Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software

Abstract

1. Introduction

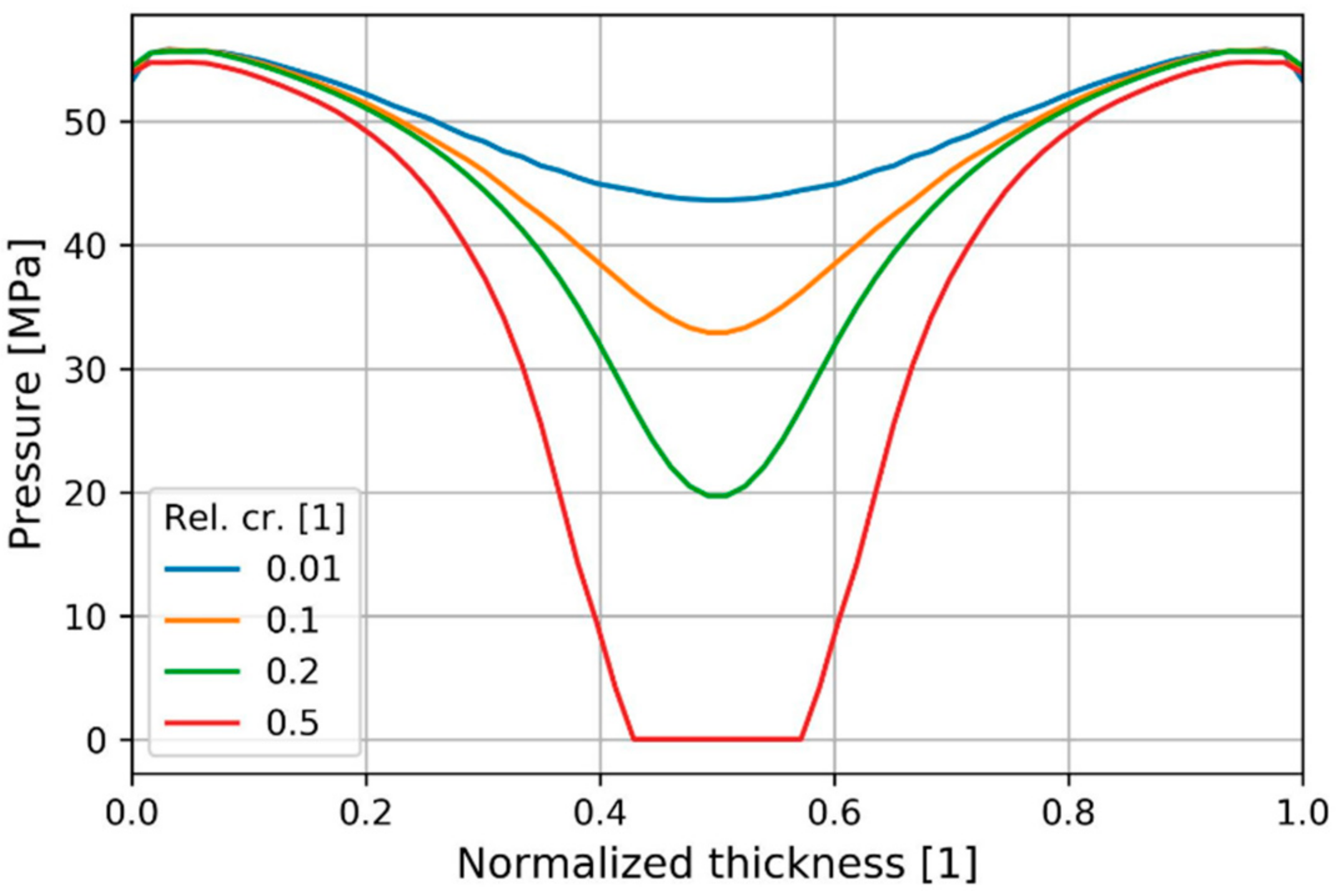

- Promote research collaboration by sharing an open-source code solution for injection molding crystallization modeling;

- Investigate crystallization modeling of HDPE and the related material data;

- Provide insight into the thermomechanical development.

2. Materials and Methods

2.1. Experimental Investigation

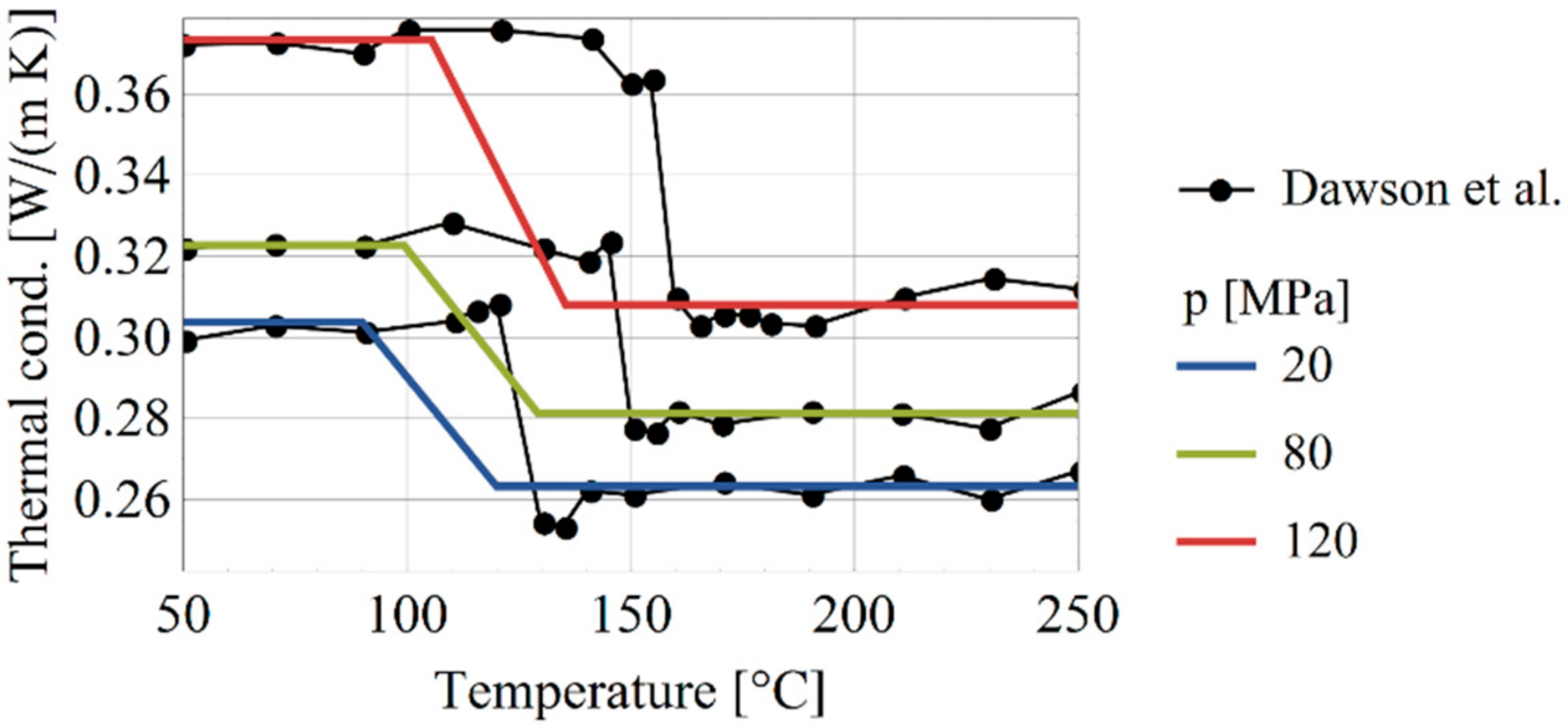

2.2. HDPE Thermal and Volumetric Behavior

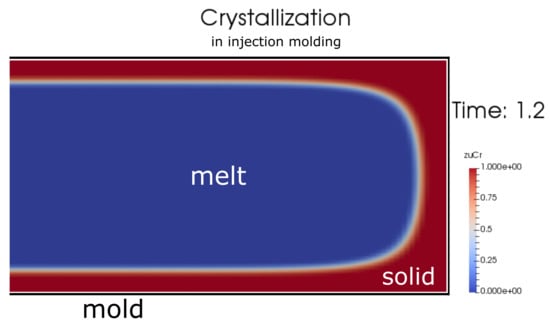

2.2.1. Crystallization

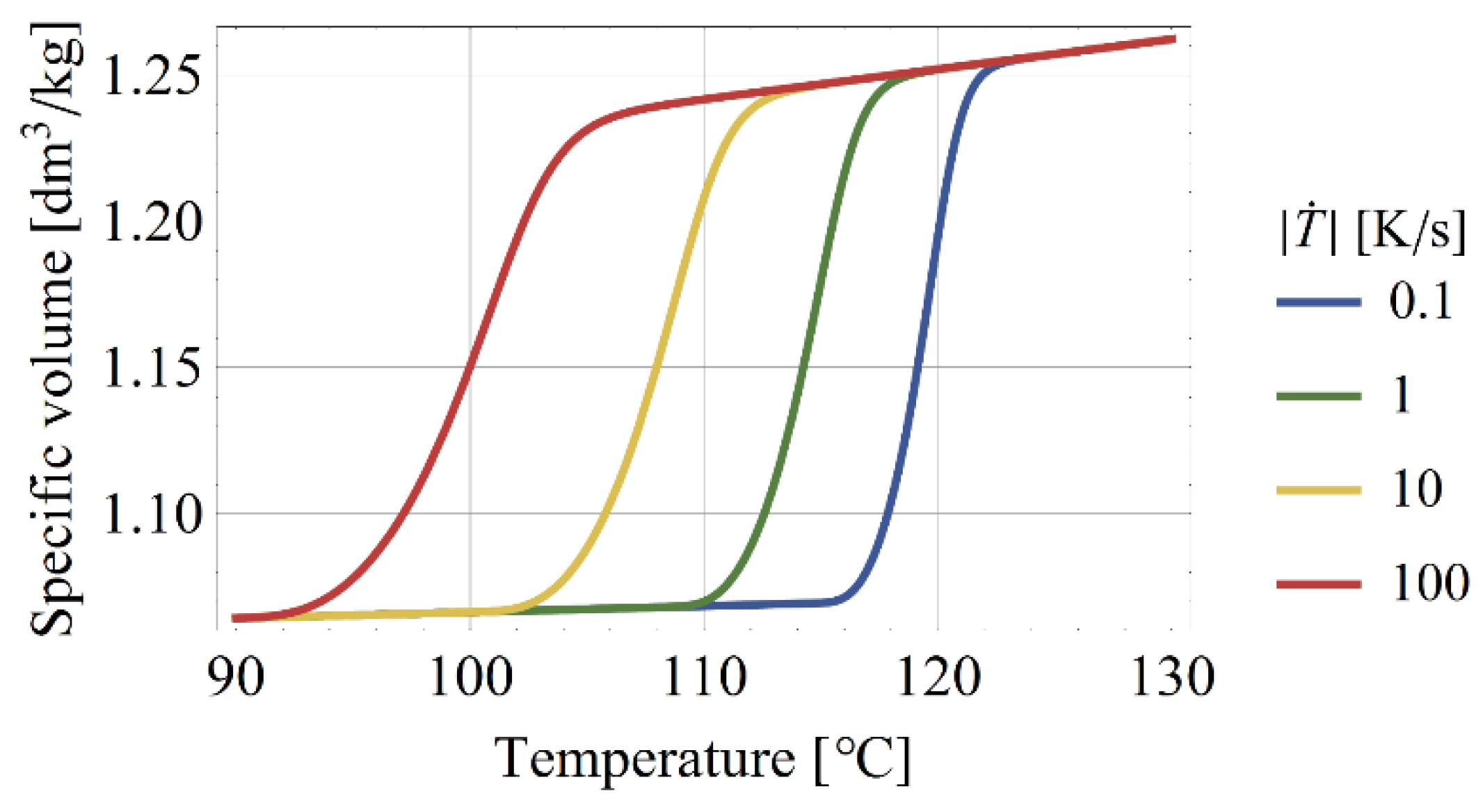

2.2.2. Specific Volume

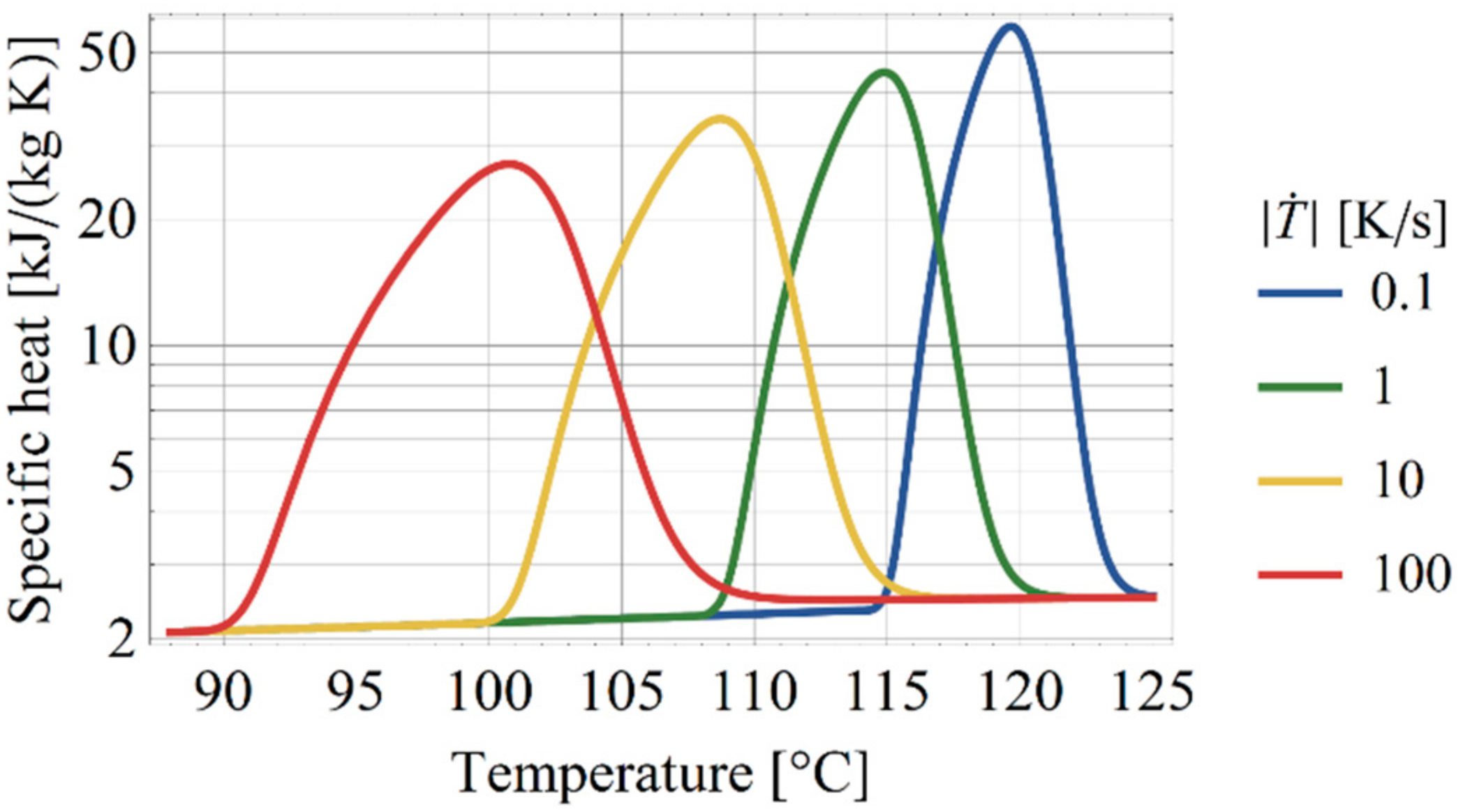

2.2.3. Specific Heat

2.3. Injection Molding Model Formulation

2.3.1. Conservation Equations

2.3.2. Viscosity

2.3.3. Constitutive Modeling

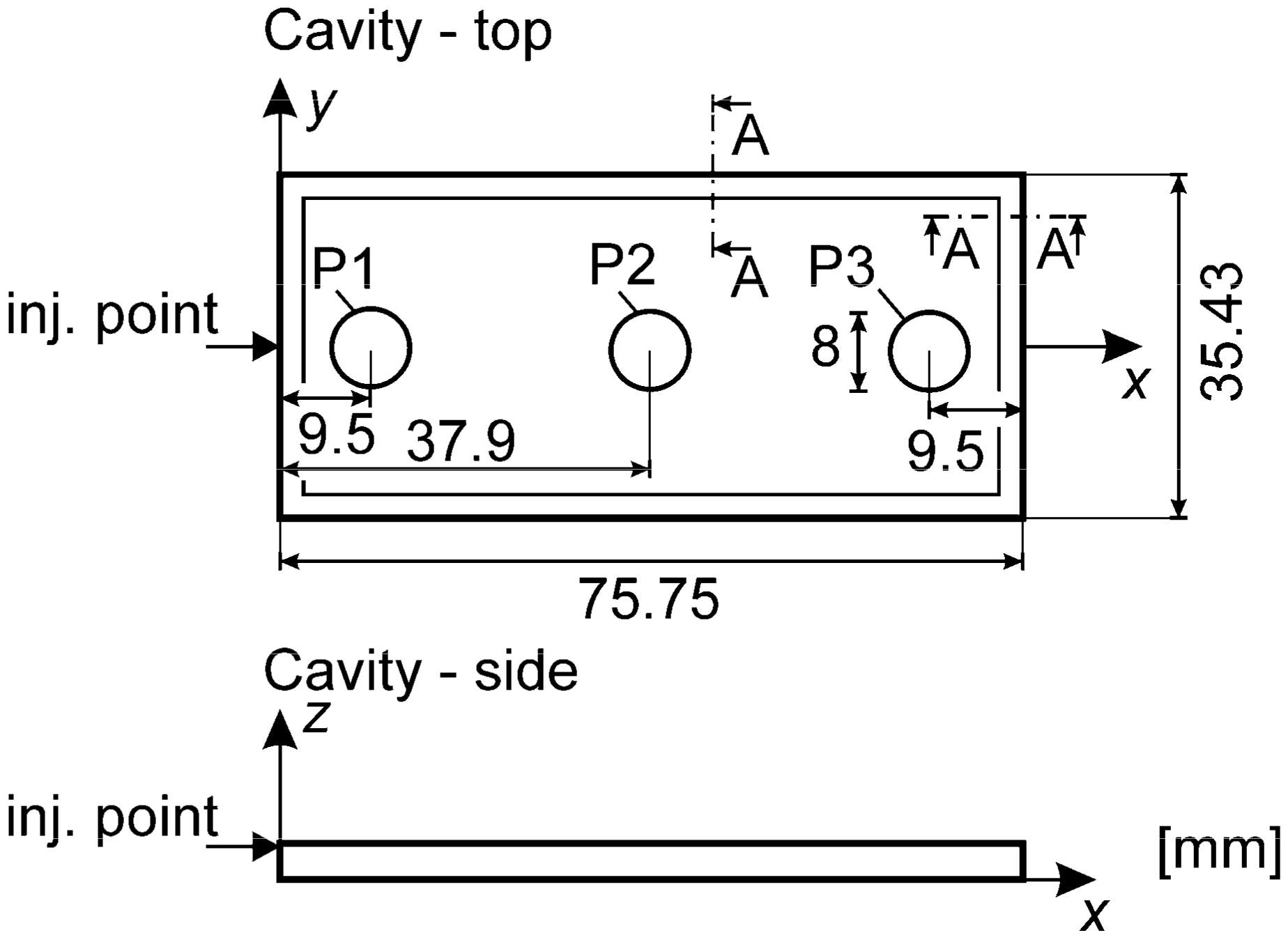

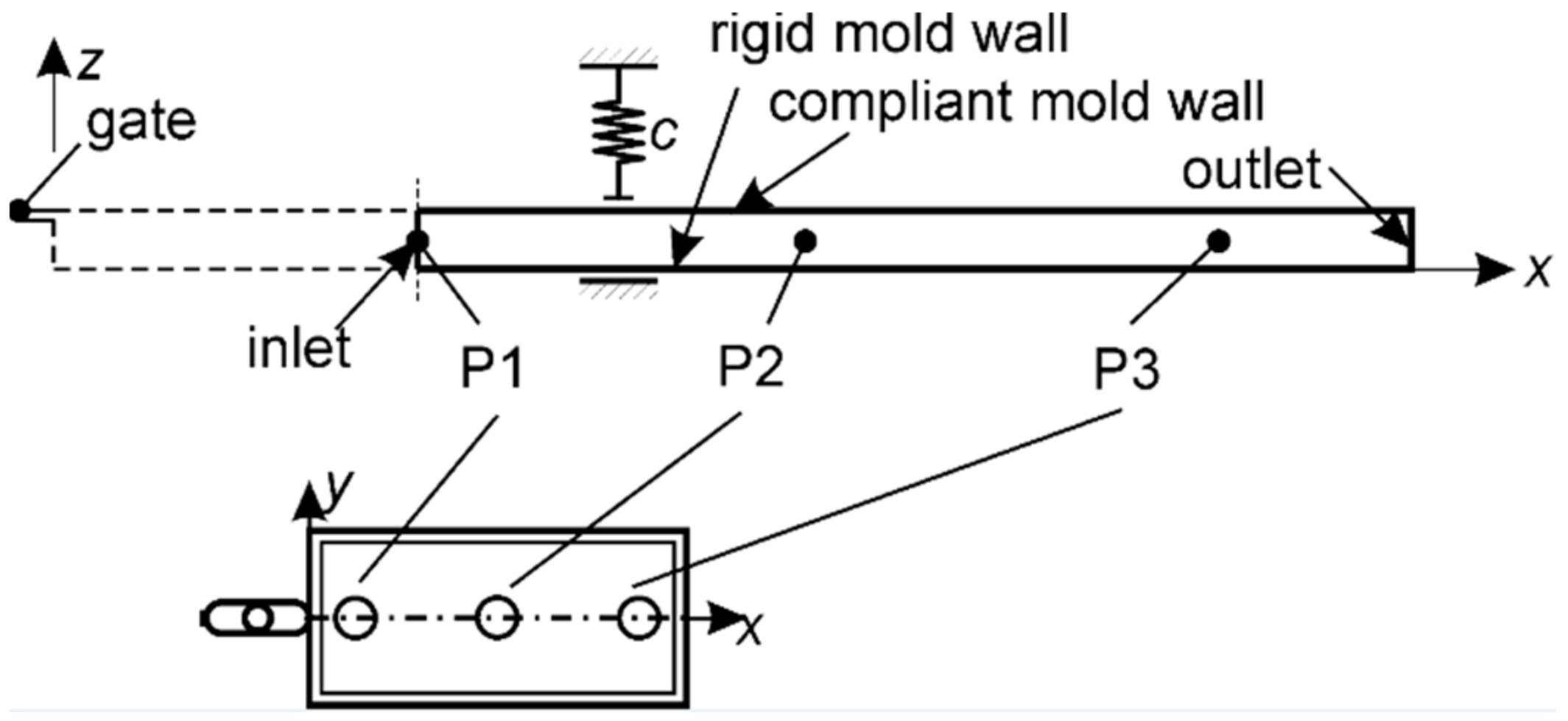

2.3.4. Geometry and Boundary Conditions

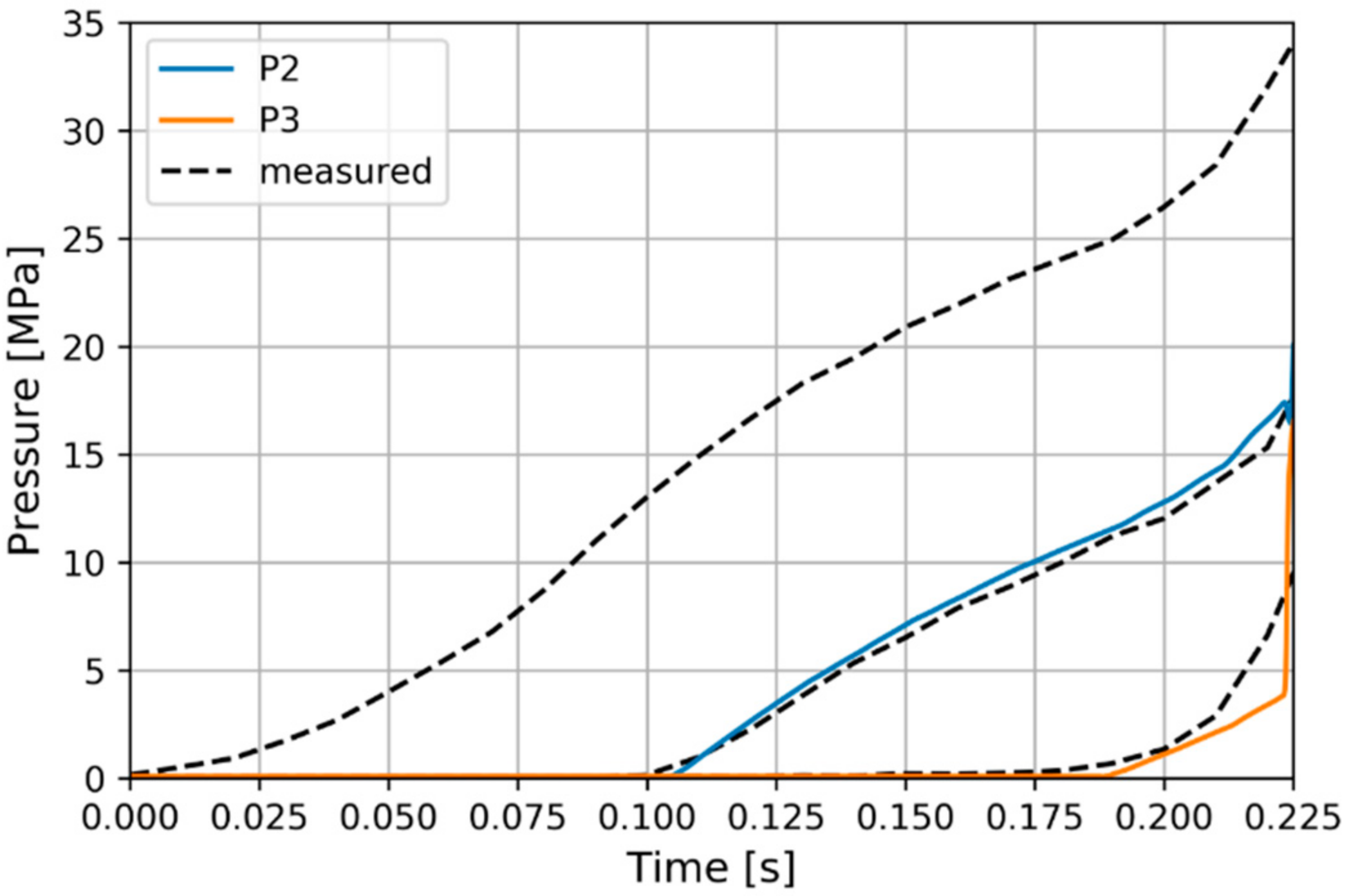

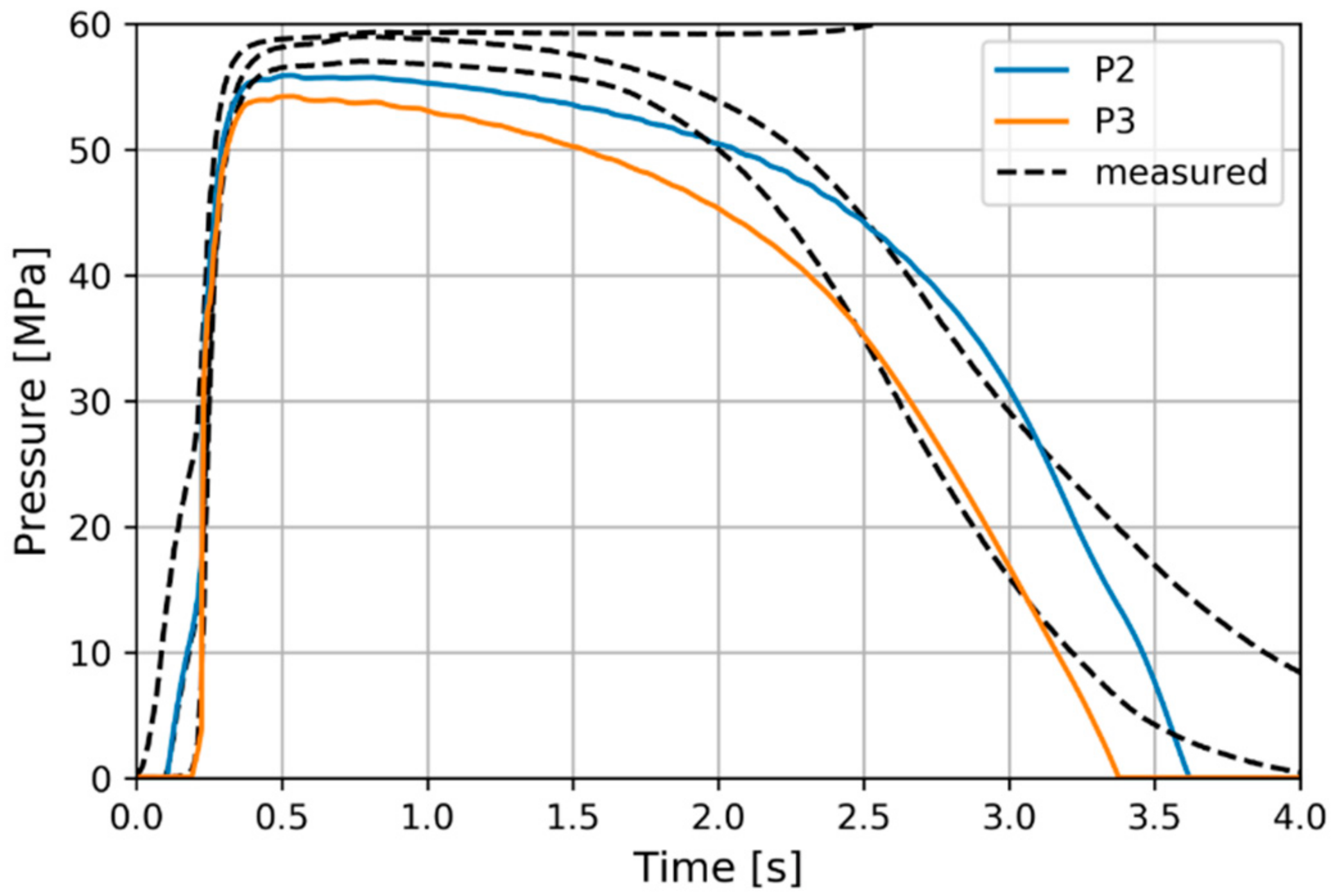

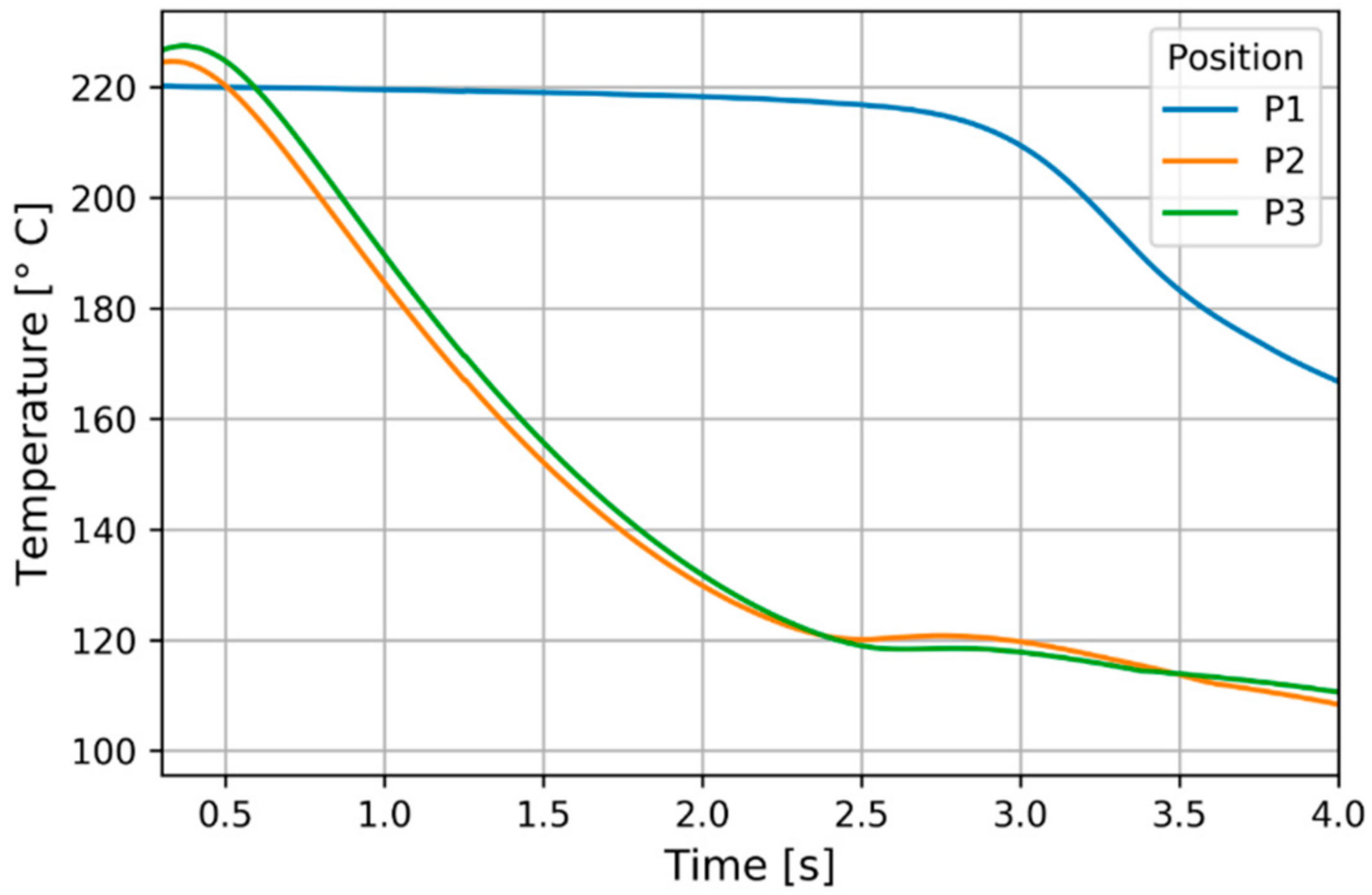

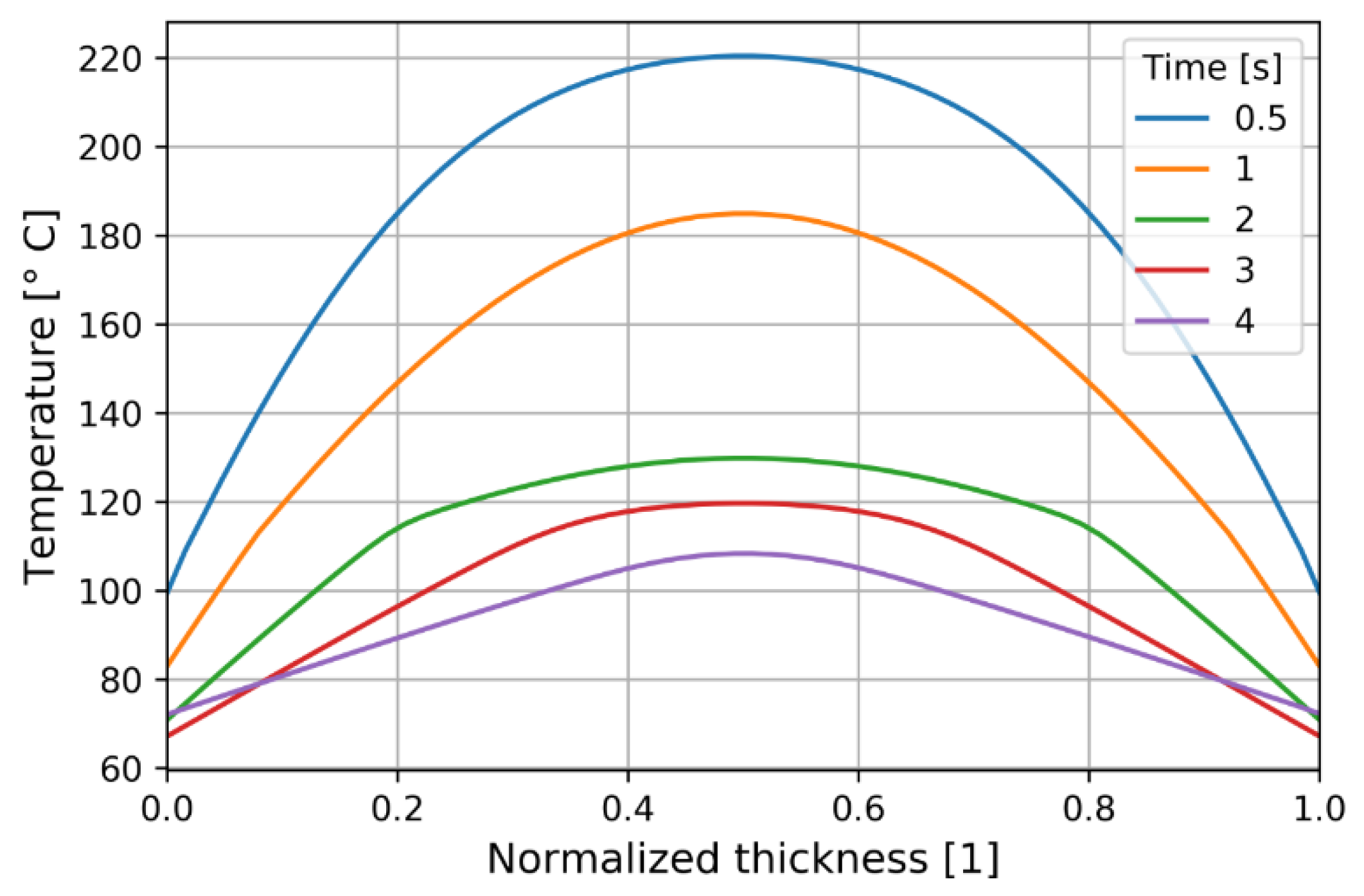

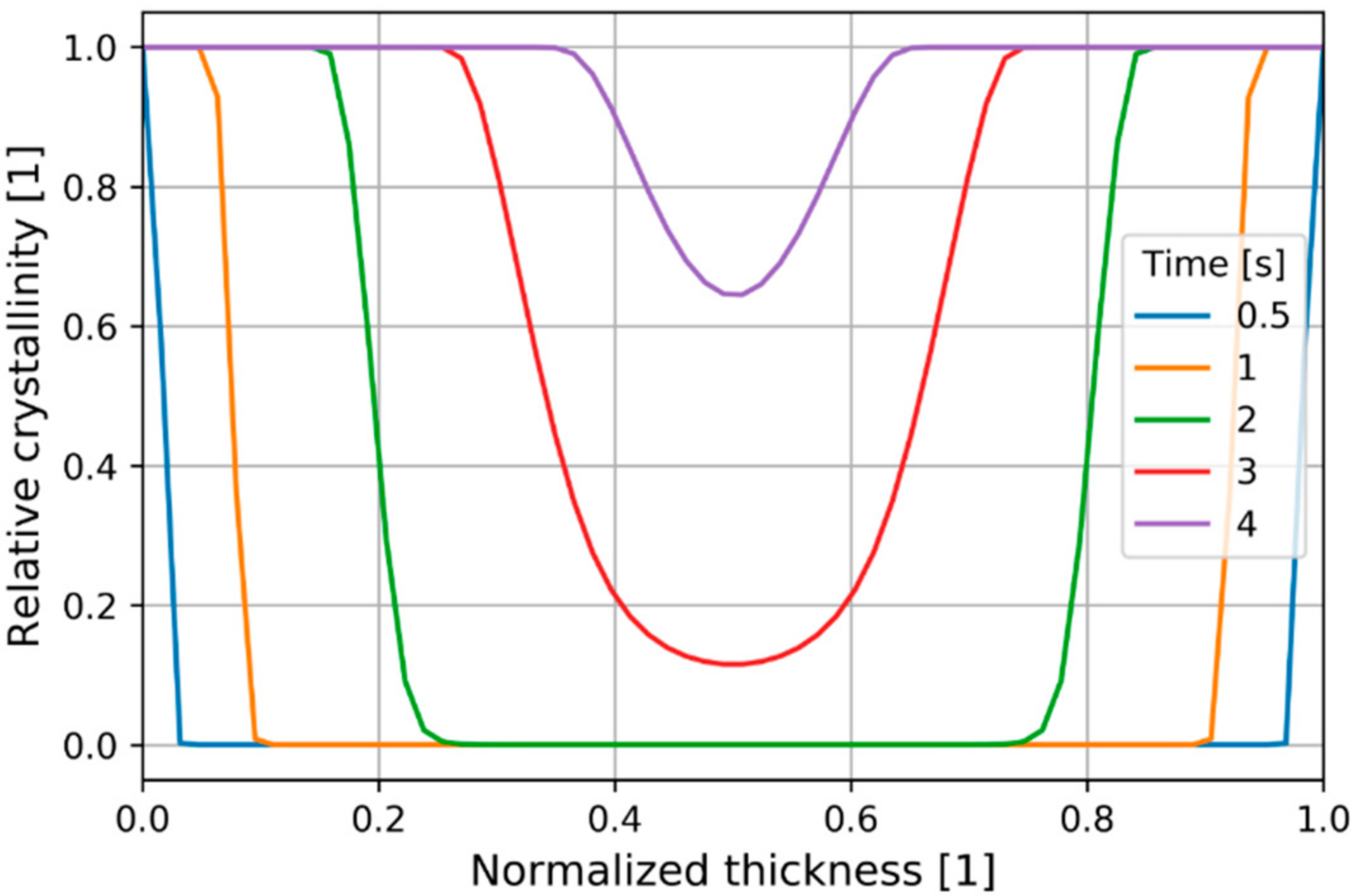

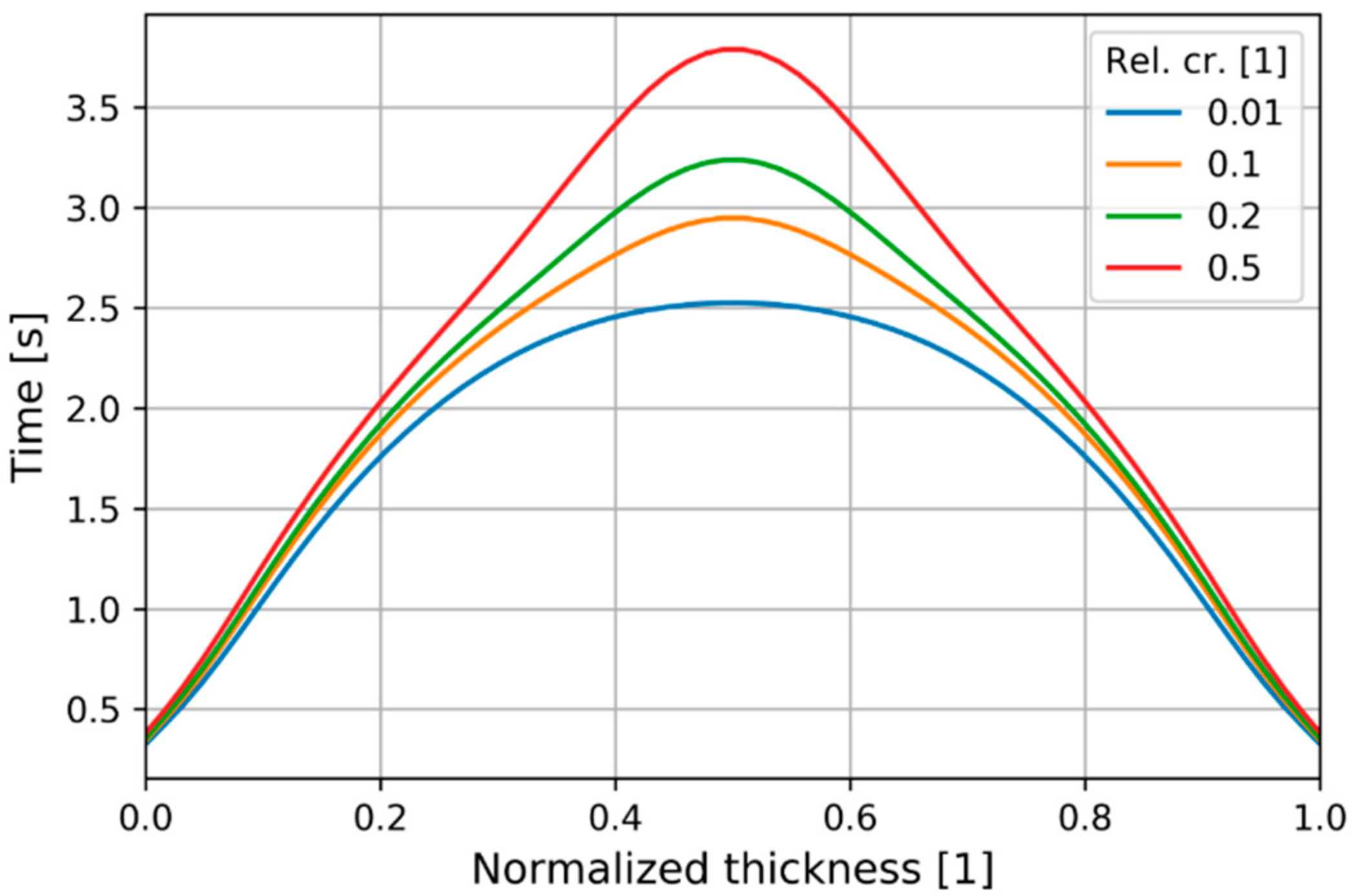

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kennedy, P.; Zheng, R. Flow Analysis of Injection Molds; Hanser Publishers: Cincinnati, OH, USA, 2013. [Google Scholar]

- Baaijens, F. Calculation of residual stresses in injection molded products. Rheol. Acta 1991, 30, 284–299. [Google Scholar] [CrossRef]

- Chang, R.-Y.; Chiou, S.-Y. A unified K-BKZ model for residual stress analysis of injection molded three-dimensional thin shapes. Polym. Eng. Sci. 1995, 35, 1733–1747. [Google Scholar] [CrossRef]

- Chang, R.-Y.; Yang, W.-H. Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int. J. Numer. Methods Fluids 2001, 37, 125–148. [Google Scholar] [CrossRef]

- Kamal, M.R.; Lai-Fook, R.A.; Hernandez-Aguilar, J.R. Residual thermal stresses in injection moldings of thermoplastics: A theoretical and experimental study. Polym. Eng. Sci. 2002, 42, 1098–1114. [Google Scholar] [CrossRef]

- Guevaramorales, A.; Figueroa-López, U. Residual stresses in injection molded products. J. Mater. Sci. 2014, 49, 4399–4415. [Google Scholar] [CrossRef]

- Pantani, R.; Speranza, V.; Titomanlio, G. Thirty Years of Modeling of Injection Molding. A Brief Review of the Contribution of UNISA Code to the Field. Int. Polym. Process. 2016, 31, 655–663. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R.; Speranza, V.; Titomanlio, G. Analysis of Shrinkage Development of a Semicrystalline Polymer during Injection Molding. Ind. Eng. Chem. Res. 2010, 49, 2469–2476. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Speranza, V.; Titomanlio, G. Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog. Polym. Sci. 2005, 30, 1185–1222. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Speranza, V.; Titomanlio, G. Morphology evolution during injection molding: Effect of packing pressure. Polymer 2007, 48, 2778–2790. [Google Scholar] [CrossRef]

- Zheng, R.; Tanner, R.I.; Wo, D.L.; Fan, X.J.; Hadinata, C.; Costa, F.S.; Kennedy, P.K.; Zhu, P.; Edward, E. Modeling of flow-induced crystallization of colored polypropylene in injection molding. Korea Aust. Rheol. J. 2010, 22, 151–162. [Google Scholar]

- Zheng, R.; Tanner, R.I.; Fan, X.-J. Injection Molding; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Janeschitz-Kriegl, H. Crystallization Modalities in Polymer Melt Processing. In Crystallization Modalities in Polymer Melt Processing; Springer International Publishing: Cham, Germany, 2018; pp. 1–69. [Google Scholar]

- Kabanemi, K.K.; Vaillancourt, H.; Wang, H.; Salloum, G. Residual stresses, shrinkage, and warpage of complex injection molded products: Numerical simulation and experimental validation. Polym. Eng. Sci. 1998, 38, 21–37. [Google Scholar] [CrossRef]

- IIinca, F.; Hétu, J.F. Three-dimensional finite element solution of gas-assisted injection moulding. Int. J. Numer. Methods Eng. 2002, 53, 2003–2017. [Google Scholar] [CrossRef]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Krebelj, K. openInjMoldSim. 2020. Available online: https://doi.org/10.5281/zenodo.4308529 (accessed on 22 December 2020).

- Krebelj, K.; Halilovič, M.; Mole, N. The cooling rate dependence of the specific volume in amorphous plastic injection molding. Int. J. Adv. Manuf. Technol. 2019, 103, 1175–1184. [Google Scholar] [CrossRef]

- Krebelj, K. openInjMoldDyMSimAmClr. 2020. Available online: https://doi.org/10.5281/zenodo.4308518 (accessed on 22 December 2020).

- Krebelj, K. openInjMoldDyMSimCr-v1.0. 2020. Available online: https://doi.org/10.5281/zenodo.4314423 (accessed on 22 December 2020).

- Mole, N.; Krebelj, K.; Stok, B. Injection molding simulation with solid semi-crystalline polymer mechanical behavior for ejection analysis. Int. J. Adv. Manuf. Technol. 2017, 93, 4111–4124. [Google Scholar] [CrossRef]

- Gaur, U.; Wunderlich, B. Heat capacity and other thermodynamic properties of linear macromolecules. II. Polyethylene. J. Phys. Chem. Ref. Data 1981, 10, 119–152. [Google Scholar] [CrossRef]

- Dawson, A.; Rides, M.; Nottay, J. The effect of pressure on the thermal conductivity of polymer melts. Polym. Test. 2006, 25, 268–275. [Google Scholar] [CrossRef]

- Schneider, W.; Köppl, A.; Berger, J. Non—Isothermal Crystallization Crystallization of Polymers. Int. Polym. Process. 1988, 2, 151–154. [Google Scholar] [CrossRef]

- Zuidema, H.H.; Peters, G.; Meijer, H.E.H. Influence of cooling rate on pVT-data of semicrystalline polymers. J. Appl. Polym. Sci. 2001, 82, 1170–1186. [Google Scholar] [CrossRef]

- Koscher, E.; Fulchiron, R. Influence of shear on polypropylene crystallization: Morphology development and kinetics. Polymer 2002, 43, 6931–6942. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Nijenhuis, K. Properties of Polymers; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Toda, A.; Taguchi, K.; Nozaki, K.; Konishi, M. Melting behaviors of polyethylene crystals: An application of fast-scan DSC. Polymer 2014, 55, 3186–3194. [Google Scholar] [CrossRef]

- Zhuravlev, E.; Madhavi, V.; Lustiger, A.; Androsch, R.; Schick, C. Crystallization of Polyethylene at Large Undercooling. ACS Macro Lett. 2016, 5, 365–370. [Google Scholar] [CrossRef]

- Mandelkern, L.; Jain, N.L.; Kim, H. Temperature dependence of the growth rate of spherulites. J. Polym. Sci. Part A 2 Polym. Phys. 2003, 6, 165–180. [Google Scholar] [CrossRef]

- Mandelkern, L. Crystallization of Polymers; McGraw-Hill: New York, NY, USA, 1964; Volume 2. [Google Scholar]

- Adamovsky, S.; Minakov, A.; Schick, C. Scanning microcalorimetry at high cooling rate. Thermochim. Acta 2003, 403, 55–63. [Google Scholar] [CrossRef]

- Androsch, R.; Di Lorenzo, M.L.; Schick, C.; Wunderlich, B. Mesophases in polyethylene, polypropylene, and poly(1-butene). Polymer 2010, 51, 4639–4662. [Google Scholar] [CrossRef]

- Luyé, J.; Régnier, G.; Le Bot, P.; Delaunay, D.; Fulchiron, R. PVT measurement methodology for semicrystalline polymers to simulate injection-molding process. J. Appl. Polym. Sci. 2001, 79, 302–311. [Google Scholar] [CrossRef]

- Autodesk Moldflow; Autodesk Inc.: Mill Valley, CA, USA, 2012.

- Zhou, H.; Xi, G.; Liu, F. Residual Stress Simulation of Injection Molding. J. Mater. Eng. Perform. 2007, 17, 422–427. [Google Scholar] [CrossRef]

- Zoetelief, W.F.; Douven, L.F.A.; Housz, A.J.I. Residual thermal stresses in injection molded products. Polym. Eng. Sci. 1996, 36, 1886–1896. [Google Scholar] [CrossRef]

- Titomanlio, G.; Speranza, V.; Brucato, V. On the Simulation of Thermoplastic Injection Moulding Process. Int. Polym. Process. 1997, 12, 45–53. [Google Scholar] [CrossRef]

- Delaunay, D.; Le Bot, P.; Fulchiron, R.; Luye, J.F.; Regnier, G. Nature of contact between polymer and mold in injection molding. Part I: Influence of a non-perfect thermal contact. Polym. Eng. Sci. 2000, 40, 1682–1691. [Google Scholar] [CrossRef]

- Krebelj, K.; Štok, B.; Mole, N. Three-dimensional modeling of the stress evolution in injection molded parts based on a known melt pressure field. Int. J. Adv. Manuf. Technol. 2016, 90, 2363–2376. [Google Scholar] [CrossRef]

- Kamal, M.R.; LaFleur, P.G. Heat transfer in injection molding of crystallizable polymers. Polym. Eng. Sci. 1984, 24, 692–697. [Google Scholar] [CrossRef]

- Delaunay, D.; Le Bot, P.; Fulchiron, R.; Luye, J.F.; Régnier, G. Nature of contact between polymer and mold in injection molding. Part II: Influence of mold deflection on pressure history and shrinkage. Polym. Eng. Sci. 2000, 40, 1692–1700. [Google Scholar] [CrossRef]

- Mannella, G.A.; La Carrubba, V.; Brucato, V.; Zoetelief, W.; Haagh, G. No-flow temperature in injection molding simulation. J. Appl. Polym. Sci. 2010, 119, 3382–3392. [Google Scholar] [CrossRef]

| Symbol | Value | Unit |

|---|---|---|

| 1 × 108 | m3 | |

| 2.5 | K | |

| 419 | K | |

| 103 | m/s | |

| 29.3 | kJ/mol | |

| 265 | K | |

| 1.5 | 1 |

| Symbol | Melt | Melt and Solid | Solid | Unit |

|---|---|---|---|---|

| / | ||||

| / | ||||

| / | ||||

| / | ||||

| / | / | |||

| / | / | |||

| / | / | |||

| / | / | |||

| / | / |

| Symbol | Value | Unit |

|---|---|---|

| 1 | ||

| kPa | ||

| Pa/s | ||

| K | ||

| K/MPa | ||

| 1 | ||

| K |

| Symbol | Value | Unit |

|---|---|---|

| 1000 | 1 | |

| 0.2 | 1 | |

| 2 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krebelj, K.; Krebelj, A.; Halilovič, M.; Mole, N. Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers 2021, 13, 138. https://doi.org/10.3390/polym13010138

Krebelj K, Krebelj A, Halilovič M, Mole N. Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers. 2021; 13(1):138. https://doi.org/10.3390/polym13010138

Chicago/Turabian StyleKrebelj, Kristjan, Anton Krebelj, Miroslav Halilovič, and Nikolaj Mole. 2021. "Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software" Polymers 13, no. 1: 138. https://doi.org/10.3390/polym13010138

APA StyleKrebelj, K., Krebelj, A., Halilovič, M., & Mole, N. (2021). Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers, 13(1), 138. https://doi.org/10.3390/polym13010138