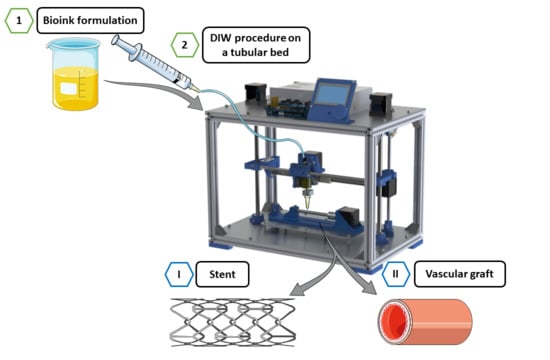

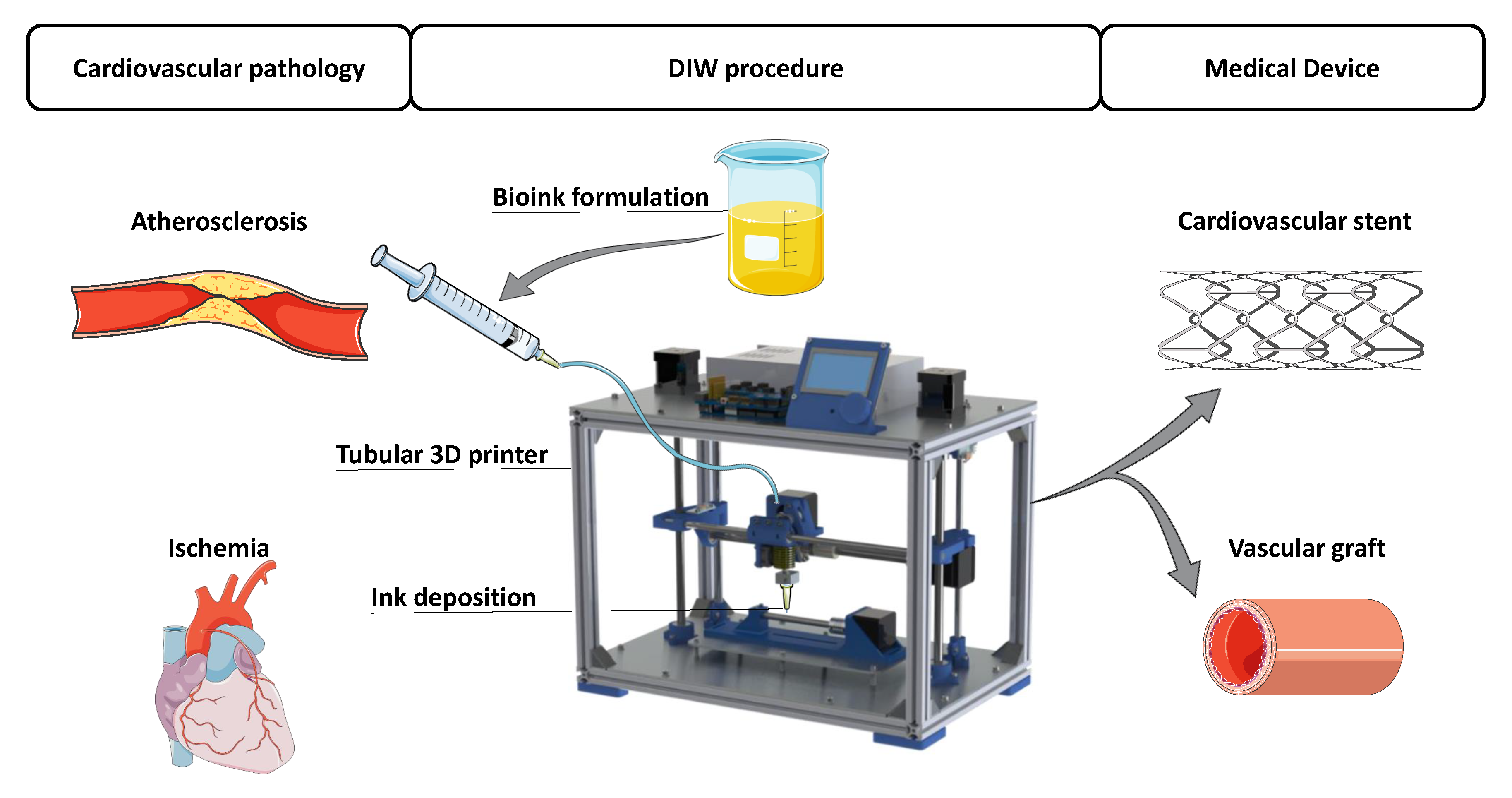

Continuous Based Direct Ink Write for Tubular Cardiovascular Medical Devices

Abstract

1. Introduction

2. Polymeric Material Features for Cardiovascular DIW

2.1. Rheological Properties

2.2. Storage Modulus and Loss Modulus Effect on Printing Resolution

3. Cardiovascular Tubular Applications

3.1. Vascular Graft

3.1.1. Silk as a Solution for Grafting Arteries

3.1.2. Cell Deposition to Fabricate Vascular Grafts

3.2. Stent

3.2.1. Ink Stents

3.2.2. Vascular Anastomosis Stent

4. Discussion

4.1. Cardiovascular Graft

4.1.1. Printing without Cells

4.1.2. Cell-Loaded Bioinks

4.2. Bioresorbable Stents from Bioinks

Vascular Anastomosis Stent

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DIW | Direct ink writing |

| SMC | Smooth muscle cell |

| EC | Endothelial cell |

| ECM | Extracellular matrix |

| PTFE | polytetrafluoroethylene |

| FDM | Fused Deposition Modeling |

| G’ | Storage Modulus |

| G” | Loss Modulus |

| Phase angle | |

| PCL | Polycaprolactone |

| PLA | Polylactic Acid |

References

- Crump, S.S. United States Patent (19) Crump (54) Apparatus and Method for Creating Three-Dimensional Objects. Technical Report. U.S. Patent 5,121,329, 9 June 1992. [Google Scholar]

- Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). In SpringerBriefs in Applied Sciences and Technology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, X.; Shen, Y.; Hang, R.; Zhang, X.; Wang, Y.; Yao, X.; Tang, B. Direct writing alginate bioink inside pre-polymers of hydrogels to create patterned vascular networks. J. Mater. Sci. 2019, 54, 7883–7892. [Google Scholar] [CrossRef]

- Marques, C.F.; Diogo, G.S.; Pina, S.; Oliveira, J.M.; Silva, T.H.; Reis, R.L. Collagen-based bioinks for hard tissue engineering applications: A comprehensive review. J. Mater. Sci. Mater. Med. 2019, 30, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Cesarano, J., III; Calvert, P.D. Freeforming Objects with Low-Binder Slurry. Technical Report. U.S. Patent 6027326, 28 October 1997. [Google Scholar]

- Shi, G.; Lowe, S.E.; Teo, A.J.; Dinh, T.K.; Tan, S.H.; Qin, J.; Zhang, Y.; Zhong, Y.L.; Zhao, H. A versatile PDMS submicrobead/graphene oxide nanocomposite ink for the direct ink writing of wearable micron-scale tactile sensors. Appl. Mater. Today 2019, 16, 482–492. [Google Scholar] [CrossRef]

- Rueschhoff, L.; Costakis, W.; Michie, M.; Youngblood, J.; Trice, R. Additive Manufacturing of Dense Ceramic Parts via Direct Ink Writing of Aqueous Alumina Suspensions. Int. J. Appl. Ceram. Technol. 2016, 13, 821–830. [Google Scholar] [CrossRef]

- Jordan, R.S.; Wang, Y. 3D printing of conjugated polymers. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 1592–1605. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Y.; Liu, J.; Zhao, J.; Zhang, H.; Zhang, Z. Shape memory epoxy composites with high mechanical performance manufactured by multi-material direct ink writing. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105903. [Google Scholar] [CrossRef]

- Ekbote, R.P.; Donley, G.J.; Liu, D.Y.; Rogers, S.A.; Krogstad, D.V. Re-entrant solid behavior of 3D-printable epoxy inks. Rheol. Acta 2020, 59, 631–638. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Xue, F.; Huang, Y.; Zhou, K.; Zhang, D. 3D printing of SiC ceramic: Direct ink writing with a solution of preceramic polymers. J. Eur. Ceram. Soc. 2018, 38, 5294–5300. [Google Scholar] [CrossRef]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of micrometric SiOC ceramic structures using a preceramic polymer. J. Eur. Ceram. Soc. 2016, 36, 1589–1594. [Google Scholar] [CrossRef]

- Franchin, G.; Wahl, L.; Colombo, P. Direct ink writing of ceramic matrix composite structures. J. Am. Ceram. Soc. 2017, 100, 4397–4401. [Google Scholar] [CrossRef]

- Zocca, A.; Franchin, G.; Elsayed, H.; Gioffredi, E.; Bernardo, E.; Colombo, P. Direct Ink Writing of a Preceramic Polymer and Fillers to Produce Hardystonite (Ca2ZnSi2O7) Bioceramic Scaffolds. J. Am. Ceram. Soc. 2016, 99, 1960–1967. [Google Scholar] [CrossRef]

- Cheng, Y.; Chan, K.H.; Wang, X.Q.; Ding, T.; Li, T.; Lu, X.; Ho, G.W. Direct-Ink-Write 3D Printing of Hydrogels into Biomimetic Soft Robots. ACS Nano 2019, 13, 13176–13184. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Parker, S.T.; Wang, X.; Kaplan, D.L.; Lewis, J.A. Direct-write assembly of microperiodic silk fibroin scaffolds for tissue engineering applications. Adv. Funct. Mater. 2008, 18, 1883–1889. [Google Scholar] [CrossRef]

- Nesaei, S.; Rock, M.; Wang, Y.; Kessler, M.R.; Gozen, A. Additive Manufacturing with Conductive, Viscoelastic Polymer Composites: Direct-Ink-Writing of Electrolytic and Anodic Poly(Ethylene Oxide) Composites. J. Manuf. Sci. Eng. Trans. ASME 2017, 139. [Google Scholar] [CrossRef]

- Dan, L.; Elias, A.L. Flexible and Stretchable Temperature Sensors Fabricated Using Solution-Processable Conductive Polymer Composites. Adv. Healthc. Mater. 2020, 9, 2000380. [Google Scholar] [CrossRef]

- Tong, Y.; Kucukdeger, E.; Halper, J.; Cesewski, E.; Karakozoff, E.; Haring, A.P.; McIlvain, D.; Singh, M.; Khandelwal, N.; Meholic, A.; et al. Low-cost sensor-integrated 3D-printed personalized prosthetic hands for children with amniotic band syndrome: A case study in sensing pressure distribution on an anatomical human-machine interface (AHMI) using 3D-printed conformal electrode arrays. PLoS ONE 2019, 14, e0214120. [Google Scholar] [CrossRef]

- Nesaei, S.; Song, Y.; Wang, Y.; Ruan, X.; Du, D.; Gozen, A.; Lin, Y. Micro additive manufacturing of glucose biosensors: A feasibility study. Anal. Chim. Acta 2018, 1043, 142–149. [Google Scholar] [CrossRef]

- Chen, B.; Jiang, Y.; Tang, X.; Pan, Y.; Hu, S. Fully Packaged Carbon Nanotube Supercapacitors by Direct Ink Writing on Flexible Substrates. ACS Appl. Mater. Interfaces 2017, 9, 28433–28440. [Google Scholar] [CrossRef]

- Ahlfeld, T.; Cidonio, G.; Kilian, D.; Duin, S.; Akkineni, A.R.; Dawson, J.I.; Yang, S.; Lode, A.; Oreffo, R.O.; Gelinsky, M. Development of a clay based bioink for 3D cell printing for skeletal application. Biofabrication 2017, 9, 034103. [Google Scholar] [CrossRef]

- Rezende, R.A.; Bártolo, P.J.; Mendes, A.; Filho, R.M. Rheological behavior of alginate solutions for biomanufacturing. J. Appl. Polym. Sci. 2009, 113, 3866–3871. [Google Scholar] [CrossRef]

- Ching, Y.C.; Ershad Ali, M.; Abdullah, L.C.; Choo, K.W.; Kuan, Y.C.; Julaihi, S.J.; Chuah, C.H.; Liou, N.S. Rheological properties of cellulose nanocrystal-embedded polymer composites: A review. Cellulose 2016, 23, 1011–1030. [Google Scholar] [CrossRef]

- Wenger, A. Development of a Hybrid Hydrogel Bio-Ink for 3D Printing of Biomimetic Tissue Constructs. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, May 2019. [Google Scholar]

- Bruneaux, J.; Therriault, D.; Heuzey, M.C. Micro-extrusion of organic inks for direct-write assembly. J. Micromech. Microeng. 2008, 18, 115020. [Google Scholar] [CrossRef]

- Fedorovich, N.E.; Alblas, J.; de Wijn, J.R.; Hennink, W.E.; Verbout, A.J.; Dhert, W.J. Hydrogels as Extracellular Matrices for Skeletal Tissue Engineering: State-of-the-Art and Novel Application in Organ Printing. Tissue Eng. 2007, 13, 1905–1925. [Google Scholar] [CrossRef] [PubMed]

- Farzin, A.; Miri, A.K.; Sharifi, F.; Faramarzi, N.; Jaberi, A.; Mostafavi, A.; Solorzano, R.; Zhang, Y.S.; Annabi, N.; Khademhosseini, A.; et al. 3D-Printed Sugar-Based Stents Facilitating Vascular Anastomosis. Adv. Healthc. Mater. 2018, 7, 1800702. [Google Scholar] [CrossRef] [PubMed]

- Ware, H.O.T.; Farsheed, A.C.; Akar, B.; Duan, C.; Chen, X.; Ameer, G.; Sun, C. High-speed on-demand 3D printed bioresorbable vascular scaffolds. Mater. Today Chem. 2018, 7, 25–34. [Google Scholar] [CrossRef]

- Habib, M.A.; Khoda, B. Development of clay based novel bio-ink for 3D bio-printing process. Procedia Manuf. 2018, 26, 846–856. [Google Scholar] [CrossRef]

- He, Y.; Yang, F.; Zhao, H.; Gao, Q.; Xia, B.; Fu, J. Research on the printability of hydrogels in 3D bioprinting. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef]

- Taylor, D.L.; in het Panhuis, M. Self-Healing Hydrogels. Adv. Mater. 2016, 28, 9060–9093. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress-a review or ’παντα ρϵι’-everything flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Homa, J.; Schwentenwein, M. A Novel Additive Manufacturing Technology for High-Performance Ceramics. In Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials; Wiley: Hoboken, NJ, USA, 2015; pp. 33–40. [Google Scholar] [CrossRef]

- Li, L.; Lin, Q.; Tang, M.; Duncan, A.J.E.; Ke, C. Advanced Polymer Designs for Direct-Ink-Write 3D Printing. Chem. Eur. J. 2019, 25, 10768–10781. [Google Scholar] [CrossRef]

- Franchin, G.; Maden, H.S.; Wahl, L.; Baliello, A.; Pasetto, M.; Colombo, P. Optimization and characterization of preceramic inks for Direct Ink Writing of Ceramic Matrix Composite structures. Materials 2018, 11, 515. [Google Scholar] [CrossRef] [PubMed]

- Tracy, E.P.; Gettler, B.C.; Zakhari, J.S.; Schwartz, R.J.; Williams, S.K.; Birla, R.K. 3D Bioprinting the Cardiac Purkinje System Using Human Adipogenic Mesenchymal Stem Cell Derived Purkinje Cells. Cardiovasc. Eng. Technol. 2020, 11, 587–604. [Google Scholar] [CrossRef] [PubMed]

- Kuthe, S. Multimaterial 3d Printing of a Mechanically Representative Aortic Model for the Testing of Novel Biomedical Implants. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2019. [Google Scholar]

- Gao, Q.; Liu, Z.; Lin, Z.; Qiu, J.; Liu, Y.; Liu, A.; Wang, Y.; Xiang, M.; Chen, B.; Fu, J.; et al. 3D Bioprinting of Vessel-like Structures with Multilevel Fluidic Channels. ACS Biomater. Sci. Eng. 2017, 3, 399–408. [Google Scholar] [CrossRef]

- Guerra, A.; Roca, A.; de Ciurana, J. A novel 3D additive manufacturing machine to biodegradable stents. Procedia Manuf. 2017, 13, 718–723. [Google Scholar] [CrossRef]

- SMART—Servier Medical ART. Available online: https://smart.servier.com/ (accessed on 1 December 2020).

- Zilla, P.; Bezuidenhout, D.; Human, P. Prosthetic vascular grafts: Wrong models, wrong questions and no healing. Biomaterials 2007, 28, 5009–5027. [Google Scholar] [CrossRef]

- Isenberg, B.C.; Williams, C.; Tranquillo, R.T. Small-diameter artificial arteries engineered in vitro. Circ. Res. 2006, 98, 25–35. [Google Scholar] [CrossRef]

- Seifu, D.G.; Purnama, A.; Mequanint, K.; Mantovani, D. Small-diameter vascular tissue engineering. Nat. Rev. Cardiol. 2013, 10, 410. [Google Scholar] [CrossRef]

- Xu, L.; Varkey, M.; Jorgensen, A.; Ju, J.; Jin, Q.; Park, J.H.; Fu, Y.; Zhang, G.; Ke, D.; Zhao, W.; et al. Bioprinting small diameter blood vessel constructs with an endothelial and smooth muscle cell bilayer in a single step. Biofabrication 2020, 12. [Google Scholar] [CrossRef]

- L’heureux, N.; Pâquet, S.; Labbé, R.; Germain, L.; Auger, F.A. A completely biological tissue-engineered human blood vessel. FASEB J. 1998, 12, 47–56. [Google Scholar] [CrossRef]

- Norotte, C.; Marga, F.S.; Niklason, L.E.; Forgacs, G. Scaffold-free vascular tissue engineering using bioprinting. Biomaterials 2009, 30, 5910–5917. [Google Scholar] [CrossRef]

- Skardal, A.; Zhang, J.; Prestwich, G.D. Bioprinting vessel-like constructs using hyaluronan hydrogels crosslinked with tetrahedral polyethylene glycol tetracrylates. Biomaterials 2010, 31, 6173–6181. [Google Scholar] [CrossRef] [PubMed]

- Kiritani, S.; Kaneko, J.; Ito, D.; Morito, M.; Ishizawa, T.; Akamatsu, N.; Tanaka, M.; Iida, T.; Tanaka, T.; Tanaka, R.; et al. Silk fibroin vascular graft: A promising tissue-engineered scaffold material for abdominal venous system replacement. Sci. Rep. 2020, 10. [Google Scholar] [CrossRef] [PubMed]

- Catto, V.; Farè, S.; Cattaneo, I.; Figliuzzi, M.; Alessandrino, A.; Freddi, G.; Remuzzi, A.; Tanzi, M.C. Small diameter electrospun silk fibroin vascular grafts: Mechanical properties, in vitro biodegradability, and in vivo biocompatibility. Mater. Sci. Eng. C 2015, 54, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Yagi, T.; Sato, M.; Nakazawa, Y.; Tanaka, K.; Sata, M.; Itoh, K.; Takagi, Y.; Asakura, T. Preparation of double-raschel knitted silk vascular grafts and evaluation of short-term function in a rat abdominal aorta. J. Artif. Organs 2011, 14, 89–99. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, K.; Mei, J.; Li, C.; Zhang, J.; Zheng, W.; An, D.; Xiao, N.; Zhao, Q.; Kong, D.; et al. Fabrication of highly interconnected porous silk fibroin scaffolds for potential use as vascular grafts. Acta Biomater. 2014, 10, 2014–2023. [Google Scholar] [CrossRef]

- Moriya, M.; Roschzttardtz, F.; Nakahara, Y.; Saito, H.; Masubuchi, Y.; Asakura, T. Rheological properties of native silk fibroins from domestic and wild silkworms, and flow analysis in each spinneret by a finite element method. Biomacromolecules 2009, 10, 929–935. [Google Scholar] [CrossRef]

- Rockwood, D.N.; Preda, R.C.; Yücel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef]

- Ma, X.; Cao, C.B.; Li, J.H.; Zhu, H.S. Novel Prosthesis Using Silk Fibroin for Small Caliber Vascular. Key Eng. Mater. 2005, 288–289, 461–464. [Google Scholar] [CrossRef]

- Unger, R.E.; Peters, K.; Wolf, M.; Motta, A.; Migliaresi, C.; Kirkpatrick, C.J. Endothelialization of a non-woven silk fibroin net for use in tissue engineering: Growth and gene regulation of human endothelial cells. Biomaterials 2004, 25, 5137–5146. [Google Scholar] [CrossRef]

- Lovett, M.; Eng, G.; Kluge, J.A.; Cannizzaro, C.; Vunjak-Novakovic, G.; Kaplan, D.L. Tubular silk scaffolds for small diameter vascular grafts. Organogenesis 2010, 6, 217–224. [Google Scholar] [CrossRef]

- Braun. VascuGraft PTFE. Available online: https://www.bbraun.co.uk/en/products/b0/vascugraft-ptfe.html (accessed on 1 December 2020).

- Dong, X.; Yuan, X.; Wang, L.; Liu, J.; Midgley, A.C.; Wang, Z.; Wang, K.; Liu, J.; Zhu, M.; Kong, D. Construction of a bilayered vascular graft with smooth internal surface for improved hemocompatibility and endothelial cell monolayer formation. Biomaterials 2018, 181, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, M.; Kluge, J.A.; Smoot, D.; Kluge, M.A.; Schmidt, D.F.; Paetsch, C.R.; Kim, P.S.; Kaplan, D.L. Fabricating mechanically improved silk-based vascular grafts by solution control of the gel-spinning process. Biomaterials 2020, 230. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhou, H.; Chairinnas. The synchronization among nozzle extrusion, nozzle speed and rotating speed based on 3D vessel bioprinter. In Proceedings of the 2016 International Conference on Instrumentation, Control, and Automation, (ICA 2016), Bandung, Indonesia, 29–31 August 2016; pp. 160–165. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, H.; Lan, H.; Liu, F.; Wang, X. Multinozzle Multichannel Temperature Deposition System for Construction of a Blood Vessel. SLAS Technol. 2018, 23, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhou, H.; Lan, H.; Liu, T.; Liu, X.; Yu, H. 3D printing of artificial blood vessel: Study on multi-parameter optimization design for vascular molding effect in alginate and gelatin. Micromachines 2017, 8, 237. [Google Scholar] [CrossRef] [PubMed]

- Bohari, S.P.; Hukins, D.W.; Grover, L.M. Effect of calcium alginate concentration on viability and proliferation of encapsulated fibroblasts. Bio-Med Mater. Eng. 2011, 21, 159–170. [Google Scholar] [CrossRef] [PubMed]

- Freeman, S.; Ramos, R.; Alexis Chando, P.; Zhou, L.; Reeser, K.; Jin, S.; Soman, P.; Ye, K. A bioink blend for rotary 3D bioprinting tissue engineered small-diameter vascular constructs. Acta Biomater. 2019, 95, 152–164. [Google Scholar] [CrossRef]

- Joo, J.Y.; Amin, M.L.; Rajangam, T.; An, S.S.A. Fibrinogen as a promising material for various biomedical applications. Mol. Cell. Toxicol. 2015, 11, 1–9. [Google Scholar] [CrossRef]

- Byrne, R.A.; Joner, M.; Kastrati, A. Stent thrombosis and restenosis: What have we learned and where are we going? the Andreas Grüntzig Lecture ESC 2014. Eur. Heart J. 2015, 36, 3320–3331. [Google Scholar] [CrossRef]

- Moore, S.S.; O’Sullivan, K.J.; Verdecchia, F. Shrinking the Supply Chain for Implantable Coronary Stent Devices. Ann. Biomed. Eng. 2016, 44, 497–507. [Google Scholar] [CrossRef]

- Guerra, A.J.; Cano, P.; Rabionet, M.; Puig, T.; Ciurana, J. 3D-printed PCL/PLA composite stents: Towards a new solution to cardiovascular problems. Materials 2018, 11, 1679. [Google Scholar] [CrossRef]

- Park, S.A.; Lee, S.J.; Lim, K.S.; Bae, I.H.; Lee, J.H.; Kim, W.D.; Jeong, M.H.; Park, J.K. In vivo evaluation and characterization of a bio-absorbable drug-coated stent fabricated using a 3D-printing system. Mater. Lett. 2015, 141, 355–358. [Google Scholar] [CrossRef]

- Jose, R.R.; Raja, W.K.; Ibrahim, A.M.; Koolen, P.G.; Kim, K.; Abdurrob, A.; Kluge, J.A.; Lin, S.J.; Beamer, G.; Kaplan, D.L. Rapid prototyped sutureless anastomosis device from self-curing silk bio-ink. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 1333–1343. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.; Nam, J.; Sun, W. Effects of dispensing pressure and nozzle diameter on cell survival from solid freeform fabrication-based direct cell writing. Tissue Eng. Part A. 2008, 14, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.; Groll, J.; Hutmacher, D.W. In 25th Anniversary Article: Engineering Hydrogels for Biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Wang, N.; Naruse, K.; Stamenović, D.; Fredberg, J.J.; Mijailovich, S.M.; Tolić-Nørrelykke, I.M.; Polte, T.; Mannix, R.; Ingber, D.E. Mechanical behavior in living cells consistent with the tensegrity model. Proc. Natl. Acad. Sci. USA 2001, 98, 7765–7770. [Google Scholar] [CrossRef]

- Bosio, V.E.; Brown, J.; Rodriguez, M.J.; Kaplan, D.L. Biodegradable porous silk microtubes for tissue vascularization. J. Mater. Chem. B 2017, 5, 1227–1235. [Google Scholar] [CrossRef]

- Zhao, D.; Zhou, R.; Sun, J.; Li, H.; Jin, Y. Experimental study of polymeric stent fabrication using homemade 3D printing system. Polym. Eng. Sci. 2019, 59, 1122–1131. [Google Scholar] [CrossRef]

- Li, C.; Guo, C.; Fitzpatrick, V.; Ibrahim, A.; Zwierstra, M.J.; Hanna, P.; Lechtig, A.; Nazarian, A.; Lin, S.J.; Kaplan, D.L. Design of biodegradable, implantable devices towards clinical translation. Nat. Rev. Mater. 2020, 5, 61–81. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Tijssen, R.Y.; van der Schaaf, R.J.; Kraak, R.P.; Vink, M.A.; Hofma, S.H.; Arkenbout, E.K.; Weevers, A.P.; Kerkmeijer, L.S.; Onuma, Y.; Serruys, P.W.; et al. Clinical outcomes at 2 years of the Absorb bioresorbable vascular scaffold versus the Xience drug-eluting metallic stent in patients presenting with acute coronary syndrome versus stable coronary disease—AIDA trial substudy. Catheter. Cardiovasc. Interv. 2020, 95, 89–96. [Google Scholar] [CrossRef]

- Hoare, D.; Bussooa, A.; Neale, S.; Mirzai, N.; Mercer, J. The Future of Cardiovascular Stents: Bioresorbable and Integrated Biosensor Technology. Adv. Sci. 2019, 6, 1900856. [Google Scholar] [CrossRef] [PubMed]

- Erne, P.; Schier, M.; Resink, T.J. The road to bioabsorbable stents: Reaching clinical reality? Cardiovasc. Interv. Radiol. 2006, 29, 11–16. [Google Scholar] [CrossRef] [PubMed]

| Polymer | Solvent | Application | ∼G’-G’’ Difference (Pa) | ∼G’’/G’ Ratio | Print Fidelity |

|---|---|---|---|---|---|

| Polyacrylamide and 6.5 wt% sodium alginate | Water | Hydraulic Artificial Tentacle [15] | 2000 | 0.5 | 4 |

| Polyacrylamide and 1.7 wt% sodium alginate | Water | No application [15] | 200 | 0.5 | 2 |

| poly(methyl-silsesquioxane), SiC and Carbon fibers | Isopropanol | Conductive viscoelastic composite [36] | 5000 | 0.75 | 3 |

| poly(methyl-silsesquioxane), fumed silica, SiC and Carbon fibers | Isopropanol | Conductive viscoelastic composite [36] | 5000 | 0.38 | 4 |

| Polymethylsilsesquioxane, fumed silica, ZnO and CaCO3 | Isopropanol | Bioceramic scaffolds for bone tissue [14] | 2000 | 0.33 | 4 |

| Polymethylsilsesquioxane, fumed silica, ZnO, CaCO3 and hardystonite filler | Isopropanol | Bioceramic scaffolds for bone tissue [14] | 1300 | 0.35 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casanova-Batlle, E.; Guerra, A.J.; Ciurana, J. Continuous Based Direct Ink Write for Tubular Cardiovascular Medical Devices. Polymers 2021, 13, 77. https://doi.org/10.3390/polym13010077

Casanova-Batlle E, Guerra AJ, Ciurana J. Continuous Based Direct Ink Write for Tubular Cardiovascular Medical Devices. Polymers. 2021; 13(1):77. https://doi.org/10.3390/polym13010077

Chicago/Turabian StyleCasanova-Batlle, Enric, Antonio J. Guerra, and Joaquim Ciurana. 2021. "Continuous Based Direct Ink Write for Tubular Cardiovascular Medical Devices" Polymers 13, no. 1: 77. https://doi.org/10.3390/polym13010077

APA StyleCasanova-Batlle, E., Guerra, A. J., & Ciurana, J. (2021). Continuous Based Direct Ink Write for Tubular Cardiovascular Medical Devices. Polymers, 13(1), 77. https://doi.org/10.3390/polym13010077