Effect of Stretching on Crystalline Structure, Ferroelectric and Piezoelectric Properties of Solution-Cast Nylon-11 Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Characterizations

3. Results and Discussion

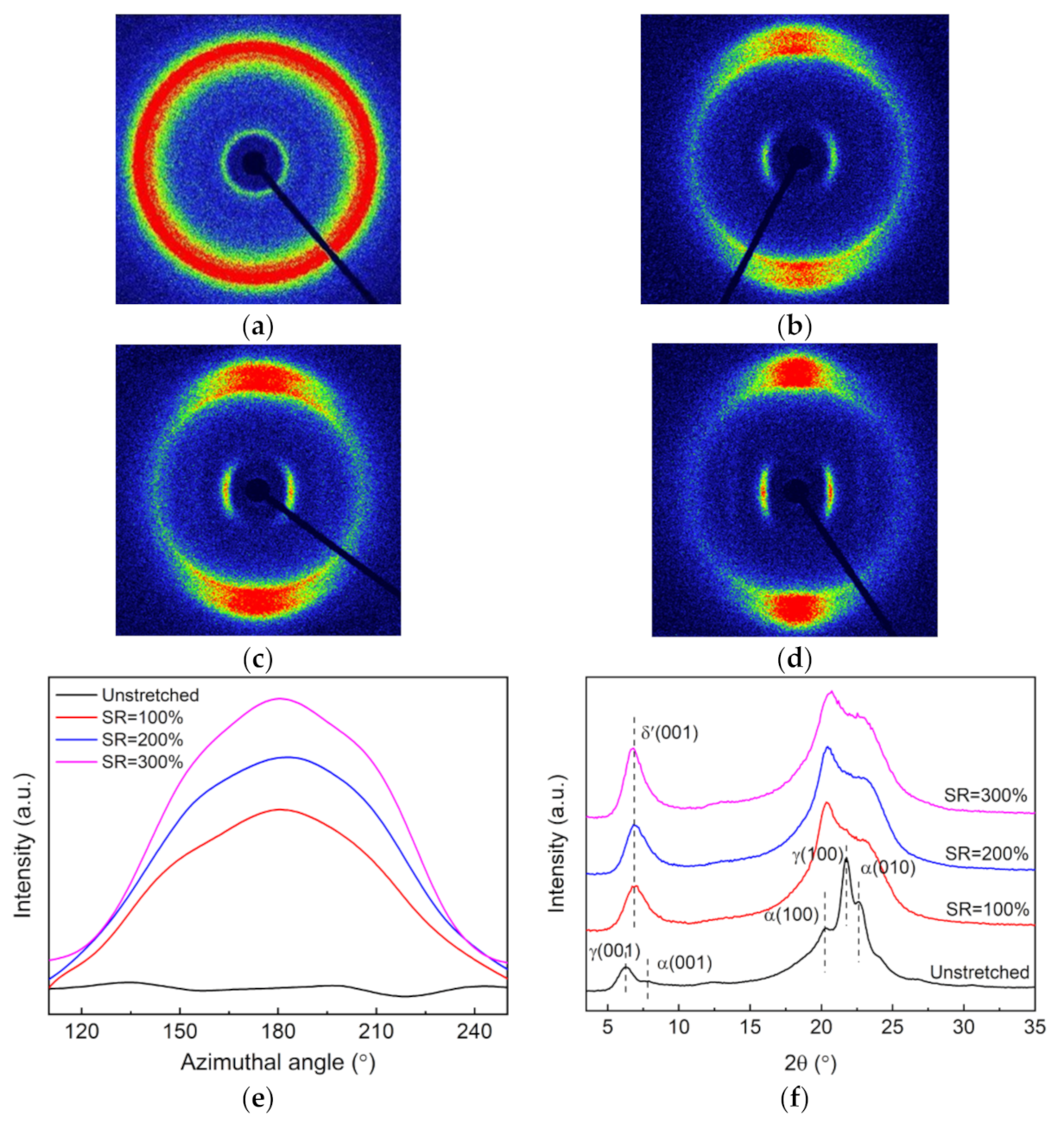

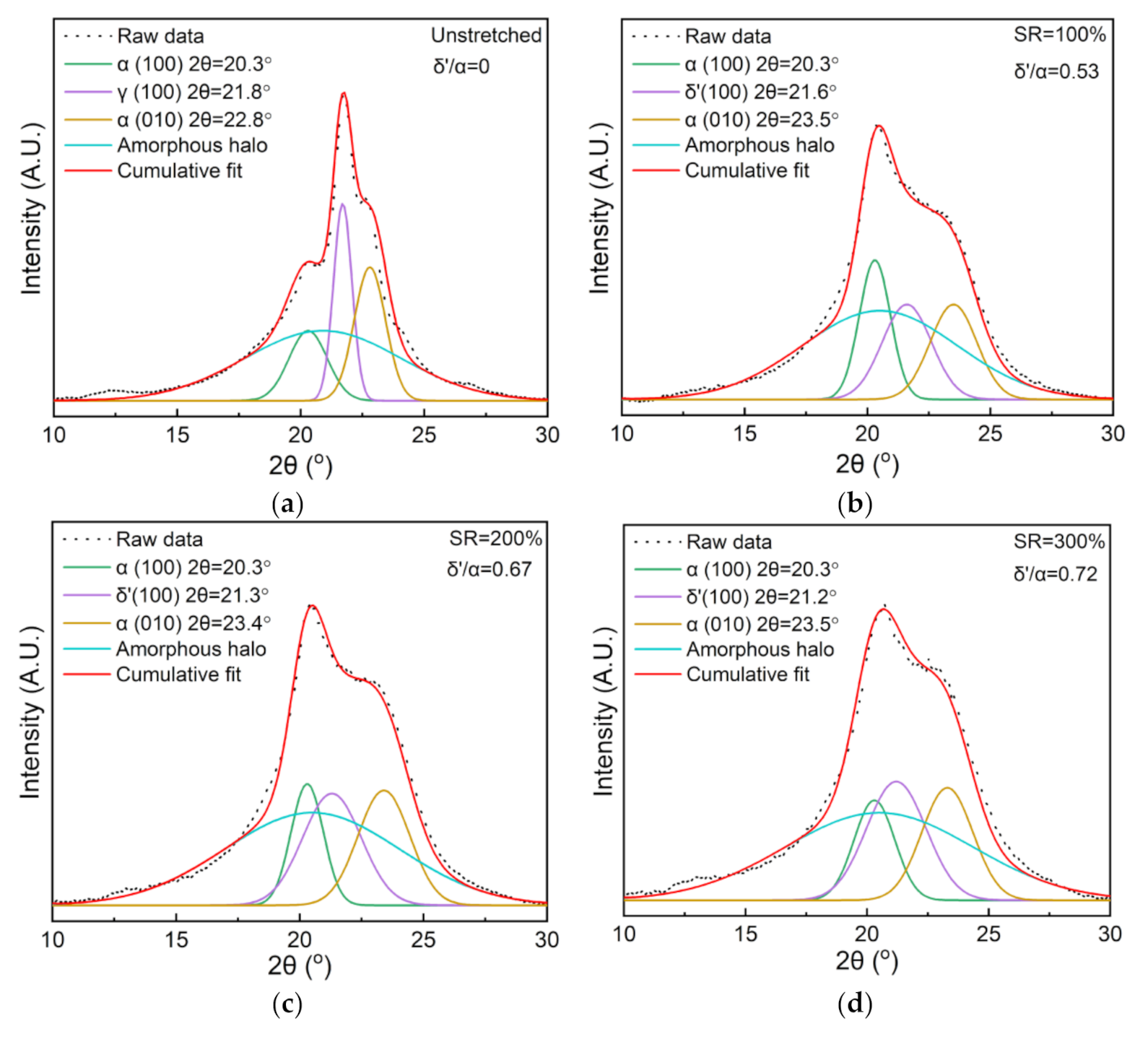

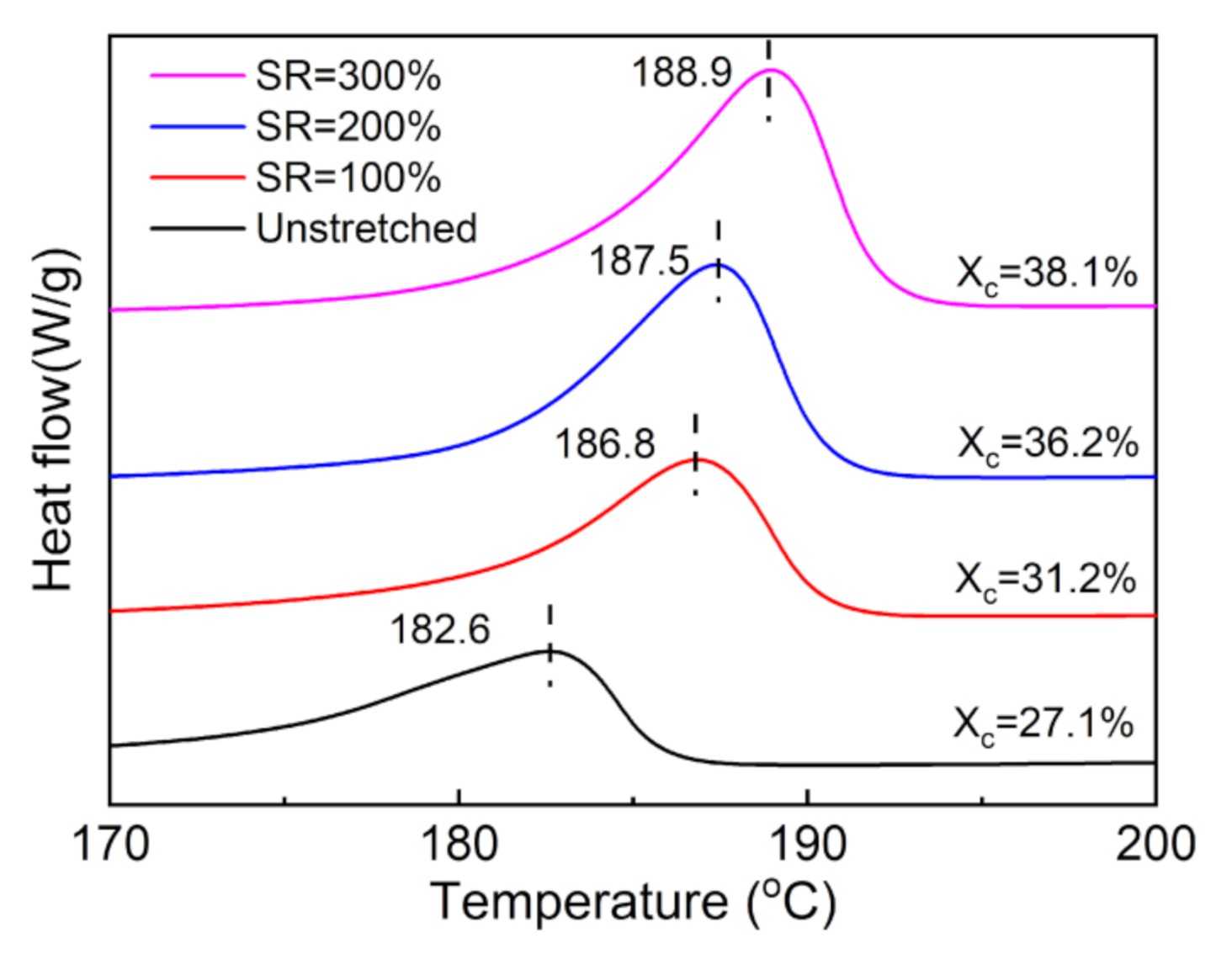

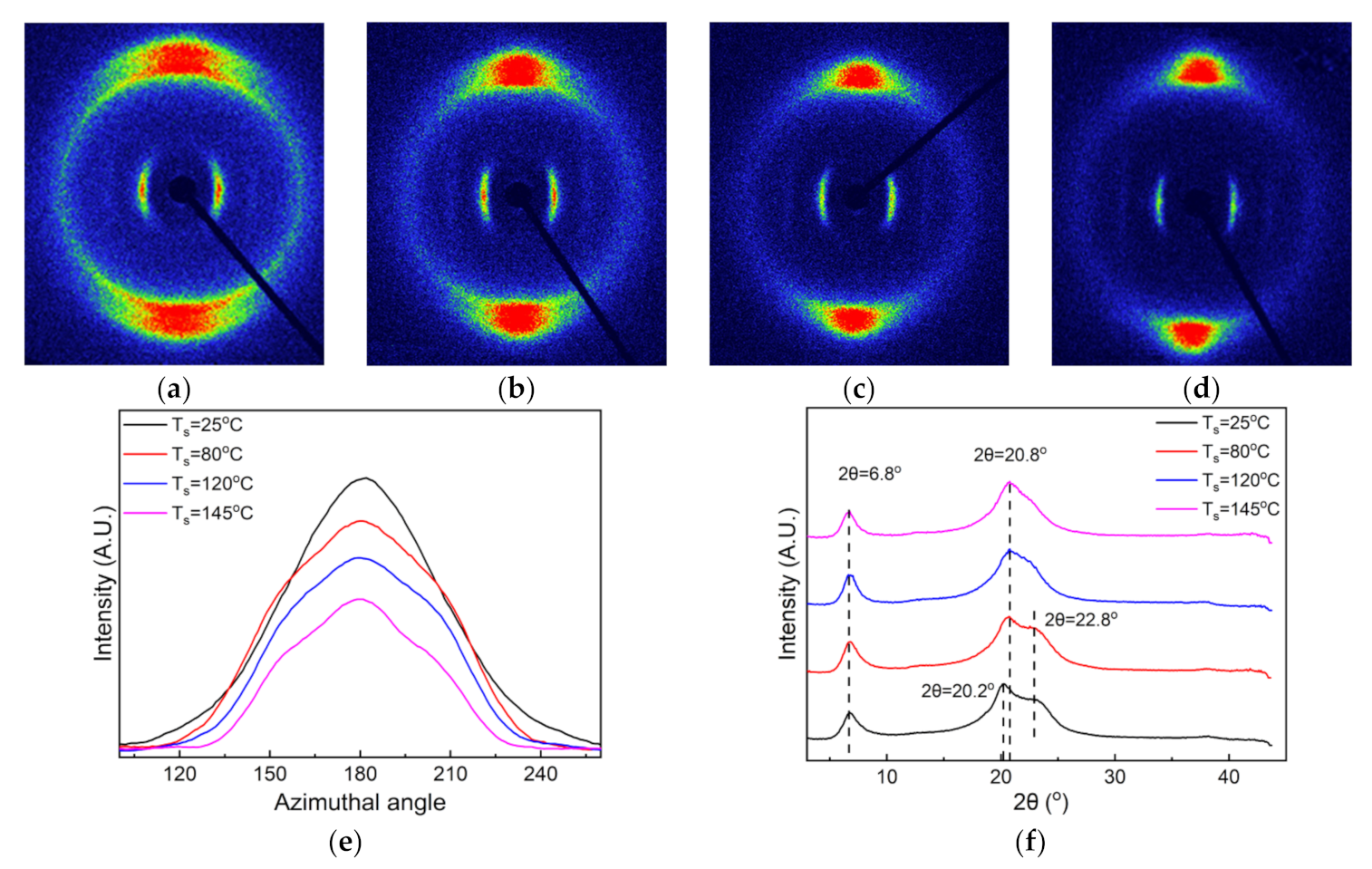

3.1. Effect of Stretching on Crystalline Structure of Nylon-11 Film

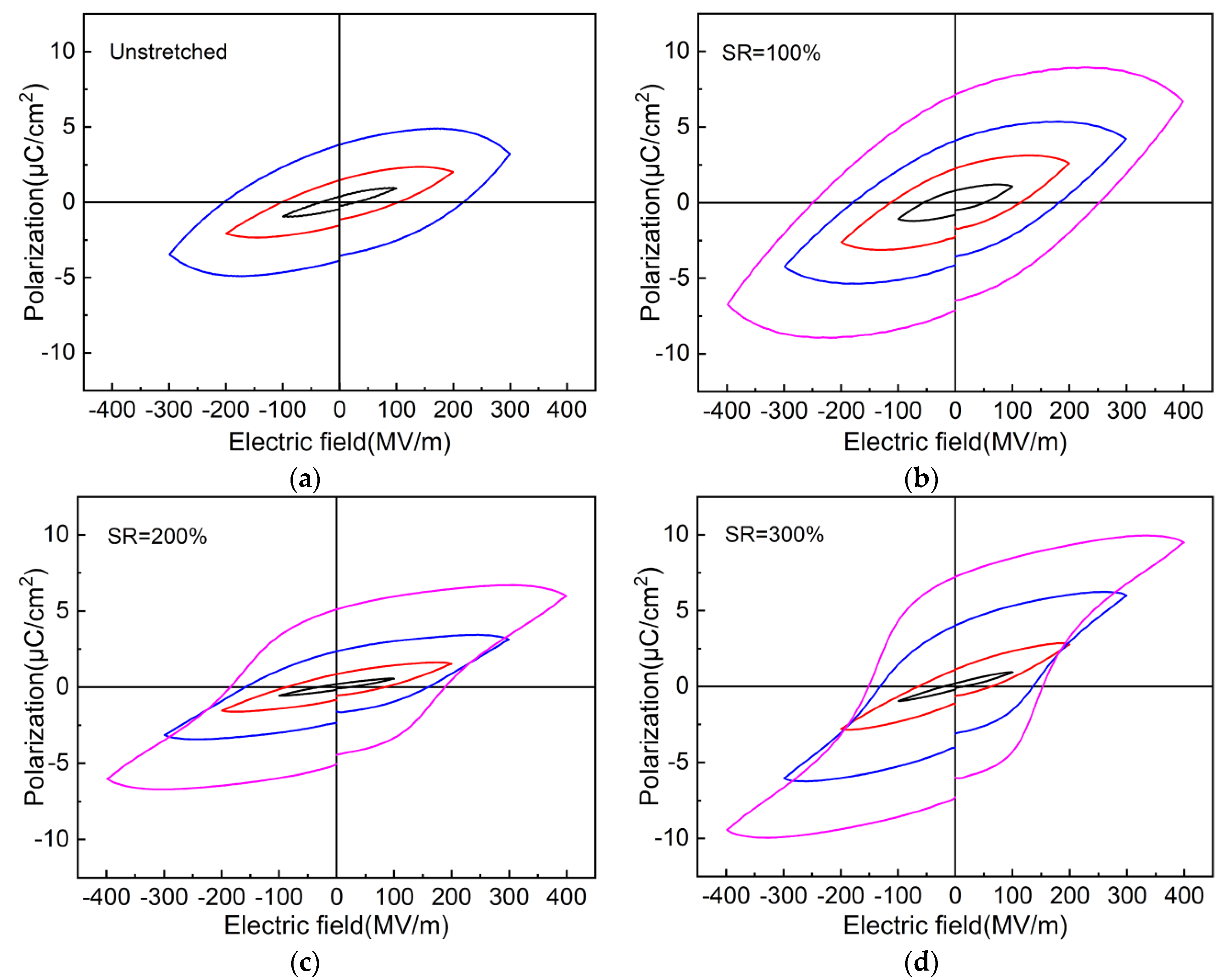

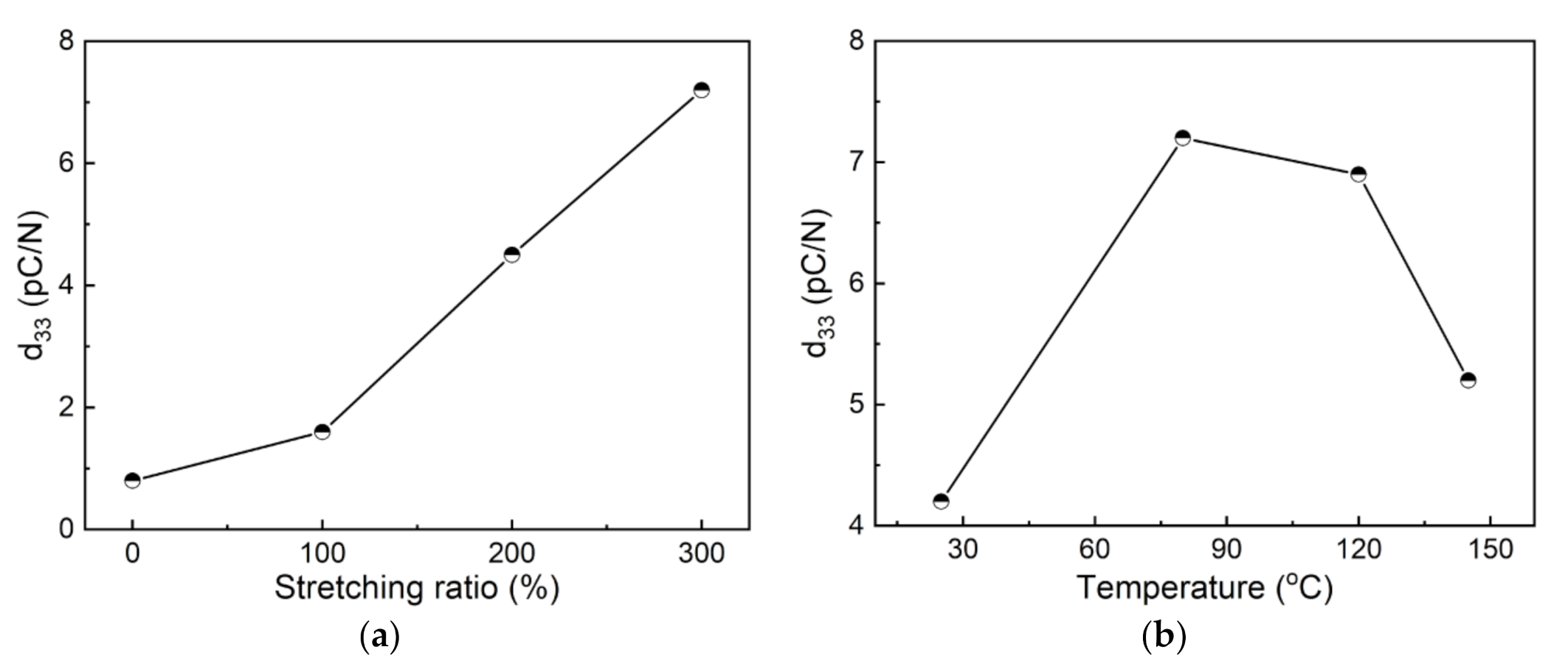

3.2. Effect of Stretching on Ferroelectric and Piezoelectric Properties of nylon-11 Film

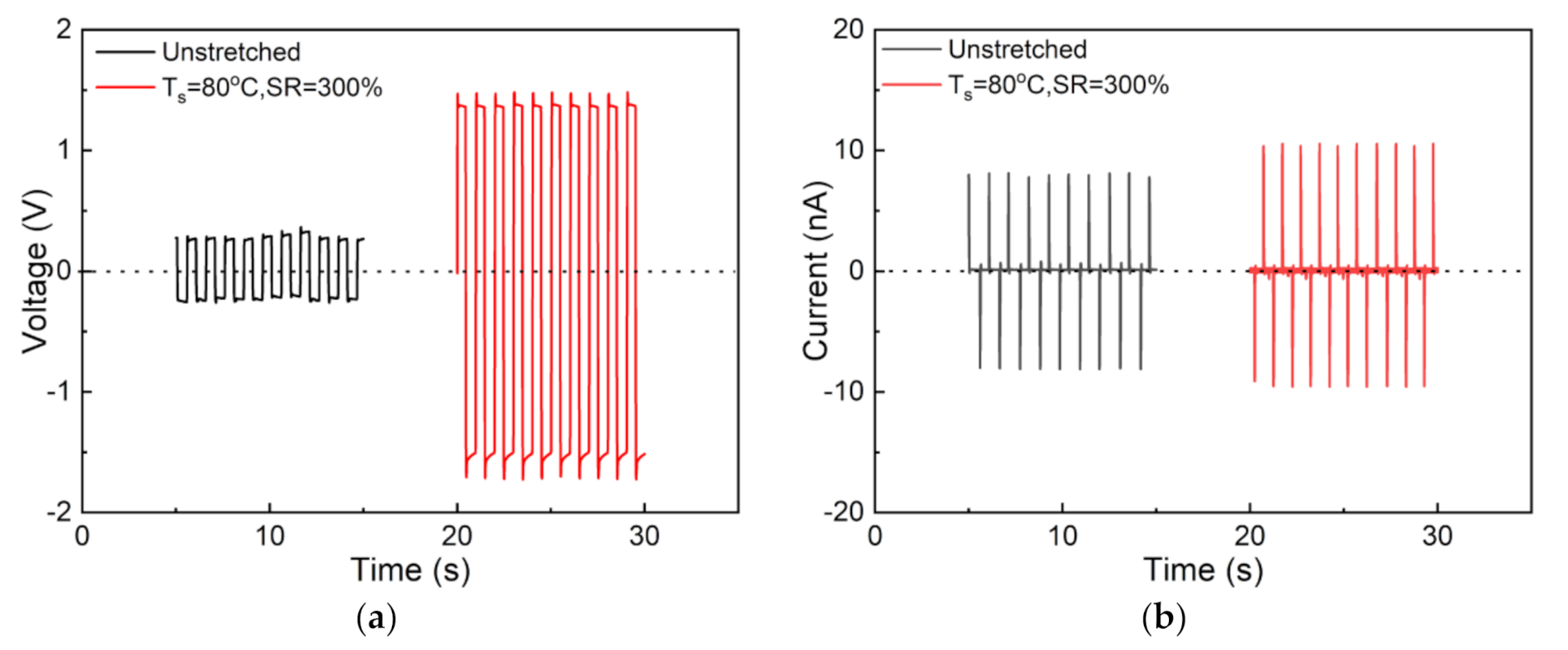

3.3. Performance of the nylon-11 based Piezoelectric Devices

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.L.; Song, J.H. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energ. Environ. Sci. 2014, 7, 25–44. [Google Scholar] [CrossRef] [Green Version]

- Chun, J.; Lee, K.Y.; Kang, C.Y.; Kim, M.W.; Kim, S.W.; Baik, J.M. Embossed hollow hemisphere-based piezoelectric nanogenerator and highly responsive pressure sensor. Adv. Funct. Mater. 2014, 24, 2038–2043. [Google Scholar] [CrossRef]

- Shin, S.H.; Kim, Y.H.; Lee, M.H.; Jung, J.Y.; Seol, J.H.; Nah, J. Lithium-doped zinc oxide nanowires-polymer composite for high performance flexible piezoelectric nanogenerator. Acs Nano 2014, 8, 10844–10850. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, T.; Wang, J.; Liao, J.; Qiu, Y.; Yang, Q.; Xue, H.; Shi, Z.; Zhao, Y.; Xiong, Z.; et al. A hybrid fibers based wearable fabric piezoelectric nanogenerator for energy harvesting application. Nano Energy 2015, 13, 298–305. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Cheng, Z.; Ruhparwar, A.; Foroughi, J. Highly stretchable self-powered wearable electrical energy generator and sensors. Adv. Mater. Technol. 2021, 6, 2000841. [Google Scholar] [CrossRef]

- Mokhtari, F.; Foroughi, J.; Zheng, T.; Cheng, Z.; Spinks, G.M. Triaxial braided piezo fiber energy harvesters for self-powered wearable technologies. J. Mater. Chem. A 2019, 7, 8245–8257. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Fay, C.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Wearable electronic textiles from nanostructured piezoelectric fibers. Adv. Mater. Technol. 2020, 5, 1900900. [Google Scholar] [CrossRef]

- Sussner, H.; Dransfeld, K. Importance of the metal–polymer interface for the piezoelectricity of polyvinylidene fluoride. J. Polym. Sci. Polym. Phys. Ed. 1978, 16, 529–543. [Google Scholar] [CrossRef]

- Newman, B.A.; Chen, P.; Pae, K.D.; Scheinbeim, J.I. Piezoelectricity in nylon 11. J. Appl. Phys. 1980, 51, 5161–5164. [Google Scholar] [CrossRef]

- Ren, K.; Wilson, W.L.; West, J.E.; Zhang, Q.M.; Yu, S.M. Piezoelectric property of hot pressed electrospun poly(γ-benzyl-α, L-glutamate) fibers. Appl. Phys. A 2012, 107, 639–646. [Google Scholar] [CrossRef]

- Ayyub, P.; Chattopadhyay, S.; Pinto, R.; Multani, M.S. Ferroelectric behavior in thin films of antiferroelectric materials. Phys. Rev. B 1998, 57, 5559–5562. [Google Scholar] [CrossRef]

- Venkatraju, J.; Swathi, I.; Ji-Ho, E.; Jihoon, C.; Soon-Gil, Y. Enhanced output performance of a flexible piezoelectric energy harvester based on stable MAPbI3-PVDF composite films. Nano Energy 2018, 53, 46–56. [Google Scholar]

- Li, Y.; Xu, M.H.; Xia, Y.S.; Wu, J.M.; Xiong, C.X. Multilayer assembly of electrospun/electrosprayed PVDF-based nanofibers and beads with enhanced piezoelectricity and high sensitivity. Chem. Eng. J. 2020, 388, 124205. [Google Scholar] [CrossRef]

- Newman, B.A.; Scheinbeim, J.I.; Lee, J.W. Ferroelectric polarization mechanisms in nylon 11. Macromolecules 1992, 25, 3729–3732. [Google Scholar]

- Zhang, Q.; Mo, Z.; Zhang, H.; Liu, S.; Cheng, S. Crystal transitions of nylon 11 under drawing and annealing. Polymer 2001, 42, 5543–5547. [Google Scholar] [CrossRef]

- Zhang, Q.X.; An, Y.X.; Yu, Y.N.; Mo, Z.S.; Mitchell, G.R. Crystal transformation of nylon 11 using in situ WAXD. Chin. Chem. Lett. 2000, 4, 365–366. [Google Scholar]

- Zhang, Z.; Litt, M.H.; Zhu, L. Understanding the paraelectric double hysteresis loop behavior in mesomorphic even-numbered nylons at high temperatures. Macromolecules 2017, 50, 5816–5829. [Google Scholar] [CrossRef]

- Slichter, W.P. Molecular motion in polyamides. J. Polym. Sci. 1959, 35, 77–92. [Google Scholar] [CrossRef]

- Kawaguchi, A.; Ikawa, T.; Fujiwara, Y.; Monobe, M. Polymorphism in lamellar single crystals of nylon 11. J. Macromol. Sci. Part B 1981, 20, 1–20. [Google Scholar] [CrossRef]

- Mathur, S.C.; Scheinbeim, J.I.; Newman, B.A. Piezoelectric properties and ferroelectric hysteresis effects in uniaxially stretched nylon films. J. Appl. Phys. 1984, 56, 2419–2425. [Google Scholar] [CrossRef]

- Fernandez, J.O.; Swallowe, G.M.; Lee, S.F. Crystallization of nylon 11 under compressive high strain rates. J. Appl. Polym. Sci. 2010, 80, 2031–2038. [Google Scholar] [CrossRef]

- Behler, K.; Havel, M.; Gogotsi, Y. New solvent for polyamides and its application to the electrospinning of polyamides 11 and 12. Polymer 2007, 48, 6617–6621. [Google Scholar] [CrossRef]

- Zhong, Z.; Wingert, M.C.; Strzalka, J.; Wang, H.H.; Sun, T.; Wang, J.; Chen, R.; Jiang, Z. Structure-induced enhancement of thermal conductivities in electrospun polymer nanofibers. Nanoscale 2014, 6, 8283–8291. [Google Scholar] [CrossRef]

- Anwar, S.; Pinkal, D.; Zajaczkowski, W.; Tiedemann, P.V.; Asadi, K. Solution-processed transparent ferroelectric nylon thin films. Sci. Adv. 2019, 5, eaav3489. [Google Scholar] [CrossRef] [Green Version]

- Anwar, S.; Amiri, M.H.; Abolhasani, M.M.; Asadi, K.; Jiang, S. Piezoelectric nylon fibers for electronic textiles, energy harvesting and sensing. Adv. Funct. Mater. 2021, 31, 2004326. [Google Scholar] [CrossRef]

- Garner, D.P.; Fasulo, P.D. The effect of composition on the properties of nylon 612 copolymers. J. Appl. Polym. Sci. 1988, 36, 495–509. [Google Scholar] [CrossRef]

- Chocinski-Arnault, L.; Gaudefroy, V.; Gacougnolle, J.L.; Rivière, A. Memory effect and crystalline structure in polyamide 11. J. Macromol. Sci. B 2007, 41, 777–785. [Google Scholar] [CrossRef]

- Nair, S.S.; Ramesh, C.; Tashiro, K. Crystalline phases in nylon-11: Studies using HTWAXS and HTFTIR. Macromolecular 2006, 39, 2841–2848. [Google Scholar] [CrossRef]

- Arkema Rilsan BESNO TL PA11. Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=078a73e26ed64ce3bcd70f8695ae222f (accessed on 15 May 2021).

- Gedde, U.W.; Hedenqvist, M.S. Fundamental Polymer Science, 2nd ed.; Springer: Cham, Switzerland, 2019; pp. 161–200. [Google Scholar]

- Wang, Z.L. On Maxwell’s displacement current for energy and sensors: The origin of nanogenerators. Mater. Today 2017, 20, 74–82. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Fu, Y.; Hu, G.-H.; Wang, S.; Xiong, C. Effect of Stretching on Crystalline Structure, Ferroelectric and Piezoelectric Properties of Solution-Cast Nylon-11 Films. Polymers 2021, 13, 2037. https://doi.org/10.3390/polym13132037

Wu J, Fu Y, Hu G-H, Wang S, Xiong C. Effect of Stretching on Crystalline Structure, Ferroelectric and Piezoelectric Properties of Solution-Cast Nylon-11 Films. Polymers. 2021; 13(13):2037. https://doi.org/10.3390/polym13132037

Chicago/Turabian StyleWu, Jima, Yuheng Fu, Guo-Hua Hu, Shan Wang, and Chuanxi Xiong. 2021. "Effect of Stretching on Crystalline Structure, Ferroelectric and Piezoelectric Properties of Solution-Cast Nylon-11 Films" Polymers 13, no. 13: 2037. https://doi.org/10.3390/polym13132037

APA StyleWu, J., Fu, Y., Hu, G.-H., Wang, S., & Xiong, C. (2021). Effect of Stretching on Crystalline Structure, Ferroelectric and Piezoelectric Properties of Solution-Cast Nylon-11 Films. Polymers, 13(13), 2037. https://doi.org/10.3390/polym13132037