Fire Retardancy, Water Absorption, and Viscoelasticity of Borated Wood—Polycarbonate Biocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Wood–PC Biocomposites

2.3. Characterization

3. Results and Discussion

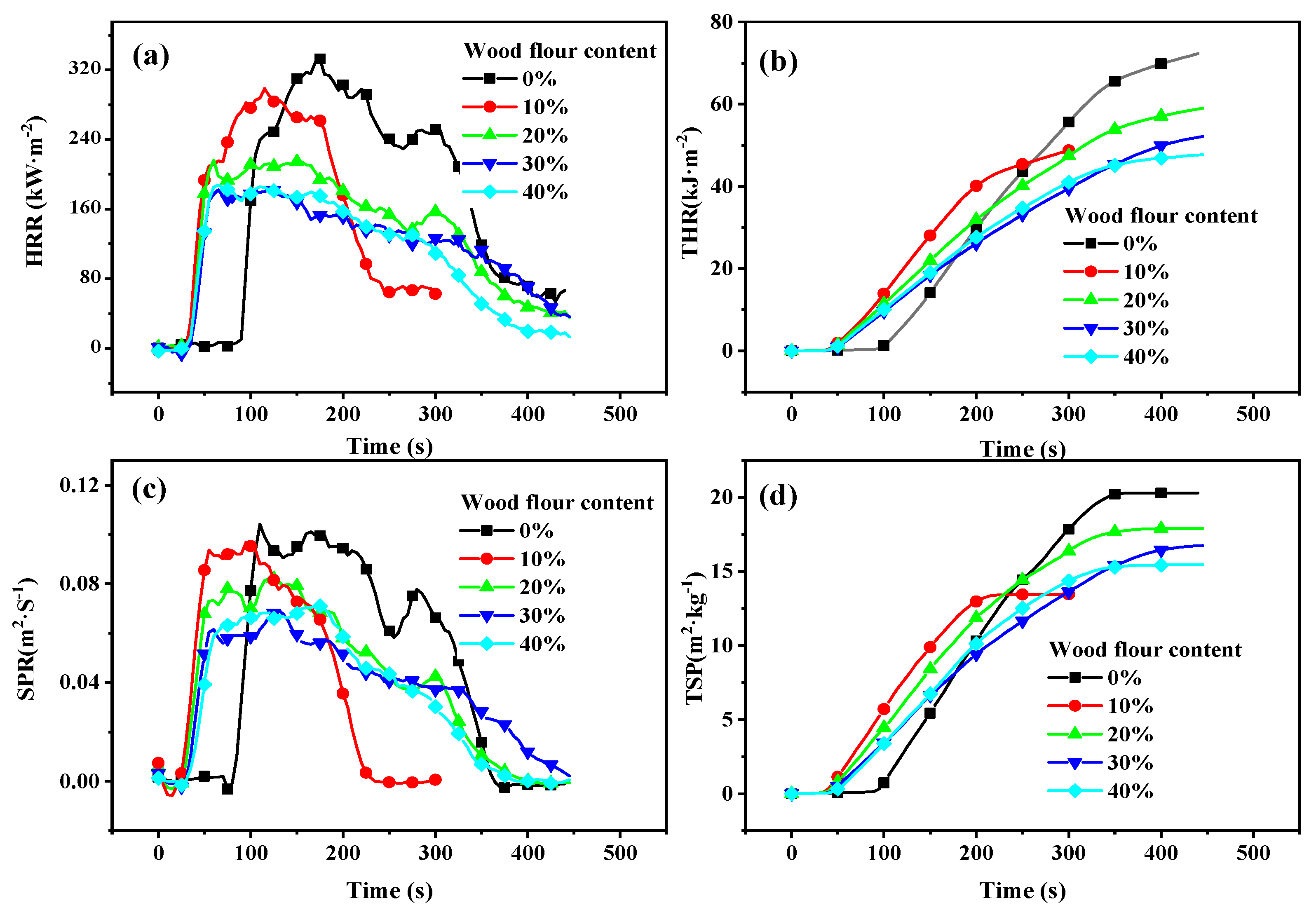

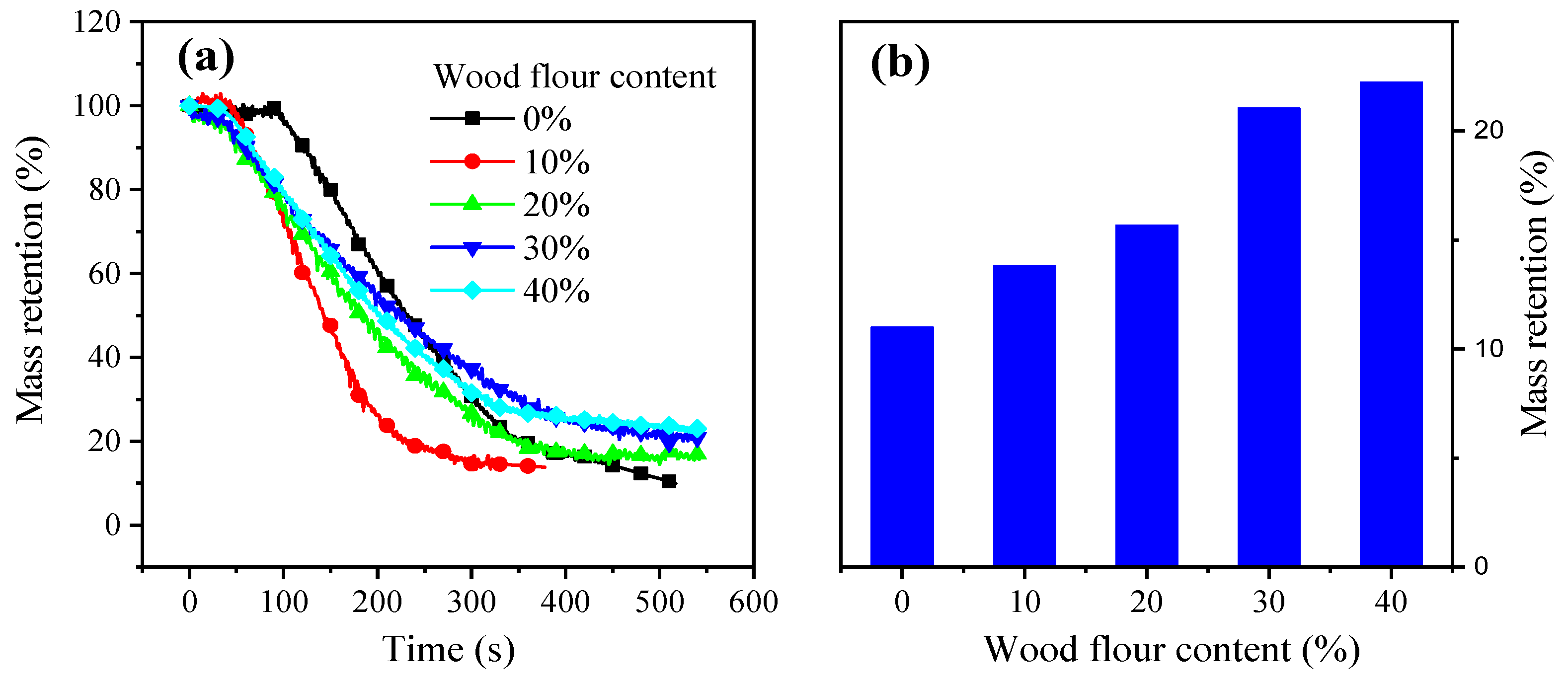

3.1. Fire Retardancy

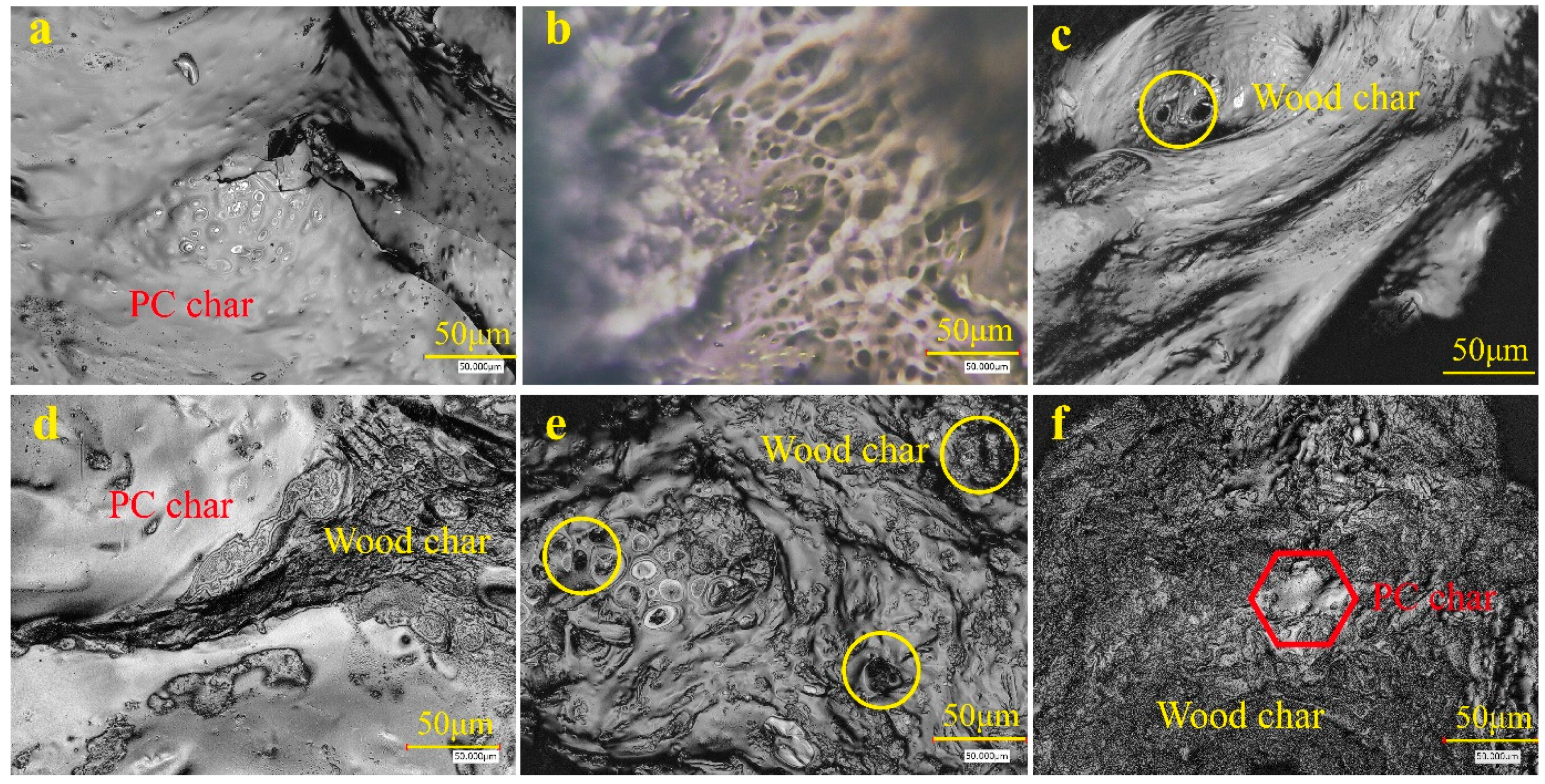

3.2. Morphological Characterization

3.3. Water Absorption

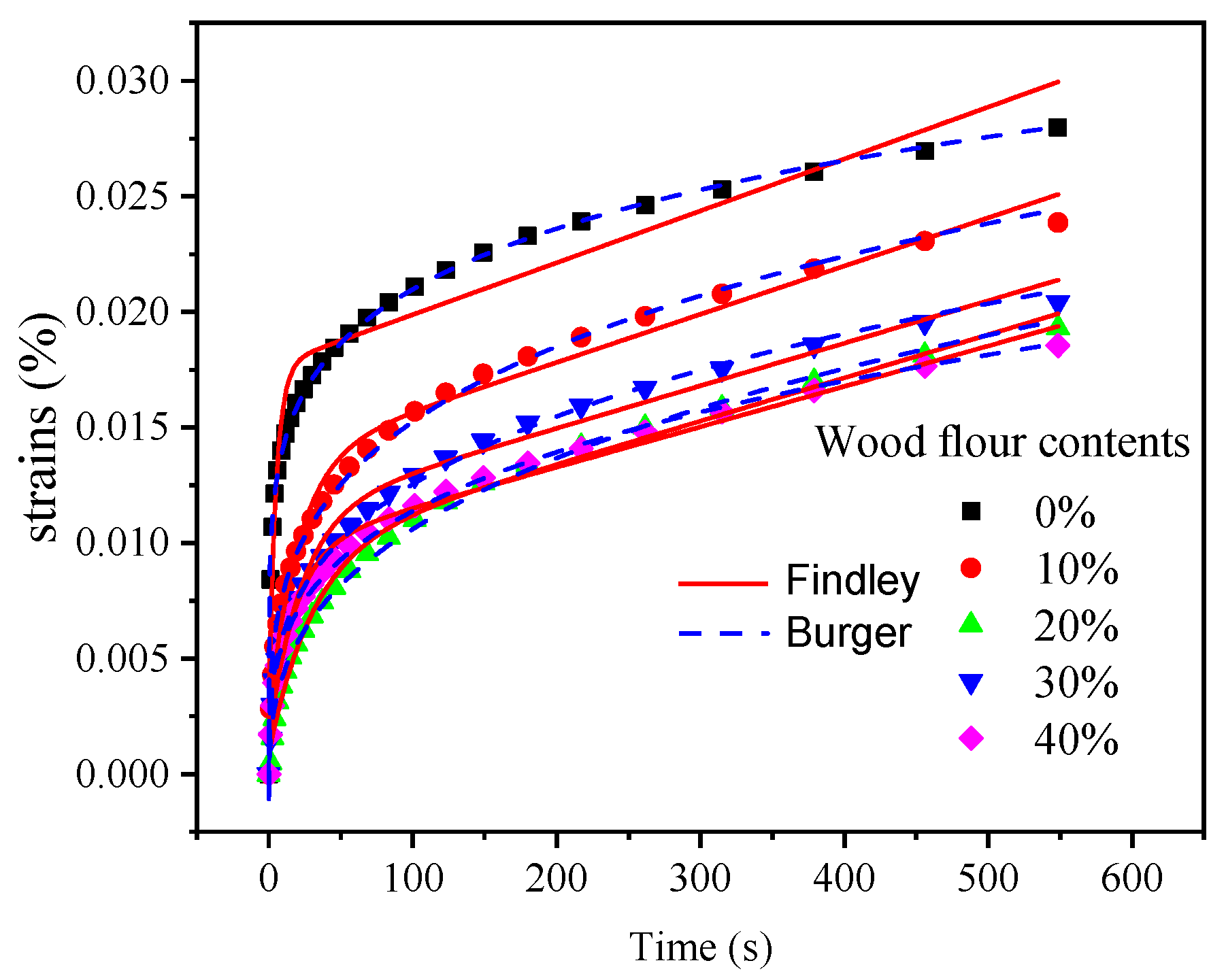

3.4. Creep Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, P.; Guo, C.; Li, L. Exploring the effect of melamine pyrophosphate and aluminum hypophosphite on flame retardant wood flour/polypropylene composites. Constr. Build. Mater. 2018, 170, 193–199. [Google Scholar] [CrossRef]

- Kaboorani, A. Characterizing water sorption and diffusion properties of wood/plastic composites as a function of formulation design. Constr. Build. Mater. 2017, 136, 164–172. [Google Scholar] [CrossRef]

- Lopez, Y.M.; Paes, J.B.; Gustave, D.; Gonçalves, F.G.; Méndez, F.C.; Nantet, A.C.T. Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products—A sustainable approach for cleaner production in Cuba. J. Clean. Prod. 2020, 244, 118723. [Google Scholar] [CrossRef]

- Sain, M. Market and product opportunities for WPCs/NFPCs beyond building industry. In Proceedings of the 9th International Conference on Wood and Biofiber Plastic Composites, Plenary Session, Madison, WI, USA, 21–23 May 2007. [Google Scholar]

- Research, G.V. Wood Plastic Composite Market Analysis Report by Type (Polyethylene, Polypropylene, Polyvinylchloride), By Application (Automotive, Construction, Industrial & Consumer Goods), and Segment Forecasts, 2018–2025; Grand View Research: San Francisco, CA, USA, 2018. [Google Scholar]

- Sun, Y.; Yuan, B.; Shang, S.; Zhang, H.; Shi, Y.; Yu, B.; Qi, C.; Dong, H.; Chen, X.; Yang, X. Surface modification of ammonium polyphosphate by supramolecular assembly for enhancing fire safety properties of polypropylene. Compos. Part B Eng. 2020, 181, 107588. [Google Scholar] [CrossRef]

- Turku, I.; Kärki, T. Accelerated weathering of fire-retarded wood–polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 81, 305–312. [Google Scholar] [CrossRef]

- Ding, C.; Pan, M.; Chen, H.; Zhang, S.; Mei, C. An anionic polyelectrolyte hybrid for wood-polyethylene composites with high strength and fire safety via self-assembly. Constr. Build. Mater. 2020, 248, 118661. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Q.; Li, G.; Li, M.-C.; Sun, X.; Ring, D. Synergistic influence of halogenated flame retardants and nanoclay on flame performance of high density polyethylene and wood flour composites. RSC Adv. 2017, 7, 24895–24902. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Z.; Wu, L.; Zhang, Y.; Mai, K. β-Crystallization and mechanical properties of aluminum hydroxide-filled poly-propylene composites. Polym. Compos. 2019, 40, E194–E201. [Google Scholar] [CrossRef]

- Guan, Y.-H.; Liao, W.; Xu, Z.-Z.; Chen, M.-J.; Huang, J.-Q.; Wang, Y.-Z. Improvement of the flame retardancy of wood-fibre/polypropylene composites with ideal mechanical properties by a novel intumescent flame retardant system. RSC Adv. 2015, 5, 59865–59873. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Pan, Y.-T.; Zhang, S.; Nie, S.; Wei, P.; Zhang, X.; Wang, R.; Wang, D.-Y. Nickel Metal-Organic Framework Derived Hierarchically Mesoporous Nickel Phosphate toward Smoke Suppression and Mechanical Enhancement of Intu-mescent Flame Retardant Wood Fiber/Poly (lactic acid) Composites. ACS Sustain. Chem. Eng. 2019, 7, 9272–9280. [Google Scholar] [CrossRef]

- Kalali, E.N.; Zhang, L.; Shabestari, M.E.; Croyal, J.; Wang, D.-Y. Flame-retardant wood polymer composites (WPCs) as potential fire safe bio-based materials for building products: Preparation, flammability and mechanical properties. Fire Saf. J. 2019, 107, 210–216. [Google Scholar] [CrossRef]

- Yu, F.; Xu, F.; Song, Y.; Fang, Y.; Zhang, Z.; Wang, Q.; Wang, F. Expandable graphite’s versatility and synergy with carbon black and ammonium polyphosphate in improving antistatic and fire-retardant properties of wood flour/polypropylene composites. Polym. Compos. 2017, 38, 767–773. [Google Scholar] [CrossRef]

- Schirp, A.; Hellmann, A. Fire retardancy improvement of high-density polyethylene composites based on thermomechanical pulp treated with ammonium polyphosphate. Polym. Compos. 2019, 40, 2410–2423. [Google Scholar] [CrossRef]

- Nishino, K.; Shindo, Y.; Ito, H.; Takayama, T. Improvement of impact strength and hydrolytic stability of PC/ABS blend using reactive polymer. J. Appl. Polym. Sci. 2016, 134. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, W.; Qin, Z.; Yang, R. Optically transparent and flame-retarded polycarbonate nanocomposite based on di-phenylphosphine oxide-containing polyhedral oligomeric silsesquioxanes. Compos. Part A Appl. Sci. Manuf. 2019, 117, 92–102. [Google Scholar] [CrossRef]

- Zhang, J.; Koubaa, A.; Xing, D.; Liu, W.; Wang, H.; Wang, X.; Wang, Q. High-performance lignocellulose/polycarbonate bio-composites fabricated by in situ reaction: Structure and properties. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106068. [Google Scholar] [CrossRef]

- Mariano, M.; El Kissi, N.; Dufresne, A. Melt processing of cellulose nanocrystal reinforced polycarbonate from a masterbatch process. Eur. Polym. J. 2015, 69, 208–223. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Preparation and characterization of cellulose nanofibril films from wood fibre and their thermoplastic polycarbonate composites. Int. J. Polym. Sci. 2012, 2012, 381342. [Google Scholar] [CrossRef]

- Liu, Y.; Li, G.; Hu, Y.; Wang, A.; Lu, F.; Zou, J.-J.; Cong, Y.; Li, N.; Zhang, T. Integrated Conversion of Cellulose to High-Density Aviation Fuel. Joule 2019, 3, 1028–1036. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Xing, D.; Wang, Q.; Wang, H.; Koubaa, A. Reinforcement of continuous fibers for extruded wood-flour/HDPE composites: Effects of fiber type and amount. Constr. Build. Mater. 2019, 228, 116718. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Malaysia, M.U.S.; Ismail, H. Thermoplastic/Natural Filler Composites: A Short Review. J. Phys. Sci. 2019, 30, 81–99. [Google Scholar] [CrossRef]

- Kandola, B.K.; Mistik, S.I.; Pornwannachai, W.; Anand, S.C. Natural fibre-reinforced thermoplastic composites from wo-ven-nonwoven textile preforms: Mechanical and fire performance study. Compos. Part B 2018, 153, 456–464. [Google Scholar] [CrossRef]

- Kandola, B.K.; Pornwannachai, W.; Ebdon, J.R. Flax/PP and Flax/PLA Thermoplastic Composites: Influence of Fire Retardants on the Individual Components. Polymers 2020, 12, 2452. [Google Scholar] [CrossRef] [PubMed]

- Hyvärinen, M.; Ronkanen, M.; Kärki, T. The effect of the use of construction and demolition waste on the mechanical and moisture properties of a wood-plastic composite. Compos. Struct. 2019, 210, 321–326. [Google Scholar] [CrossRef]

- Chun, K.S.; Fahamy, N.M.Y.; Yeng, C.Y.; Choo, H.L.; Ming, P.M.; Thai, K.Y. Wood-plastic composites made from corn husk fiber and recycled polystyrene foam. J. Eng. Sci. Technol. 2018, 13, 3445–3456. [Google Scholar]

- Feng, J.; Li, S.; Peng, R.; Sun, T.; Xie, X.; Shi, Q. Effects of fungal decay on properties of mechanical, chemical, and water absorption of wood plastic composites. J. Appl. Polym. Sci. 2021, 138, 50022. [Google Scholar] [CrossRef]

- Kamau-Devers, K.; Kortum, Z.; Miller, S.A. Hydrothermal aging of bio-based poly (lactic acid) (PLA) wood polymer compo-sites: Studies on sorption behavior, morphology, and heat conductance. Constr. Build. Mater. 2019, 214, 290–302. [Google Scholar] [CrossRef]

- Zhang, J.; Koubaa, A.; Xing, D.; Wang, H.; Wang, Y.; Liu, W.; Zhang, Z.; Wang, X.; Wang, Q. Conversion of lignocellulose into biochar and furfural through boron complexation and esterification reactions. Bioresour. Technol. 2020, 312, 123586. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.M.; Lin, P.C.; Murakami, R. Long-term creep behavior of self-reinforced PET composites. Express Polym. Lett. 2017, 11, 820–831. [Google Scholar] [CrossRef]

- Stark, N.M.; Mueller, S.A.; White, R.H.; Osswald, T.A. Effect of fire retardants on heat release rate of wood flour-polyethylene composites. In Proceedings of the 10th International Conference on Wood & Biofiber Plastic Composite and Cellulose Nanocomposites Symposium, Madison, WI, USA, 11–12 May 2009; pp. 103–109. [Google Scholar]

- Chapple, S.; Anandjiwala, R. Flammability of Natural Fiber-reinforced Composites and Strategies for Fire Retardancy: A Review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Nikolaeva, M.; Kärki, T.I.M.O. A review of fire retardant processes and chemistry, with discussion of the case of wood-plastic composites. Baltic For 2011, 17, 314326. [Google Scholar]

- Grand, A.F.; Wilkie, C.A. Fire Retardancy of Polymeric Materials; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Sun, L.; Xie, Y.; Ou, R.; Guo, C.; Hao, X.; Wu, Q.; Wang, Q. The influence of double-layered distribution of fire retardants on the fire retardancy and mechanical properties of wood fiber polypropylene composites. Constr. Build. Mater. 2020, 242, 118047. [Google Scholar] [CrossRef]

- Navarro-Gonzalez, R.; Coll, P.; Aliev, R. Pyrolysis of γ-irradiated bisphenol-A polycarbonate. Polym. Bull. 2002, 48, 43–51. [Google Scholar] [CrossRef]

- Mu, B.; Wang, H.; Hao, X.; Wang, Q. Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition. Polymers 2018, 10, 308. [Google Scholar] [CrossRef] [PubMed]

- Azeh, Y.; Olatunji, G.A.; Mamza, P.A. Scanning Electron Microscopy and Kinetic Studies of Ketene-Acetylated Wood/Cellulose High-Density Polyethylene Blends. Int. J. Carbohydr. Chem. 2012, 29, 1–7. [Google Scholar] [CrossRef]

- Benthien, J.T.; Ohlmeyer, M. Thickness swelling and water absorption of WPC after immersion in cold and boiling water. Eur. J. Wood Wood Prod. 2013, 71, 437–442. [Google Scholar] [CrossRef]

- Feng, J.; Shi, Q.; Chen, Y.; Huang, X. Mold Resistance and Water Absorption of Wood/HDPE and Bamboo/HDPE Composites. J. Appl. Sci. 2014, 14, 776–783. [Google Scholar] [CrossRef][Green Version]

- Wang, W.-H.; Huang, H.-B.; Du, H.-H.; Wang, H. Effects of fiber size on short-term creep behavior of wood fiber/HDPE composites. Polym. Eng. Sci. 2014, 55, 693–700. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Yang, H.-S.; Kim, H.-J.; Jeong, C.-S.; Lim, B.-S.; Lee, J.-N. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- The Engineering ToolBox. Young’s Modulus-Tensile and Yield Strength for Common Materials. Engineering ToolBox United States, 2003. Available online: https://www.engineeringtoolbox.com/young-modulus-d_417.html (accessed on 22 May 2021).

- Rimdusit, S.; Wongsongyot, S.; Jittarom, S.; Suwanmala, P.; Tiptipakorn, S. Effects of gamma irradiation with and without compatibilizer on the mechanical properties of polypropylene/wood flour composites. J. Polym. Res. 2011, 18, 801–809. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Creep behaviour of HDPE/wood particle composites. Int. J. Microstruct. Mater. Prop. 2013, 8, 225–238. [Google Scholar] [CrossRef]

| Composition | WPCC0 | WPCC10 | WPCC20 | WPCC30 | WPCC40 |

|---|---|---|---|---|---|

| Wood flour (wt. %) | 0 | 10 | 20 | 30 | 40 |

| Polycarbonate (wt. %) | 100 | 90 | 80 | 70 | 60 |

| Samples | IT (s) | PHRR (kW m−2) | Flaming Dripping | Self-Extinguishing |

|---|---|---|---|---|

| Neat PC | 88 | 332.3 | No | Yes |

| WPC10 | 28 | 298.3 | No | Yes |

| WPC20 | 31 | 216.3 | No | Yes |

| WPC30 | 31 | 182.8 | No | Yes |

| WPC40 | 32 | 187.9 | No | Yes |

| Burgers Model | Findley’s Power Law Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wood Flour Content | E1 (MPa) | E2 (MPa) | η1 (MPa s) | η2 (MPa s) | R2 | ε0 | A | n | R2 |

| 0% | 6391.482 | 1378.851 | 890,473.587 | 6951.743 | 1.00 | −6.4998 × 10−4 | 0.00336 | 0.27717 | 0.995 |

| 10% | 8158.469 | 1787.585 | 958,608.082 | 36,341.878 | 1.00 | −1.09 × 10−3 | 0.00248 | 0.33628 | 0.995 |

| 20% | 11,716.722 | 2089.627 | 1,086,001.610 | 48,037.217 | 1.00 | −9.1809 × 10−4 | 0.00363 | 0.2847 | 0.995 |

| 30% | 21,637.338 | 2286.305 | 1,070,591.423 | 70,117.161 | 1.00 | −8.4842 × 10−4 | 0.00474 | 0.26555 | 0.996 |

| 40% | 13,531.938 | 2410.191 | 1,142,779.012 | 43,057.373 | 1.00 | −2.2283 × 10−4 | 0.00977 | 0.16832 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Koubaa, A.; Xing, D.; Godard, F.; Li, P.; Tao, Y.; Wang, X.-M.; Wang, H. Fire Retardancy, Water Absorption, and Viscoelasticity of Borated Wood—Polycarbonate Biocomposites. Polymers 2021, 13, 2234. https://doi.org/10.3390/polym13142234

Zhang J, Koubaa A, Xing D, Godard F, Li P, Tao Y, Wang X-M, Wang H. Fire Retardancy, Water Absorption, and Viscoelasticity of Borated Wood—Polycarbonate Biocomposites. Polymers. 2021; 13(14):2234. https://doi.org/10.3390/polym13142234

Chicago/Turabian StyleZhang, Jingfa, Ahmed Koubaa, Dan Xing, François Godard, Peng Li, Yubo Tao, Xiang-Ming Wang, and Haigang Wang. 2021. "Fire Retardancy, Water Absorption, and Viscoelasticity of Borated Wood—Polycarbonate Biocomposites" Polymers 13, no. 14: 2234. https://doi.org/10.3390/polym13142234

APA StyleZhang, J., Koubaa, A., Xing, D., Godard, F., Li, P., Tao, Y., Wang, X.-M., & Wang, H. (2021). Fire Retardancy, Water Absorption, and Viscoelasticity of Borated Wood—Polycarbonate Biocomposites. Polymers, 13(14), 2234. https://doi.org/10.3390/polym13142234