Enhancement of Flame Retardancy and Mechanical Properties of Polylactic Acid with a Biodegradable Fire-Retardant Filler System Based on Bamboo Charcoal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

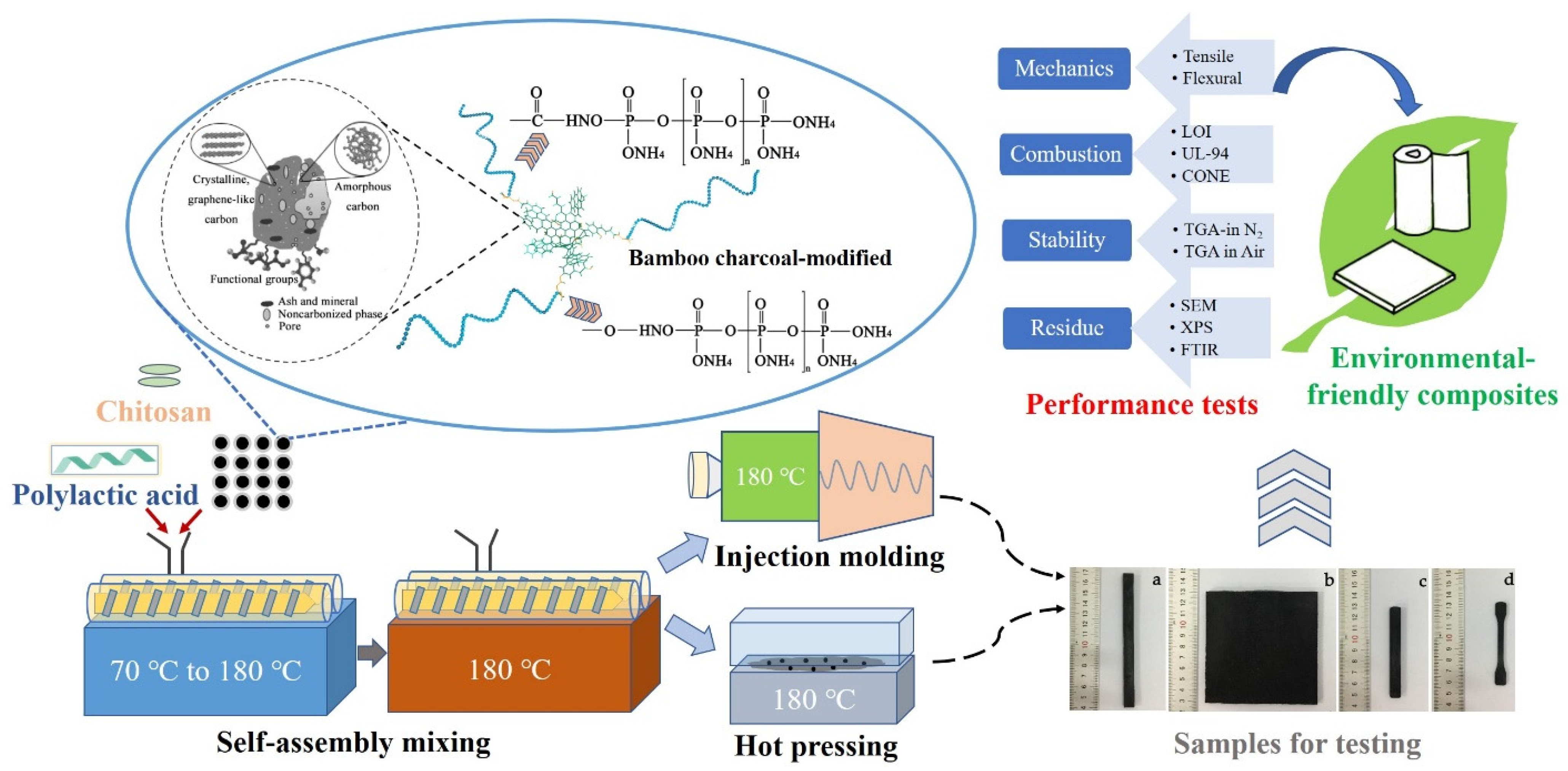

2.2. Preparation

2.2.1. Grafting Modification of BC

2.2.2. Preparation of Flame-Retardant PLA Composites

2.3. Measurement and Characterization

2.3.1. Characterization of PLA Composites

2.3.2. Mechanical Properties

2.3.3. Thermal Behavior

2.3.4. Combustion Properties Tests

2.3.5. Residue Analysis

3. Results

3.1. Characterization of PLA and FPLA Composites

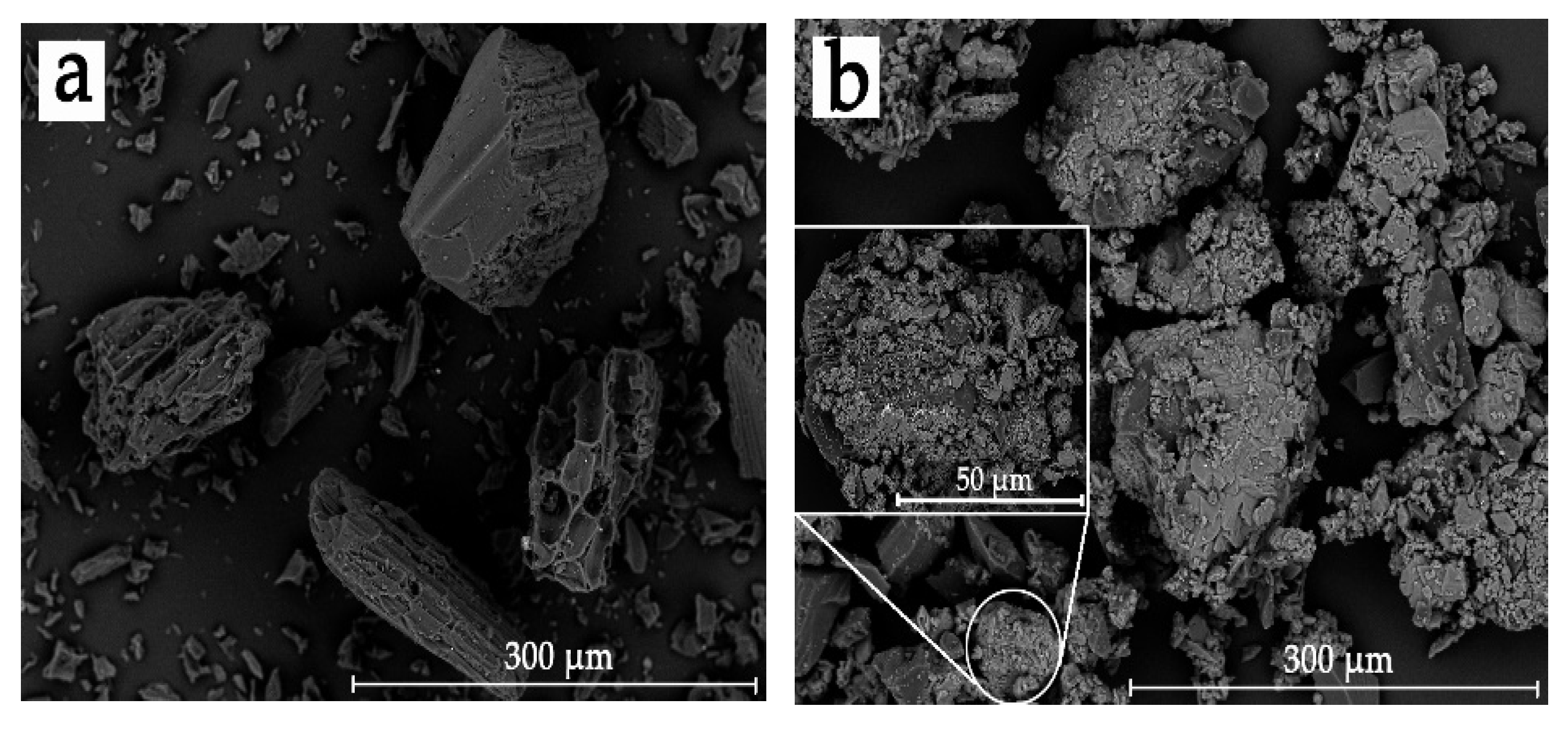

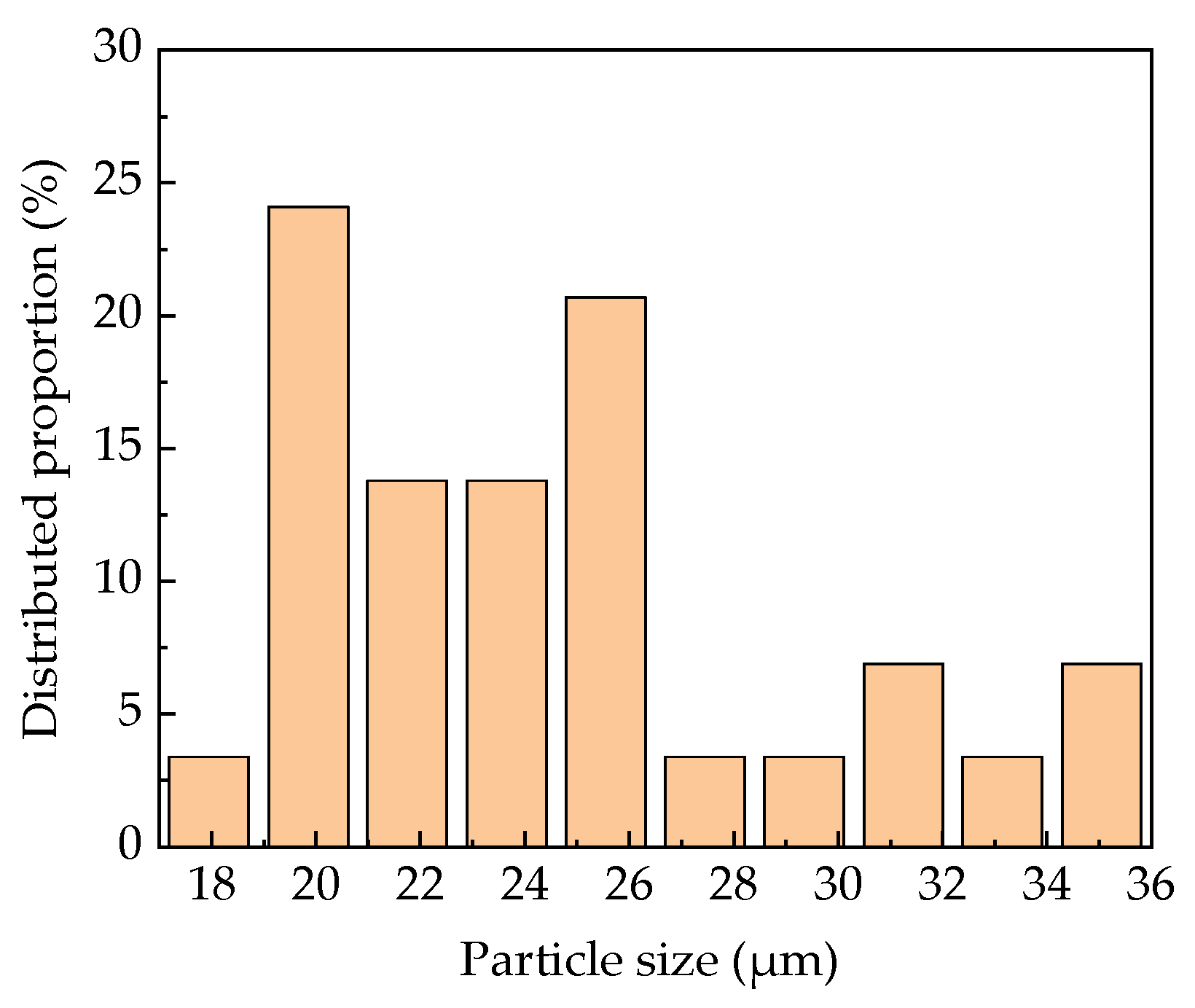

3.1.1. Micromorphology and Dispersibility

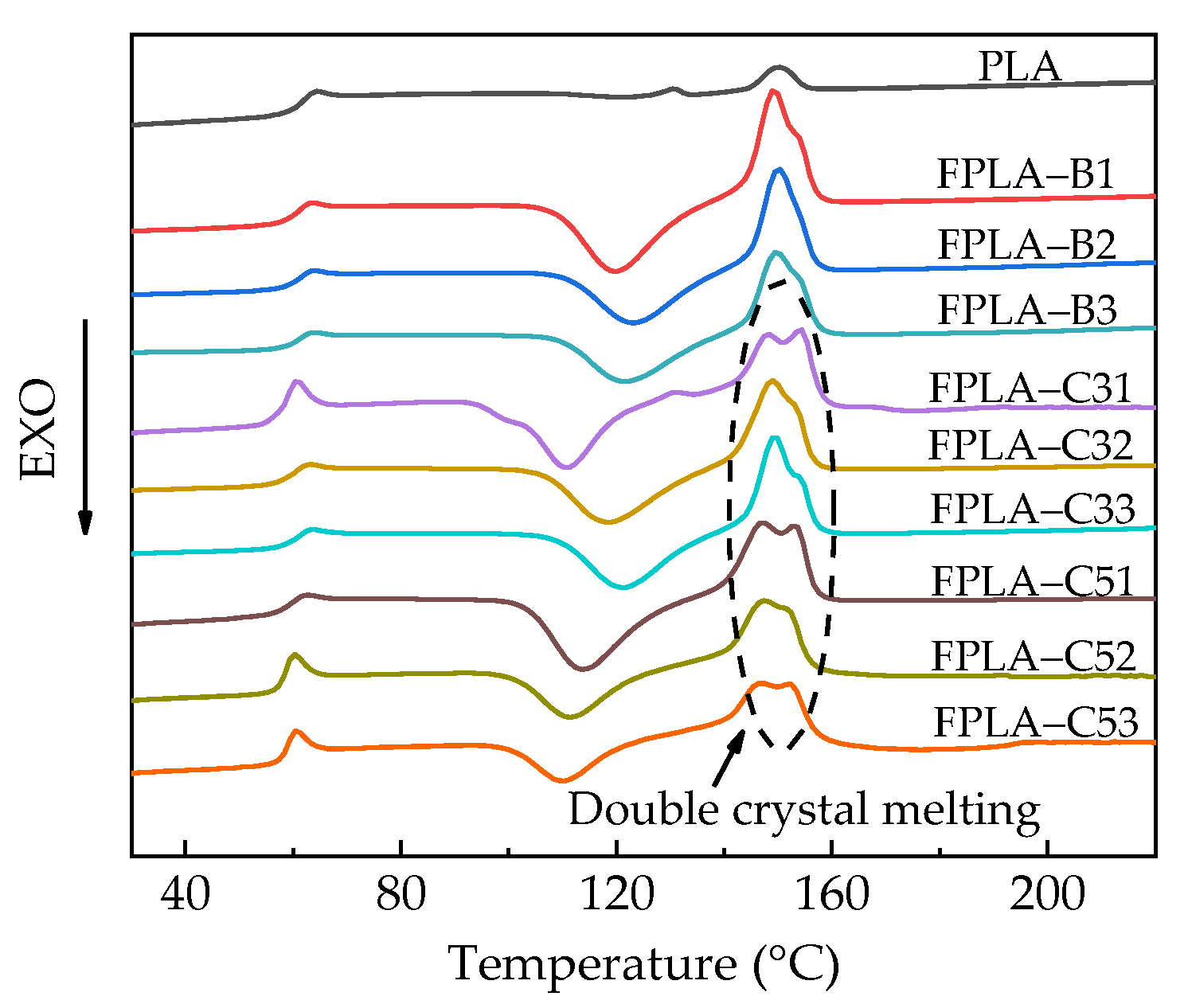

3.1.2. Thermal Properties

3.1.3. X-ray Diffraction Analysis

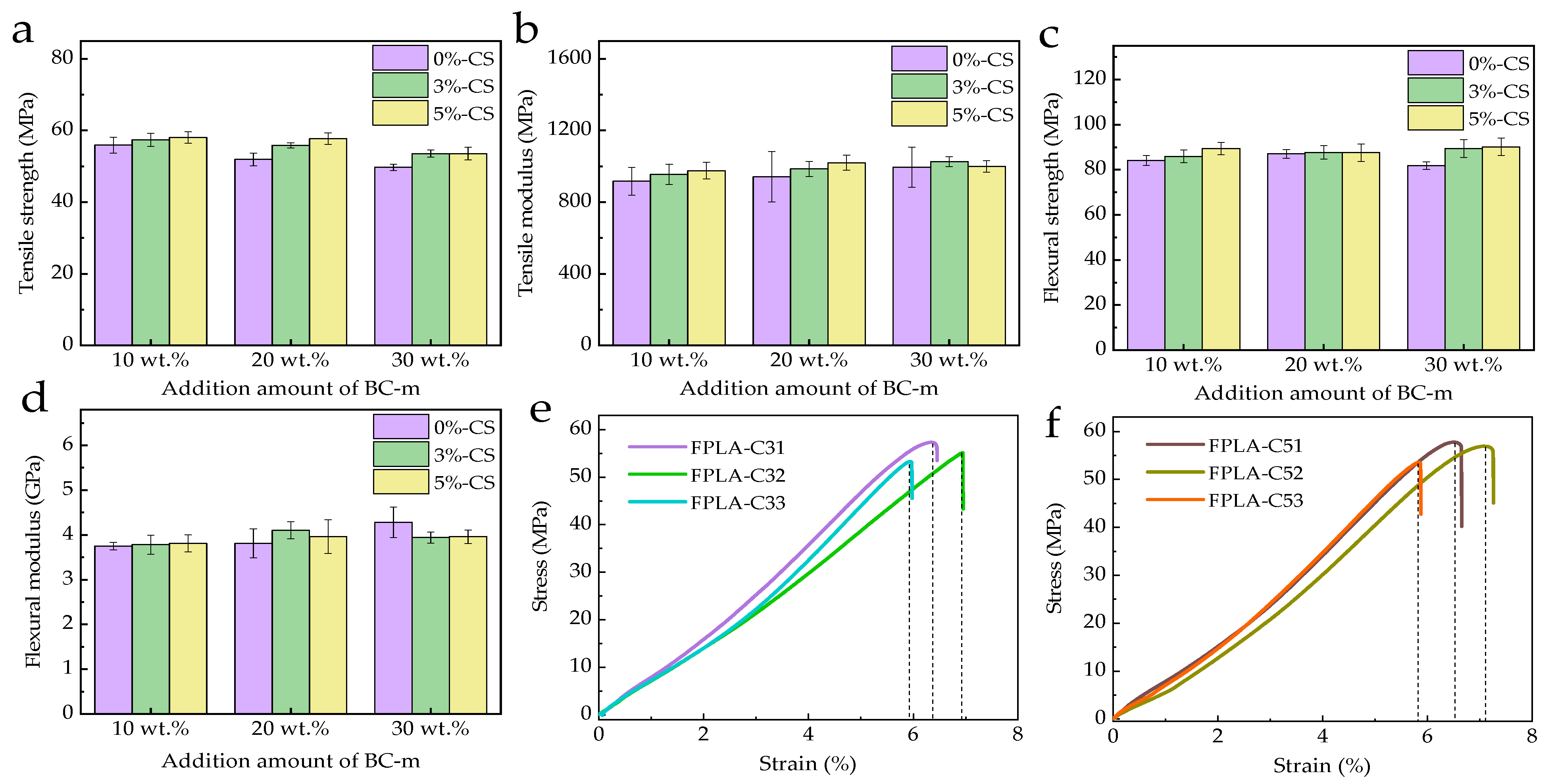

3.2. Mechanical Properties

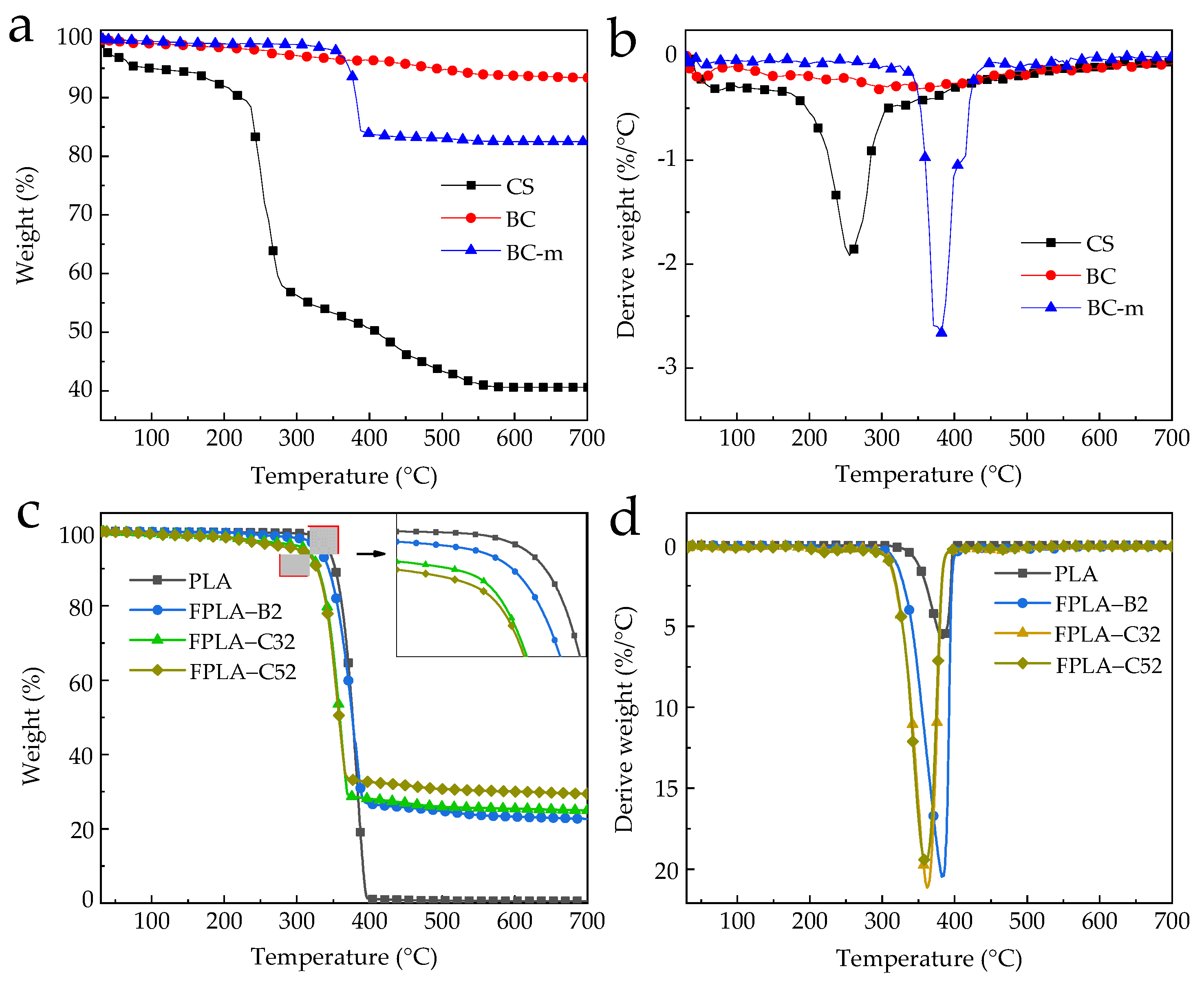

3.3. Thermal Degradation Behavior

3.3.1. TG in N2

3.3.2. TG in Air

3.4. Combustion Characterization

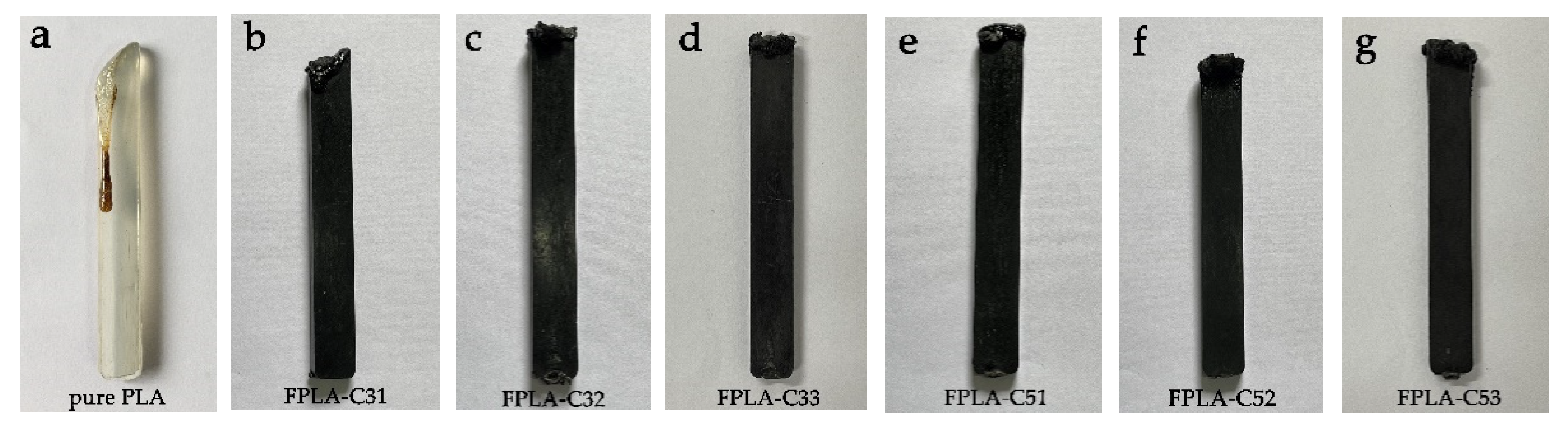

3.4.1. LOI and UL-94

3.4.2. Cone Calorimeter (CONE) Results

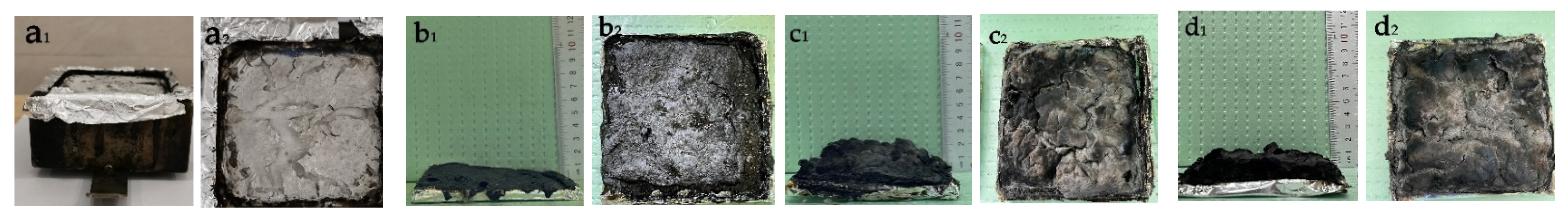

3.5. Residue Analysis

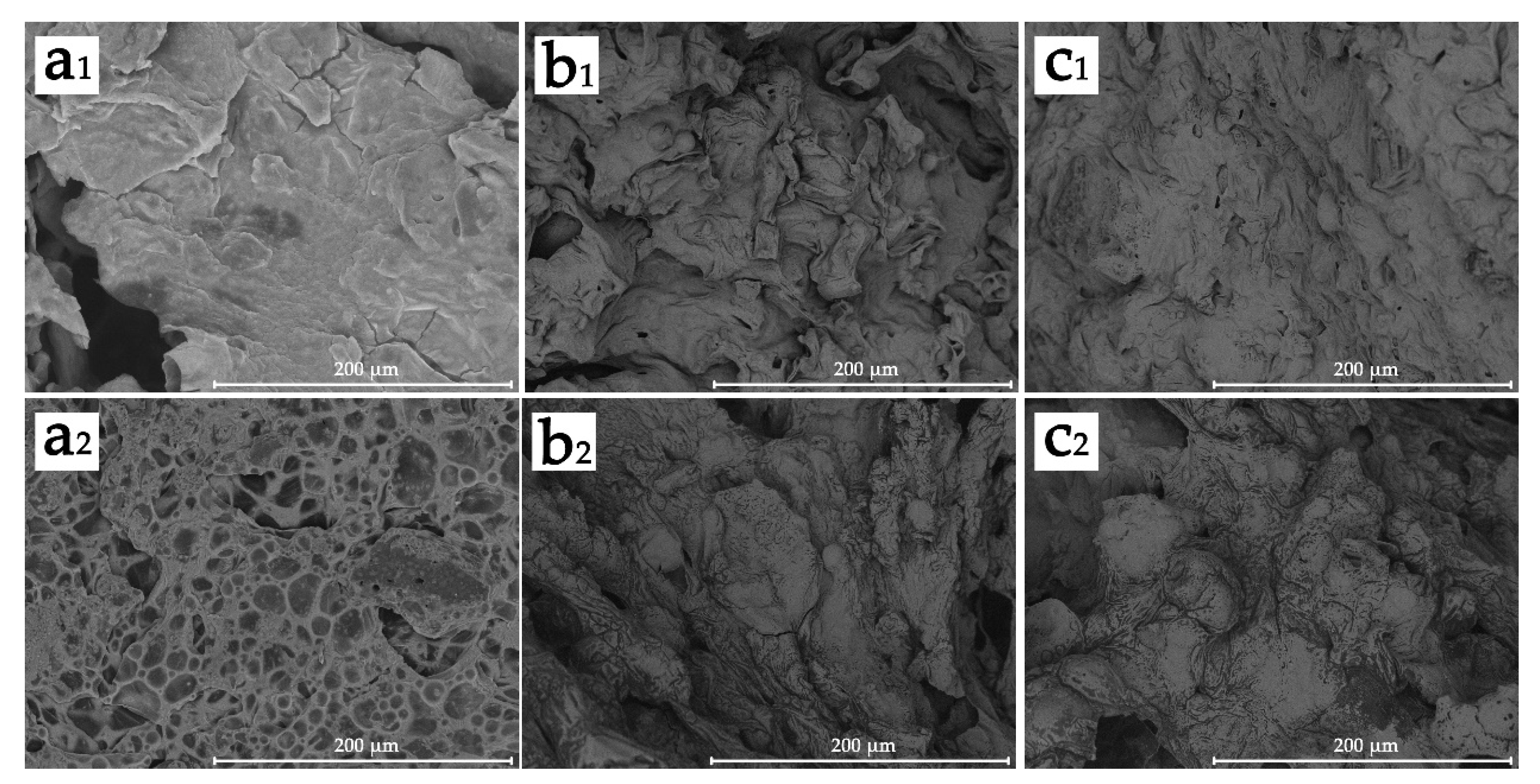

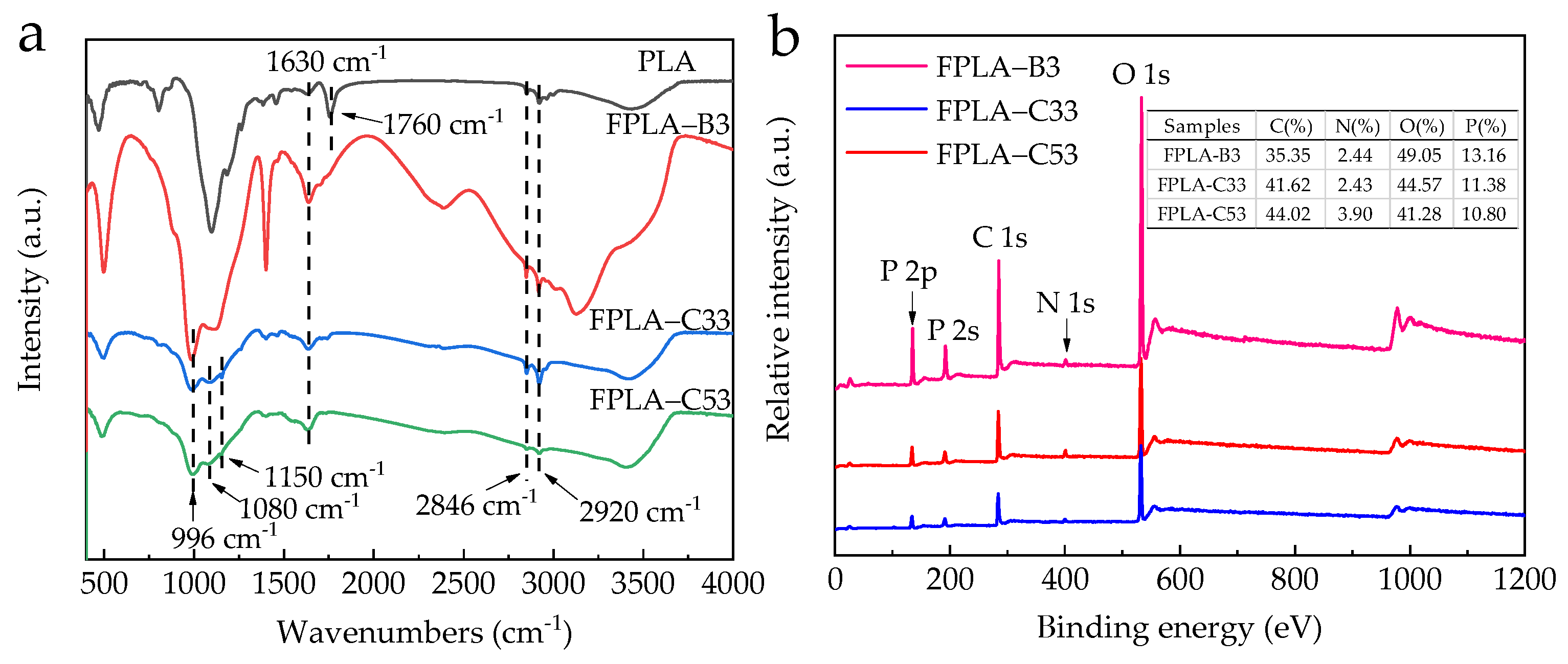

3.5.1. Morphology of Residue Surfaces and Inner Layers

3.5.2. Structure and Composition

4. Conclusions

- (1)

- Co-adding 3 or 5 wt.% CS with BC-m to PLA enhanced tensile properties of PLA. CS is an interfacial adhesion promoter which improves the interfacial compatibility between BC-m and PLA. Adding 3 wt.% CS and 30 wt.% BC-m increased the crystallinity to 38.92% or 43 times that of pure PLA (0.9%). The internal crystal structure was reorganized by CS addition and the crystallinity index was increased.

- (2)

- TGA showed early thermal degradation of CS-added PLA/BC-m composites and enhanced residue mass. In nitrogen atmosphere co-adding 5 wt.% CS and 20 wt.% BC-m, the corresponding residue (29.4%) was 55.1% higher than the theoretical value (18.97%).

- (3)

- Co-adding 5 wt.% CS and 30 wt.% BC-m, increased LOI to 33.6 vol%; 4.7% higher than adding BC-m alone. UL-94 V-0 rating at low BC-m addition (10 wt.%) was improved correspondingly. Cooperative effectiveness analysis (Ce) on LOI results suggest that active cooperation between CS and BC-m improves the flame retardancy of PLA/BC-m composites.

- (4)

- CONE results showed very effective further combustion suppression with just 3% CS co-addition to the effective baseline of 20% or more BC-m addition. For example peak heat release rate (pHRR) was reduced by almost 27% for 3% CS + 20% BC-m, and total heat release (THR) was reduced by 30.5%. Analysis of char morphology, chemical elements, and structure reveals that CS and BC-m form a denser, more stable carbonized layer that is effective in heat and oxygen insulation, resulting in improved flame retardancy of PLA composites.

- (5)

- A mix of just 20 wt.% BC-m + 3 wt.% CS may be a viable flame-retardant system that meets the requirements for a non-toxic, strong and biodegradable PLA packaging product.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, X.; Li, J.; Wu, Y. Synergistic effect of aluminum hypophosphite and intumescent flame-retardants in polylactide. Polym. Adv. Technol. 2015, 26, 255–265. [Google Scholar] [CrossRef]

- Gu, L.; Qiu, J.; Qiu, C.; Yao, Y.; Sakai, E.; Yang, L. Mechanical properties and degrading behaviors of aluminum hypophosphite-poly (Lactic Acid) (PLA) nanocomposites. Polym. Plast. Technol. Mater. 2019, 58, 126–138. [Google Scholar] [CrossRef]

- Nurul Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Mohamad Haafiz, M.K.; Saurabh, C.K.; Hussin, M.H.; HPS, A.K. Green composites made of bamboo fabric and poly (lactic) acid for packaging applications—A review. Materials 2016, 9, 435. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.W.; Shim, J.K.; Selke, S.E.; Soto-Valdez, H.; Matuana, L.; Rubino, M.; Auras, R. Poly (L-lactic acid) with added α-tocopherol and resveratrol: Optical, physical, thermal and mechanical properties. Polym. Int. 2012, 61, 418–425. [Google Scholar] [CrossRef]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-Manchadob, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef] [Green Version]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Zhan, J.; Liu, X.; Cao, C. Synergistic effect of OZrP on the combustion properties and thermal degradation behavior of intumescent flame retardant polylactide. In IOP Conference Series: Materials Science and Engineering; IOP: London, UK, 2020; Volume 740, p. 012070. [Google Scholar]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Li, S.; Yuan, H.; Yu, T.; Yuan, W.; Ren, J. Flame-retardancy and anti-dripping effects of intumescent flame-retardant incorporating montmorillonite on poly(lactic acid). Polym. Adv. Technol. 2009, 20, 1114–1120. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; Xing, W.; Zhang, P.; Wang, B.; Hong, N.; Yang, W.; Hu, Y.; Song, L. Thermal degradation and flame retardance of biobased polylactide composites based on aluminum hypophosphite. Ind. Eng. Chem. Res. 2012, 51, 12009–12016. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.M.; Dubois, P. New prospects in flame-retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Li, L.; Mao, X.; Ju, R.; Chen, Y.; Qian, L. Synergistic effect of organo-montmorillonite on intumescent flame-retardant PLA. Ferroelectrics 2018, 527, 25–36. [Google Scholar] [CrossRef]

- Gu, L.; Qiu, J.; Yao, Y.; Sakai, E.; Yang, L. Functionalized MWCNTs modified flame retardant PLA nanocomposites and cold rolling process for improving mechanical properties. Compos. Sci. Technol. 2018, 161, 39–49. [Google Scholar] [CrossRef]

- Vahabi, H.; Shabanian, M.; Aryanasab, F.; Mangin, R.; Laoutid, F.; Saeb, M.R. Inclusion of modified lignocellulose and nano-hydroxyapatite in development of new bio-based adjuvant flame retardant for poly (lactic acid). Thermochim. Acta 2018, 666, 51–59. [Google Scholar] [CrossRef]

- Shabanian, M.; Hajibeygi, M.; Hedayati, K.; Khaleghi, M.; Khonakdar, H.A. New ternary PLA/organoclay-hydrogel nanocomposites: Design, preparation and study on thermal, combustion and mechanical properties. Mater. Des. 2016, 110, 811–820. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Semple, K.; Zhang, M.; Zhang, W.; Dai, C. Development of biodegradable flame-retardant bamboo charcoal composites, Part I: Thermal and elemental analyses. Polymers 2020, 12, 2217. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Semple, K.; Zhang, M.; Zhang, W.; Dai, C. Development of biodegradable flame-retardant bamboo charcoal composites, Part II: Thermal degradation, gas phase, and elemental analyses. Polymers 2020, 12, 2238. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Chai, W.; Li, W.; Kate Semple k Yin, N.; Zhang, W.; Dai, C. Intumescent-Grafted Bamboo Charcoal: A Natural Nontoxic Fire-Retardant Filler for Polylactic Acid (PLA) Composites; ACS OMEGA: Washington, DC, USA, 2021; in press. [Google Scholar]

- Feng, C.; Liang, M.; Jiang, J.; Huang, J.; Liu, H. Flame retardant properties and mechanism of an efficient intumescent flame retardant PLA composites. Polym. Adv. Technol. 2016, 27, 693–700. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, H.; Shen, L.; Fang, Z.; Zhang, X.; Wang, J.; Zhang, B. Chitosan/phytic acid polyelectrolyte complex: A green and renewable intumescent flame retardant system for ethylene–vinyl acetate copolymer. Ind. Eng. Chem. Res. 2014, 53, 19199–19207. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Hu, Y.; Peng, X.; Yang, H.; Qian, X. Phosphorylated chitosan-cobalt complex: A novel green flame retardant for polylactic acid. Polym. Adv. Technol. 2018, 29, 860–866. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Wang, B.; Wen, P.; Song, L.; Hu, Y.; Zhang, P. Comparative study on the effect of beta-cyclodextrin and polypseudorotaxane as carbon sources on the thermalstability and flame-retardance of polylactic acid. Ind. Eng. Chem. Res. 2013, 52, 3287–3294. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Q.; Zheng, W.; Zhai, W. Improved flame-retardant properties of poly(lactic acid) foams using starch as a natural charring agent. Ind. Eng. Chem. Res. 2014, 53, 1422–1430. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly(lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Réti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R Rep. 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Amri, F.; Husseinsyah, S.; Hussin, K. Mechanical, morphological and thermal properties of chitosan filled polypropylene composites: The effect of binary modifying agents. Compos. Part A Appl. Sci. Manuf. 2013, 46, 89–95. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Recent advances in graft copolymerization and applications of chitosan: A review. ACS Sustain. Chem. Eng. 2014, 2, 2637–2652. [Google Scholar] [CrossRef]

- Chen, C.; Gu, X.; Jin, X.; Sun, J.; Zhang, S. The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydr. Polym. 2017, 157, 1586–1593. [Google Scholar] [CrossRef]

- Bertolino, V.; Cavallaro, G.; Milioto, S.; Lazzara, G. Polysaccharides/Halloysite nanotubes for smart bionanocomposite materials. Carbohydr. Polym. 2020, 245, 116502. [Google Scholar] [CrossRef] [PubMed]

- Cavallaro, G.; Micciulla, S.; Chiappisi, L.; Lazzara, G. Chitosan-based smart hybrid materials: A physico-chemical perspective. J. Mater. Chem. B 2021, 9, 597–611. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Song, L.; Pan, H.; Hu, Y. Thermal properties and combustion behaviors of chitosan based flame retardant combining phosphorus and nickel. Ind. Eng. Chem. Res. 2012, 51, 3663–3669. [Google Scholar] [CrossRef]

- Fang, F.; Zhang, X.; Meng, Y.; Gu, Z.; Bao, C.; Ding, X.; Li, S.; Chen, X.; Tian, X. Intumescent flame retardant coatings on cotton fabric of chitosan and ammonium polyphosphate via layer-by-layer assembly. Surf. Coat. Technol. 2015, 262, 9–14. [Google Scholar] [CrossRef]

- Hu, S.; Song, L.; Pan, H.; Hu, Y.; Gong, X. Thermal properties and combustion behaviors of flame retarded epoxy acrylate with a chitosan based flame retardant containing phosphorus and acrylate structure. J. Anal. Appl. Pyrolysis 2012, 97, 109–115. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly (lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Standard Test Method for Plastics-Determination of Burning Behaviour by Oxygen Index; ISO 4589-2; ISO: Geneva, Switzerland, 2017.

- Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in A Vertical Position; ATSM D3801-10; ASTM: Philadelphia, PA, USA, 2020.

- Reaction to Fire Tests-Heat Release, Smoke Production and Mass Loss Rate; ISO 5660-1; ISO: Geneva, Switzerland, 2015.

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Halász, K.; Csóka, L. Plasticized biodegradable poly (lactic acid) based composites containing cellulose in micro-and nanosize. J. Eng. 2013, 329379. [Google Scholar] [CrossRef] [Green Version]

- Zhai, W.; Ko, Y.; Zhu, W.; Wong, A.; Park, C.B. A study of the crystallization, melting, and foaming behaviors of polylactic acid in compressed CO2. Int. J. Mol. Sci. 2009, 10, 5381–5397. [Google Scholar] [CrossRef] [PubMed]

- Yasuniwa, M.; Tsubakihara, S.; Iura, K.; Ono, Y.; Dan, Y.; Takahashi, K. Crystallization behavior of poly (L-lactic acid). Polymer 2006, 47, 7554–7563. [Google Scholar] [CrossRef]

- Spiridon, I.; Paduraru, O.M.; Zaltariov, M.F.; Darie, R.N. Influence of keratin on polylactic acid/chitosan composite properties. Behavior upon accelerated weathering. Ind. Eng. Chem. Res. 2013, 52, 9822–9833. [Google Scholar] [CrossRef]

- Mihai, M.; Huneault, M.A.; Favis, B.D. Crystallinity development in cellular poly (lactic acid) in the presence of supercritical carbon dioxide. J. Appl. Polym. Sci. 2009, 113, 2920–2932. [Google Scholar] [CrossRef] [Green Version]

- Bian, Y.; Han, C.; Han, L.; Lin, H.; Zhang, H.; Bian, J.; Dong, L. Toughening mechanism behind intriguing stress–strain curves in tensile tests of highly enhanced compatibilization of biodegradable poly (lactic acid)/poly (3-hydroxybutyrate-co-4-hydroxybutyrate) blends. RSC Adv. 2014, 4, 41722–41733. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Su, B.; Ramakrishna, S.; Lim, C.T. Chitosan nanofibers from an easily electrospinnable UHMWPEO-doped chitosan solution system. Biomacromolecules 2008, 9, 136–141. [Google Scholar] [CrossRef]

- Boonyeun, N.; Rujiravanit, R.; Saito, N. Deposition of carbon–tungsten carbide on coir pulp to improve its compatibility with polylactic acid. Cellulose 2021, 28, 4119–4136. [Google Scholar] [CrossRef]

- Husseinsyah, S.; Amri, F.; Husin, K.; Ismail, H. Mechanical and thermal properties of chitosan-filled polypropylene composites: The effect of acrylic acid. J. Vinyl Addit. Technol. 2011, 17, 125–131. [Google Scholar] [CrossRef]

- Shukor, F.; Hassan, A.; Islam, M.S.; Mokhtar, M.; Hasan, M. Effect of ammonium polyphosphate on flame-retardancy, thermal stability and mechanical properties of alkali treated kenaf fiber filled PLA biocomposites. Mater. Des. 2014, 54, 425–429. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Tang, X.; Zhou, Y.; Li, X.; Kandola, B.K.; Fang, Z. Layer by layer deposition of polyethylenimine and bio-based polyphosphate on ammonium polyphosphate: A novel hybrid for simultaneously improving the flame-retardancy and toughness of polylactic acid. Polymer 2017, 108, 361–371. [Google Scholar] [CrossRef]

- Lewin, M.; Weil, E.D. Mechanisms and modes of action in flame retardancy of polymers. Fire Retard. Mater. 2001, 1, 31–68. [Google Scholar]

- Horrocks, A.R.; Smart, G.; Nazaré, S.; Kandola, B.; Price, D. Quantification of zinc hydroxystannate** and stannate** synergies in halogen-containing flame-retardant polymeric formulations. J. Fire Sci. 2010, 28, 217–248. [Google Scholar] [CrossRef]

- Schartel, B.; Bartholmai, M.; Knoll, U. Some comments on the use of cone calorimeter data. Polym. Degrad. Stab. 2005, 88, 540–547. [Google Scholar] [CrossRef]

- Kim, H.; Kim, D.W.; Vasagar, V.; Ha, H.; Nazarenko, S.; Ellison, C.J. Polydopamine-graphene oxide flame retardant nanocoatings applied via an aqueous liquid crystalline scaffold. Adv. Funct. Mater. 2018, 28, 1803172. [Google Scholar] [CrossRef]

- Hassan, M.; Nour, M.; Abdelmonem, Y.; Makhlouf, G.; Abdelkhalik, A. Synergistic effect of chitosan-based flame retardant and modified clay on the flammability properties of LLDPE. Polym. Degrad. Stab. 2016, 133, 8–15. [Google Scholar] [CrossRef]

- Yin, W.; Chen, L.; Lu, F.; Song, P.; Dai, J.; Meng, L. Mechanically robust, flame-retardant poly (lactic acid) biocomposites via combining cellulose nanofibers and ammonium polyphosphate. ACS Omega 2018, 3, 5615–5626. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, R.; Wang, X.; Wang, B.; Song, L.; Hu, Y.; Gong, X. Enhancement of flame retardant performance of bio-based polylactic acid composites with the incorporation of aluminum hypophosphite and expanded graphite. J. Macromol. Sci. Part A 2013, 50, 255–269. [Google Scholar] [CrossRef]

- Yu, Y.; Song, P.A.; Jin, C.; Fu, S.; Zhao, L.; Wu, Q.; Ye, J. Catalytic effects of nickel (cobalt or zinc) acetates on thermal and flammability properties of polypropylene-modified lignin composites. Ind. Eng. Chem. Res. 2012, 51, 12367–12374. [Google Scholar] [CrossRef]

- Xu, B.; Ma, W.; Shao, L.; Qian, L.; Qiu, Y. Enhancement of an organic–metallic hybrid charring agent on flame retardancy of ethylene-vinyl acetate copolymer. R. Soc. Open Sci. 2019, 6, 181413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prabhakar, M.N.; Raghavendra, G.M.; Vijaykumar, B.V.D.; Patil, K.; Seo, J.; Jung-il, S. Synthesis of a novel compound based on chitosan and ammonium polyphosphate for flame retardancy applications. Cellulose 2019, 26, 8801–8812. [Google Scholar] [CrossRef]

| Scheme 100 | Composition (wt.%) | ||

|---|---|---|---|

| PLA | BC-m | CS | |

| PLA | 100 | 0 | 0 |

| FPLA-C3 | 97 | 0 | 3 |

| FPLA-C5 | 95 | 0 | 5 |

| FPLA-B1 | 90 | 10 | 0 |

| FPLA-B2 | 80 | 20 | 0 |

| FPLA-B3 | 70 | 30 | 0 |

| FPLA-C31 | 87 | 10 | 3 |

| FPLA-C32 | 77 | 20 | 3 |

| FPLA-C33 | 67 | 30 | 3 |

| FPLA-C51 | 85 | 10 | 5 |

| FPLA-C52 | 75 | 20 | 5 |

| FPLA-C53 | 65 | 30 | 5 |

| Sample | Tg (°C) | Tcc (°C) | Tm1 (°C) | Tm2 (°C) | ΔHc (J/g) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|---|

| PLA | 59.1 | 108.1 | 150.8 | - | 0.84 | 4.06 | 0.90 |

| FPLA-B1 | 58.1 | 119.8 | 149.2 | - | 27.39 | 27.77 | 32.51 |

| FPLA-B2 | 58.4 | 123.2 | 150.1 | - | 22.27 | 22.87 | 29.74 |

| FPLA-B3 | 58.7 | 121.6 | 149.7 | - | 21.26 | 20.71 | 32.45 |

| FPLA-C31 | 56.9 | 110.8 | 148.2 | 154.2 | 27.19 | 20.98 | 33.39 |

| FPLA-C32 | 57.1 | 118.4 | 149.0 | - | 25.63 | 24.44 | 35.56 |

| FPLA-C33 | 58.1 | 121.1 | 149.3 | - | 24.41 | 23.36 | 38.92 |

| FPLA-C51 | 57.1 | 114.0 | 147.2 | 152.9 | 30.43 | 28.8 | 38.25 |

| FPLA-C52 | 57.2 | 120.4 | 148.7 | 154.0 | 25.91 | 25.18 | 36.91 |

| FPLA-C53 | 57.6 | 112.1 | 145.1 | 152.6 | 18.99 | 18.16 | 31.21 |

| Sample | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|

| a PLA | 58.12 ± 1.76 | 774.24 ± 33.43 | 95.76 ± 0.80 | 3.73 ± 0.17 |

| a FPLA-B1 | 55.91 ± 2.23 | 917.06 ± 77.74 | 84.15 ± 2.18 | 3.75 ± 0.08 |

| a FPLA-B2 | 51.94 ± 1.77 | 941.15 ±141.33 | 87.01 ± 1.90 | 3.81 ± 0.32 |

| a FPLA-B3 | 49.71 ± 0.88 | 995.70 ± 112.20 | 81.77 ± 1.65 | 4.28 ± 0.34 |

| FPLA-C31 | 57.40 ± 1.83 | 955.02 ± 56.03 | 85.95 ± 2.84 | 3.78 ± 0.21 |

| FPLA-C32 | 55.84 ± 0.67 | 985.16 ± 42.75 | 87.70 ± 2.94 | 4.10 ± 0.19 |

| FPLA-C33 | 53.56 ± 1.02 | 1026.41 ± 27.41 | 89.37 ± 3.94 | 3.94 ± 0.12 |

| FPLA-C51 | 58.00 ± 1.61 | 976.00 ± 47.30 | 89.40 ± 2.68 | 3.81 ± 0.19 |

| FPLA-C52 | 57.71 ± 1.57 | 1020.43 ± 41.14 | 87.55 ± 3.90 | 3.96 ± 0.38 |

| FPLA-C53 | 53.54 ± 1.77 | 999.86 ± 32.44 | 90.12 ± 3.87 | 3.95 ± 0.14 |

| Samples | T-5% (°C) | Rpeak/Tmax (%·min−1/°C) | Residue Mass (%) |

|---|---|---|---|

| 700 (°C) | |||

| BC | 484 | 0.32/295 | 93.39 |

| BC-m | 373 | 2.66/382 | 82.47 |

| CS | 103 | 1.92/255 | 40.60 |

| PLA | 343 | 5.72/382 | 0.60 |

| a FPLA-B1 | 334 | 25.33/385 | 8.64 |

| a FPLA-B2 | 331 | 20.94/383 | 21.81 |

| a FPLA-B3 | 331 | 19.52/380 | 29.83 |

| FPLA-C31 | 316 | 22.24/365 | 8.97 |

| FPLA-C32 | 314 | 21.14/362 | 24.92 |

| FPLA-C33 | 311 | 18.81/359 | 29.56 |

| FPLA-C51 | 312 | 23.46/365 | 9.64 |

| FPLA-C52 | 306 | 19.55/360 | 29.42 |

| FPLA-C53 | 304 | 18.65/356 | 32.74 |

| Samples | T-5% (°C) | Rpeak/Tmax (%·min−1/°C) | Residue Mass (%) |

|---|---|---|---|

| 700 (°C) | |||

| FPLA-C31 | 317 | 38.48/363 | 3.01 |

| FPLA-C32 | 314 | 36.57/362 | 6.99 |

| FPLA-C33 | 311 | 25.30/358 | 10.48 |

| FPLA-C51 | 324 | 39.14/360 | 4.30 |

| FPLA-C52 | 313 | 37.76/360 | 8.10 |

| FPLA-C53 | 307 | 22.90/355 | 10.70 |

| Samples | LOI ± 0.2 (vol%) | UL-94 | Ce | ||

|---|---|---|---|---|---|

| a t1 (s)/t2 (s) | Dripping | Rating | |||

| PLA | 20.7 | b TB | Yes | c NR | - |

| FPLA-C3 | 21.5 | TB | Yes | NR | - |

| FPLA-C5 | 21.7 | TB | Yes | NR | - |

| d FPLA-B1 | 28.0 | 5.6/2.3 | Yes | V-2 | - |

| d FPLA-B2 | 29.2 | 2.1/1.1 | No | V-0 | - |

| d FPLA-B3 | 32.1 | 1.2/1.4 | No | V-0 | - |

| FPLA-C31 | 29.0 | 4.7/2.0 | No | V-1 | 1.02 |

| FPLA-C32 | 31.3 | 1.9/1.1 | No | V-0 | 1.14 |

| FPLA-C33 | 33.0 | 1.2/1.3 | No | V-0 | 1.01 |

| FPLA-C51 | 29.2 | 4.6/2.1 | No | V-1 | 1.02 |

| FPLA-C52 | 32.4 | 1.8/1.2 | No | V-0 | 1.23 |

| FPLA-C53 | 33.6 | 1.0/1.0 | No | V-0 | 1.04 |

| Samples | TTI (s) | pHRR (kW/m2) | THR (MJ/m2) | pMLR (g/s) | aEHC (MJ/kg) | RM (%) |

|---|---|---|---|---|---|---|

| PLA | 56 | 435.58 | 86.06 | 0.60 | 16.37 | 2.29 |

| b FPLA-B1 | 34 | 418.11 | 68.64 | 0.51 | 16.15 | 6.45 |

| b FPLA-B2 | 33 | 201.02 | 53.48 | 0.48 | 15.08 | 18.99 |

| b FPLA-B3 | 31 | 181.61 | 41.10 | 0.35 | 14.52 | 47.71 |

| FPLA-C31 | 37 | 216.33 | 54.19 | 0.67 | 12.28 | 8.36 |

| FPLA-C32 | 35 | 146.97 | 37.17 | 0.61 | 12.04 | 23.17 |

| FPLA-C33 | 34 | 123.38 | 29.00 | 0.37 | 11.01 | 35.99 |

| FPLA-C51 | 36 | 268.56 | 42.04 | 0.52 | 12.68 | 8.22 |

| FPLA-C52 | 37 | 156.85 | 38.79 | 0.74 | 11.67 | 26.26 |

| FPLA-C53 | 34 | 125.49 | 25.65 | 0.53 | 10.66 | 38.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Zhang, L.; Chai, W.; Yin, N.; Semple, K.; Li, L.; Zhang, W.; Dai, C. Enhancement of Flame Retardancy and Mechanical Properties of Polylactic Acid with a Biodegradable Fire-Retardant Filler System Based on Bamboo Charcoal. Polymers 2021, 13, 2167. https://doi.org/10.3390/polym13132167

Li W, Zhang L, Chai W, Yin N, Semple K, Li L, Zhang W, Dai C. Enhancement of Flame Retardancy and Mechanical Properties of Polylactic Acid with a Biodegradable Fire-Retardant Filler System Based on Bamboo Charcoal. Polymers. 2021; 13(13):2167. https://doi.org/10.3390/polym13132167

Chicago/Turabian StyleLi, Wenzhu, Liang Zhang, Weisheng Chai, Ningning Yin, Kate Semple, Lu Li, Wenbiao Zhang, and Chunping Dai. 2021. "Enhancement of Flame Retardancy and Mechanical Properties of Polylactic Acid with a Biodegradable Fire-Retardant Filler System Based on Bamboo Charcoal" Polymers 13, no. 13: 2167. https://doi.org/10.3390/polym13132167

APA StyleLi, W., Zhang, L., Chai, W., Yin, N., Semple, K., Li, L., Zhang, W., & Dai, C. (2021). Enhancement of Flame Retardancy and Mechanical Properties of Polylactic Acid with a Biodegradable Fire-Retardant Filler System Based on Bamboo Charcoal. Polymers, 13(13), 2167. https://doi.org/10.3390/polym13132167