Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes

Abstract

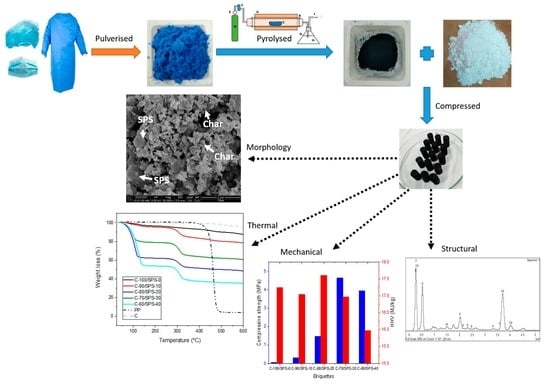

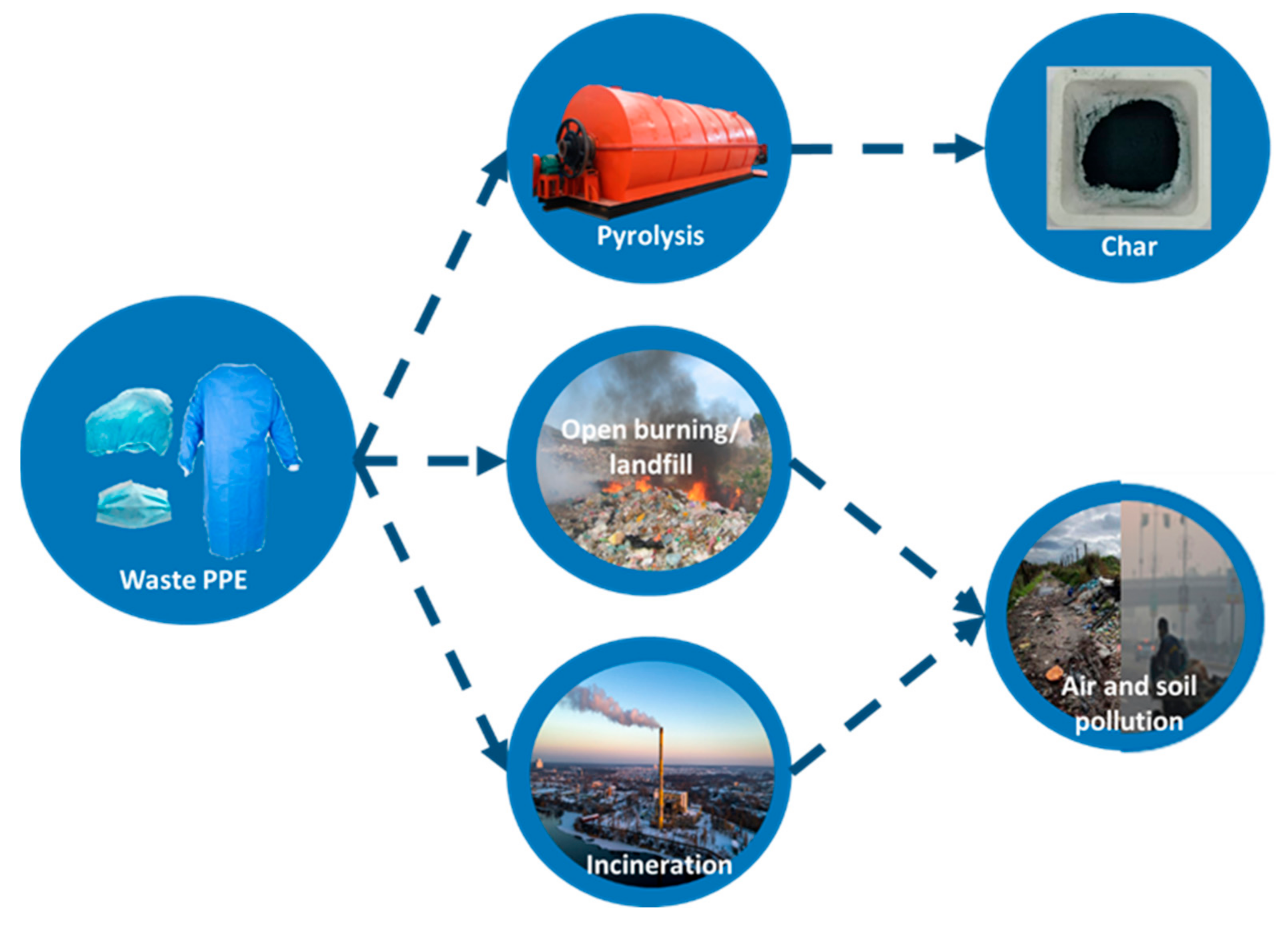

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Slow Pyrolysis Process and Char Preparation

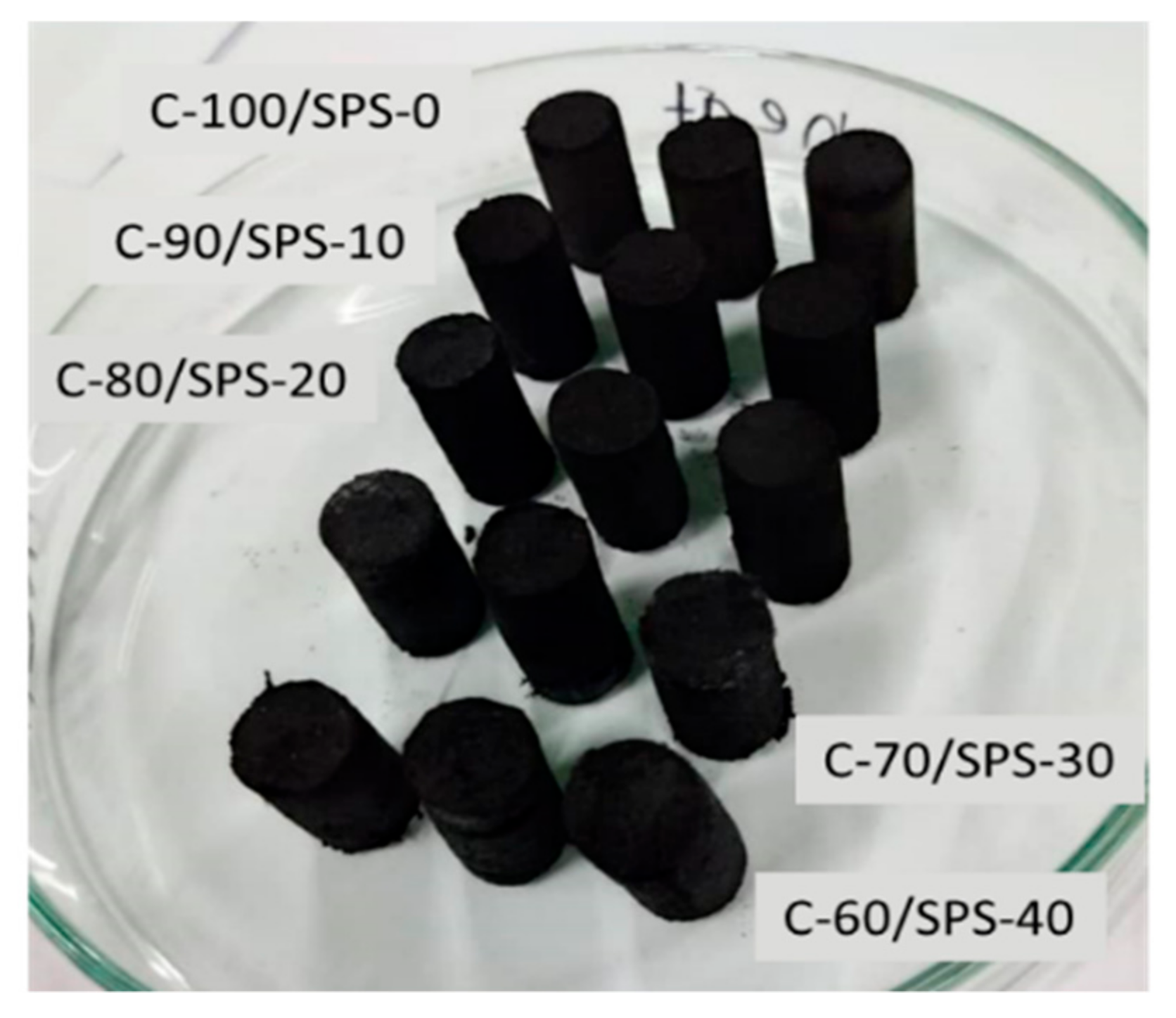

2.3. Char Briquette Preparation

2.4. Biocomposite Briquette Characterizations

2.5. Density and Compressive Strength Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Morphological and Elemental Analysis

3.2. Proximate Analysis

3.3. Functional Group Analysis

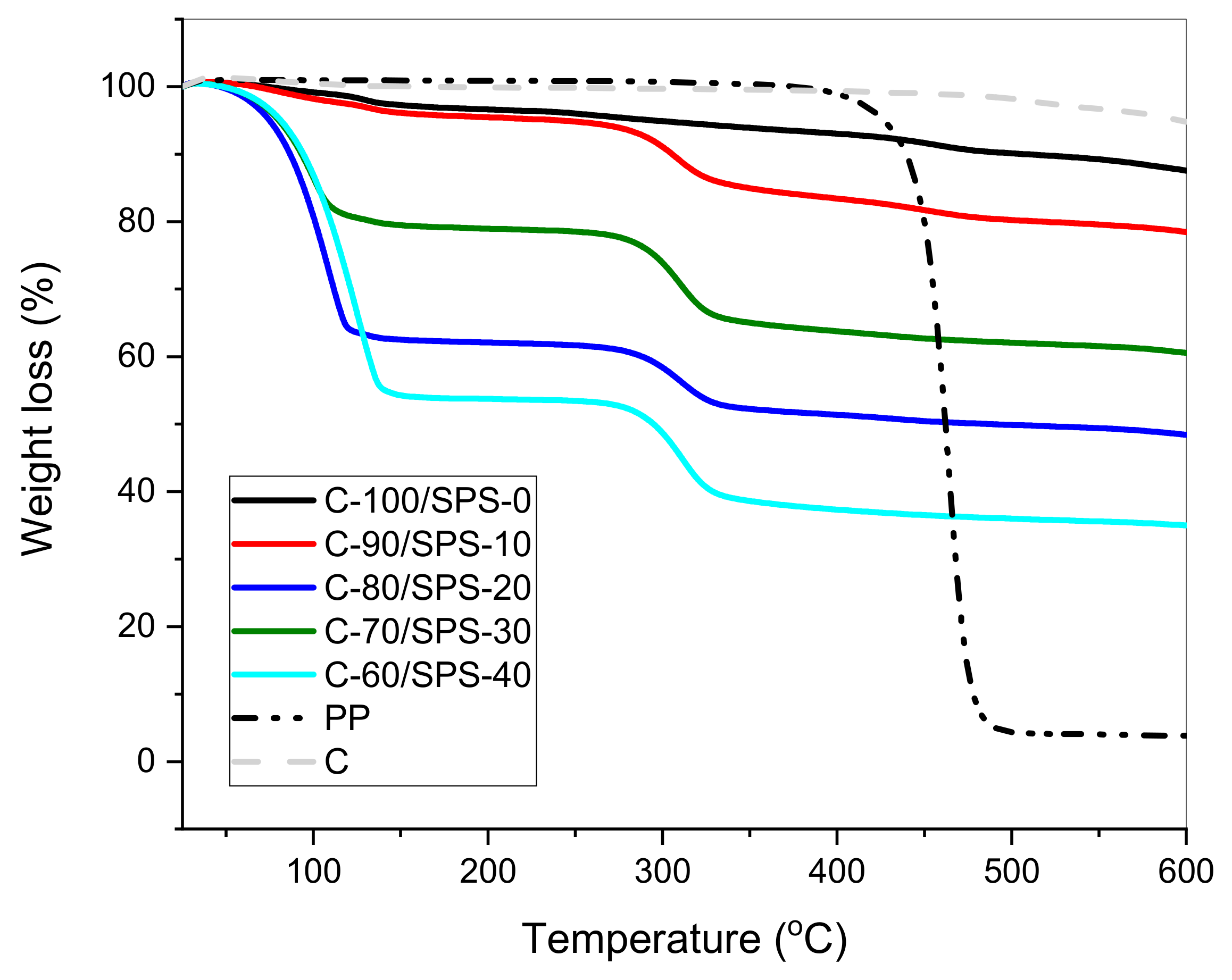

3.4. Thermogravimetric Analysis

3.5. Higher Heating Value (HHV) Analysis

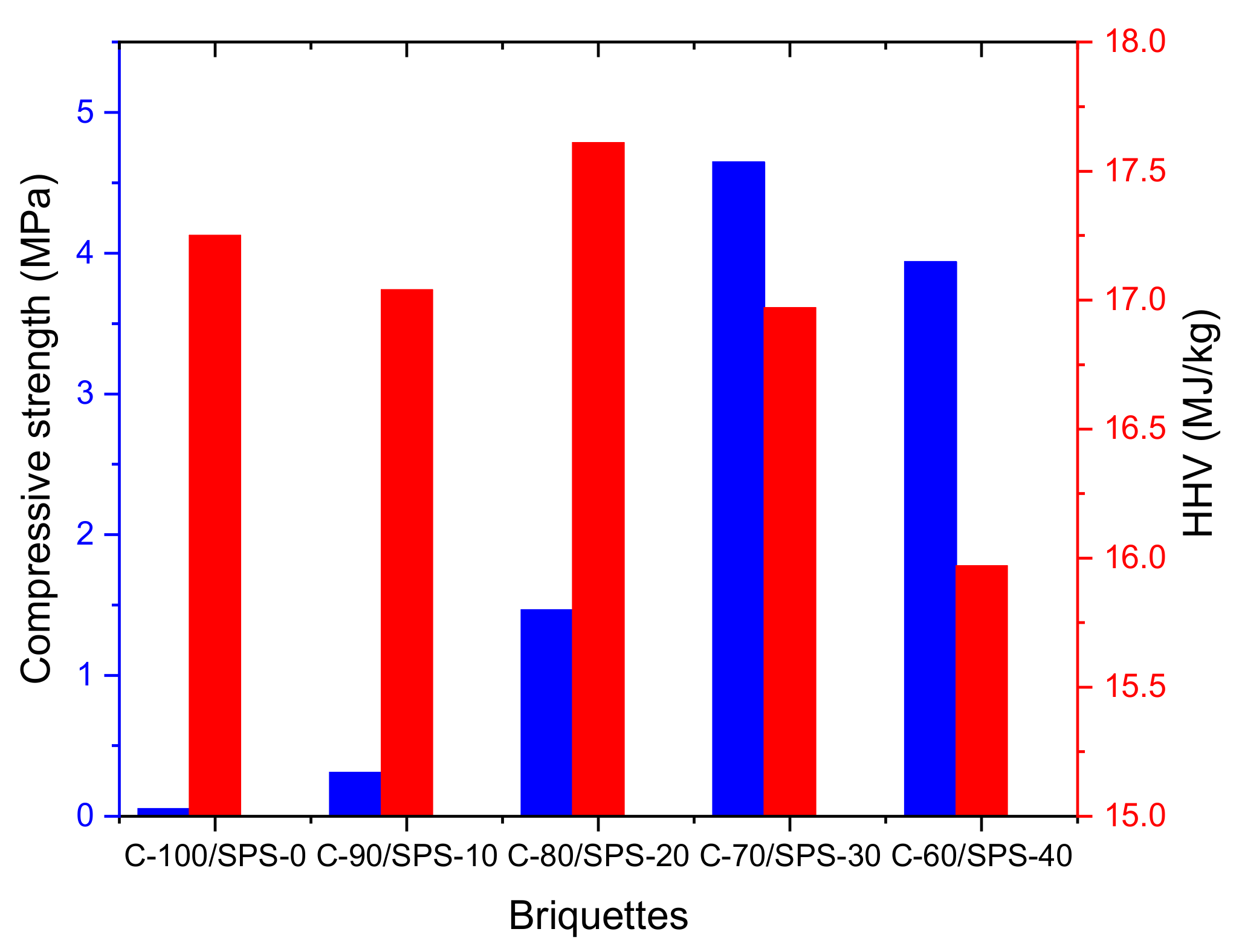

3.6. Density and Compressive Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MOH. Procedure for Disinfection COVID-19; Press Statement Ministry of Health Malaysia: Putrajaya, Malaysia, 2020; Volume 15, pp. 28–30.

- MOH. Updates on the Coronavirus Disease 2019 (COVID-19) Situation in Malaysia 21 July 2020; Press Statement Ministry of Health Malaysia: Putrajaya, Malaysia, 2020; pp. 1–8.

- Yaşar, H. World of plastics. Ankara TMMOB Mech. Eng. Publ. 2004, 1, 59–63. [Google Scholar]

- Verma, R.; Vinoda, K.S.; Papireddy, M.; Gowda, A.N.S. Toxic pollutants from plastic waste-a review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Yang, Z.; Lü, F.; Zhang, H.; Wang, W.; Shao, L.; Ye, J.; He, P. Is incineration the terminator of plastics and microplastics? J. Hazard. Mater. 2021, 401, 123429. [Google Scholar] [CrossRef] [PubMed]

- Harussani, M.M.; Sapuan, S.M.; Khalina, A.; Ilyas, R.A.; Hazrol, M.D. Review on Green Technology Pyrolysis for Plastic Wastes. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020; Universiti Putra Malaysia: Serdang, Malaysia, 2020; pp. 50–53. [Google Scholar]

- Mohd Nurazzi, N.; Muhammad Asyraf, M.R.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Harussani, M.M.; Zulaikha, N.D.S.; Norhana, A.H.; Syakir, M.I.; Norli, A. Composites based on conductive polymer with carbon nanotubes in DMMP gas sensors–an overview. Polimery 2021, 66, 85–97. [Google Scholar] [CrossRef]

- Verma, A.; Budiyal, L.; Sanjay, M.R.; Siengchin, S. Processing and characterization analysis of pyrolyzed oil rubber (from waste tires)-epoxy polymer blend composite for lightweight structures and coatings applications. Polym. Eng. Sci. 2019, 59, 2041–2051. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Gerasimov, N.; Hadden, R.M.; Torero, J.L.; Welch, S. Methodology for estimating pyrolysis rates of charring insulation materials using experimental temperature measurements. J. Build. Eng. 2016, 8, 249–259. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel. Waste Manag. 2018, 79, 615–624. [Google Scholar] [CrossRef]

- Miandad, R.; Kumar, R.; Barakat, M.A.; Basheer, C.; Aburiazaiza, A.S.; Nizami, A.S.; Rehan, M. Untapped conversion of plastic waste char into carbon-metal LDOs for the adsorption of Congo red. J. Colloid Interface Sci. 2018, 511, 402–410. [Google Scholar] [CrossRef]

- Worrel, W.A.; Vesilind, P.A. Solid Waste Engineering; CENGAGE Learning: Stamford, CT, USA, 2012. [Google Scholar]

- Lee, C.H.; Khalina, A.; Nurazzi, N.M.; Norli, A.; Harussani, M.M.; Rafiqah, S.; Aisyah, H.A.; Ramli, N. The Challenges and Future Perspective of Woven Kenaf Reinforcement in Thermoset Polymer Composites in Malaysia: A Review. Polymers 2021, 13, 1390. [Google Scholar] [CrossRef]

- Nwabue, F.I.; Unah, U.; Itumoh, E.J. Production and characterization of smokeless bio-coal briquettes incorporating plastic waste materials. Environ. Technol. Innov. 2017, 8, 233–245. [Google Scholar] [CrossRef]

- Citrasari, N.; Pinatih, T.A.; Kuncoro, E.P.; Soegianto, A.S.; Irawan, B. Potency of bio-charcoal briquette from leather cassava tubers and industrial sludge. AIP Conference Proceedings, Surabaya, Indonesia, 15 October 2016; AIP Publishing LLC: Melville, NY, USA, 2017; Volume 1854, p. 20007. [Google Scholar]

- Zannikos, F.; Kalligeros, S.; Anastopoulos, G.; Lois, E. Converting biomass and waste plastic to solid fuel briquettes. J. Renew. Energy 2013, 2013, 360368. [Google Scholar] [CrossRef]

- Garrido, M.A.; Conesa, J.A.; Garcia, M.D. Characterization and production of fuel briquettes made from biomass and plastic wastes. Energies 2017, 10, 850. [Google Scholar] [CrossRef]

- Zanella, E.; Della Zassa, M.; Navarini, L.; Canu, P. Low-temperature co-pyrolysis of polypropylene and coffee wastes to fuels. Energy Fuels 2013, 27, 1357–1364. [Google Scholar] [CrossRef]

- Tienne, L.; Deschamps, M.C.; Andrade, A.M. Production of coal and coal by-products from orange (Citrus sinensis) peel and bagasse by pyrolysis. Biomassa Energ. 2004, 1, 191–197. [Google Scholar]

- Onukak, I.E.; Mohammed-Dabo, I.A.; Ameh, A.O.; Okoduwa, S.I.R.; Fasanya, O.O. Production and characterization of biomass briquettes from tannery solid waste. Recycling 2017, 2, 17. [Google Scholar] [CrossRef]

- Teixeira, S.R.; Souza, A.E.; Peña, A.F.V.; Lima, R.G.; Miguel, Á.G. Use of charcoal and partially pirolysed biomaterial in fly ash to produce briquettes: Sugarcane bagasse. Altern. Fuel 2011, 346. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Alias, A.H.; Rushdan, A.I.; Norrrahim, M.N.F.; Abdan, K.; Abdullah, N. Treatments of Natural Fibre as Reinforcement in Polymer Composites-Short Review. Funct. Compos. Struct. 2021. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A.; Muhairwe, F.; Kihedu, J. Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renew. Energy 2020, 148, 1002–1016. [Google Scholar] [CrossRef]

- Vivero, L.; Barriocanal, C.; Alvarez, R.; Diez, M.A. Effects of plastic wastes on coal pyrolysis behaviour and the structure of semicokes. J. Anal. Appl. Pyrolysis 2005, 74, 327–336. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Valorization of packaging plastic waste by slow pyrolysis. Resour. Conserv. Recycl. 2018, 128, 69–77. [Google Scholar] [CrossRef]

- Ward, B.J.; Yacob, T.W.; Montoya, L.D. Evaluation of solid fuel char briquettes from human waste. Environ. Sci. Technol. 2014, 48, 9852–9858. [Google Scholar] [CrossRef] [PubMed]

- Lubwama, M.; Yiga, V.A. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew. Energy 2017, 111, 532–542. [Google Scholar] [CrossRef]

- Brand, M.A.; Jacinto, R.C.; Antunes, R.; da Cunha, A.B. Production of briquettes as a tool to optimize the use of waste from rice cultivation and industrial processing. Renew. Energy 2017, 111, 116–123. [Google Scholar] [CrossRef]

- Romallosa, A.R.D.; Kraft, E. Feasibility of biomass briquette production from municipal waste streams by integrating the informal sector in the Philippines. Resources 2017, 6, 12. [Google Scholar] [CrossRef]

- Chatziaras, N.; Psomopoulos, C.S.; Themelis, N.J. Use of waste derived fuels in cement industry: A review. Manag. Environ. Qual. Int. J. 2016, 27, 178–193. [Google Scholar] [CrossRef]

- Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter; ASTM Standard E711-88; ASTM International: West Conshohocken, PA, USA, 2004.

- Standard Test Method for Compressive Properties of Rigid Plastics; ASTM Standard D695-10; ASTM International: West Conshohocken, PA, USA, 2010.

- Hamid, M.F.; Idroas, M.Y.; Ishak, M.Z.; Zainal Alauddin, Z.A.; Miskam, M.A.; Abdullah, M.K. An experimental study of briquetting process of torrefied rubber seed kernel and palm oil shell. Biomed. Res. Int. 2016, 2016, 1679734. [Google Scholar] [CrossRef]

- Basu, P. Torrefaction. In Biomass Gasification, Pyrolysis and Torrefaction; Academic Press: Cambridge, MA, USA, 2013; pp. 87–145. [Google Scholar]

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.W.; Kim, H.J. Characterization of Tapioca Starch Biopolymer Composites Reinforced with Micro Scale Water Hyacinth Fibers. Starch/Staerke 2018, 70, 1–8. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Ilyas, R.A.; Sapuan, S.M.; Jumaidin, R. Sugar palm starch-based composites for packaging applications. In Bionanocomposites for Packaging Applications; Springer: Berlin, Germany, 2018; pp. 125–147. [Google Scholar]

- Biswas, B.; Pandey, N.; Bisht, Y.; Singh, R.; Kumar, J.; Bhaskar, T. Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk. Bioresour. Technol. 2017, 237, 57–63. [Google Scholar] [CrossRef]

- Stuart, B. Infrared Spectroscopy: Fundamental and Applications; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Smidt, E.; Meissl, K. The applicability of Fourier transform infrared (FT-IR) spectroscopy in waste management. Waste Manag. 2007, 27, 268–276. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Behaviour of waste polypropylene pyrolysis char-based epoxy composite materials. Environ. Sci. Pollut. Res. 2020, 27, 3871–3884. [Google Scholar] [CrossRef]

- Kiang, J.K.Y.; Uden, P.C.; Chien, J.C.W. Polymer reactions—Part VII: Thermal pyrolysis of polypropylene. Polym. Degrad. Stab. 1980, 2, 113–127. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, P.; Su, Z.; Wei, P.; Wang, G.; Tang, X. Synergistic effect of phosphorus, nitrogen, and silicon on flame-retardant properties and char yield in polypropylene. J. Appl. Polym. Sci. 2005, 96, 854–860. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Witkowski, A.; Stec, A.A.; Hull, T.R. Thermal decomposition of polymeric materials. In SFPE Handbook of Fire Protection Engineering; Springer: Berlin, Germany, 2016; pp. 167–254. [Google Scholar]

- Demirbas, A.; Sahin-Demirbas, A. Briquetting properties of biomass waste materials. Energy Sources 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

| Char Briquette | Calorific Value (MJ/kg) | Reference |

|---|---|---|

| Sugarcane bagasse | 28.32 | [22] |

| Orange bagasse | 26.47 | [19] |

| Human waste | 25.1 | [27] |

| Groundnut shells | 22.50 | [28] |

| Waste plastic and coal | 19.27 | [15] |

| Rice husk | 17.04 | [29] |

| Rice straw and rice husk ash | 17.01 | [29] |

| Paper and saw dust | 16.68 | [30] |

| Waste oil | 14.65 | [31] |

| Leather cassava tubers and sludge | 7.68 | [16] |

| Used COVID-19 polypropylene isolation gown waste | - | Current work |

| Element | Peak (keV) | Weight (%) | Atomic (%) |

|---|---|---|---|

| C K | 0.28 | 31.36 | 43.28 |

| O K | 0.52 | 44.53 | 46.14 |

| Al K | 1.49 | 0.55 | 0.34 |

| P K | 2.02 | 3.57 | 1.91 |

| S K | 2.33 | 0.49 | 0.25 |

| K K | 3.31 | 0.37 | 0.16 |

| Ca K | 3.63 | 19.13 | 7.91 |

| Total | 100.00 |

| Briquette | Moisture | Volatile Matter | Ash | Fixed Carbon |

|---|---|---|---|---|

| C-100/SPS-0 | 1.33 | 4.88 | 6.37 | 88.75 |

| C-90/SPS-10 | 2.36 | 11.60 | 7.76 | 80.64 |

| C-80/SPS-20 | 18.53 | 15.34 | 5.85 | 78.81 |

| C-70/SPS-30 | 36.52 | 10.36 | 5.01 | 84.63 |

| C-60/SPS-40 | 44.67 | 15.23 | 5.26 | 79.51 |

| Briquettes | HHV (J/g) |

|---|---|

| C-100/SPS-0 | 17,251.96 |

| C-90/SPS-10 | 17,041.92 |

| C-80/SPS-20 | 17,614.30 |

| C-70/SPS-30 | 16,969.61 |

| C-60/SPS-40 | 15,967.31 |

| Briquettes | Density (g/cm3) | Yield Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| C-100/SPS-0 | 0.541 a ± 0.010 | 0.037 a ± 0.032 | 0.050 a ± 0.010 |

| C-90/SPS-10 | 0.539 a ± 0.023 | 0.177 a ± 0.035 | 0.310 a ± 0.066 |

| C-80/SPS-20 | 0.601 b ± 0.020 | 1.337 b ± 0.515 | 1.463 b ± 0.424 |

| C-70/SPS-30 | 0.673 c ± 0.019 | 4.380 c ± 0.686 | 4.647 c ± 0.779 |

| C-60/SPS-40 | 0.700 c ± 0.033 | 3.700 c ± 0.161 | 3.937 c ± 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harussani, M.M.; Sapuan, S.M.; Rashid, U.; Khalina, A. Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes. Polymers 2021, 13, 1707. https://doi.org/10.3390/polym13111707

Harussani MM, Sapuan SM, Rashid U, Khalina A. Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes. Polymers. 2021; 13(11):1707. https://doi.org/10.3390/polym13111707

Chicago/Turabian StyleHarussani, M. M., S. M. Sapuan, Umer Rashid, and A. Khalina. 2021. "Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes" Polymers 13, no. 11: 1707. https://doi.org/10.3390/polym13111707

APA StyleHarussani, M. M., Sapuan, S. M., Rashid, U., & Khalina, A. (2021). Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes. Polymers, 13(11), 1707. https://doi.org/10.3390/polym13111707