Effects of Particle Size on the Dielectric, Mechanical, and Thermal Properties of Recycled Borosilicate Glass-Filled PTFE Microwave Substrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PTFE/Recycled BRS Composites

2.3. Characterisations

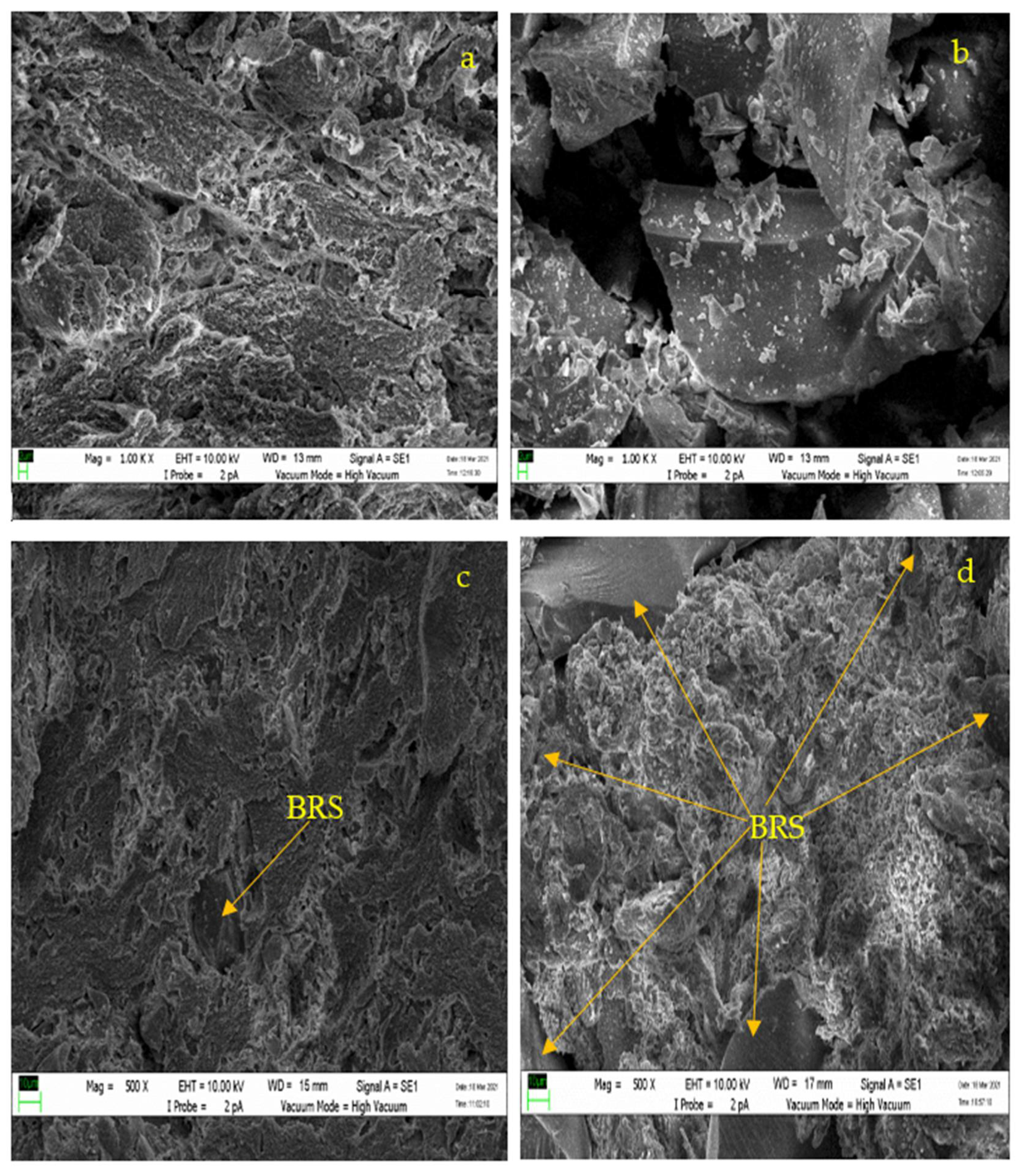

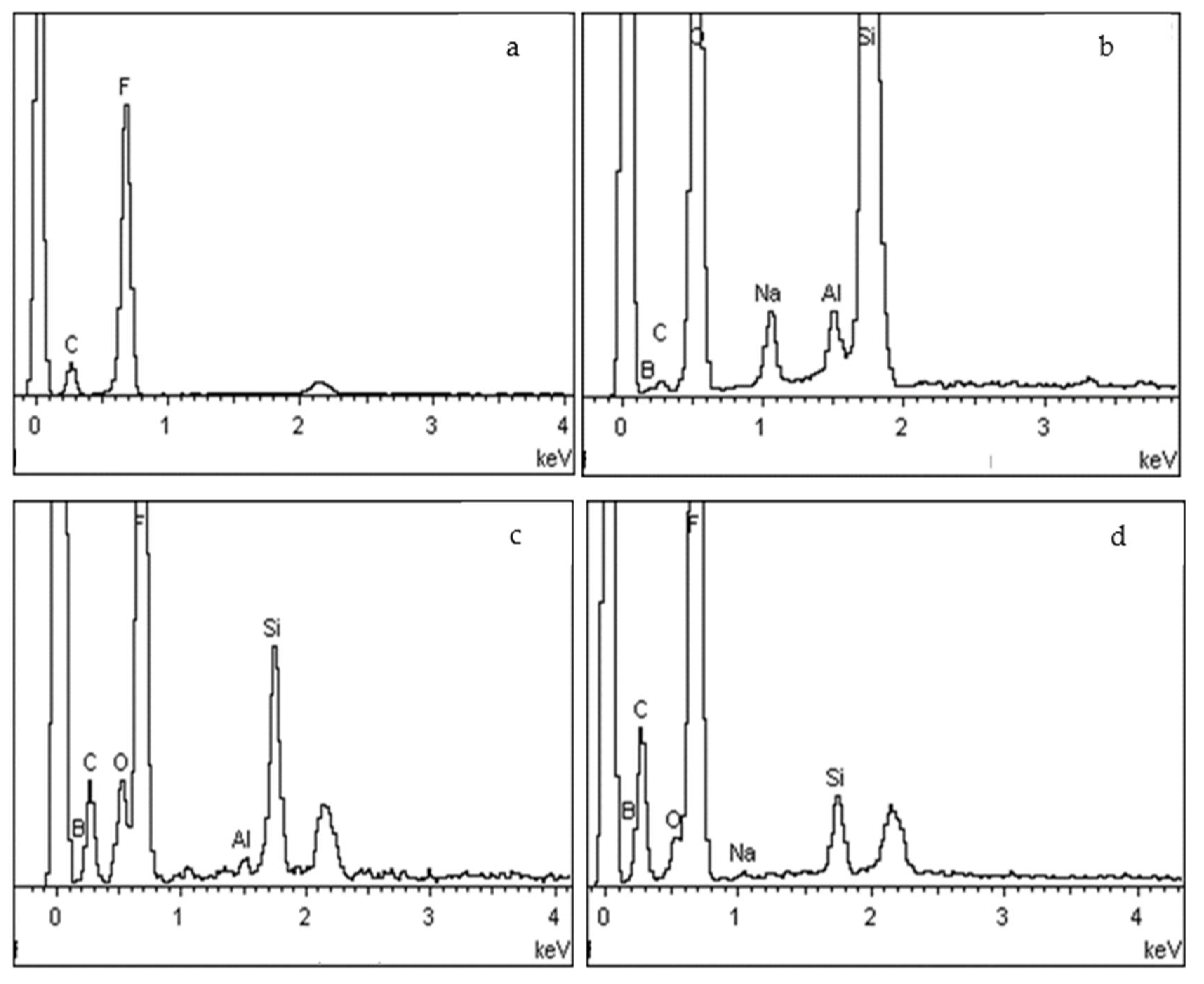

2.3.1. Phase, Morphology and Composition

2.3.2. Moisture Absorption

2.3.3. Density

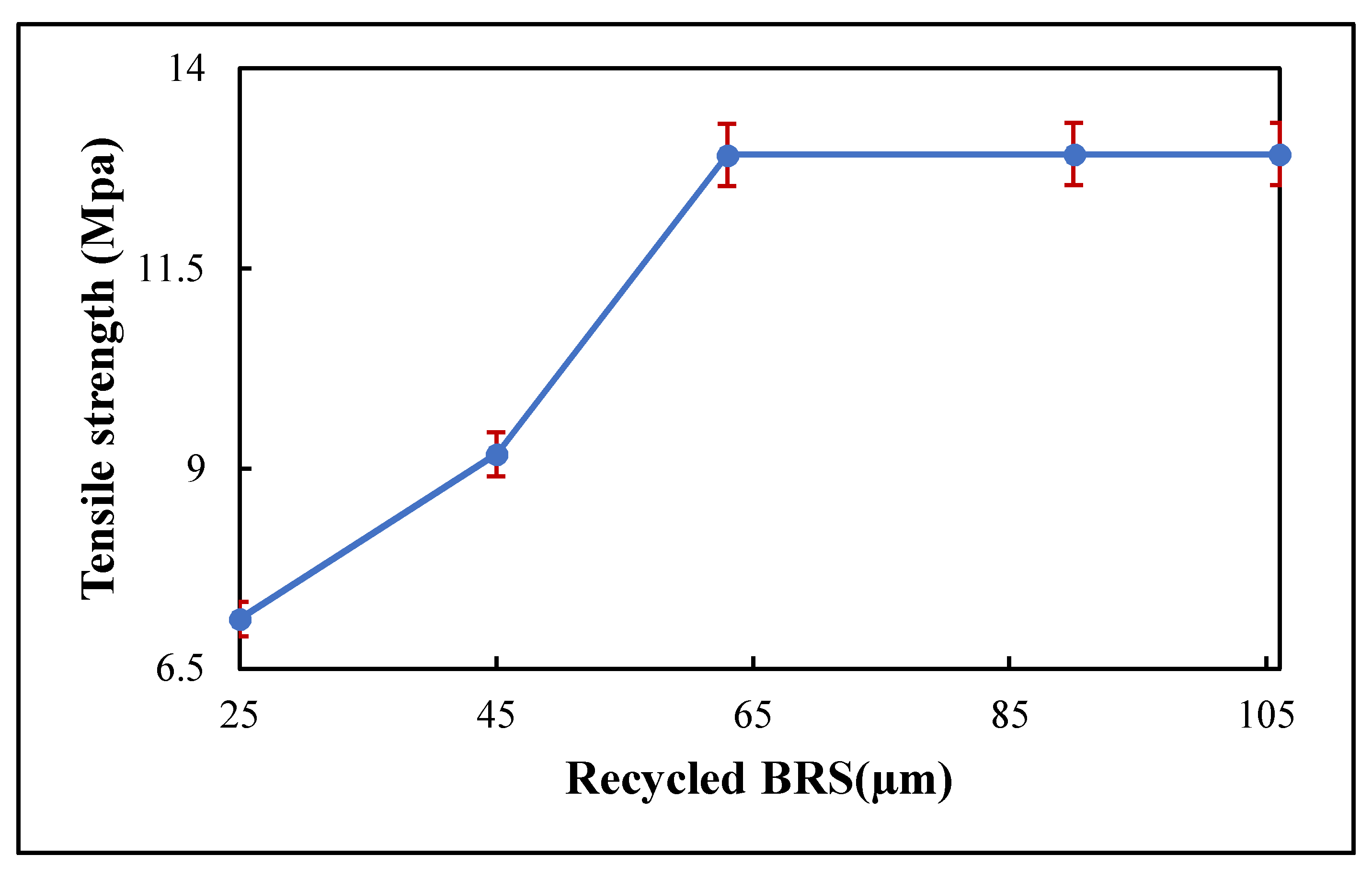

2.3.4. Tensile Strength

2.3.5. Coefficient of Thermal Expansion (CTE)

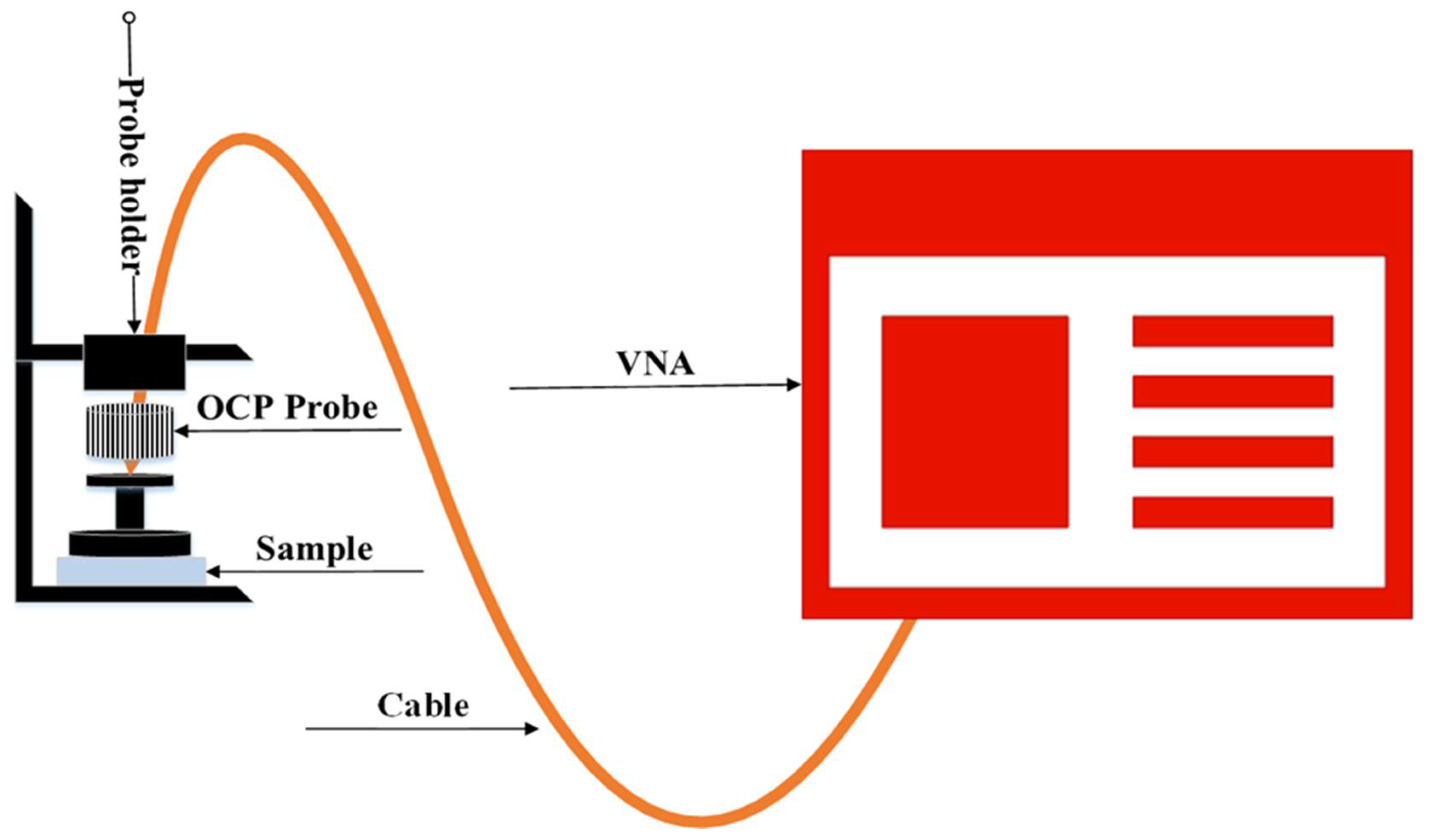

2.3.6. Complex Permittivity

2.3.7. Signal Propagation Speed

3. Results and Discussion

3.1. Phase, Morphology and Composition

3.2. Moisture Absorption

3.3. Density

3.4. Tensile Strength

3.5. Coefficient of Thermal Expansion (CTE)

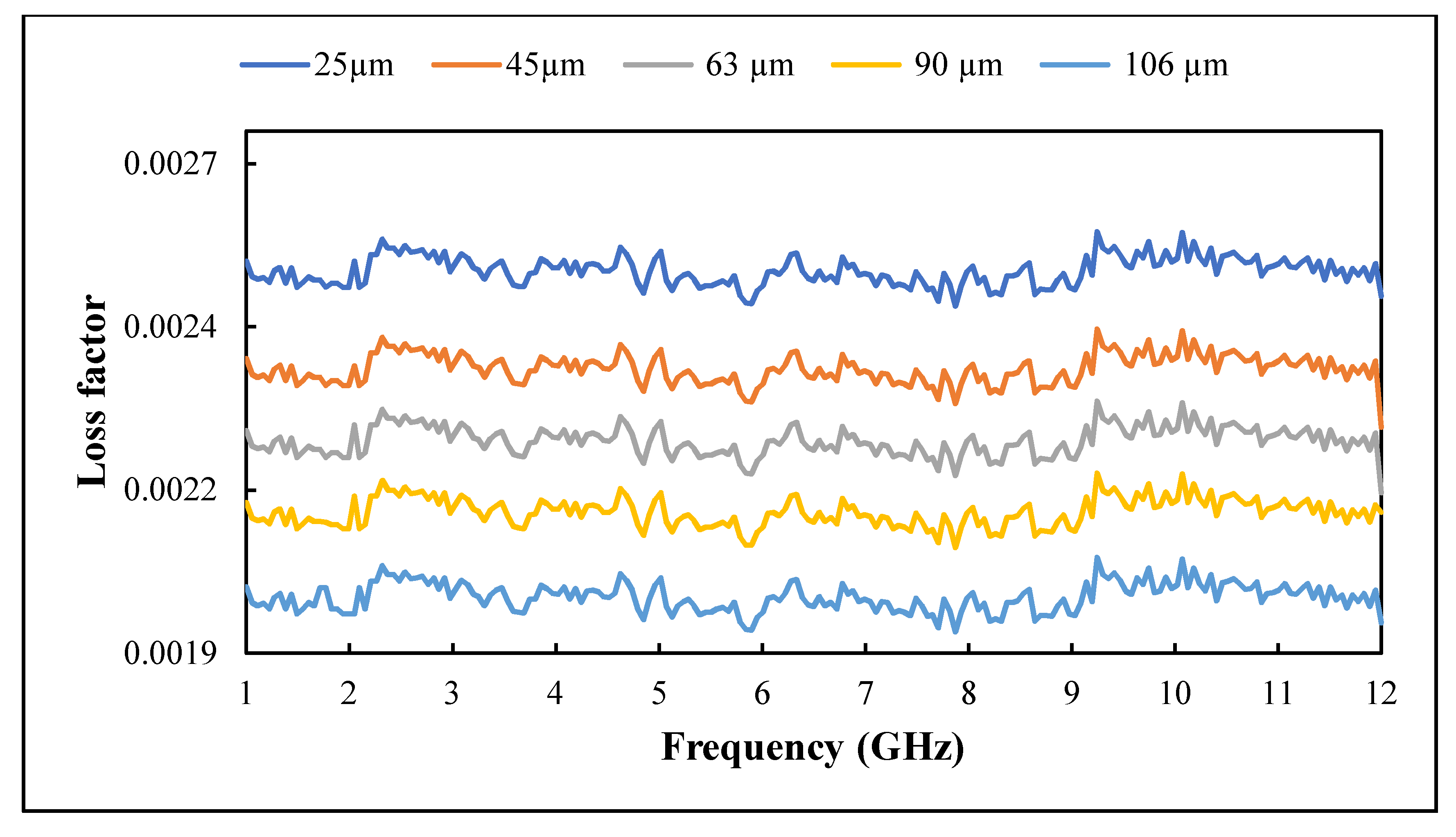

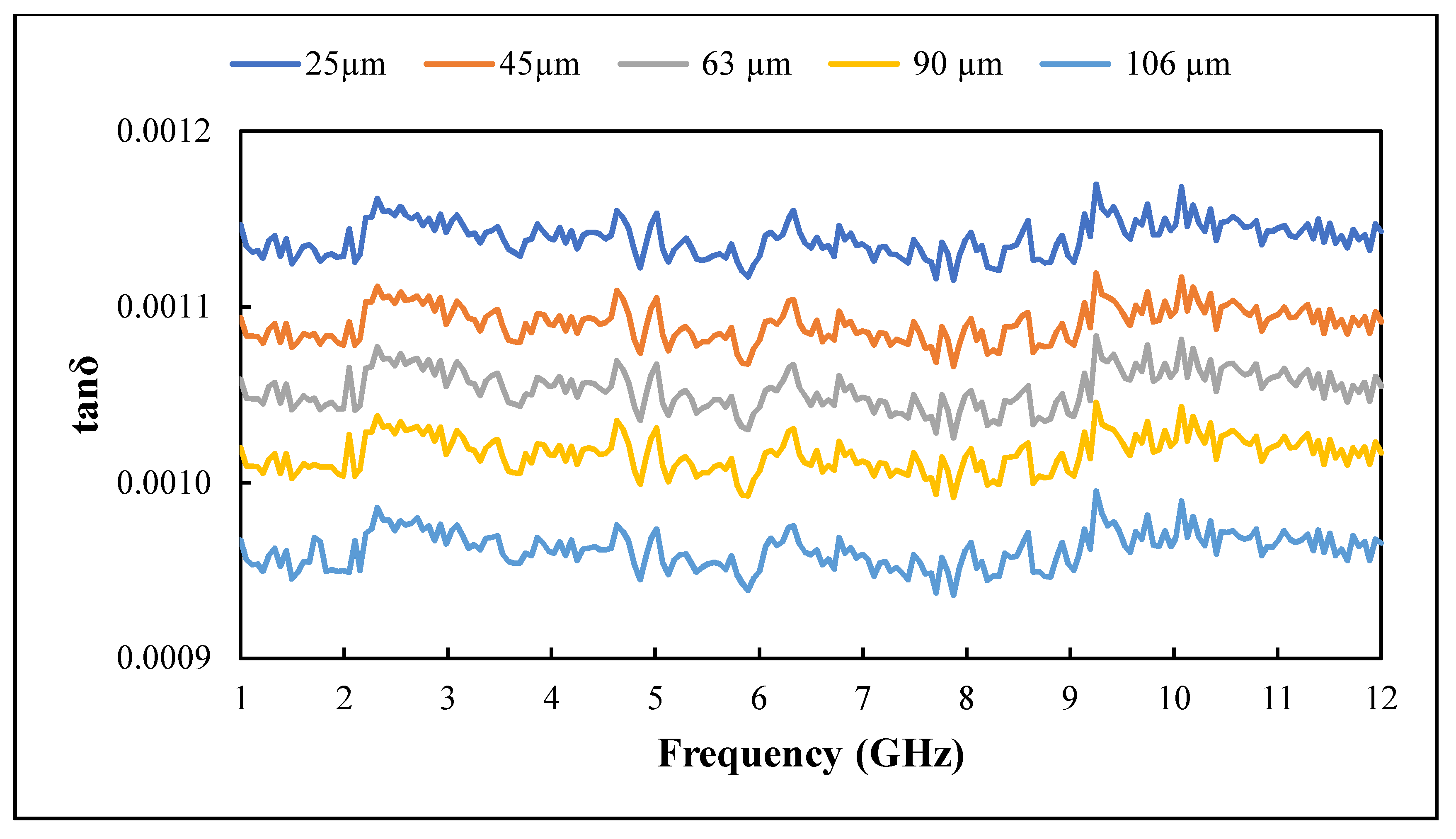

3.6. Complex Permittivity

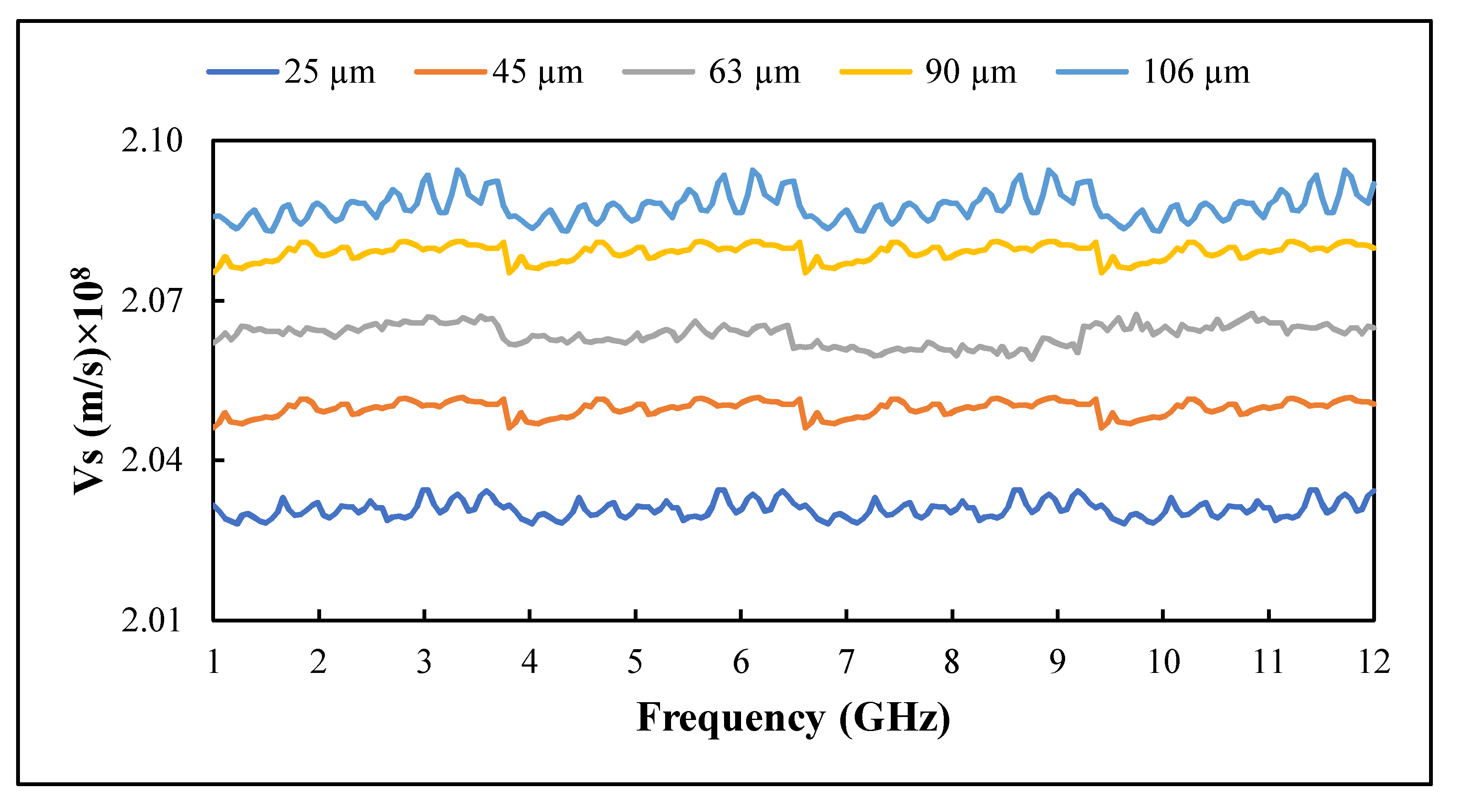

3.7. Signal Transmission Speed

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manu, K.; Ananthakumar, S.; Sebastian, M. Electrical and thermal properties of low permittivity Sr2Al2SiO7 ceramic filled HDPE composites. Ceram. Int. 2013, 39, 4945–4951. [Google Scholar] [CrossRef]

- Manu, K.M.; Soni, S.; Murthy, V.R.K.; Sebastian, M.T. Ba(Zn1/3Ta2/3)O3 ceramics reinforced high density polyethylene for microwave applications. J. Mater. Sci. Mater. Electron. 2013, 24, 2098–2105. [Google Scholar] [CrossRef]

- Xie, C.; Liang, F.; Ma, M.; Chen, X.; Lu, W.; Jia, Y. Microstructure and dielectric properties of PTFE-based composites filled by micron/submicron-blended CCTO. Crystals 2017, 7, 126. [Google Scholar] [CrossRef]

- Murali, K.P.; Rajesh, S.; Nijesh, K.J.; Ratheesh, R. Effect of particle size on the microwave dielectric properties of alumina-filled PTFE substrates. Int. J. Appl. Ceram. Technol. 2010, 7, 475–481. [Google Scholar] [CrossRef]

- Rajesh, S.; Murali, K.; Jantunen, H.; Ratheesh, R. The effect of filler on the temperature coefficient of the relative permittivity of PTFE/ceramic composites. Phys. B Condens. Matter 2011, 406, 4312–4316. [Google Scholar] [CrossRef]

- Varghese, J.; Nair, D.R.; Mohanan, P.; Sebastian, M.T. Dielectric, thermal and mechanical properties of zirconium silicate reinforced high density polyethylene composites for antenna applications. Phys. Chem. Chem. Phys. 2015, 17, 14943–14950. [Google Scholar] [CrossRef]

- Murali, K.; Rajesh, S.; Prakash, O.; Kulkarni, A.; Ratheesh, R. Preparation and properties of silica filled PTFE flexible laminates for microwave circuit applications. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1179–1185. [Google Scholar] [CrossRef]

- Jiang, Z.; Yuan, Y. Effects of particle size distribution of silica on properties of PTFE/SiO2 composites. Mater. Res. Express 2018, 5, 066306. [Google Scholar] [CrossRef]

- Mazur, K.; Gądek-Moszczak, A.; Liber-Kneć, A.; Kuciel, S. Mechanical behavior and morphological study of polytetrafluoroethylene (PTFE) composites under static and cyclic loading condition. Materials 2021, 14, 1712. [Google Scholar] [CrossRef]

- Huang, F.; Yuan, Y.; Jiang, Z.; Tang, B.; Zhang, S. Microstructures and properties of glass fiber reinforced PTFE composite substrates with laminated construction. Mater. Res. Express 2019, 6, 075305. [Google Scholar] [CrossRef]

- Luo, F.; Yuan, Y.; Tang, B.; Yang, J.; Zhang, S. The effects of TiO2 particle size on the properties of PTFE/TiO2 composites. J. Mater. Sci. Chem. Eng. 2017, 05, 53–60. [Google Scholar] [CrossRef][Green Version]

- Thomas, S.; Kavil, J.; Malayil, A.M. Dielectric properties of PTFE loaded with micro- and nano-Sm2Si2O7 ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 9780–9788. [Google Scholar] [CrossRef]

- Francis, L.F. Powder Processes; Elsevier: Amsterdam, The Netherlands, 2016; pp. 343–414. [Google Scholar]

- Meli, A.D.; Abbas, Z.; Zaid, M.H.M.; Ibrahim, N.A. The effects of SLS on structural and complex permittivity of SLS-HDPE composites. Adv. Polym. Technol. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the environment. Phys. Status Solidi A 1992, 131, 625–638. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Rafferty, A.; Sajjia, M.; Olabi, A.-G. Properties of glass materials. In Reference Module in Materials Science and Materials Engineering; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Kochetov, R.; Tsekmes, I.A.; Morshuis, P.H.F.; Smit, J.J.; Wanner, A.J.; Wiesbrock, F.; Kern, W. Effect of water absorption on dielectric spectrum of nanocomposites. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 579–582. [Google Scholar] [CrossRef]

- Zou, C.; Fothergill, J.C.; Rowe, S.W. The effect of water absorption on the dielectric properties of epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 106–117. [Google Scholar] [CrossRef]

- Ismail, N.Q.A.; Saat, N.K.; Zaid, M.H.M. Effect of soda lime silica glass doping on ZnO varistor ceramics: Dry milling method. J. Asian Ceram. Soc. 2020, 8, 909–914. [Google Scholar] [CrossRef]

- Chaichanawong, J.; Thongchuea, C.; Areerat, S. Effect of moisture on the mechanical properties of glass fiber reinforced polyamide composites. Adv. Powder Technol. 2016, 27, 898–902. [Google Scholar] [CrossRef]

- Vartak, D.; Ghotekar, Y.; Deshpande, N.; Munjal, B.; Bhatt, P.; Satyanarayana, B.; Vyas, K.; Lal, A. New horizons of space qualification of single-walled carbon nano tubes-carbon fibre reinforced polymer composite. J. Physics Conf. Ser. 2021, 1854, 012001. [Google Scholar] [CrossRef]

- Mensah, E.E.; Abbas, Z.; Azis, R.S.; Khamis, A.M. Enhancement of complex permittivity and attenuation properties of recycled hematite (α-Fe2O3) using nanoparticles prepared via ball milling technique. Materials 2019, 12, 1696. [Google Scholar] [CrossRef]

- Khamis, A.M.; Abbas, Z.; Ahmad, A.F.; Azis, R.S.; Abdalhadi, D.M.; Mensah, E.E. Experimental and computational study on epoxy resin reinforced with micro-sized OPEFB using rectangular waveguide and finite element method. IET Microw. Antennas Propag. 2020, 14, 752–758. [Google Scholar] [CrossRef]

- Ratheesh, R.; Sebastian, M. Polymer-Ceramic Composites for Microwave Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017; Volume 50, pp. 481–535. [Google Scholar]

- Irshidat, M.R.; Al-Saleh, M.H.; Sanad, S. Effect of nanoclay on the expansive potential of cement mortar due to alkali-silica reaction. ACI Mater. J. 2015, 112. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Kido, H.; Ukita, Y.; Kishihara, M.; Utsumi, Y. Anisotropic pyrochemical microetching of poly(tetrafluoroethylene) initiated by synchrotron radiation-induced scission of molecule bonds. Appl. Phys. Lett. 2016, 108, 51610. [Google Scholar] [CrossRef]

- Feng, W.; Yin, L.; Han, Y.; Wang, J.; Xiao, K.; Li, J. Tribological and physical properties of PTFE-NBR self-lubricating composites under water lubrication. Ind. Lubr. Tribol. 2021, 73, 82–87. [Google Scholar] [CrossRef]

- Lago, E.D.; Cagnin, E.; Boaretti, C.; Roso, M.; Lorenzetti, A.; Modesti, M. Influence of different carbon-based fillers on electrical and mechanical properties of a PC/ABS blend. Polymers 2019, 12, 29. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chattopadhyay, S.; Dhanania, S.; Bhowmick, A.K. Improved dispersion and physico-mechanical properties of rubber/silica composites through new silane grafting. Polym. Eng. Sci. 2020, 60, 3115–3134. [Google Scholar] [CrossRef]

- Hubert, M.; Faber, A.J. On the structural role of boron in borosilicate glasses. Phys. Chem. Glas. Eur. J. Glas. Sci. Technol. Part B 2014, 55, 136–158. [Google Scholar]

- Nasrazadani, S.; Hassani, S. Modern analytical techniques in failure analysis of aerospace, chemical, and oil and gas industries. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Elsevier: Amsterdam, The Netherlands, 2016; pp. 39–54. [Google Scholar]

- Yuan, Y.; Zhang, S.; Zhou, X.; Li, E. MgTiO3 filled PTFE composites for microwave substrate applications. Mater. Chem. Phys. 2013, 141, 175–179. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, F.; Guo, J.; Yang, H.; Tong, J.; Zhang, Q. Modified BCZN particles filled PTFE composites with high dielectric constant and low loss for microwave substrate applications. Ceram. Int. 2020, 46, 7531–7540. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Liu, H.; Zhou, D. Microwave dielectric properties of PTFE/CaTiO3 polymer ceramic composites. Ceram. Int. 2011, 37, 1609–1613. [Google Scholar] [CrossRef]

- Murali, K.P.; Rajesh, S.; Jacob, K.S.; Prakash, O.; Kulkarni, A.R.; Ratheesh, R. Preparation and characterization of cordierite filled PTFE laminates for microwave substrate applications. J. Mater. Sci. Mater. Electron. 2010, 21, 192–198. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Lin, H.-C.; Lee, Y.-D. The effects of filler content and size on the properties of PTFE/SIO2 composites. J. Polym. Res. 2003, 10, 247–258. [Google Scholar] [CrossRef]

- Xu, G.; Yu, Y.; Zhang, Y.; Li, T.; Wang, T. Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite. Sci. Eng. Compos. Mater. 2019, 26, 53–61. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A.; Khosrovaneh, A. Effect of water absorption on tensile and fatigue behaviors of two short glass fiber reinforced thermoplastics. SAE Int. J. Mater. Manuf. 2015, 8, 435–443. [Google Scholar] [CrossRef]

- JA, M.H.; Majid, M.S.A.; Afendi, M.; Marzuki, H.; Hilmi, E.A.; Fahmi, I.; Gibson, A. Effects of water absorption on Napier grass fibre/polyester composites. Compos. Struct. 2016, 144, 138–146. [Google Scholar] [CrossRef]

- Thomas, D.; Sebastian, M.T. HDPE matrix composites filled with Ca4La6(SiO4)4(PO4)2O2 for microwave substrate applications. J. Electron. Packag. 2014, 136, 031002. [Google Scholar] [CrossRef]

- Han, K.; Zhou, J.; Li, Q.; Shen, J.; Qi, Y.; Yao, X.; Chen, W. Effect of filler structure on the dielectric and thermal properties of SiO2/PTFE composites. J. Mater. Sci. Mater. Electron. 2020, 31, 9196–9202. [Google Scholar] [CrossRef]

- Elloumi, I.; Koubaa, A.; Kharrat, W.; Bradai, C.; Elloumi, A. Dielectric properties of wood-polymer composites: Effects of frequency, fiber nature, proportion, and chemical composition. J. Compos. Sci. 2021, 5, 141. [Google Scholar] [CrossRef]

- Rayssi, C.; Kossi, S.E.; Dhahri, J.; Khirouni, K. Frequency and temperature-dependence of dielectric permittivity and electric modulus studies of the solid solution Ca0.85Er0.1Ti1−xCo4x/3O3 (0 ≤ x ≤ 0.1). RSC Adv. 2018, 8, 17139–17150. [Google Scholar] [CrossRef]

- Yang, G.; Cui, J.; Ohki, Y.; Wang, D.; Li, Y.; Tao, K. Dielectric and relaxation properties of composites of epoxy resin and hyperbranched-polyester-treated nanosilica. RSC Adv. 2018, 8, 30669–30677. [Google Scholar] [CrossRef]

- Abdalhadi, D.M.; Abbas, Z.; Ahmad, A.F.; Matori, K.A.; Esa, F. Controlling the properties of OPEFB/PLA polymer composite by using Fe2O3 for microwave applications. Fibers Polym. 2018, 19, 1513–1521. [Google Scholar] [CrossRef]

- Frank Gladson, T.S.; Ramesh, R.; Kavitha, C. Experimental investigation of mechanical, tribological and dielectric properties of alumina nano wire-reinforced PEEK/PTFE composites. Mater. Res. Express 2019, 6, 115327. [Google Scholar] [CrossRef]

- Khan, M.S.; Osada, M.; Kim, H.-J.; Ebina, Y.; Sugimoto, W.; Sasaki, T. High-temperature dielectric responses in all-nanosheet capacitors. Jpn. J. Appl. Phys. 2017, 56, 06GH09. [Google Scholar] [CrossRef]

- Todd, M.G.; Shi, F.G. Validation of a novel dielectric constant simulation model and the determination of its physical parameters. Microelectron. J. 2002, 33, 627–632. [Google Scholar] [CrossRef]

- Advanced Connectivity Solution. AD Series® Laminates 2021:1–4. Available online: https://rogerscorp.com/advanced-connectivity-solutions/ad-series-laminates (accessed on 23 January 2021).

- Microwave & RF Laminates Products. TLX High Volume Fiberglass Reinforced Microwave Substrate 2020. Available online: https://www.agc-multimaterial.com/page/microwave--rf-laminates-66.html (accessed on 5 July 2021).

| 25 | |

| 45 | |

| 63 | |

| 90 | |

| 106 |

| 25 | 2.18 | 0.0026 | 0.0011 |

| 45 | 2.14 | 0.0024 | 0.0011 |

| 63 | 2.11 | 0.0022 | 0.0011 |

| 90 | 2.08 | 0.0021 | 0.0010 |

| 106 | 2.07 | 0.0020 | 0.0010 |

| Name | Tensile Strength (MPa) | CTE (ppm/°C) | Moisture Absorption (%) | Reference | ||

|---|---|---|---|---|---|---|

| At 10 GHz | ||||||

| PTFE/recycled BRS composite | 2.11 ± 0.05 | 0.0011 ± 0.00005 | 12.92 ± 0.005 | 60.45 ± 0.01 | 0.02 ± | This study |

| AD250C | 2.50 | 0.0013 | 6.00 | 196.00 | 0.04 | [49] |

| AD255C | 2.60 | 0.0013 | 8.1 | 196.00 | 0.03 | [49] |

| TLX-8 | 2.55 | 0.0017 | 245 | 215.00 | 0.02 | [50] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhaji, I.A.; Abbas, Z.; Mohd Zaid, M.H.; Khamis, A.M. Effects of Particle Size on the Dielectric, Mechanical, and Thermal Properties of Recycled Borosilicate Glass-Filled PTFE Microwave Substrates. Polymers 2021, 13, 2449. https://doi.org/10.3390/polym13152449

Alhaji IA, Abbas Z, Mohd Zaid MH, Khamis AM. Effects of Particle Size on the Dielectric, Mechanical, and Thermal Properties of Recycled Borosilicate Glass-Filled PTFE Microwave Substrates. Polymers. 2021; 13(15):2449. https://doi.org/10.3390/polym13152449

Chicago/Turabian StyleAlhaji, Ibrahim Abubakar, Zulkifly Abbas, Mohd Hafiz Mohd Zaid, and Ahmad Mamoun Khamis. 2021. "Effects of Particle Size on the Dielectric, Mechanical, and Thermal Properties of Recycled Borosilicate Glass-Filled PTFE Microwave Substrates" Polymers 13, no. 15: 2449. https://doi.org/10.3390/polym13152449

APA StyleAlhaji, I. A., Abbas, Z., Mohd Zaid, M. H., & Khamis, A. M. (2021). Effects of Particle Size on the Dielectric, Mechanical, and Thermal Properties of Recycled Borosilicate Glass-Filled PTFE Microwave Substrates. Polymers, 13(15), 2449. https://doi.org/10.3390/polym13152449