Thermal Mending of Electroactive Carbon/Epoxy Laminates Using a Porous Poly(ε-caprolactone) Electrospun Mesh

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

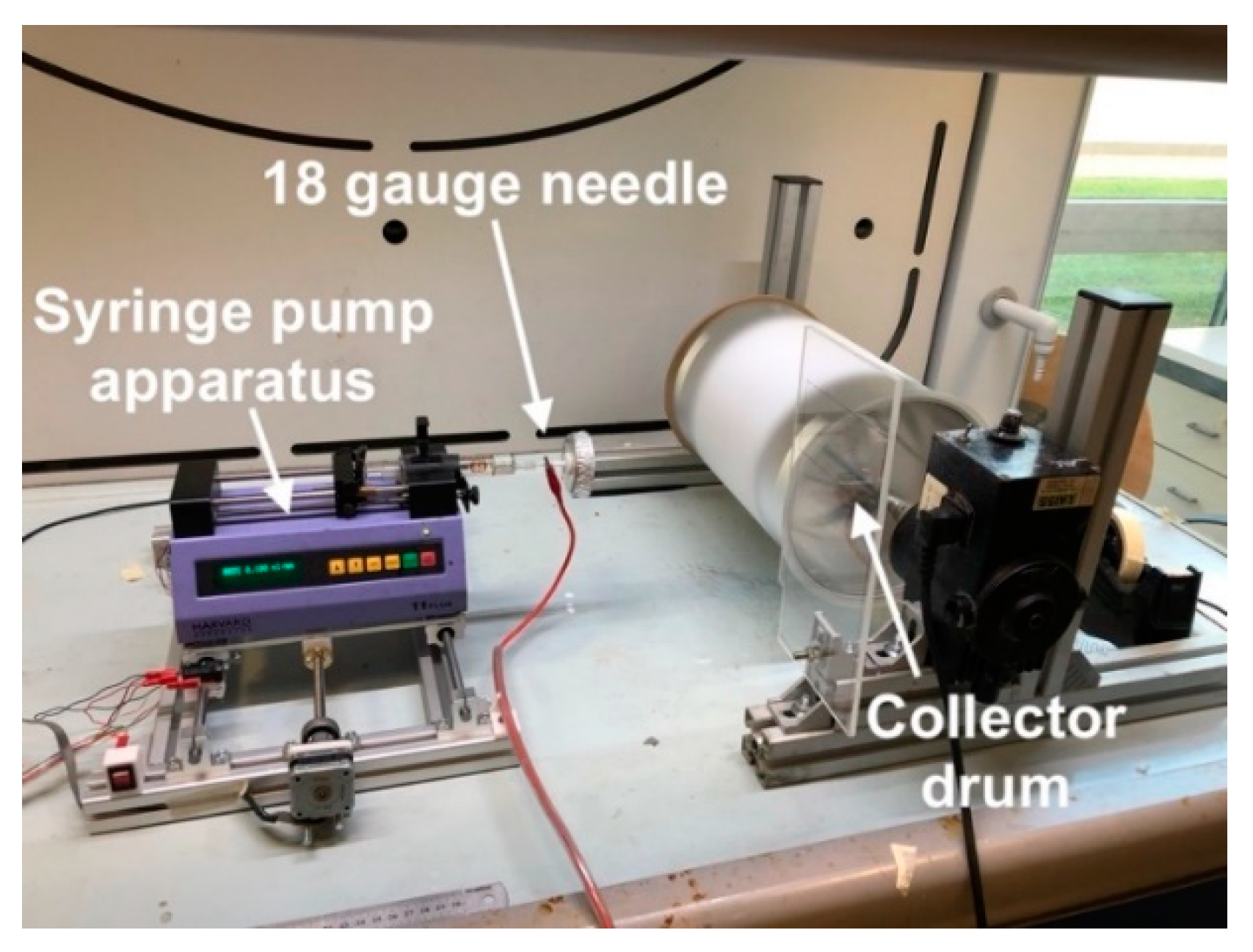

2.2.1. Electrospinning of PCL Fibers

2.2.2. Preparation of the Composites

2.3. Experimental Techniques

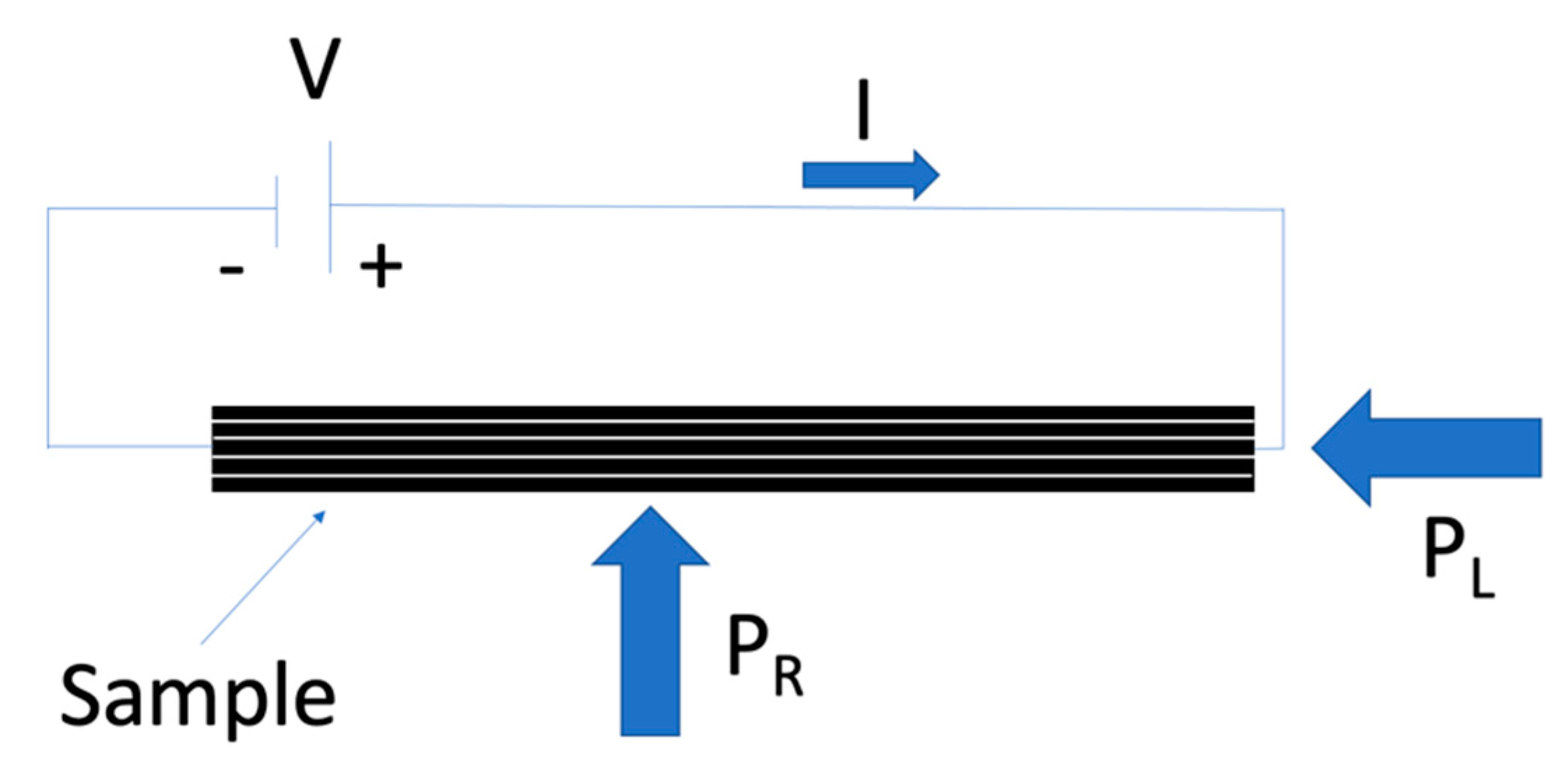

2.3.1. Characterization of the Laminates

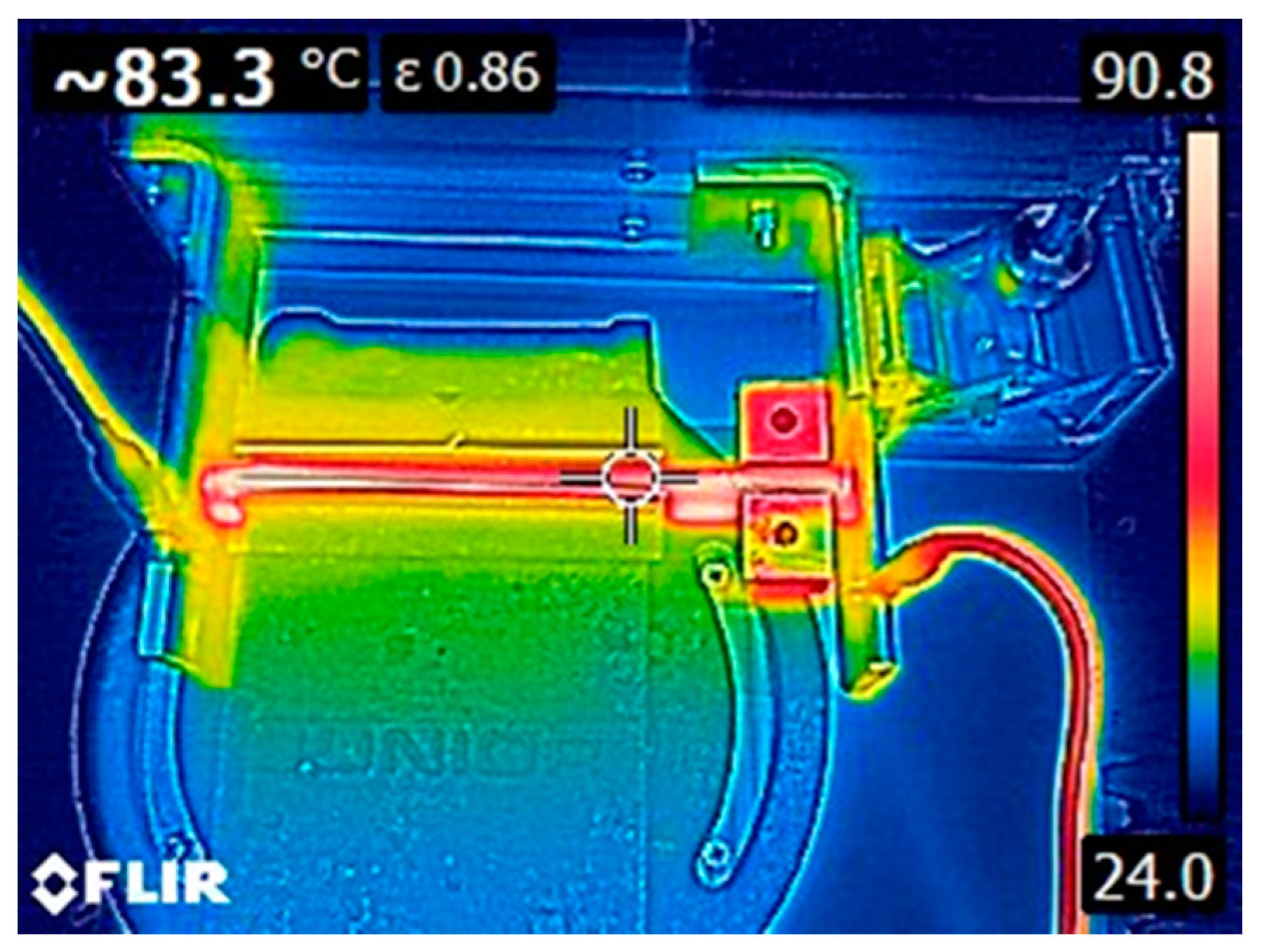

2.3.2. Healing Process of the Composites

3. Results and Discussions

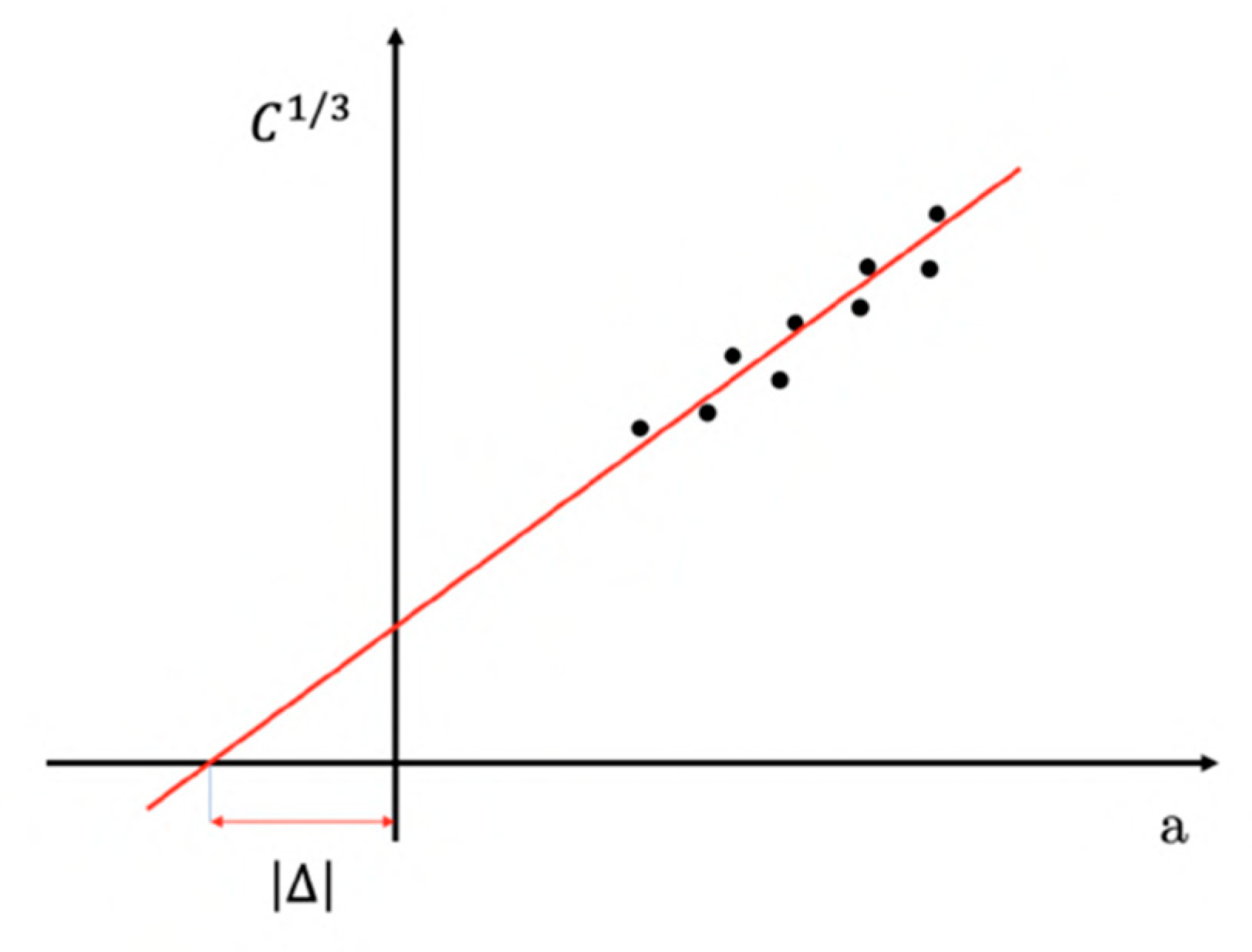

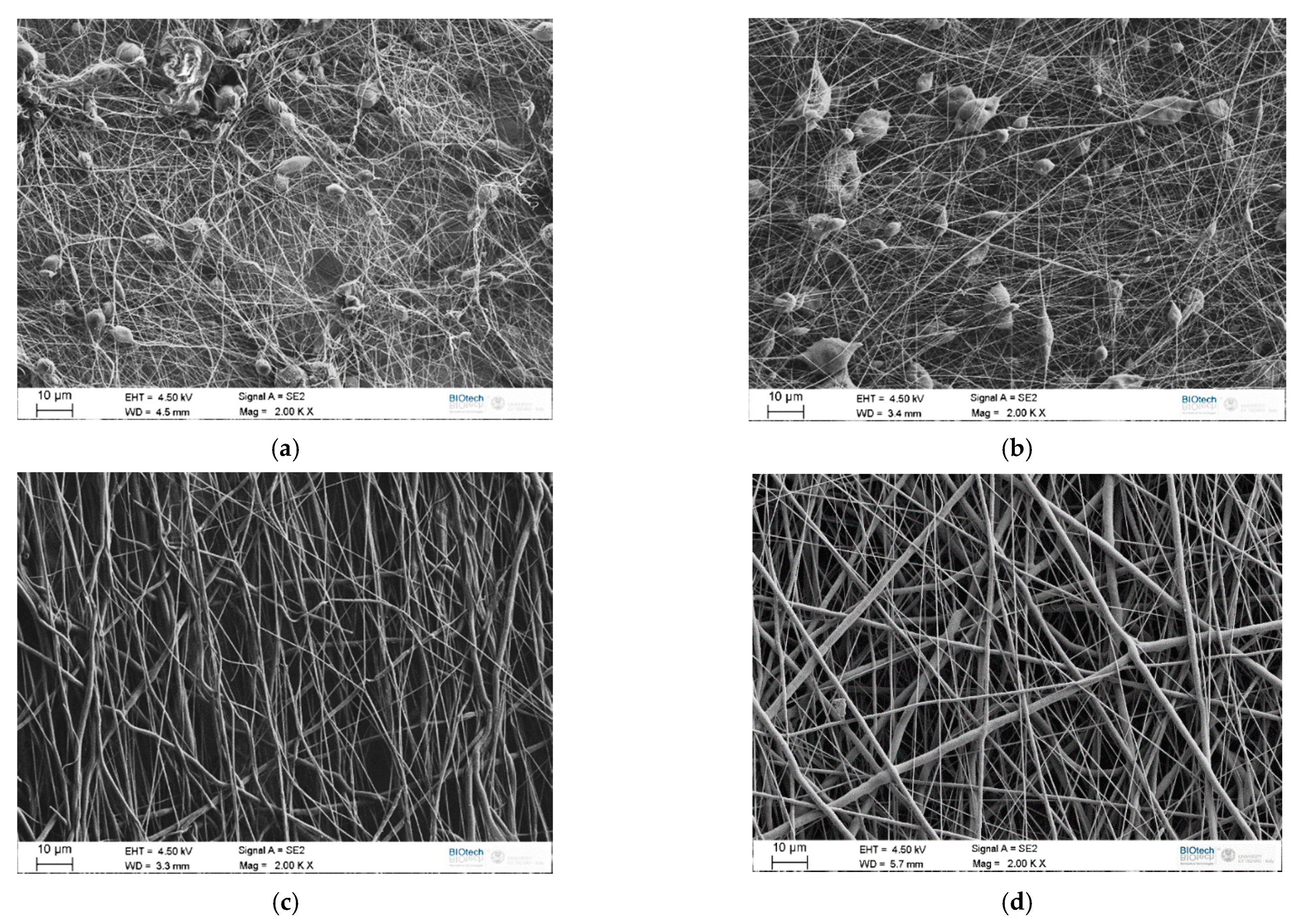

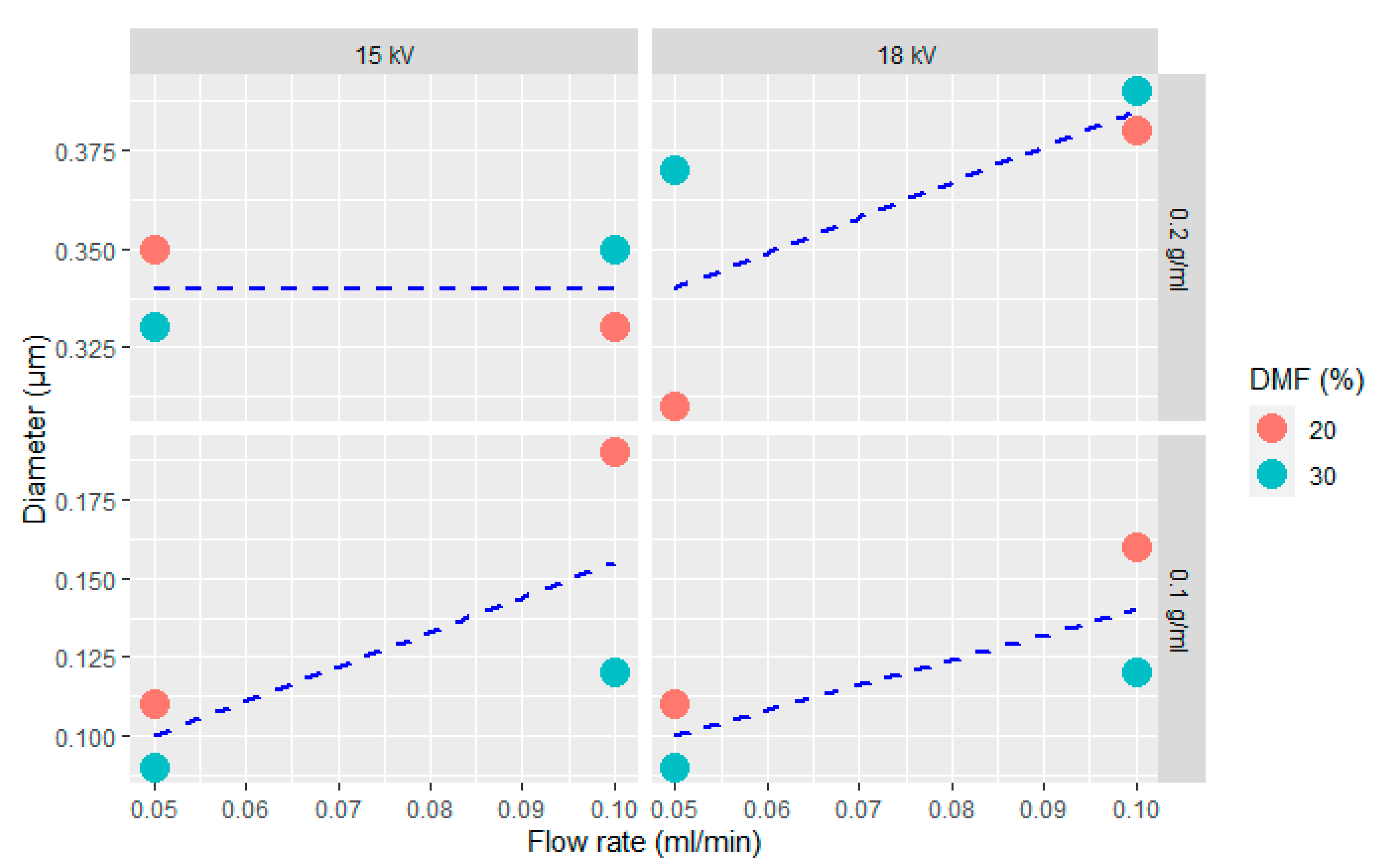

3.1. Characterization of PCL Electrospun Meshes

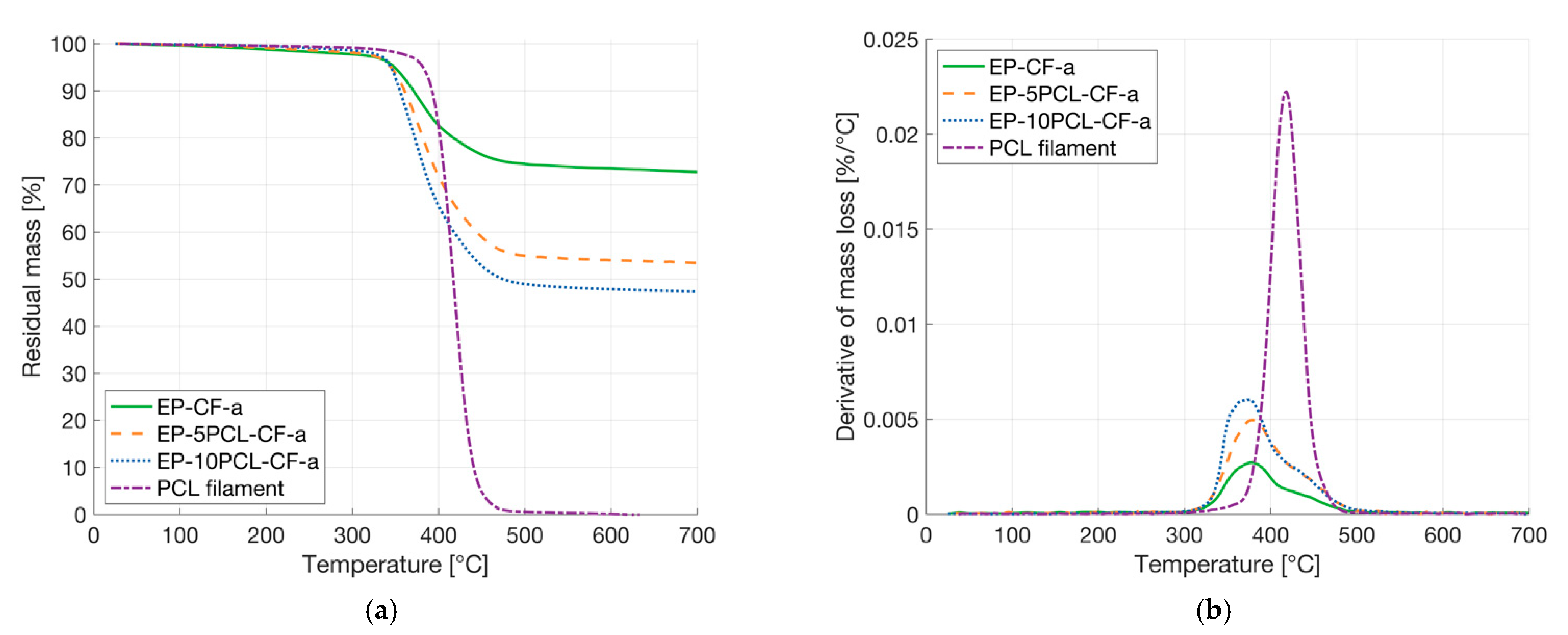

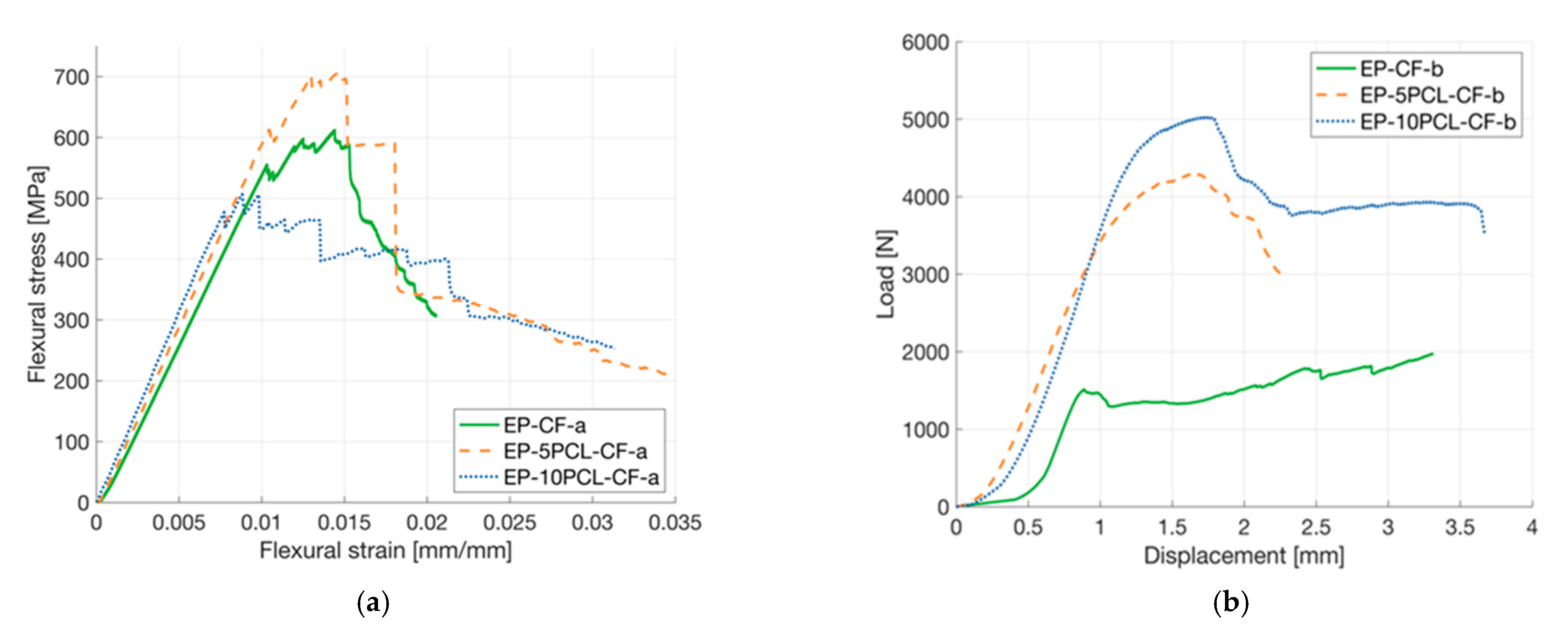

3.2. Characterization of the Composites

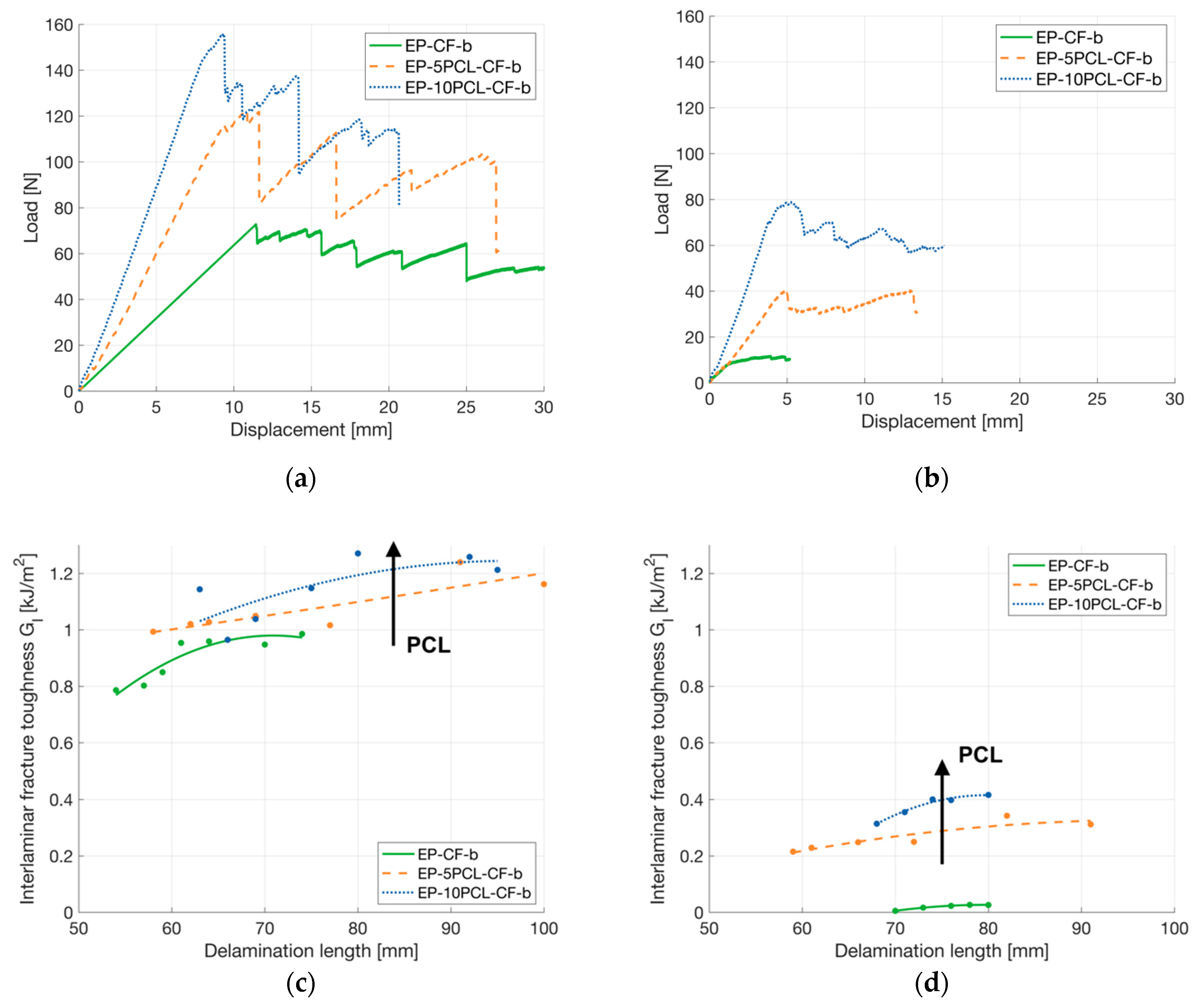

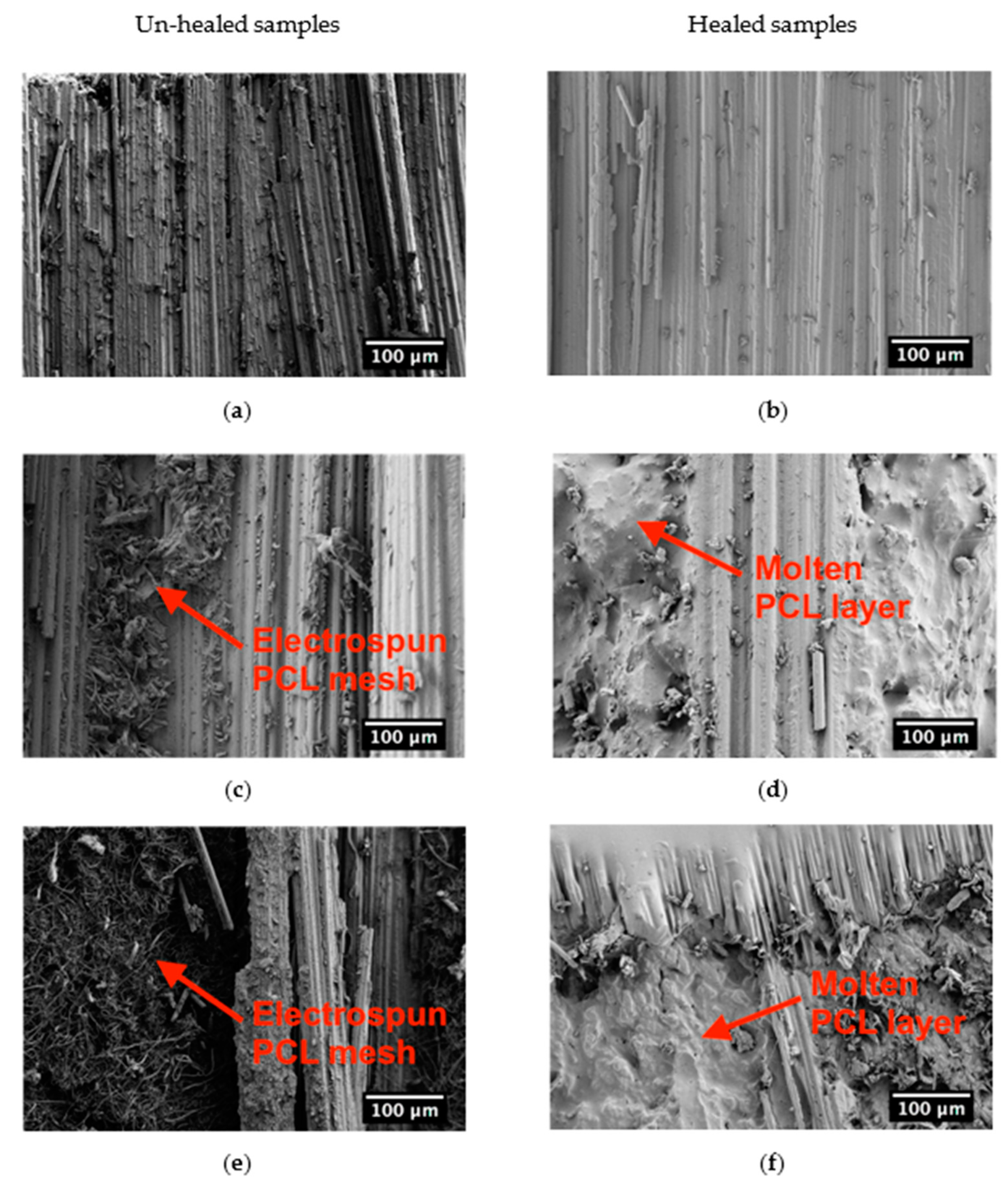

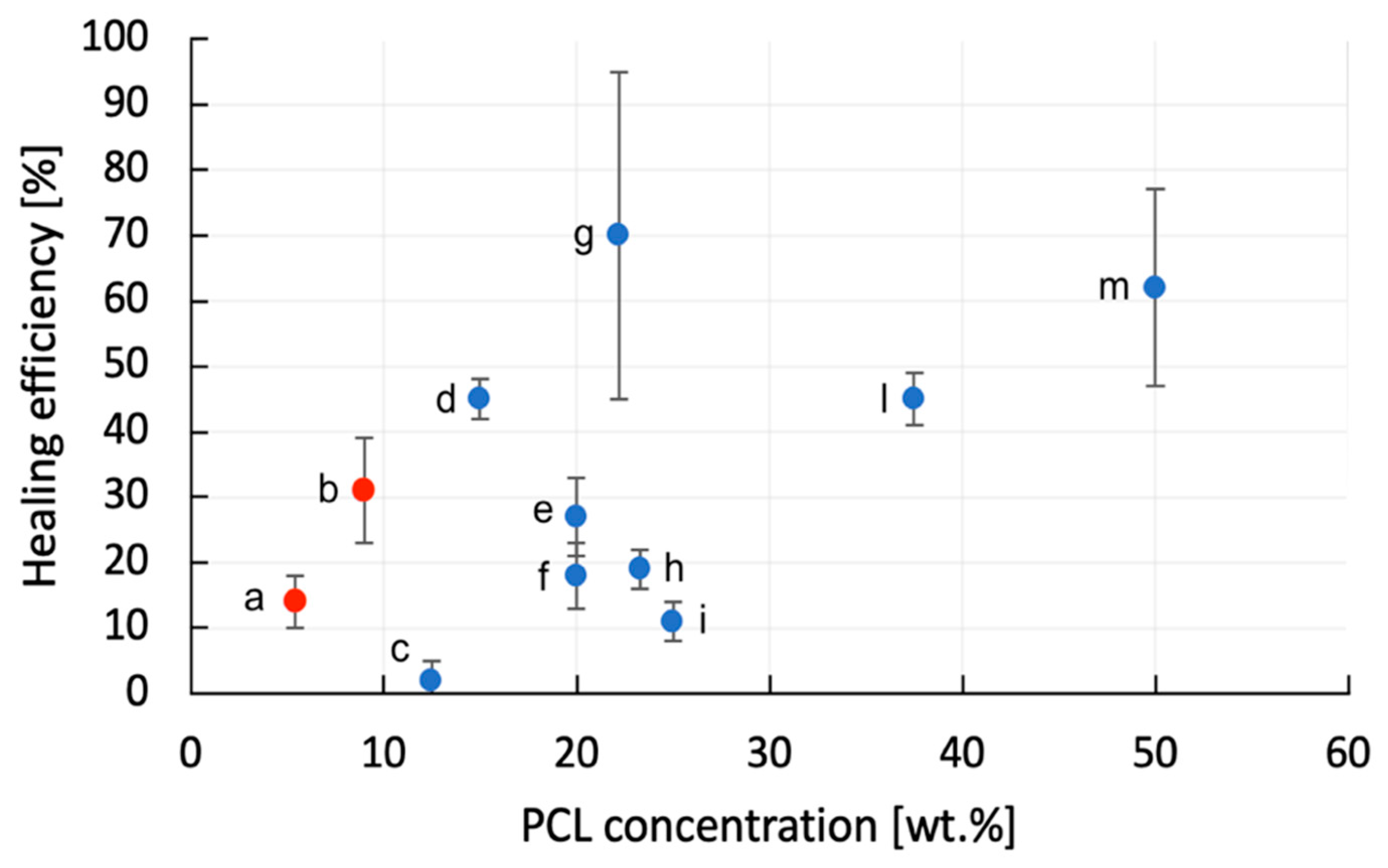

3.3. Evaluation of the Healing Efficiency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Agarwal, B.D.; Broutman, L.J.; Bert, C.W. Analysis and Performance of Fiber Composites. J. Appl. Mech. 1981, 48, 213. [Google Scholar] [CrossRef]

- Kelly, A.; Zweben, C. Comprehensive composite materials. Mater. Today 1999, 2, 20–21. [Google Scholar] [CrossRef]

- Grzesik, W. Advanced Machining Processes of Metallic Materials, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- White, S.R.; Geubelle, P.H.; Sottos, N.R. Multiscale Modeling and Experiments for Design of Self-Healing Structural Composite Materials. Multiscale Modeling Exp. Des. Self-Heal. Struct. Compos. Mater. 2005, 8, 743–753. [Google Scholar] [CrossRef]

- Jawaid, M.; Thariq, M.; Saba, N. Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-healing composites: A state-of-the-art review. Compos. Part A Appl. Sci. Manuf. 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Verdejo, R.; Lopez-Manchado, M.A.; Santana, M.H. Evolution of self-healing elastomers, from extrinsic to combined intrinsic mechanisms: A review. Mater. Horiz. 2020, 7, 2882–2902. [Google Scholar] [CrossRef]

- Song, M.-M.; Wang, Y.-M.; Liang, X.-Y.; Zhang, X.-Q.; Zhang, S.; Li, B.-J. Functional materials with self-healing properties: A review. Soft Matter 2019, 15, 6615–6625. [Google Scholar] [CrossRef]

- Teixeira, R.F.A.; Hillewaere, X.K.D.; Billiet, S.; Du Prez, F.E. Chemistry of Crosslinking Processes for Self-Healing Polymers. Self-Heal. Polym. 2013, 4, 215–246. [Google Scholar] [CrossRef]

- Garcia, S. Effect of polymer architecture on the intrinsic self-healing character of polymers. Eur. Polym. J. 2014, 53, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Liang, D.; Cheng, B. Preparation and research of intrinsic self-healing elastomers based on hydrogen and ionic bond. Compos. Sci. Technol. 2020, 193, 108127. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Cheung, S.C.P.; Wang, C.H. The effect of carbon nanofibres on self-healing epoxy/poly(ε-caprolactone) blends. Compos. Sci. Technol. 2012, 72, 1952–1959. [Google Scholar] [CrossRef]

- Cohades, A.; Manfredi, E.; Plummer, C.J.; Michaud, V. Thermal mending in immiscible poly(ε-caprolactone)/epoxy blends. Eur. Polym. J. 2016, 81, 114–128. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, H.; Dorigato, A.; Pegoretti, A. Thermal mending in novel epoxy/cyclic olefin copolymer blends. Express Polym. Lett. 2020, 14, 368–383. [Google Scholar] [CrossRef]

- Dorigato, A.; Mahmood, H.; Pegoretti, A. Optimization of the thermal mending process in epoxy/cyclic olefin copolymer blends. J. Appl. Polym. Sci. 2021, 138, 49937. [Google Scholar] [CrossRef]

- Mahmood, H.; Dorigato, A.; Pegoretti, A. Healable Carbon Fiber-Reinforced Epoxy/Cyclic Olefin Copolymer Composites. Materials 2020, 13, 2165. [Google Scholar] [CrossRef]

- Zovi, R.C.; Mahmood, H.; Dorigato, A.; Fredi, G.; Pegoretti, A. Cyclic Olefin Copolymer Interleaves for Thermally Mendable Carbon/Epoxy Laminates. Molecules 2020, 25, 5347. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Ait Hocine, N. Clays and carbon nanotubes as hybrid nanofillers in thermoplastic-based nanocomposites – A review. Appl. Clay Sci. 2020, 185, 105408. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, J.; Lu, H.; Xu, B.; Fu, Y.; Liu, Y.; Leng, J. Thermosetting epoxy resin/thermoplastic system with combined shape memory and self-healing properties. Smart Mater. Struct. 2015, 25, 015021. [Google Scholar] [CrossRef]

- Wu, X.-F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Self-healing properties of epoxy resins with poly(ε-caprolactone) healing agent. Polym. Bull. 2016, 73, 3081–3093. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Peidong, F.; Ren, J.; Cheng, Y.; Zhao, J.; Song, R. Self-healing thermoplastic polyurethane (TPU)/polycaprolactone (PCL) /multi-wall carbon nanotubes (MWCNTs) blend as shape-memory composites. Compos. Sci. Technol. 2018, 168, 255–262. [Google Scholar] [CrossRef]

- Rodriguez, E.D.; Luo, X.; Mather, P.T. Linear/Network Poly(ε-caprolactone) Blends Exhibiting Shape Memory Assisted Self-Healing (SMASH). ACS Appl. Mater. Interfaces 2011, 3, 152–161. [Google Scholar] [CrossRef] [PubMed]

- Abdelhak, B.; Noureddine, M.; Hacen, M. Improvement of the Interfacial Adhesion Between Fiber and Matrix. Mech. Mech. Eng. 2018, 22, 885–894. [Google Scholar] [CrossRef]

- Kwok, N.; Hahn, H.T. Resistance Heating for Self-healing Composites. J. Compos. Mater. 2007, 41, 1635–1654. [Google Scholar] [CrossRef]

- Pattanashetti, N.A.; Achari, D.D.; Torvi, A.I.; Doddamani, R.V.; Kariduraganavar, M.Y. Development of multilayered nanofibrous scaffolds with PCL and PVA: NaAlg using electrospinning technique for bone tissue regeneration. Materialia 2020, 12, 100826. [Google Scholar] [CrossRef]

- Cho, S.J.; Jung, S.M.; Kang, M.; Shin, H.S.; Youk, J.H. Preparation of hydrophilic PCL nanofiber scaffolds via electrospinning of PCL/PVP-b-PCL block copolymers for enhanced cell biocompatibility. Polymer 2015, 69, 95–102. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1991; pp. 521–568. [Google Scholar]

- Seo, Y.-A.; Pant, H.R.; Nirmala, R.; Lee, J.-H.; Song, K.G.; Kim, H.Y. Fabrication of highly porous poly (ε-caprolactone) microfibers via electrospinning. J. Porous Mater. 2012, 19, 217–223. [Google Scholar] [CrossRef]

- Kim, K.; Mousa, H.M.; Park, C.H.; Kim, C.S. Enhanced corrosion resistance and biocompatibility of AZ31 Mg alloy using PCL/ZnO NPs via electrospinning. Appl. Surf. Sci. 2017, 396, 249–258. [Google Scholar] [CrossRef]

- Hotaling, N.A.; Bharti, K.; Kriel, H.; Simon, C. DiameterJ: A validated open source nanofiber diameter measurement tool. Biomaterials 2015, 61, 327–338. [Google Scholar] [CrossRef] [Green Version]

- ASTM-D5528-13. Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM-D792-13. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM-D790-15. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM-D2344/D2344M-13. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Hayes, S.A.; Swait, T.J.; Lafferty, A.D. Chap. 9—Self-sensing and self-healing in composites. In Recent Advances in Smart Self-healing Polymers and Composites; Woodhead Publishing: Cambridge, UK, 2015; pp. 243–261. [Google Scholar]

- Webster, J.G. Chap. 7—Electrical Conductivity and Resistivity. In Electrical Measurement, Signal Processing, and Displays; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–17. [Google Scholar]

- Eddib, A.A.; Chung, D. The importance of the electrical contact between specimen and testing fixture in evaluating the electromagnetic interference shielding effectiveness of carbon materials. Carbon 2017, 117, 427–436. [Google Scholar] [CrossRef]

- Wang, S.; Kowalik, D.P.; Chung, D.D.L. Effects of the temperature, humidity, and stress on the interlaminar interface of carbon fiber polymer-matrix composites, studied by contact electrical resistivity measurement. J. Adhes. 2002, 78, 189–200. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C. One-Dimensional Nanostructures; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Cramariuc, B.; Cramariuc, R.; Scarlet, R.; Manea, L.R.; Lupu, I.G.; Cramariuc, O. Fiber diameter in electrospinning process. J. Electrost. 2013, 71, 189–198. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, X.; Wang, L.; Huang, Y. Electrospinning of ethyl-cyanoethyl cellulose/tetrahydrofuran solutions. J. Appl. Polym. Sci. 2003, 91, 242–246. [Google Scholar] [CrossRef]

- Shenoy, S.L.; Bates, W.D.; Frisch, H.L.; Wnek, G.E. Role of chain entanglements on fiber formation during electrospinning of polymer solutions: Good solvent, non-specific polymer–polymer interaction limit. Polymers 2005, 46, 3372–3384. [Google Scholar] [CrossRef]

- Pillay, V.; Dott, C.; Choonara, Y.; Tyagi, C.; Tomar, L.; Kumar, P.; du Toit, L.; Ndesendo, V.M.K. A Review of the Effect of Processing Variables on the Fabrication of Electrospun Nanofibers for Drug Delivery Applications. J. Nanomater. 2013, 2013, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Hirai, N.; Ishikawa, H.; Ohki, Y. Electrical conduction properties of several biodegradable polymers. In Proceedings of the 2007 Annual Report-Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007; pp. 592–595. [Google Scholar]

- Imran, K.; Shivakumar, K. Enhancement of electrical conductivity of epoxy using graphene and determination of their thermo-mechanical properties. J. Reinf. Plast. Compos. 2017, 32, 118–133. [Google Scholar] [CrossRef]

- Zheng, N.; Liu, H.-Y.; Gao, J.; Mai, Y.-W. Synergetic improvement of interlaminar fracture energy in carbon fiber/epoxy composites with nylon nanofiber/polycaprolactone blend interleaves. Compos. Part B Eng. 2019, 171, 320–328. [Google Scholar] [CrossRef]

- Daelemans, L.; Van Der Heijden, S.; De Baere, I.; Rahier, H.; VAN Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef]

- Dorigato, A.; Rigotti, D.; Pegoretti, A. Novel Poly(Caprolactone)/Epoxy Blends by Additive Manufacturing. Materials 2020, 13, 819. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Yao, Y.; Liu, Y.; Leng, J. A dual-functional polymeric system combining shape memory with self-healing properties. Compos. Part B Eng. 2015, 83, 7–13. [Google Scholar] [CrossRef]

| Code | Variable | Value = −1 | Value = +1 |

|---|---|---|---|

| x1 | polymer concentration (g/mL) | 0.1 | 0.2 |

| x2 | DMF concentration (wt.%) | 20 | 30 |

| x3 | applied voltage (kV) | 15 | 18 |

| x4 | flow rate (mL/min) | 0.05 | 0.1 |

| CF Layers | PCL Layers | PCL (wt.%) | Thickness (mm) | |

|---|---|---|---|---|

| EP-CF-a | 4 | 0 | 0 | 1.2 |

| EP-5PCL-CF-a | 4 | 3 | 5 | 1.2 |

| EP-10PCL-CF-a | 4 | 3 | 10 | 1.3 |

| EP-CF-b | 16 | 0 | 0 | 3.3 |

| EP-5PCL-CF-b | 16 | 15 | 5 | 5.3 |

| EP-10PCL-CF-b | 16 | 15 | 10 | 7.2 |

| Trial | Polymer Concentration in Solution [g/mL] | DMF Concentration in Solution [%] | Applied Voltage [kV] | Solution Flow Rate [mL/min] | Diameter of the Fibers [μm] | Microstructural Defects |

|---|---|---|---|---|---|---|

| 1 | 0.1 | 20 | 15 | 0.05 | 0.11 ± 0.04 | Beads |

| 2 | 0.1 | 30 | 15 | 0.05 | 0.09 ± 0.04 | Beads |

| 3 | 0.1 | 20 | 18 | 0.05 | 0.11 ± 0.02 | Beads |

| 4 | 0.1 | 30 | 18 | 0.05 | 0.09 ± 0.04 | Beads |

| 5 | 0.1 | 20 | 15 | 0.10 | 0.19 ± 0.06 | Beads |

| 6 | 0.1 | 30 | 15 | 0.10 | 0.12 ± 0.04 | Beads |

| 7 | 0.1 | 20 | 18 | 0.10 | 0.16 ± 0.06 | Beads |

| 8 | 0.1 | 30 | 18 | 0.10 | 0.12 ± 0.06 | Beads |

| 9 | 0.2 | 20 | 15 | 0.05 | 0.35 ± 0.11 | - |

| 10 | 0.2 | 30 | 15 | 0.05 | 0.33 ± 0.13 | - |

| 11 | 0.2 | 20 | 18 | 0.05 | 0.31 ± 0.12 | - |

| 12 | 0.2 | 30 | 18 | 0.05 | 0.37 ± 0.15 | - |

| 13 | 0.2 | 20 | 15 | 0.10 | 0.33 ± 0.12 | - |

| 14 | 0.2 | 30 | 15 | 0.10 | 0.35 ± 0.12 | - |

| 15 | 0.2 | 20 | 18 | 0.10 | 0.38 ± 0.14 | - |

| 16 | 0.2 | 30 | 18 | 0.10 | 0.39 ± 0.19 | - |

| ρexp [g/cm3] | ρt [g/cm3] | wPCL [wt.%] | wEP [wt.%] | wCF [wt.%] | VPCL [vol.%] | VEP [vol.%] | VCF [vol.%] | VV [vol.%] | |

|---|---|---|---|---|---|---|---|---|---|

| EP-CF-a | 1.542 ± 0.007 | 1.563 | 0.0 | 45.6 | 54.4 | 0.0 | 55.8 | 43.2 | 0.8 ± 0.2 |

| EP-5PCL-CF-a | 1.359 ± 0.005 | 1.399 | 6.2 | 43.2 | 50.6 | 8.1 | 51.5 | 39.2 | 1.2 ± 0.1 |

| EP-10PCL-CF-a | 1.341 ± 0.005 | 1.393 | 10.0 | 42.0 | 48.0 | 12.1 | 48.7 | 37.6 | 1.6 ± 0.1 |

| Sample | T1% [°C] | T5% [°C] | TdEP [°C] | TdPCL [°C] | m700 [%] |

|---|---|---|---|---|---|

| EP-CF-a | 181.1 | 349.1 | 377.8 | - | 72.7 |

| EP-5PCL-CF-a | 216.2 | 344.8 | 378.5 | - | 53.4 |

| EP-10PCL-CF-a | 262.3 | 344.8 | 376.1 | - | 47.4 |

| PCL filament | 316.3 | 382.1 | 418.1 | 0.1 |

| Flexural Modulus [GPa] | Flexural Strength [MPa] | Flexural Strain at Break [%] | Pm [N] | ILSS [MPa] | |

|---|---|---|---|---|---|

| EP-CF | 60.8 ± 3.4 | 621.4 ± 72.3 | 1.3 ± 0.1 | 2016 ±139 | 67.0 ± 3.7 |

| EP-5PCL-CF | 66.1 ± 3.4 | 698.4 ± 37.3 | 1.3 ± 0.2 | 4342 ± 155 | 50.9 ± 1.5 |

| EP-10PCL-CF | 65.0 ± 2.7 | 512.1 ± 34.7 | 1.1 ± 0.1 | 5073 ± 146 | 40.6 ± 1.3 |

| Electrical Resistivity [Ω mm] | |

|---|---|

| EP-CF-a | 0.065 ± 0.014 |

| EP-5PCL-CF-a | 0.052 ± 0.017 |

| EP-10PCL-CF-a | 0.051 ± 0.012 |

| Sample | PMAX [N] | GINL [kJ/m2] | Healing Efficiency [%] | ||

|---|---|---|---|---|---|

| Virgin | Healed | Virgin | Healed | ||

| EP-CF-b | 69.7 ± 3.6 | 10.8 ± 0.8 | 0.78 ± 0.01 | 0.01 ± 0.01 | 0.4 ± 0.2 |

| EP-5PCL-CF-b | 123.7 ± 6.5 | 51.1 ± 9.3 | 0.97 ± 0.12 | 0.15 ± 0.04 | 14.8 ± 4.4 |

| EP-10PCL-CF-b | 150.2 ± 15.7 | 76.4 ± 26.9 | 0.98 ± 0.05 | 0.31 ± 0.08 | 31.5 ± 8.8 |

| Code | Composite | PCL Content [%wt] | Mending Process | Healing Parameters | Healing Efficiency [%] | Ref. |

|---|---|---|---|---|---|---|

| a | EP/PCL/CF | 5.4 | 30 min at 80 °C | Max load in delamination test | 43 ± 7 | This work |

| b | EP/PCL/CF | 9.9 | 30 min at 80 °C | Max load in delamination test | 50 ± 7 | This work |

| c | EP/PCL blend | 12.5 | 30 min at 80 °C | Max load in compact tension test | 2 ± 1 | [22] |

| d | EP/PCL electrospun | 15.0 | 10 min at 80 °C | Max load in tensile test | 45 ± 1 | [20] |

| e | EP/PCL blend | 20.0 | 30 min at 80 °C | Max load in quasi static test | 18 ± 5 | [50] |

| f | EP/PCL blend | 20.0 | 30 min at 80 °C | Fracture toughness in impact test | 27 ± 6 | [50] |

| g | EP/PCL blend | 22.2 | 30 min at 150 °C | Fracture toughness in tapered double cantilever beam (TDCB) test | 70 ± 25 | [14] |

| h | Epoxy/SMP/PCL | 23.3 | 30 min at 84 °C | Max load in single edge notched bending (SENB) test | 19 ± 1 | [51] |

| i | EP/PCL blend | 25.0 | 30 min at 80 °C | Max load in compact tension test | 11 ± 1 | [22] |

| l | EP/PCL blend | 37.5 | 30 min at 80 °C | Max load in compact tension test | 45 ± 4 | [22] |

| m | EP/PCL blend | 50.0 | 30 min at 80 °C | Max load in compact tension test | 62 ± 15 | [22] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cescato, R.; Rigotti, D.; Mahmood, H.; Dorigato, A.; Pegoretti, A. Thermal Mending of Electroactive Carbon/Epoxy Laminates Using a Porous Poly(ε-caprolactone) Electrospun Mesh. Polymers 2021, 13, 2723. https://doi.org/10.3390/polym13162723

Cescato R, Rigotti D, Mahmood H, Dorigato A, Pegoretti A. Thermal Mending of Electroactive Carbon/Epoxy Laminates Using a Porous Poly(ε-caprolactone) Electrospun Mesh. Polymers. 2021; 13(16):2723. https://doi.org/10.3390/polym13162723

Chicago/Turabian StyleCescato, Roberto, Daniele Rigotti, Haroon Mahmood, Andrea Dorigato, and Alessandro Pegoretti. 2021. "Thermal Mending of Electroactive Carbon/Epoxy Laminates Using a Porous Poly(ε-caprolactone) Electrospun Mesh" Polymers 13, no. 16: 2723. https://doi.org/10.3390/polym13162723

APA StyleCescato, R., Rigotti, D., Mahmood, H., Dorigato, A., & Pegoretti, A. (2021). Thermal Mending of Electroactive Carbon/Epoxy Laminates Using a Porous Poly(ε-caprolactone) Electrospun Mesh. Polymers, 13(16), 2723. https://doi.org/10.3390/polym13162723