Influence of Humidity on Fatigue Performance of CFRP: A Molecular Simulation

Abstract

1. Introduction

2. Material and Model Method

2.1. Force Field

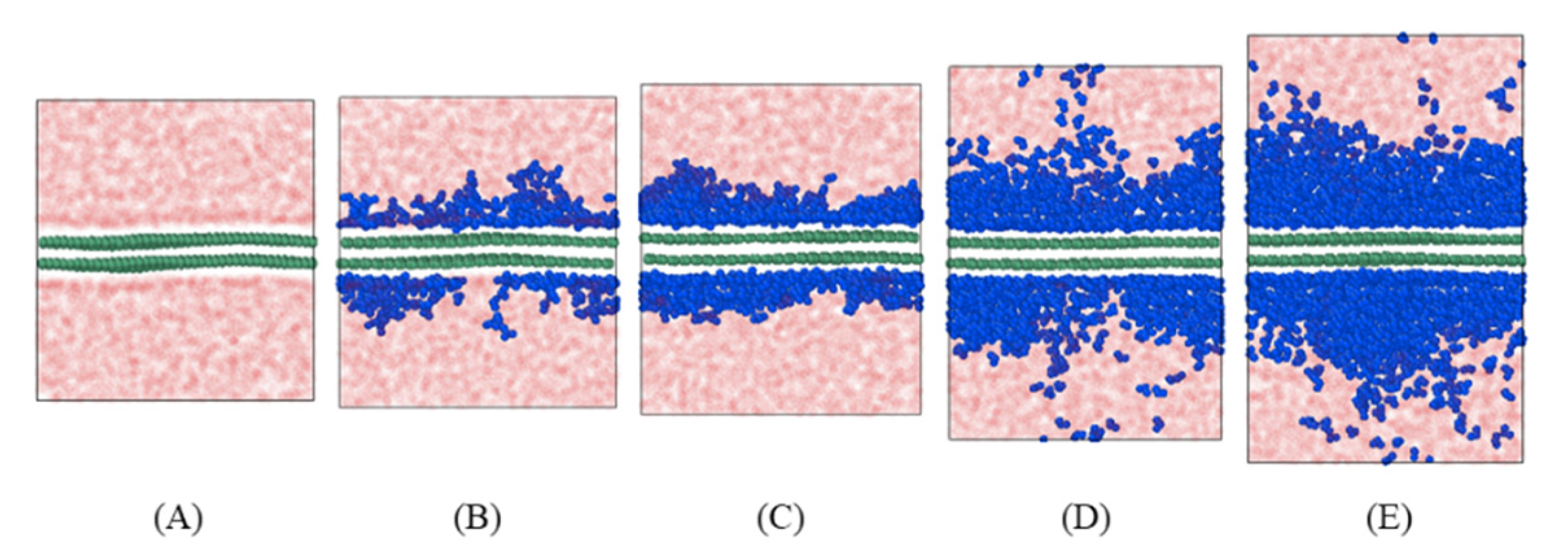

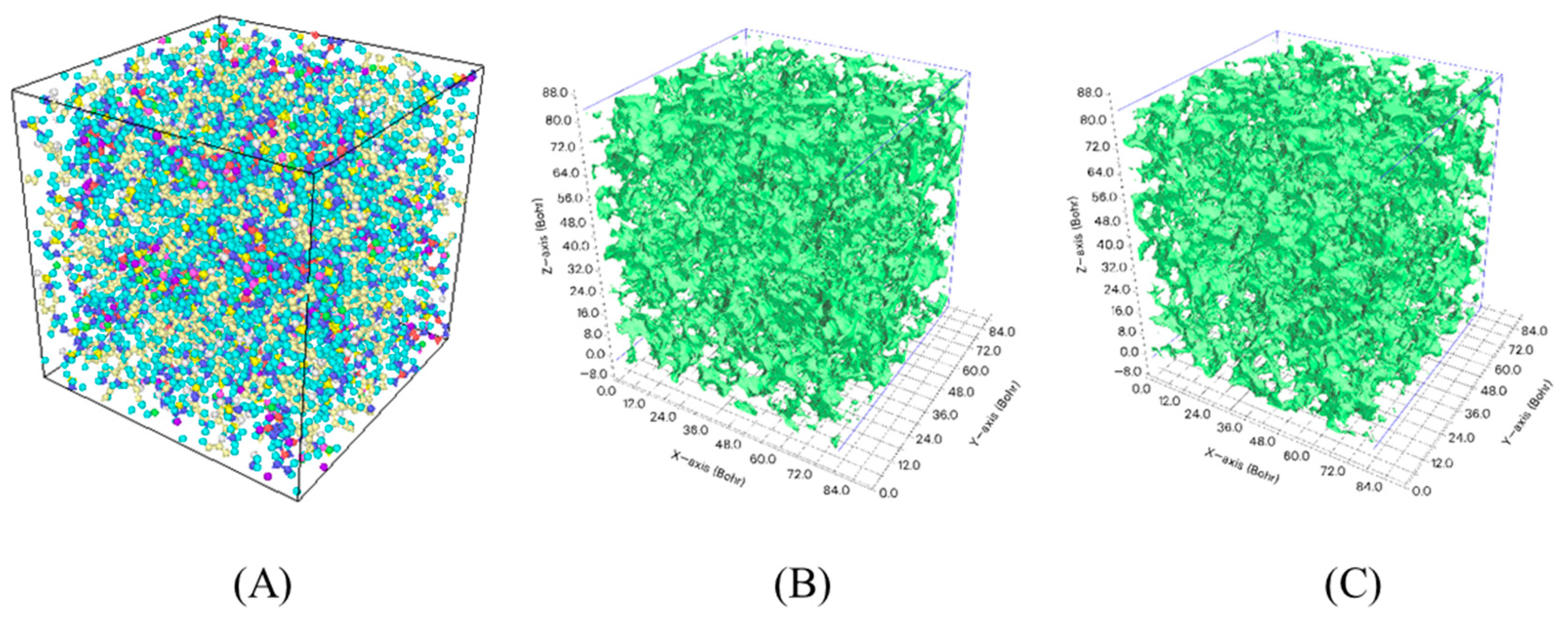

2.2. Materials and Molecular Model

2.2.1. Crosslinked Epoxy Resin and Its Composites

2.2.2. Equilibrium

3. Results and Discussion

3.1. Uniaxial Tensile

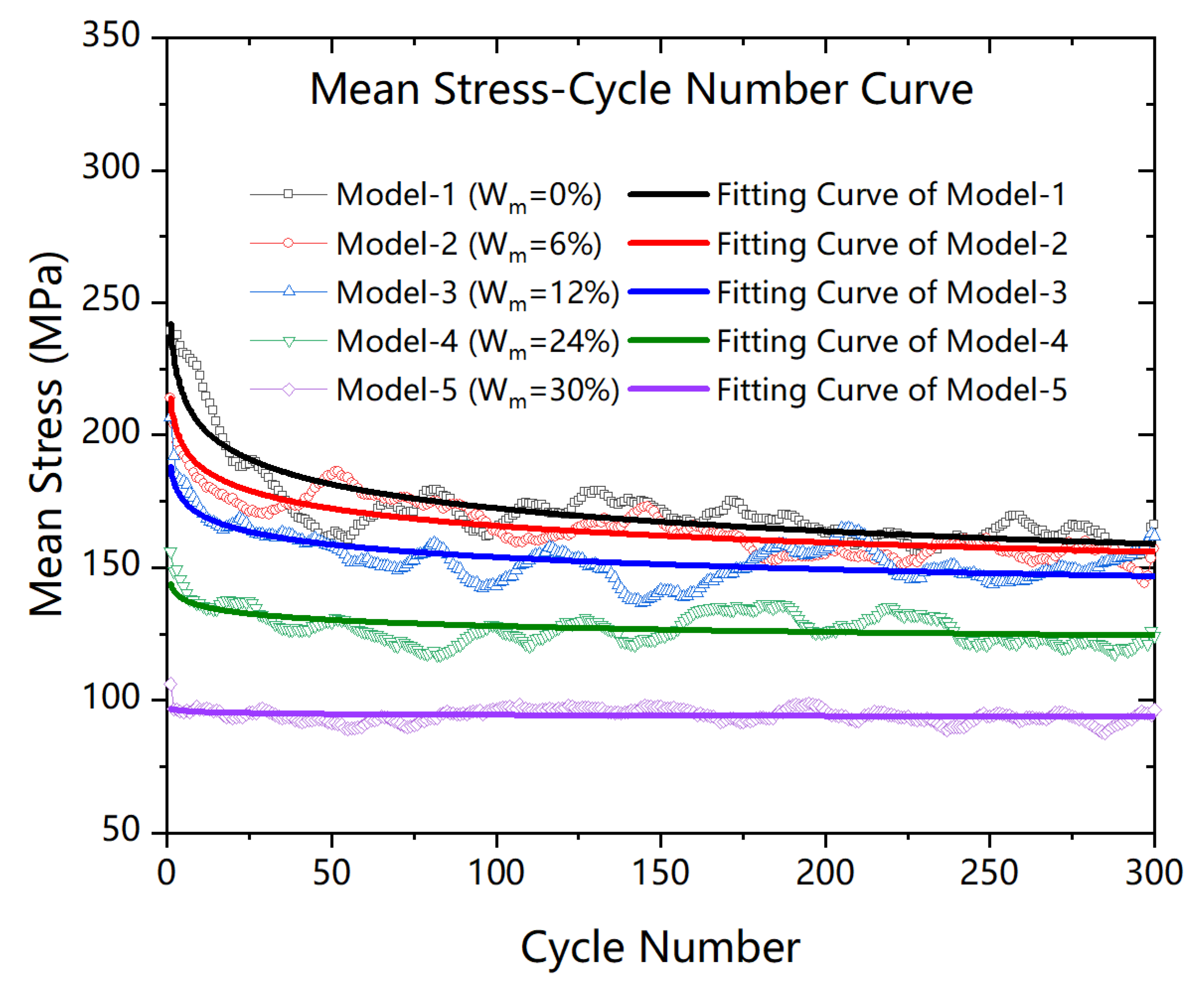

3.2. Tensile-Tensile Fatigue

3.3. Energy Analysis

3.3.1. Individual Potential Energy

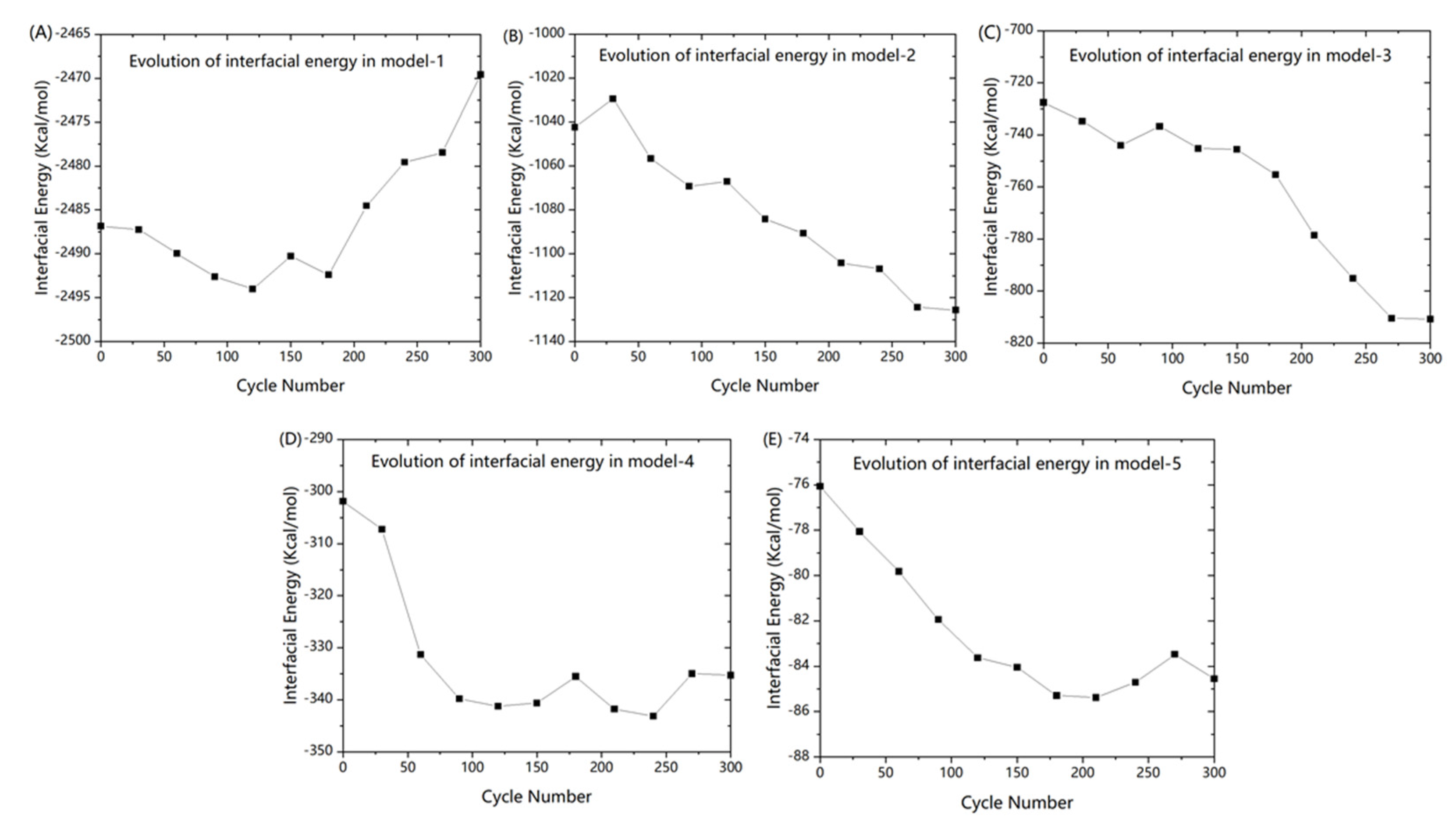

3.3.2. Interfacial Energy

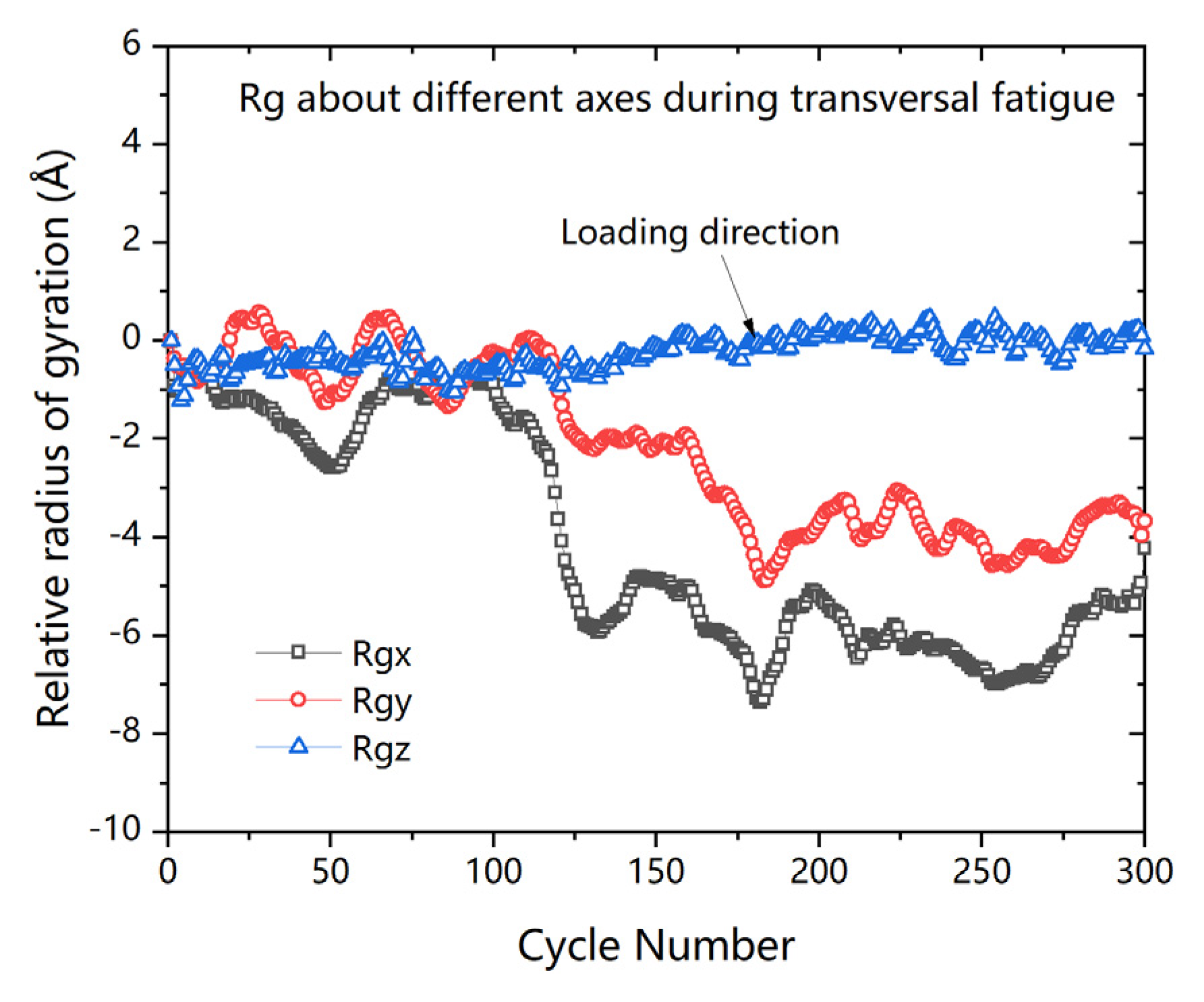

3.4. Micro-Structure Analysis

4. Conclusions

- (1)

- Presence of water in the polymer-graphene interface weakened the stiffness and interfacial adhesive performance in the vertical fiber direction. Higher humidity led to a weakened stiffness and adhesive performance.

- (2)

- During the process of transversal fatigue, molecular fragments tended to align along the loading direction leading to performance degradation. With regards to microscopic energy, this phenomenon is primarily reflected by the decline of van der Waals, while in terms of macroscopic performance, it is mainly reflected by the decrease in mean stress.

- (3)

- During the process of fatigue, interfacial energy of dry system decreased with the cycle numbers. This phenomenon indicates that the distance became larger. However, different results and increase in interfacial energy were observed in the wet system. To understand this phenomenon, another molecular model consisting of pure epoxy resin was established and the free volume of the model before fatigue and after fatigue were relatively calculated. Free volume amplified slightly after fatigue. Increase in the free volume in epoxy resin made it easy for the water molecules to diffuse into the inside of epoxy resin. The diffusion of water molecules reduced the water layer in the polymer-graphene. The thinner water layer led to a stronger interfacial adhesion properties. This conclusion can be confirmed by the evolution of interfacial energy and the mean squared displacement of the epoxy resin and water molecules during fatigue. Besides, interfacial energy of the dry system decreased with the cycle numbers. This phenomenon indicates that the distance became larger.

- (4)

- Higher humidity led to a slower rate of performance degradation during fatigue as the performance degraded fast in first several cycles and less prominently in the last several cycles. The performance of composites with high humidity was so poor that no more significant degradation occurred. However, performance continues to decrease because molecular arrangement is the main cause of the performance degradation, even if the interfacial performance improved slightly. In addition, initial performance and rate of performance degradation show a linear relationship with the change of moisture content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brod, M.; Dean, A.; Scheffler, S.; Gerendt, C.; Rolfes, R. Numerical modeling and experimental validation of fatigue damage in cross-ply CFRP composites under inhomogeneous stress states. Compos. Part B Eng. 2020, 200, 108050. [Google Scholar] [CrossRef]

- Tsigkourakos, G.; Silberschmidt, V.V.; Ashcroft, I.A. Damage analysis of CFRP under impact fatigue. Shock Vib. 2012, 19, 573–584. [Google Scholar] [CrossRef][Green Version]

- Huang, J.; Li, C.; Liu, W. Investigation of internal friction and fracture fatigue entropy of CFRP laminates with various stacking sequences subjected to fatigue loading. Thin Walled Struct. 2020, 155, 106978. [Google Scholar] [CrossRef]

- Wei, Q.; Zhu, L.; Zhu, J.; Zhuo, L.; Hao, W.; Xie, W. Characterization of impact fatigue damage in CFRP composites using nonlinear acoustic resonance method. Compos. Struct. 2020, 253, 112804. [Google Scholar] [CrossRef]

- Bowkett, M.; Thanapalan, K. Comparative analysis of failure detection methods of composites materials’ systems. Syst. Sci. Control Eng. 2017, 5, 168–177. [Google Scholar] [CrossRef]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Bradaigh, C.M.O. The fatigue of carbon fibre reinforced plastics—A review. Composites 2019, 166, 555–579. [Google Scholar] [CrossRef]

- Withers, P.J.; Preuss, M. Fatigue and damage in structural materials studied by X-ray tomography. Annu. Rev. Mater. Res. 2012, 42, 81–103. [Google Scholar] [CrossRef]

- Skinner, T.; Datta, S.; Chattopadhyay, A.; Asha, H. Fatigue damage behavior in carbon fiber polymer composites under biaxial loading. Compos. Part B Eng. 2019, 174, 106942. [Google Scholar] [CrossRef]

- Tao, G.; Xia, Z. An experimental study of uniaxial fatigue behavior of an epoxy resin by a new noncontact real-time strain measurement and control system. Polym. Eng. Sci. 2010, 47, 780–788. [Google Scholar] [CrossRef]

- Tao, G.; Xia, Z. Mean stress/strain effect on fatigue behavior of an epoxy resin. Int. J. Fatigue 2007, 29, 2180–2190. [Google Scholar] [CrossRef]

- Shen, X.; Xia, Z.; Ellyin, F. Cyclic deformation behavior of an epoxy polymer. Part I: Experimental investigation. Polym. Eng. Sci. 2010, 44, 2240–2246. [Google Scholar] [CrossRef]

- Clark, T.R.; Hertzberg, R.W.; Mohammadi, N. Fatigue mechanisms in poly (methyl methacrylate) at threshold: Effects of molecular weight and mean stress. J. Mater. Sci. 1993, 28, 5161–5168. [Google Scholar] [CrossRef]

- Ma, B.; Feng, Y.; He, Y.; Zhang, T.; Zhang, S.; Zhang, T. Effect of hygrothermal environment on the tension–tension fatigue performance and reliable fatigue life of T700/MTM46 composite laminates. J. Zhejiang Univ. Sci. A 2019, 20, 499–514. [Google Scholar] [CrossRef]

- Yoshi, T.; Okubo, K.; Fujii, T. Stiffness reduction of woven CFRP and CFRTP spring under ultra high cyclic fatigue for vibration conveyor. Adv. Mater. Res. 2010, 123–125, 217–220. [Google Scholar] [CrossRef]

- Galvez, P.; Armentia SL, D.; Abenojar, J.; Martinez, M.A. Effect of moisture and temperature on thermal and mechanical properties of structural polyurethane adhesive joints. Compos. Struct. 2020, 247, 112443. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, P.; Yao, G.; Guo, X.; Yang, Y.; Li, W.; Wu, B. Experimental study on fatigue performance of RC beams strengthened with CFRP under variable amplitude overload and hot-wet environment. Compos. Struct. 2020, 244, 112308. [Google Scholar] [CrossRef]

- Qin, G.; Huang, P.; Zhou, H.; Guo, X.; Zheng, X. Fatigue and durability behavior of RC beams strengthened with CFRP under hot-wet environment. Constr. Build. Mater. 2016, 111, 735–742. [Google Scholar] [CrossRef]

- Wang, Y.L.; Guo, X.Y.; Huang, P.Y.; Huang, K.N.; Yang, Y.; Chen, Z.B. Finite element investigation of fatigue performance of CFRP-strengthened beams in hygrothermal environments. Compos. Struct. 2019, 234, 111676. [Google Scholar] [CrossRef]

- Yu, S.; Yang, S.; Cho, M. Multi-scale modeling of cross-linked epoxy nanocomposites. Polym. Lond. 2009, 50, 945–952. [Google Scholar] [CrossRef]

- Yadav, A.; Kumar, A.; Singh, P.K.; Sharma, K. Glass transition temperature of functionalized graphene epoxy composites using molecular dynamics simulation. Integr. Ferroelectr. 2018, 186, 106–114. [Google Scholar] [CrossRef]

- Choi, J.; Yu, S.; Yang, S.; Cho, M. The glass transition and thermoelastic behavior of epoxy-based nanocomposites: A molecular dynamics study. Polymer 2011, 52, 5197–5203. [Google Scholar] [CrossRef]

- Arab, B.; Shokuhfar, A. Molecular dynamics simulation of cross-linked epoxy polymers: The effect of force field on the estimation of properties. J. Nano Electron. Phys. 2013, 5, 298–303. [Google Scholar]

- Sahputra, I.H.; Echtermeyer, A.T. Creep-fatigue relationship in polymer: Molecular dynamics simulations approach. Macromol. Theory Simul. 2015, 24, 65–73. [Google Scholar] [CrossRef]

- Sahputra, I.H.; Echtermeyer, A.T. Molecular dynamics simulations of strain-controlled fatigue behaviour of amorphous polyethylene. J. Polym. Res. 2014, 21. [Google Scholar] [CrossRef]

- Bao, Q.; Yang, Z.; Lu, Z. Molecular dynamics simulation of amorphous polyethylene (PE) under cyclic tensile-compressive loading below the glass transition temperature. Polymer 2020, 186, 121968. [Google Scholar] [CrossRef]

- Li, C.; Jaramillo, E.; Strachan, A. Molecular dynamics simulations on cyclic deformation of an epoxy thermoset. Polymer 2013, 54, 881–890. [Google Scholar] [CrossRef]

- Rigigleman, R.A.; Schweizer, K.S.; Poblo, J.J.D. Nonlinear creep in a polymer glass. Marcromolecules 2008, 41, 4969–4977. [Google Scholar] [CrossRef]

- Jian, W.; Lau, D. Creep performance of CNT-based nanocomposites: A parametric study. Carbon 2019, 153, 745–756. [Google Scholar] [CrossRef]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of shrinkage reducing admixture on the new-to-old concrete interface. Compos. Part B Eng. 2018, 169, 346–355. [Google Scholar] [CrossRef]

- Li, C.; Browning, A.R.; Christensen, S.; Strachan, A. Atomistic simulations on multilayer graphene reinforced epoxy composites. Compos. Part A 2012, 43, 1293–1300. [Google Scholar] [CrossRef]

- Moeini, M.; Barbaz Isfahani, R.; Saber-Samandari, S.; Aghdam, M.M. Molecular dynamics simulations of the effect of temperature and strain rate on mechanical properties of graphene–epoxy nanocomposites. Mol. Simul. 2020, 46, 1–11. [Google Scholar] [CrossRef]

- Mallick, P.K.; Zhou, Y. Effect of mean stress on stress-controlled fatigue of a short E-glass fiber reinforced polyamide-6,6. Int. J. Fatigue 2004, 26, 941–946. [Google Scholar] [CrossRef]

- Kwofie, S. An exponential stress function for predicting fatigue strength and life due to mean stresses. Int. J. Fatigue 2001, 23, 829–836. [Google Scholar] [CrossRef]

- Shang, T.S.; Zhao, M.; Chen, Y.H. Low cycle fatigue life prediction method based on threeparameter power function. J. Propuls. Technol. 2015, 36, 907–911. [Google Scholar]

| Type | LJ Epsilon/Sigma of O | LJ Epsilon/Sigma of H | K/r0 of OH Bond | K/theta of HOH Angle |

|---|---|---|---|---|

| Parameters | 0.102/3.188 | 0.0/0.0 | 450/0.9572 | 55/104.52 |

| Model-1 | Model-2 | Model-3 | Model-4 | Model-5 | |

|---|---|---|---|---|---|

| Moisture content (%) | 0 | 6% | 12% | 24% | 30% |

| Final density (g/cm3) | 1.316 | 1.298 | 1.276 | 1.209 | 1.150 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Chen, J.; Lv, Y.; Huang, L.; Zhang, X. Influence of Humidity on Fatigue Performance of CFRP: A Molecular Simulation. Polymers 2021, 13, 140. https://doi.org/10.3390/polym13010140

Li B, Chen J, Lv Y, Huang L, Zhang X. Influence of Humidity on Fatigue Performance of CFRP: A Molecular Simulation. Polymers. 2021; 13(1):140. https://doi.org/10.3390/polym13010140

Chicago/Turabian StyleLi, Bowen, Jianzhong Chen, Yong Lv, Li Huang, and Xiaoyu Zhang. 2021. "Influence of Humidity on Fatigue Performance of CFRP: A Molecular Simulation" Polymers 13, no. 1: 140. https://doi.org/10.3390/polym13010140

APA StyleLi, B., Chen, J., Lv, Y., Huang, L., & Zhang, X. (2021). Influence of Humidity on Fatigue Performance of CFRP: A Molecular Simulation. Polymers, 13(1), 140. https://doi.org/10.3390/polym13010140