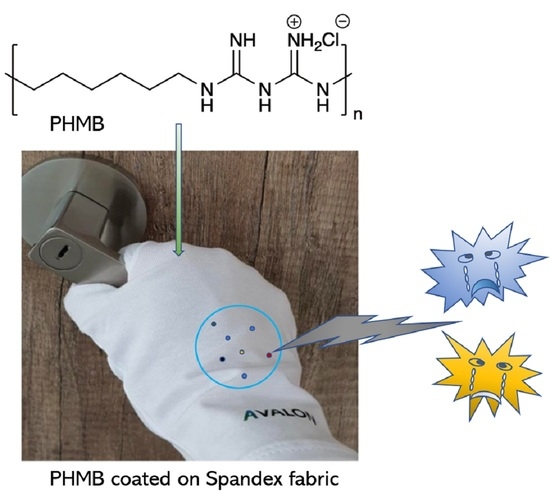

Study on the Development of Antiviral Spandex Fabric Coated with Poly(Hexamethylene Biguanide) Hydrochloride (PHMB)

Abstract

:1. Introduction

2. Materials and Methods

2.1. PHMB Coating Treatment

2.2. Qualitative Analysis of PHMB

2.3. Antiviral Activity

2.4. Antibacterial Property

2.5. Hand Feel Evaluation

3. Results and Discussion

3.1. Qualitative Analysis of PHMB Coated on the Surface of Spandex Fabric

3.2. Antiviral Activity of PHMB Coated Spandex Fabric

3.3. Antibacterial Properties of PHMB-Coated Spandex Fabric

3.4. Hand Feel Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singha, K. Analysis of Spandex/Cotton Elastomeric Properties: Spinning and Applications. Int. J. Compos. Mater. 2012, 2, 11–16. [Google Scholar] [CrossRef]

- Tezel, S.; Kavuşturan, Y. Experimental Investigation of Effects of Spandex Brand and Tightness Factor on Dimensional and Physical Properties of Cotton/Spandex Single Jersey Fabrics. Text. Res. J. 2008, 78, 966–976. [Google Scholar] [CrossRef]

- Islam, S.; Alam, S.M.; Akter, S. The consequences of temperature on the shrinkage properties of cotton spandex woven fabric. J. Text. Polym. 2019, 7, 2–7. [Google Scholar]

- Li, Q.; Ni, L.; Wang, J.; Quan, H.; Zhou, Y. Establishing an ultrasound-assisted activated peroxide system for efficient and sustainable scouring-bleaching of cotton/spandex fabric. Ultrason. Sonochem. 2020, 68, 105220. [Google Scholar] [CrossRef] [PubMed]

- Akter, N. Performance analysis of spandex incorporated single jersey fabrics for sportswear. Indian J. Sci. Technol. 2020, 13, 1998–2009. [Google Scholar] [CrossRef]

- Gohain, J.; Raichurkar, P. Study effect of different parameters in heat setting of spandex fabric and other quality. J. Text. Excell. 2011, 3, 41–49. [Google Scholar]

- Schollenberger, C.S.; Stewart, F.D. Thermoplastic Polyurethane Hydrolysis Stability. J. Elastoplast. 1971, 3, 28–56. [Google Scholar] [CrossRef]

- Gokarneshan, N.; Thangamani, K. An investigation into the properties of cotton/spandex and polyester/spandex knitted fab-rics. J. Text. Inst. 2010, 101, 182–186. [Google Scholar] [CrossRef]

- Team, I.C.F. Modeling COVID-19 scenarios for the United States. Nat. Med. 2021, 27, 94–105. [Google Scholar]

- Chin, A.W.H.; Chu, J.T.S.; Perera, M.R.A.; Hui, K.P.Y.; Yen, H.L.; Chan, M.C.W.; Peiris, M.; Poon, L.L.M. Stability of SARS-CoV-2 in different environmental conditions. Lancet 2020, 1, e145. [Google Scholar]

- Iyigundogdu, Z.U.; Demir, O.; Asutay, A.B.; Sahin, F. Developing Novel Antimicrobial and Antiviral Textile Products. Appl. Biochem. Biotechnol. 2017, 181, 1155–1166. [Google Scholar] [CrossRef] [PubMed]

- De Paula, G.F.; Netto, G.I.; Mattoso, L.H.C. Physical and Chemical Characterization of Poly(hexamethylene biguanide) Hydrochloride. Polymers 2011, 3, 928–941. [Google Scholar] [CrossRef]

- Blackburn, R.S.; Harvey, A.; Kettle, L.L.; Payne, J.D.; Russell, S.J. Sorption of Poly(hexamethylenebiguanide) on Cellulose: Mechanism of Binding and Molecular Recognition. Langmuir 2006, 22, 5636–5644. [Google Scholar] [CrossRef] [PubMed]

- Chindera, K.; Mahato, M.; Sharma, A.K.; Horsley, H.; Kloc-Muniak, K.; Kamaruzzaman, N.F.; Kumar, S.; McFarlane, A.; Stach, J.; Bentin, T.; et al. The antimicrobial polymer PHMB enters cells and selectively condenses bac-terial chromosomes. Sci. Rep. 2016, 6, 23121. [Google Scholar] [CrossRef] [PubMed]

- Kaehn, K. Polihexanide: A Safe and Highly Effective Biocide. Ski. Pharmacol. Physiol. 2010, 23, 7–16. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.-Y.; Kan, C.-W. An eco-friendly dyeing method: Bromophenol blue (BPB) applied for dyeing cotton fabrics coated with cationic finishing agents. Cellulose 2020, 27, 9045–9059. [Google Scholar] [CrossRef]

- Lau, J.Y.N.; Chan, D.S.B.; Chiou, J.; Kan, C.W.; Lam, K.H.; Lam, W.H.; Yung, K.F. Durable Antimicrobial Treatment of Textile for Use in Healthcare Environment. U.S. Patent Application No. 17/045,659, 4 April 2019. [Google Scholar]

- Pinto, F.; Maillard, J.-Y.; Denyer, S.; McGeechan, P. Polyhexamethylene biguanide exposure leads to viral aggregation. J. Appl. Microbiol. 2009, 108, 1880–1888. [Google Scholar] [CrossRef] [PubMed]

- Pinto, F. Mechanisms of Action of Polyhexamethylene Biguanide-Based Biocides Against Non-Enveloped Virus. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2010. [Google Scholar]

| Sample | Logarithm Average of Infectivity Titer (PFU/vial) | Antiviral Activity | Percentage/% | |

|---|---|---|---|---|

| Control | Immediately after inoculation | 5.71 | N/A | N/A |

| After contacting for 2 h | 5.24 | 0.47 | 66.29 | |

| PHMB-treated spandex fabric | After contacting for 2 h | 3.50 | 2.21 | 99.38 |

| Sample | Inhibition Zone/mm | Inhibition/% | ||

|---|---|---|---|---|

| SA | KP | SA | KP | |

| Control | 0 | 0 | N/A | N/A |

| PHMB-treated spandex fabric | 2.40 | 1.15 | 100 | 100 |

| Sample | Resilience | Softness | Smoothness | Wrinkle Recovery/% |

|---|---|---|---|---|

| Control | 41.85 | 88.58 | 54.44 | 65.2 |

| PHMB-treated spandex fabric | 39.69 | 88.37 | 55.56 | 73.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.-Y.; Yim, S.-L.; Wong, C.-H.; Kan, C.-W. Study on the Development of Antiviral Spandex Fabric Coated with Poly(Hexamethylene Biguanide) Hydrochloride (PHMB). Polymers 2021, 13, 2122. https://doi.org/10.3390/polym13132122

Wang W-Y, Yim S-L, Wong C-H, Kan C-W. Study on the Development of Antiviral Spandex Fabric Coated with Poly(Hexamethylene Biguanide) Hydrochloride (PHMB). Polymers. 2021; 13(13):2122. https://doi.org/10.3390/polym13132122

Chicago/Turabian StyleWang, Wen-Yi, Sui-Lung Yim, Chun-Ho Wong, and Chi-Wai Kan. 2021. "Study on the Development of Antiviral Spandex Fabric Coated with Poly(Hexamethylene Biguanide) Hydrochloride (PHMB)" Polymers 13, no. 13: 2122. https://doi.org/10.3390/polym13132122

APA StyleWang, W.-Y., Yim, S.-L., Wong, C.-H., & Kan, C.-W. (2021). Study on the Development of Antiviral Spandex Fabric Coated with Poly(Hexamethylene Biguanide) Hydrochloride (PHMB). Polymers, 13(13), 2122. https://doi.org/10.3390/polym13132122