A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formation Mechanism of Dual-Scale Infiltration Flow

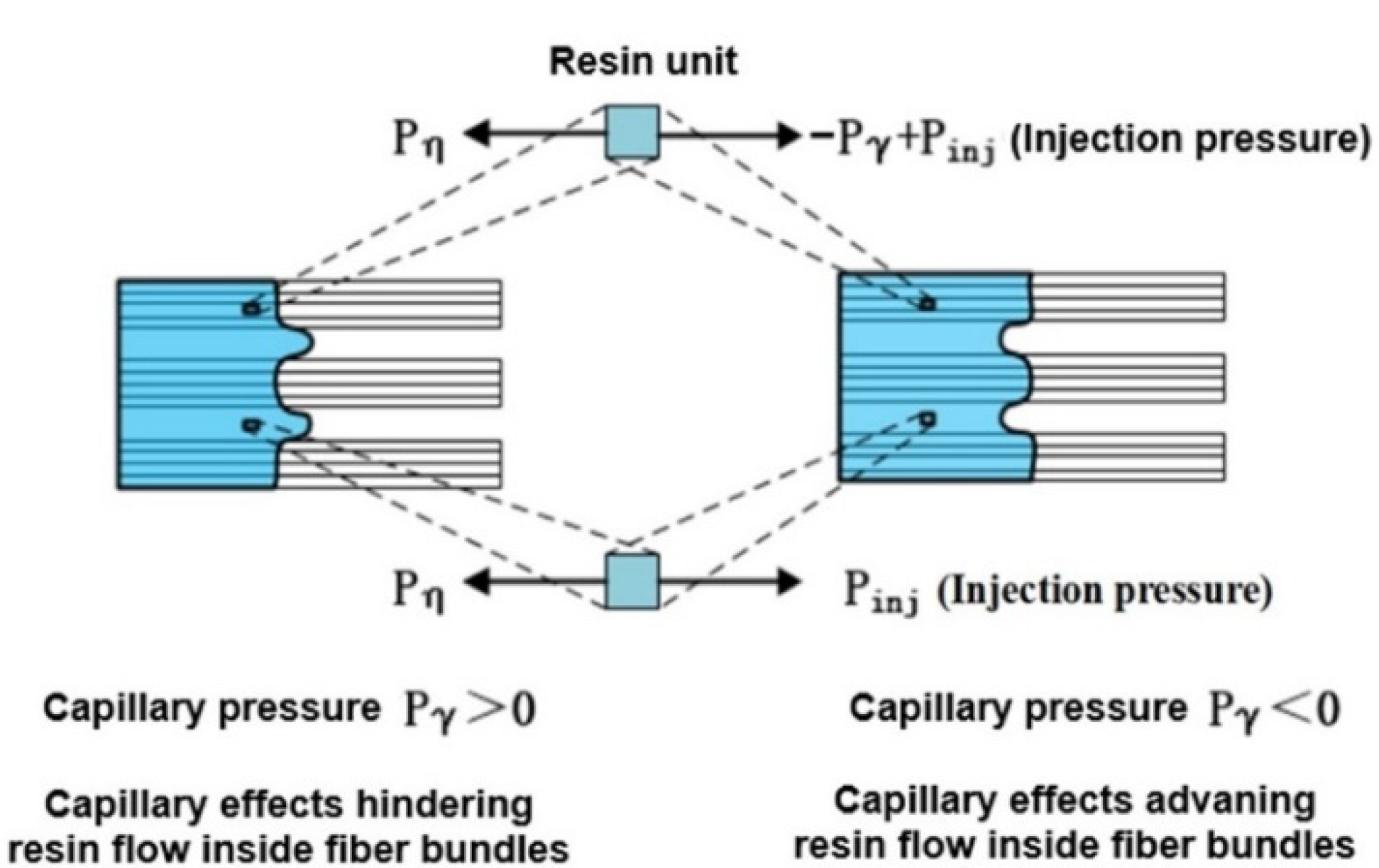

2.2. Mechanism of Capillary Pressure

2.3. Numerical Simulation

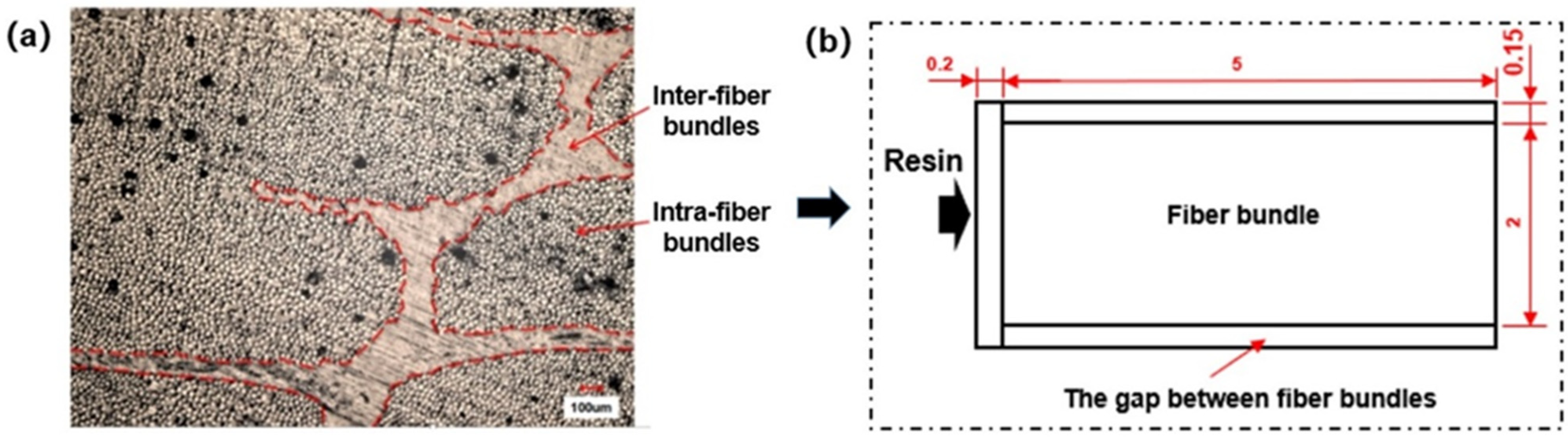

2.3.1. Physical Model

2.3.2. Mathematical Modeling

Control Equation between Fiber Bundles:

Control Equation in Fiber Bundles:

2.3.3. Level Set Tracking

2.3.4. Boundary Conditions

2.4. Experimentation

2.4.1. Constant Flow Rate Infiltration Flow Characterization

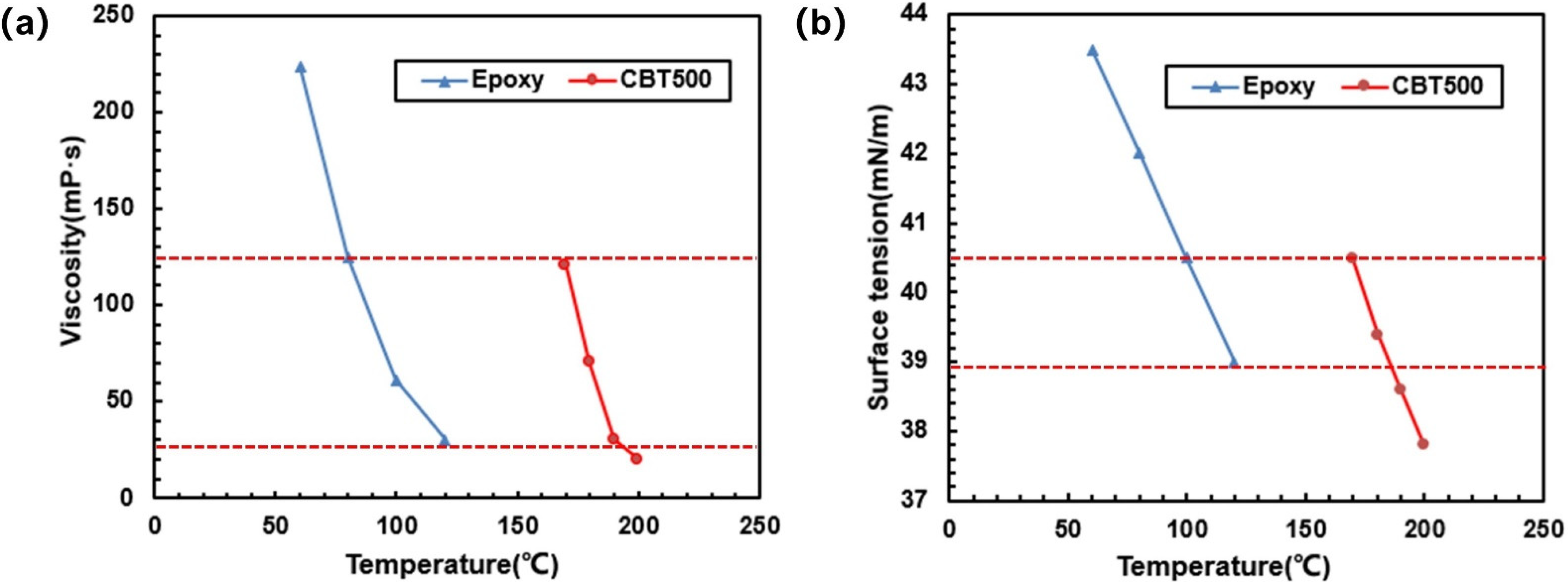

Materials

Experimental Platform

Experimental Principle

2.4.2. Composites Preparation and Characterization

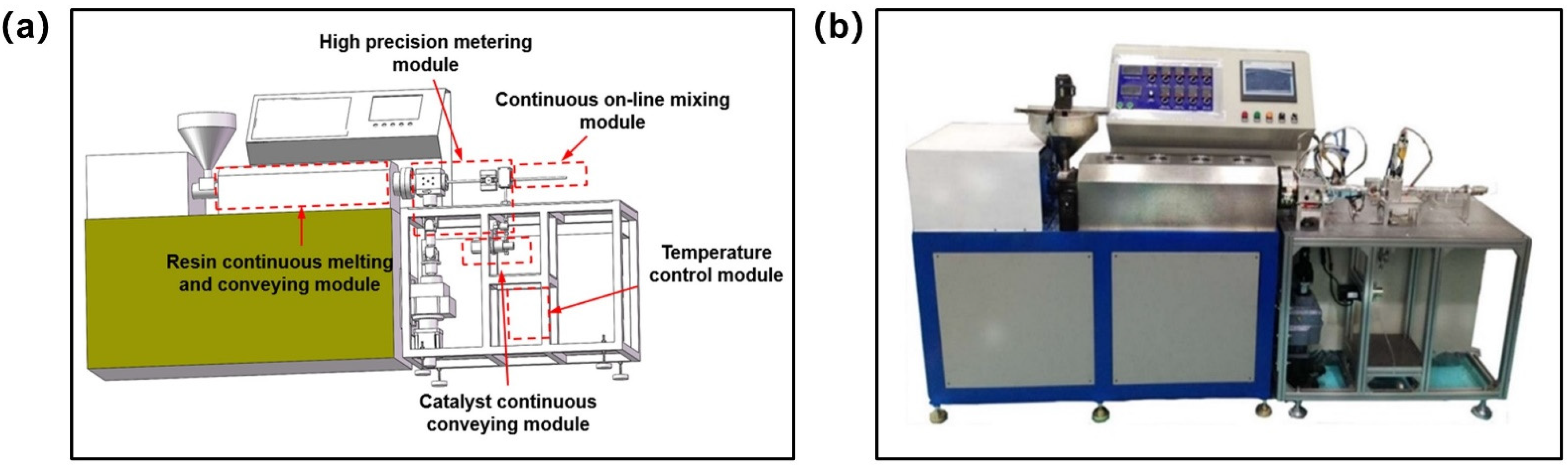

In Situ Injection Molding Device

Preparation and Characterization of Composite Materials

3. Results and Discussion

3.1. Simulation Result Analysis

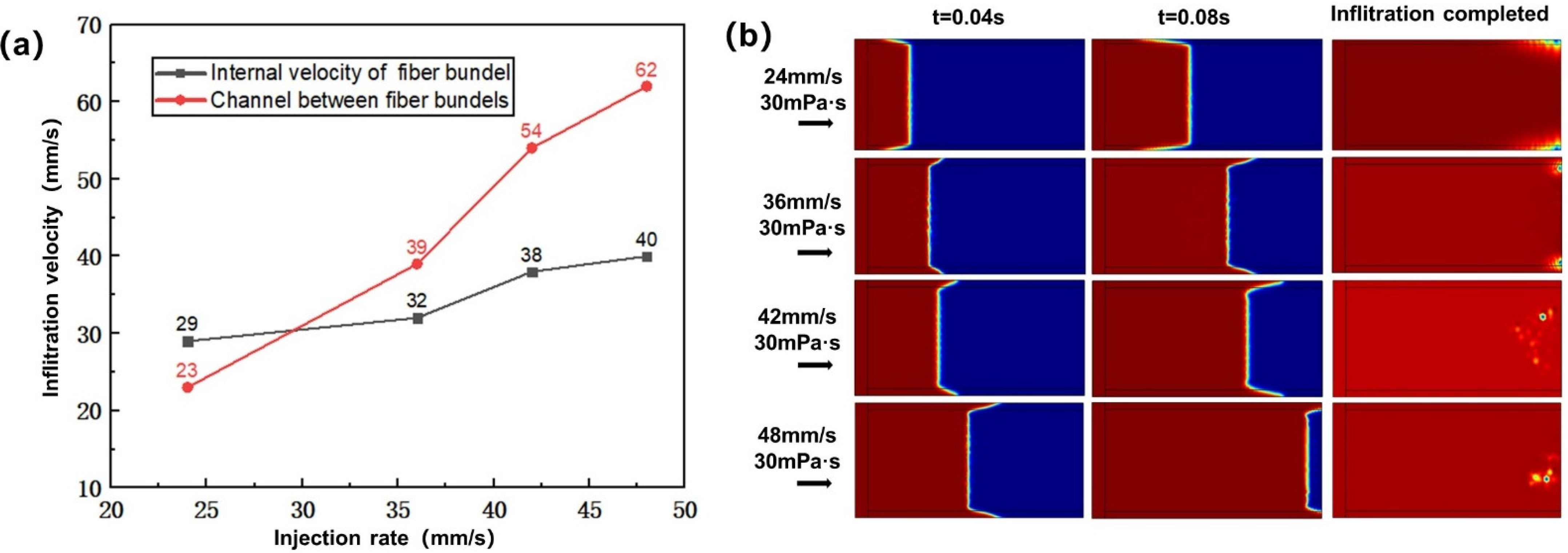

3.1.1. Influence of Injection Rate on Infiltration Flow

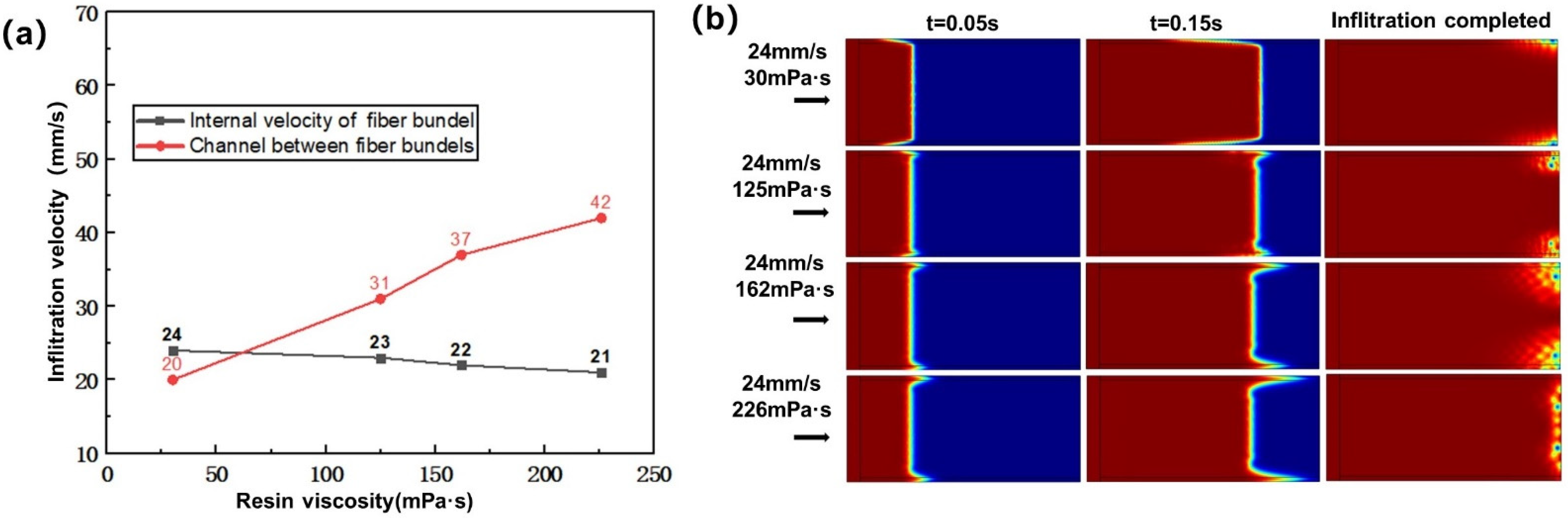

3.1.2. Influence of Resin Viscosity on Infiltration Flow

3.1.3. Influence of Fiber Volume Fraction on Infiltration Flow

3.1.4. Influence of Capillary Number on Infiltration Flow

3.2. Experimental Results Analysis

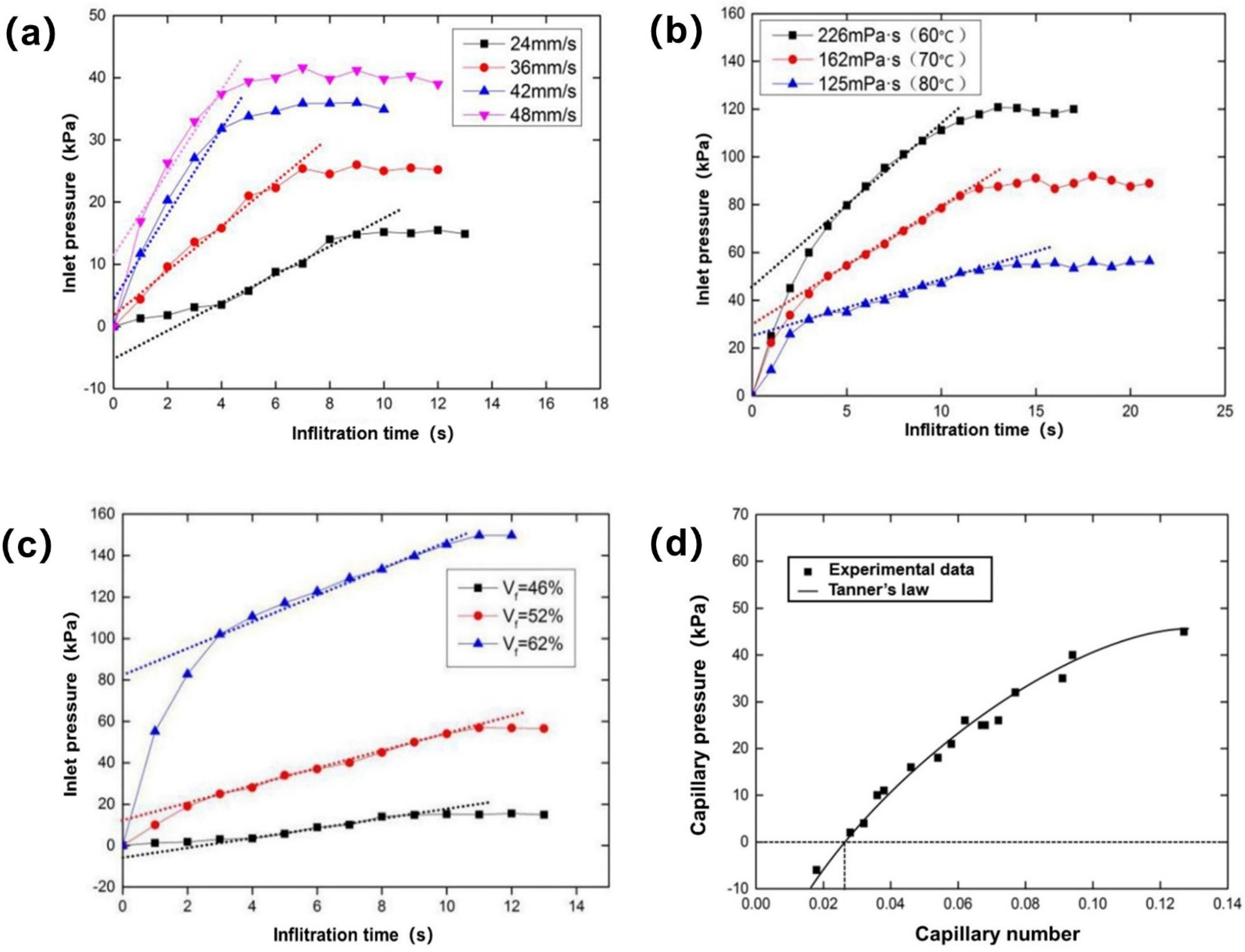

3.2.1. Influence of Injection Rate on Capillary Pressure of Infiltration Flow

3.2.2. Influence of Resin Viscosity on Capillary Pressure of Infiltration Flow

3.2.3. Influence of Fiber Volume Fraction on Capillary Pressure of Infiltration Flow

3.2.4. Influence of Capillary Number on Capillary Pressure and Flow Balance of Infiltration Flow

3.3. Properties of the Composites

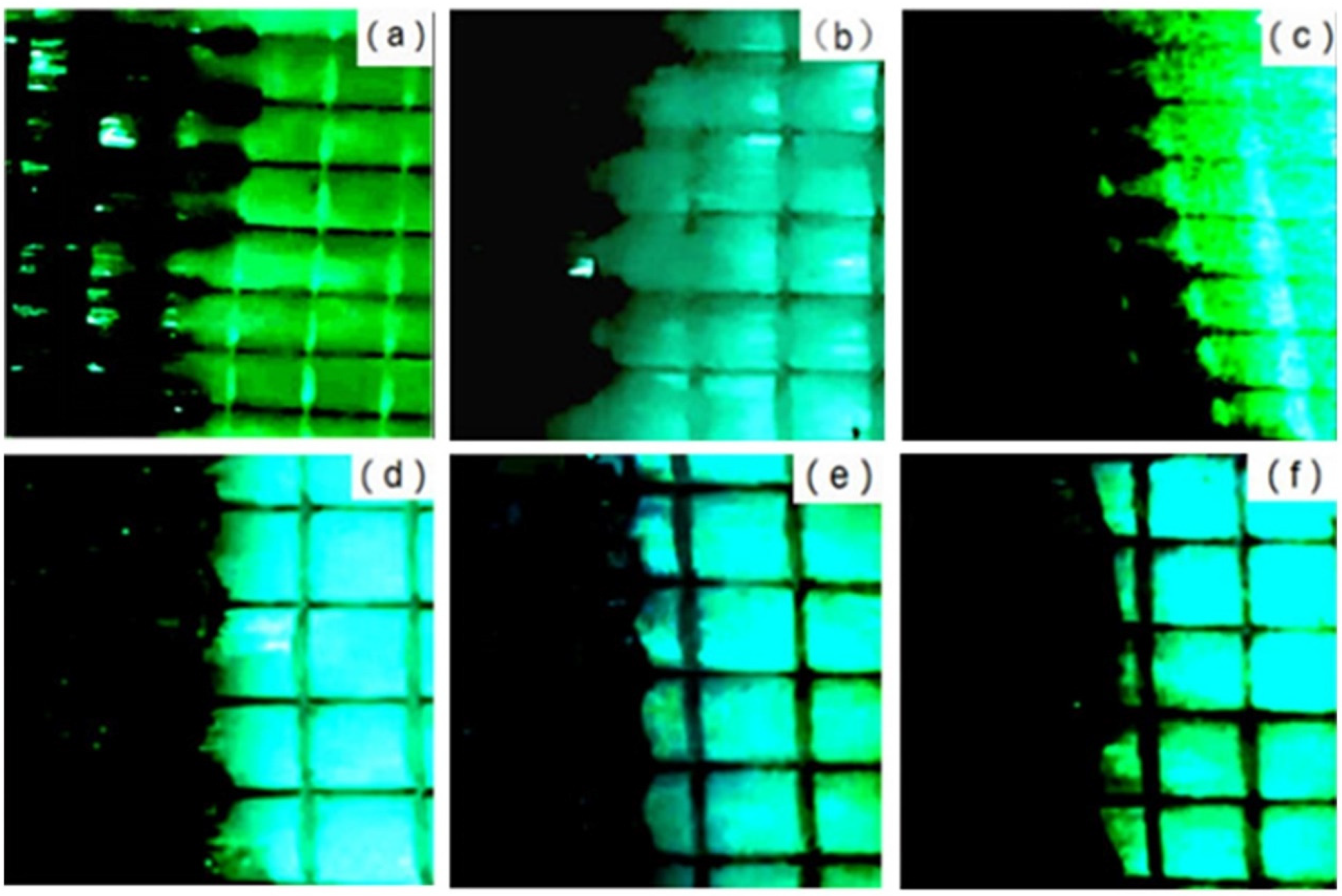

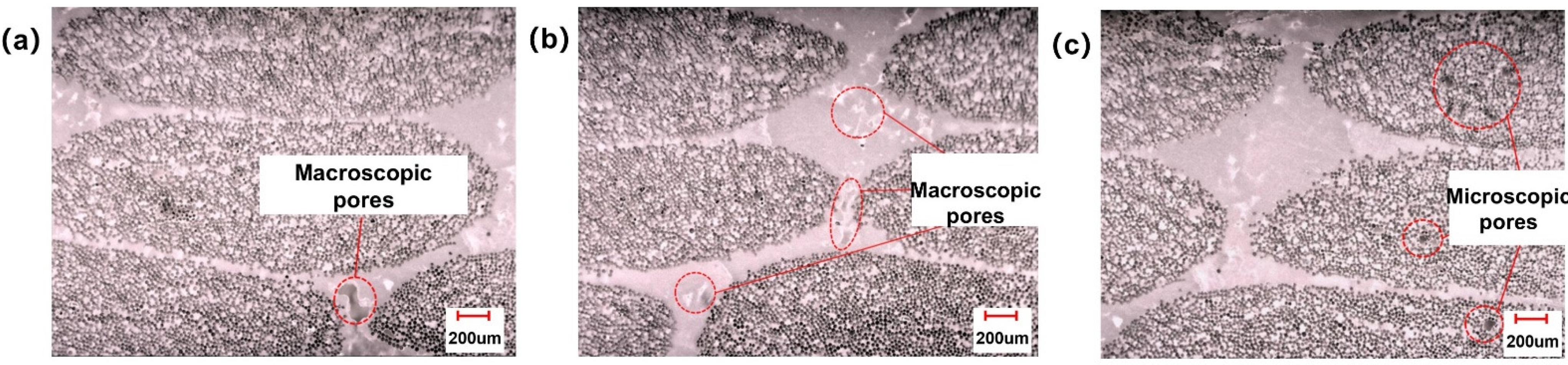

3.3.1. Pore Distribution

3.3.2. Interlaminar Shear Strength

4. Conclusions

- The analysis of numerical simulation results shows that the injection rate and viscosity of resin have significant influence on the infiltration flow. With the increase of fiber volume fraction and capillary number, both the capillary pressure and the flow resistance in the fiber bundle increases, and the flow resistance in the fiber bundle increases. The flow velocity in the channel between fiber bundles is faster, which results in the flow front being unable to flow forward flush.

- Through the in situ injection molding dual-scale infiltration experiment, the influence of process parameters on capillary pressure and flow balance in dual-scale infiltration flow were obtained. The results show that the numerical model can accurately reflect the unbalanced osmotic flow between and within fiber bundles caused by the changes of injection rate, resin viscosity, fiber volume fraction and capillary number.

- The infiltration flow velocity in inter- and intra-fiber bundles can be efficiently tuned by the capillary number, which is mainly determined by the injection rate for a specified resin system.

- Pore distribution and interlaminar shear strength of continuous glass fiber reinforced thermoplastic pCBT matrix composites are affected by capillary number. When the capillary number continues to increase, the pores in fiber bundles gradually increase, while the pores in the channels between fiber bundles gradually decrease. Then the interlaminar shear strength increases gradually and then decreases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, A.; Bao, L. Manufacture of Fabric Reinforced Thermoplastic Composites with High Fiber Volume Fraction. In Silk, Protective Clothing and Eco-Textiles; Bai, L., Chen, G.Q., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2013; Volume 796, pp. 301–305. [Google Scholar]

- Khurshid, M.F.; Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Recent Developments in The Processing of Waste Carbon Fibre for Thermoplastic Composites—A Review. J. Compos. Mater. 2020, 54, 1925–1944. [Google Scholar] [CrossRef]

- Gizynski, M.; Romelczyk-Baishya, B. Investigation of Carbon Fiber-Reinforced Thermoplastic Polymers Using Thermogravi-metric Analysis. J. Thermoplast. Compos. Mater. 2021, 34, 126–140. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Friedrich, K. Carbon Fiber Reinforced Thermoplastic Composites for Future Automotive Applications. In VIII International Conference on Times of Polymers and Composites: From Aerospace to Nanotechnology, Proceedings of the 8th International Conference on Times of Polymers (TOP) & Composites, Naples, Italy, 19–23 June 2016; D’Amore, A., Acierno, D., Grassia, L., Eds.; American Institut of Physics: Melville, NY, USA, 2016; Volume 1736. [Google Scholar]

- Wada, T.; Churei, H.; Yokose, M.; Iwasaki, N.; Takahashi, H.; Uo, M. Application of Glass Fiber and Carbon Fiber-Reinforced Thermoplastics in Face Guards. Polymers 2021, 13, 18. [Google Scholar] [CrossRef] [PubMed]

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight Concrete—From Basics to Innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, Z.; Wang, S.; Zhang, Z. Energy Saving Latent Heat Storage and Environmental Friendly Humidity-Controlled Materials for Indoor Climate. Renew. Sustain. Energy Rev. 2012, 16, 3136–3145. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of Fibre Reinforced Thermoplastic Composites. Int. Mater. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Abt, T.; Sánchez-Soto, M. A Review of the Recent Advances in Cyclic Butylene Terephthalate Technology and its Composites. Crit. Rev. Solid State Mater. Sci. 2017, 42, 173–217. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, M. Flax (Linum usitatissimum L.) Fibre Reinforced Polymer Composite Materials: A Review on Preparation, Properties and Prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Barick, A.K.; Tripathy, D.K. Preparation, Characterization and Properties of Acid Functionalized Multi-Walled Carbon Nanotube Reinforced Thermoplastic Polyurethane Nanocomposites. Mater. Sci. Eng. B 2011, 176, 1435–1447. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Bersee, H.E.N. Reactive Processing of Textile Fiber-Reinforced Thermoplastic Composites—An Overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Zereshkian, A.; Sain, M. Preparation and Characterization of Wheat Straw Fibers for Reinforcing Application in Injection Molded Thermoplastic Composites. Bioresour. Technol. 2006, 97, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Saiter, J.-M.; Esposito, A.; Dobircau, L.; Turner, J.A.; Adhikari, R. Synthetic Polymer Composites Reinforced by Bamboo Fibers. Macromol. Symp. 2013, 327, 114–120. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Bersee, H.E.N.; Jager, W.F.; Picken, S.J. Optimisation of Anionic Polyamide-6 for Vacuum Infusion of Thermoplastic Composites: Choice of Activator and Initiator. Compos. Part A Appl. Sci. Manuf. 2006, 37, 949–956. [Google Scholar] [CrossRef]

- Hao, K.; Wang, Z.; Zhou, L. Mechanical Properties of Thermoplastic Composites via In-situ Polymerization from Cyclic Oligomers. In Advanced Engineering Materials III, Pts 1–3; Bu, J., Kim, Y.H., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2013; Volume 750–752, pp. 7–10. [Google Scholar]

- Yan, C.; Li, H.; Zhang, X.; Zhu, Y.; Fan, X.; Yu, L. Preparation and Properties of Continuous Glass Fiber Reinforced Anionic Polyamide-6 Thermoplastic Composites. Mater. Des. 2013, 46, 688–695. [Google Scholar] [CrossRef]

- Boros, R.; Rajamani, P.K.; Kovács, J.G. Thermoplastic Overmolding onto Injection-Molded and In Situ Polymerization-Based Polyamides. Materials 2018, 11, 2140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aliaga, C.; Castillo, C.; Gutierrez, D.; Otaduy, M.A.; Lopez-Moreno, J.; Jarabo, A. An Appearance Model for Textile Fibers. Comput. Graph. Forum 2017, 36, 35–45. [Google Scholar] [CrossRef]

- Yeager, M.; Hwang, W.R.; Advani, S. Prediction of Capillary Pressure for Resin Flow within Fiber Unit Cells; Xiao, X., Loos, A., Liu, D., Eds.; Destech Publications, Inc.: Lancaster, UK, 2015. [Google Scholar]

- Salceda-Delgado, G.; Van Newkirk, A.; Antonio-Lopez, J.E.; Martinez-Rios, A.; Schulzgen, A.; Amezcua-Correa, R. Optical Capillary Fiber Mode Interferometer for Pressure Sensing. IEEE Sens. J. 2020, 20, 2253–2260. [Google Scholar] [CrossRef]

- Varley, R.J.; Dao, B.; Pillsbury, C.; Kalista, S.J.; Jones, F.R. Low-Molecular-Weight Thermoplastic Modifiers as Effective Healing Agents in Mendable Epoxy Networks. J. Intell. Mater. Syst. Struct. 2014, 25, 107–117. [Google Scholar] [CrossRef]

- Vierle, M.; Steinhauser, N.; Nuyken, O.; Obrecht, W. Preparation of EPDM/SAN Dry Blends by Reactive Processing. Macromol. Mater. Eng. 2003, 288, 209–218. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, X.; Ma, J. Capillary Effect in the Impregnation of Jute Fiber Mat Reinforced Polypropylene Composites. J. Compos. Mater. 2014, 48, 447–453. [Google Scholar] [CrossRef]

- Verrey, J.; Michaud, V.; Månson, J.-A.E. Dynamic Capillary Effects in Liquid Composite Moulding with Non-Crimp Fabrics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 92–102. [Google Scholar] [CrossRef]

- Kurihara, K.; Hokari, R.; Takada, N. Capillary Effect Enhancement in a Plastic Capillary Tube by Nanostructured Surface. Polymers 2021, 13, 628. [Google Scholar] [CrossRef] [PubMed]

- Kovačič, A.; Ren, Z. On the Porosity of Advanced Pore Morphology Structures. Compos. Struct. 2016, 158, 235–244. [Google Scholar] [CrossRef]

- Karabutov, A.A.; Podymova, N.B.; Cherepetskaya, E.B. Measuring the Dependence of the Local Young’s Modulus on the Porosity of Isotropic Composite Materials by a Pulsed Acoustic Method Using a Laser Source of Ultrasound. J. Appl. Mech. Tech. Phys. 2013, 54, 500–507. [Google Scholar] [CrossRef]

- Gu, J.; Wu, G.; Zhang, Q. Effect of Porosity on the Damping Properties of Modified Epoxy Composites Filled with Fly Ash. Scr. Mater. 2007, 57, 529–532. [Google Scholar] [CrossRef]

- Kim, K.-B.; Hsu, D.K.; Barnard, D.J. Estimation of Porosity Content of Composite Materials by Applying Discrete Wavelet Transform to Ultrasonic Backscattered Signal. NDT E Int. 2013, 56, 10–16. [Google Scholar] [CrossRef]

- He, Y.; Li, Y.; Hao, X.; Zhou, J.; Liu, S. Micro-Flow Sensor for Continuous Resin Fluidity Monitoring between Fibers. Sens. Actuators B Chem. 2019, 282, 177–186. [Google Scholar] [CrossRef]

- Yeager, M.; Simacek, P.; Advani, S.G. Role of Fiber Distribution and Air Evacuation Time on Capillary Driven Flow into Fiber Tows. Compos. Part A Appl. Sci. Manuf. 2017, 93, 144–152. [Google Scholar] [CrossRef]

- Beard, J.D.; Rouholamin, D.; Farmer, B.L.; Evans, K.E.; Ghita, O.R. Control and Modelling of Capillary Flow of Epoxy Resin in Aligned Carbon Nanotube Forests. RSC Adv. 2015, 5, 39433–39441. [Google Scholar] [CrossRef] [Green Version]

- Zingraff, L.; Michaud, V.; Bourban, P.-E.; Månson, J.-A.E. Resin Transfer Moulding of Anionically Polymerised Polyamide 12. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1675–1686. [Google Scholar] [CrossRef]

- Leclerc, J.S.; Ruiz, E. Porosity Reduction Using Optimized Flow Velocity in Resin Transfer Molding. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1859–1868. [Google Scholar] [CrossRef]

- Lawrence, J.M.; Neacsu, V.; Advani, S.G. Modeling the Impact of Capillary Pressure and Air Entrapment on Fiber Tow Saturation during Resin Infusion in LCM. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1053–1064. [Google Scholar] [CrossRef]

- LeBel, F.; Fanaei, A.E.; Ruiz, E.; Trochu, F. Experimental Characterization by Fluorescence of Capillary Flows in Dual-Scale Engineering Fabrics. Text. Res. J. 2013, 83, 1634. [Google Scholar] [CrossRef]

- Härter, F.V.; Souza, J.A.; Isoldi, L.A.; Dos Santos, E.D.; Amico, S.C. Transverse Permeability Determination and Influence in Resin Flow through an Orthotropic Medium in the RTM Process. Matéria 2017, 22. [Google Scholar] [CrossRef]

- Maung, P.P.; Malysheva, G. Modeling the Effect of Fabric Weaving Pattern on the Kinetics of the Impregnation Process in the Manufacturing of the Fiber Reinforced Plastic Structures. In Proceedings of the XLIII Academic Space Conference: Dedicated to the Memory of Academician S.P. Korolev and Other Outstanding Russian scientists—Pioneers of Space Exploration, Moscow, Russia, 28 January–1 February 2019; Volume 2171. [Google Scholar]

- Gupta, S.; Das, S.; Dutta, R. Nonlocal Stress Analysis of an Irregular FGFPM Structure Imperfectly Bonded to Fiber-Reinforced Substrate Subjected to Moving Load. Soil Dyn. Earthq. Eng. 2021, 147, 106744. [Google Scholar] [CrossRef]

- Zhang, C.; Gong, J.; Li, H.; Zhang, J. Fiber-Based Flexible Composite with Dual-Gradient Structure for Sound Insulation. Compos. Part B Eng. 2020, 198, 108166. [Google Scholar] [CrossRef]

- Vo, H.N.; Pucci, M.F.; Corn, S.; Le Moigne, N.; Garat, W.; Drapier, S.; Liotier, P.J. Capillary Wicking in Bio-Based Reinforcements Undergoing Swelling—Dual Scale Consideration of Porous Medium. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105893. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Tensile and Flexural Response of 3D Printed Solid and Porous CCFRPC Structures and Fracture Interface Study Using Image Processing Technique. J. Mater. Res. Technol. 2021, 14, 731–742. [Google Scholar] [CrossRef]

- Patel, N.; Lee, L.J. Modeling of Void Formation and Removal in Liquid Composite Molding. Part I: Wettability Analysis. Polym. Compos. 2010, 17, 96–103. [Google Scholar] [CrossRef]

- Michaud, V.; Mortensen, A. Infiltration Processing of Fibre Reinforced Composites: Governing Phenomena. Compos. Part A Appl. Sci. Manuf. 2001, 32, 981–996. [Google Scholar] [CrossRef]

- Mortensen, A.; Wong, T. Infiltration of Fibrous Preforms by a Pure Metal: Part III. Capillary Phenomena. Met. Mater. Trans. A 1990, 21, 2257–2263. [Google Scholar] [CrossRef]

- Michels, R.; Siebert, D.N.; dos Santos, L.O.E. Investigation on the Influence of Capillary Number on Drainage in Porous Media Using a Lattice Boltzmann Method. J. Pet. Sci. Eng. 2021, 205, 108918. [Google Scholar] [CrossRef]

- Wang, Y.; Song, R.; Liu, J.-J.; Cui, M.-M.; Ranjith, P.G. Pore Scale Investigation on Scaling-Up Micro-Macro Capillary Number and Wettability on Trapping and Mobilization of Residual Fluid. J. Contam. Hydrol. 2019, 225, 103499. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, E.J.F.; Ekstrom, H.; Fontes, E. COMSOL Multiphysics (R): Finite Element Software for Electrochemical Analysis. A Mini-Review. Electrochem. Commun. 2014, 40, 71–74. [Google Scholar] [CrossRef]

- Li, Q.; Ito, K.; Wu, Z.; Lowry, C.S.; Ii, S.P.L. COMSOL Multiphysics: A Novel Approach to Ground Water Modeling. Ground Water 2009, 47, 480–487. [Google Scholar] [CrossRef]

- Wang, X.; Yue, H.; Liu, G.; Zhao, Z. The Application of COMSOL Multiphysics in Direct Current Method Forward Modeling. In 2011 Xi’an International Conference on Fine Exploration and Control of Water & Gas in Coal Mines; Shuning, D., Qun, Z., Li, W., Yongsheng, Q., Yujing, X., Hong, F., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2011; Volume 3, pp. 266–272. [Google Scholar]

- Adam, T.; Hashim, U. COMSOL Multiphysics Simulation in Biomedical Engineering. In Nanoscience, Nanotechnology and Nanoengineering; Mamat, M.H., Khusaimi, Z., Bakar, S.A., Nor, A.M., Soga, T., Mahmood, M.R., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2014; Volume 832, pp. 511–516. [Google Scholar]

- Ata, K.; Sahin, M. An Integral Equation Approach for the Solution of the Stokes Flow with Hermite Surfaces. Eng. Anal. Bound. Elements 2018, 96, 14–22. [Google Scholar] [CrossRef]

- Wu, B.; Zhu, H.; Barnett, A.; Veerapaneni, S. Solution of Stokes Flow in Complex Nonsmooth 2D Geometries via a Linear-Scaling High-Order Adaptive Integral Equation Scheme. J. Comput. Phys. 2020, 410, 109361. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.Y. Review of Similarity Stretching Exact Solutions of the Navier–Stokes Equations. Eur. J. Mech. B Fluids 2011, 30, 475–479. [Google Scholar] [CrossRef]

- Galkin, V.S.; Rusakov, S.V. Status of the Navier-Stokes Equations in Gas Dynamics. A Review. Fluid Dyn. 2018, 53, 152–168. [Google Scholar] [CrossRef]

- Rempfer, D. On Boundary Conditions for Incompressible Navier-Stokes Problems. Appl. Mech. Rev. 2006, 59, 107–125. [Google Scholar] [CrossRef]

- Ferreira, L.D.P.; Oliveira, T.D.S.; Surmas, R.; da Silva, M.A.P.; Peçanha, R.P. Brinkman Equation in Reactive Flow: Contribution of Each Term in Carbonate Acidification Simulations. Adv. Water Resour. 2020, 144, 103696. [Google Scholar] [CrossRef]

- Jorne, F.; Henriques, F.M.A. Evaluation of the Grout Injectability and Types of Resistance to Grout Flow. Constr. Build. Mater. 2016, 122, 171–183. [Google Scholar] [CrossRef]

- Luo, K.; Shao, C.; Chai, M.; Fan, J. Level Set Method for Atomization and Evaporation Simulations. Prog. Energy Combust. Sci. 2019, 73, 65–94. [Google Scholar] [CrossRef]

- Gibou, F.; Fedkiw, R.; Osher, S. A review of Level-Set Methods and Some Recent Applications. J. Comput. Phys. 2018, 353, 82–109. [Google Scholar] [CrossRef]

- Lenda, T.; Mridha, S. Influence of Moisture Absorption on Impact Strength and Failure Behavior of Hybrid Jute-Carbon/Epoxy Composite. Adv. Mater. Res. 2011, 264–265, 457–462. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, C.; Han, X.; Zhang, X.; Ikechukwu, O. Bond Performance between Magnetized Rebar and Self-Compacting Steel Fiber Reinforced Concrete. J. Adv. Concr. Technol. 2019, 17, 686–699. [Google Scholar] [CrossRef] [Green Version]

- Compston, P.; Jar, P.-Y.B. The Influence of Fibre Volume Fraction on the Mode I Interlaminar Fracture Toughness of a Glass-Fibre/Vinyl Ester Composite. Appl. Compos. Mater. 1999, 6, 353–368. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Heating temperature of mold (°C) | ≤300 |

| Injection flow rate (mL/min) | 0–1000 |

| Injection pressure (MPa) | ≤1 |

| Measurement accuracy (mL/min) | ±1 |

| Pressure accuracy (MPa) | ±0.001 |

| Resin temperature control (°C) | ±1 |

| Parameter | Value |

|---|---|

| Heating temperature of mold (°C) | ≤300 |

| Resin flow rate (mL/min) | 100–900 |

| Catalyst flow rate (mL/min) | 0–100 |

| Injection pressure (MPa) | ≤1 |

| Measurement accuracy (mL/min) | ±1 |

| Pressure accuracy (MPa) | ±0.001 |

| Resin temperature control (°C) | ±1 |

| Mixture ratio | 0:1–1:1 |

| Mixing mode | SK static mixing head |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Liu, Y.; Wu, W. A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites. Polymers 2021, 13, 2689. https://doi.org/10.3390/polym13162689

He X, Liu Y, Wu W. A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites. Polymers. 2021; 13(16):2689. https://doi.org/10.3390/polym13162689

Chicago/Turabian StyleHe, Xiansong, Yi Liu, and Wangqing Wu. 2021. "A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites" Polymers 13, no. 16: 2689. https://doi.org/10.3390/polym13162689

APA StyleHe, X., Liu, Y., & Wu, W. (2021). A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites. Polymers, 13(16), 2689. https://doi.org/10.3390/polym13162689