [Google Scholar] [CrossRef]

- Shenogina, N.B.; Tsige, M.; Patnaik, S.S.; Mukhopadhyay, S.M. Molecular Modeling of Elastic Properties of Thermosetting Polymers Using a Dynamic Deformation Approach. Polymer 2013, 54, 3370–3376. [Google Scholar] [CrossRef]

- Frick, B.; Richter, D. The Microscopic Basis of the Glass Transition in Polymers from Neutron Scattering Studies. Science 1995, 267, 1939–1945. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Strachan, A. Molecular Dynamics Predictions of Thermal and Mechanical Properties of Thermoset Polymer EPON862/DETDA. Polymer 2011, 52, 2920–2928. [Google Scholar] [CrossRef]

- Hanwell, M.D.; Curtis, D.E.; Lonie, D.C.; Vandermeersch, T.; Zurek, E.; Hutchison, G.R. Avogadro: An Advanced Semantic Chemical Editor, Visualization, and Analysis Platform. Available online: http://www.jcheminf.com/content/4/1/17 (accessed on 13 August 2020).

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Jorgensen, W.L.; Tirado-Rives, J. The OPLS [Optimized Potentials for Liquid Simulations] Potential Functions for Proteins, Energy Minimizations for Crystals of Cyclic Peptides and Crambin. J. Am. Chem. Soc. 1988, 110, 1657–1666. [Google Scholar] [CrossRef]

- Tamir, E.; Srebnik, S.; Sidess, A. Prediction of the Relaxation Modulus of a Fluoroelastomer Using Molecular Dynamics Simulation. Chem. Eng. Sci. 2020, 225, 115786. [Google Scholar] [CrossRef]

- Aramoon, A.; Breitzman, T.D.; Woodward, C.; El-Awady, J.A. Correlating Free-Volume Hole Distribution to the Glass Transition Temperature of Epoxy Polymers. Ind. Eng. Chem. Res. 2017, 121, 8399–8407. [Google Scholar] [CrossRef]

- Vashisth, A.; Ashraf, C.; Bakis, C.E.; van Duin, A.C.T. Effect of Chemical Structure on Thermo-Mechanical Properties of Epoxy Polymers: Comparison of Accelerated ReaxFF Simulations and Experiments. Polymer 2018, 158, 354–363. [Google Scholar] [CrossRef]

- Littell, J.D.; Ruggeri, C.R.; Goldberg, R.K.; Roberts, G.D.; Arnold, W.A.; Binienda, W.K. Measurement of Epoxy Resin Tension, Compression, and Shear Stress–Strain Curves over a Wide Range of Strain Rates Using Small Test Specimens. J. Aerosp. Eng. 2008, 21, 162–173. [Google Scholar] [CrossRef]

- Ting, T.; Chen, T. Poisson’s Ratio for Anisotropic Elastic Materials Can Have No Bounds. Q. J. Mech. Appl. Math. 2005, 58, 73–82. [Google Scholar] [CrossRef]

- Péron, M.; Sobotka, V.; Boyard, N.; Corre, S.L. Bulk Modulus Evolution of Thermoset Resins during Crosslinking: Is a Direct and Accurate Measurement Possible? J. Compos. Mater. 2016, 51, 463–477. [Google Scholar] [CrossRef]

- Tamir, E.; Sidess, A.; Srebnik, S. Thermodynamic, Structural, and Mechanical Properties of Fluoropolymers from Molecular Dynamics Simulation: Comparison of Force Fields. Chem. Eng. Sci. 2019, 205, 332–340. [Google Scholar] [CrossRef]

- Gavrielides, A.; Duguet, T.; Aufray, M.; Lacaze-Dufaure, C. Model of the DGEBA-EDA Epoxy Polymer: Experiments and Simulation Using Classical Molecular Dynamics. Int. J. Polym. Sci. 2019, 2019, 9604714. [Google Scholar] [CrossRef]

- Eslami, H.; Kesik, M.; Karimi-Varzaneh, H.A.; Müller-Plathe, F. Sorption and Diffusion of Carbon Dioxide and Nitrogen in Poly(Methyl Methacrylate). J. Chem. Phys. 2013, 139, 124902. [Google Scholar] [CrossRef]

- Afzal, M.A.F.; Browning, A.R.; Goldberg, A.; Halls, M.D.; Gavartin, J.L.; Morisato, T.; Hughes, T.F.; Giesen, D.J.; Goose, J.E. High-Throughput Molecular Dynamics Simulations and Validation of Thermophysical Properties of Polymers for Various Applications. ACS Appl. Polym. Mater. 2021, 3, 620–630. [Google Scholar] [CrossRef]

- Gupta, V.B.; Drzal, L.T.; Lee, C.Y.C.; Rich, M.J. The Temperature-Dependence of Some Mechanical Properties of a Cured Epoxy Resin System. Polym. Eng. Sci. 1985, 25, 812–823. [Google Scholar] [CrossRef]

| −5 °C | RT | 60 °C | |

|---|---|---|---|

| Modulus [GPa] | 3.0 | 2.6 | 0.3 |

| Tensile strength [MPa] | 2.6 | 40 | 22 |

| Poisson’s ratio | 0.39 | 0.37 | 0.45 |

| Elongation at failure [%] | 0.7 | 1.7 | 1.6 |

| After 7 Days | After 1 Year | |

|---|---|---|

| Tg [°C] first heating cycle | 43 | 57 |

| Tg [°C] second heating cycle | 49 | 60 |

| Compound | Density [g/cm3] | Calculated Density [g/cm3] |

|---|---|---|

| DGEBA | 1.13 | 1.156 ± 0.003 |

| BGE | 0.91 | 0.897 ± 0.004 |

| Epikure 3140 | 0.97 | 0.965 ± 0.005 |

| EPON | 1.10 | 1.126 ± 0.008 |

| Epoxy | 1.12 | 1.117 ± 0.003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maicas, R.; Yungerman, I.; Weber, Y.B.; Srebnik, S. United-Atom Molecular Dynamics Study of the Mechanical and Thermomechanical Properties of an Industrial Epoxy. Polymers 2021, 13, 3443. https://doi.org/10.3390/polym13193443

Maicas R, Yungerman I, Weber YB, Srebnik S. United-Atom Molecular Dynamics Study of the Mechanical and Thermomechanical Properties of an Industrial Epoxy. Polymers. 2021; 13(19):3443. https://doi.org/10.3390/polym13193443

Chicago/Turabian StyleMaicas, Riki, Irena Yungerman, Yarden B. Weber, and Simcha Srebnik. 2021. "United-Atom Molecular Dynamics Study of the Mechanical and Thermomechanical Properties of an Industrial Epoxy" Polymers 13, no. 19: 3443. https://doi.org/10.3390/polym13193443

APA StyleMaicas, R., Yungerman, I., Weber, Y. B., & Srebnik, S. (2021). United-Atom Molecular Dynamics Study of the Mechanical and Thermomechanical Properties of an Industrial Epoxy. Polymers, 13(19), 3443. https://doi.org/10.3390/polym13193443