Scientometric Analysis and Systematic Review of Multi-Material Additive Manufacturing of Polymers

Abstract

1. Introduction

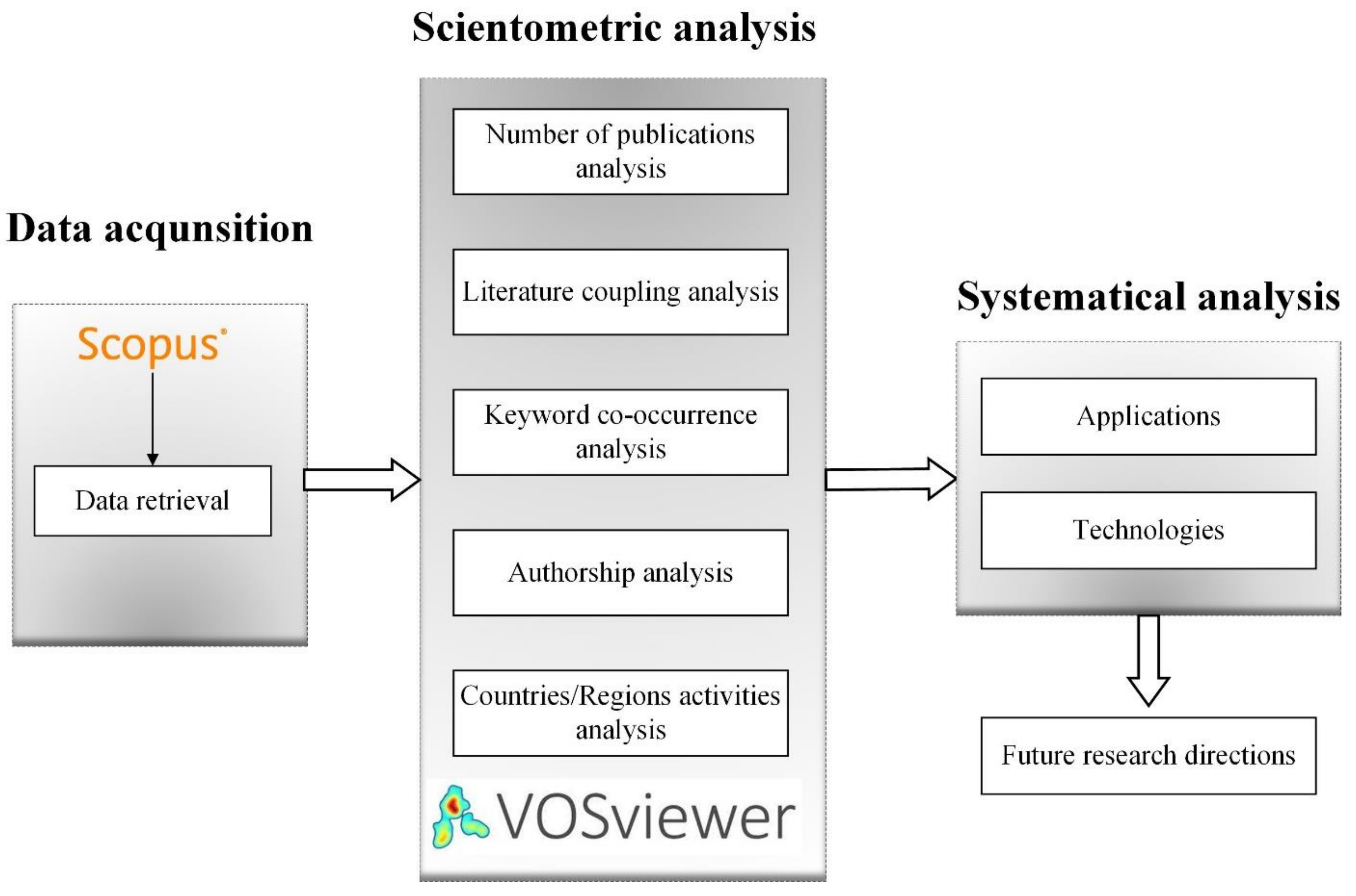

2. Research Method

2.1. Data Acquisition

2.2. Scientometric Analysis

2.3. Systematic Review

3. Results and Analysis

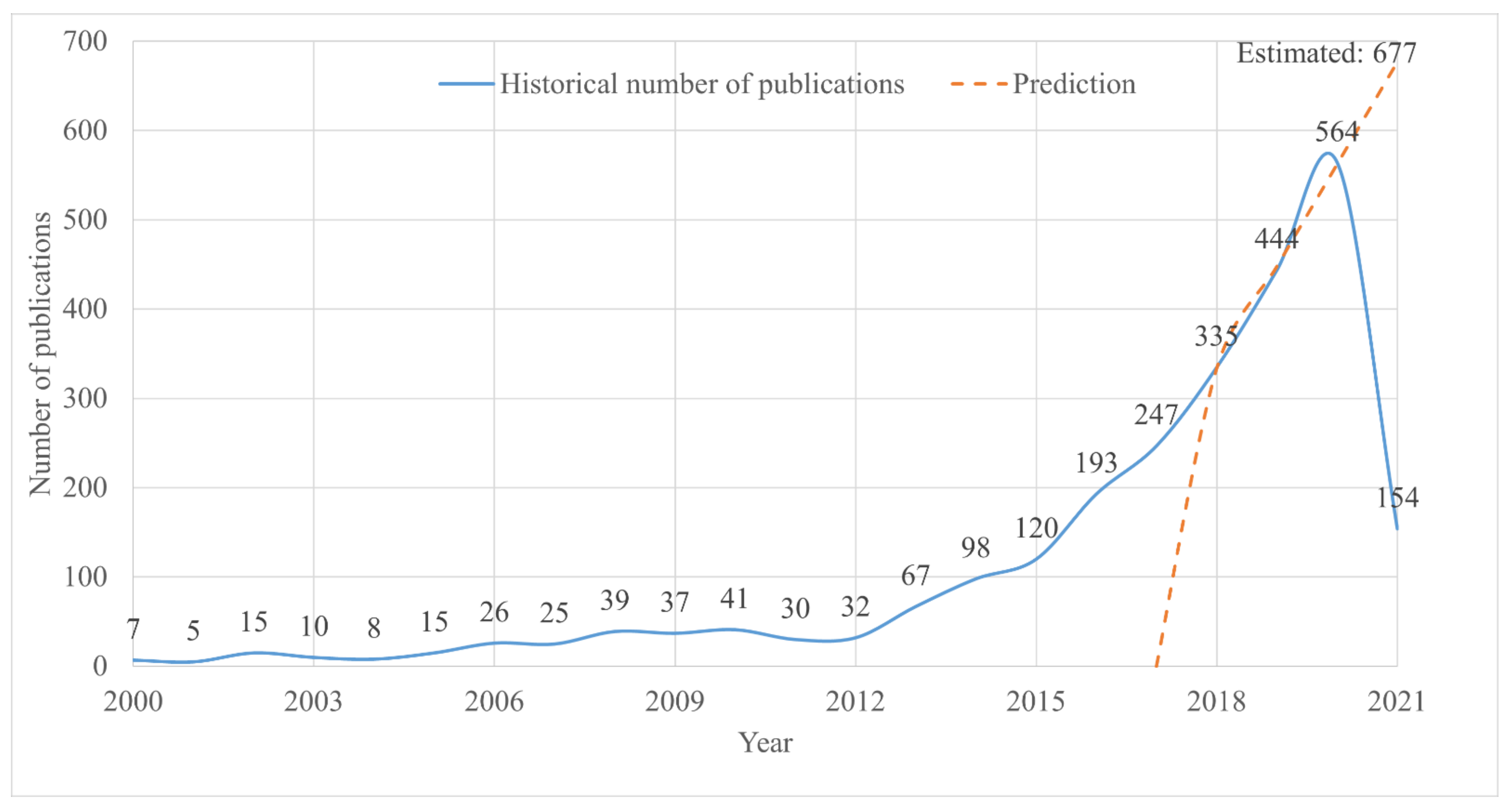

3.1. Number of Publications Analysis

3.2. Literature Coupling Analysis

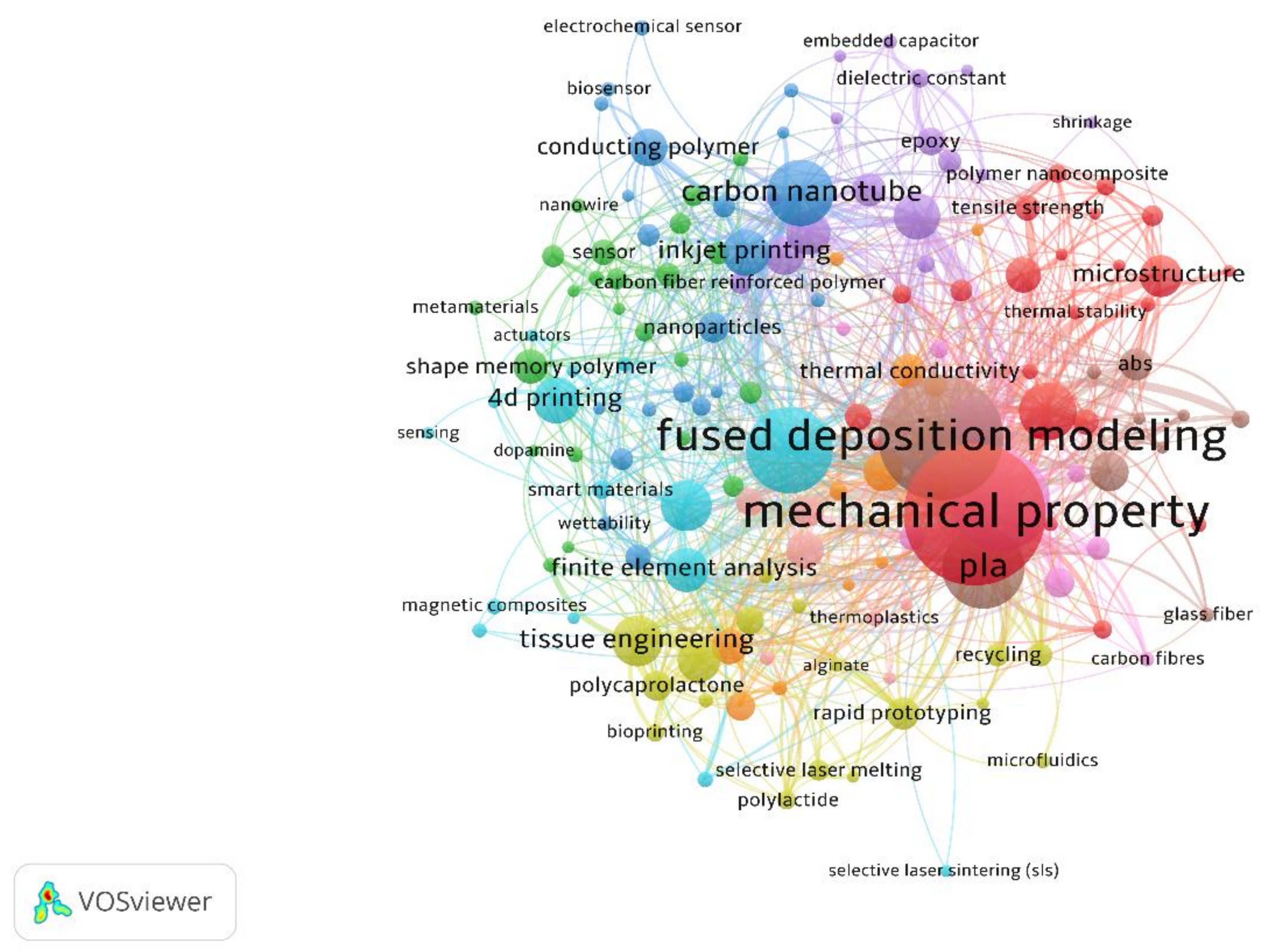

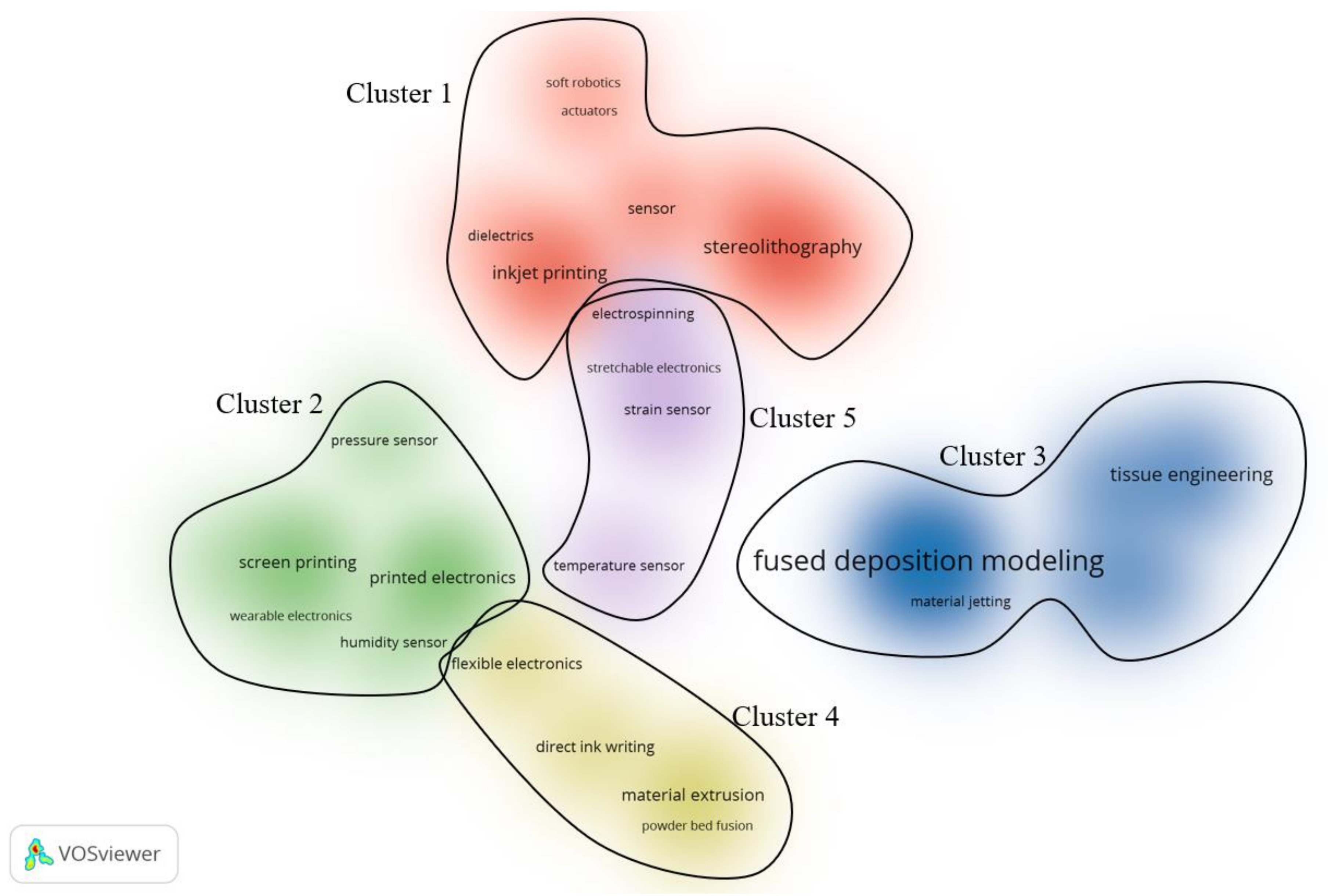

3.3. Keyword Co-Occurrence Analysis

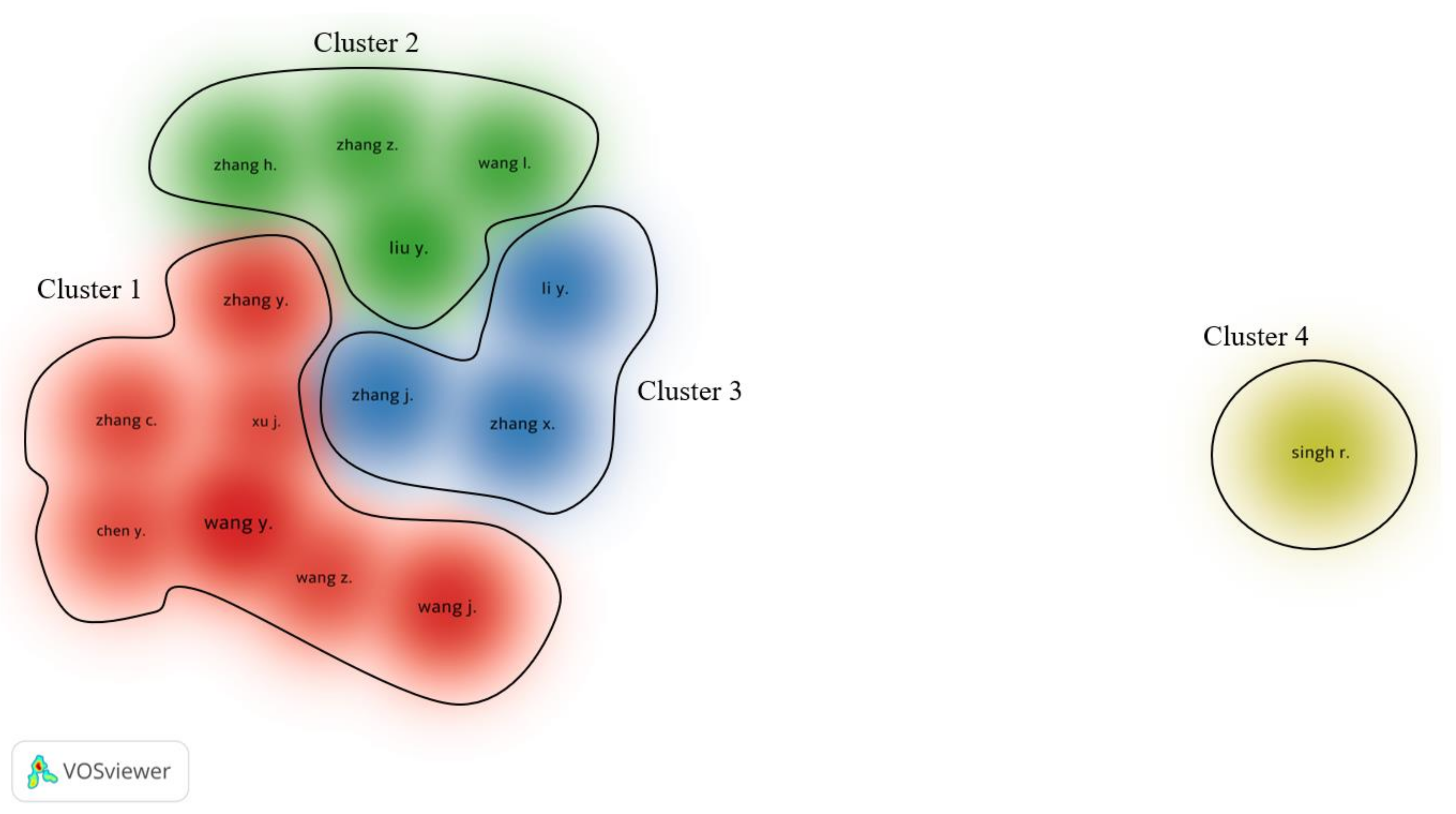

3.4. Authorship Analysis

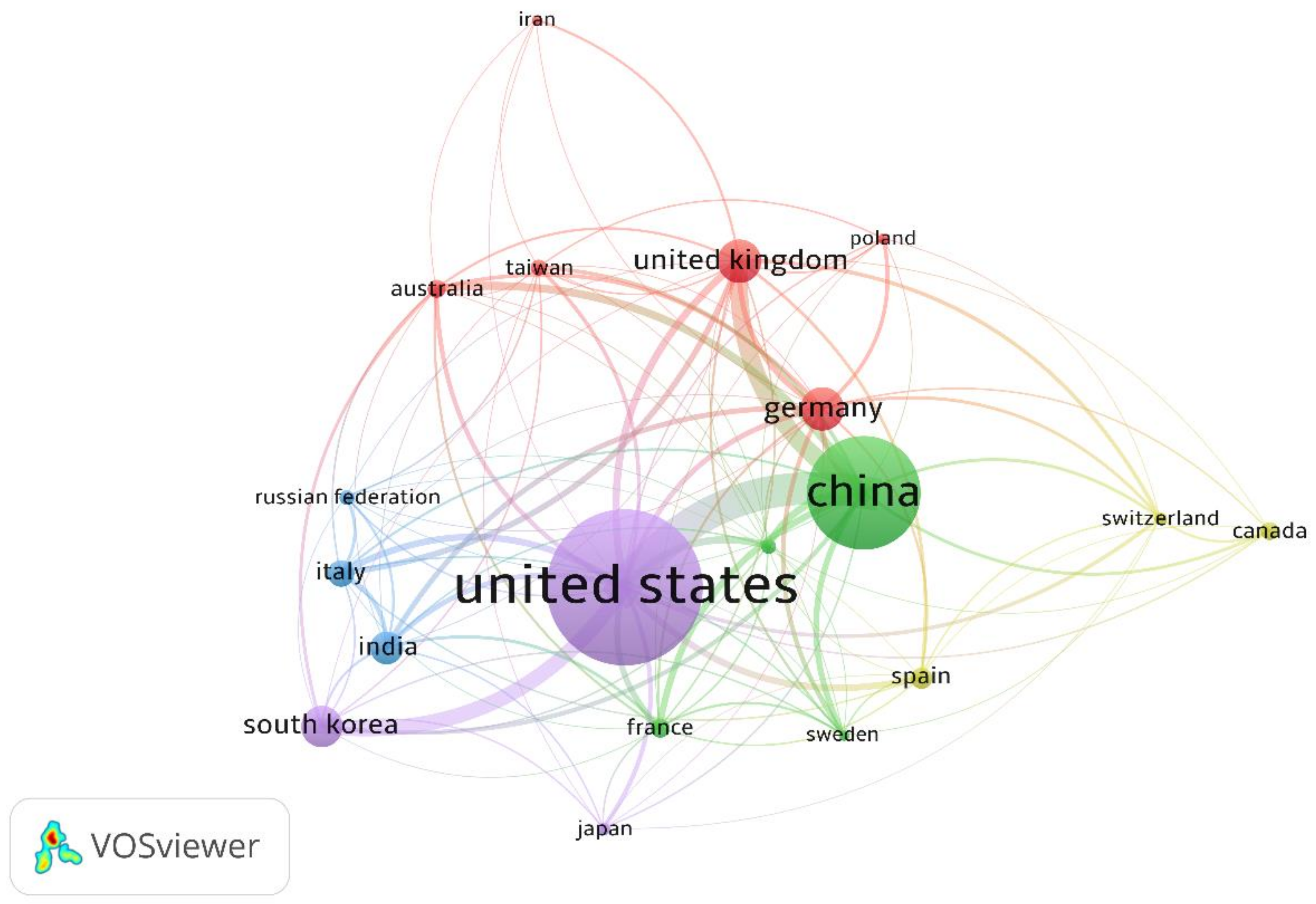

3.5. Countries/Regions Activities Analysis

4. Systematic Review of Current Research

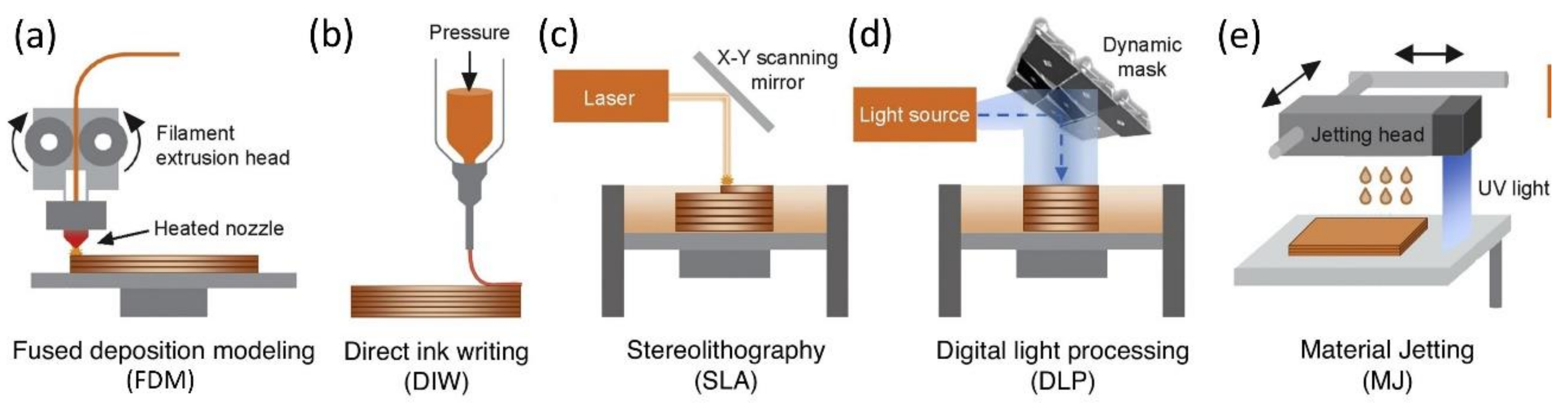

4.1. Technologies

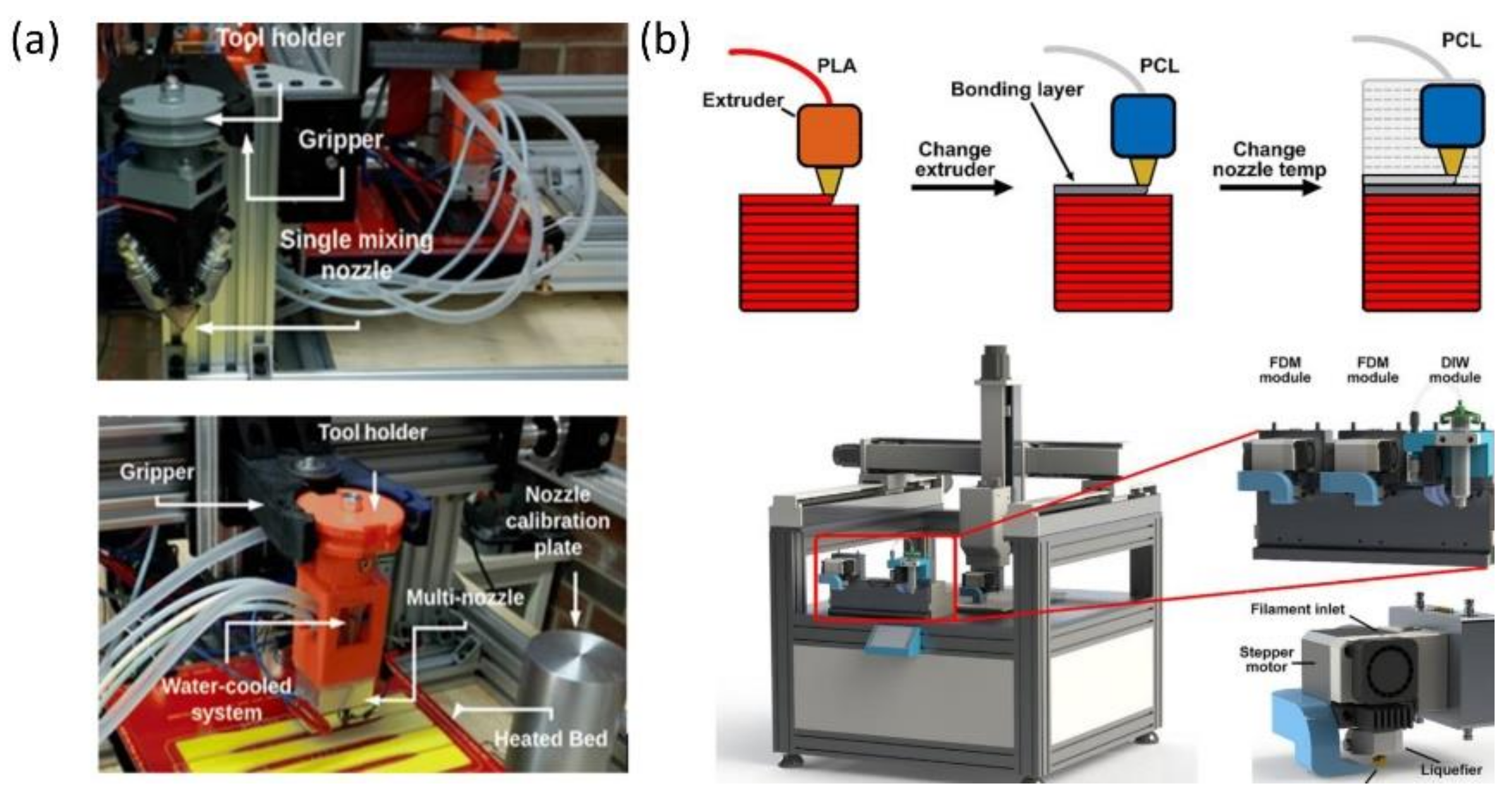

4.1.1. Fused Deposition Modeling

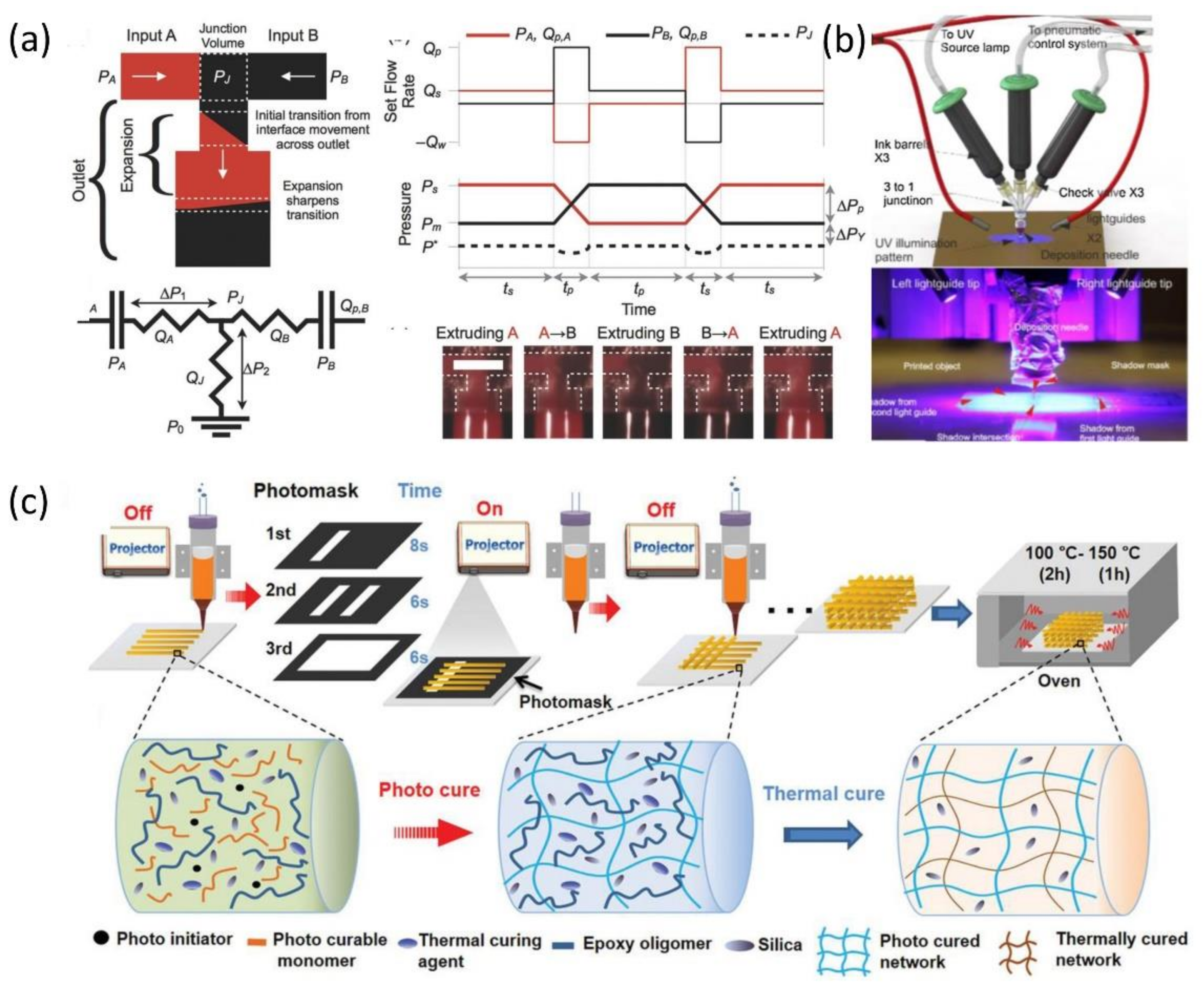

4.1.2. Direct Ink Writing

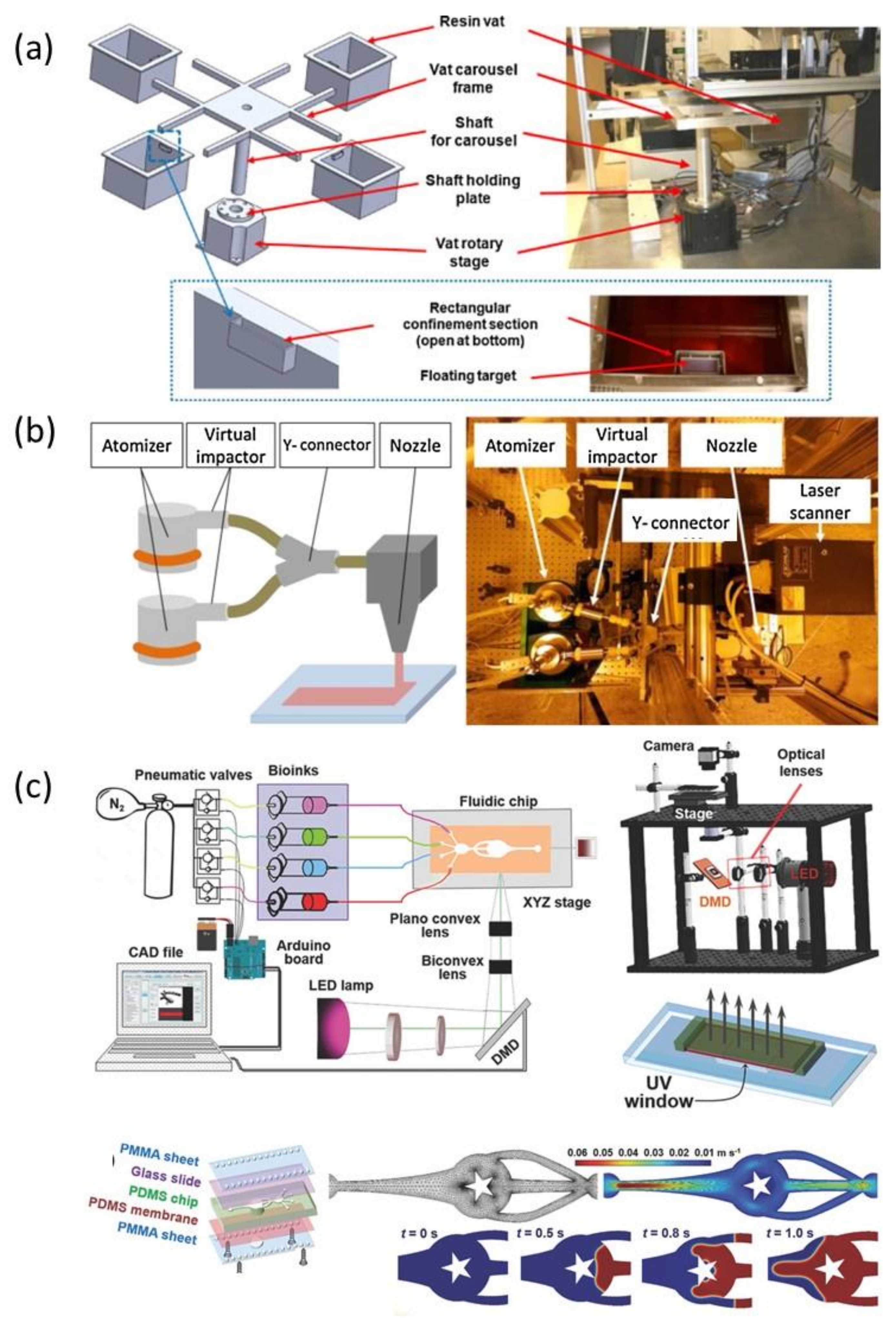

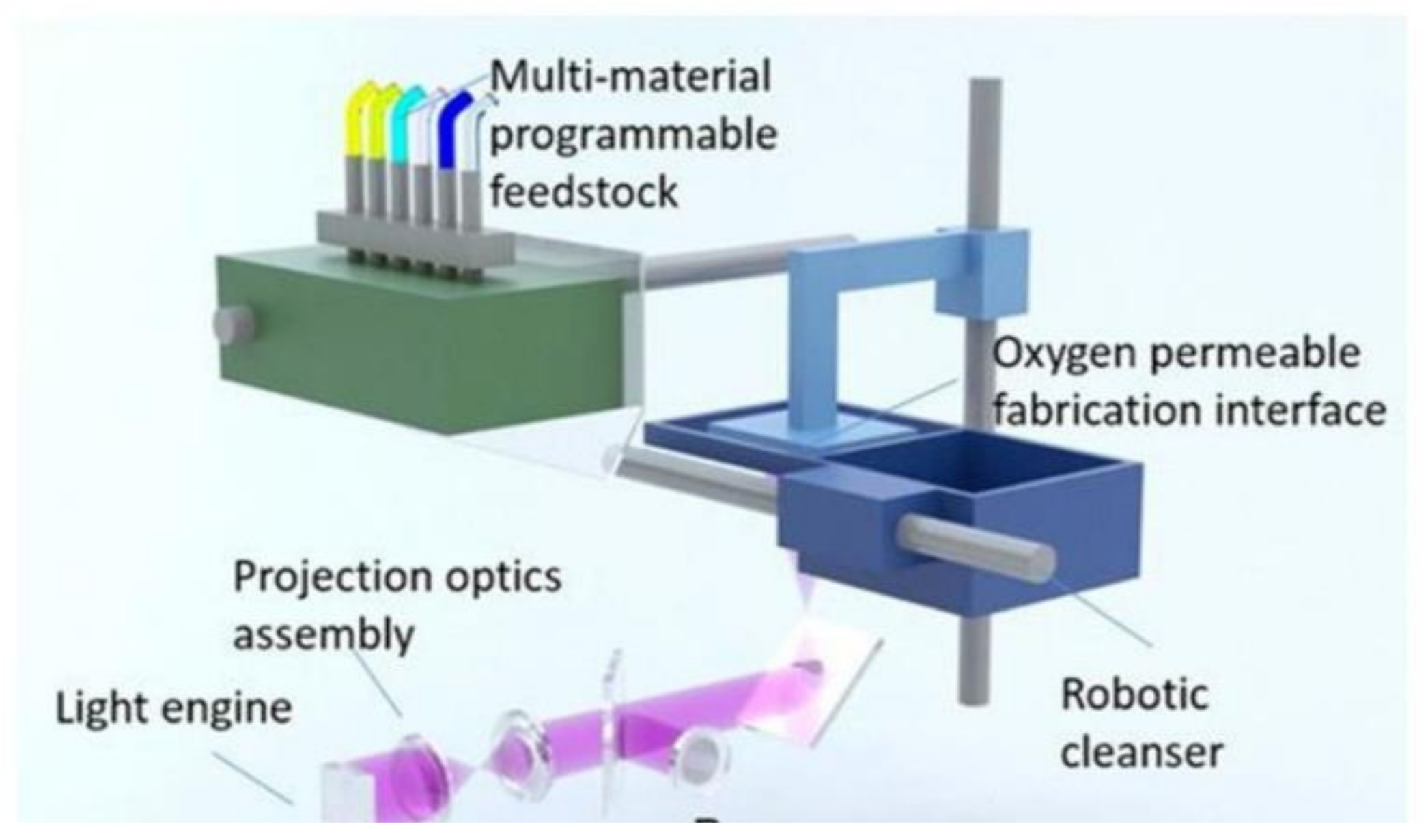

4.1.3. Vat Photopolymerization

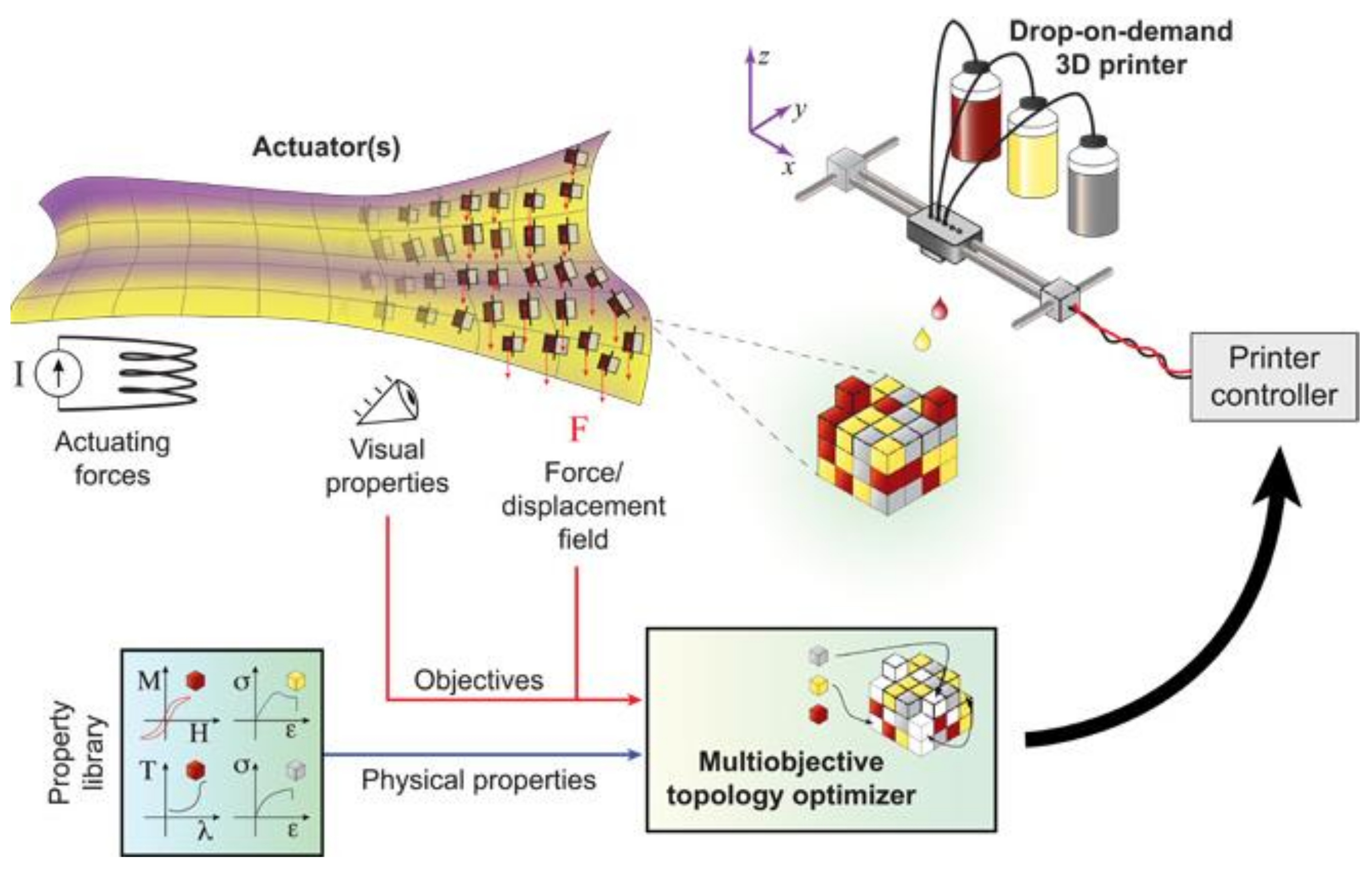

4.1.4. Material Jetting

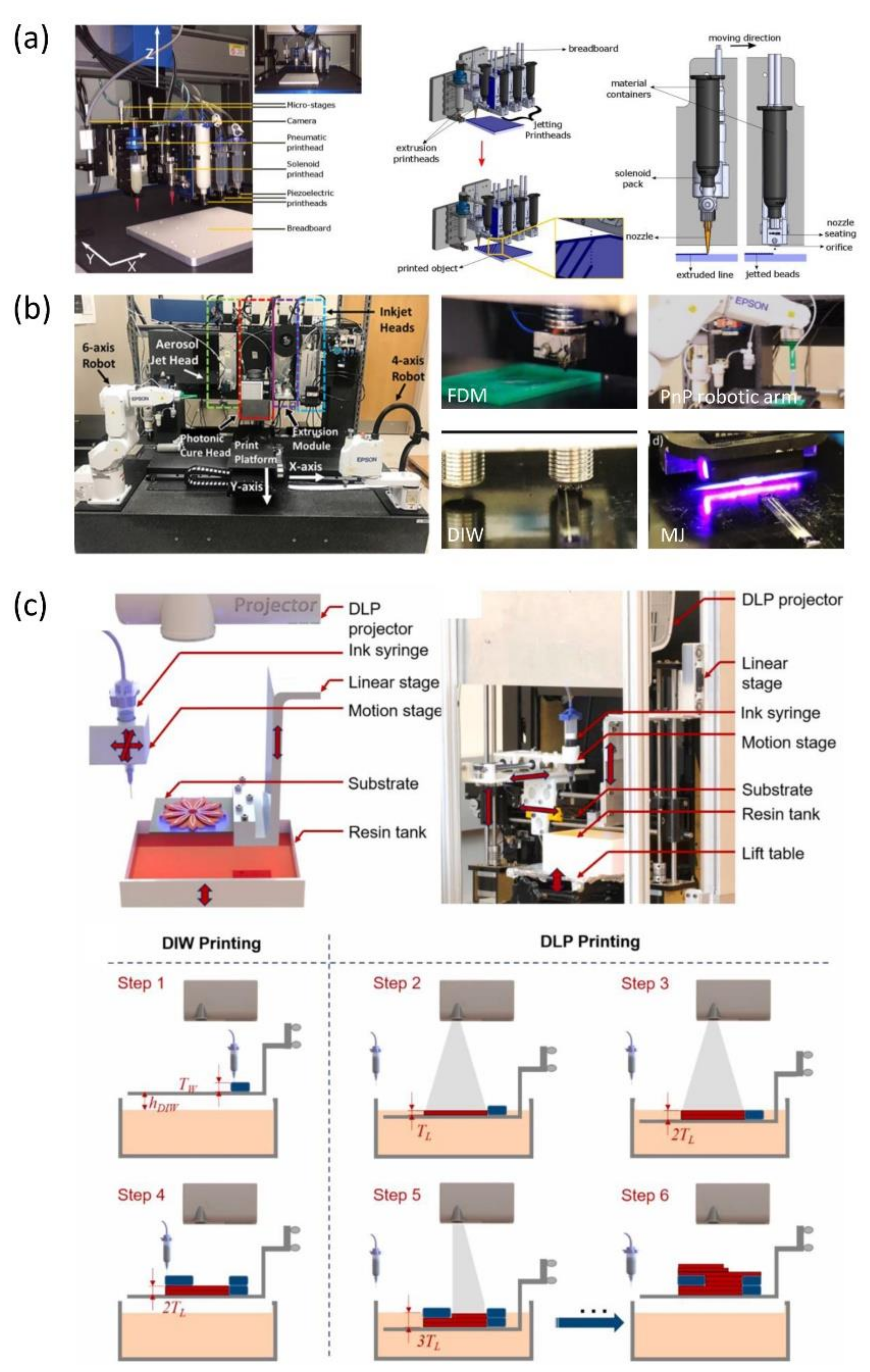

4.1.5. Hybrid AM Systems

4.2. Applications

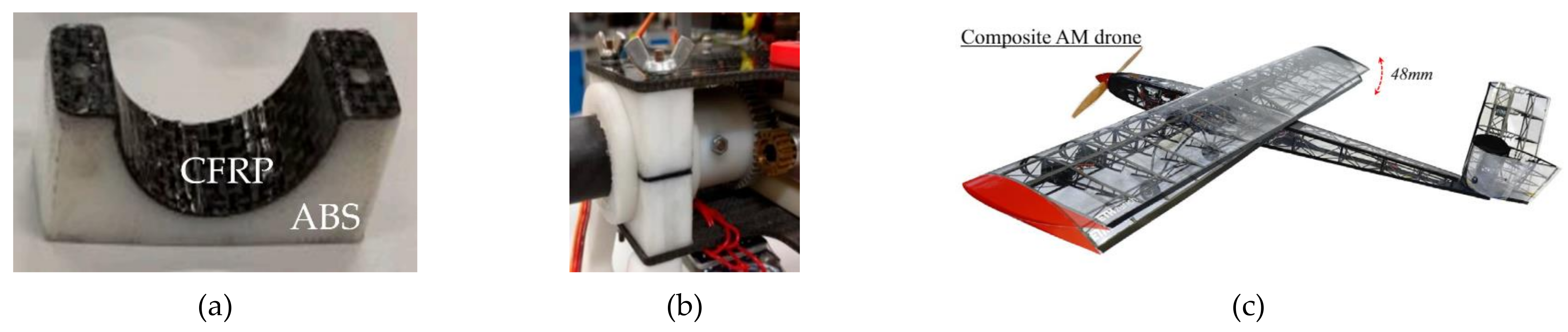

4.2.1. Engineering

4.2.2. Healthcare

4.2.3. Electronics

5. Discussion and Future Trends

5.1. Overview

5.2. Future Trend

5.2.1. Microscale/Nanoscale Multi-Material 3D Printing

5.2.2. Printing Efficiency

5.2.3. Interfacial Bonding Strength

5.2.4. 4D Multi-Material Printing

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Mutltidiscip. Opt. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing-integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. Environmental impact assessment of an innovative strategy based on an additive and subtractive manufacturing combination. J. Clean. Prod. 2017, 164, 508–523. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The impact of metal additive manufacturing on the aerospace industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Xu, X.; Awad, A.; Robles-Martinez, P.; Gaisford, S.; Goyanes, A.; Basit, A.W. Vat photopolymerization 3D printing for advanced drug delivery and medical device applications. J. Control. Release 2021, 329, 743–757. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3d printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Chartrain, N.A.; Williams, C.B.; Whittington, A.R. A review on fabricating tissue scaffolds using vat photopolymerization. Acta Biomater. 2018, 74, 90–111. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

- Chatham, C.A.; Long, T.E.; Williams, C.B. A review of the process physics and material screening methods for polymer powder bed fusion additive manufacturing. Prog. Polym. Sci. 2019, 93, 68–95. [Google Scholar] [CrossRef]

- Bourell, D.; Coholich, J.; Chalancon, A.; Bhat, A. Evaluation of energy density measures and validation for powder bed fusion of polyamide. CIRP Ann. Manuf. Technol. 2017, 66, 217–220. [Google Scholar] [CrossRef]

- Awad, A.; Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D printing: Principles and pharmaceutical applications of selective laser sintering. Int. J. Pharm. 2020, 586. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, C.; Yao, D.; Chen, G. 3D printing of oil paintings based on material jetting and its reduction of staircase effect. Polymers 2020, 12, 2536. [Google Scholar] [CrossRef]

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36. [Google Scholar] [CrossRef]

- Jabari, E.; Liravi, F.; Davoodi, E.; Lin, L.; Toyserkani, E. High speed 3D material-jetting additive manufacturing of viscous graphene-based ink with high electrical conductivity. Addit. Manuf. 2020, 35. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, J.; Bae, J.; Park, S.; Choi, J.; Lee, J.H.; Kim, E. Mechanical analysis of ceramic/polymer composite with mesh-type lightweight design using binder-jet 3D printing. Materials 2018, 11, 1941. [Google Scholar] [CrossRef]

- Zhao, Z.; Gou, J.; Bietto, S.; Ibeh, C.; Hui, D. Fire retardancy of clay/carbon nanofiber hybrid sheet in fiber reinforced polymer composites. Compos. Sci. Technol. 2009, 69, 2081–2087. [Google Scholar] [CrossRef]

- Zhang, C.S.; Ni, Q.Q. Bending behavior of shape memory polymer based laminates. Compos. Struct. 2007, 78, 153–161. [Google Scholar] [CrossRef]

- Szymczyk-Ziolkowska, P.; Labowska, M.B.; Detyna, J.; Michalak, I.; Gruber, P. A review of fabrication polymer scaffolds for biomedical applications using additive manufacturing techniques. Biocybern. Biomed. Eng. 2020, 40, 624–638. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7. [Google Scholar] [CrossRef]

- Hood, W.W.; Wilson, C.S. The literature of bibliometrics, scientometrics, and informetrics. Scientometrics 2001, 52, 291–314. [Google Scholar] [CrossRef]

- Martinez, P.; Al-Hussein, M.; Ahmad, R. A scientometric analysis and critical review of computer vision applications for construction. Autom. Constr. 2019, 107. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P.-P.; Altman, D.G.; et al. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118. [Google Scholar] [CrossRef]

- Kim, M.J.; Wang, X.; Love, P.E.D.; Li, H.; Kang, S.C. Virtual reality for the built environment: A critical review of recent advances. J. Inf. Technol. Constr. 2013, 18, 279–305. [Google Scholar]

- Granovsky, Y.V. Is it possible to measure science? V. V. Nalimov’s research in scientometrics. Scientometrics 2001, 52, 127–150. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, R. An evolutionary analysis of collaboration networks in scientometrics. Scientometrics 2016, 107, 759–772. [Google Scholar] [CrossRef]

- Chen, K.; Wang, J.; Yu, B.; Wu, H.; Zhang, J. Critical evaluation of construction and demolition waste and associated environmental impacts: A scientometric analysis. J. Clean. Prod. 2021, 287. [Google Scholar] [CrossRef]

- Tariq, S.; Hu, Z.; Zayed, T. Micro-electromechanical systems-based technologies for leak detection and localization in water supply networks: A bibliometric and systematic review. J. Clean. Prod. 2021, 289. [Google Scholar] [CrossRef]

- Zheng, C.; Yuan, J.; Zhu, L.; Zhang, Y.; Shao, Q. From digital to sustainable: A scientometric review of smart city literature between 1990 and 2019. J. Clean. Prod. 2020, 258. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M. A scientometric review of global research on sustainability and sustainable development. J. Clean. Prod. 2018, 183, 231–250. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Song, J.; Zhang, H.; Dong, W. A review of emerging trends in global PPP research: Analysis and visualization. Scientometrics 2016, 107, 1111–1147. [Google Scholar] [CrossRef]

- Sun, Y.; Li, C.; Zhao, Y.; Sun, J. Trends and developments in oral health literacy: A scientometric research study (1991–2020). BDJ Open 2021, 7. [Google Scholar] [CrossRef]

- Shi, S.; Yin, J. Global research on carbon footprint: A scientometric review. Environ. Impact Assess. Rev. 2021, 89. [Google Scholar] [CrossRef]

- Kim, M.C.; Chen, C. A scientometric review of emerging trends and new developments in recommendation systems. Scientometrics 2015, 104, 239–263. [Google Scholar] [CrossRef]

- Heilig, L.; Vob, S. A scientometric analysis of cloud computing literature. IEEE Trans. Cloud Comput. 2014, 2, 266–278. [Google Scholar] [CrossRef]

- Feng, S.; Zhang, H.; Lv, J.; Dyck, M.; Wu, Q.; He, H. A scientometric review of research status on unfrozen soil water. Water 2021, 13, 708. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Milojević, S. International Encyclopedia of the Social & Behavioral Sciences, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 322–327. [Google Scholar]

- Pollack, J.; Adler, D. Emergent trends and passing fads in project management research: A scientometric analysis of changes in the field. Int. J. Proj. Manage. 2015, 33, 236–248. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Su, H.N.; Lee, P.C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer New York: New York, NY, USA, 2015; pp. 1–498. [Google Scholar]

- Chueh, Y.H.; Wei, C.; Zhang, X.; Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Addit. Manuf. 2020, 31. [Google Scholar] [CrossRef]

- Chueh, Y.H.; Zhang, X.; Ke, J.C.R.; Li, Q.; Wei, C.; Li, L. Additive manufacturing of hybrid metal/polymer objects via multiple-material laser powder bed fusion. Addit. Manuf. 2020, 36. [Google Scholar] [CrossRef]

- Santos-Rosales, V.; Iglesias-Mejuto, A.; García-González, C.A. Solvent-free approaches for the processing of scaffolds in regenerative medicine. Polymers 2020, 12, 533. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Perez-Escribano, M.; Marquez-Segura, E. Parameters Characterization of Dielectric Materials Samples in Microwave and Millimeter-Wave Bands. IEEE Trans. Microw. Theory Tech. 2021, 69, 1723–1732. [Google Scholar] [CrossRef]

- Luo, C.; Mrinal, M.; Wang, X.; Hong, Y. Bonding widths of deposited polymer strands in additive manufacturing. Materials 2021, 14, 871. [Google Scholar] [CrossRef]

- Ameri, B.; Taheri-Behrooz, F.; Aliha, M.R.M. Evaluation of the geometrical discontinuity effect on mixed-mode I/II fracture load of FDM 3D-printed parts. Theor. Appl. Fract. Mech. 2021, 113. [Google Scholar] [CrossRef]

- Oberdiek, F.; Vargas, C.I.; Rider, P.; Batinic, M.; Görke, O.; Radenković, M.; Najman, S.; Baena, J.M.; Jung, O.; Barbeck, M. Ex Vivo and In Vivo analyses of novel 3d-printed bone substitute scaffolds incorporating biphasic calcium phosphate granules for bone regeneration. Int. J. Mol. Sci. 2021, 22, 3588. [Google Scholar] [CrossRef]

- Kong, B.; Chen, Y.; Liu, R.; Liu, X.; Liu, C.; Shao, Z.; Xiong, L.; Liu, X.; Sun, W.; Mi, S. Fiber reinforced GelMA hydrogel to induce the regeneration of corneal stroma. Nat. Commun. 2020, 11. [Google Scholar] [CrossRef]

- Gong, L.; Li, J.; Zhang, J.; Pan, Z.; Liu, Y.; Zhou, F.; Hong, Y.; Hu, Y.; Gu, Y.; Ouyang, H.; et al. An interleukin-4-loaded bi-layer 3D printed scaffold promotes osteochondral regeneration. Acta Biomater. 2020, 117, 246–260. [Google Scholar] [CrossRef]

- Chou, P.Y.; Chou, Y.C.; Lai, Y.H.; Lin, Y.T.; Lu, C.J.; Liu, S.J. Fabrication of drug-eluting nano-hydroxylapatite filled polycaprolactone nanocomposites using solution-extrusion 3d printing technique. Polymers 2021, 13, 318. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.M.; Arias, A. Conductive 3D printed PLA composites: On the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265. [Google Scholar] [CrossRef]

- Mishra, P.K.; Senthil, P.; Adarsh, S.; Anoop, M.S. An investigation to study the combined effect of different infill pattern and infill density on the impact strength of 3D printed polylactic acid parts. Compos. Commun. 2021, 24. [Google Scholar] [CrossRef]

- Basa, B.; Jakab, G.; Kállai-Szabó, N.; Borbás, B.; Fülöp, V.; Balogh, E.; Antal, I. Evaluation of biodegradable PVA-based 3D printed carriers during dissolution. Materials 2021, 14, 1350. [Google Scholar] [CrossRef]

- Saeed, K.; McIlhagger, A.; Harkin-Jones, E.; Kelly, J.; Archer, E. Predication of the in-plane mechanical properties of continuous carbon fibre reinforced 3D printed polymer composites using classical laminated-plate theory. Compos. Struct. 2021, 259. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Effect of printing temperature on microstructure, thermal behavior and tensile properties of 3D printed nylon using fused deposition modeling. J. Appl. Polym. Sci. 2021, 138. [Google Scholar] [CrossRef]

- Díaz-Rodríguez, J.G.; Pertúz-Comas, A.D.; González-Estrada, O.A. Mechanical properties for long fibre reinforced fused deposition manufactured composites. Compos. Part B Eng. 2021, 211. [Google Scholar] [CrossRef]

- Tiboni, M.; Tiboni, M.; Pierro, A.; Del Papa, M.; Sparaventi, S.; Cespi, M.; Casettari, L. Microfluidics for nanomedicines manufacturing: An affordable and low-cost 3D printing approach. Int. J. Pharm. 2021, 599. [Google Scholar] [CrossRef]

- Hou, J.; Zhong, M.; Pan, X.; Chen, L.; Wu, X.; Kong, Z.; Yuan, Y.; Yan, S.; Zhang, J.; Duan, Y. Fabricating 3D printable BIIR/PP TPV via masterbatch and interfacial compatibilization. Compos. Part B Eng. 2020, 199. [Google Scholar] [CrossRef]

- Bertolino, M.; Battegazzore, D.; Arrigo, R.; Frache, A. Designing 3D printable polypropylene: Material and process optimisation through rheology. Addit. Manuf. 2021, 40. [Google Scholar] [CrossRef]

- Thiele, M.; Kutlu, Y.; Dobbelstein, H.; Petermann, M.; Esen, C.; Ostendorf, A. Direct generation of 3D structures by laser polymer deposition. J. Laser Appl. 2021, 33. [Google Scholar] [CrossRef]

- Hu, B.; Li, M.; Jiang, J.; Zhai, W. Development of microcellular thermoplastic polyurethane honeycombs with tailored elasticity and energy absorption via CO2 foaming. Int. J. Mech. Sci. 2021, 197. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Lu, H.; Wang, Y.; Xu, J.; Zhu, J.; Zhang, C.; Liu, T. Cryopolymerization enables anisotropic polyaniline hybrid hydrogels with superelasticity and highly deformation-tolerant electrochemical energy storage. Nat. Commun. 2020, 11. [Google Scholar] [CrossRef]

- Hann, S.Y.; Cui, H.; Esworthy, T.; Zhou, X.; Lee, S.J.; Plesniak, M.W.; Zhang, L.G. Dual 3D printing for vascularized bone tissue regeneration. Acta Biomater. 2021, 123, 263–274. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Coogan, T.J.; Kazmer, D.O. Prediction of interlayer strength in material extrusion additive manufacturing. Addit. Manuf. 2020, 35. [Google Scholar] [CrossRef]

- Sathies, T.; Senthil, P.; Anoop, M.S. A review on advancements in applications of fused deposition modelling process. Rapid Prototyp. J. 2020, 26, 669–687. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing—Part 1: A review. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Khudiakova, A.; Arbeiter, F.; Spoerk, M.; Wolfahrt, M.; Godec, D.; Pinter, G. Inter-layer bonding characterisation between materials with different degrees of stiffness processed by fused filament fabrication. Addit. Manuf. 2019, 28, 184–193. [Google Scholar] [CrossRef]

- Lin, W.; Shen, H.; Xu, G.; Zhang, L.; Fu, J.; Deng, X. Single-layer temperature-adjusting transition method to improve the bond strength of 3D-printed PCL/PLA parts. Compos. Part A Appl. Sci. Manuf. 2018, 115, 22–30. [Google Scholar] [CrossRef]

- Ribeiro, M.; Sousa Carneiro, O.; Ferreira da Silva, A. Interface geometries in 3D multi-material prints by fused filament fabrication. Rapid Prototyp. J. 2019, 25, 38–46. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Asad, A.; Sameoto, D. Printing with mechanically interlocked extrudates using a custom bi-extruder for fused deposition modelling. Rapid Prototyp. J. 2018, 24, 921–934. [Google Scholar] [CrossRef]

- Zheng, M.; Guo, Q.; Yin, X.; Getangama, N.N.; de Bruyn, J.R.; Xiao, J.; Bai, Y.; Liu, M.; Yang, J. Direct ink writing of recyclable andin siturepairable photothermal polyurethane for sustainable 3D printing development. J. Mater. Chem. A 2021, 9, 6981–6992. [Google Scholar] [CrossRef]

- Huo, C.; Tian, X.; Chen, C.; Zhang, J.; Nan, Y.; Zhong, Q.; Huang, X.; Hu, J.; Li, D. Hierarchically porous alumina catalyst carrier with biomimetic vein structure prepared by direct ink writing. J. Eur. Ceram. Soc. 2021, 41, 4231–4241. [Google Scholar] [CrossRef]

- Huang, K.; Elsayed, H.; Franchin, G.; Colombo, P. Embedded direct ink writing of freeform ceramic components. Appl. Mater. Today 2021, 23. [Google Scholar] [CrossRef]

- Coffigniez, M.; Gremillard, L.; Balvay, S.; Lachambre, J.; Adrien, J.; Boulnat, X. Direct-ink writing of strong and biocompatible titanium scaffolds with bimodal interconnected porosity. Addit. Manuf. 2021, 39. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, J.; Chen, Z.; Xu, C.; Tang, W.; Yang, G.; Lai, C.; Xu, Q.; Yang, J.; Peng, C. Direct Ink Writing of Moldable Electrochemical Energy Storage Devices: Ongoing Progress, Challenges, and Prospects. Adv. Eng. Mater. 2021. [Google Scholar] [CrossRef]

- Pinargote, N.W.S.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct ink writing technology (3d printing) of graphene-based ceramic nanocomposites: A review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef]

- Jiang, P.; Ji, Z.; Zhang, X.; Liu, Z.; Wang, X. Recent advances in direct ink writing of electronic components and functional devices. Prog. Addit. Manuf. 2018, 3, 65–86. [Google Scholar] [CrossRef]

- Hao, L.; Tang, D.; Sun, T.; Xiong, W.; Feng, Z.; Evans, K.E.; Li, Y. Direct Ink Writing of Mineral Materials: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 665–685. [Google Scholar] [CrossRef]

- Pack, R.C.; Compton, B.G. Material Extrusion Additive Manufacturing of Metal Powder-Based Inks Enabled by Carrageenan Rheology Modifier. Adv. Eng. Mater. 2021, 23. [Google Scholar] [CrossRef]

- Rahim, M.A.; Centurion, F.; Han, J.; Abbasi, R.; Mayyas, M.; Sun, J.; Christoe, M.J.; Esrafilzadeh, D.; Allioux, F.M.; Ghasemian, M.B.; et al. Polyphenol-Induced Adhesive Liquid Metal Inks for Substrate-Independent Direct Pen Writing. Adv. Funct. Mater. 2021, 31. [Google Scholar] [CrossRef]

- Lin, T.; Jin, L.P.; Yuan, J.Y.; Shao, H.P.; Yu, F.C.; Li, W.Y.; He, X.B.; Deng, X. Direct ink writing of TiC-316L metal matrix composites with an epoxy resin-absolute ethanol system. Rare Met. 2021, 40, 590–599. [Google Scholar] [CrossRef]

- Jin, H.; Jia, D.; Yang, Z.; Zhou, Y. Mechanical and dielectric properties of direct ink writing Si2N2O composites. J. Eur. Ceram. Soc. 2021, 41, 2579–2586. [Google Scholar] [CrossRef]

- Troksa, A.L.; Eshelman, H.V.; Chandrasekaran, S.; Rodriguez, N.; Ruelas, S.; Duoss, E.B.; Kelly, J.P.; Cerón, M.R.; Campbell, P.G. 3D-printed nanoporous ceramics: Tunable feedstock for direct ink write and projection microstereolithography. Mater. Des. 2021, 198. [Google Scholar] [CrossRef]

- Liu, Z.; Tian, X.; Liu, M.; Duan, S.; Ren, Y.; Ma, H.; Tang, K.; Shi, J.; Hou, S.; Jin, H.; et al. Direct Ink Writing of Li1.3Al0.3Ti1.7(PO4)3-Based Solid-State Electrolytes with Customized Shapes and Remarkable Electrochemical Behaviors. Small 2021, 17. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Xu, C. Nanocellulose-based inks for 3d bioprinting: Key aspects in research development and challenging perspectives in applications—a mini review. Bioengineering 2020, 7, 40. [Google Scholar] [CrossRef]

- Shin, Y.J.; Shafranek, R.T.; Tsui, J.H.; Walcott, J.; Nelson, A.; Kim, D.H. 3D bioprinting of mechanically tuned bioinks derived from cardiac decellularized extracellular matrix. Acta Biomater. 2021, 119, 75–88. [Google Scholar] [CrossRef]

- Guo, J.; Ling, S.; Li, W.; Chen, Y.; Li, C.; Omenetto, F.G.; Kaplan, D.L. Coding Cell Micropatterns Through Peptide Inkjet Printing for Arbitrary Biomineralized Architectures. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Ajdary, R.; Huan, S.; Zanjanizadeh Ezazi, N.; Xiang, W.; Grande, R.; Santos, H.A.; Rojas, O.J. Acetylated Nanocellulose for Single-Component Bioinks and Cell Proliferation on 3D-Printed Scaffolds. Biomacromolecules 2019, 20, 2770–2778. [Google Scholar] [CrossRef]

- Romberg, S.K.; Islam, M.A.; Hershey, C.J.; DeVinney, M.; Duty, C.E.; Kunc, V.; Compton, B.G. Linking thermoset ink rheology to the stability of 3D-printed structures. Addit. Manuf. 2021, 37. [Google Scholar] [CrossRef]

- Joseph, V.S.; Calais, T.; Stalin, T.; Jain, S.; Thanigaivel, N.K.; Sanandiya, N.D.; Valdivia y Alvarado, P. Silicone/epoxy hybrid resins with tunable mechanical and interfacial properties for additive manufacture of soft robots. Appl. Mater. Today 2021, 22. [Google Scholar] [CrossRef]

- Chen, Q.; Sukmanee, T.; Rong, L.; Yang, M.; Ren, J.; Ekgasit, S.; Advincula, R. A Dual Approach in Direct Ink Writing of Thermally Cured Shape Memory Rubber Toughened Epoxy. ACS Appl. Polym. Mater. 2020, 2, 5492–5500. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, L.; Kuang, X.; Li, V.; Lei, M.; Kang, G.; Wang, Z.L.; Qi, H.J. Dynamic Photomask-Assisted Direct Ink Writing Multimaterial for Multilevel Triboelectric Nanogenerator. Adv. Funct. Mater. 2019, 29, 1903568. [Google Scholar] [CrossRef]

- Rocha, V.G.; Saiz, E.; Tirichenko, I.S.; García-Tuñón, E. Direct ink writing advances in multi-material structures for a sustainable future. J. Mater. Chem. A 2020, 8, 15646–15657. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Zlatin, M.; Selvaganapathy, P.R.; Brook, M.A. Multiple modulus silicone elastomers using 3D extrusion printing of low viscosity inks. Addit. Manuf. 2018, 24, 86–92. [Google Scholar] [CrossRef]

- Hardin, J.O.; Ober, T.J.; Valentine, A.D.; Lewis, J.A. Microfluidic Printheads for Multimaterial 3D Printing of Viscoelastic Inks. Adv. Mater. 2015, 27, 3279–3284. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Wilts, E.M.; Pekkanen, A.M.; White, B.T.; Meenakshisundaram, V.; Aduba, D.C., Jr.; Williams, C.B.; Long, T.E. Vat photopolymerization of charged monomers: 3D printing with supramolecular interactions. Polym. Chem. 2019, 10, 1442–1451. [Google Scholar] [CrossRef]

- Straathof, M.H.; van Driel, C.A.; van Lingen, J.N.J.; Ingenhut, B.L.J.; ten Cate, A.T.; Maalderink, H.H. Development of Propellant Compositions for Vat Photopolymerization Additive Manufacturing. Propellants Explos. Pyrotech. 2020, 45, 36–52. [Google Scholar] [CrossRef]

- Della Bona, A.; Cantelli, V.; Britto, V.T.; Collares, K.F.; Stansbury, J.W. 3D printing restorative materials using a stereolithographic technique: A systematic review. Dent. Mater. 2021, 37, 336–350. [Google Scholar] [CrossRef]

- Agrawaal, H.; Thompson, J.E. Additive manufacturing (3D printing) for analytical chemistry. Talanta Open 2021, 3, 100036. [Google Scholar] [CrossRef]

- Yang, J.; Yu, R.; Li, X.; He, Y.; Wang, L.; Huang, W.; Jiao, J. Silicon carbide whiskers reinforced SiOC ceramics through digital light processing 3D printing technology. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Kadry, H.; Wadnap, S.; Xu, C.; Ahsan, F. Digital light processing (DLP) 3D-printing technology and photoreactive polymers in fabrication of modified-release tablets. Eur. J. Pharm. Sci. 2019, 135, 60–67. [Google Scholar] [CrossRef]

- Thomas, A.; Orellano, I.; Lam, T.; Noichl, B.; Geiger, M.A.; Amler, A.K.; Kreuder, A.E.; Palmer, C.; Duda, G.; Lauster, R.; et al. Vascular bioprinting with enzymatically degradable bioinks via multi-material projection-based stereolithography. Acta Biomater. 2020, 117, 121–132. [Google Scholar] [CrossRef]

- Grigoryan, B.; Sazer, D.W.; Avila, A.; Albritton, J.L.; Padhye, A.; Ta, A.H.; Greenfield, P.T.; Gibbons, D.L.; Miller, J.S. Development, characterization, and applications of multi-material stereolithography bioprinting. Sci. Rep. 2021, 11. [Google Scholar] [CrossRef]

- Choi, J.-W.; Kim, H.-C.; Wicker, R. Multi-material stereolithography. J. Mater. Process. Technol. 2011, 211, 318–328. [Google Scholar] [CrossRef]

- Overmeyer, L.; Hohnholz, A.; Suttmann, O.; Kaierle, S. Multi-material laser direct writing of aerosol jet layered polymers. CIRP Ann. 2019, 68, 217–220. [Google Scholar] [CrossRef]

- Miri, A.K.; Nieto, D.; Iglesias, L.; Goodarzi Hosseinabadi, H.; Maharjan, S.; Ruiz-Esparza, G.U.; Khoshakhlagh, P.; Manbachi, A.; Dokmeci, M.R.; Chen, S.; et al. Microfluidics-Enabled Multimaterial Maskless Stereolithographic Bioprinting. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef]

- Kowsari, K.; Akbari, S.; Wang, D.; Fang, N.X.; Ge, Q. High-Efficiency High-Resolution Multimaterial Fabrication for Digital Light Processing-Based Three-Dimensional Printing. 3D Print. Addit. Manuf. 2018, 5, 185–193. [Google Scholar] [CrossRef]

- Chen, D.; Zheng, X. Multi-material Additive Manufacturing of Metamaterials with Giant, Tailorable Negative Poisson’s Ratios. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef]

- Pearson, M.; Kwok, T.H.; Dafoe, A.; Matte, C.-D.; Trottier-Cournoyer, F. Automated storage and active cleaning for multi-material digital-light-processing printer. Rapid Prototyp. J. 2019, 25, 864–874. [Google Scholar] [CrossRef]

- Han, D.; Yang, C.; Fang, N.X.; Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 2019, 27, 606–615. [Google Scholar] [CrossRef]

- Methani, M.M.; Cesar, P.F.; de Paula Miranda, R.B.; Morimoto, S.; Özcan, M.; Revilla-León, M. Additive Manufacturing in Dentistry: Current Technologies, Clinical Applications, and Limitations. Curr. Oral Health Rep. 2020, 7, 327–334. [Google Scholar] [CrossRef]

- Khorsandi, D.; Fahimipour, A.; Abasian, P.; Saber, S.S.; Seyedi, M.; Ghanavati, S.; Ahmad, A.; De Stephanis, A.A.; Taghavinezhaddilami, F.; Leonova, A.; et al. 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater. 2021, 122, 26–49. [Google Scholar] [CrossRef]

- Dahmen, T.; Henriksen, N.G.; Dahl, K.V.; Lapina, A.; Pedersen, D.B.; Hattel, J.H.; Christiansen, T.L.; Somers, M.A.J. Densification, microstructure, and mechanical properties of heat-treated MAR-M247 fabricated by Binder Jetting. Addit. Manuf. 2021, 39. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharjee, A.; Banerjee, D.; Boccaccini, A.R.; Bandyopadhyay, A. Influence of random and designed porosities on 3D printed tricalcium phosphate-bioactive glass scaffolds. Addit. Manuf. 2021, 40. [Google Scholar] [CrossRef]

- Fahad, M.; Dickens, P.; Gilbert, M. Novel polymeric support materials for jetting based additive manufacturing processes. Rapid Prototyp. J. 2013, 19, 230–239. [Google Scholar] [CrossRef]

- Yap, Y.L.; Sing, S.L.; Yeong, W.Y. A review of 3D printing processes and materials for soft robotics. Rapid Prototyp. J. 2020, 26, 1345–1361. [Google Scholar] [CrossRef]

- VanHorn, A.; Zhou, W. Design and optimization of a high temperature microheater for inkjet deposition. Int. J. Adv. Manuf. Technol. 2016, 86, 3101–3111. [Google Scholar]

- Gao, C.; Hou, X.; Xing, T.; Chen, G. Development and design of low volatile waterborne disperse ink using LF-NMR. Colloids Surf. A Physicochem. Eng. Asp. 2020, 592. [Google Scholar] [CrossRef]

- Krainer, S.; Smit, C.; Hirn, U. The effect of viscosity and surface tension on inkjet printed picoliter dots. RSC Adv. 2019, 9, 31708–31719. [Google Scholar] [CrossRef]

- Lamont, C.A.; Eggenhuisen, T.M.; Coenen, M.J.J.; Slaats, T.W.L.; Andriessen, R.; Groen, P. Tuning the viscosity of halogen free bulk heterojunction inks for inkjet printed organic solar cells. Org. Electron. 2015, 17, 107–114. [Google Scholar] [CrossRef]

- Sundaram, S.; Skouras, M.; Kim, D.S.; van den Heuvel, L.; Matusik, W. Topology optimization and 3D printing of multimaterial magnetic actuators and displays. Sci. Adv. 2019, 5, eaaw1160. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.-S.; Jang, K.-H.; Kim, E.; Lee, H.-T.; Ahn, S.-H. Hybrid 3D printing by bridging micro/nano processes. J. Micromechanics Microengineering 2017, 27, 065006. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Compatible hybrid 3D printing of metal and nonmetal inks for direct manufacture of end functional devices. Sci. China Technol. Sci. 2014, 57, 2089–2095. [Google Scholar] [CrossRef]

- MacDonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D printing for the rapid prototyping of structural electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353, aaf2093. [Google Scholar] [CrossRef]

- Ashwin, A.J.; Jafferson, J.M. State of the art direct ink writing (DIW) and experimental trial on DIW of HAp bio-ceramics. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Li, V.C.-F.; Kuang, X.; Hamel, C.M.; Roach, D.; Deng, Y.; Qi, H.J. Cellulose nanocrystals support material for 3D printing complexly shaped structures via multi-materials-multi-methods printing. Addit. Manuf. 2019, 28, 14–22. [Google Scholar] [CrossRef]

- Song, Y.; Fang, K.; Bukhari, M.N.; Zhang, K.; Tang, Z. Improved inkjet printability of dye-based inks through enhancing the interaction of dye molecules and polymer nanospheres. J. Mol. Liq. 2021, 324, 114702. [Google Scholar] [CrossRef]

- Zhang, Y.-F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Vatani, M.; Lu, Y.; Engeberg, E.D.; Choi, J.-W. Combined 3D printing technologies and material for fabrication of tactile sensors. Int. J. Precis. Eng. Manuf. 2015, 16, 1375–1383. [Google Scholar] [CrossRef]

- Liravi, F.; Toyserkani, E. A hybrid additive manufacturing method for the fabrication of silicone bio-structures: 3D printing optimization and surface characterization. Mater. Des. 2018, 138, 46–61. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29. [Google Scholar] [CrossRef]

- Peng, X.; Kuang, X.; Roach, D.J.; Wang, Y.; Hamel, C.M.; Lu, C.; Qi, H.J. Integrating digital light processing with direct ink writing for hybrid 3D printing of functional structures and devices. Addit. Manuf. 2021, 40, 101911. [Google Scholar] [CrossRef]

- Lopez, D.M.B.; Ahmad, R. Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef]

- Koštial, P.; Jančíková, Z.K.; Ružiak, I.; Gajtanska, M. Case Study of Chosen Sandwich-Structured Composite Materials for Means of Transport. Coatings 2020, 10, 750. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Brischetto, S.; Ferro, C.G.; Torre, R.; Maggiore, P. 3D FDM production and mechanical behavior of polymeric sandwich specimens embedding classical and honeycomb cores. Curved Layer. Struct. 2018, 5, 80–94. [Google Scholar] [CrossRef]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive manufacturing in unmanned aerial vehicles (UAVs): Challenges and potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef]

- Fischer, S.; Pfister, A.; Galitz, V.; Lyons, B.; Robinson, C.; Rupel, K.; Booth, R.; Kubiak, S. A High-Performance Material for Aerospace Applications: Development of Carbon Fiber Filled PEKK for Laser Sintering. 2016, pp. 808–813. Available online: https://images-insite.sgp1.digitaloceanspaces.com/dunia_buku/koleksi-buku-lainnya/development-of-carbon-fiber-filled-pekk-for-laser-sintering-pdfdrivecom-84801584680836.pdf (accessed on 11 June 2021).

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite additive manufacturing of morphing aerospace structures. Manuf. Let. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Espalin, D.; Ramirez, J.; Medina, F.; Wicker, R. Multi-material, Multi-technology FDM System. 2012, pp. 828–835. Available online: http://utw10945.utweb.utexas.edu/Manuscripts/2012/2012-63-Espalin.pdf (accessed on 11 June 2021).

- Marinho De Brito, F.; Junior, G.D.C.; Frazzon, E.M.; Basto, J.P.T.V.; Alcala, S.G.S. Design Approach for Additive Manufacturing in Spare Part Supply Chains. IEEE Trans. Ind. Inf. 2021, 17, 757–765. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Bickel, B.; Bächer, M.; Otaduy, M.A.; Lee, H.R.; Pfister, H.; Gross, M.; Matusik, W. Design and fabrication of materials with desired deformation behavior. ACM Trans. Graph. 2010, 29. [Google Scholar] [CrossRef]

- Oxman, N. Variable property rapid prototyping: Inspired by nature, where form is characterized by heterogeneous compositions, the paper presents a novel approach to layered manufacturing entitled variable property rapid prototyping. Virtual Phys. Prototyp. 2011, 6, 3–31. [Google Scholar] [CrossRef]

- Ng, W.L.; Chua, C.K.; Shen, Y.F. Print Me An Organ! Why We Are Not There Yet. Prog. Polym. Sci. 2019, 97. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An overview of additive manufacturing of polymers and associated composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef]

- Goyanes, A.; Kobayashi, M.; Martínez-Pacheco, R.; Gaisford, S.; Basit, A.W. Fused-filament 3D printing of drug products: Microstructure analysis and drug release characteristics of PVA-based caplets. Int. J. Pharm. 2016, 514, 290–295. [Google Scholar] [CrossRef]

- Alhnan, M.A.; Okwuosa, T.C.; Sadia, M.; Wan, K.W.; Ahmed, W.; Arafat, B. Emergence of 3D Printed Dosage Forms: Opportunities and Challenges. Pharm. Res. 2016, 33, 1817–1832. [Google Scholar] [CrossRef]

- Guerra, A.J.; Ciurana, J. 3D-printed bioabsordable polycaprolactone stent: The effect of process parameters on its physical features. Mater. Des. 2018, 137, 430–437. [Google Scholar] [CrossRef]

- Colpani, A.; Fiorentino, A.; Ceretti, E. Design and fabrication of customized tracheal stents by additive manufacturing. Procedia Manuf. 2020, 47, 1029–1035. [Google Scholar]

- Yan, Y.; Xiong, Z.; Hu, Y.; Wang, S.; Zhang, R.; Zhang, C. Layered manufacturing of tissue engineering scaffolds via multi-nozzle deposition. Mater. Lett. 2003, 57, 2623–2628. [Google Scholar] [CrossRef]

- Iannazzo, D.; Pistone, A.; Salamò, M.; Galvagno, S. Hybrid ceramic/polymer composites for bone tissue regeneration. In Hybrid Polymer Composite Materials: Processing; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 125–155. [Google Scholar]

- Javaid, M.; Haleem, A. 4D printing applications in medical field: A brief review. Clin. Epidemiol. Global Health 2019, 7, 317–321. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, F.; Qi, B.; Ding, Z.; Rosen, D.W.; Ge, Q. 3D printing of multi-material composites with tunable shape memory behavior. Mater. Des. 2020, 193. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D printing of soft robotic systems. Nat. Rev. Mater. 2018, 3, 84–100. [Google Scholar] [CrossRef]

- Zhou, H.; Mohammadi, A.; Oetomo, D.; Alici, G. A Novel Monolithic Soft Robotic Thumb for an Anthropomorphic Prosthetic Hand. IEEE Robot. Autom. 2019, 4, 602–609. [Google Scholar] [CrossRef]

- Maroti, P.; Varga, P.; Abraham, H.; Falk, G.; Zsebe, T.; Meiszterics, Z.; Mano, S.; Csernatony, Z.; Rendeki, S.; Nyitrai, M. Printing orientation defines anisotropic mechanical properties in additive manufacturing of upper limb prosthetics. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Comotti, C.; Regazzoni, D.; Rizzi, C.; Vitali, A. Multi-material design and 3D printing method of lower limb prosthetic sockets. In Proceedings of the 3rd 2015 Workshop on ICTs for improving Patients Rehabilitation Research Techniques (REHAB ’15), New York, NY, USA, 1 October 2015; pp. 42–45. [Google Scholar]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Dental ceramic prostheses by stereolithography-based additive manufacturing: Potentials and challenges. Adv. Appl. Ceram. 2019, 118, 30–36. [Google Scholar] [CrossRef]

- Jindal, P.; Juneja, M.; Siena, F.L.; Bajaj, D.; Breedon, P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 694–701. [Google Scholar] [CrossRef]

- Revilla-León, M.; Sadeghpour, M.; Özcan, M. An update on applications of 3D printing technologies used for processing polymers used in implant dentistry. Odontology 2020, 108, 331–338. [Google Scholar] [CrossRef]

- Jammalamadaka, U.; Tappa, K. Recent advances in biomaterials for 3D printing and tissue engineering. J. Funct. Biomater. 2018, 9, 22. [Google Scholar] [CrossRef]

- Egorov, A.A.; Fedotov, A.Y.; Mironov, A.V.; Komlev, V.S.; Popov, V.K.; Zobkov, Y.V. 3D printing of mineral-polymer bone substitutes based on sodium alginate and calcium phosphate. Beilstein J. Nanotechnol. 2016, 7, 1794–1799. [Google Scholar] [CrossRef]

- Zhu, W.; Xu, C.; Ma, B.P.; Zheng, Z.B.; Li, Y.L.; Ma, Q.; Wu, G.L.; Weng, X.S. Three-dimensional printed scaffolds with gelatin and platelets enhance In Vitro preosteoblast growth behavior and the sustained-release effect of growth factors. Chin. Med. J. 2016, 129, 2576–2581. [Google Scholar] [CrossRef]

- Alluri, R.; Jakus, A.; Bougioukli, S.; Pannell, W.; Sugiyama, O.; Tang, A.; Shah, R.; Lieberman, J.R. 3D printed hyperelastic “bone” scaffolds and regional gene therapy: A novel approach to bone healing. J. Biomed. Mater. Res. Part A 2018, 106, 1104–1110. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Lin, H.Y.; Chen, Y.W.; Lin, C.Y.; Hsu, T.T.; Kao, C.T. Laser sintered magnesium-calcium silicate/poly-ε-caprolactone scaffold for bone tissue engineering. Materials 2017, 10, 65. [Google Scholar] [CrossRef]

- Lee, C.H.; Hajibandeh, J.; Suzuki, T.; Fan, A.; Shang, P.; Mao, J.J. Three-dimensional printed multiphase scaffolds for regeneration of periodontium complex. Tissue Eng. Part A 2014, 20, 1342–1351. [Google Scholar] [CrossRef]

- Wang, W.; Caetano, G.; Ambler, W.S.; Blaker, J.J.; Frade, M.A.; Mandal, P.; Diver, C.; Bártolo, P. Enhancing the hydrophilicity and cell attachment of 3D printed PCL/graphene scaffolds for bone tissue engineering. Materials 2016, 9, 992. [Google Scholar] [CrossRef]

- Shor, L.; Güçeri, S.; Wen, X.; Gandhi, M.; Sun, W. Fabrication of three-dimensional polycaprolactone/hydroxyapatite tissue scaffolds and osteoblast-scaffold interactions In Vitro. Biomaterials 2007, 28, 5291–5297. [Google Scholar] [CrossRef]

- Hwang, K.S.; Choi, J.W.; Kim, J.H.; Chung, H.Y.; Jin, S.; Shim, J.H.; Yun, W.S.; Jeong, C.M.; Huh, J.B. Comparative efficacies of collagen-based 3D printed PCL/PLGA/β-TCP composite block bone grafts and biphasic calcium phosphate bone substitute for bone regeneration. Materials 2017, 10, 421. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Cesewski, E.; Haring, A.P.; Tong, Y.; Singh, M.; Thakur, R.; Laheri, S.; Read, K.A.; Powell, M.D.; Oestreich, K.J.; Johnson, B.N. Additive manufacturing of three-dimensional (3D) microfluidic-based microelectromechanical systems (MEMS) for acoustofluidic applications. Lab Chip 2018, 18, 2087–2098. [Google Scholar] [CrossRef]

- Emon, M.O.F.; Alkadi, F.; Philip, D.G.; Kim, D.H.; Lee, K.C.; Choi, J.W. Multi-material 3D printing of a soft pressure sensor. Addit. Manuf. 2019, 28, 629–638. [Google Scholar] [CrossRef]

- Hainsworth, T.; Smith, L.; Alexander, S.; MacCurdy, R. A Fabrication Free, 3D Printed, Multi-Material, Self-Sensing Soft Actuator. IEEE Robot. Autom. 2020, 5, 4118–4125. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Islam, M.T.; Islam, M.D.; Chavez, L.A.; Garcia Rosales, C.A.; Wilburn, B.R.; Stewart, C.M.; Noveron, J.C.; Tseng, T.L.B.; et al. Increased piezoelectric response in functional nanocomposites through multiwall carbon nanotube interface and fused-deposition modeling three-dimensional printing. MRS Commun. 2017, 7, 960–966. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D additive manufacturing (AM) and corresponding AM composites. Compos. Part A Appl. Sci. Manuf. 2020, 139. [Google Scholar] [CrossRef]

- Ebrahimi, S.H. Singularity analysis of cracks in hybrid CNT reinforced carbon fiber composites using finite element asymptotic expansion and XFEM. Int. J. Solids Struct. 2021, 214-215, 1–17. [Google Scholar] [CrossRef]

- Ooms, T.; Vantyghem, G.; Van Coile, R.; De Corte, W. A parametric modelling strategy for the numerical simulation of 3D concrete printing with complex geometries. Addit. Manuf. 2021, 38. [Google Scholar] [CrossRef]

- Fu, Y.; Downey, A.; Yuan, L.; Pratt, A.; Balogun, Y. In situ monitoring for fused filament fabrication process: A review. Addit. Manuf. 2021, 38. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. J. Clean. Prod. 2021, 278. [Google Scholar] [CrossRef]

- Ahmed, S.W.; Hussain, G.; Altaf, K.; Ali, S.; Alkahtani, M.; Abidi, M.H.; Alzabidi, A. On the effects of process parameters and optimization of interlaminate bond strength in 3D printed ABS/CF-PLA composite. Polymers 2020, 12, 2155. [Google Scholar] [CrossRef]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The influence of slicing parameters on the multi-material adhesion mechanisms of FDM printed parts: An exploratory study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Lai, C.Q.; Markandan, K.; Luo, B.; Lam, Y.C.; Chung, W.C.; Chidambaram, A. Viscoelastic and high strain rate response of anisotropic graphene-polymer nanocomposites fabricated with stereolithographic 3D printing. Addit. Manuf. 2021, 37. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, T.; Kim, Y.H.; Yang, Z.; Li, Y.; Yu, T. Different-structured nanoclays incorporated composites: Computational and experimental analysis on mechanical properties. Compos. Sci. Technol. 2021, 203. [Google Scholar] [CrossRef]

- Alghamdi, S.S.; John, S.; Choudhury, N.R.; Dutta, N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

| JOURNAL | Number of Relevant Articles | % Total Publications | Number of Total Citations from These Articles | Number of Average Citations per Article |

|---|---|---|---|---|

| Additive Manufacturing | 98 | 5.02% | 1828 | 18.7 |

| ACS Applied Materials and Interfaces | 92 | 4.71% | 1397 | 15.2 |

| Materials | 80 | 4.10% | 913 | 11.4 |

| Composites Part B Engineering | 66 | 3.38% | 1951 | 29.6 |

| Polymers | 66 | 3.38% | 359 | 5.4 |

| Journal of Applied Polymer Science | 65 | 3.33% | 1107 | 17.0 |

| Composites Science and Technology | 64 | 3.28% | 1991 | 31.1 |

| Materials and Design | 44 | 2.25% | 956 | 21.7 |

| Rapid Prototyping Journal | 44 | 2.25% | 934 | 21.2 |

| Advanced Functional Materials | 39 | 2.00% | 890 | 22.8 |

| Composites Part A Applied Science and Manufacturing | 31 | 1.59% | 732 | 23.6 |

| Rsc Advances | 29 | 1.49% | 215 | 7.4 |

| Scientific Reports | 29 | 1.49% | 1591 | 54.9 |

| Advanced Materials | 24 | 1.23% | 1952 | 81.3 |

| Journal of Composite Materials | 24 | 1.23% | 270 | 11.3 |

| Advanced Engineering Materials | 23 | 1.18% | 300 | 13.0 |

| Journal of Polymer Materials | 23 | 1.18% | 25 | 1.1 |

| Materials Science and Engineering C | 23 | 1.18% | 305 | 13.3 |

| Polymer Composites | 22 | 1.13% | 171 | 7.8 |

| Materials Letters | 21 | 1.08% | 224 | 10.7 |

| Sensors and Actuators B Chemical | 21 | 1.08% | 321 | 15.3 |

| Composite Structures | 20 | 1.02% | 367 | 18.4 |

| Keyword | Occur. | Links | Total Link Strength | Avg. Pub. Year | Avg. Citations |

|---|---|---|---|---|---|

| fused deposition modeling | 127 | 65 | 167 | 2019 | 21.7 |

| stereolithography | 35 | 28 | 36 | 2018 | 18.5 |

| inkjet printing | 31 | 24 | 30 | 2016 | 12.4 |

| selective laser sintering | 24 | 17 | 22 | 2018 | 15.6 |

| material extrusion | 21 | 12 | 13 | 2020 | 3.5 |

| screen printing | 19 | 20 | 25 | 2016 | 18.6 |

| extrusion | 17 | 26 | 35 | 2019 | 15.5 |

| direct ink writing | 12 | 14 | 14 | 2020 | 3.9 |

| photopolymerization | 11 | 5 | 5 | 2018 | 31.8 |

| electrospinning | 9 | 10 | 11 | 2016 | 17.8 |

| digital light processing | 7 | 11 | 11 | 2019 | 24.7 |

| material jetting | 6 | 4 | 4 | 2019 | 35.7 |

| powder bed fusion | 5 | 3 | 4 | 2020 | 2.6 |

| Keyword | Occur. | Links | Total Link Strength | Avg. Pub. Year | Avg. Citations |

|---|---|---|---|---|---|

| tissue engineering | 35 | 24 | 51 | 2018 | 38.6 |

| scaffold | 28 | 23 | 46 | 2016 | 51.8 |

| printed electronics | 24 | 22 | 34 | 2017 | 26.6 |

| bone tissue engineering | 16 | 10 | 14 | 2019 | 15.1 |

| sensor | 13 | 14 | 17 | 2018 | 16.5 |

| bone regeneration | 11 | 11 | 13 | 2019 | 14.5 |

| flexible electronics | 11 | 11 | 13 | 2018 | 37.0 |

| strain sensor | 10 | 10 | 14 | 2017 | 19.0 |

| electrochemical sensor | 7 | 2 | 2 | 2018 | 13.6 |

| drug delivery | 6 | 3 | 3 | 2019 | 13.2 |

| temperature sensor | 6 | 8 | 9 | 2018 | 14.0 |

| humidity sensor | 6 | 3 | 3 | 2018 | 9.0 |

| dielectrics | 6 | 6 | 7 | 2017 | 3.8 |

| biosensor | 6 | 3 | 3 | 2017 | 12.3 |

| pressure sensor | 6 | 7 | 7 | 2015 | 12.3 |

| embedded capacitor | 6 | 4 | 7 | 2006 | 58.7 |

| actuators | 5 | 8 | 9 | 2019 | 20.6 |

| soft robotics | 5 | 6 | 7 | 2019 | 17.6 |

| wearable electronics | 5 | 3 | 3 | 2019 | 6.0 |

| stretchable electronics | 5 | 4 | 5 | 2018 | 17.2 |

| Scholar | Num. of Publications | Citations | Avg. Pub. Year | Avg. Citations |

|---|---|---|---|---|

| Wang Y. | 32 | 928 | 2018 | 29.0 |

| Wang J. | 25 | 503 | 2017 | 20.1 |

| Liu Y. | 23 | 335 | 2018 | 14.6 |

| Zhang J. | 21 | 206 | 2019 | 9.8 |

| Zhang X. | 21 | 269 | 2018 | 12.8 |

| Li Y. | 20 | 201 | 2019 | 10.1 |

| Singh R. | 20 | 287 | 2019 | 14.4 |

| Zhang Y. | 20 | 367 | 2018 | 18.4 |

| Wang L. | 18 | 476 | 2017 | 26.4 |

| Zhang H. | 17 | 125 | 2018 | 7.4 |

| Zhang Z. | 17 | 275 | 2019 | 16.2 |

| Wang Z. | 16 | 583 | 2018 | 36.4 |

| Zhang C. | 16 | 307 | 2018 | 19.2 |

| Chen Y. | 15 | 514 | 2018 | 34.3 |

| Xu J. | 15 | 220 | 2019 | 14.7 |

| Country/Region | Num. of Publications | Citations | Avg. Pub. Year | Avg. Citations |

|---|---|---|---|---|

| United States | 519 | 17544 | 2017 | 33.8 |

| China | 378 | 6450 | 2018 | 17.1 |

| United Kingdom | 147 | 3541 | 2017 | 24.1 |

| Germany | 145 | 1925 | 2017 | 13.3 |

| South Korea | 139 | 2801 | 2016 | 20.2 |

| India | 112 | 1318 | 2017 | 11.8 |

| Italy | 91 | 2334 | 2017 | 25.6 |

| Spain | 71 | 1269 | 2018 | 17.9 |

| France | 66 | 1172 | 2018 | 17.8 |

| Australia | 62 | 1499 | 2018 | 24.2 |

| Canada | 60 | 477 | 2018 | 8.0 |

| Taiwan | 55 | 944 | 2016 | 17.2 |

| Russian Federation | 52 | 668 | 2018 | 12.8 |

| Singapore | 50 | 2323 | 2017 | 46.5 |

| Japan | 45 | 2492 | 2014 | 55.4 |

| Switzerland | 44 | 1220 | 2017 | 27.7 |

| Poland | 39 | 307 | 2018 | 7.9 |

| Iran | 34 | 270 | 2019 | 7.9 |

| Sweden | 34 | 452 | 2017 | 13.3 |

| Ceramics | Polymer | AM Technology | Reference |

|---|---|---|---|

| Calcium chloride, glutamic acid, ammonium hydrogen phosphate | Sodium alginate | Material extrusion | [190] |

| Titanium, platelets | Gelatin | PBF | [191] |

| HA, solvent system | PLGA | Material extrusion | [192] |

| Calcium silicate, magnesium PCL Laser sintering | PCL | PBF | [193] |

| HA, PLGA microspheres | PCL | Material extrusion | [194] |

| Graphene | PCL | Material extrusion | [195] |

| HA | PCL | Material extrusion | [196] |

| BCP | PLGA, PCL, collagen | Material extrusion | [197] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Zhang, W.; Baca Lopez, D.M.; Ahmad, R. Scientometric Analysis and Systematic Review of Multi-Material Additive Manufacturing of Polymers. Polymers 2021, 13, 1957. https://doi.org/10.3390/polym13121957

Zheng Y, Zhang W, Baca Lopez DM, Ahmad R. Scientometric Analysis and Systematic Review of Multi-Material Additive Manufacturing of Polymers. Polymers. 2021; 13(12):1957. https://doi.org/10.3390/polym13121957

Chicago/Turabian StyleZheng, Yufan, Wenkang Zhang, David Moises Baca Lopez, and Rafiq Ahmad. 2021. "Scientometric Analysis and Systematic Review of Multi-Material Additive Manufacturing of Polymers" Polymers 13, no. 12: 1957. https://doi.org/10.3390/polym13121957

APA StyleZheng, Y., Zhang, W., Baca Lopez, D. M., & Ahmad, R. (2021). Scientometric Analysis and Systematic Review of Multi-Material Additive Manufacturing of Polymers. Polymers, 13(12), 1957. https://doi.org/10.3390/polym13121957