Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Design of Concrete Beams

2.2. Sizes and Amount of Raw Materials of Beams

2.3. Life Cycle Assessment

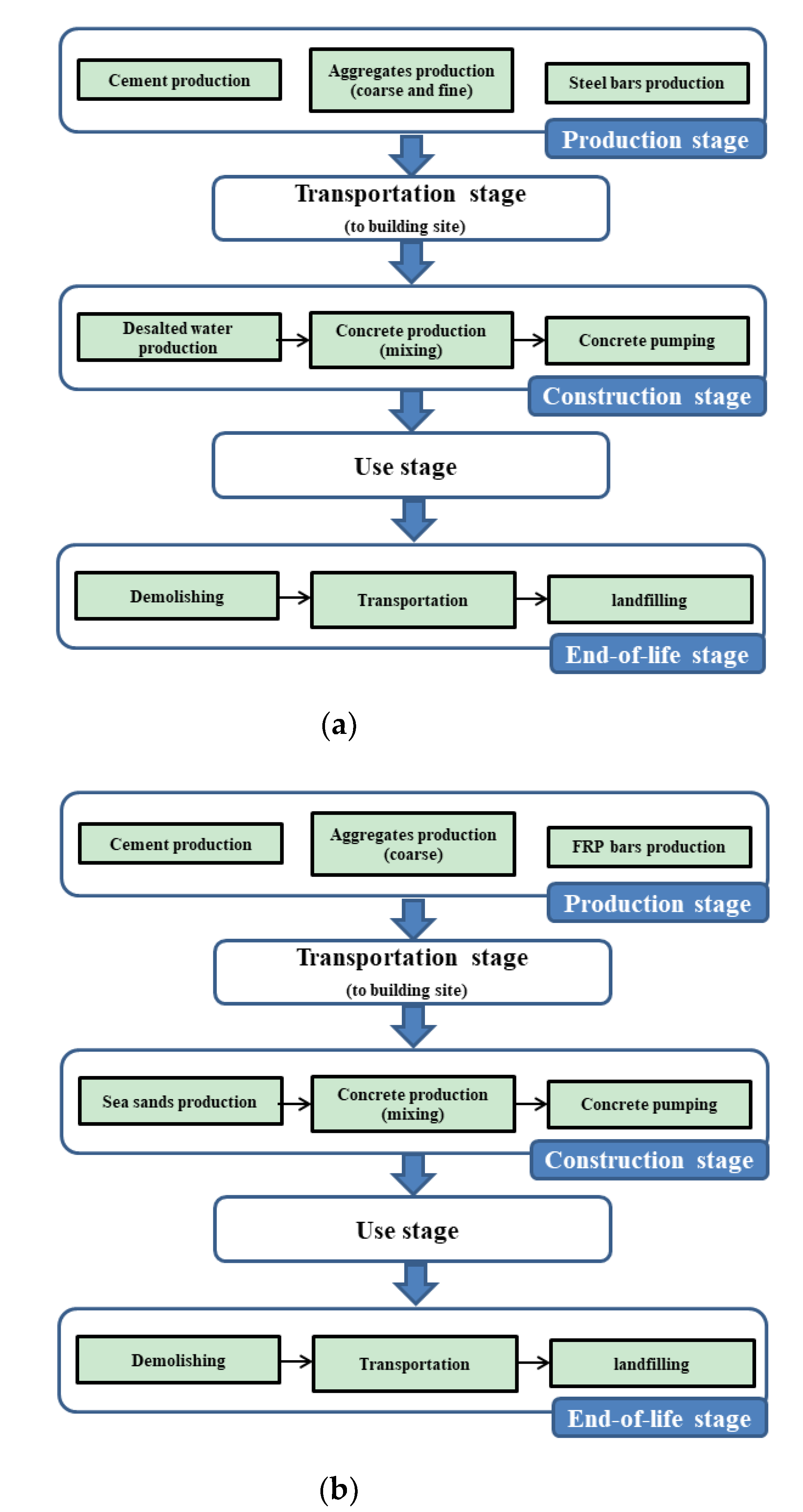

2.3.1. Goal and Scope Definition

2.3.2. Life Cycle Inventory Analysis (LCI)

2.3.3. Life Cycle Impact Assessment (LCIA)

2.3.4. Interpretation

2.3.5. Sensitivity Analysis

3. Results and Discussion

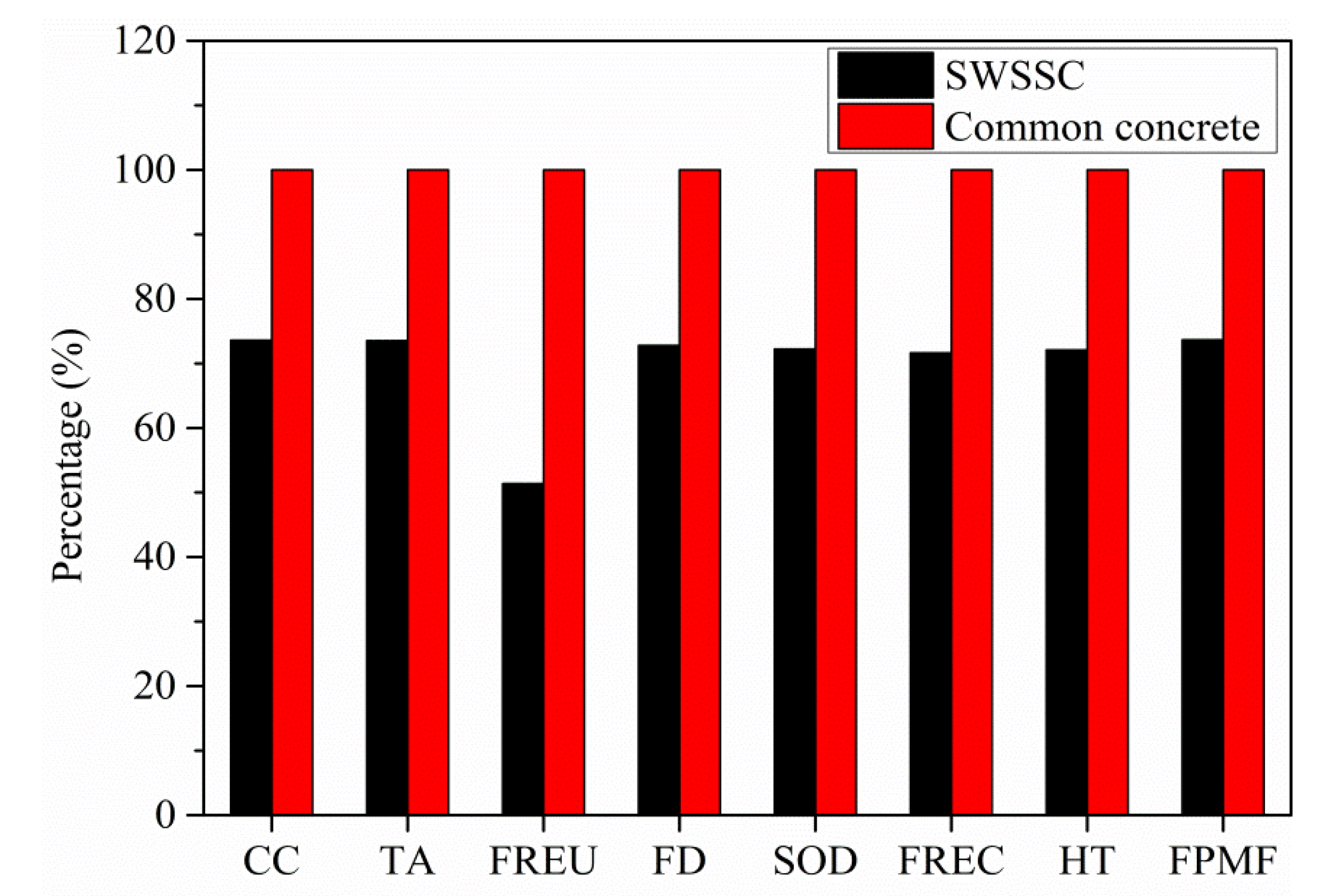

3.1. Environmental Impacts of SWSSC and Common Concrete of 1 Cubic Meter

3.2. Effects of Transportation Distance on the Environmental Impacts of Three Beams

3.3. Effects of Service Life on the Environmental Impacts of the Three Beams

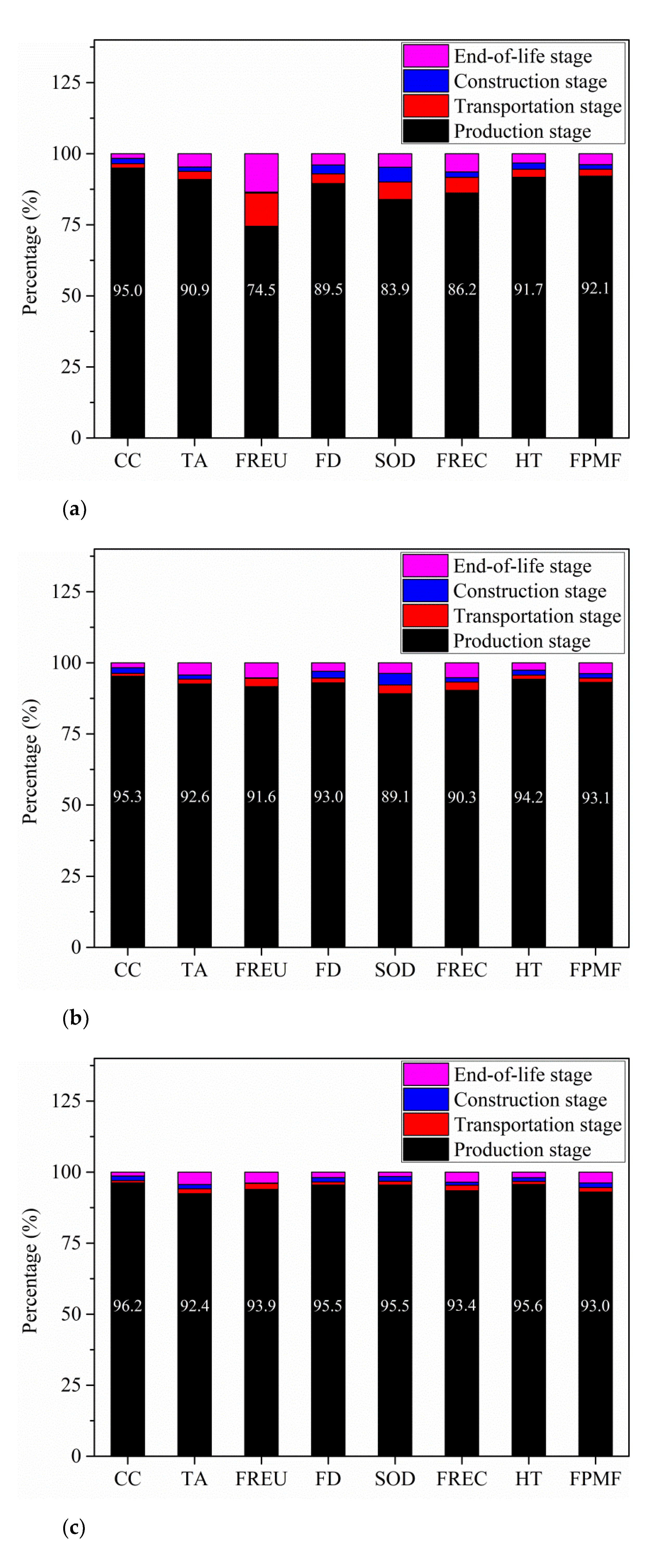

3.4. Environmental Impacts Contribution Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Clear cover of reinforcement or FRP bars [mm] |

| db | Diameter of reinforcing bar [mm] |

| fc’ | Specified compressive strength [MPa] |

References

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Adel, Y.; Usama, A.E.; Antonio, N. Applicability of using seawater accompanied by FRP reinforcement in concrete structures: A perspective. In Proceedings of the Ninth International Structural Engineering and Construction Conference, Valencia, Spain, 24–29 July 2017. [Google Scholar]

- Ministry of housing and urban rural development of the people’s Republic of China. JGJ 206-2010 Technical Specification for Sea Sand Concrete; China Architecture & Building Press: Beijing, Chian, 2010. (In Chinese)

- Tao, Y.; Jinguang, T.; Jianguo, D.; Guangming, C. FRP composites in new construction: Current status and opportunities. In Proceedings of the Infrastructure (Supplementary Issue of Industrial Construction), 7th National Conference on FRP Composition, Hangzhou, China, 15–16 October 2011. [Google Scholar]

- Feng, P.; Wang, J.; Zhang, X.; Ye, L. Development and innovation on combining FRP and seasand concrete forstructures (in Chinese). Fiber Reinf. Plast. Compos. 2014, 12, 13–18. [Google Scholar]

- Chenggao, L.; Guijun, X.; Hui, L. Tension-tension fatigue performance of a large-diameter pultruded carbon/glass hybrid rod. Int. J. Fatigue 2019, 120, 141–149. [Google Scholar] [CrossRef]

- Chenggao, L.; Guijun, X.; Hui, L. Effect of postcuring immersed in water under hydraulic pressure on fatigue performance of large-diameter pultruded carbon/glass hybrid rod. Fatigue Fract. Eng. 2019, 42, 1148–1160. [Google Scholar] [CrossRef]

- Chenggao, L.; Guijun, X. Design optimization and experimental validation of a novel wedge-shaped bond anchorage system for prestressed CFRP plates. Polym. Test. 2019, 75, 167–174. [Google Scholar] [CrossRef]

- Charles, E.B. Life cycle analysis issues in the use of FRP composites in civil infrastructure. In Proceedings of the US-Japan Workshop on Life Cycle Assessment of Sustainable Infrastructure Materials, Sapporo, Japan, 21–22 October 2009. [Google Scholar]

- Ayesha, S.; Al Mamun, M.A.; Wahid, F.; Rayed, A. Performances, challenges and opportunities in strengthening reinforced concrete structures by using FRPs—A state-of-the-art review. Eng. Fail. Anal. 2020, 111, 104480. [Google Scholar] [CrossRef]

- Metallurgical Construction Association. GB 50608-2010 Technical Code for Infrastructure Application of FRP Composites; China Planning Press: Beijing, Chian, 2010. (In Chinese) [Google Scholar]

- American Concrete Institute. ACI 440.1R-2015 Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bar; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Japan Society of Civil Engineers. Recommendation for Design and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; Japan Society of Civil Engineers: Tokyo, Japan, 1997. [Google Scholar]

- Canadian Standards Association. CSA-S806-12—Design and Construction of Building Components with Fibre-Reinforced Polymers; Canadian Standards Association: Toronto, ON, Canada, 2012. [Google Scholar]

- Jianzhuang, X.; Chengbing, Q.; Antonio, N.; Kaijian, Z. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr. Build. Mater. 2017, 156, 985–1004. [Google Scholar] [CrossRef]

- Guo, F.; Singh Raman, R.K.; Al-Saadi, S.; Zhao, X. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment. Corros. Sci. 2018, 141, 1–13. [Google Scholar] [CrossRef]

- Zhiqiang, D.; Gang, W.; Xiao-Ling, Z.; Hong, Z.; Jin-Long, L. Durability test on the flexural performance of seawater sea-sand concrete beams completely reinforced with FRP bars. Constr. Build. Mater. 2018, 192, 671–682. [Google Scholar] [CrossRef]

- Zike, W.; Xiao-Ling, Z.; Guijun, X.; Gang, W.; Singh Raman, R.K.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar] [CrossRef]

- Allan, M.; Ginghis, M.; Brahim, B.; Patrice, C.; Omar, A.; Wahid, F.; Ray, L.; Gangarao, H. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhao, X.L.; Singh Raman, R.K.; Al-Saadi, S. Tests on seawater and sea sand concrete-filled CFRP, BFRP and stainless steel tubular stub columns. Thin Walled Struct. 2016, 108, 163–184. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhao, X.L.; Singh Raman, R.K.; Al-Saadi, S. Experimental study on seawater and sea sand concrete filled GFRP and stainless steel tubular stub columns. Thin Walled Struct. 2016, 106, 390–406. [Google Scholar] [CrossRef]

- Li, Y.L.; Teng, J.G.; Zhao, X.L.; Singh Raman, R.K. Theoretical model for seawater and sea sand concrete-filled circular FRP tubular stub columns under axial compression. Eng. Struct. 2018, 160, 71–84. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14040 Environmental Management-Life Cycle Assessment-Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044 Environmental Management-Life Cycle Assessment-Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Ignacio, Z.B.; Antonio, V.C.; Alfonso, A.U. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Pouya, S.; Adélio, M.; Vítor, L.; João, M.G.; Nuno, C. A sustainability assessment of advanced materials for novel housing solutions. Build. Environ. 2015, 92, 182–191. [Google Scholar] [CrossRef]

- Gian, A.B. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Yovanna, E.V.B.; José, M.G.S.; María, C.G.S.; Fernando, L.G. An Epitome of Building Floor Systems by Means of LCA Criteria. Sustainability 2020, 12, 5442. [Google Scholar] [CrossRef]

- Diana, C.G.G.; José, M.G.S.; Ramón, C.H.; Héctor, S.M.; María, C.G.S.; Susana, P.A.R. A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements. Sustainability 2018, 10, 2748. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 318-2014 Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- American Concrete Institute. ACI 440.5M-2008 Specification for Construction with Fiber-Reinforced Polymer Reinforcing Bars; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- American Concrete Institute. ACI 440.6M-08 Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- American Concrete Institute. ACI211.1-91 (Reapproved 2009) Standard Practice for Selecting Proportion for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- GaBi Software. Available online: http://www.gabi-software.com/china/gabi/ (accessed on 25 June 2020).

- Sebastian, G.M.; Nicolae, T. 24—Life Cycle Analysis of Strengthening Concrete Beams with FRP; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar] [CrossRef]

- Alp, Ö.; Zerrin, G.; Aysun, Ö.; Orbay, E.; Muammer, B.; Müfide, B. Life cycle Assessment of Steel Rebar Production with Induction Melting Furnace: Case Study in Turkey. J. Hazard. Toxic Radioact. Waste 2018, 22, 04017027.1–04017027.6. [Google Scholar] [CrossRef]

- Worrell, E.; van Heijningen, R.J.J.; de Castro, J.F.M.; Hazewinkel, J.H.O.; de Beer, J.G.; Faaij, A.P.C.; Vringer, K. New gross energy requirement figures for material production. Energy 1994, 19, 627–640. [Google Scholar] [CrossRef]

- Leif, G.; Roger, S. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 2006, 41, 940–951. [Google Scholar] [CrossRef]

- Sjunnesson, J. Life Cycle Assessment of Concrete; Department of Technology and Society, Lund University: Lund, Sweden, 2005. [Google Scholar]

- Tetsuya, S.; Jun, T. Prediction of energy intensity of carbon fiber reinforced plastics for mass-produced passenger car. In Proceedings of the 9th Japan international SAMPE symposium, Tokyo, Japan, 29 November–2 December 2005; pp. 9–14. [Google Scholar]

- Tae-goun, K. Efficient management of marine resources in conflict: An empirical study of marine sand mining, Korea. J. Environ. Manag. 2009, 91, 78–86. [Google Scholar] [CrossRef]

- Fanhou, Z. Design Technology and Application of 250 Square per Hour Sand and Pebble Mining Vessel. Ship Ocean. Eng. 1980, 1, 48–55. (In Chinese) [Google Scholar]

- Balance Table of Electricity. Available online: http://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 25 June 2020).

- Visintin, P.; Xie, T.; Bennett, B. A large-scale life-cycle assessment of recycled aggregate concrete: The influence of functional unit, emissions allocation and carbon dioxide uptake. J. Clean. Prod. 2020, 248, 1–18. [Google Scholar] [CrossRef]

- Rawaz, K.; José, D.S.; de Jorge, B. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Maziar, F.; Marwa, M.H.; Natalie, D.; Tyson, R. Evaluation of the reuse and recycling of drill cuttings in concrete applications. Constr. Build. Mater. 2018, 164, 400–409. [Google Scholar] [CrossRef]

- Bruno, E.; José, D.S.; de Jorge, B.; Manuel, D.P. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Tao, D.; Jianzhuang, X.; Vivian, W.Y.T. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Marinkovic, S.B.; Ignjatović, I.S.; Radonjanin, V. 23—Life-Cycle Assessment (LCA) of Concrete with Recycled Aggregates (RAs); Woodhead Publishing: Sawston, UK, 2013. [Google Scholar] [CrossRef]

- Halvard, E.; Nystrom, S.E.; Watkins, A.N.; Susan, M. Financial Viability of Fiber-Reinforced Polymer (FRP) Bridges. J. Manag. Eng. 2003, 19, 2–8. [Google Scholar] [CrossRef]

| Requirements | SRC Beam | FRP-SWSSC Beams |

|---|---|---|

| Minimum C/mm | 63.5 1 | 40 2 |

| Minimum inside bend diameter of 90-degreee hook stirrups/mm | 4 db for bar size from 9.52 to 15.88 3 | 6 db 4 |

| Minimum straight extension of stirrups/mm | Greater of 6db and 76.2 for bar size from 9.52 to 15.88 3 | 12 db 4 |

| Minimum distance between tension reinforcements/mm | Greatest of 25.4, db, and (4/3) dagg 5 | Greatest of 25.4, db, and (4/3) dagg 5 |

| Minimum fc’/MPa | 35 6 | 17.23 7 |

| Maximum water cement ratio | 0.4 6 | None |

| Item | Unit | SRC Beam | GFRP-SWSSC Beam | CFRP-SWSSC Beams |

|---|---|---|---|---|

| Width of rectangular cross section | mm | 270 | 240 | 210 |

| Overall height of flexural member | mm | 540 | 480 | 420 |

| Diameter of tension bar | mm | 19.05 | 25.4 | 19.1 |

| Diameter of stirrups | mm | 9.52 | 6.4 | 6.4 |

| C | mm | 64 | 40 | 40 |

| fc’ | MPa | 35 | 21 | 21 |

| Water cement ratio | - | 0.4 | 0.54 | 0.54 |

| Steel bar | kg | 34.30 | - | - |

| Glass fiber | kg | - | 10.21 | - |

| Carbon fiber | kg | - | - | 3.11 |

| Epoxy resin | kg | - | 4.01 | 1.70 |

| Cement | kg | 296.64 | 172.12 | 132.74 |

| Desalted water | kg | 118.65 | - | - |

| Sea water | kg | - | 92.94 | 71.68 |

| Sea sand | kg | - | 347.07 | 267.67 |

| Aggregates | kg | 939.88 | 450.31 | 347.29 |

| Environmental Impact Category | Unit | SWSSC | Common Concrete |

|---|---|---|---|

| CC | kg CO2 eq. | 292 | 397 |

| TA | kg SO2 eq. | 0.43 | 0.59 |

| FREU | kg P eq. | 6.63 × 10−5 | 1.29 × 10−4 |

| FD | kg oil eq. | 33.75 | 46.37 |

| SOD | kg CFC-11 eq. | 2.04 × 10−5 | 2.82 × 10−5 |

| FREC | kg 1,4 DB eq. | 1.21 × 10−2 | 1.69 × 10−2 |

| HT | kg 1,4-DB eq. | 3.64 × 10−2 | 5.05 × 10−2 |

| FPMF | kg PM2.5 eq. | 0.16 | 0.22 |

| Environmental Impact Category | Unit | SRC Beam | GFRP-SWSSC Beam | CFRP-SWSSC Beam |

|---|---|---|---|---|

| CC | kg CO2 eq. | 256.26 | 189.39 | 181.71 |

| TA | kg SO2 eq. | 0.41 | 0.35 | 0.26 |

| FREU | kg P eq. | 1.67 × 10−4 | 3.29 × 10−4 | 3.46 × 10−4 |

| FD | kg oil eq. | 35.47 | 36.51 | 43.55 |

| SOD | kg CFC-11 eq. | 2.55 × 10−5 | 2.53 × 10−5 | 4.67 × 10−5 |

| FREC | kg 1,4 DB eq. | 1.25 × 10−2 | 1.20 × 10−2 | 1.35 × 10−2 |

| HT | kg 1,4-DB eq. | 3.44 × 10−2 | 3.36 × 10−2 | 3.41 × 10−2 |

| FPMF | kg PM2.5 eq. | 0.15 | 0.12 | 9.05 × 10−2 |

| Environmental Impact Category | Unit | SRC Beam | GFRP-SWSSC Beam | CFRP-SWSSC Beam |

|---|---|---|---|---|

| CC | kg CO2 eq. | 252.99 | 187.40 | 180.19 |

| TA | kg SO2 eq. | 0.40 | 0.34 | 0.25 |

| FREU | kg P eq. | 1.50 × 10−4 | 3.19 × 10−4 | 3.38 × 10−4 |

| FD | kg oil eq. | 34.44 | 35.88 | 43.08 |

| SOD | kg CFC-11 eq. | 2.41 × 10−5 | 2.45 × 10−5 | 4.61 × 10−5 |

| FREC | kg 1,4 DB eq. | 1.20 × 10−2 | 1.16 × 10−2 | 1.32 × 10−2 |

| HT | kg 1,4-DB eq. | 3.35 × 10−2 | 3.31 × 10−2 | 3.37 × 10−2 |

| FPMF | kg PM2.5 eq. | 0.15 | 0.12 | 8.90 × 10−2 |

| Environmental Impact Category | Unit | SRC Beam | GFRP-SWSSC Beam | CFRP-SWSSC Beam |

|---|---|---|---|---|

| CC | kg CO2 eq. | 266.53 | 195.23 | 186.16 |

| TA | kg SO2 eq. | 0.44 | 0.36 | 0.27 |

| FREU | kg P eq. | 2.18 × 10−4 | 3.59 × 10−4 | 3.68 × 10−4 |

| FD | kg oil eq. | 38.69 | 38.34 | 44.95 |

| SOD | kg CFC-11 eq. | 2.97 × 10−5 | 2.77 × 10−5 | 4.86 × 10−5 |

| FREC | kg 1,4 DB eq. | 1.44 × 10−2 | 1.30 × 10−2 | 1.43 × 10−2 |

| HT | kg 1,4-DB eq. | 3.69 × 10−2 | 3.51 × 10−2 | 3.52 × 10−2 |

| FPMF | kg PM2.5 eq. | 0.16 | 0.13 | 9.47 × 10−2 |

| Environmental Impact Category | Unit | SRC Beam | GFRP-SWSSC Beam | CFRP-SWSSC Beam |

|---|---|---|---|---|

| CC | kg CO2 eq. | 399.79 | 195.23 | 186.16 |

| TA | kg SO2 eq. | 0.66 | 0.36 | 0.27 |

| FREU | kg P eq. | 3.27 × 10−4 | 3.59 × 10−4 | 3.68 × 10−4 |

| FD | kg oil eq. | 58.04 | 38.34 | 44.95 |

| SOD | kg CFC-11 eq. | 4.45 × 10−5 | 2.77 × 10−5 | 4.86 × 10−5 |

| FREC | kg 1,4 DB eq. | 2.16 × 10−2 | 1.30 × 10−2 | 1.43 × 10−2 |

| HT | kg 1,4-DB eq. | 5.54 × 10−2 | 3.51 × 10−2 | 3.52 × 10−2 |

| FPMF | kg PM2.5 eq. | 0.24 | 0.13 | 9.47 × 10−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Li, C.; Xian, G. Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study. Polymers 2021, 13, 154. https://doi.org/10.3390/polym13010154

Dong S, Li C, Xian G. Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study. Polymers. 2021; 13(1):154. https://doi.org/10.3390/polym13010154

Chicago/Turabian StyleDong, Shaoce, Chenggao Li, and Guijun Xian. 2021. "Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study" Polymers 13, no. 1: 154. https://doi.org/10.3390/polym13010154

APA StyleDong, S., Li, C., & Xian, G. (2021). Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study. Polymers, 13(1), 154. https://doi.org/10.3390/polym13010154