Technology is advancing with each passing day. Desktop technologies, including 3D, 4D, 5D and 6D printing technology, also known as additive manufacturing (AM) [

1,

2,

3], has been evolving to meet the requirements of low prices, low consumables, and low operating costs of industry. AM has the advantages of providing lightweight microporous structures with customized features and being environmentally safe. It is widely used in medical sciences, the aerospace industry, biological research, engineering applications, and other fields [

4,

5,

6,

7].

In recent years, there has been a lot of research on AM technology, mainly to improve the material properties and control the manufacturing processes [

8,

9,

10]. Additive manufacturing methods include fused deposition modeling (FDM), stereolithography appearance (SLA), selective laser sintering (SLS), etc. Among the many additive manufacturing methods, FDM is relatively low-cost, wastes less material, and has a lower technical threshold, but has higher requirements of control parameters such as nozzle temperature, process speed, filling percentage, material characteristics, etc. [

11,

12]. These reasons lead to low dimensional accuracy and low strength of objects produced by FDM, which results in a failure to meet traditional manufacturing standards. Thermoplastic materials such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polypropylene (PP) and polyethylene (PE) are more commonly used in extrusion methods, as well as materials that could improve mechanical properties such as polyamide (PA), polycarbonate (PC), polyetheretherketone (PEEK), etc. Compared with other thermoplastic materials, PLA has a lower price, better biocompatibility and biodegradability, higher retrievability, and good mechanical properties [

13]. Therefore, it is regarded as an environmentally friendly alternative to petrochemical plastics. During the material-stacking process if it cannot completely stack or completely cure, this results in a decrease in the mechanical properties of the final material. Therefore, post-curing technologies have been developed to perform a secondary curing of the molded material through UV light wavelength irradiation to reduce the unevenness between layers and improve the final mechanical properties. This process is however cumbersome and time-consuming [

14,

15].

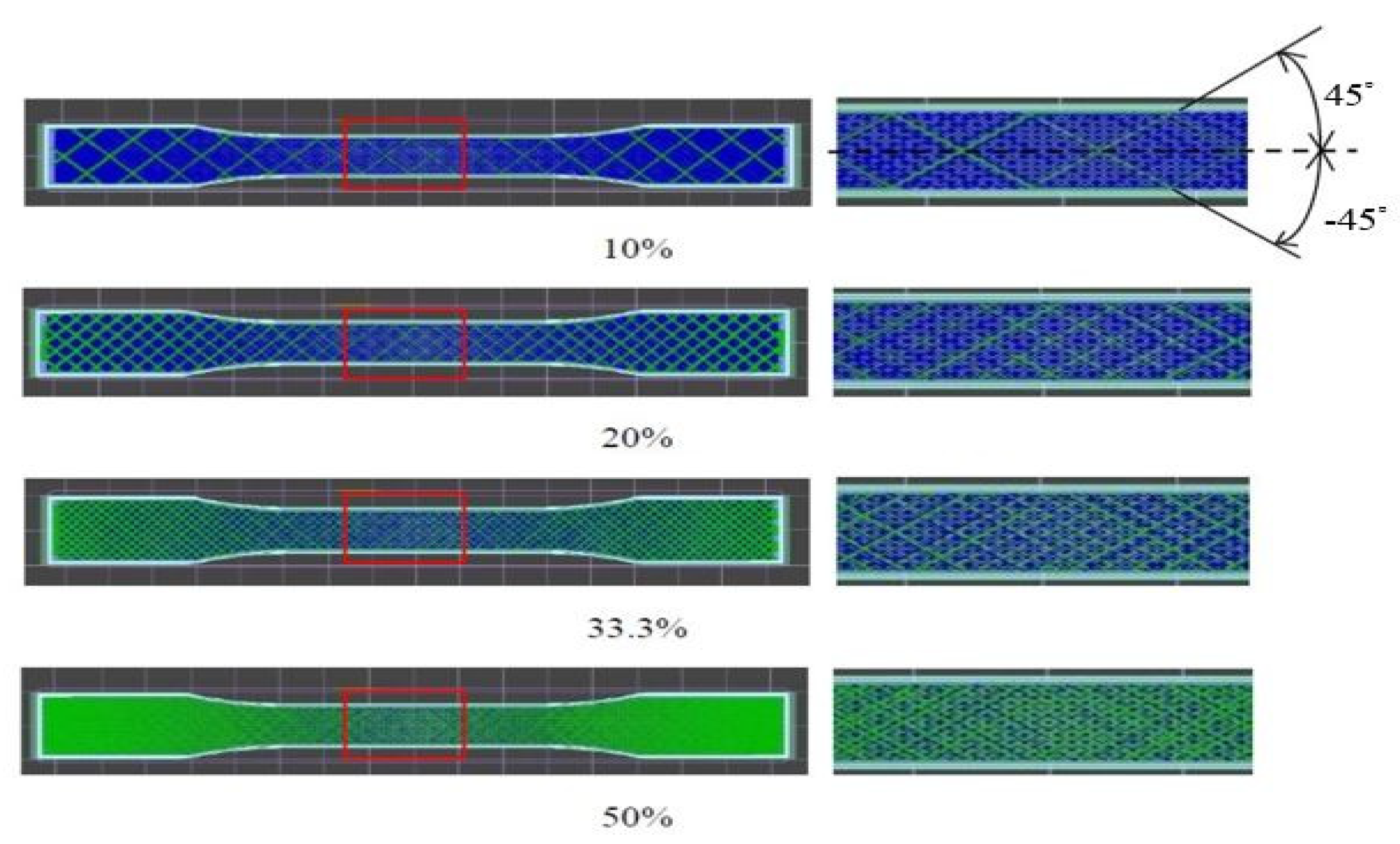

In the past few years, researchers have discussed the impact of printing process parameters and UV curing secondary processing on FDM technology. To improve the performance and quality of the parts, the material structure performance and shortened printing build time must be ensured. Luzanin et al. [

16] studied the influence of five construction parameters including layer thickness, deposition angle, filling, extrusion speed, and extrusion temperature on the maximum flexural force of a sample made of PLA and its interactions. DSD statistical analysis revealed that the deposition angle and filler mainly affect the bending characteristics. The filling percentage was set at 10%, 20%, and 30% to reduce the construction time and improve efficiency. Akhoundi et al. [

17] investigated that the effect of filling patterns on the tensile and flexural strength and modulus of parts printed via FDM and 3D printers. The result shows that infill percentage and filling pattern are the primary factors affecting the mechanical properties of 3D-printed products. The results indicated that the concentric pattern yields the most desirable tensile and flexural tensile properties, at all filling percentages, apparently due to the alignment of deposited rasters with the loading direction. Hilbert curve patterns also yield a dramatic improvement in the properties at 100% filling. Aloyaydi et al. [

18] investigated the influence of infill density on the microstructure and flexural behavior of thermoplastic 3D-printed PLA parts processed by fusion deposition modeling. As the filling percentage increases, the porosity decreases, so that the contact and bonding between the layers increases. This means that the bending characteristics have a high correlation with the filling percentage. Observed in the microstructure, brittle fracture modes (smooth areas) and ductile failure modes (deformation mode) as the filling percentage increase and ductile failure modes (deformation mode) increase. Grasso et al. [

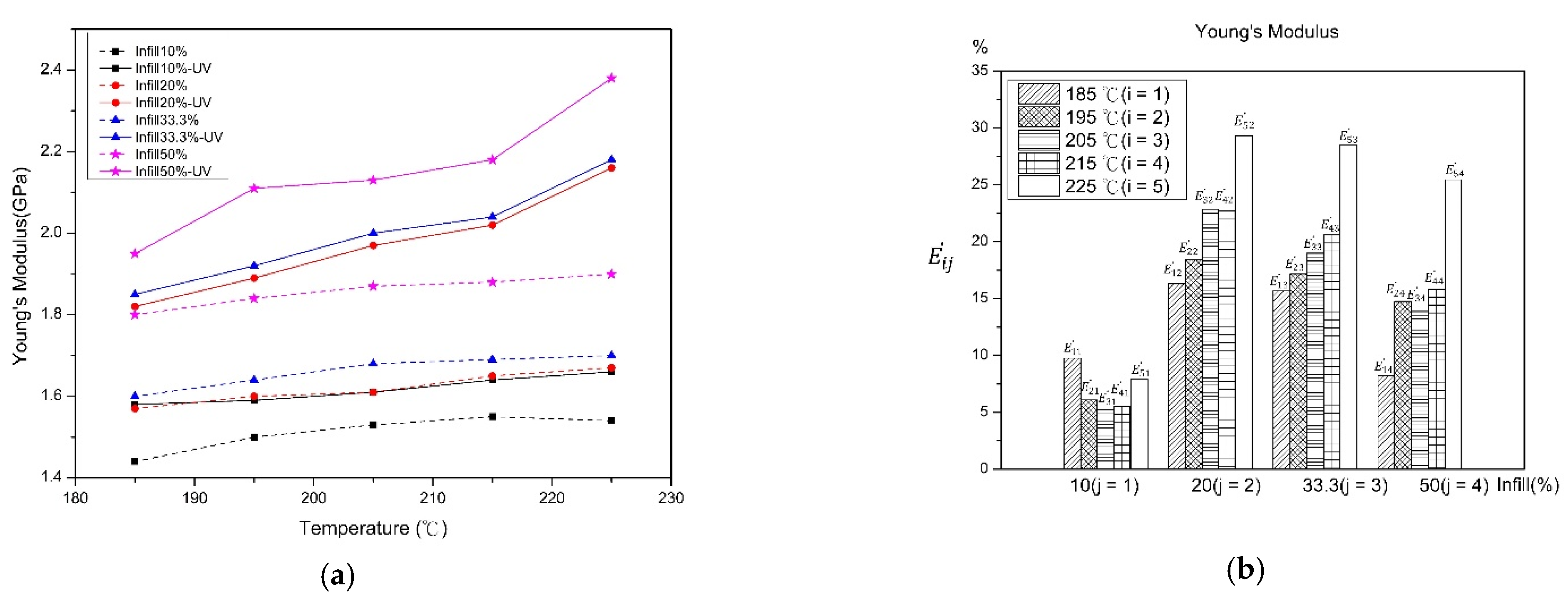

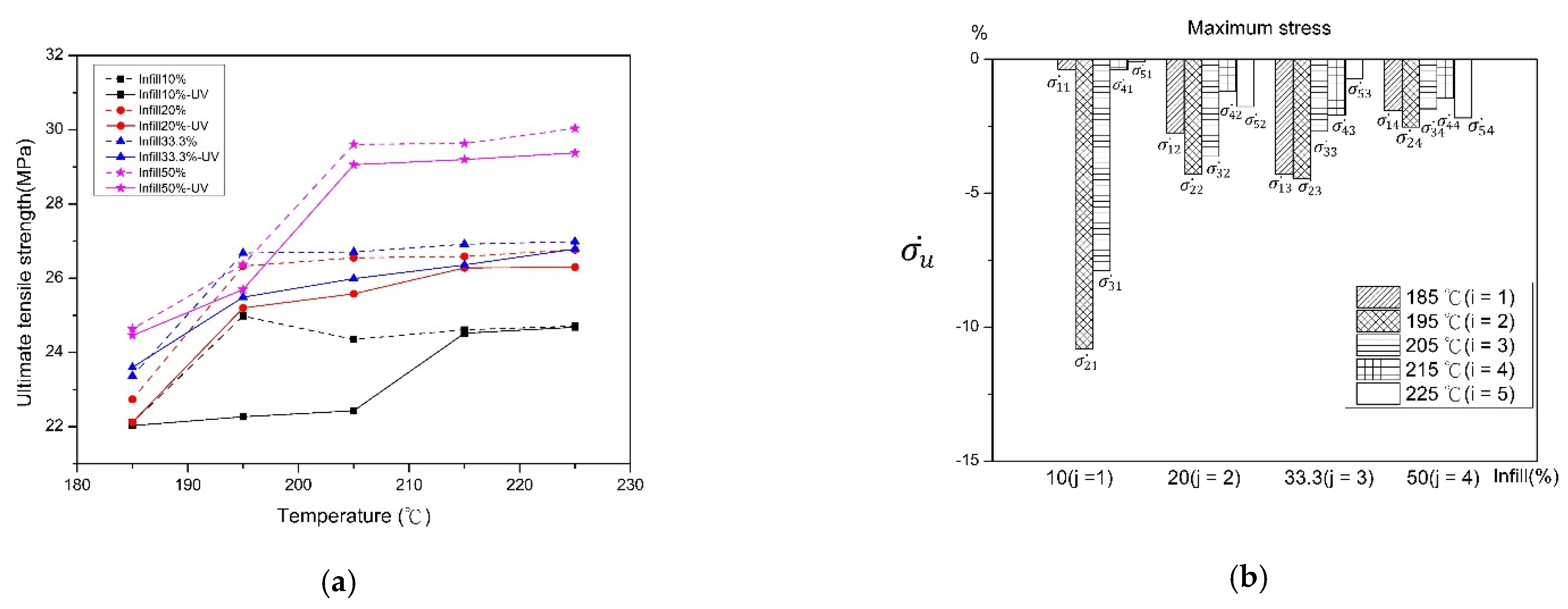

19] studied the influence of temperature on the mechanical properties of PLA materials in FDM technology 3D printing. As the temperature increased, the cold crystallization effect of the polymer and the rearrangement of the molecular chains along the test direction increased the stiffness of the material. At higher temperatures, closer to the glass transition temperature of PLA (i.e., 40 °C), this caused stress to redistribute and the failure stress decreased as the temperature increased. Wang et al. [

20] found that the FDM in the 3D printing technology is at the high temperature of the nozzle and the heating platform. They observed that the deposited filaments undergo diffusion bonding in the cross-sectional profile and between adjacent filaments. The diffusion between the filaments establishes the surface roughness of the object. The molecular diffusion between filaments affects the cross-sectional area shape and the bonding area of the filaments, which further affects the combination of heat transfer and diffusion. As the nozzle temperature and platform temperature increase, the surface roughness decreases. However, as the temperature rises, the influence of nozzle temperature on the surface roughness of the platform is greater than that of the platform temperature. Using a higher or lower printing speed or a thinner layer thickness deteriorates the surface quality because the nozzle extrusion deteriorates the surface morphology. Behzadnasab et al. [

21] discussed the influence of printing temperature, filling pattern, and annealing on the tensile strength and Young’s modulus of PLA by open-source 3D printer technology. The printing conditions have been found to have a significant impact on the final performance of the object. For example, the fracture stress increases from 34 MPa to 56 MPa as the nozzle temperature rises, which is close to the value of 65 MPa seen for injection molded samples. However, the tensile strength increases with the printing temperature, but the annealing process has a negative impact on the mechanical properties of the samples. Tertyshnaya [

22] studied the effect of 3D printing technology on the physical properties of composite materials mixed with PLA and low-density polyethylene (LDPE) in FDM materials. They observed that the melting temperature changed by 1–2 °C, and with the glass transition temperature of 70–80 wt%, LDPE increased by 4–5 °C. After irradiating with UV light, LDPE showed brittle failure with the increase in irradiation time. Can et al. [

23] investigated that the FDM technology for 3D printing, adding micron and nanometer size TiO

2 particles and benzotriazole as UV absorbers into PLA. They found that TiO

2 particles have a strengthening and toughening effect. Due to effective stiffening, strengthening, and toughening actions of TiO

2 particles, as well as due to their very significant UV screening actions absorbing the photons of the UV irradiation, thus decreasing the degree of the detrimental photodegradation reactions leading to chain scissions in their PLA matrix. The low-temperature aging of PLA material from the molten state to the quenched state of the FDM technology of 3D printing was studied by Zhao et al. [

24], to slow down the aging of physical properties and the transformation of entanglement into a secondary ordered structure. UV radiation entangles, and the amorphous chain inhibits the formation of secondary structures during the aging process of physical properties, while the continuous amorphous phase with high entanglement density indicates that the polymer has higher toughness.

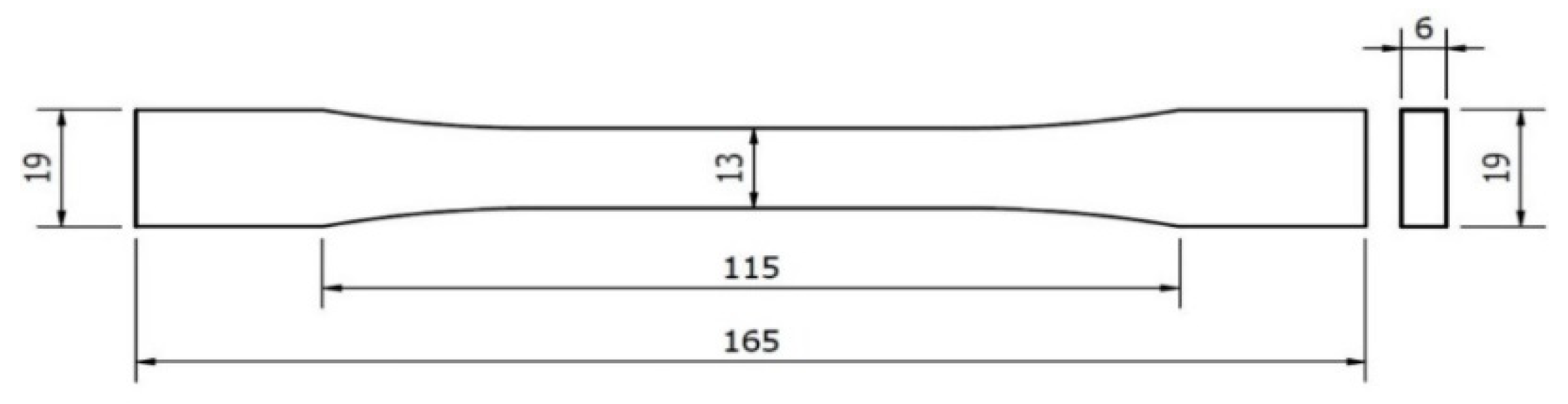

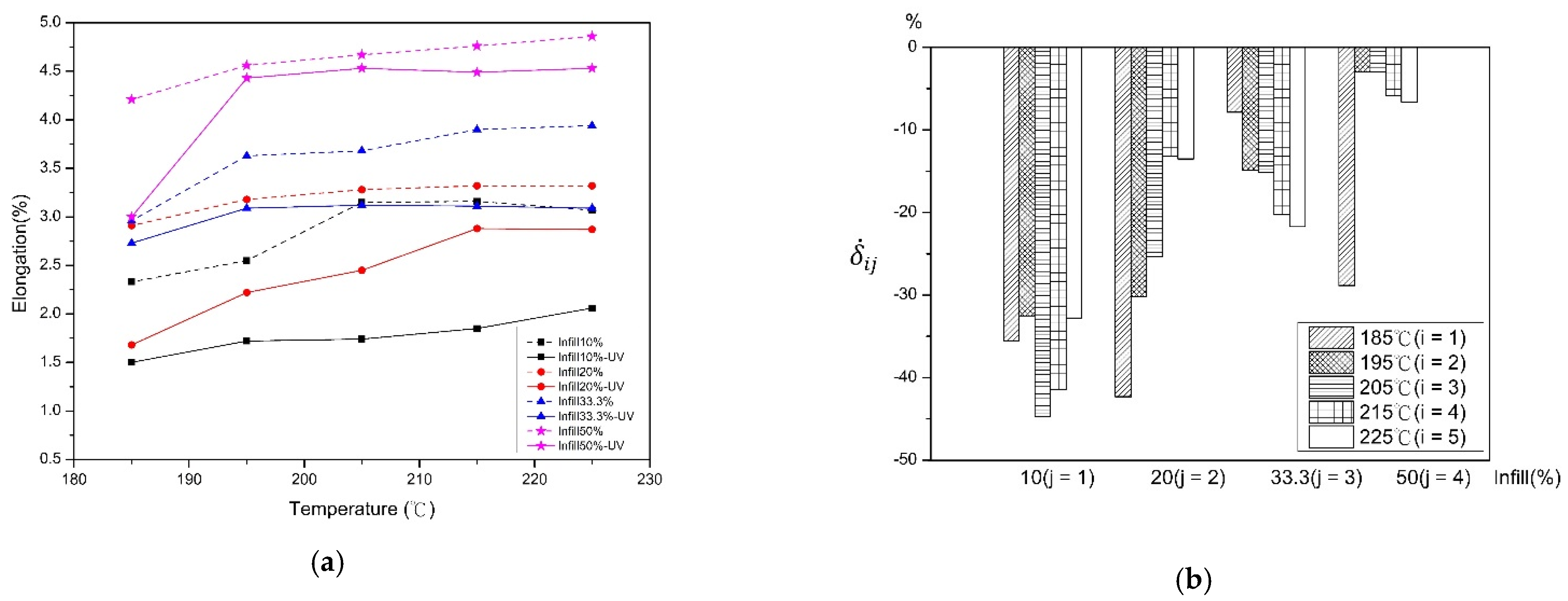

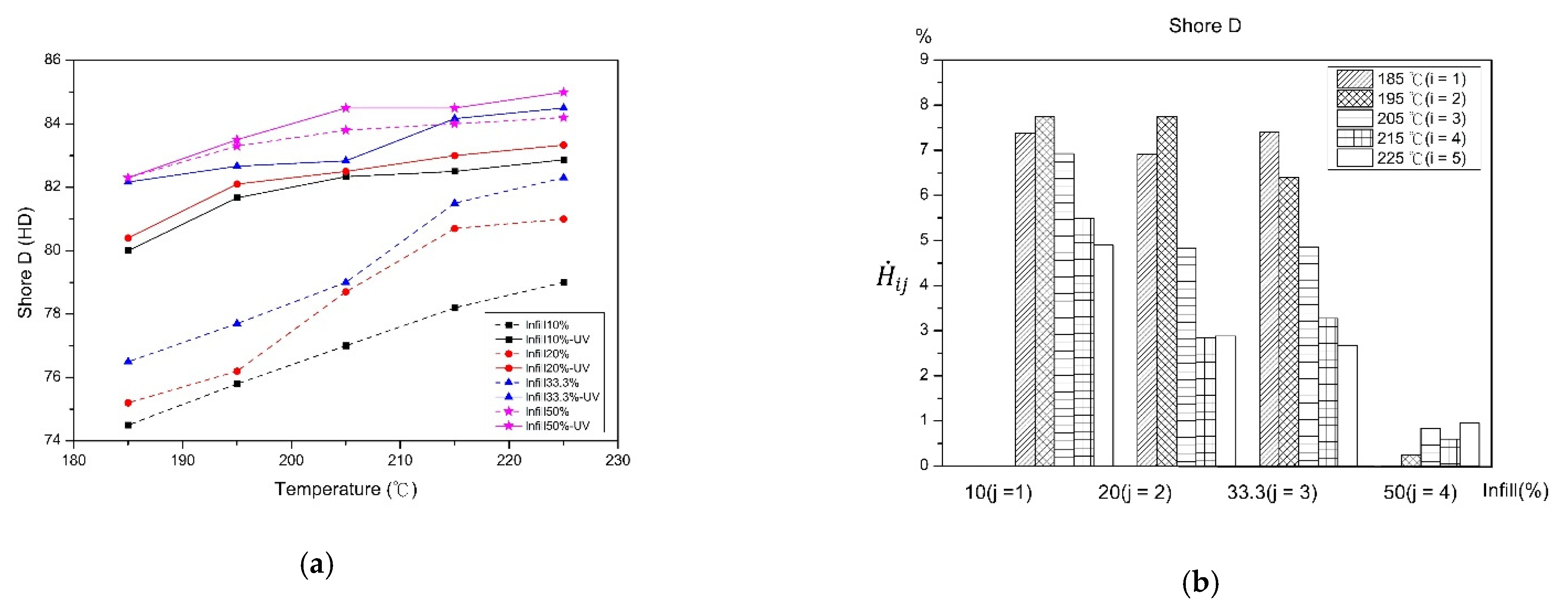

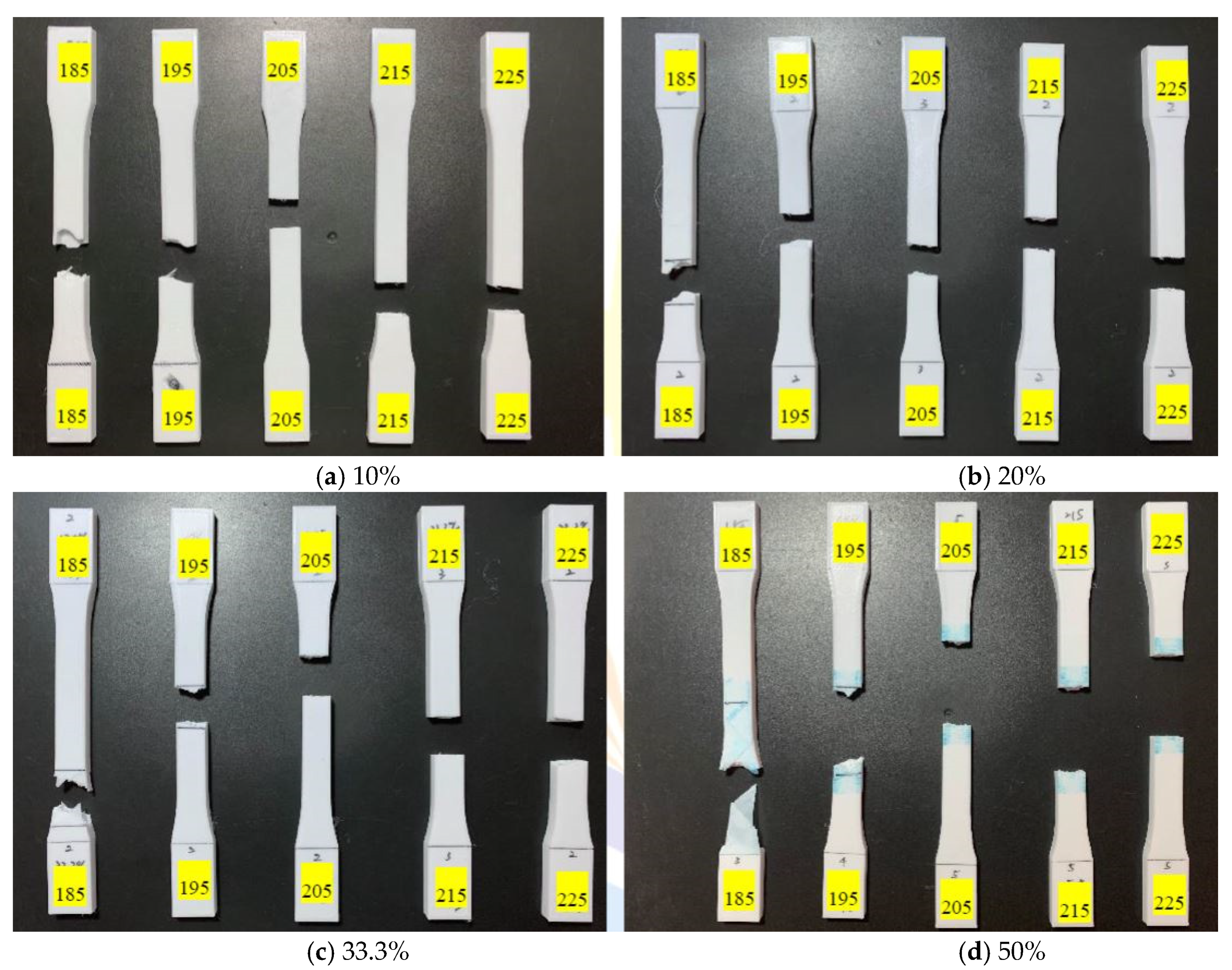

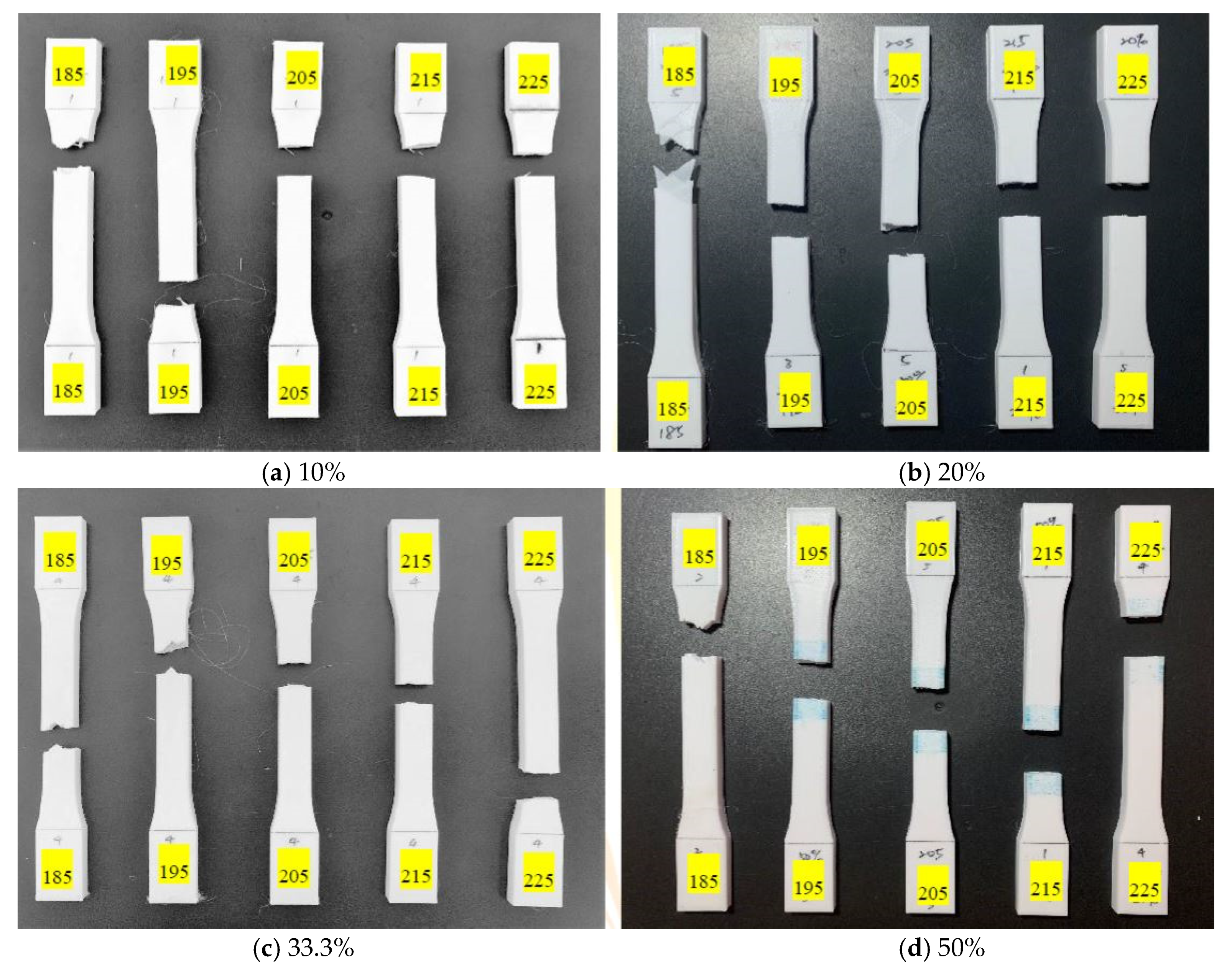

To avoid the loss of time and materials, the FDM technology was used in this study to analyze the impact of different filling percentages and nozzle temperatures on the mechanical properties of PLA materials. We also studied whether UV-curing PLA materials could reduce the unevenness between layers and improve the mechanical properties and quality of the materials. The findings of this study will provide standards for future commercialization, avoiding waste and sustainable environmental protection of the earth’s resources.