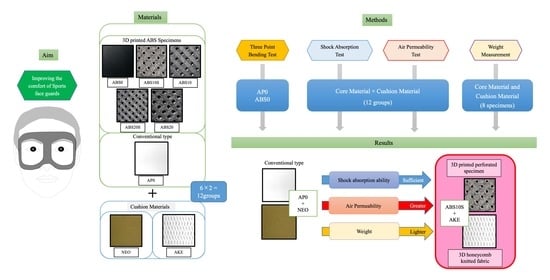

Air Permeability, Shock Absorption Ability, and Flexural Strength of 3D-Printed Perforated ABS Polymer Sheets with 3D-Knitted Fabric Cushioning for Sports Face Guard Applications

Abstract

1. Introduction

2. Materials and Methods

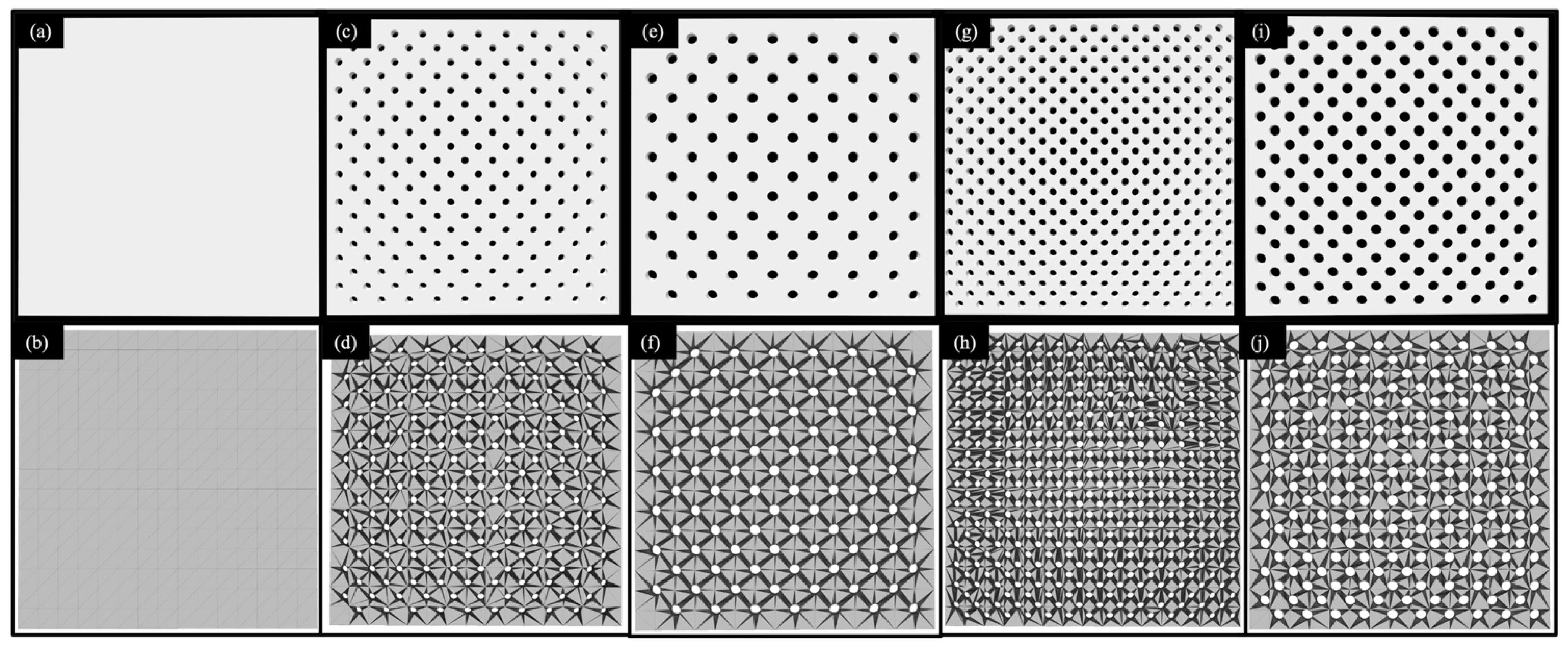

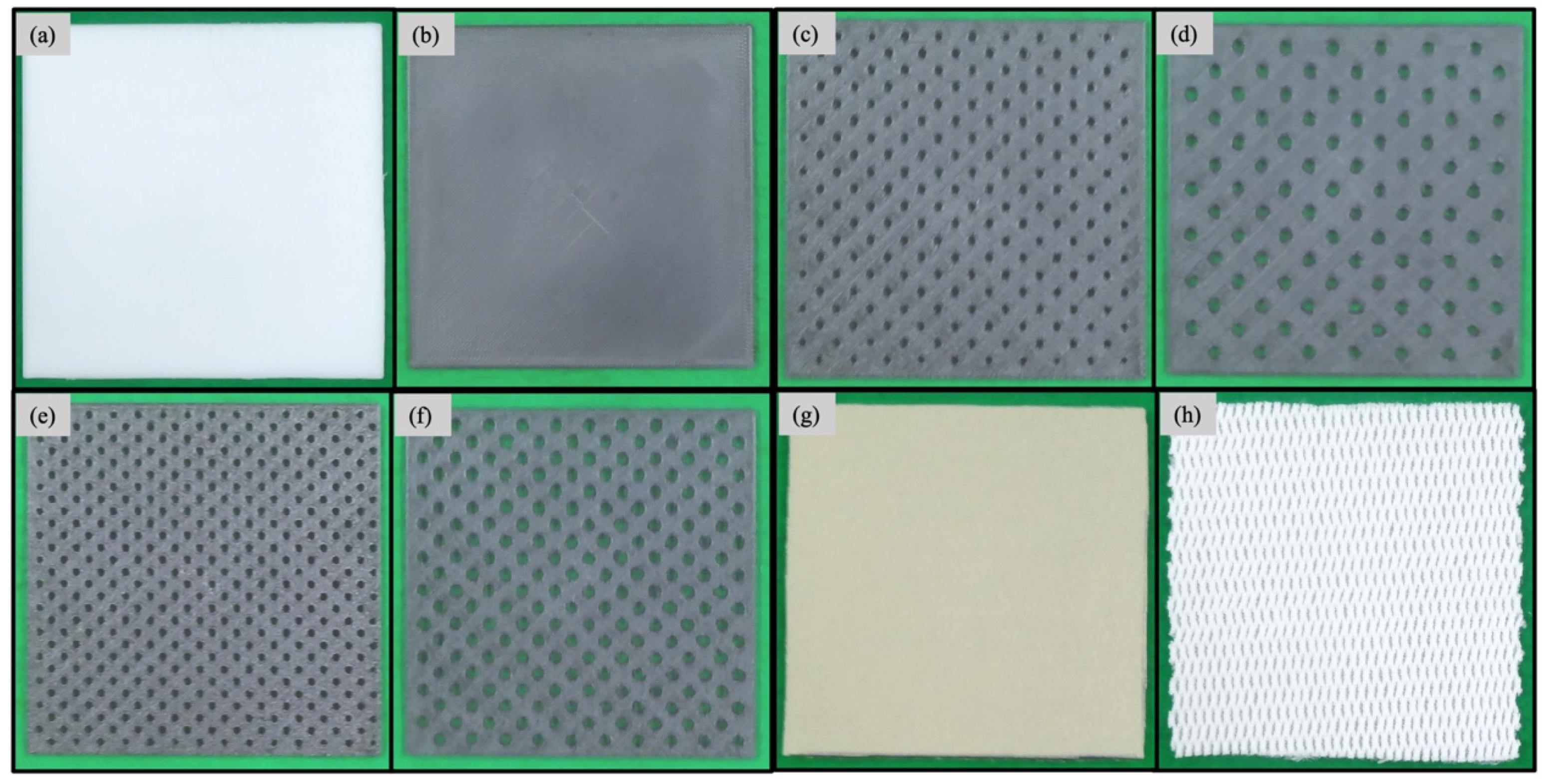

2.1. Sample Preparation

2.2. Weight Measurements

2.3. Three-Point Bending Test

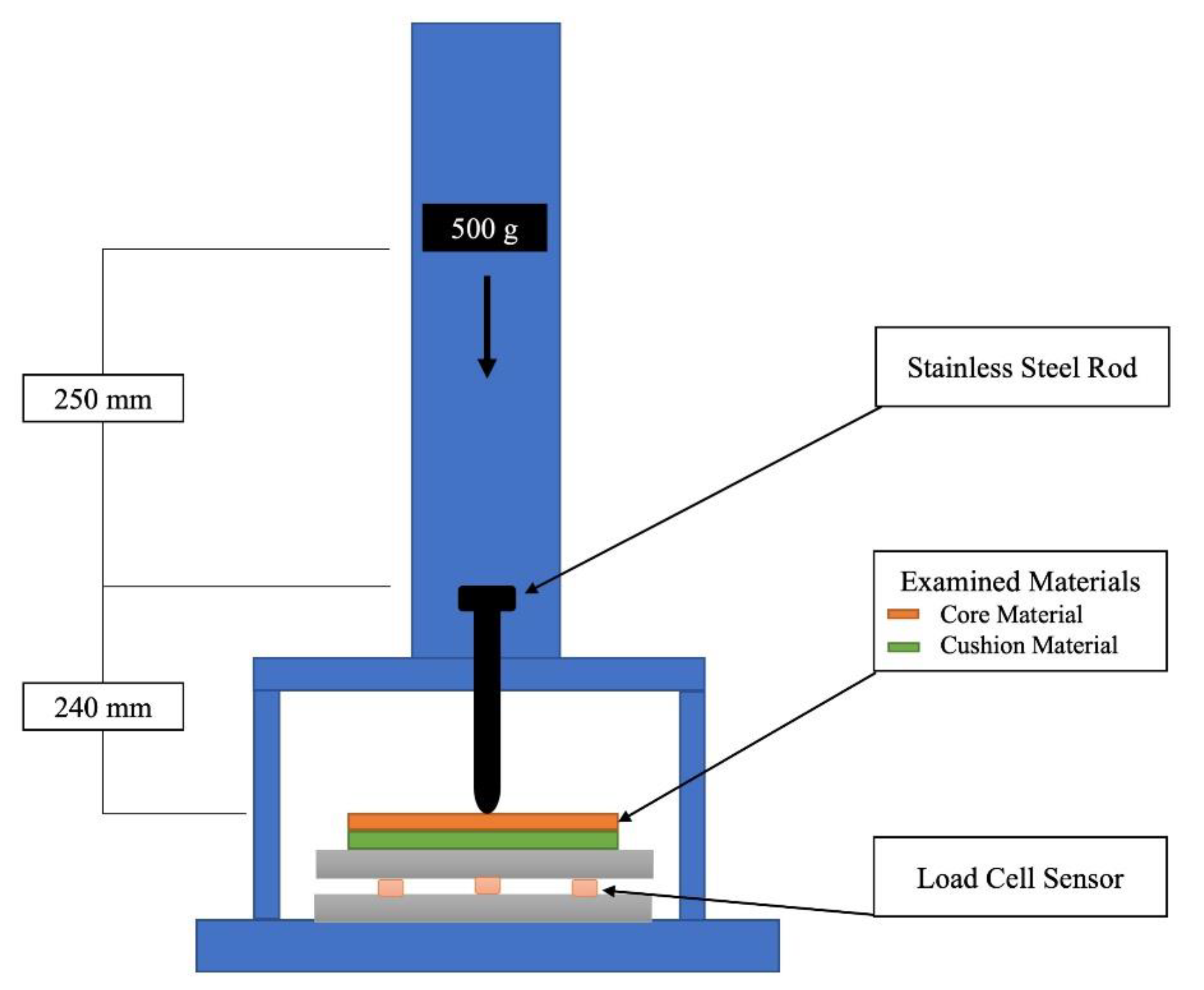

2.4. Shock Absorption Test

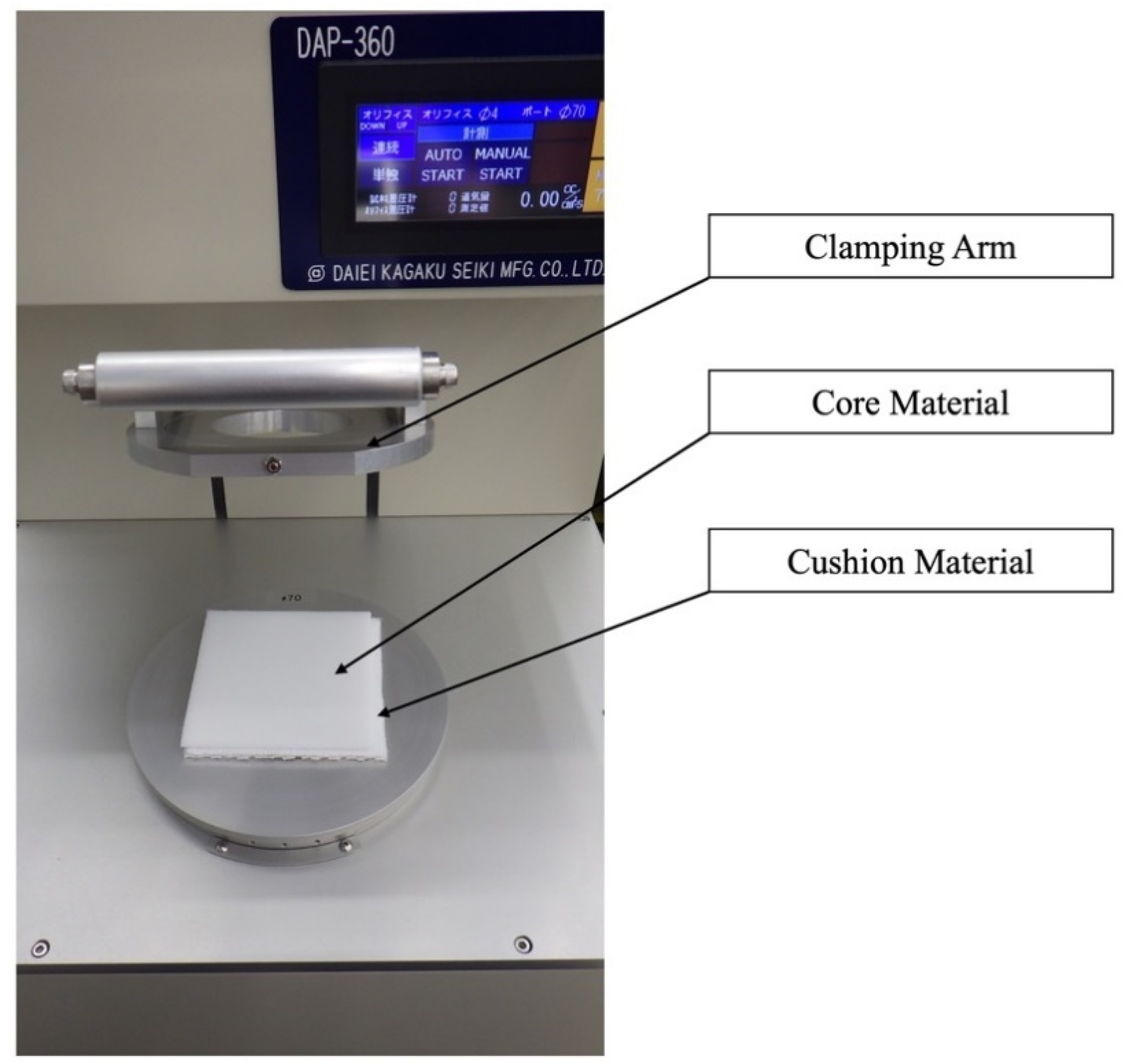

2.5. Air Permeability Test

2.6. Statistical Analysis

3. Results

3.1. Weight Measurements

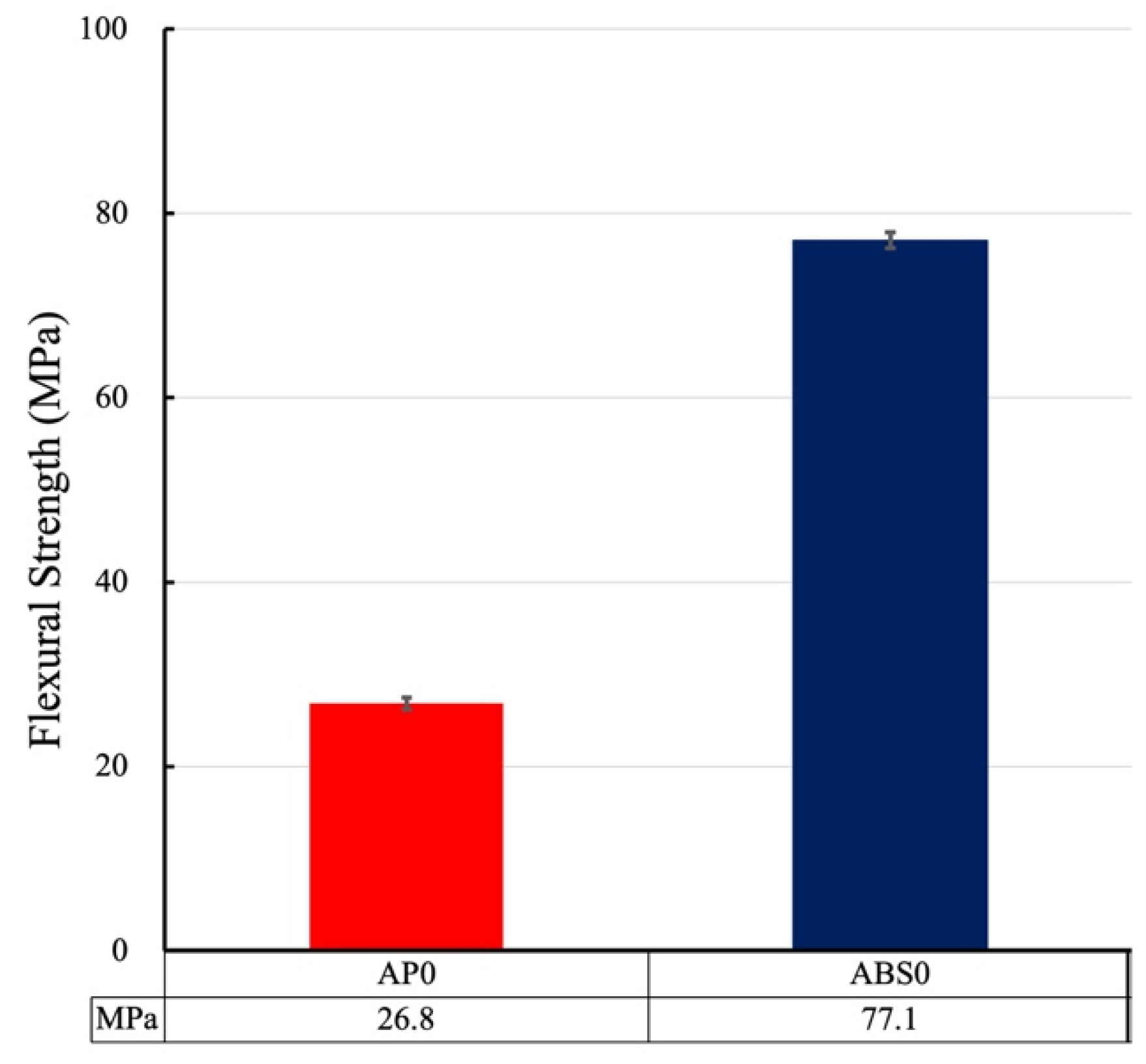

3.2. Three-Point Bending Test (Flexural Strength)

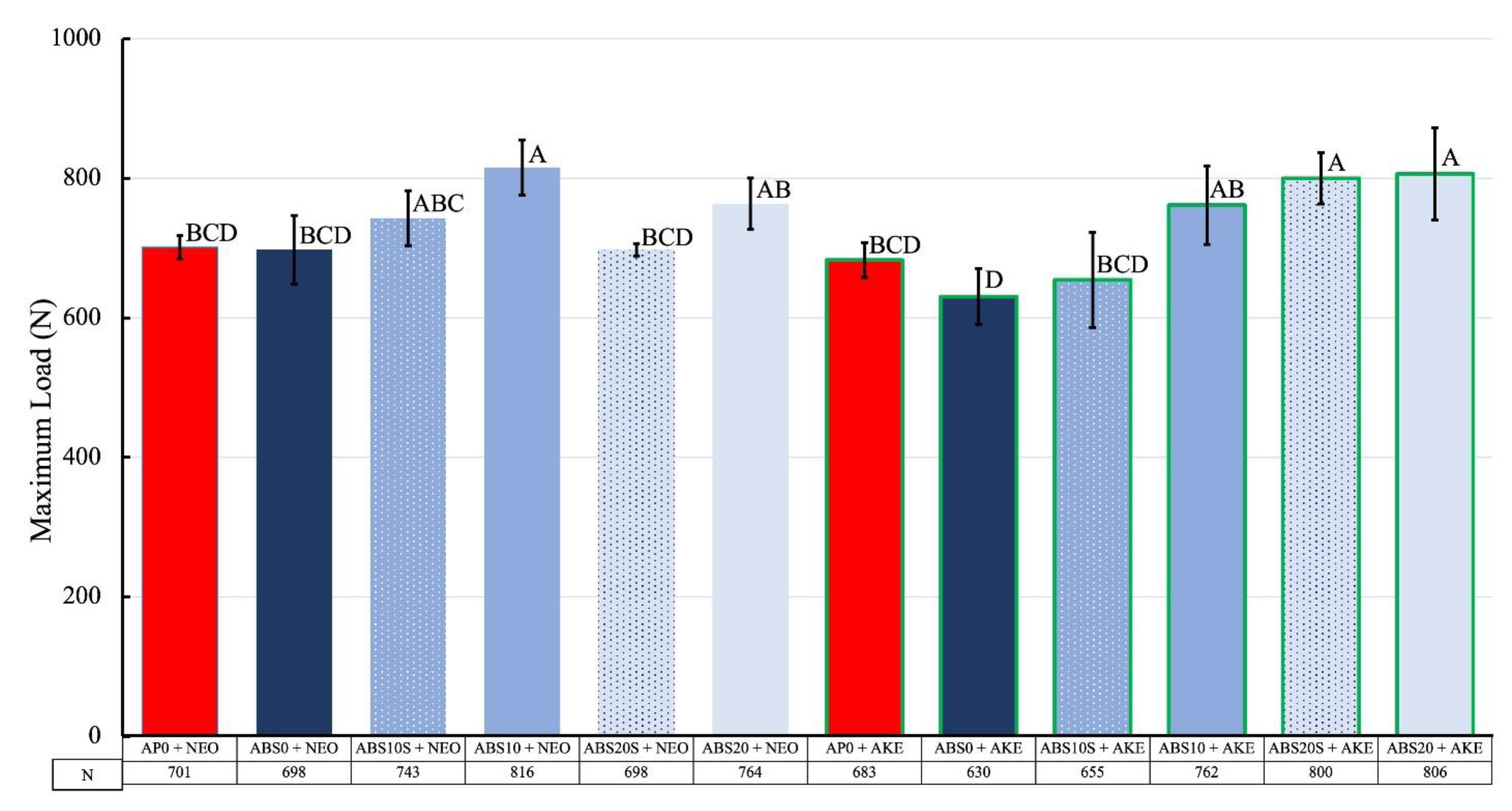

3.3. Maximum Load (ML) during Impact Test

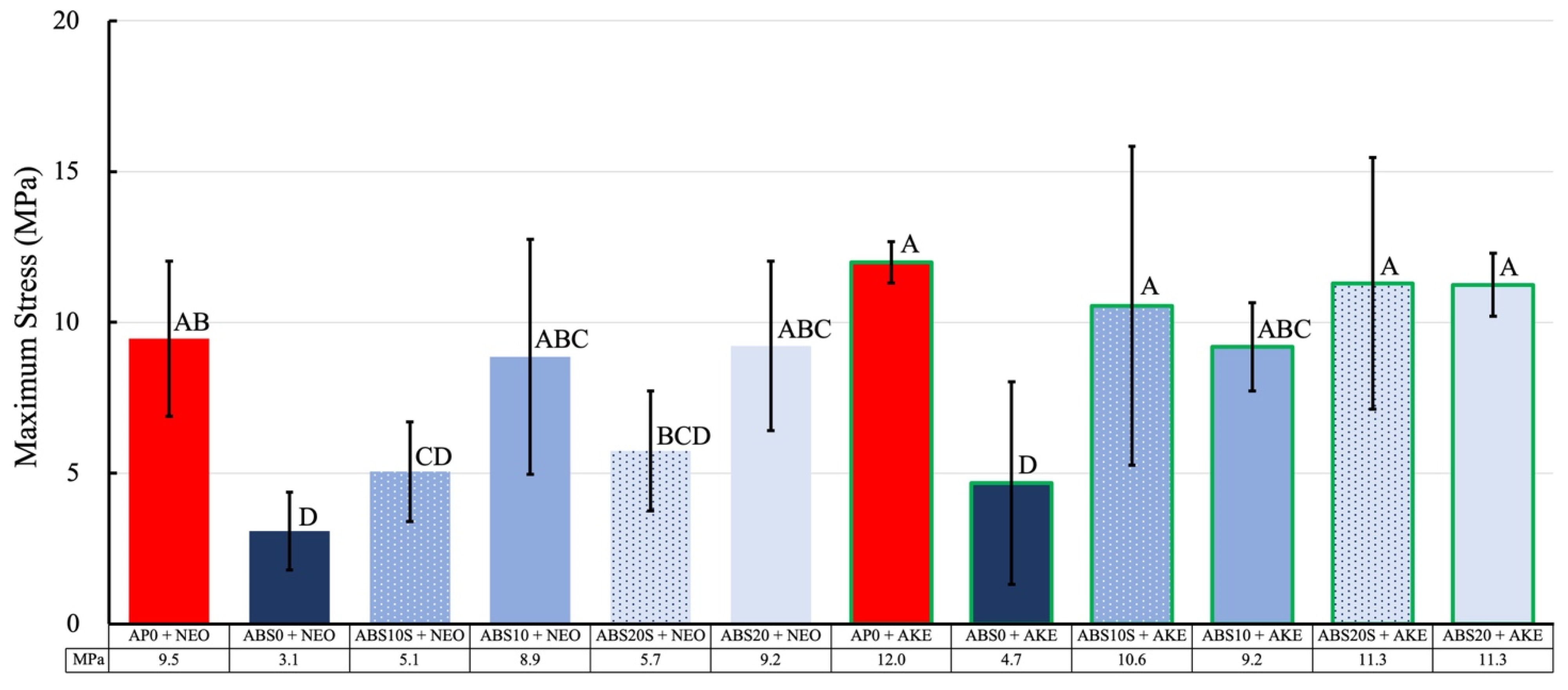

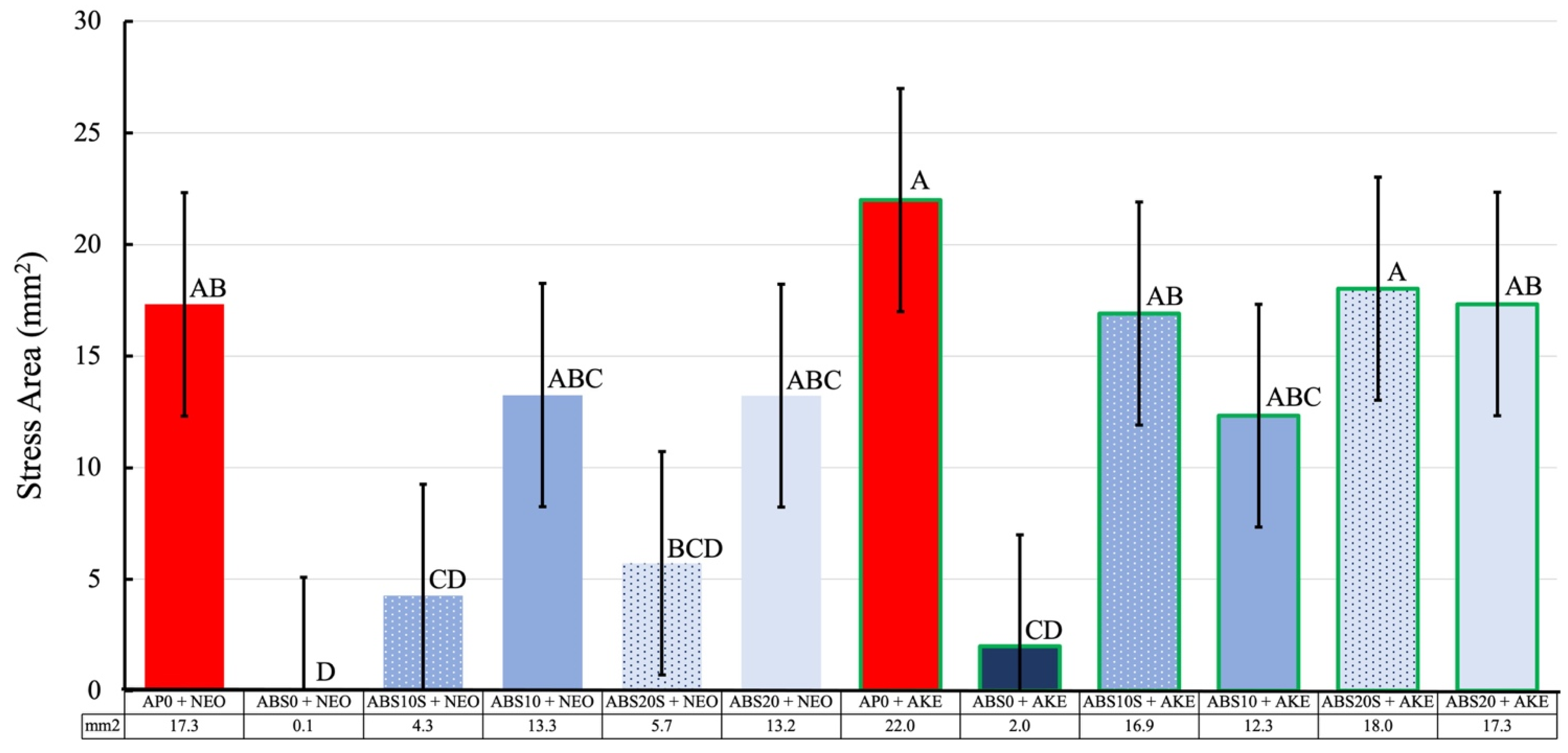

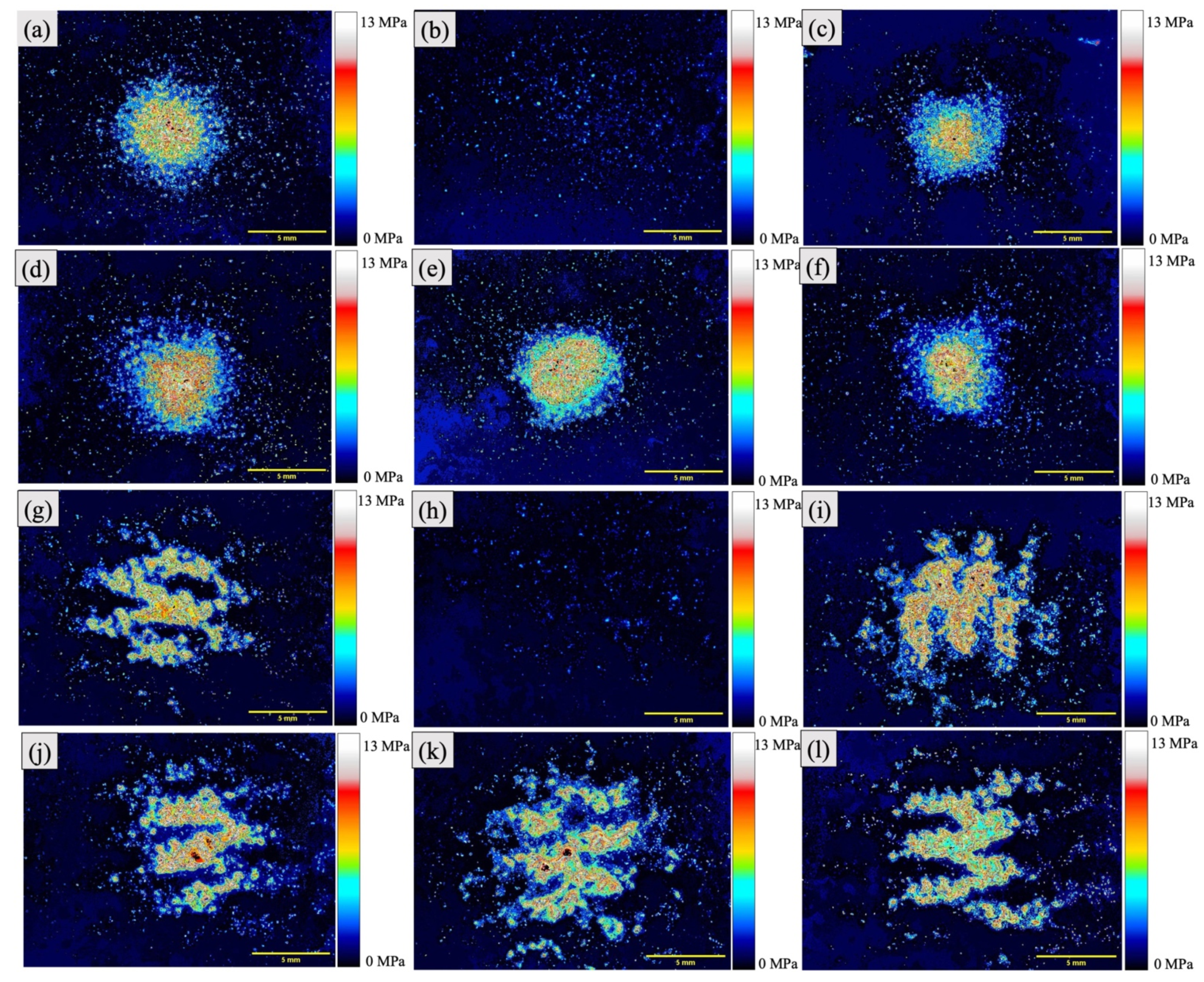

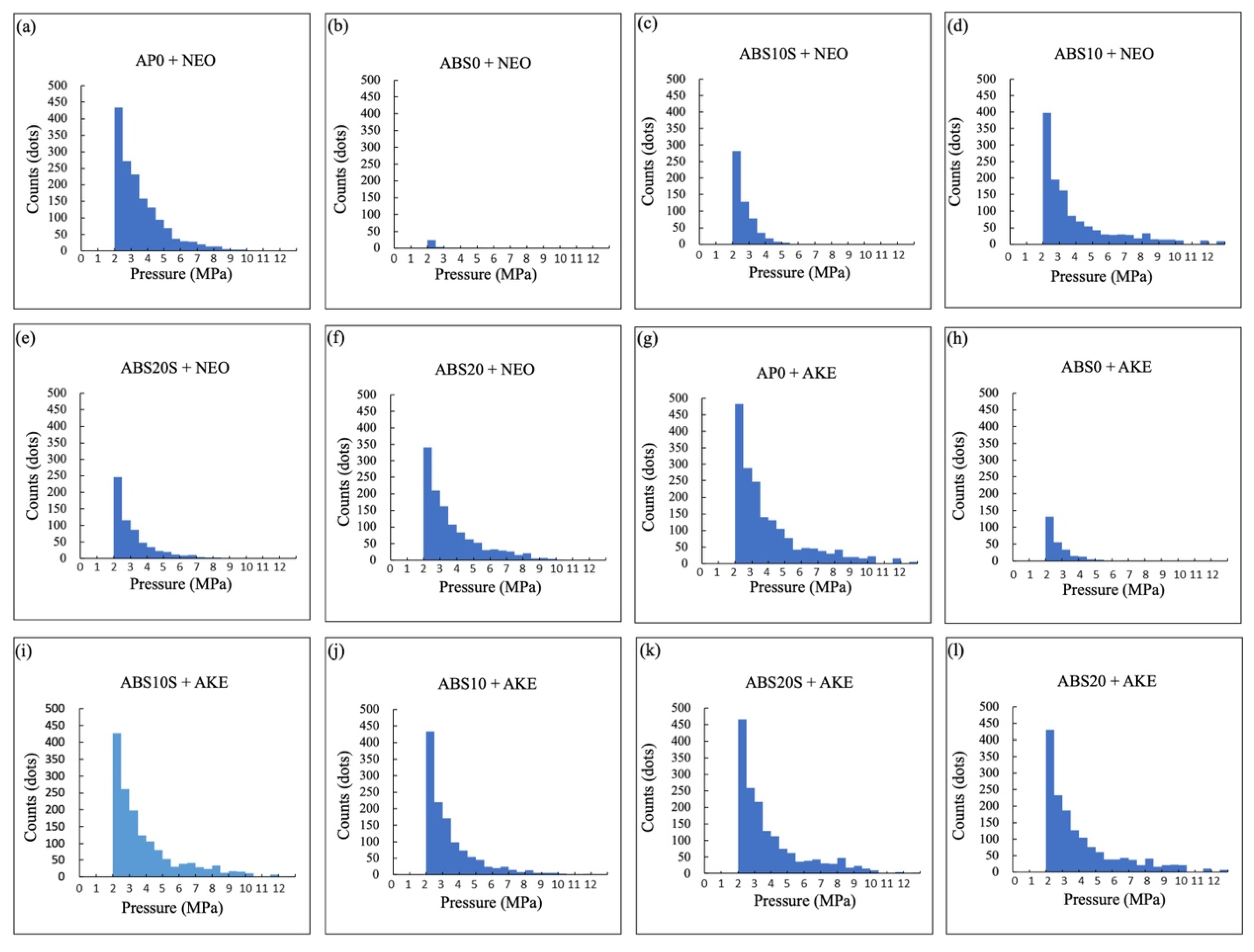

3.4. Pressure Distribution under FG

3.5. Air Permeability Test

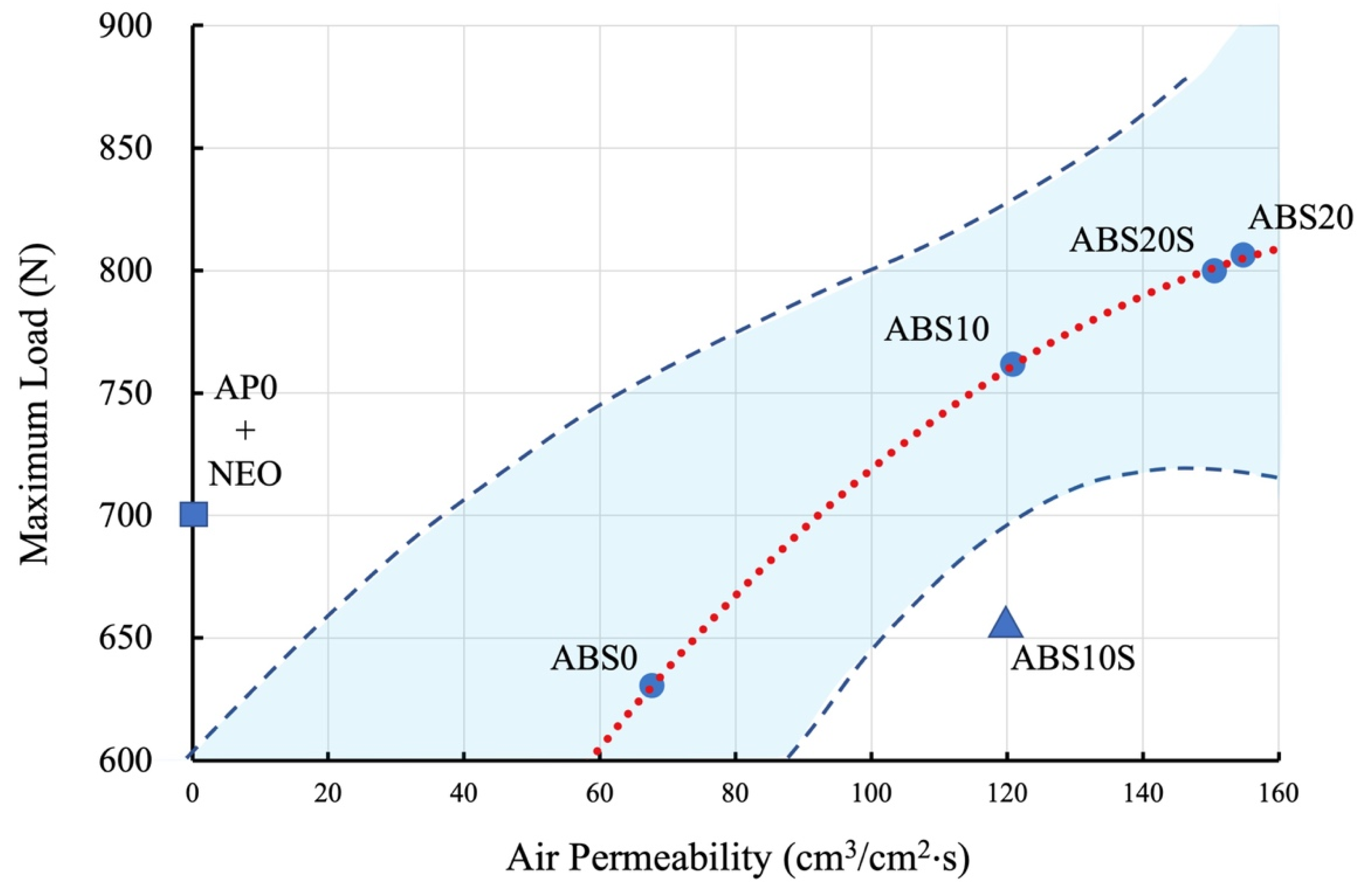

3.6. Relationship between ML and Air Permeability

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tanaka, J. Sports and Protectors; Face Guard of Football Player from the Viewpoint of Orthopedics (Japanese). Jpn. J. Clin. Sports Med. 2004, 21, 415–421. [Google Scholar]

- Kaplan, S.; Driscoll, C.F.; Singer, M.T. Fabrication of a facial shield to prevent facial injuries during sporting events: A clinical report. J. Prosthet. Dent. 2000, 84, 387–389. [Google Scholar] [CrossRef] [PubMed]

- Oriya, S.; Shiraishi, M. Treatment of the Professional Soccer Player Who Returned Quickly to Play after a Mandibular Fracture (Japanese, English abstract). J. Sports Dent. 2001, 4, 28–31. [Google Scholar]

- Heise, M.; Eufinger, H.; Rarreck, T. Individualized Facial Protection after Fracture Management of the Nasal Bone and Zygomatic Arch in Professional Soccer Players. Mund Kiefer Gesichtschirurgie MKG 2001, 5, 320–322. [Google Scholar] [CrossRef]

- Nishino, S.; Irie, Y.; Nakajima, H.; Masunari, M.; Amano, M.; Kawamura, K. Sports and Protectors Facial Guard for Soccer Players-Fabrication of Nasal Bone Protectors (Japanese). J. Clin. Sports Med. 2004, 21, 433–440. [Google Scholar]

- De Baat, C.; Peters, R.; van Iperen-Keiman, C.; de Vlccschouwer, M. A Face Shield for a Sportsman with an Orofacial Trauma (Dutch, English Abstract). Ned. Tijdschr. Tandheelkd. 2005, 112, 177–180. [Google Scholar]

- Yoshida, K.; Nishiyama, S.; Ito, M. Fabrication of a Facial Guard after Zygomatic Arch Fracture (Japanese). PO Acad. J. 2006, 14, 150–151. [Google Scholar]

- Morita, R.; Shimada, K.; Kawakami, S. Facial Protection Masks after Fracture Treatment of the Nasal Bone to Prevent Re-injury in Contact Sports. J. Craniofac. Surg. 2007, 18, 143–145. [Google Scholar] [CrossRef]

- Cascone, P.; Petrucci, B.; Ramieri, V.; TitoMatteo, M. Security Hi-Tech Individual Extra-Light Device Mask. J. Craniofac. Surg. 2008, 19, 772–776. [Google Scholar] [CrossRef]

- Procacci, P.; Ferrari, F.; Bettini, G.; Bissolotti, G.; Trevisiol, L.; Nocini, P.F. Soccer-Related Facial Fractures: Postoper-ative Management with Facial Protective Shields. J. Craniofac. Surg. 2009, 20, 15–20. [Google Scholar] [CrossRef]

- Fujino, S.; Churei, H.; Abe, K.; Miura, H.; Takahashi, T.; Ueno, T. A Custom Faceguard for a Soccer Player Injured with a Complex Fracture of the Zygomatic Bone and Orbit: A Case Report (Japanese, English Abstract). J. Sports Dent. 2010, 13, 108–113. [Google Scholar]

- Churei, H.; Abe, K.; Fujino, S.; Sharika, S.; Chowdhury, R.U.; Saito, S.; Isoyama, E.; Shiraishi, M.; Tateishi, T.; Yui, N.; et al. Clinical Effectiveness of a Custom Faceguard for a Futsal Player Injured with a Nasal Bone Fracture for Early and Safe Return: A Case Report. Int. J. Sports Dent. 2011, 4, 34–40. [Google Scholar]

- The International Football Association Board Laws of the Game 2020/2021. Available online: http://www.theifab.com/laws (accessed on 1 April 2021).

- Churei, H.; Fujino, S.; Ihara, C.; Sumita, Y.; Ueno, T. Clinical Effectiveness of a Custom Faceguard for Rugby Football Player Injured with a Nasal Bone Fracture-Feedback from Visual Field Test (Japanese, English abstract). Jpn. J. Clin. Sports Med. 2007, 15, 163. [Google Scholar]

- Ueno, T.; Churei, H.; Abe, K.; Fujino, S.; Takahashi, T. Clinical Assessment of Custom Faceguards Provided for Sport-Related Maxillofacial Bone Fracture Cases (Japanese). J. Sports Dent. 2011, 14, 108. [Google Scholar]

- Ueno, T.; Churei, H. Fabrication Technique for Custom Faceguard with Thermoforming Material. Int. J. Sports Dent. 2008, 1, 67–71. [Google Scholar]

- Abe, K.; Takahashi, H.; Churei, H.; Iwasaki, N.; Ueno, T. Flexural Properties and Shock-Absorbing Capabilities of New Faceguard Materials Reinforced with Fiberglass Cloth. Dent. Traumatol. 2013, 29, 23–28. [Google Scholar] [CrossRef]

- Onal, L.; Yildirim, M. Comfort properties of functional three-dimensional knitted spacer fabrics for home-textile applications. Text. Res. J. 2012, 82, 1751–1764. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, P. Application of Knitting Structure Textiles in Medical Areas. Autex Res. J. 2018, 18, 181–191. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Vijayan, A.; Wang, L.; Padhye, R.; Arnold, L. Design of 3D knitted structures for impact absorption in sportswear. KnE Eng. 2017, 2, 127. [Google Scholar] [CrossRef]

- Churei, H.; Abe, K.; Yokota, K.; Takahashi, H.; Ueno, T. Fundamental Evaluation of the Physical Properties of Face Guard Materials-II. Impact Absorption (Effect of Perforation Pattern) (Japanese, English abstract). J. Sports Dent. 2008, 14, 17–21. [Google Scholar]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef]

- Tun, P.S.; Churei, H.; Hikita, K.; Kamijo, S.; Oki, M.; Tanabe, G.; Hayashi, K.; Aung, T.K.; Win, A.; Hlaing, S.; et al. Fabrication of Shock Absorbing Photopolymer Composite Material for 3D Printing Sports Mouthguard. J. Photopolym. Sci. Technol. 2020, 33, 615–622. [Google Scholar] [CrossRef]

- Nakamura, T.; Dei, N.; Kojima, T.; Wakabayashi, K. Marginal and Internal Fit of Cerec 3 CAD? CAM All-Ceremic Crowns. Int. J. Prosthodont. 2003, 16, 244–248. [Google Scholar]

- Tsitrou, E.A.; Northeast, S.E.; van Noort, R. Brittleness index of machinable dental materials and its relation to the marginal chipping factor. J. Dent. 2007, 35, 897–902. [Google Scholar] [CrossRef] [PubMed]

- Suárez, M.J.; Lozano, J.F.L.; Salido, M.P.; Martínez, F. Three-Year Clinical Evaluation of In-Ceram Zirconia Posterior FPDs. Int. J. Prosthodont. 2004, 17, 35–38. [Google Scholar] [PubMed]

- Esquivel-Upshaw, J.F.; Anusavice, K.J.; Young, H.; Jones, J.; Gibbs, C. Clinical performance of a lithia disilicate-based core ceramic for three-unit posterior FPDs. Int. J. Prosthodont. 2004, 17, 469–475. [Google Scholar]

- Williams, R.; Bibb, R.; Eggbeer, D.; Collis, J. Use of CAD/CAM technology to fabricate a removable partial denture framework. J. Prosthet. Dent. 2006, 96, 96–99. [Google Scholar] [CrossRef]

- Awada, A.; Nathanson, D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J. Prosthet. Dent. 2015, 114, 587–593. [Google Scholar] [CrossRef] [PubMed]

- Orabona, G.D.; Abbate, V.; Maglitto, F.; Bonavolontà, P.; Salzano, G.; Romano, A.; Reccia, A.; Committeri, U.; Iaconetta, G.; Califano, L. Low-cost, self-made CAD/CAM-guiding system for mandibular reconstruction. Surg. Oncol. 2018, 27, 200–207. [Google Scholar] [CrossRef]

- Sutter, E.; Lotz, M.; Rechenberg, D.-K.; Stadlinger, B.; Rücker, M.; Valdec, S. Guided Apicoectomy Using a CAD/CAM Drilling Templatet. Int. J. Comput. Dent. 2019, 22, 363–369. [Google Scholar] [PubMed]

- Odén, A.; Andersson, M.; Krystek-Ondracek, I.; Magnusson, D. Five-year clinical evaluation of Procera All Ceram crowns. J. Prosthet. Dent. 1998, 80, 450–456. [Google Scholar] [CrossRef]

- Monzón, M.D.; Ortega, Z.; Martínez, A.; Ortega, F. Standardization in additive manufacturing: Activities carried out by international organizations and projects. Int. J. Adv. Manuf. Technol. 2014, 76, 1111–1121. [Google Scholar] [CrossRef]

- Takeuchi, Y.; Shikamaru, T.; Kuriyama, A. Fabrication and Evaluation of Face Guards for Nasal Bone Fracture Used in Soccer (Japanese). PO Acad. J. 2005, 13, 130–131. [Google Scholar]

- Feng, J.; Carpanese, C.; Fina, A. Thermal decomposition investigation of ABS containing Lewis-acid type metal salts. Polym. Degrad. Stab. 2016, 129, 319–327. [Google Scholar] [CrossRef]

- McKeen, L.W. Fatigue and Tribological Properties of Plastics and Elastomers, 3rd ed.; William Andrew: Norwich, NY, USA, 2016. [Google Scholar]

- Martinho, G.; Pires, A.; Saraiva, L.; Ribeiro, R. Composition of plastics from waste electrical and electronic equipment (WEEE) by direct sampling. Waste Manag. 2012, 32, 1213–1217. [Google Scholar] [CrossRef]

- Huang, G.; Huo, S.; Xu, X.; Chen, W.; Jin, Y.; Li, R.; Song, P.; Wang, H. Realizing simultaneous improvements in mechanical strength, flame retardancy and smoke suppression of ABS nanocomposites from multifunctional graphene. Compos. Part B Eng. 2019, 177, 107377. [Google Scholar] [CrossRef]

- Ziąbka, M.; Dziadek, M.; Menaszek, E.; Banasiuk, R.; Królicka, A. Middle Ear Prosthesis with Bactericidal Efficacy—In Vitro Investigation. Molecules 2017, 22, 1681. [Google Scholar] [CrossRef]

- Ziabka, M. A Review of Materials Used in Middle Ear Prosthetics. J. Ceram. Mater. 2018, 70, 65–85. [Google Scholar]

- Ziąbka, M.; Menaszek, E.; Tarasiuk, J.; Wroński, S. Biocompatible Nanocomposite Implant with Silver Nanoparticles for Otology—In Vivo Evaluation. Nanomaterials 2018, 8, 764. [Google Scholar] [CrossRef]

- Aung, T.K.; Churei, H.; Kinjo, R.; Tun, P.S.; Takahashi, Y.; Tanabe, G.; Ueno, T. Shock Absorbing Ability of Different Cushion Materials Used in Face Guard. In Proceedings of the 40th Myanmar Dental Conference, Yangon, Myanmar, 7–9 January 2020; p. 53. [Google Scholar]

- Churei, H.; Yokota, K.; Takahashi, H.; Ueno, T. Evaluation of Fundamental Physical-Properties of Face Guard Materials I—Impact Absorption (Japanese, English Abstract). J. Sports Dent. 2008, 11, 90–95. [Google Scholar]

- Nahum, A.M.; Gatts, J.D.; Gadd, C.W.; Danforth, J. Impact Tolerance of the Skull and Face. In Proceedings of the 12th Stapp Car Crash Conferences, New York, NY, USA, 1 February 1968; pp. 302–316. [Google Scholar]

- Takeda, T.; Ishigami, K.; Shintaro, K.; Nakajima, K.; Shimada, A.; Regner, C.W. The influence of impact object characteristics on impact force and force absorption by mouthguard material. Dent. Traumatol. 2004, 20, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Wada, T.; Churei, H.; Takayanagi, H.; Iwasaki, N.; Ueno, T.; Takahashi, H.; Uo, M. Improvement of the Shock Absorption Ability of a Face Guard by Incorporating a Glass-Fiber-Reinforced Thermoplastic and Buffering Space. BioMed Res. Int. 2018, 2018, 6503568. [Google Scholar] [CrossRef] [PubMed]

- Sayed, A.M. Numerical Analysis of the Perforated Steel Sheets Under Uni-Axial Tensile Force. Metals 2019, 9, 632. [Google Scholar] [CrossRef]

- O’ Donell & Associates. Strength of Perforated Metal. Designers, Specifiers and Buyers Handbook for Perforated Metals; A Publication of the Industrial Perforators Association: Huston, TX, USA, 1993; pp. 12–13. [Google Scholar]

- Phunthikaphadr, T.; Takahashi, H.; Arksornnukit, M. Pressure transmission and distribution under impact load using artificial denture teeth made of different materials. J. Prosthet. Dent. 2009, 102, 319–327. [Google Scholar] [CrossRef]

- Asanovic, K.A.; Cerovic, D.D.; Mihailovic, T.V.; Kostic, M.M.; Reljic, M. Quality of Clothing Fabrics in Terms of Their Comfort Properties. Indian J. Fibre Text. Res. 2015, 40, 363–372. [Google Scholar]

- Churei, H.; Fujino, S.; Yagishita, K.; Ueno, T. A Case Study of a Custom-Made Face Guard for a Professional Soccer Player Suffered Maxillary Bone Fracture (Japanese). Jpn. J. Clin. Sports Med. 2008, 16, S165. [Google Scholar]

| ABS0 | ABS10S | ABS10 | ABS20S | ABS20 | |

|---|---|---|---|---|---|

| Triangle | 1140 | 892,108 | 300,604 | 1,133,968 | 611,892 |

| Apex | 3420 | 2,676,324 | 901,812 | 3,401,904 | 1,835,676 |

| File size (kB) | 57 | 44,605 | 15,030 | 56,698 | 30,594 |

| Sample Group | Core Materials | Cushioning Materials | |||||

|---|---|---|---|---|---|---|---|

| Materials & Thickness | Composition & Manufacturer | Open Area % | Hole Size | Materials & Thickness | Composition & Manufacturer | ||

| AP0 + NEO | AP (3.2 mm) | Polycaprolactone (Homecraft Rolyan) | 0 | - | NEO (4.5 mm) | Polychloroprene with nylon lining (Homecraft Rolyan) | |

| ABS0 + NEO | ABS (3 mm) | Acrylonitrile, butadiene, and styrene (NCI Sales) | 0 | - | |||

| ABS10 + NEO | 10 | 3.64 mm rounded | |||||

| ABS10S + NEO | S | 2.52 mm rounded | |||||

| ABS20 + NEO | 20 | 3.57 mm rounded | |||||

| ABS20S + NEO | S | 2.55 mm rounded | |||||

| AP0 + AKE | AP (3.2 mm) | Polycaprolactone (Homecraft Rolyan) | 0 | - | AKE (4.3 mm) | 3D-knitted fabric (Asahi Kasei) | |

| ABS0 + AKE | ABS (3 mm) | Acrylonitrile, butadiene, and styrene (NCI Sales) | 0 | - | |||

| ABS10 + AKE | 10 | 3.64 mm rounded | |||||

| ABS10S + AKE | S | 2.52 mm rounded | |||||

| ABS20 + AKE | 20 | 3.57 mm rounded | |||||

| ABS20S + AKE | S | 2.55 mm rounded | |||||

| Materials | AP0 | ABS0 | ABS10S | ABS10 | ABS20S | ABS20 | NEO | AKE |

|---|---|---|---|---|---|---|---|---|

| weight (g) | 36.2 ± 0.1 | 30.5 ± 0.1 | 27.6 ± 0.1 | 27.4 ± 0.1 | 25.5 ± 0.1 | 24.8 ± 0.1 | 8.5 ± 0.1 | 5.7 ± 0.1 |

| without Core Material | AP0 | ABS0 | ABS10S | ABS10 | ABS20S | ABS20 | |

|---|---|---|---|---|---|---|---|

| NEO | 0.2 ± 0.0 | 0.2 ± 0.0 A | 0.2 ± 0.0 A | 0.2 ± 0.0 A | 0.2 ± 0.0 A | 0.2 ± 0.0 A | 0.2 ± 0.0 A |

| AKE | 178.9 ± 1.6 | 69.0 ± 0.4 C | 67.7 ± 0.6 B | 121.8 ± 1.0 D | 120.9 ± 0.9 D | 150.6 ± 0.7 E | 154.8 ± 0.9 F |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aung, T.K.; Churei, H.; Tanabe, G.; Kinjo, R.; Togawa, K.; Li, C.; Tsuchida, Y.; Tun, P.S.; Hlaing, S.; Takahashi, H.; et al. Air Permeability, Shock Absorption Ability, and Flexural Strength of 3D-Printed Perforated ABS Polymer Sheets with 3D-Knitted Fabric Cushioning for Sports Face Guard Applications. Polymers 2021, 13, 1879. https://doi.org/10.3390/polym13111879

Aung TK, Churei H, Tanabe G, Kinjo R, Togawa K, Li C, Tsuchida Y, Tun PS, Hlaing S, Takahashi H, et al. Air Permeability, Shock Absorption Ability, and Flexural Strength of 3D-Printed Perforated ABS Polymer Sheets with 3D-Knitted Fabric Cushioning for Sports Face Guard Applications. Polymers. 2021; 13(11):1879. https://doi.org/10.3390/polym13111879

Chicago/Turabian StyleAung, Thet Khaing, Hiroshi Churei, Gen Tanabe, Rio Kinjo, Kaito Togawa, Chenyuan Li, Yumi Tsuchida, Phyu Sin Tun, Shwe Hlaing, Hidekazu Takahashi, and et al. 2021. "Air Permeability, Shock Absorption Ability, and Flexural Strength of 3D-Printed Perforated ABS Polymer Sheets with 3D-Knitted Fabric Cushioning for Sports Face Guard Applications" Polymers 13, no. 11: 1879. https://doi.org/10.3390/polym13111879

APA StyleAung, T. K., Churei, H., Tanabe, G., Kinjo, R., Togawa, K., Li, C., Tsuchida, Y., Tun, P. S., Hlaing, S., Takahashi, H., & Ueno, T. (2021). Air Permeability, Shock Absorption Ability, and Flexural Strength of 3D-Printed Perforated ABS Polymer Sheets with 3D-Knitted Fabric Cushioning for Sports Face Guard Applications. Polymers, 13(11), 1879. https://doi.org/10.3390/polym13111879