An Investigation on the Feasibility of Fabricating Composites Using Outdated Waste Carbon Fibers and Easily Disposable Polyolefin Resins

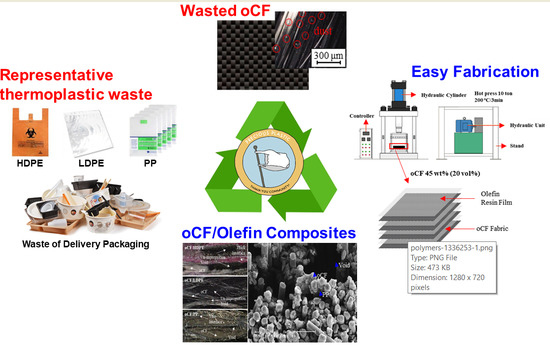

Abstract

:1. Introduction

2. Materials and Methods

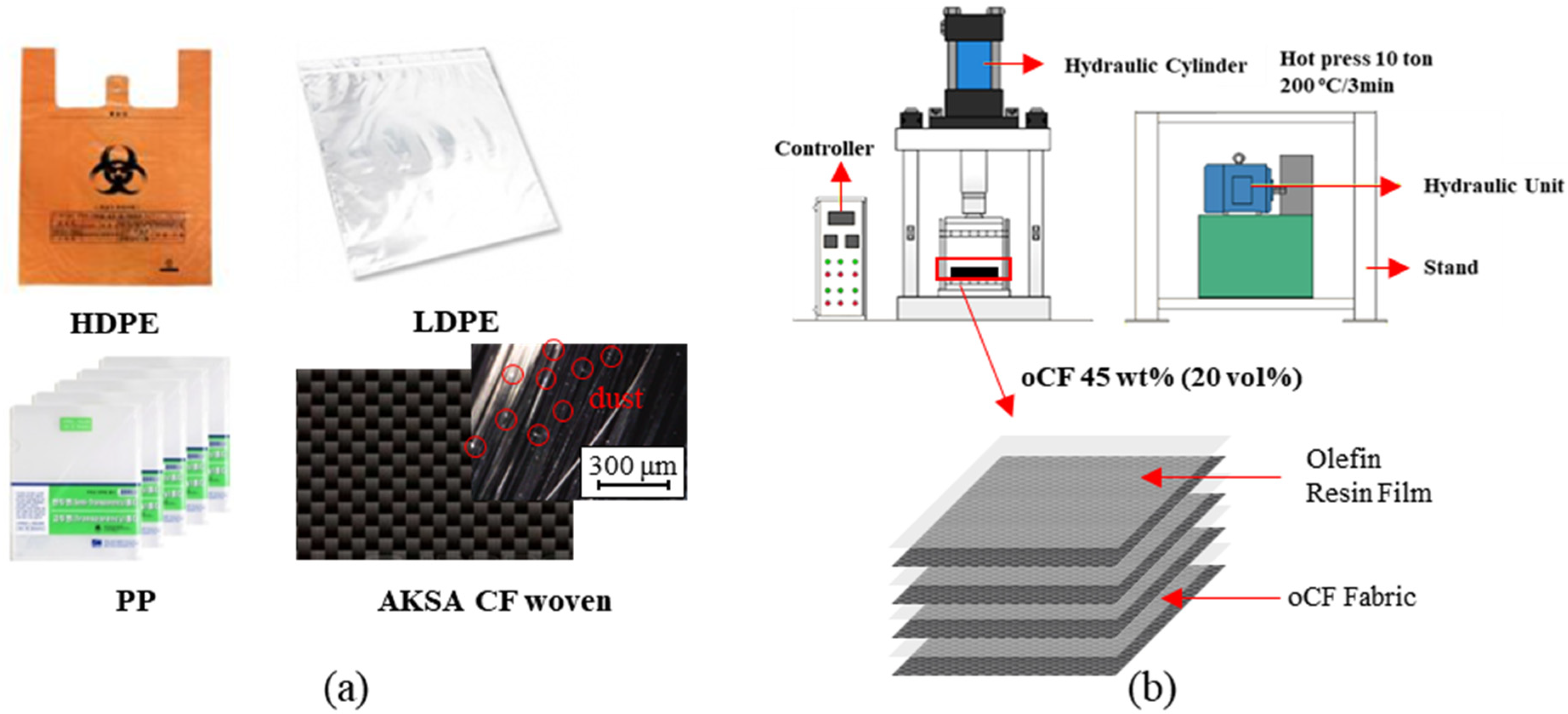

2.1. Materials

2.2. Methodologies

2.2.1. Fabrication of oCFOCs

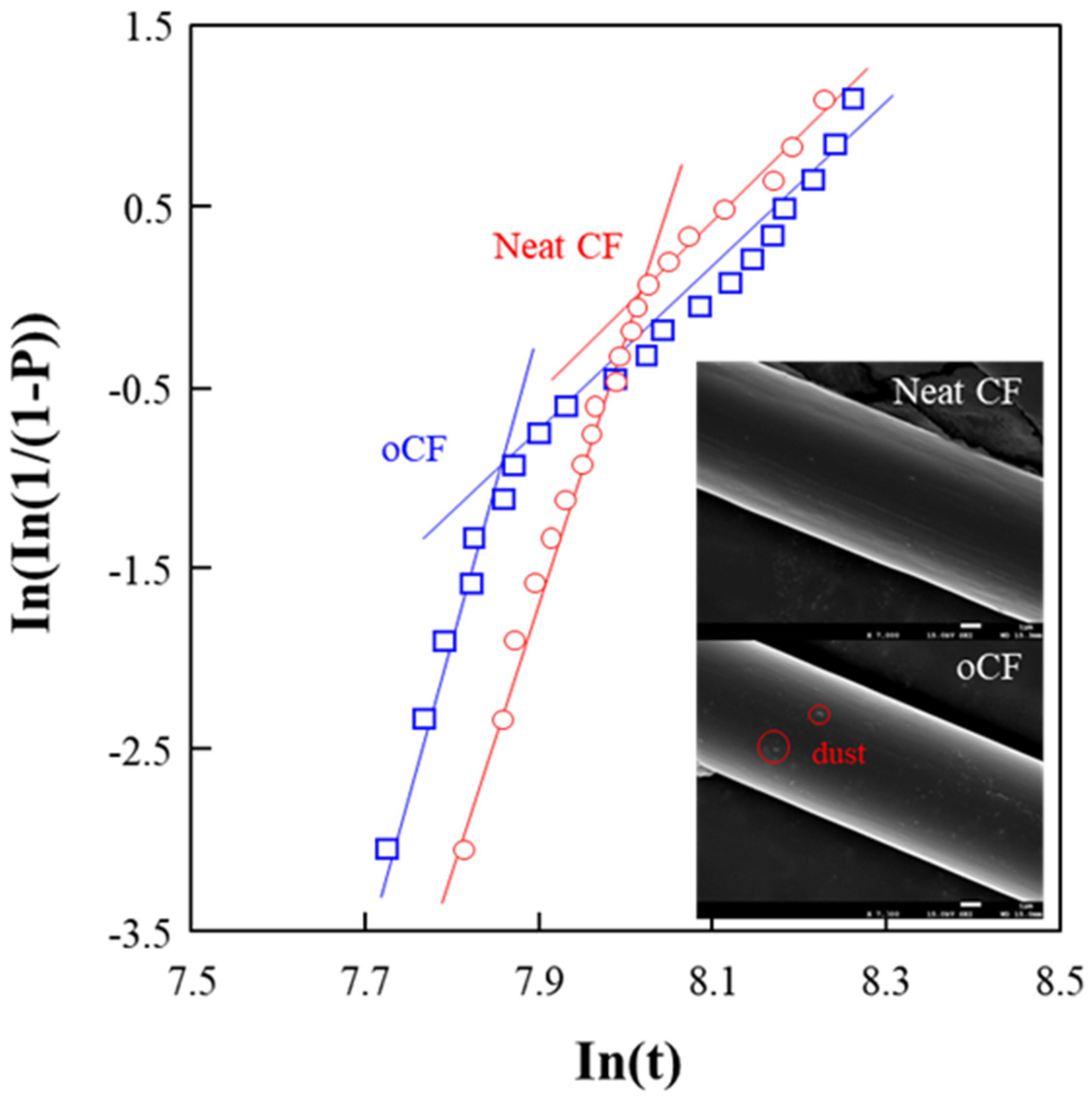

2.2.2. Tensile Strength Comparison between Neat Carbon Fiber (CF) and Outdated Waste Carbon Fiber (oCF)

2.2.3. Evaluation of Melting Indices (MIs) of Olefin Resins and Spreading of the Resins into the oCF Tows

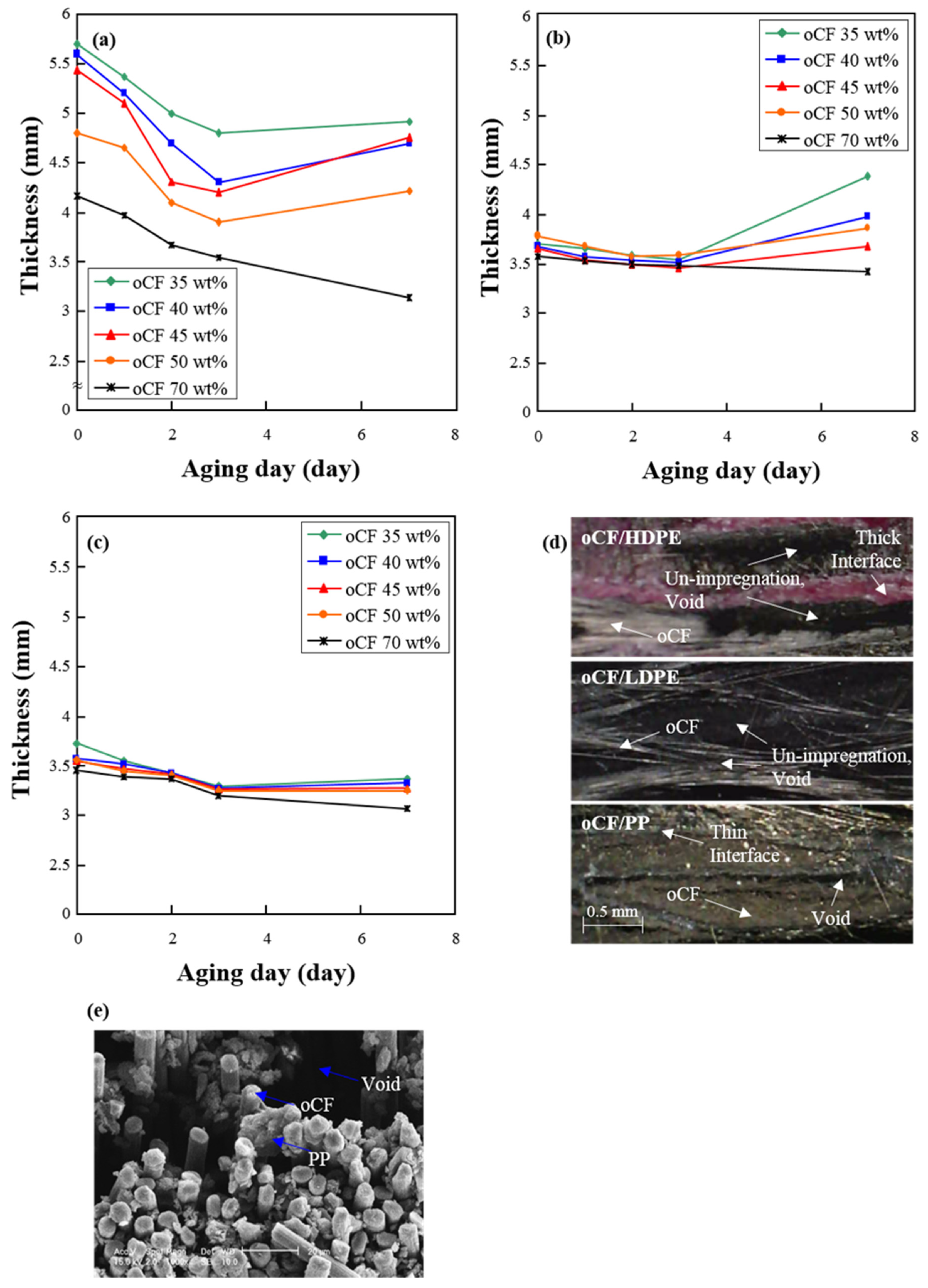

2.2.4. Evaluation of Thickness Variation, Flexural Strength, Impact Strength, and Interfacial Shear Strength of oCFOCs, and Analysis of the Chemical Functional Group of Olefin Resins According to Aging Days and Olefin Resin Types

3. Results and Discussion

3.1. Comparison of Tensile Strength between Neat Carbon Fiber (CF) and Outdated Waste Carbon Fiber (oCF)

3.2. Comparison of Properties of Olefin Resins Spreading into the oCF Tows with Their Melting Indices (MIs)

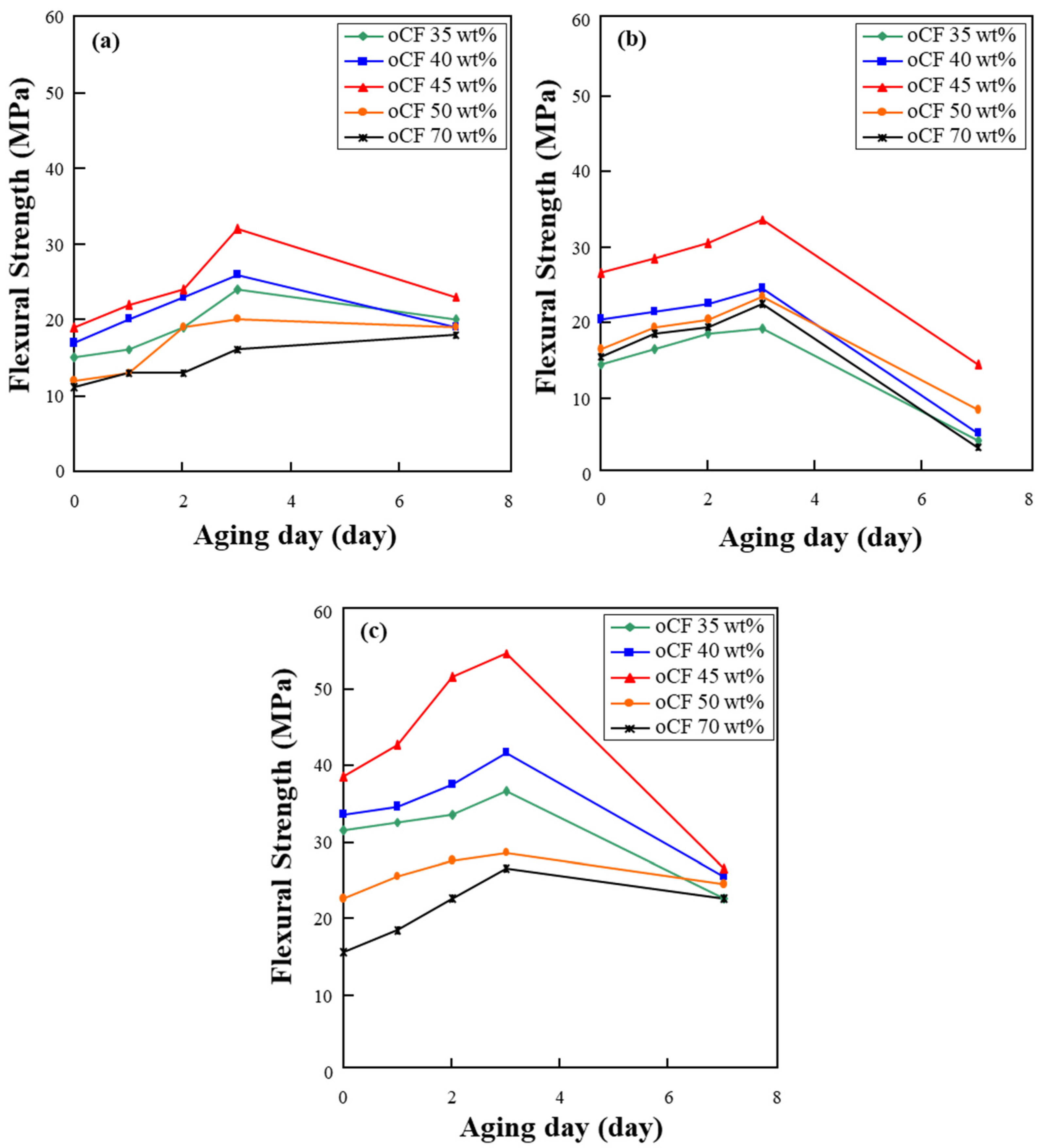

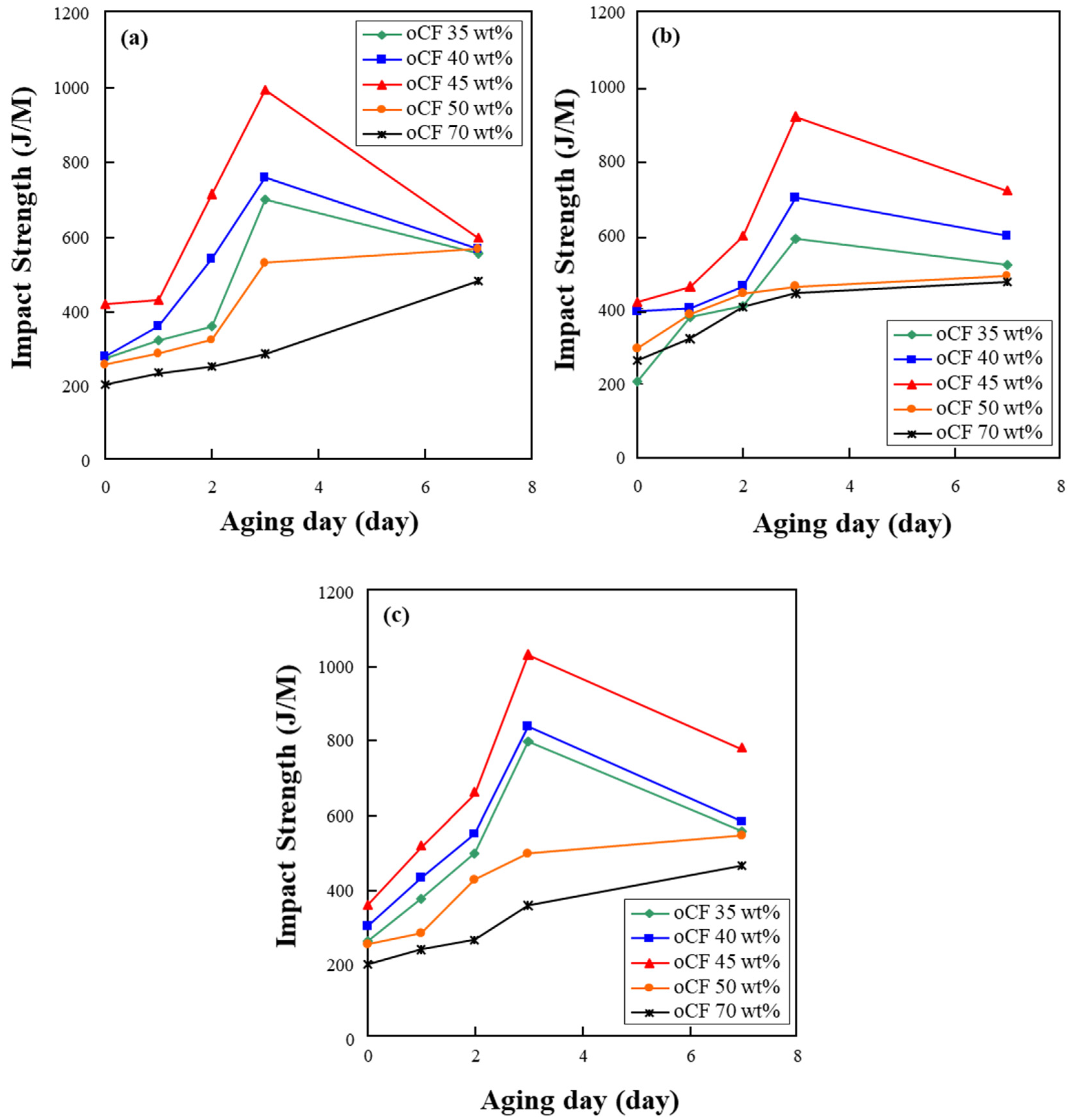

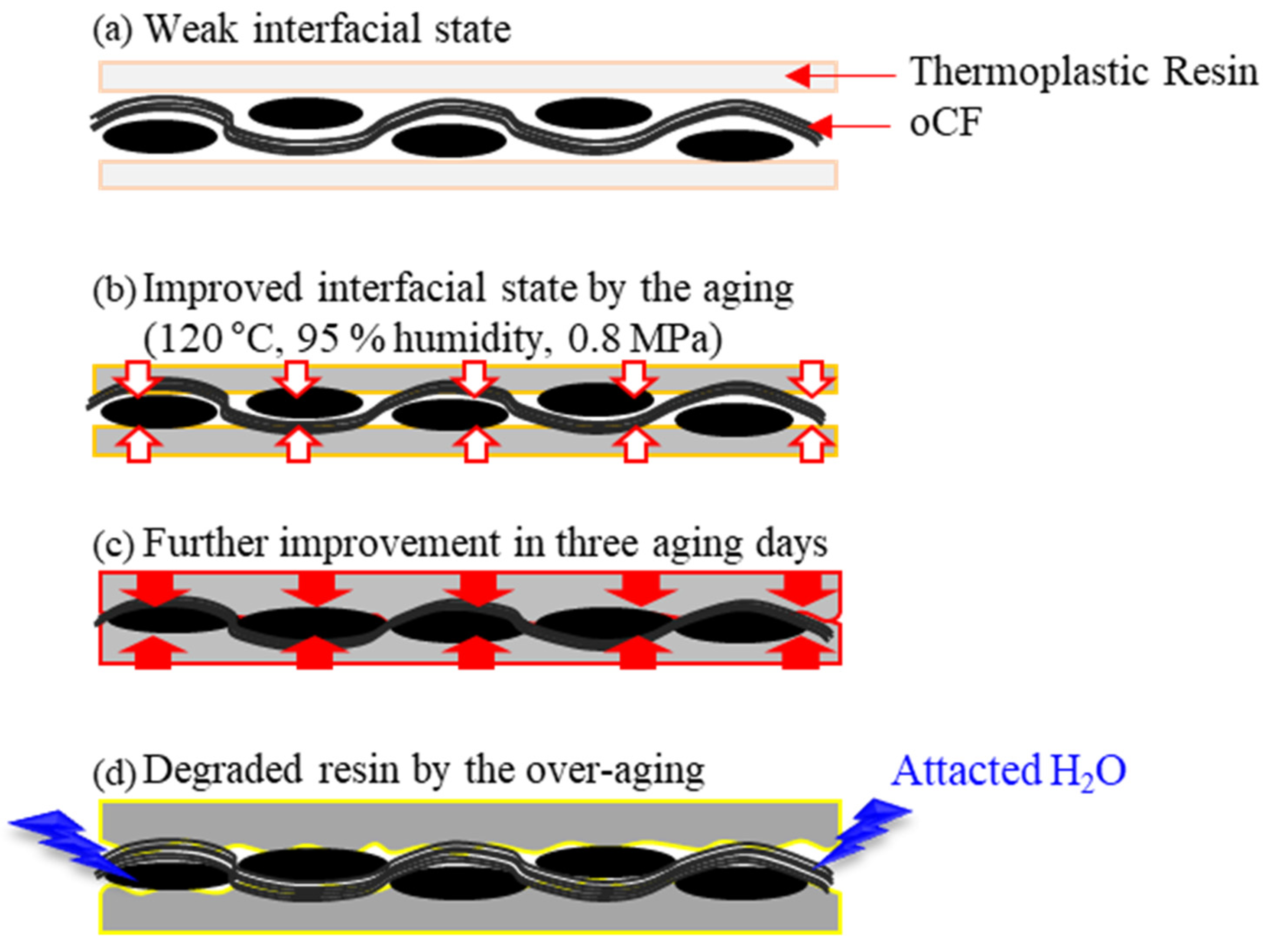

3.3. Molding, Flexural and Impact Properties of oCFOCs According to Aging Days under Hot and Humid Conditions

3.4. Properties of the Chemical Functional Group of Olefin Resins According to Aging Days

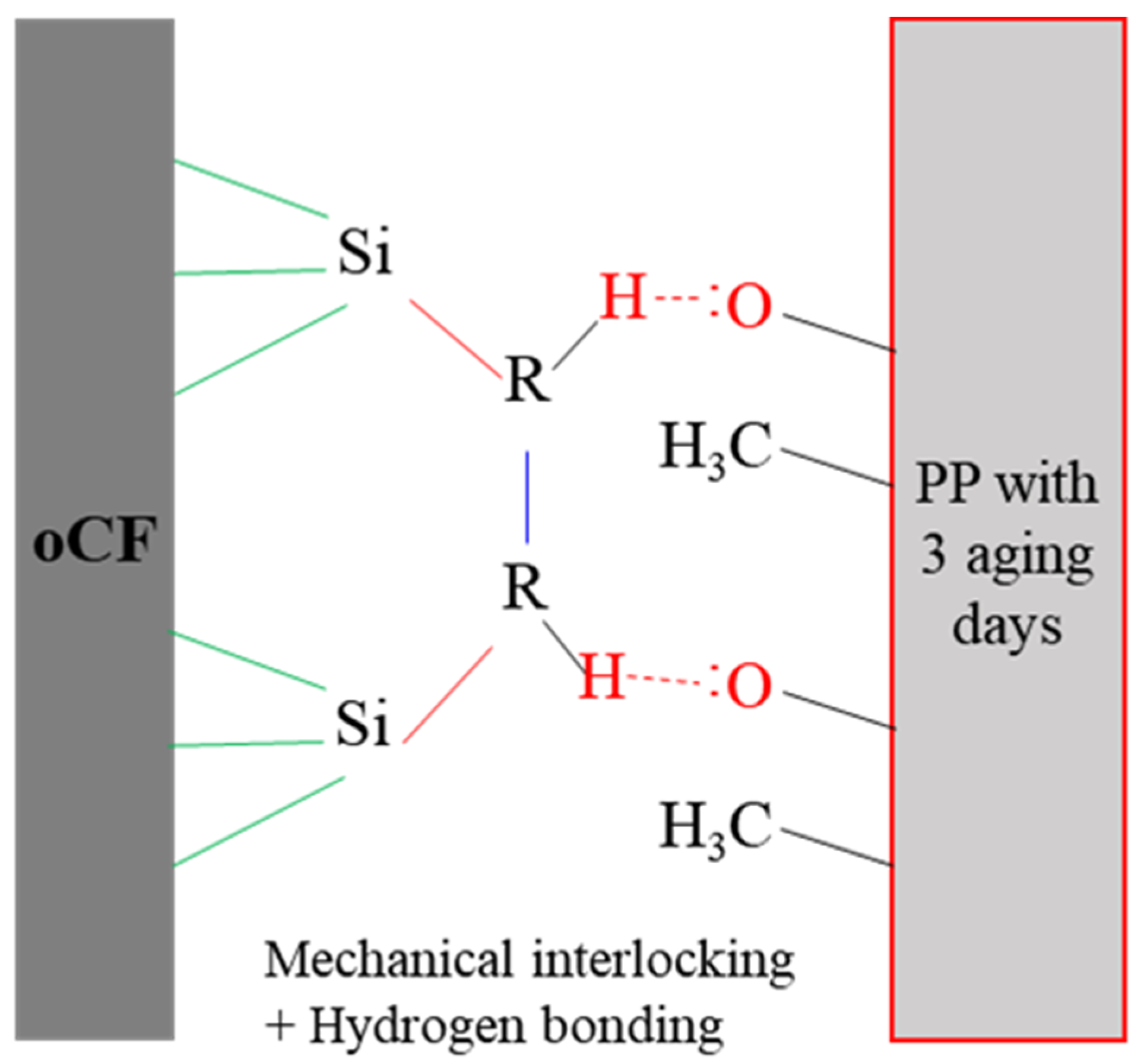

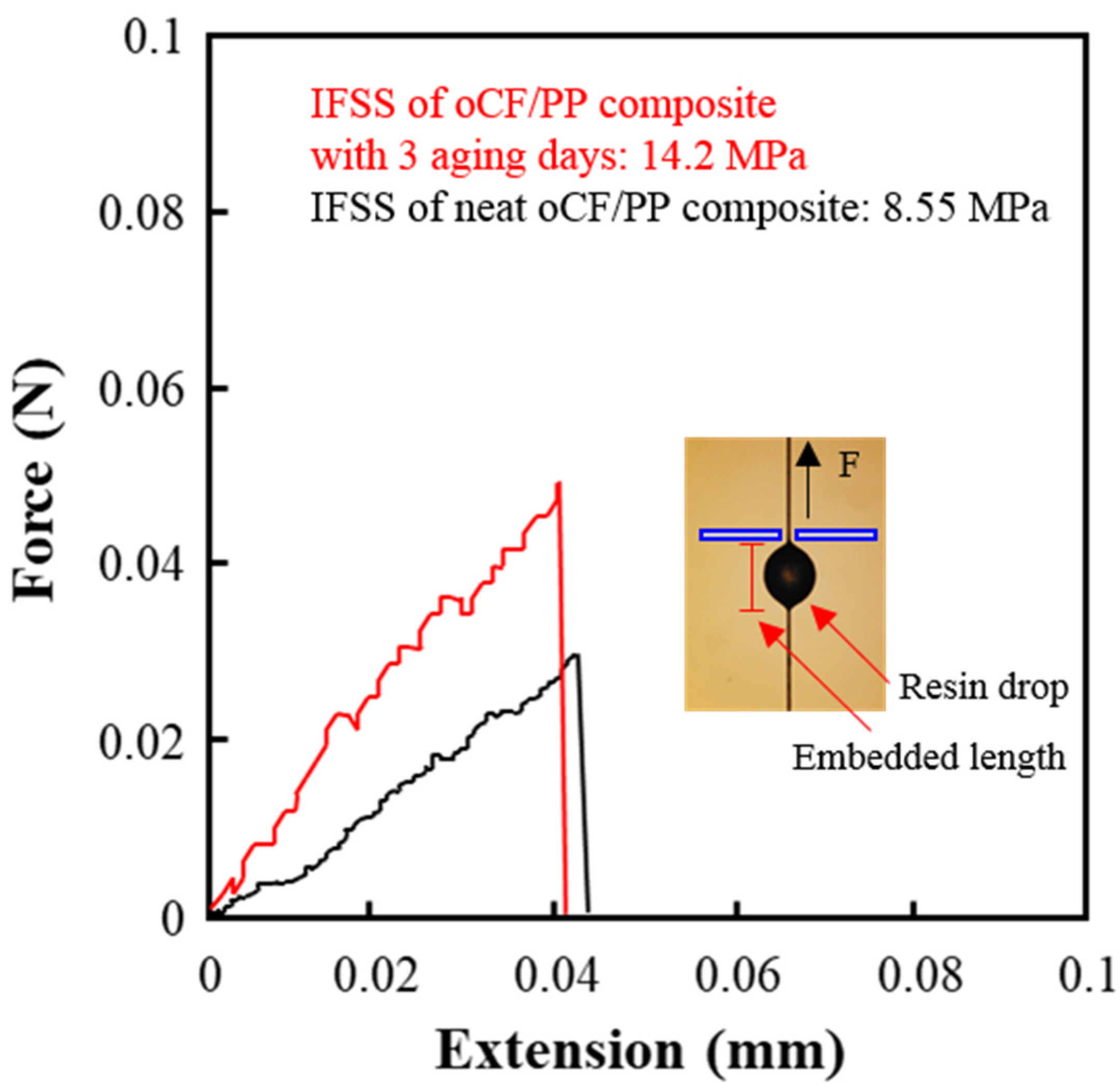

3.5. Interfacial Properties of oCFOCs According to Aging Days

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xue, Y.; Wang, Y. Green electrochemical redox mediation for valuable metal extraction and recycling from industrial waste. Green Chem. 2020, 22, 6288–6309. [Google Scholar] [CrossRef]

- De Weerdt, L.; Sasao, T.; Compernolle, T.; Van Passel, S.; De Jaeger, S. The effect of waste incineration taxation on industrial plastic waste generation: A panel analysis. Resour. Conserv. Recycl. 2020, 157, 104717. [Google Scholar] [CrossRef]

- Silva, A.L.P.; Prata, J.C.; Walker, T.R.; Duarte, A.C.; Ouyang, W.; Barcelò, D.; Rocha-Santos, T. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem. Eng. J. 2021, 405, 126683. [Google Scholar] [CrossRef]

- Ghayebzadeh, M.; Taghipour, H.; Aslani, H. Estimation of plastic waste inputs from land into the Persian Gulf and the Gulf of Oman: An environmental disaster, scientific and social concerns. Sci. Total. Environ. 2020, 733, 138942. [Google Scholar] [CrossRef]

- Precious Plastic Universe: A Big Bang for Plastic Recycling. One Army. Available online: https://youtu.be/Os7dREQ00l4 (accessed on 7 January 2020).

- Kamble, Z.; Behera, B.K.; Mishra, R.; Behera, P.K. Influence of cellulosic and non-cellulosic particle fillers on mechanical, dynamic mechanical, and thermogravimetric properties of waste cotton fibre reinforced green composites. Compos. Part B Eng. 2021, 207, 108595. [Google Scholar] [CrossRef]

- Kim, K.-W.; Lee, H.-M.; An, J.-H.; Chung, D.-C.; An, K.-H.; Kim, B.-J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef]

- Yan, H.; Lu, C.-X.; Jing, D.-Q.; Chang, C.-B.; Liu, N.-X.; Hou, X.-L. Recycling of carbon fibers in epoxy resin composites using supercritical 1-propanol. New Carbon Mater. 2016, 31, 46–54. [Google Scholar] [CrossRef]

- Lee, H.; Ohsawa, I.; Takahashi, J. Effect of plasma surface treatment of recycled carbon fiber on carbon fiber-reinforced plastics (CFRP) interfacial properties. Appl. Surf. Sci. 2015, 328, 241–246. [Google Scholar] [CrossRef]

- Morin, C.; Loppinet-Serani, A.; Cansell, F.; Aymonier, C. Near- and supercritical solvolysis of carbon fibre reinforced polymers (CFRPs) for recycling carbon fibers as a valuable resource: State of the art. J. Supercrit. Fluids 2012, 66, 232–240. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of carbon fibers from carbon fiber reinforced polymer using electrochemical method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Jiang, J.; Deng, G.; Chen, X.; Gao, X.; Guo, Q.; Xu, C.; Zhou, L. On the successful chemical recycling of carbon fiber/epoxy resin composites under the mild condition. Compos. Sci. Technol. 2017, 151, 243–251. [Google Scholar] [CrossRef]

- Goel, A.; Chawla, K.; Vaidya, U.; Chawla, N.; Koopman, M. Characterization of fatigue behavior of long fiber reinforced thermoplastic (LFT) composites. Mater. Charact. 2009, 60, 537–544. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Asmatulu, E.; Twomey, J.M.; Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2013, 48, 593–608. [Google Scholar] [CrossRef]

- Pang, E.; Chan, A.; Pickering, S. Thermoelectrical properties of intercalated recycled carbon fibre composite. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1406–1411. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Parandoush, P.; Tucker, L.; Zhou, C.; Lin, D. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites. Mater. Des. 2017, 131, 186–195. [Google Scholar] [CrossRef]

- Vaneker, T. Material Extrusion of Continuous Fiber Reinforced Plastics Using Commingled Yarn. Procedia CIRP 2017, 66, 317–322. [Google Scholar] [CrossRef]

- Uhlmann, E.; Meier, P. Carbon Fibre Recycling from Milling Dust for the Application in Short Fibre Reinforced Thermoplastics. Procedia CIRP 2017, 66, 277–282. [Google Scholar] [CrossRef]

- Saburow, O.; Huether, J.; Maertens, R.; Trauth, A.; Kechaou, Y.; Henning, F.; Weidenmann, K. A Direct Process to Reuse Dry Fiber Production Waste for Recycled Carbon Fiber Bulk Molding Compounds. Procedia CIRP 2017, 66, 265–270. [Google Scholar] [CrossRef]

- Bondy, M.; Pinter, P.; Altenhof, W. Experimental characterization and modelling of the elastic properties of direct compounded compression molded carbon fibre/polyamide 6 long fibre thermoplastic. Mater. Des. 2017, 122, 184–196. [Google Scholar] [CrossRef]

- Kwon, D.-J.; Shin, P.-S.; Kim, J.-H.; DeVries, K.L.; Park, J.-M. Evaluation of dispersion and damage sensing of carbon fiber/polypropylene (PP)-polyamide (PA) composites using 2 dimensional electrical resistance mapping. Compos. Part A Appl. Sci. Manuf. 2016, 90, 417–423. [Google Scholar] [CrossRef]

- Park, J.-M.; Kwon, D.-J.; Wang, Z.-J.; Gu, G.-Y.; DeVries, K.L. Effect of thermal treatment temperatures on the reinforcing and interfacial properties of recycled carbon fiber–phenolic composites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 156–164. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Ranjan, N.; Penna, R.; Fraternali, F. On the recyclability of polyamide for sustainable composite structures in civil engineering. Compos. Struct. 2018, 184, 704–713. [Google Scholar] [CrossRef]

- Liu, Y.; Farnsworth, M.; Tiwari, A. A review of optimisation techniques used in the composite recycling area: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2017, 140, 1775–1781. [Google Scholar] [CrossRef] [Green Version]

- Mouritz, A.P.; Kootsookos, A.; Mathys, G. Stability of polyester- and vinyl ester-based composites in seawater. J. Mater. Sci. 2004, 39, 6073–6077. [Google Scholar] [CrossRef]

- Issa, A.A.; Luyt, A.S. Kinetics of Alkoxysilanes and Organoalkoxysilanes Polymerization: A Review. Polymers 2019, 11, 537. [Google Scholar] [CrossRef] [Green Version]

- Kwon, D.-J.; Shin, P.-S.; Kim, J.-H.; Park, H.-S.; Beak, Y.-M.; DeVries, K.L.; Park, J.-M. Reinforcing effects of glass fiber/p-DCPD with fiber concentrations, types, lengths and surface treatment. Compos. Part B Eng. 2017, 123, 74–80. [Google Scholar] [CrossRef]

- Winslow, F.H. Photooxidation of high polymers. Pure Appl. Chem. 1977, 49, 495–502. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, D.-J.; Cho, K.R.; Seo, H.-S. An Investigation on the Feasibility of Fabricating Composites Using Outdated Waste Carbon Fibers and Easily Disposable Polyolefin Resins. Polymers 2021, 13, 2938. https://doi.org/10.3390/polym13172938

Kwon D-J, Cho KR, Seo H-S. An Investigation on the Feasibility of Fabricating Composites Using Outdated Waste Carbon Fibers and Easily Disposable Polyolefin Resins. Polymers. 2021; 13(17):2938. https://doi.org/10.3390/polym13172938

Chicago/Turabian StyleKwon, Dong-Jun, Kang Rae Cho, and Hyoung-Seock Seo. 2021. "An Investigation on the Feasibility of Fabricating Composites Using Outdated Waste Carbon Fibers and Easily Disposable Polyolefin Resins" Polymers 13, no. 17: 2938. https://doi.org/10.3390/polym13172938

APA StyleKwon, D.-J., Cho, K. R., & Seo, H.-S. (2021). An Investigation on the Feasibility of Fabricating Composites Using Outdated Waste Carbon Fibers and Easily Disposable Polyolefin Resins. Polymers, 13(17), 2938. https://doi.org/10.3390/polym13172938