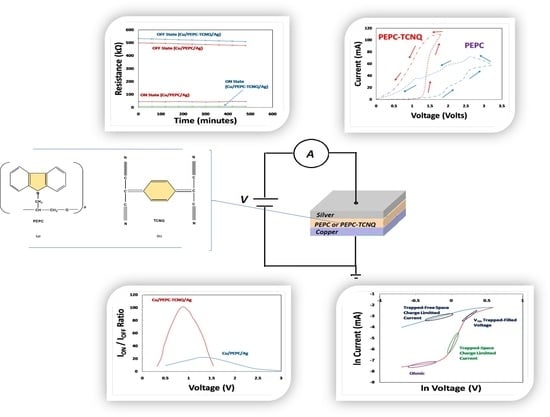

A Novel Poly-N-Epoxy Propyl Carbazole Based Memory Device

Abstract

1. Introduction

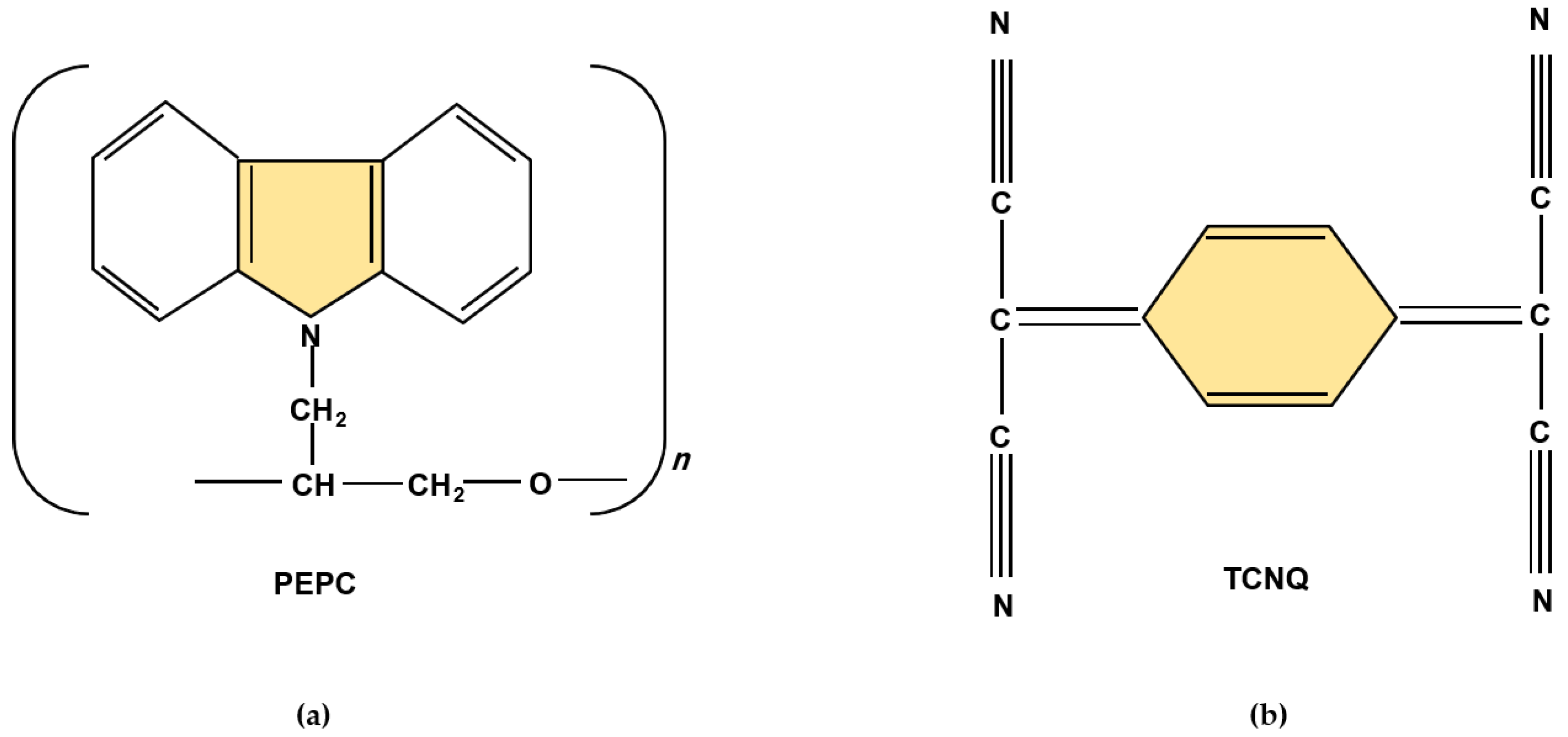

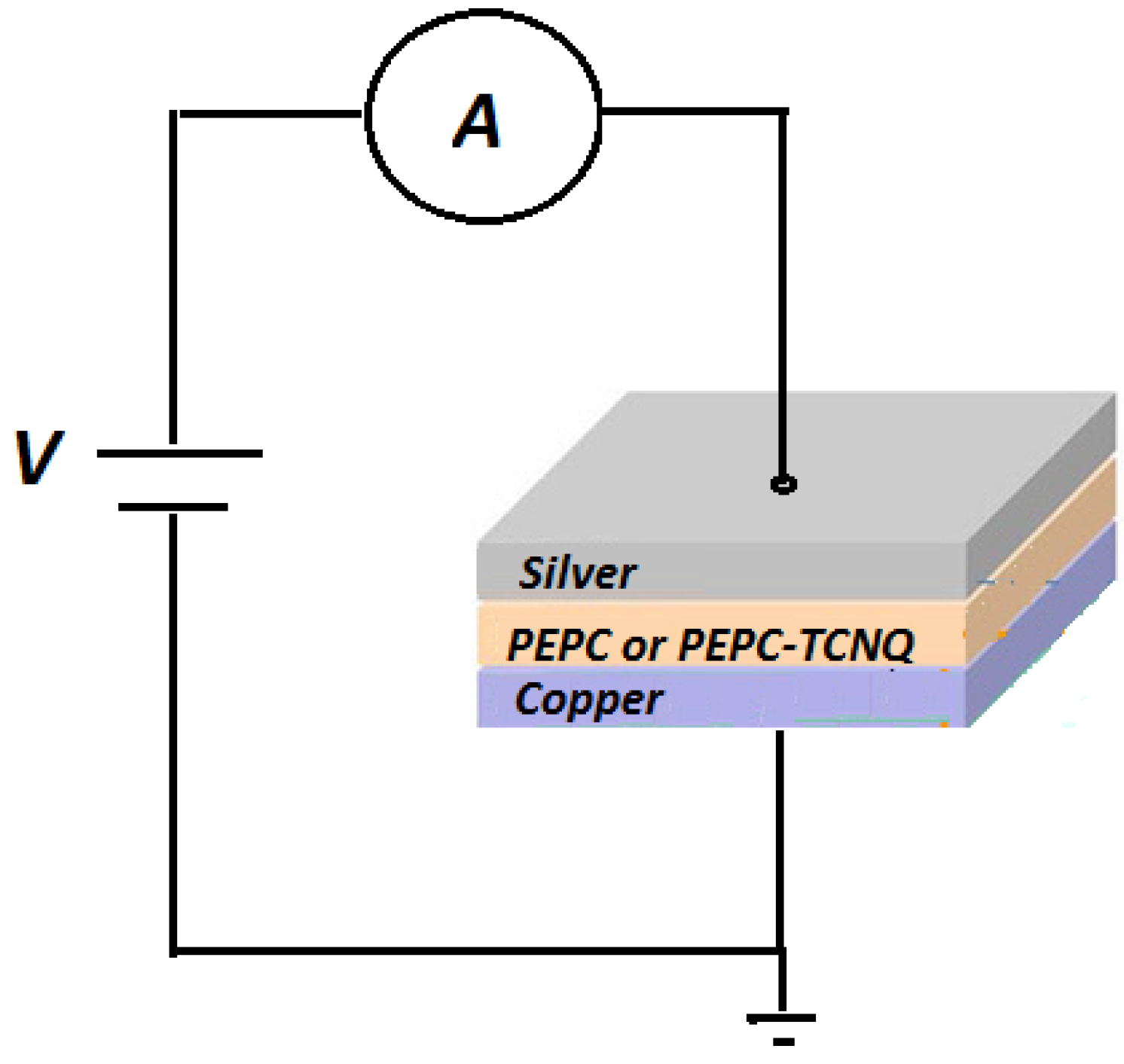

2. Device Fabrication

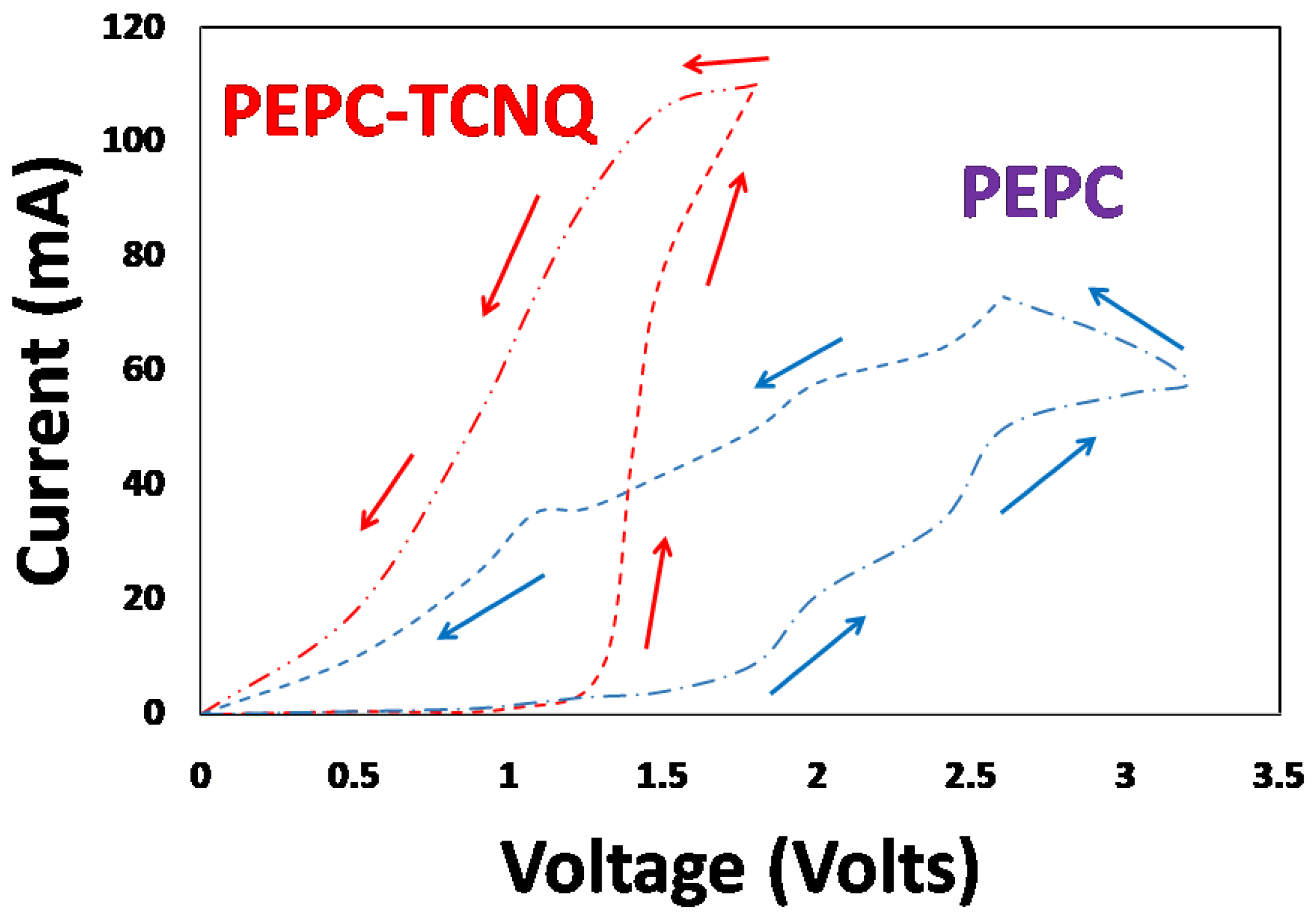

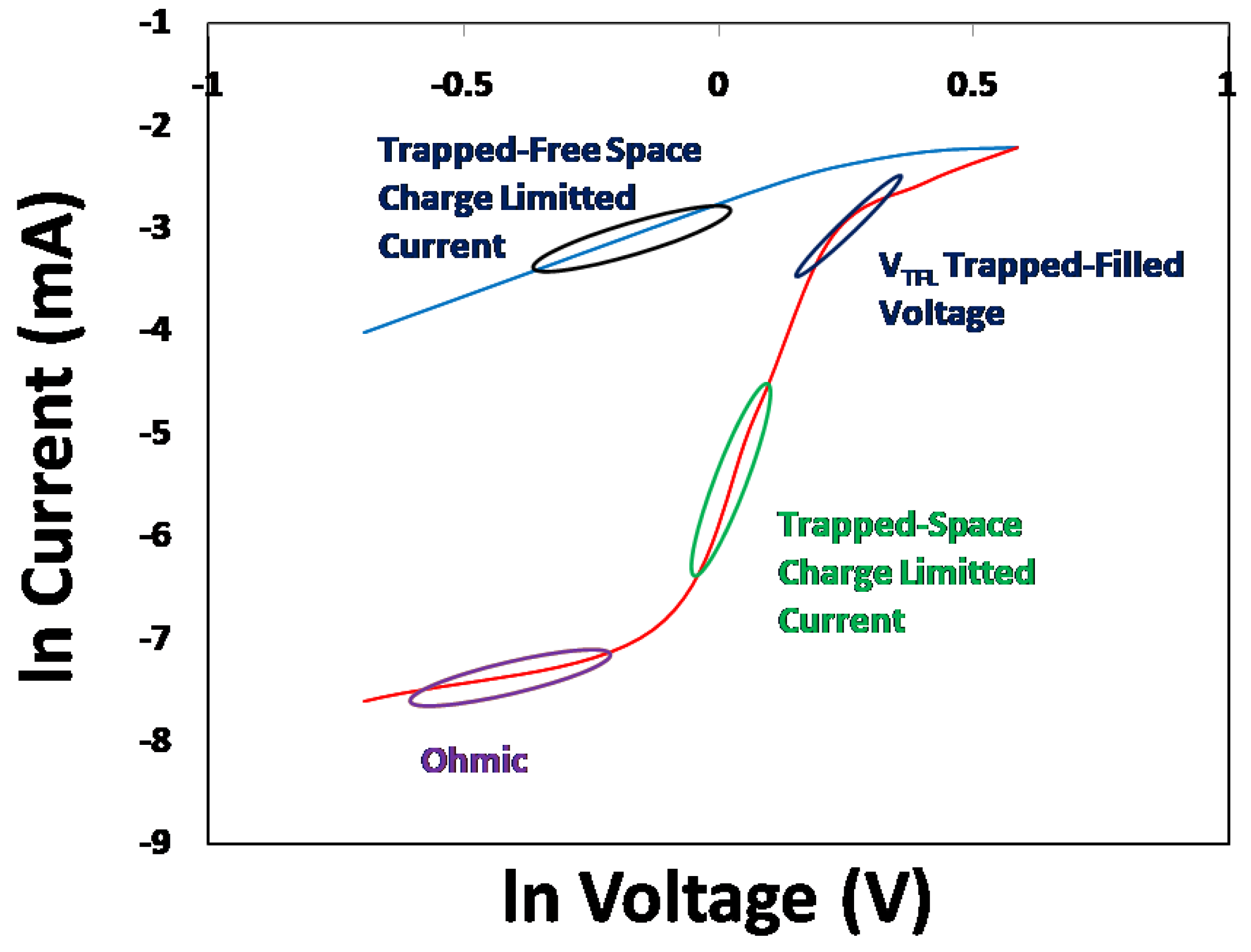

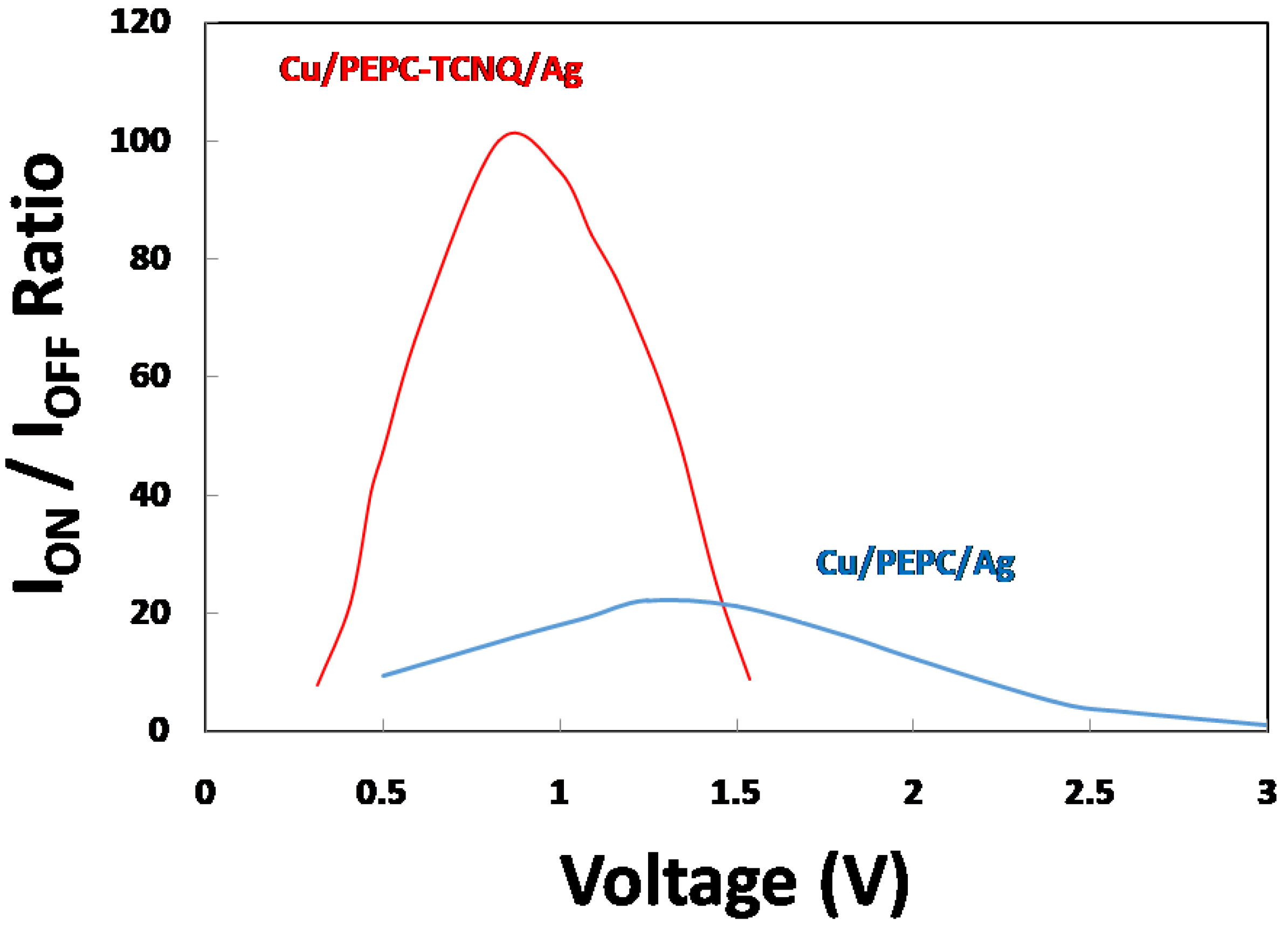

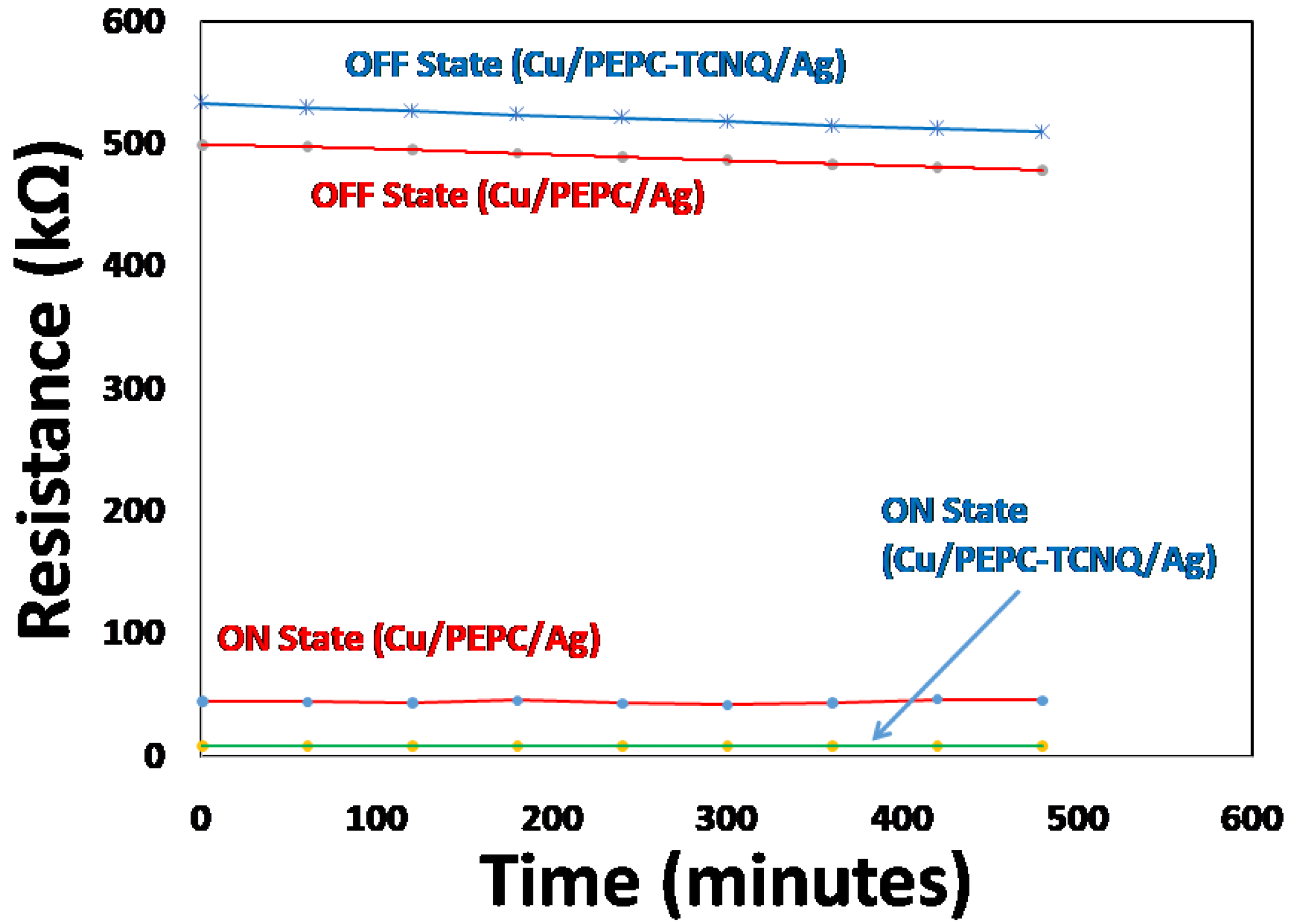

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ying, S.; Ma, Z.; Zhou, Z.; Tao, R.; Yan, K.; Xin, M.; Li, Y.; Pan, L.; Shi, Y. Device Based on Polymer Schottky Junctions and Their Applications: A Review. IEEE Access 2020, 8, 189646–189660. [Google Scholar] [CrossRef]

- Zheng, Y.; Fischer, A.; Sawatzki, M.; Doan, D.H.; Liero, M.; Glitzky, A.; Reineke, S.; Mannsfeld, S.C.B. Introducing PinMOS Memory: A Novel, Nonvolatile Organic Memory Device. Adv. Funct. Mater. 2020, 30, 1907119. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alahmadi, A.N.M.; Karimov, K.S. Improved Organic Solar Cell by Incorporating Silver Nanoparticles Embedded Polyaniline as Buffer Layer. Solid State Electron. 2020, 163, 107658. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alahmadi, A.N.M.; Aljohani, A.J. Design of Silicon Nanowire Array for PEDOT:PSS-Silicon Nanowire-Based Hybrid Solar Cell. Energies 2020, 13, 3797. [Google Scholar] [CrossRef]

- Melling, D.; Martinez, J.G.; Jager, E.W.H. Conjugated Polymer Actuators and Devices: Progress and Opportunities. Adv. Mater. 2019, 31, 1808210. [Google Scholar] [CrossRef]

- Lewis, J. Material Challenge for Flexible Organic Devices. Mater. Today 2006, 9, 38–45. [Google Scholar] [CrossRef]

- Kruijne, W.; Bohte, S.M.; Roelfsema, P.R.; Olivers, C.N.L. Flexible Working Memory through Selective Gating and Attentional Tagging. Neural Comput. 2021, 33, 1–40. [Google Scholar] [CrossRef]

- Yang, Y.; Ouyang, J.; Ma, L.; Tseng, R.J.-H.; Chu, C.-W. Electrical Switching and Bistability in Organic/Polymeric Thin Films and Memory Devices. Adv. Funct. Mater. 2006, 16, 1001–1014. [Google Scholar] [CrossRef]

- Kim, S.-J.; Lee, J.-S. Flexible Organic Transistor Memory Devices. Nano Lett. 2010, 10, 2884–2890. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Ling, Q.-D.; Lim, S.-L.; Tan, Y.-P.; Zhu, C.; Chan, D.S.H.; Kang, E.-T.; Neoh, K.-G. A Flexible Polymer Memory Device. Org. Electron. 2007, 8, 401–406. [Google Scholar] [CrossRef]

- Wu, H.-C.; Liu, C.-L.; Chen, W.-C. Donor–Acceptor Conjugated Polymers of Arylene Vinylene with Pendent Phenanthro[9,10-d]Imidazole for High-Performance Flexible Resistor-Type Memory Applications. Polym. Chem. 2013, 4, 5261–5269. [Google Scholar] [CrossRef]

- Moiz, S.A.; Karimov, K.S.; Ahmed, M.M. Effect of Gravity Condition on Charge Transport Properties of Polymer Thin Film Deposited by Centrifigual Method. Optoelectron. Adv. Mater. Rapid Commun. 2011, 5, 577–580. [Google Scholar]

- Moiz, S.A.; Ahmed, M.M.; Karimov, K.H.S.; Mehmood, M. Temperature-Dependent Current–Voltage Characteristics of Poly-N-Epoxypropylcarbazole Complex. Thin Solid Film. 2007, 516, 72–77. [Google Scholar] [CrossRef]

- Chen, W.-C. Electrical Memory Materials and Devices; Polymer Chemistry Series; The Royal Society of Chemistry: London, UK, 2016. [Google Scholar] [CrossRef]

- Saitov, S.R.; Amasev, D.V.; Tameev, A.R.; Kazanskii, A.G. A Simple Approach for Determination of Density of States Distribution in an Organic Photoconductor. Org. Electron. 2020, 86, 105889. [Google Scholar] [CrossRef]

- Sun, Y.; Wen, D.; Sun, F. Influence of Blending Ratio on Resistive Switching Effect in Donor-Acceptor Type Composite of PCBM and PVK-Based Memory Devices. Org. Electron. 2019, 65, 141–149. [Google Scholar] [CrossRef]

- Jeong, D.S.; Thomas, R.; Katiyar, R.S.; Scott, J.F.; Kohlstedt, H.; Petraru, A.; Hwang, C.S. Emerging Memories: Resistive Switching Mechanisms and Current Status. Rep. Prog. Phys. 2012, 75, 076502. [Google Scholar] [CrossRef] [PubMed]

- Ling, Q.-D.; Liaw, D.-J.; Zhu, C.; Chan, D.S.-H.; Kang, E.-T.; Neoh, K.-G. Polymer Electronic Memories: Materials, Devices and Mechanisms. Prog. Polym. Sci. 2008, 33, 917–978. [Google Scholar] [CrossRef]

- Majumdar, H.S.; Bandyopadhyay, A.; Bolognesi, A.; Pal, A.J. Memory Device Applications of a Conjugated Polymer: Role of Space Charges. J. Appl. Phys. 2002, 91, 2433–2437. [Google Scholar] [CrossRef]

- Murari, N.M.; Hwang, Y.-J.; Kim, F.S.; Jenekhe, S.A. Organic Nonvolatile Memory Devices Utilizing Intrinsic Charge-Trapping Phenomena in an n-Type Polymer Semiconductor. Org. Electron. 2016, 31, 104–110. [Google Scholar] [CrossRef]

- Bozano, L.D.; Kean, B.W.; Beinhoff, M.; Carter, K.R.; Rice, P.M.; Scott, J.C. Organic Materials and Thin-Film Structures for Cross-Point Memory Cells Based on Trapping in Metallic Nanoparticles. Adv. Funct. Mater. 2005, 15, 1933–1939. [Google Scholar] [CrossRef]

- Moiz, S.A.; Ahmed, M.M.; Karimov, K.S. Estimation of Electrical Parameters of OD Organic Semiconductor Diode from Measured I-V Characteristics. ETRI J. 2005, 27, 319–325. [Google Scholar] [CrossRef]

- Karimov, K.S.; Ahmed, M.M.; Moiz, S.A.; Babadzhanov, P.; Marupov, R.; Turaeva, M.A. Electrical Properties of Organic Semiconductor Orange Nitrogen Dye Thin Films Deposited from Solution at High Gravity. Eurasian Chem. Technol. J. 2007, 5, 109–113. [Google Scholar] [CrossRef]

- Xu, X.; Li, L.; Liu, B.; Zou, Y. Organic Semiconductor Memory Devices Based on a Low-Band Gap Polyfluorene Derivative with Isoindigo as Electron-Trapping Moieties. Appl. Phys. Lett. 2011, 98, 063303. [Google Scholar] [CrossRef]

- Potember, R.S.; Poehler, T.O.; Cowan, D.O. Electrical Switching and Memory Phenomena in Cu-TCNQ Thin Films. Appl. Phys. Lett. 1979, 34, 405–407. [Google Scholar] [CrossRef]

- Karimov, K.S. Transversal Tensity Resistive Effect in TEA (TCNQ)2 Crystals. Synth. Met. 1991, 44, 103–106. [Google Scholar] [CrossRef]

- Karimov, K.S. Electrical Conductivity of TEA(TCNQ)2 Crystals under Uniaxial Tension and Compression. Solid State Commun. 1994, 89, 1029–1031. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Karimov, K.S.; Moiz, S.A. Temperature-Dependent I-V Characteristics of Organic-Inorganic Heterojunction Diodes. IEEE Trans. Electron. Devices 2004, 51, 121–126. [Google Scholar] [CrossRef]

- Erlbacher, T.; Jank, M.P.M.; Ryssel, H.; Frey, L.; Engl, R.; Walter, A.; Sezi, R.; Dehm, C. Self-Aligned Growth of Organometallic Layers for Nonvolatile Memories: Comparison of Liquid-Phase and Vapor-Phase Deposition. J. Electrochem. Soc. 2008, 155, H693. [Google Scholar] [CrossRef]

- Zhang, Q.; Kong, L.; Zhang, Q.; Wang, W.; Hua, Z. The Effect of Heat Treatment on Bistable Ag-TCNQ Thin Films. Solid State Commun. 2004, 130, 799–802. [Google Scholar] [CrossRef]

- Rose, A. Space-Charge-Limited Currents in Solids. Phys. Rev. 1955, 97, 1538–1544. [Google Scholar] [CrossRef]

- Campbell, A.J.; Bradley, D.D.C.; Lidzey, D.G. Space-Charge Limited Conduction with Traps in Poly(Phenylene Vinylene) Light Emitting Diodes. J. Appl. Phys. 1997, 82, 6326–6342. [Google Scholar] [CrossRef]

- Moiz, S.A.; Younis, W.A.; Yilmaz, K.S.K.E.-F. Space Charge–Limited Current Model for Polymers. In Conducting Polymers; Khan, I.A., Ed.; IntechOpen: Rijeka, Croatia, 2016; p. 5. [Google Scholar] [CrossRef]

- Toman, P.; Menšík, M.; Bartkowiak, W.; Pfleger, J. Modelling of the Charge Carrier Mobility in Disordered Linear Polymer Materials. Phys. Chem. Chem. Phys. 2017, 19, 7760–7771. [Google Scholar] [CrossRef] [PubMed]

- Shah, M.; Karimov, K.S.; Ahmad, Z.; Sayyad, M.H. Electrical Characteristics of A1/CNT/NiPc/PEPC/Ag Surface-Type Cell. Chin. Phys. Lett. 2010, 27, 106102. [Google Scholar] [CrossRef]

- Kadashchuk, A.; Weiss, D.S.; Borsenberger, P.M.; Ostapenko, N.; Zaika, V.; Skryshevski, Y. Effect of Extrinsic Traps on Thermally Stimulated Luminescence in Molecularly Doped Polymers. Synth. Met. 2000, 109, 177–180. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alahmadi, A.N.M.; Karimov, K.S. A Novel Poly-N-Epoxy Propyl Carbazole Based Memory Device. Polymers 2021, 13, 1594. https://doi.org/10.3390/polym13101594

Alahmadi ANM, Karimov KS. A Novel Poly-N-Epoxy Propyl Carbazole Based Memory Device. Polymers. 2021; 13(10):1594. https://doi.org/10.3390/polym13101594

Chicago/Turabian StyleAlahmadi, Ahmed. N. M., and Khasan S. Karimov. 2021. "A Novel Poly-N-Epoxy Propyl Carbazole Based Memory Device" Polymers 13, no. 10: 1594. https://doi.org/10.3390/polym13101594

APA StyleAlahmadi, A. N. M., & Karimov, K. S. (2021). A Novel Poly-N-Epoxy Propyl Carbazole Based Memory Device. Polymers, 13(10), 1594. https://doi.org/10.3390/polym13101594