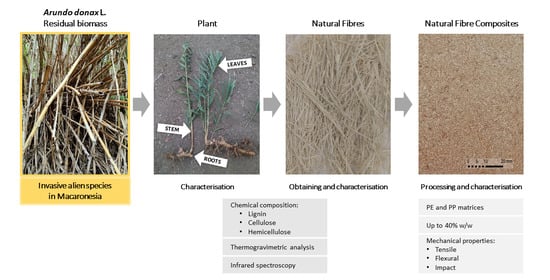

Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Characterisation

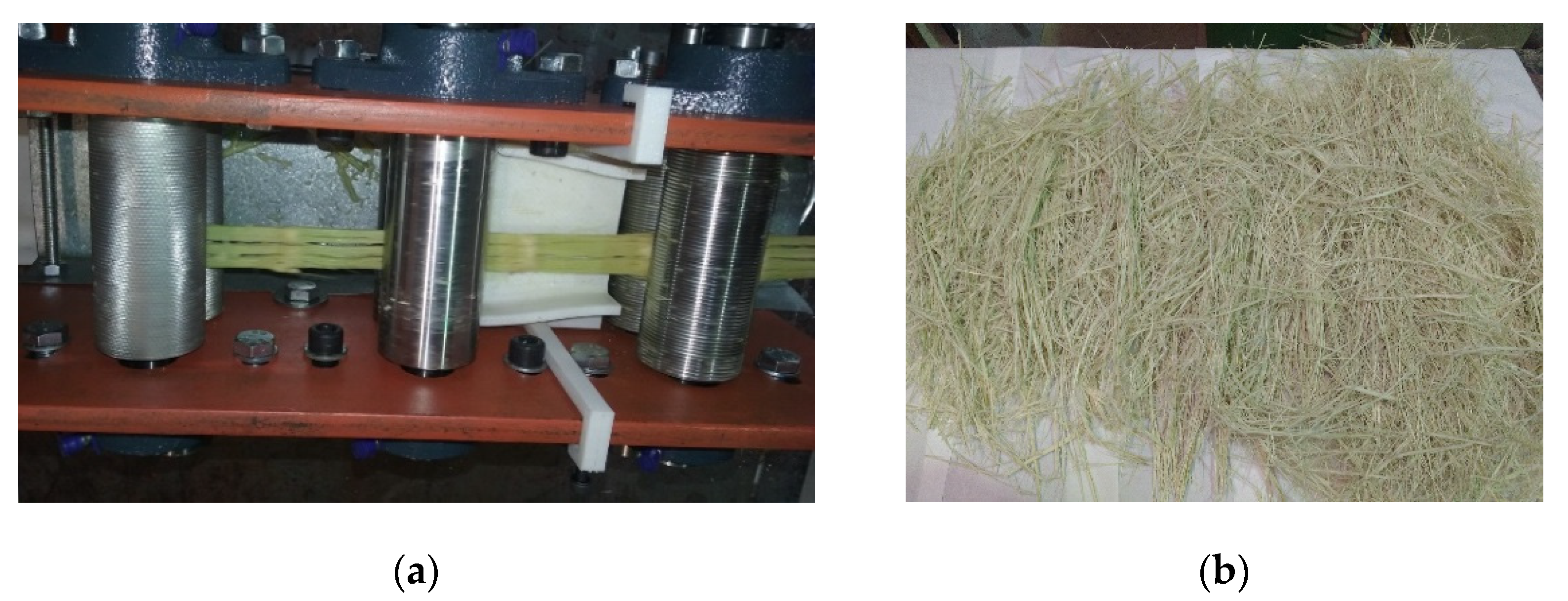

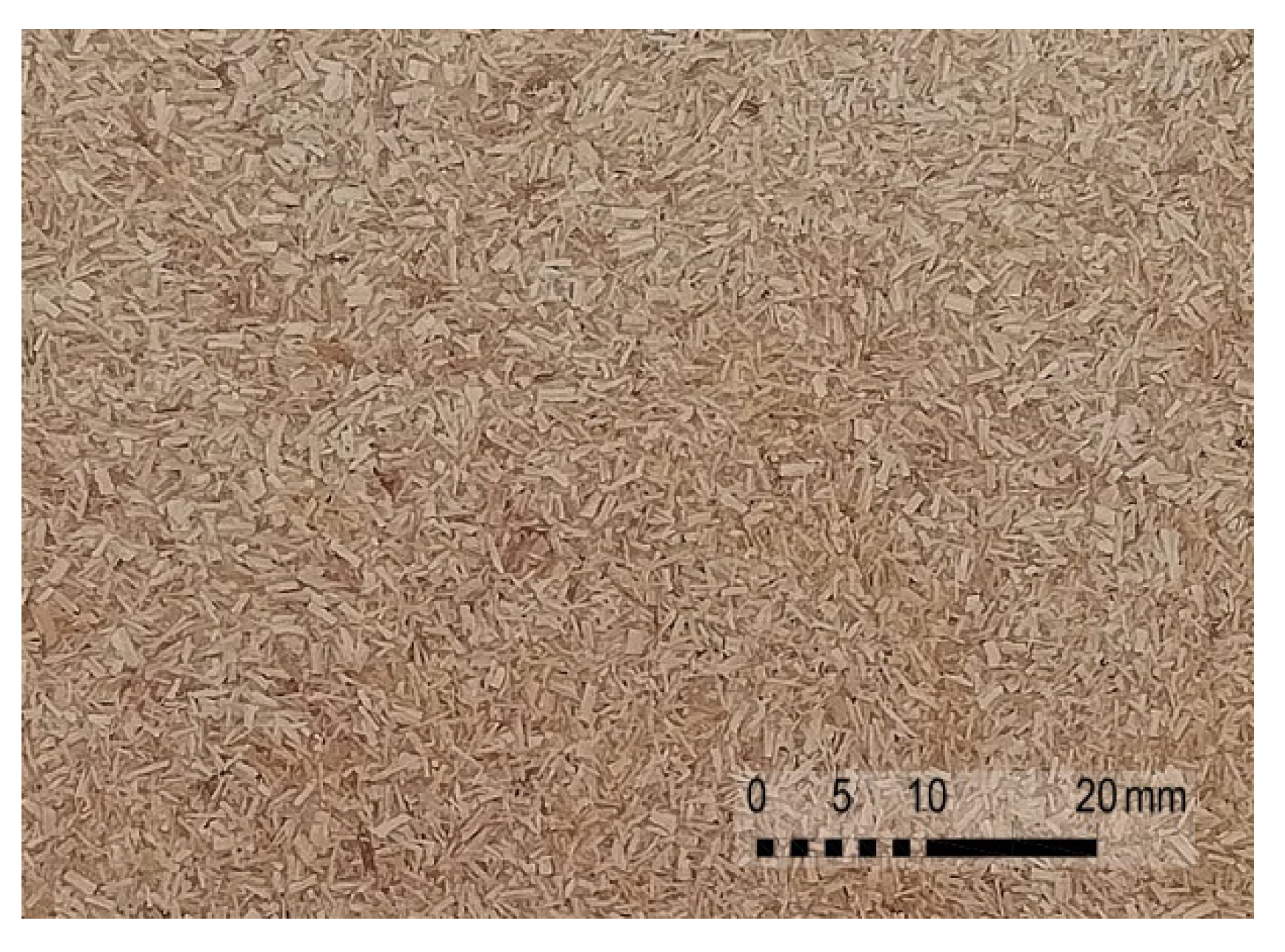

2.2. Fibre Obtaining and Characterisation

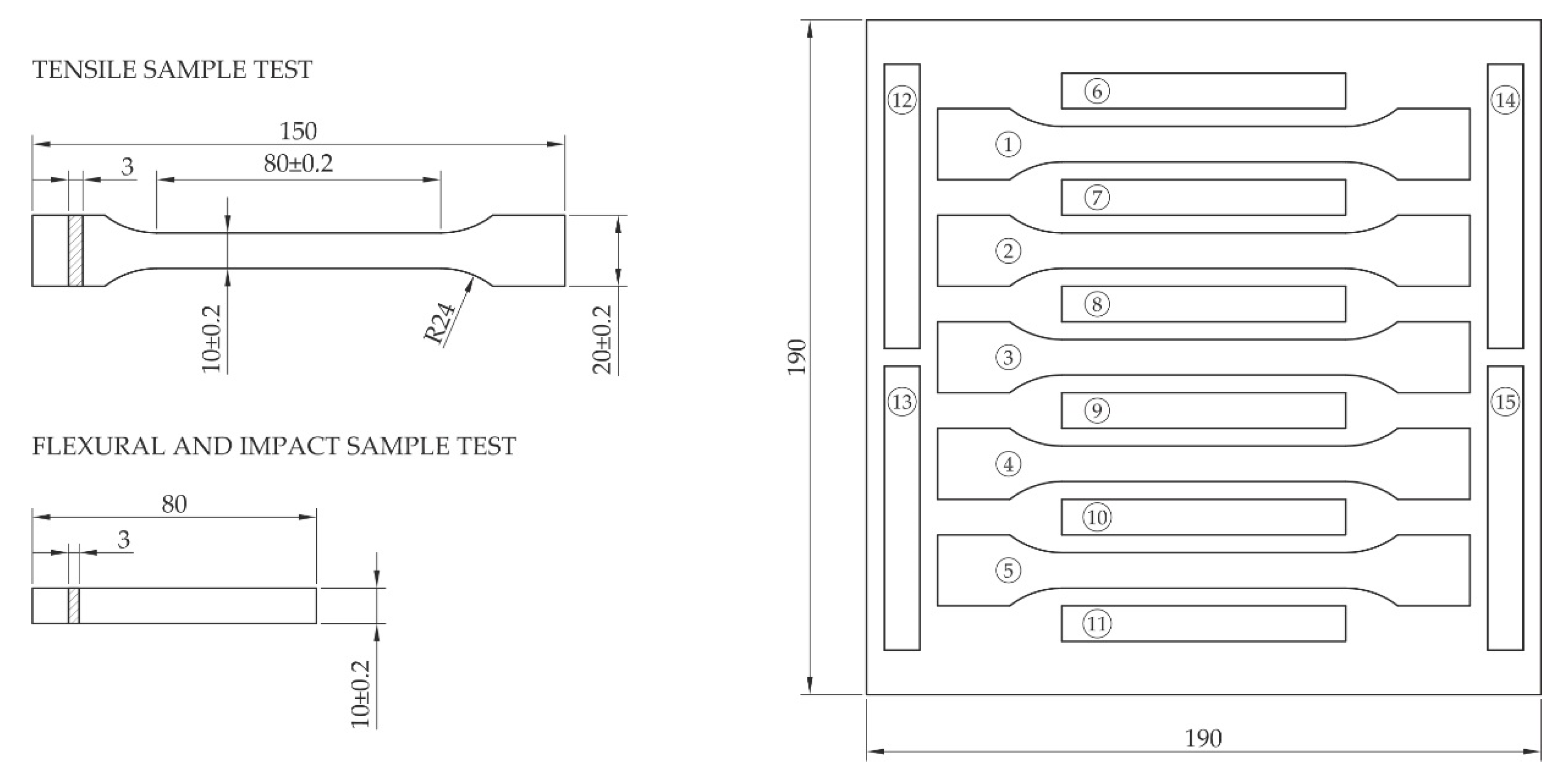

2.3. Composites Obtaining and Characterisation

3. Results

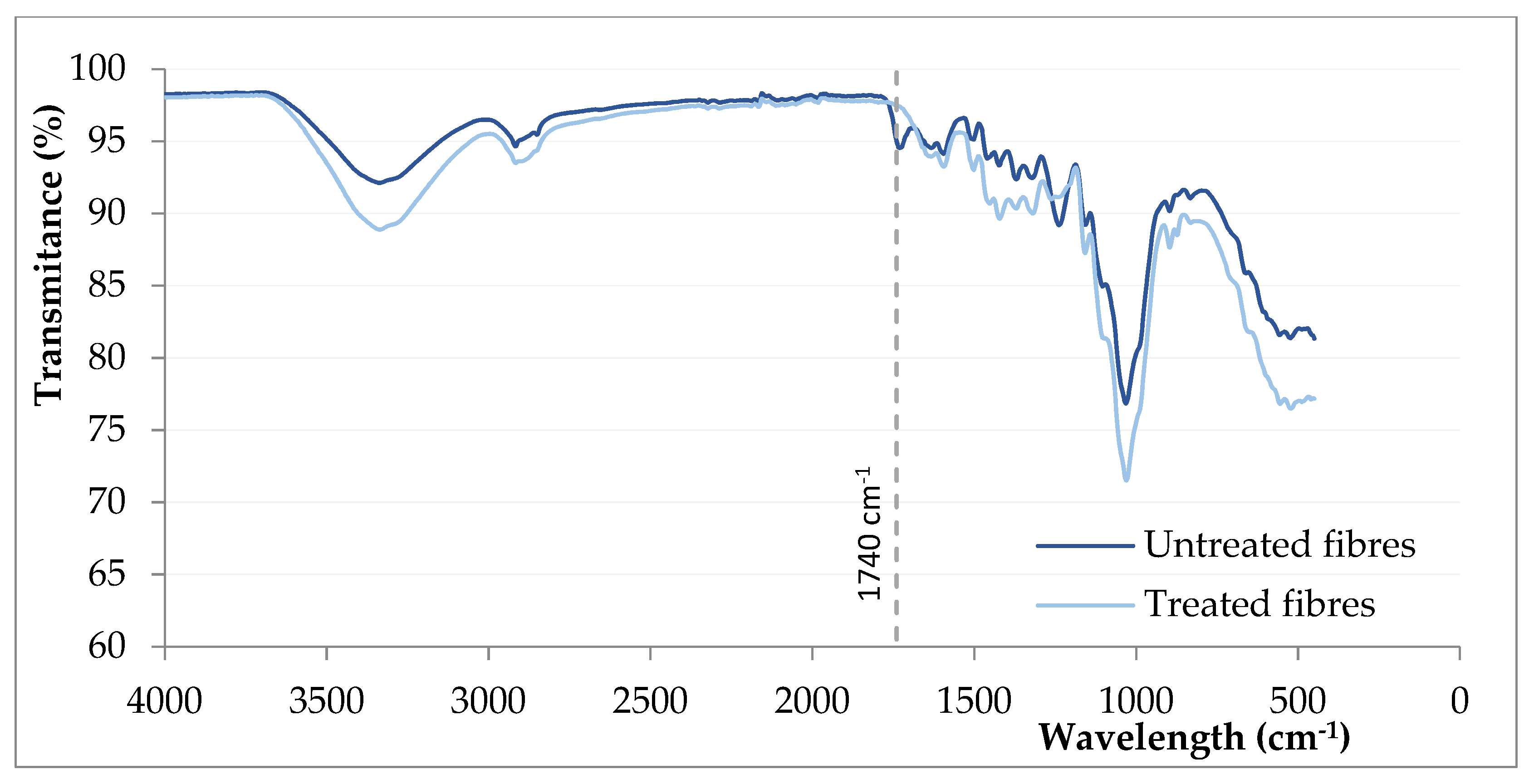

3.1. Plant and Fibre Characterisation

3.2. Composites Characterisation

4. Discussion

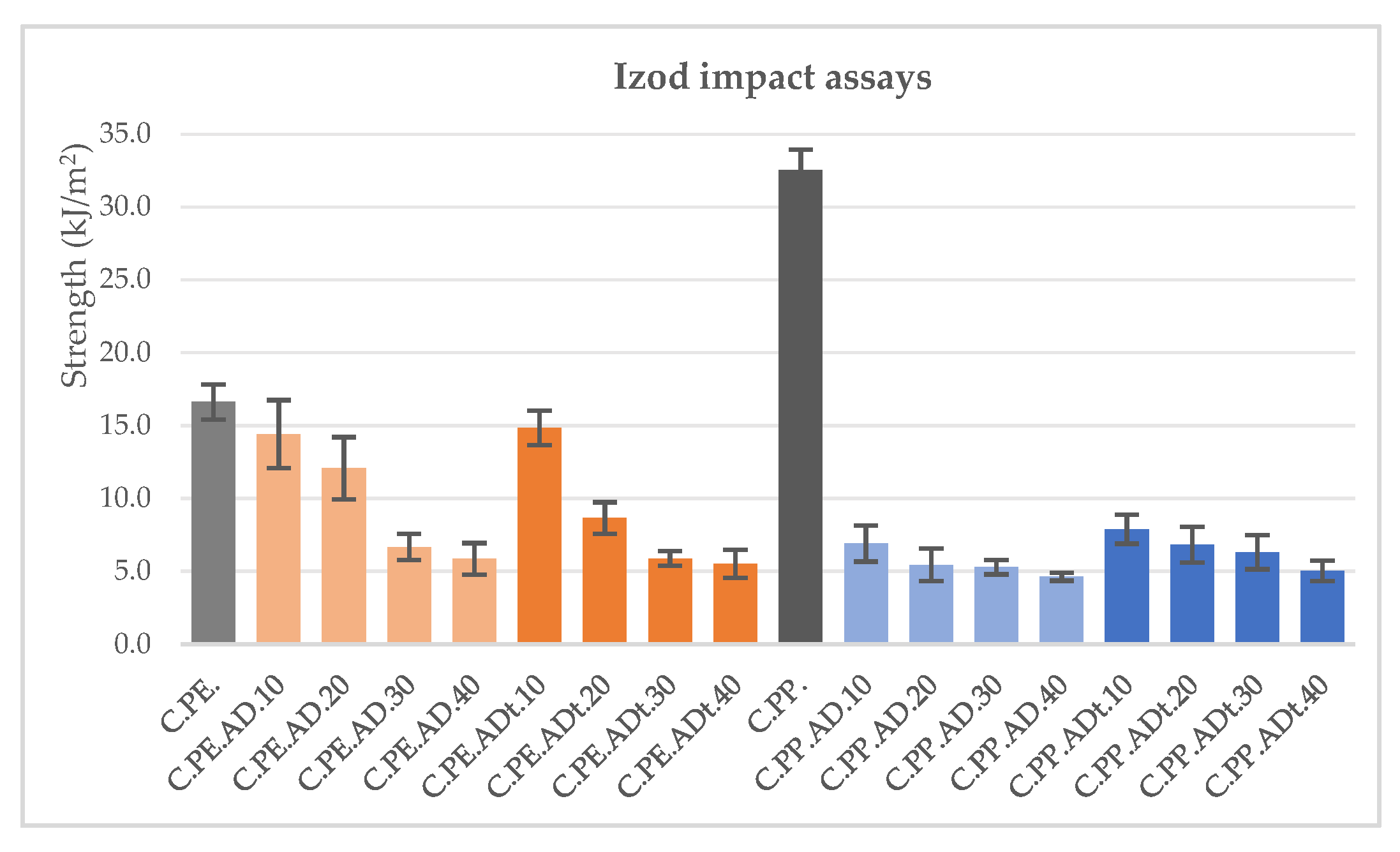

- In terms of impact strength, no differences are observed between composites with the same fibre content, whether treated or untreated.

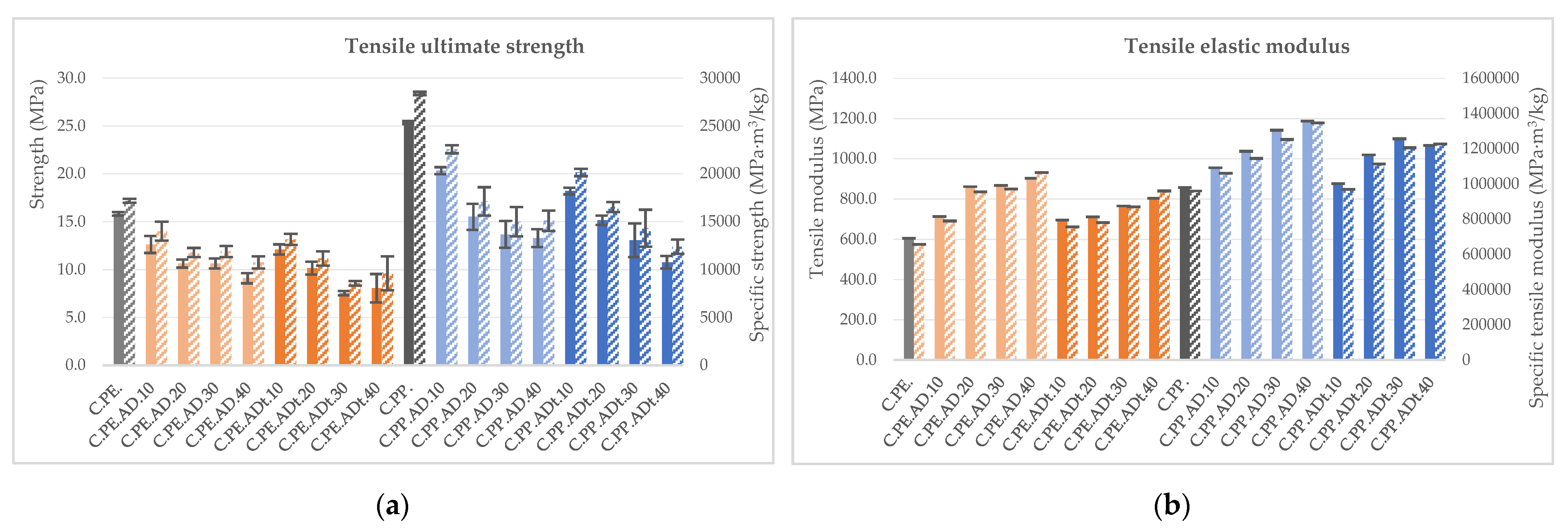

- Ultimate tensile strength shows a worsening performance trend similar to that observed for the impact strength properties as the fibre content increases, which is in line with the findings of Fiore et al. [18] for PLA composites with Arundo fibres. The elastic modulus only shows significant differences with the neat matrix when the proportion of fibre is equal or higher than 20%, obtaining slightly better results with the untreated fibre.

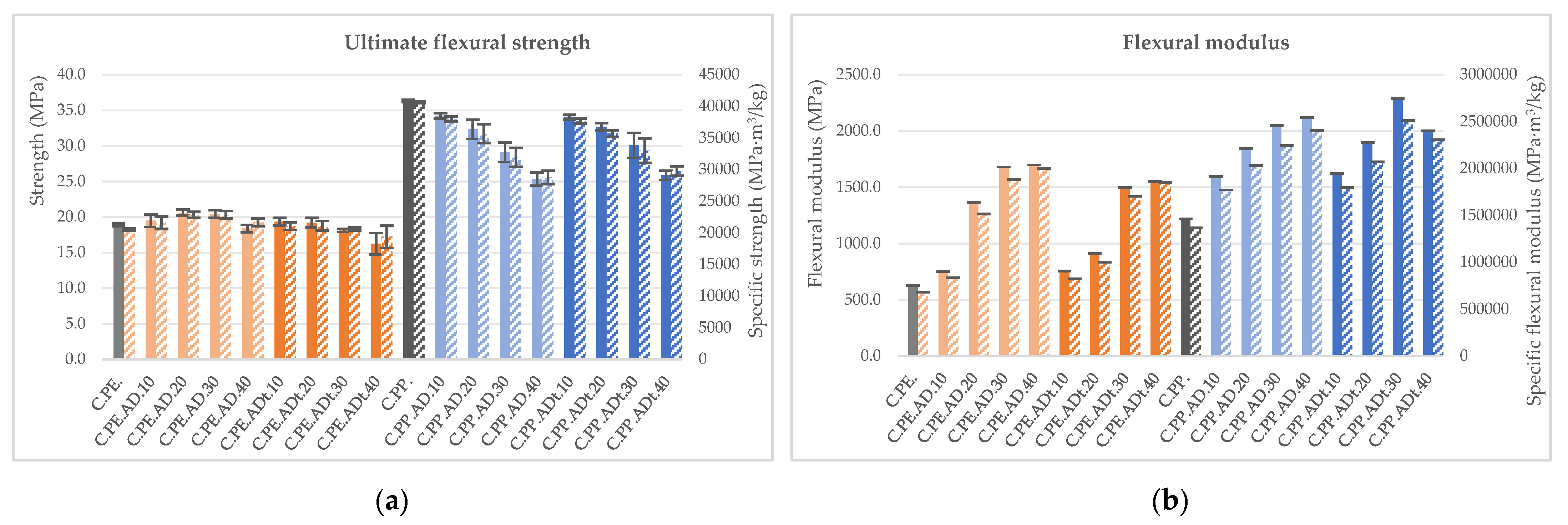

- The incorporation of Arundo fibres in the composite material does not seem to affect the ultimate strength and yield strength under bending loads. However, the elastic modulus in bending does show significant differences from 20% untreated fibre content and 30% for the treated ones.

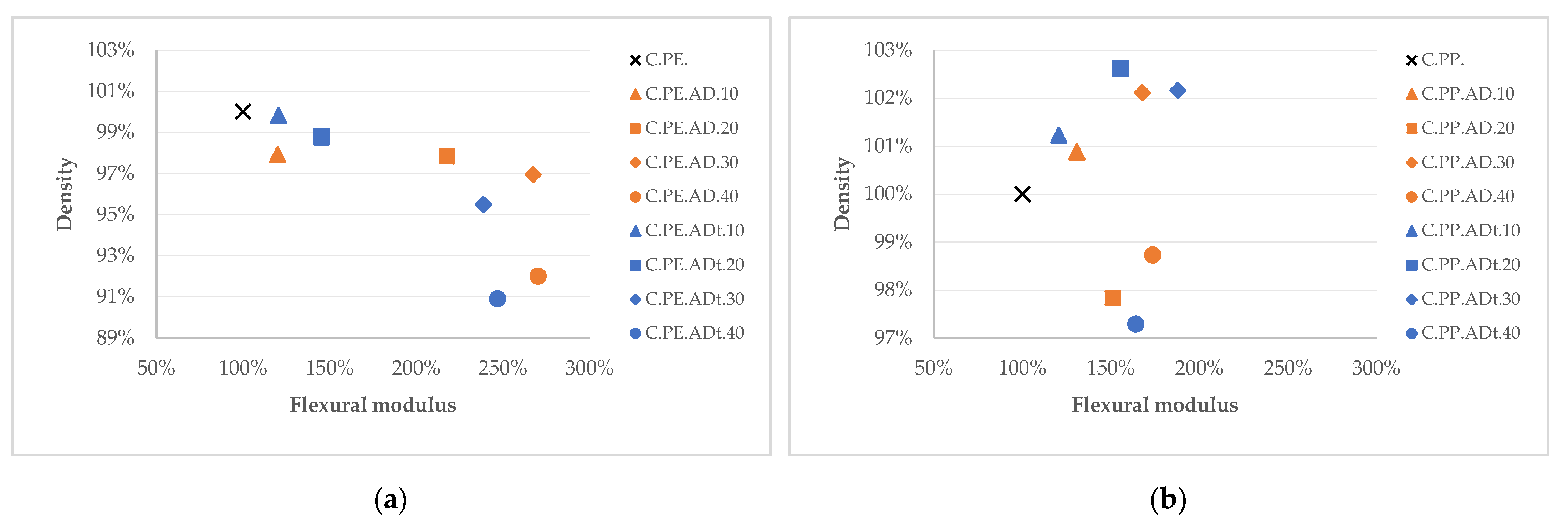

- As shown in Table 5, based on specific properties, the best stiffness results, both in bending and tensile, are obtained for the 40% untreated PE formulation.

- The absorbed impact energy is substantially reduced even for low fibre contents, with no significant differences when fibre content exceeds 20%.

- The tensile behaviour is similar to that observed for composites with PE matrix: The ultimate strength decreases and the elastic modulus gradually increases, which is in accordance with the behaviour observed by Arrakhiz et al. for PP composites reinforced with alpha fibre [48]; no significant differences are observed when the fibre content is increased to more than 30%. The yield strength value remains practically unchanged except for composites reinforced with 40% of NaOH treated fibre.

- Variations in ultimate flexural strength only seem to be relevant for formulations with higher fibre content (30 and 40%). Meanwhile, the flexural stiffness behaviour improves as the fibre content increases, except for 40% treated fibres, where a drop in this property is observed (Table 6).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lowe, S.; Brown, M.; Boudejelas, D.P. 100 of the World’s Worst Invasive Alien Species: A Selection From The Global Invasive Species Database. In Encyclopedia of Biological Invasions; The Invasive Species Specialist Group (ISSG): Auckland, New Zealand, 2020; pp. 715–716. [Google Scholar]

- Global Invasive Species Database Species profile: Arundo donax. Available online: http://www.iucngisd.org/gisd/species.php?sc=112 (accessed on 21 April 2021).

- Sanz Elorza, M.; Dana Sáncehz, E.D.; Sobrino Vesperinas, E. Atlas de las Plantas Alóctonas Invasoras en España; Dirección General para la Biodiversidad: Madrid, Spain, 2004; ISBN 8480145757. [Google Scholar]

- Silva, L.; Ojeda Land, E.; Rodríguez-Luengo, J.L. Flora y Fauna Terrestre Invasora en la Macaronesia—Top. 100 en Azores, Madeira y Canarias; ARENA: Ponta Delgada, Portugal, 2008; ISBN 9789899591011. [Google Scholar]

- Jiménez-Ruiz, J.; Hardion, L.; Del Monte, J.P.; Vila, B.; Santín-Montanyá, M.I. Monographs on invasive plants in Europe N° 4: Arundo donax L. Bot. Lett. 2021, 168, 131–151. [Google Scholar] [CrossRef]

- Giessow, J.; Casanova, J.; Leclerc, R.; MacArthur, R.; Fleming, G. Arundo Donax. Distribution and Impact Report; California Invasive Plant Council: Richmond, CA, USA, 2011.

- Coffman, G.C.; Ambrose, R.F.; Rundel, P.W. Wildfire promotes dominance of invasive giant reed (Arundo donax) in riparian ecosystems. Biol. Invasions 2010, 12, 2723–2734. [Google Scholar] [CrossRef] [Green Version]

- Antonetti, C.; Bonari, E.; Licursi, D.; Di Nasso, N.N.; Galletti, A.M.R. Hydrothermal conversion of giant reed to furfural and levulinic acid: Optimization of the process under microwave irradiation and investigation of distinctive agronomic parameters. Molecules 2015, 20, 21232–21353. [Google Scholar] [CrossRef] [Green Version]

- Proietti, S.; Moscatello, S.; Fagnano, M.; Fiorentino, N.; Impagliazzo, A.; Battistelli, A. Chemical composition and yield of rhizome biomass of Arundo donax L. grown for biorefinery in the Mediterranean environment. Biomass Bioenergy 2017, 107, 191–197. [Google Scholar] [CrossRef]

- Mirza, N.; Mahmood, Q.; Pervez, A.; Ahmad, R.; Farooq, R.; Shah, M.M.; Azim, M.R. Phytoremediation potential of Arundo donax in arsenic-contaminated synthetic wastewater. Bioresour. Technol. 2010, 101, 5815–5819. [Google Scholar] [CrossRef]

- Alwared, A.I.; Jaeel, A.J.; Ismail, Z.Z. New application of eco-friendly biosorbent giant reed for removal of reactive dyes from water followed by sustainable path for recycling the dyes-loaded sludge in concrete mixes. J. Mater. Cycles Waste Manag. 2020, 22, 1036–1046. [Google Scholar] [CrossRef]

- Calabrese, L.; Piperopoulos, E.; Fiore, V. Arundo donax fibers as green materials for oil spill recovery. In Biofibers and Biopolymers for Biocomposites: Synthesis, Characterization and Properties; Springer: Cham, Switzerland, 2020; pp. 259–283. ISBN 9783030403010. [Google Scholar]

- Martínez Gabarrón, A.; Flores Yepes, J.A.; Pastor Pérez, J.J.; Berná Serna, J.M.; Arnold, L.C.; Sánchez Medrano, F.J. Increase of the flexural strength of construction elements made with plaster (calcium sulfate dihydrate) and common reed (Arundo donax L.). Constr. Build. Mater. 2014, 66, 436–441. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Jaeel, A.J. A novel use of undesirable wild giant reed biomass to replace aggregate in concrete. Constr. Build. Mater. 2014, 67, 68–73. [Google Scholar] [CrossRef]

- Guillamet, G.V. Arundo donax structures as economic and ecological formwork for concrete shells. In Proceedings of the International fib Symposium on Conceptual Design of Structures; International Federation for Structural Concrete: Hormigón y Acero: Madrid, Spain, 2019; pp. 369–376. [Google Scholar]

- Andreu-Rodriguez, J.; Medina, E.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Paredes, C.; Bustamante, M.A.; Moreno-Caselles, J. Agricultural and Industrial Valorization of Arundo donax L. Commun. Soil Sci. Plant. Anal. 2013, 44, 598–609. [Google Scholar] [CrossRef]

- Ferrandez-García, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Assessment of the physical, mechanical and acoustic properties of Arundo donax L. biomass in low pressure and temperature particleboards. Polymers 2020, 12, 1361. [Google Scholar] [CrossRef]

- Fiore, V.; Botta, L.; Scaffaro, R.; Valenza, A.; Pirrotta, A. PLA based biocomposites reinforced with Arundo donax fillers. Compos. Sci. Technol. 2014, 105, 110–117. [Google Scholar] [CrossRef]

- Scalici, T.; Fiore, V.; Valenza, A. Effect of plasma treatment on the properties of Arundo Donax L. leaf fibres and its bio-based epoxy composites: A preliminary study. Compos. Part. B Eng. 2016, 94, 167–175. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- García-Ortuño, T.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Evaluation of the physical and mechanical properties of particleboard made from giant reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Standard Test. Methods for Lignin in Wood—D 1106-56. 1977a; ASTM: Washington, DC, USA, 1977.

- Browing, B.L. Methods of wood chemistry. Polym. Phys. 1967, 6, 1943–1944. [Google Scholar]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Velásquez Restrepo, S.M.; Peaéz Arroyave, G.J.; Giraldo Vásquez, D. Uso de fibras vegetales en materiales compuestos de matriz polimérica: Una revisión con miras a su aplicación en el diseño de nuevos productos. SENA Cent. Nac. Asist. Técnica Ind. 2016, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Benítez, A.N.; Monzón, M.D.; Angulo, I.; Ortega, Z.; Hernández, P.M.; Marrero, M.D. Treatment of banana fiber for use in the reinforcement of polymeric matrices. Meas. J. Int. Meas. Confed. 2013, 46, 1065–1073. [Google Scholar] [CrossRef]

- Mccleary, B.V.; Cox, J. Evolution of a Definition for Dietary Fiber and Methodology to Service this Definition. Luminacoids Res. 2017, 21, 9–21. [Google Scholar]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi Jnior, H.L.; Zattera, A.J. Thermal Decomposition of Natural Fibers: Kinetics and Degradation Mechanisms. In Reactions and Mechanisms in Thermal Analysis of Advanced Materials; Wiley Blackwell: Hoboken, NJ, USA, 2015; pp. 515–545. ISBN 9781119117711. [Google Scholar]

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Oliveira, M.A.S.; Pickering, K.L.; Sunny, T.; Lin, R.J.T. Treatment of hemp fibres for use in rotational moulding. J. Polym. Res. 2021, 28, 3. [Google Scholar] [CrossRef]

- Fuentes, R.; Gordillo, M.; Mendoza, M.; Amezquita, F. Mechanical response of composites with arundo donax as enforcer to polyster resins. Nat. Tecnol. 2011, 3. [Google Scholar]

- Neto, C.P.; Seca, A.; Nunes, A.M.; Coimbra, M.A.; Domingues, F.; Evtuguin, D.; Silvestre, A.; Cavaleiro, J.A.S. Variations in chemical composition and structure of macromolecular components in different morphological regions and maturity stages of Arundo donax. Ind. Crops Prod. 1997, 6, 51–58. [Google Scholar] [CrossRef]

- Krička, T.; Matin, A.; Bilandžija, N.; Jurišić, V.; Antonović, A.; Voća, N.; Grubor, M. Biomass valorisation of Arundo donax L., Miscanthus × giganteus and Sida hermaphrodita for biofuel production. Int. Agrophys. 2017, 31, 575–581. [Google Scholar] [CrossRef]

- Temiz, A.; Akbas, S.; Panov, D.; Terziev, N.; Alma, M.H.; Parlak, S.; Kose, G. Chemical composition and efficiency of bio-oil obtained from giant cane (arundo donax l.) as a wood preservative. BioResources 2013, 8, 2084–2098. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.J. Potential of Arundo donax L. stems as renewable precursors for activated carbons and utilization for wastewater treatments: Review. J. Taiwan Inst. Chem. Eng. 2016, 63, 336–343. [Google Scholar] [CrossRef]

- De Bari, I.; Liuzzi, F.; Villone, A.; Braccio, G. Hydrolysis of concentrated suspensions of steam pretreated Arundo donax. Appl. Energy 2013, 102, 179–189. [Google Scholar] [CrossRef]

- Komolwanich, T.; Tatijarern, P.; Prasertwasu, S.; Khumsupan, D.; Chaisuwan, T.; Luengnaruemitchai, A.; Wongkasemjit, S. Comparative potentiality of Kans grass (Saccharum spontaneum) and Giant reed (Arundo donax) as lignocellulosic feedstocks for the release of monomeric sugars by microwave/chemical pretreatment. Cellulose 2014, 21, 1327–1340. [Google Scholar] [CrossRef]

- Ávalos García, A.; Pérez-Urria Carril, E. Metabolismo secundario de plantas. REDUCA 2009, 2, 119–145. [Google Scholar]

- Shalwan, A.; Yousif, B.F. In state of art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2013, 48, 14–24. [Google Scholar] [CrossRef]

- Prathap, K.A. Comparative Study on the Mechanical Properties of Arundo Donax Epoxy Composites with Bamboo Epoxy Composites. Int. J. Eng. Res. 2019, V8. [Google Scholar] [CrossRef]

- Baquero Basto, D.; Alarcón, J.M.; Sánchez Cruz, M. Experimental characterization of composite panels made with Arundo Dónax fibers and vegetable resin. Sci. Tech. Año XXII 2018, 23, 119–125. [Google Scholar]

- Monsalve Alarcón, J.; Sánchez Cruz, M.; Baquero Bastos, D. Evaluation of the physical and mechanical properties of caña brava (Arundo donax) reinforced panels. INGE CUC 2018, 14, 66–74. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental evaluation of a new giant reed (Arundo donax L.) composite using citric acid as a natural binder. Agronomy 2019, 9, 882. [Google Scholar] [CrossRef] [Green Version]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, Q.; Yao, F.; Xu, Y. Preparation and properties of recycled HDPE/natural fiber composites. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 1664–1674. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; Elachaby, M.; Bouhfid, R.; Vaudreuil, S.; Essassi, M.; Qaiss, A. Mechanical and thermal properties of polypropylene reinforced with Alfa fiber under different chemical treatment. Mater. Des. 2012, 35, 318–322. [Google Scholar] [CrossRef]

| Section of the Plant | Lignin (%) | Holocellulose (%) | |

|---|---|---|---|

| Cellulose (%) | Hemicellulose (%) | ||

| Roots | 19.11 ± 2.08 | 21.00 ± 1.01 | 29.57 ± 2.87 |

| Stems | 21.11 ± 0.86 | 37.95 ± 4.59 | 34.02 ± 1.46 |

| Leaves | 15.52 ± 2.00 | 27.68 ± 3.51 | 34.09 ± 3.28 |

| Untreated fibres | 24.12 ± 1.40 | 45.16 ± 2.97 | 35.10 ± 2.80 |

| NaOH-treated fibres | 22.21 ± 0.87 | 56.95 ± 1.68 | 21.00 ± 1.86 |

| Composite | Density | Impact Properties | Tensile Properties (MPa) | Flexural Properties (MPa) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (g/cm3) | Strength (kJ/m2) | Ultimate Strength | E | Yield Strength | Ultimate Strength | Ef | Yield Strength | |||||||||

| C.PE. | 0.921 a | 16.6 | ±1.21 a | 15.8 | ±0.19 a | 605.6 | ±21.88 a | 4.6 | ±0.17 a | 18.9 | ±0.59 ab | 628.3 | ±61.40 a | 10.6 | ±1.52 a | |

| C.PE.AD.10 | 0.902 a | 14.4 | ±2.34 ab | 12.6 | ±0.89 b | 712.3 | ±19.00 ab | 6.5 | ±0.38 bc | 19.5 | ±1.17 ab | 752.9 | ±22.30 a | 11.9 | ±0.90 a | |

| C.PE.AD.20 | 0.902 a | 12.1 | ±2.13 bc | 10.6 | ±0.42 cde | 861.2 | ±36.4 cd | 6.9 | ±0.20 c | 20.6 | ±1.93 b | 1366.8 | ±210.02 b | 11.1 | ±1.67 a | |

| C.PE.AD.30 | 0.893 ab | 6.7 | ±0.91 d | 10.6 | ±0.52 d | 867.7 | ±33.35 cd | 7.8 | ±0.48 d | 20.4 | ±1.04 b | 1679.1 | ±164.32 b | 11.0 | ±1.30 a | |

| C.PE.AD.40 | 0.848 b | 5.9 | ±1.08 d | 9.1 | ±0.54 cf | 902.7 | ±99.17 d | 7.0 | ±0.30 bcd | 18.4 | ±1.74 ab | 1697.7 | ±199.43 b | 10.5 | ±1.72 a | |

| C.PE.ADt.10 | 0.920 a | 14.8 | ±1.18 ab | 12.1 | ±0.54 be | 695.8 | ±30.77 ab | 5.9 | ±0.48 be | 19.4 | ±0.73 ab | 756.5 | ±69.02 a | 12.9 | ±0.32 a | |

| C.PE.ADt.20 | 0.910 a | 8.6 | ±1.09 c | 10.2 | ±0.68 cd | 710.7 | ±45.80 b | 6.6 | ±0.54 bc | 19.2 | ±0.77 ab | 912.8 | ±140.95 a | 13.3 | ±2.22 a | |

| C.PE.ADt.30 | 0.880 ab | 5.9 | ±0.50 d | 7.6 | ±0.22 g | 764.9 | ±79.41 bc | 5.4 | ±0.41 ae | 18.1 | ±3.33 ab | 1499.0 | ±298.96 b | 11.2 | ±2.18 a | |

| C.PE.ADt.40 | 0.838 ab | 5.5 | ±0.95 d | 8.1 | ±1.49 fg | 803.6 | ±22.76 cd | 6.9 | ±0.89 bcd | 16.3 | ±1.47 a | 1551.0 | ±212.11 b | 10.1 | ±1.08 a | |

| Composite | Density | Impact Properties | Tensile Properties (MPa) | Flexural Properties (MPa) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (g/cm3) | Strength (kJ/m2) | Ultimate Strength | E | Yield Strength | Ultimate Strength | Ef | Yield Strength | |||||||||

| C.PP. | 0.893 a | 32.5 | ±1.40 a | 25.4 | ±0.15 a | 857.2 | ±13.80 a | 11.1 | ±0.41 a | 36.3 | ±1.02 a | 1220.6 | ±81.77 a | 22.2 | ±1.76 a | |

| C.PP.AD.10 | 0.901 a | 6.9 | ±1.24 bc | 20.3 | ±0.37 b | 955.4 | ±28.22 bc | 11.7 | ±0.66 a | 34.2 | ±0.48 ab | 1595.3 | ±121.32 ab | 19.6 | ±1.65 ab | |

| C.PP.AD.20 | 0.906 a | 5.4 | ±1.12 bd | 15.5 | ±1.34 c | 1037.8 | ±29.77 cde | 10.4 | ±0.97 a | 32.3 | ±1.21 ac | 1842.2 | ±246.29 bc | 17.8 | ±1.91 b | |

| C.PP.AD.30 | 0.912 a | 5.3 | ±0.49 bd | 13.7 | ±1.38 cd | 1142.0 | ±81.88 ef | 10.7 | ±1.08 a | 29.1 | ±3.05 cd | 2046.8 | ±268,55 bc | 18.6 | ±2.54 ab | |

| C.PP.AD.40 | 0.881 a | 4.6 | ±0.27 d | 13.3 | ±0.94 de | 1186.7 | ±29.89 f | 10.4 | ±0.58 a | 25.4 | ±3.94 d | 2119.5 | ±412.60 c | 16.2 | ±3.01 b | |

| C.PP.ADt.10 | 0.904 a | 7.9 | ±0.99 c | 18.2 | ±0.34 f | 876.2 | ±43.15 ab | 10.7 | ±0.73 a | 34.1 | ±1.53 ab | 1622.8 | ±111.31 b | 17.5 | ±1.23 b | |

| C.PP.ADt.20 | 0.916 a | 6.8 | ±1.22 cd | 15.2 | ±0.48 ce | 1019.1 | ±52.90 cd | 10.3 | ±0.44 a | 32.7 | ±1.00 ac | 1897.3 | ±51.60 bc | 18.1 | ±1.85 b | |

| C.PP.ADt.30 | 0.912 a | 6.3 | ±1.17 cd | 13.1 | ±1.75 d | 1099.7 | ±97.62 df | 10.0 | ±0.77 ab | 30.1 | ±2.17 bce | 2291.5 | ±170.05 c | 18.2 | ±2.54 b | |

| C.PP.ADt.40 | 0.869 a | 5.0 | ±0.69 bd | 10.8 | ±0.65 g | 1066.3 | ±46.23 de | 8.4 | ±0.39 b | 25.9 | ±4.19 de | 2002.3 | ±348.35 bc | 15.8 | ±2.53 b | |

| Composite | Density | TENSILE Specific (MPa·m3/kg) | FLEXURAL Specific (MPa·m3/kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (g/cm3) | Specific Strength (kJ·m/kg) | Ultimate Strength | E | Yield Strength | Ultimate Strength | Ef | Yield Strength | ||

| C.PE. | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | |

| C.PE.AD.10 | 97.9% | 88.6% | 81.6% | 120.1% | 146.7% | 105.4% | 122.4% | 114.7% | |

| C.PE.AD.20 | 97.8% | 74.3% | 68.7% | 145.3% | 154.8% | 111.5% | 222.4% | 106.6% | |

| C.PE.AD.30 | 96.9% | 41.4% | 69.3% | 147.8% | 177.4% | 111.6% | 275.7% | 106.6% | |

| C.PE.AD.40 | 92.0% | 38.3% | 62.6% | 162.0% | 167.7% | 105.8% | 293.7% | 107.0% | |

| C.PE.ADt.10 | 99.8% | 89.4% | 76.6% | 115.1% | 130.6% | 102.8% | 120.6% | 121.5% | |

| C.PE.ADt.20 | 98.8% | 52.7% | 65.0% | 118.8% | 147.4% | 103.0% | 147.1% | 126.4% | |

| C.PE.ADt.30 | 95.5% | 37.0% | 50.0% | 132.3% | 125.2% | 100.5% | 249.9% | 110.4% | |

| C.PE.ADt.40 | 90.9% | 36.5% | 56.0% | 146.0% | 167.6% | 94.7% | 271.6% | 104.6% | |

| C.PP. | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% | |

| C.PP.AD.10 | 100.9% | 21.0% | 79.4% | 110.5% | 104.7% | 93.4% | 129.6% | 87.2% | |

| C.PP.AD.20 | 101.5% | 16.5% | 60.3% | 119.3% | 92.7% | 87.7% | 148.7% | 79.0% | |

| C.PP.AD.30 | 102.1% | 15.9% | 52.8% | 130.5% | 94.4% | 78.5% | 164.2% | 81.9% | |

| C.PP.AD.40 | 98.7% | 14.4% | 53.1% | 140.2% | 95.1% | 70.7% | 175.9% | 73.9% | |

| C.PP.ADt.10 | 101.2% | 23.9% | 70.9% | 101.0% | 95.0% | 92.7% | 131.3% | 77.7% | |

| C.PP.ADt.20 | 102.6% | 20.4% | 58.2% | 115.9% | 90.6% | 87.7% | 151.5% | 79.5% | |

| C.PP.ADt.30 | 102.2% | 19.0% | 50.5% | 125.6% | 88.5% | 81.0% | 183.8% | 80.2% | |

| C.PP.ADt.40 | 97.3% | 15.9% | 43.7% | 127.9% | 78.2% | 73.2% | 168.6% | 73.1% | |

| Composite | E Tensile Specific Modulus (MPa·m3/g) | Ef Flexural Specific Modulus (MPa·m3/g) | ||

|---|---|---|---|---|

| C.PE. | 654.6 | ±23.71 a | 684.6 | ±68.81 a |

| C.PE.AD.10 | 778.9 | ±21.31 bc | 846.1 | ±39.38 a |

| C.PE.AD.20 | 946.1 | ±44.34 de | 1519.6 | ±216.38 b |

| C.PE.AD.30 | 959.8 | ±39.50 de | 1891.8 | ±207.7 bc |

| C.PE.AD.40 | 1032.4 | ±50.55 e | 1991.5 | ±234.1 c |

| C.PE.ADt.10 | 748.1 | ±33.13 ab | 827.5 | ±893.3 a |

| C.PE.ADt.20 | 773.0 | ±55.61 b | 1020.9 | ±157.8 a |

| C.PE.ADt.30 | 866.8 | ±90.69 cd | 1694.1 | ±297.8 bc |

| C.PE.ADt.40 | 943.3 | ±46.7 de | 1791.8 | ±207.7 bc |

| Composite | E Tensile Specific Modulus (MPa·m3/g) | Ef Flexural Specific Modulus (MPa·m3/g) | ||

|---|---|---|---|---|

| C.PP. | 959.1 | ±16.60 a | 1371.6 | ±95.14 a |

| C.PP.AD.10 | 1063.5 | ±31.02 ab | 1768.1 | ±127.32 b |

| C.PP.AD.20 | 1149.6 | ±0.03 bcd | 2032.8 | ±0.25 bc |

| C.PP.AD.30 | 1251.5 | ±0.08 de | 2266.9 | ±0.27 cde |

| C.PP.AD.40 | 1287.6 | ±0.03 e | 2496.7 | ±0.41 de |

| C.PP.ADt.10 | 968.7 | ±0.04 a | 1791.0 | ±0.11 b |

| C.PP.ADt.20 | 1111.4 | ±0.05 bc | 2085.0 | ±0.05 bd |

| C.PP.ADt.30 | 1194.8 | ±0.09 ce | 2506.6 | ±0.17 e |

| C.PP.ADt.40 | 1172.9 | ±0.05 be | 2318.7 | ±0.35 cde |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suárez, L.; Castellano, J.; Romero, F.; Marrero, M.D.; Benítez, A.N.; Ortega, Z. Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites. Polymers 2021, 13, 2101. https://doi.org/10.3390/polym13132101

Suárez L, Castellano J, Romero F, Marrero MD, Benítez AN, Ortega Z. Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites. Polymers. 2021; 13(13):2101. https://doi.org/10.3390/polym13132101

Chicago/Turabian StyleSuárez, Luis, Jessica Castellano, Francisco Romero, María Dolores Marrero, Antonio Nizardo Benítez, and Zaida Ortega. 2021. "Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites" Polymers 13, no. 13: 2101. https://doi.org/10.3390/polym13132101

APA StyleSuárez, L., Castellano, J., Romero, F., Marrero, M. D., Benítez, A. N., & Ortega, Z. (2021). Environmental Hazards of Giant Reed (Arundo donax L.) in the Macaronesia Region and Its Characterisation as a Potential Source for the Production of Natural Fibre Composites. Polymers, 13(13), 2101. https://doi.org/10.3390/polym13132101