Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method

Abstract

:1. Introduction

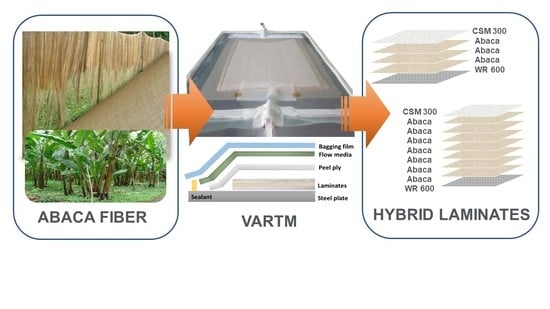

2. Materials and Methods

2.1. Materials

2.2. Composite Lamination Preparation

2.3. Characterization

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Tensile Properties

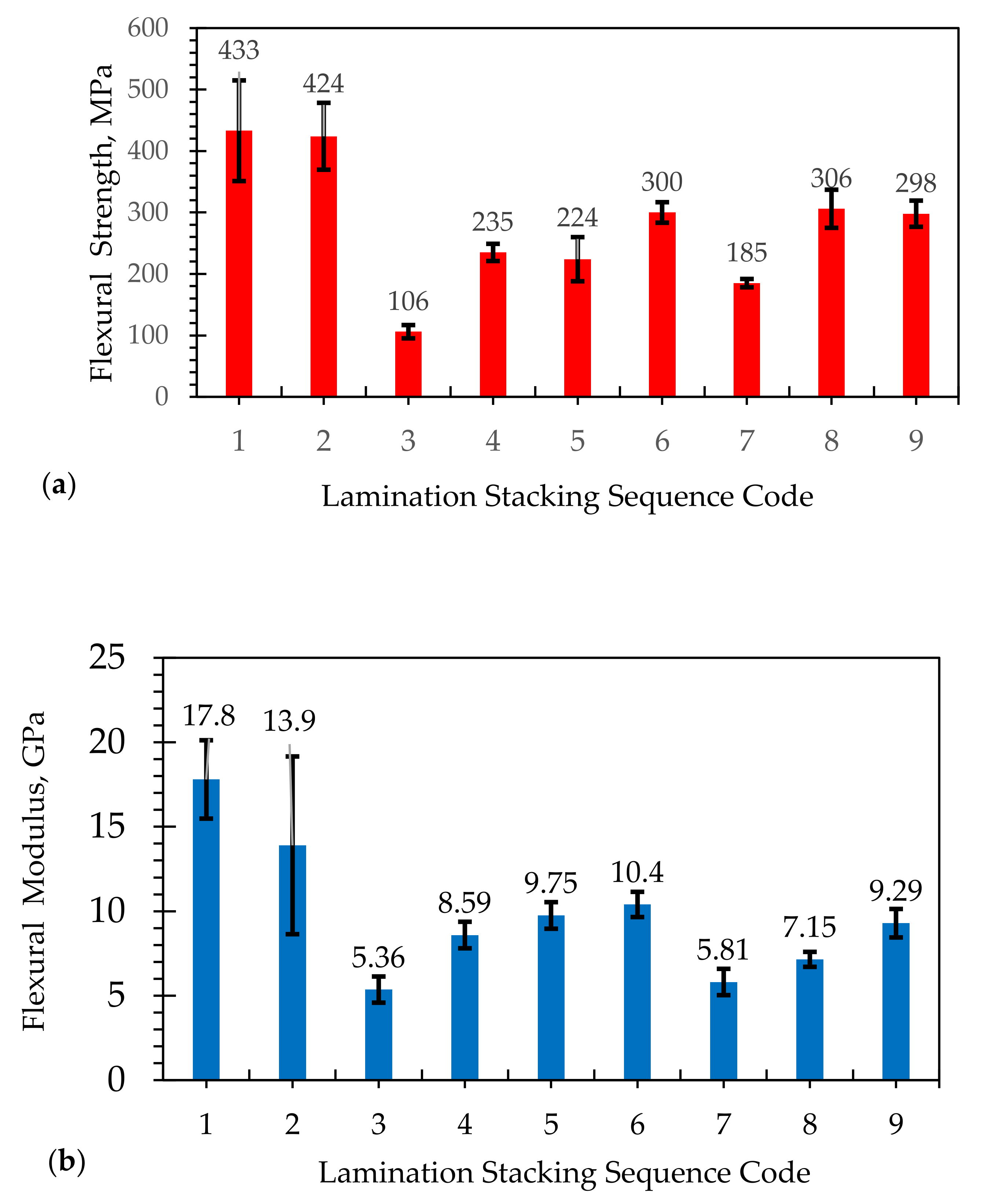

3.1.2. Flexural Properties

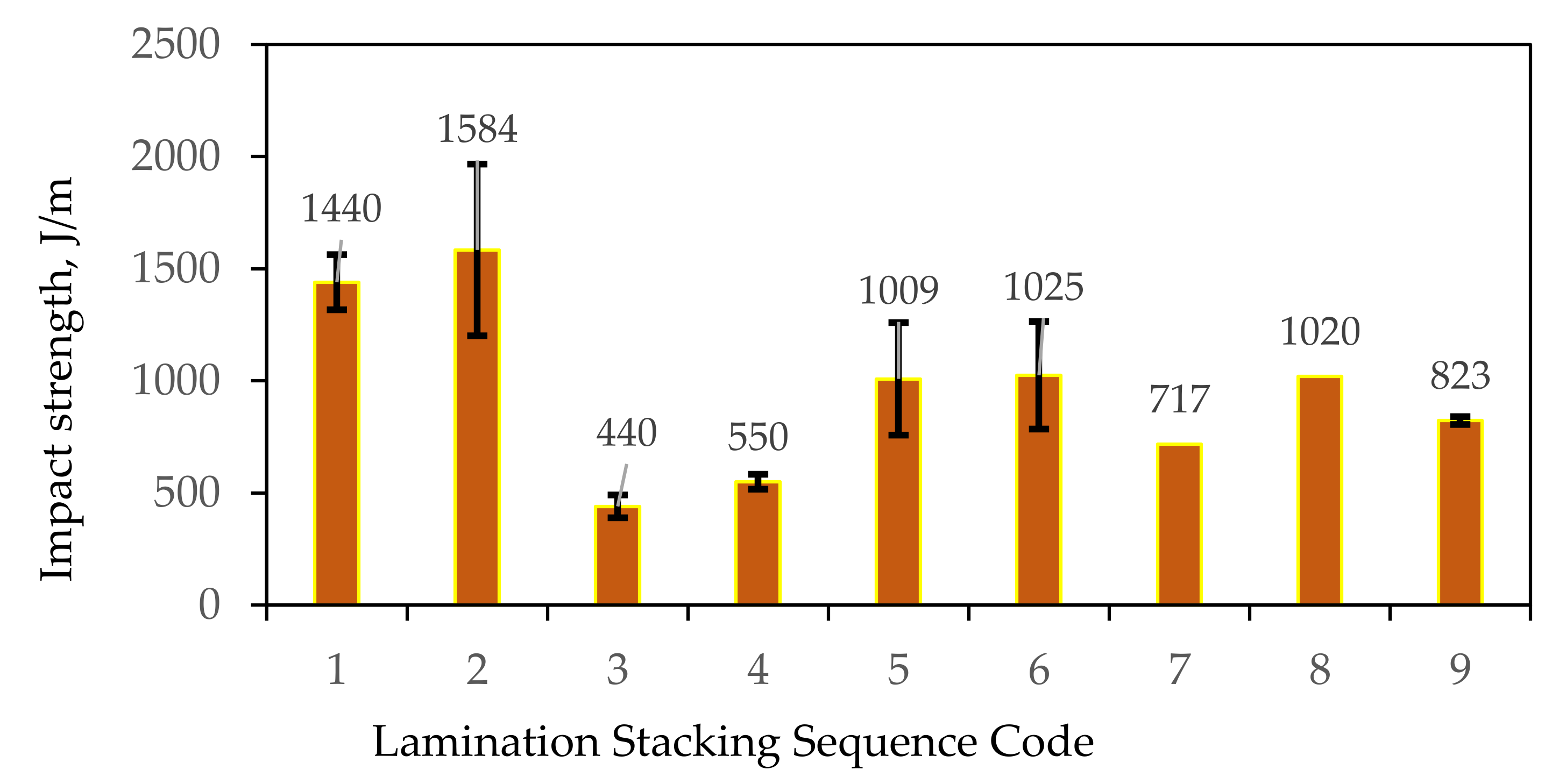

3.1.3. Impact Strength

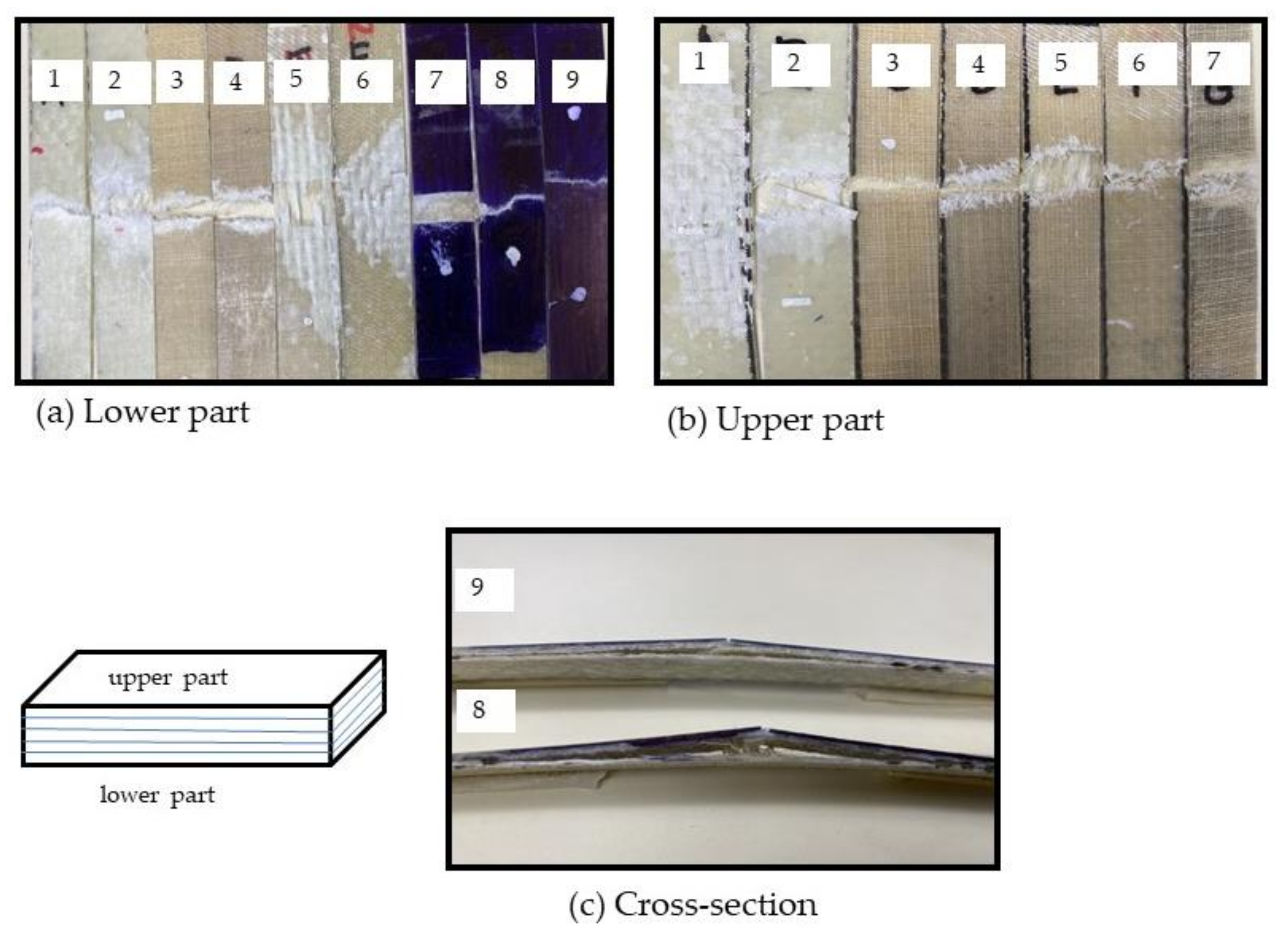

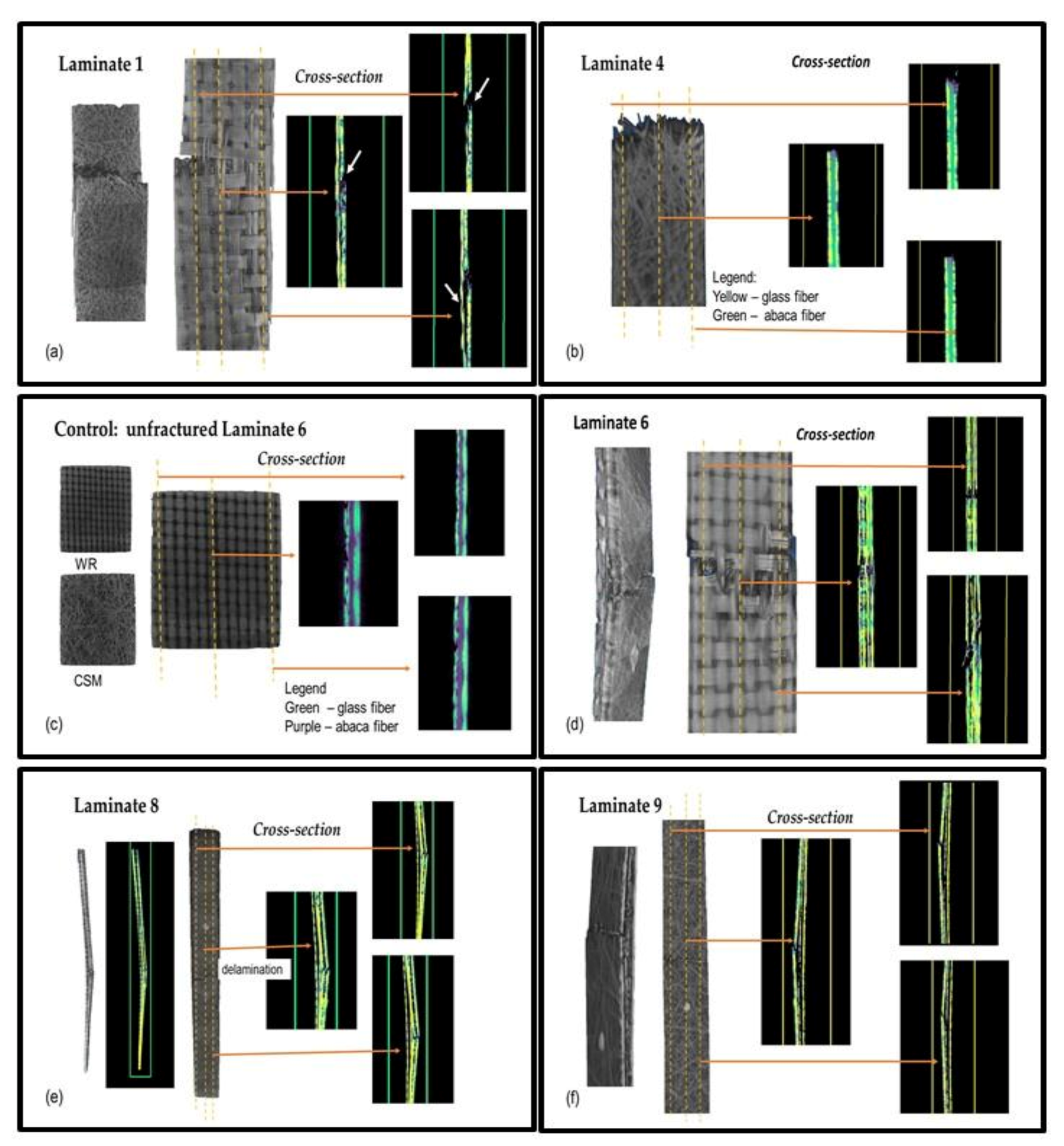

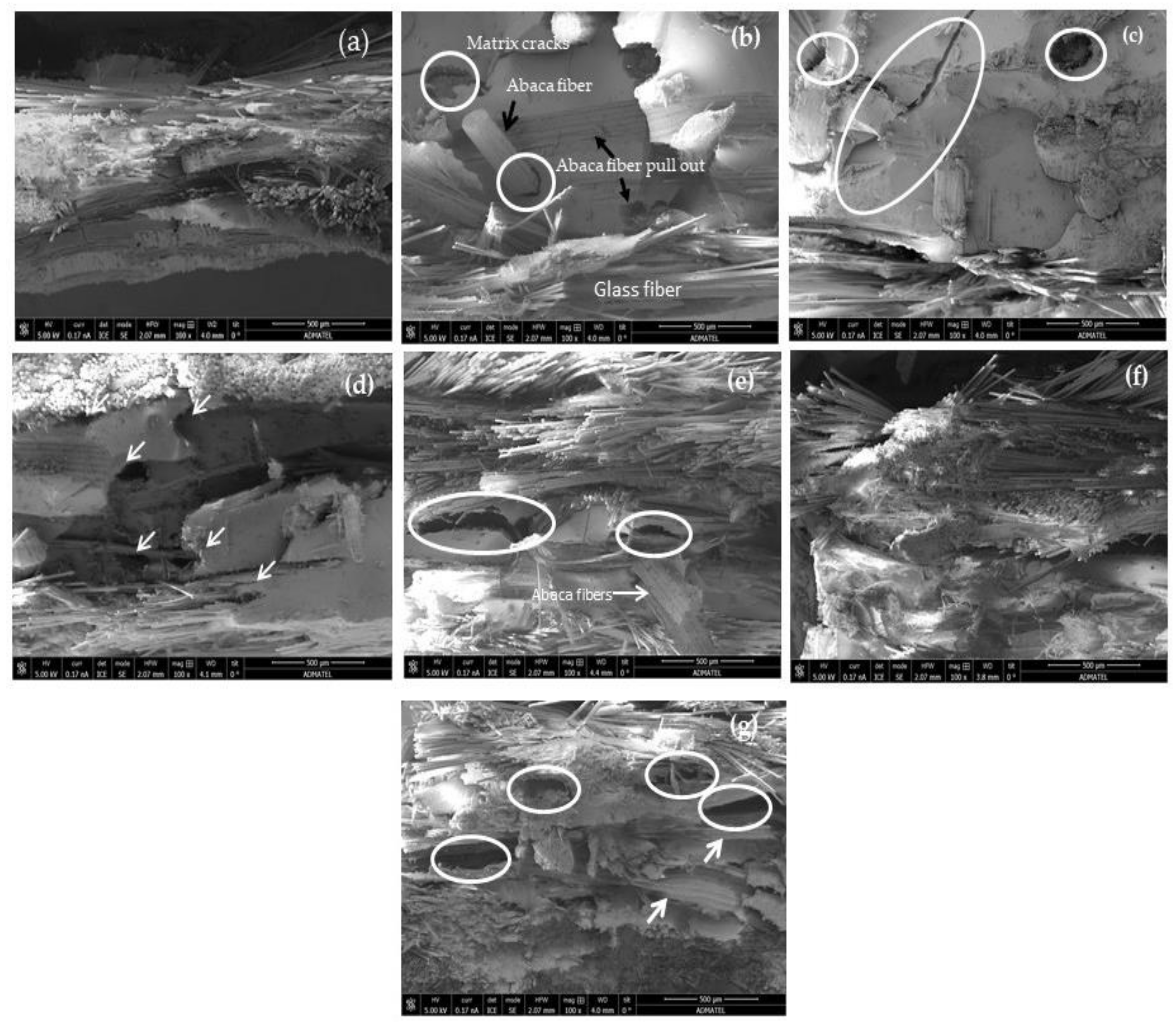

3.2. Failure Morphology of the Laminates

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Mai, Y.W.; Ye, L. Sisal Fiber and its Composite. Compos. Sci. Technol. 2000, 60, 2017–2055. [Google Scholar] [CrossRef]

- Salman, S.D.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. Kenaf/Synthetic and Kevlar/Cellulosic Fiber Reinforced Hybrid Composites: A Review. Bioresources 2015, 10, 8580–8603. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Sathish, S.; Gokulkumar, S.; Karthi, N.; Rajeshkumar, L.; Balaji, D.; Vigneshkumar, N.; Etlango, A.K. A review on natural fiber reinforced hybrid composites: Chemical treatments, manufacturing methods and potential applications. Mater. Today Proc. 2021, 45, 8080–8085. [Google Scholar] [CrossRef]

- Suriani, M.J.; Rapi, H.Z.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M. Delamination and manufacturing Deffects in natural Fiber-Reinforced Hybrid composite: A review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef]

- Wallenberger, F.T. Structural Silicate and Silica Glass Fibers. In Advanced Inorganic Fiber Processes, Structures, Properties, Applications; Wallenberger, F.T., Ed.; Kluwer Academic Publishers: New York, NY, USA, 1999; pp. 129–168. [Google Scholar]

- Wallenberger, F.T.; Watson, J.C.; Li, H. Glass Fibers @2001 ASM International. In ASM Handbook Volume 21—Composites; ASM International, Materials Park: Cleveland, OH, USA, 2001. [Google Scholar]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/Synthetic Fiber Reinforced Polymer Hybrid Composites: A Review. Carbohyd. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Kumar, S.; Gangil, B.; Prasad, L.; Patel, V.K. A Review on Mechanical Behavior of Bast-Glass Fibre Based Hybrid Polymer Composites. Mater. Today Proc. 2017, 4, 9576–9580. [Google Scholar] [CrossRef]

- Santhosh, S.; Bhanuprakash, N. A Review on Mechanical and Thermal Properties of Natural Fiber Reinforced Hybrid Composites. Int. Res. J. Eng. Technol. 2017, 4, 3053–3057. [Google Scholar]

- Kaliappan, P.; Kesavan, R.; Vijaya, R.B. Investigation on Effect of Fibre Hybridization and Orientation on Mechanical Behaviour of Natural Fibre Epoxy Composite. Bull. Mater. Sci. 2017, 40, 773–782. [Google Scholar] [CrossRef]

- Abdullah, A.L.K.; Abedin, M.Z.; Beg, M.D.H.; Pickering, K.L.; Khan, M.A. Study on the Mechanical Properties of Jute/Glass Fiber-Reinforced Unsaturated Hybrid Composites: Effect of Surface Modification by Ultraviolet Radiation. J. Reinf. Plast. Comp. 2006, 25, 575–588. [Google Scholar] [CrossRef]

- De Carvalho, L.H.; Cavalcanti, W.S.; De Lima, A.G.B. Water Sorption in Unsaturated Polyester Composites Reinforced Jute and Jute/Glass Fiber Fabrics: Modelling, Simulation and Experimentation. Polimeros 2010, 20, 78–83. [Google Scholar]

- Koradiya, S.B.; Paterl, J.P.; Parsania, P.H. Preparation and Physiochemial Study of Glass, Jute and Hybrid Glass-jute Bispenol-c-Based Epoxy Resin Composites. Polym-Plast Technol. 2010, 49, 1445–1449. [Google Scholar] [CrossRef]

- Srivastav, A.K.; Behera, M.K.; Ray, B.C. Loading Rate Sensitivity of Jute/Glass Hybrid Reinforced Epoxy Composites: Effect of Surface Modifications. J. Reinf. Plast. Comp. 2007, 26, 851–860. [Google Scholar] [CrossRef]

- Abhistek, M.R.; Suresh, P.M.; Sreedhar Murthy, H.S. Evaluation of Mechanical Properties of Jute/E-Glass Epoxy Hybrid Composites by Varying Fibre Loading with and without Shear Thickening Fluid. Mater. Today Proc. 2007, 4, 10858–10862. [Google Scholar] [CrossRef]

- Arasu, P.M.; Karthikayam, A.; Venkatachalam, R. Mechanical and Thermal Behavior of Hybrid Glass/Jute Fiber Reinforced Composites with Epoxy/Polyester Resin. Polimery 2019, 64, 504–508. [Google Scholar] [CrossRef]

- Reddy, G.V.; Rani, R.T.S.; Rao, K.C.; Naidu, S.V. Flexural, Compressive, and Interlaminar Shear Strength Properties of Kapok/Glass Composites. J. Reinf. Plast. Comp. 2009, 28, 1665–1677. [Google Scholar] [CrossRef]

- Reddy, G.V.; Naidu, S.V. Kapok/Glass Polyester Hybrid Composites: Tensile and Hardness Properties. J. Reinf. Plast. Comp. 2008, 27, 1775–1787. [Google Scholar] [CrossRef]

- John, K.; Naidu, S.V. Chemical Resistance of Sisal/Glass Reinforced Unsaturated Hybrid Composites. J. Reinf. Plast. Comp. 2008, 28, 373–376. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, H. Mechanical Property Evaluation of Sisal-Jute-Glass Fiber Reinforced Polyester. Compos. B. Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Natarajan, N.; Bharathidhasan, S.; Thanigaivelan, R.; Suresh, P. Sisal Fiber/Glass Fiber Nano Composite: The Tensile and Compressive Properties. In Proceedings of the 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, India, 12–14 December 2014; pp. 103-1–103-6. [Google Scholar]

- Arpitha, G.R.; Sanjay, M.R.; Naik, L.L.; Yogesha, B. Mechanical Properties of Epoxy Based Hybrid Composites with Sisal/SIC/Glass Fibers. Int. J. Eng. Res. Gen. Sci. 2014, 2, 398–405. [Google Scholar]

- Mandal, S.; Alam, S.; Varma, I.K.; Maiti, S.N. Studies on Bamboo/Glass Fiber Reinforced USP and VE Resin. J. Reinf. Plast. Compos. 2010, 29, 43–51. [Google Scholar] [CrossRef]

- Devi Uma, L.; Bhagawan, S.S.; Thomas, S. Dynamic Mechanical Analysis of Pineapple Leaf/Glass Hybrid Fiber Reinforced Polyester Composites. Polym. Compos. 2010, 31, 956–965. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and Interfacial Properties of Unidirectional Flax/Glass Fiber Reinforced Composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Portella, E.H.; Romanzini, D.; Angrizani, C.C.; Amico, S.C.; Zattera, A.J. Influence of Stacking Sequence on the Mechanical and Dynamic Mechanical Properties of Cotton/Glass Fiber Reinforced Polyester Composites. Mater. Res. 2016, 19, 542–547. [Google Scholar] [CrossRef] [Green Version]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fudholi, A. A review on natural fibers for development of eco-friendly biocomposite: Characterustucs and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Philippine Abaca Helps in Global Environment Conservation. Available online: http://www.philfida.da.gov.ph/index.php/archived-articles/19-philippine-abaca-helps-in-global-environment-conservation (accessed on 8 December 2020).

- Bledzki, A.K.; Mamun, A.A.; Faruk, O. Abaca Fibre Reinforced PP Composites and Comparison with Jute and Flax Fibre and Flax Fibre PP Composites. Polym. Lett. 2007, 1, 755–762. [Google Scholar] [CrossRef]

- Vilaseca, F.; Gonzales, A.V.; Herrera-Franco, P.J.; Pelach, M.A.; Lopez, J.P.; Mutje, P. Biocomposites from Abaca Strands and Polypropylene, Part 1: Evaluation of the Tensile Properties. Bioresour. Technol. 2010, 101, 387–395. [Google Scholar] [CrossRef]

- Girones, J.; Lopez, J.P.; Vilaseca, F.; Bayer, J.; Herrera-Franco, P.J.; Mutje, P. Biocomposites from Musa Textilis and Polypropylene: Evaluation of Flexural Properties and Impact Strength. Compos. Sci. Tech. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Paglicawan, M.A.; Rodriquez, M.P.; Celorico, J.R. Thermomechanical Properties of Woven Abaca Reinforced Nanocomposites. Polym. Compos. 2020, 41, 1763–1773. [Google Scholar] [CrossRef]

- Paglicawan, M.A.; Basilia, B.A.; Kim, B.S. Water Uptake and Tensile Properties of Plasma Treated Abaca Reinforced Epoxy Composite. Compos. Res. 2013, 26, 165–169. [Google Scholar] [CrossRef] [Green Version]

- Paglicawan, M.A.; Kim, B.S.; Basilia, B.A.; Emolaga, C.S.; Marasigan, D.D.; Maglalang, P.E.C. Plasma-Treated Abaca Fabric/Unsaturated Polyester Composite Fabricated by Vacuum-Assisted Resin Transfer Molding. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 241–246. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Zhang, X.; Takagi, H.; Yang, Z.; Wang, D. Effect of Chemical Treatments on Transverse Thermal Conductivity of Unidirectional Abaca Fiber/Epoxy Composite. Compos. Part. A Appl. Sci. Manuf. 2014, 66, 227–236. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I.N. Effect of Alkali Treatment on Interfacial Bonding in Abaca Fiber Reinforced Composites. Compos. Part. A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S.B. Effect of Alkali Treatment on Surface Morphology of Abaca Fiber. Mater. Today Proc. 2017, 8993–8996. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S.B. Experimental Investigation of Surface Modified Abaca Fibre. Mater. Sci. Forum. 2020, 978, 291–295. [Google Scholar] [CrossRef]

- Vijaya, R.B.; Manickavasagam, V.M.; Elanchezhian, C.; Vinodh, K.C.; Karthik, S.; Saravanan, K. Determination of Mechanical Properties of Intra-layer Abaca-Jute-Glass Fiber Reinforced Composite. Mater. Des. 2014, 60, 643–652. [Google Scholar] [CrossRef]

- Xia, C.; Shi, S.Q.; Cai, L.; Hua, J. Property Enhancement of Kenaf Fiber Composites by means of Vacuum-Assisted Resin Transfer Molding (VARTM). Holzforschung 2015, 69, 307–312. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Kokan, S.J.; Raja, R.N.; Sathyanarayan, R.; Elanchezhian Prasad, A.R.; Prasad, V.M.; Manickayasagam, V.M. Evaluation of Mechanical Properties of Abaca-Jute-Glass Fibre Reinforced Epoxy Composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Prabhakaran, R.D.; Toftegaard, H.; Markussen, C.M.; Madsen, B. Experimental and Theoretical Assessment of Flexural Properties of Hybrid Natural Fibre Composites. Acta Mech. 2014, 225, 2775–2782. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Santulli, C.; Sarazini, F.; Valente, M. Effect of Loading-Unloading Cycles on Impact-Damaged Jute/Glass Hybrid Laminates. Polym. Compos. 2009, 30, 1879–1887. [Google Scholar] [CrossRef]

| Lamination Stacking Sequence Code | Stacking Sequence | % VAF (Abaca Fiber) | %VGF (Glass Fiber) | Thickness (mm) |

|---|---|---|---|---|

| 1 | (CSM450)(CSM300) (WR600) | 0 | 53 | 1.50 |

| 2 | (CSM450)(WR600) (CSM450) | 0 | 62 | 1.68 |

| 3 | (CSM450)(abaca)7 | 21 | 12 | 2.27 |

| 4 | (CSM450)(abaca)7 (CSM300) | 18 | 19 | 2.67 |

| 5 | (WR600)(abaca)7 (CSM300) | 17 | 18 | 2.58 |

| 6 | (WR600)(abaca)3(CSM300) | 10 | 18 | 1.81 |

| 7 | (CSM300)(CSM450)(abaca)3 (WR600)(abaca) | 8 | 29 | 3.1 |

| 8 | (CSM300)(CSM450)(abaca)2 (WR600)(abaca) | 7 | 31 | 2.95 |

| 9 | (CSM450)(abaca)3 (CSM300)(abaca)(WR600)(CSM300) | 8 | 40 | 3.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paglicawan, M.A.; Emolaga, C.S.; Sudayon, J.M.B.; Tria, K.B. Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers 2021, 13, 2719. https://doi.org/10.3390/polym13162719

Paglicawan MA, Emolaga CS, Sudayon JMB, Tria KB. Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers. 2021; 13(16):2719. https://doi.org/10.3390/polym13162719

Chicago/Turabian StylePaglicawan, Marissa A., Carlo S. Emolaga, Johanna Marie B. Sudayon, and Kenneth B. Tria. 2021. "Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method" Polymers 13, no. 16: 2719. https://doi.org/10.3390/polym13162719

APA StylePaglicawan, M. A., Emolaga, C. S., Sudayon, J. M. B., & Tria, K. B. (2021). Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers, 13(16), 2719. https://doi.org/10.3390/polym13162719