End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective

Abstract

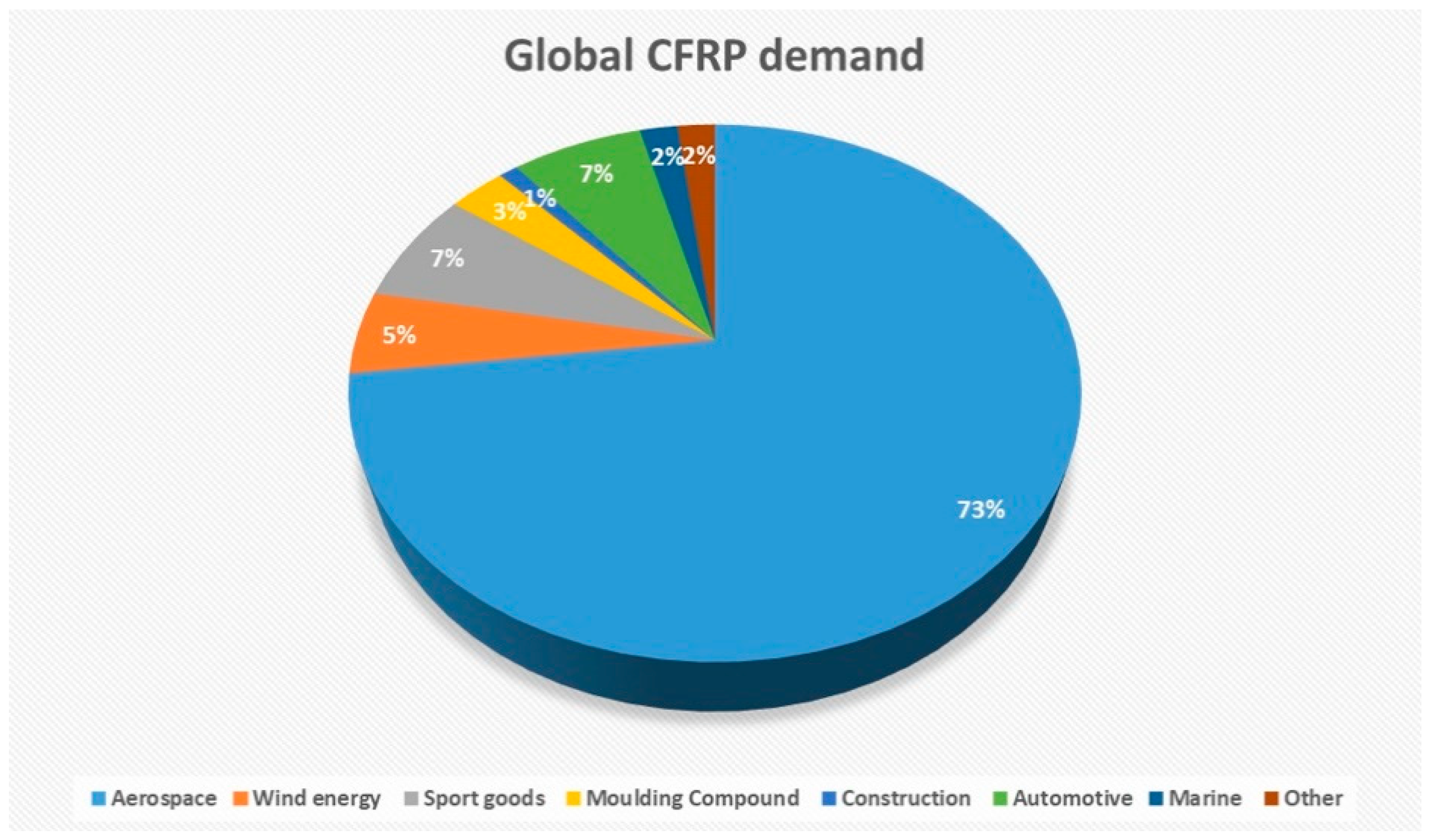

1. Introduction

2. Methodology

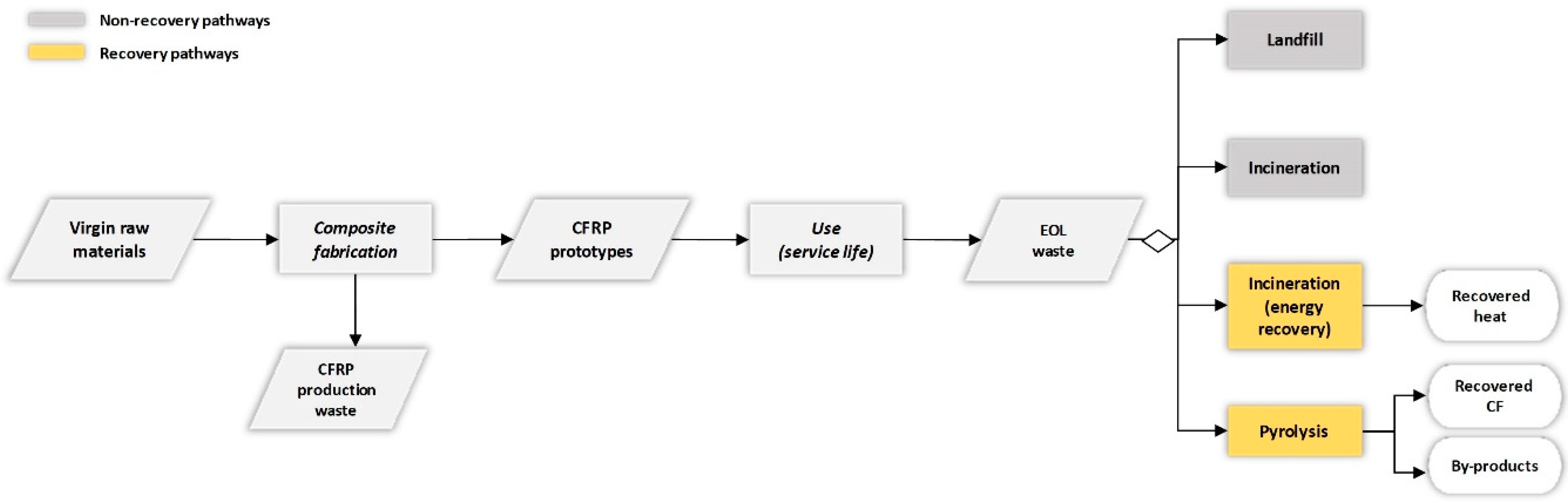

2.1. Goal and Scope

2.2. Inventory Data Collection

2.2.1. SleekFast Sailing Boat Case

2.2.2. Handbrake Lever for Motorcycle Case

2.2.3. Assumptions Applicable for Both Test Cases

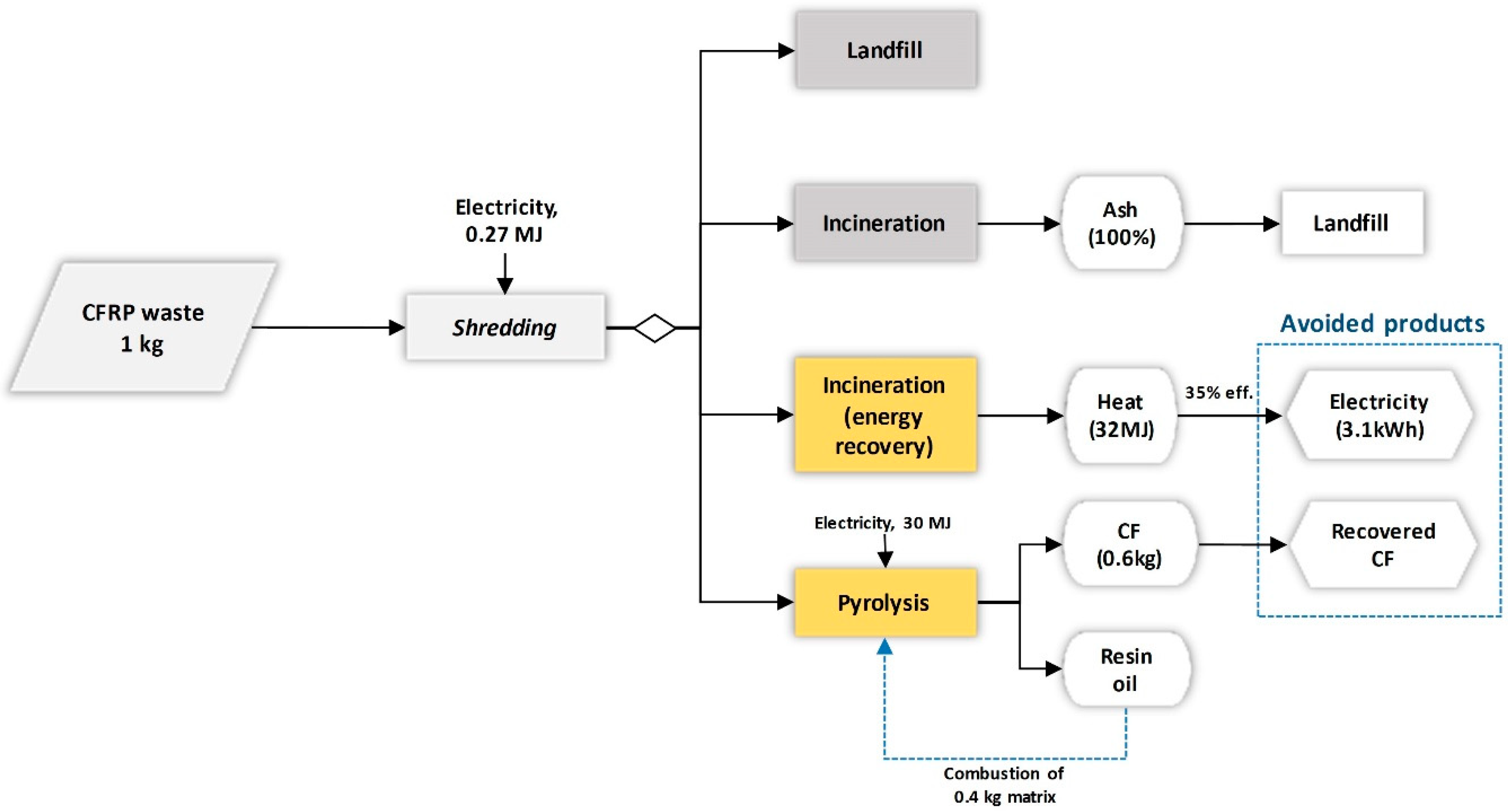

2.3. Scenario Analysis for the End of Life Stage

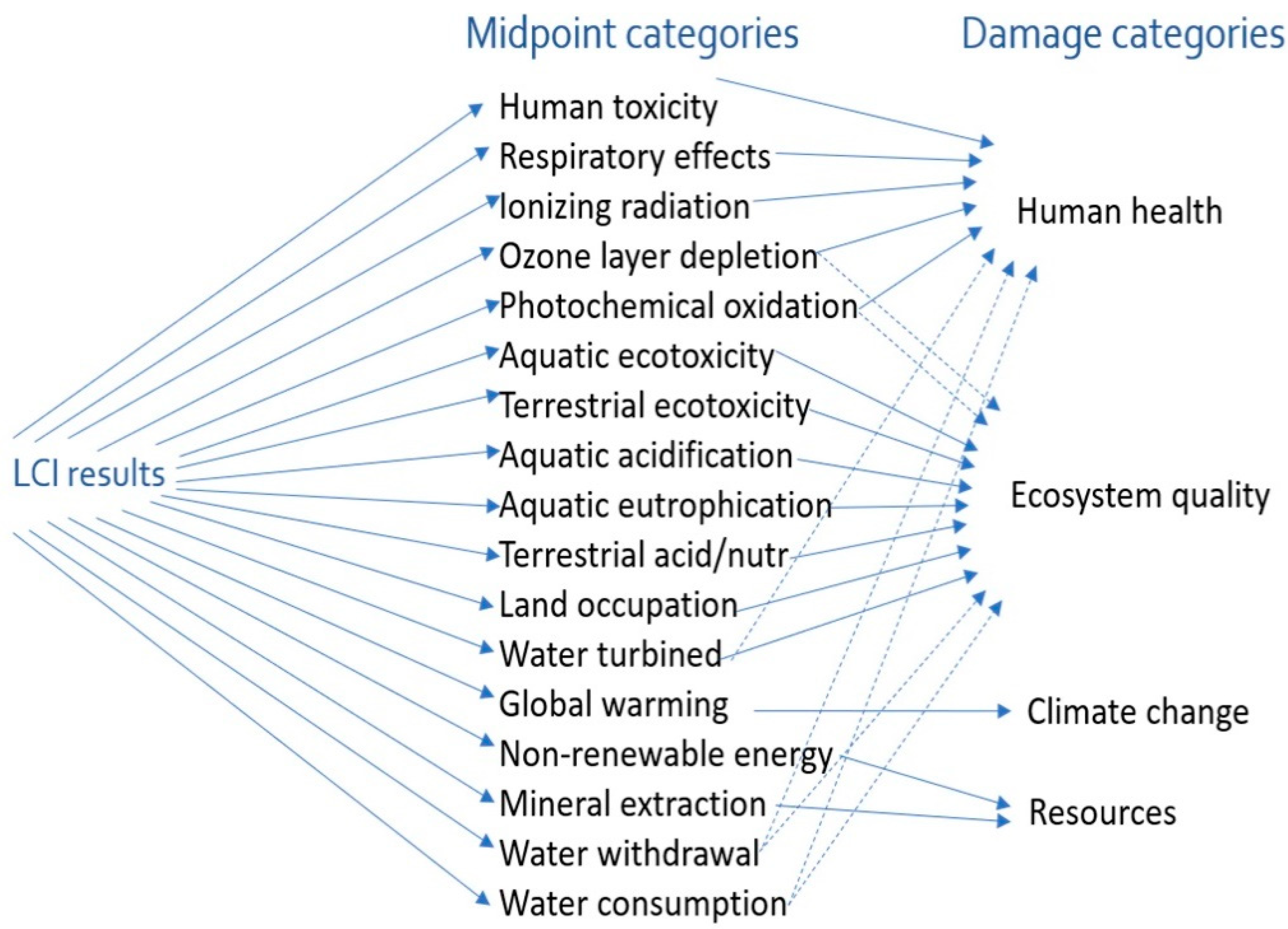

2.4. Impact Assessment Indicators

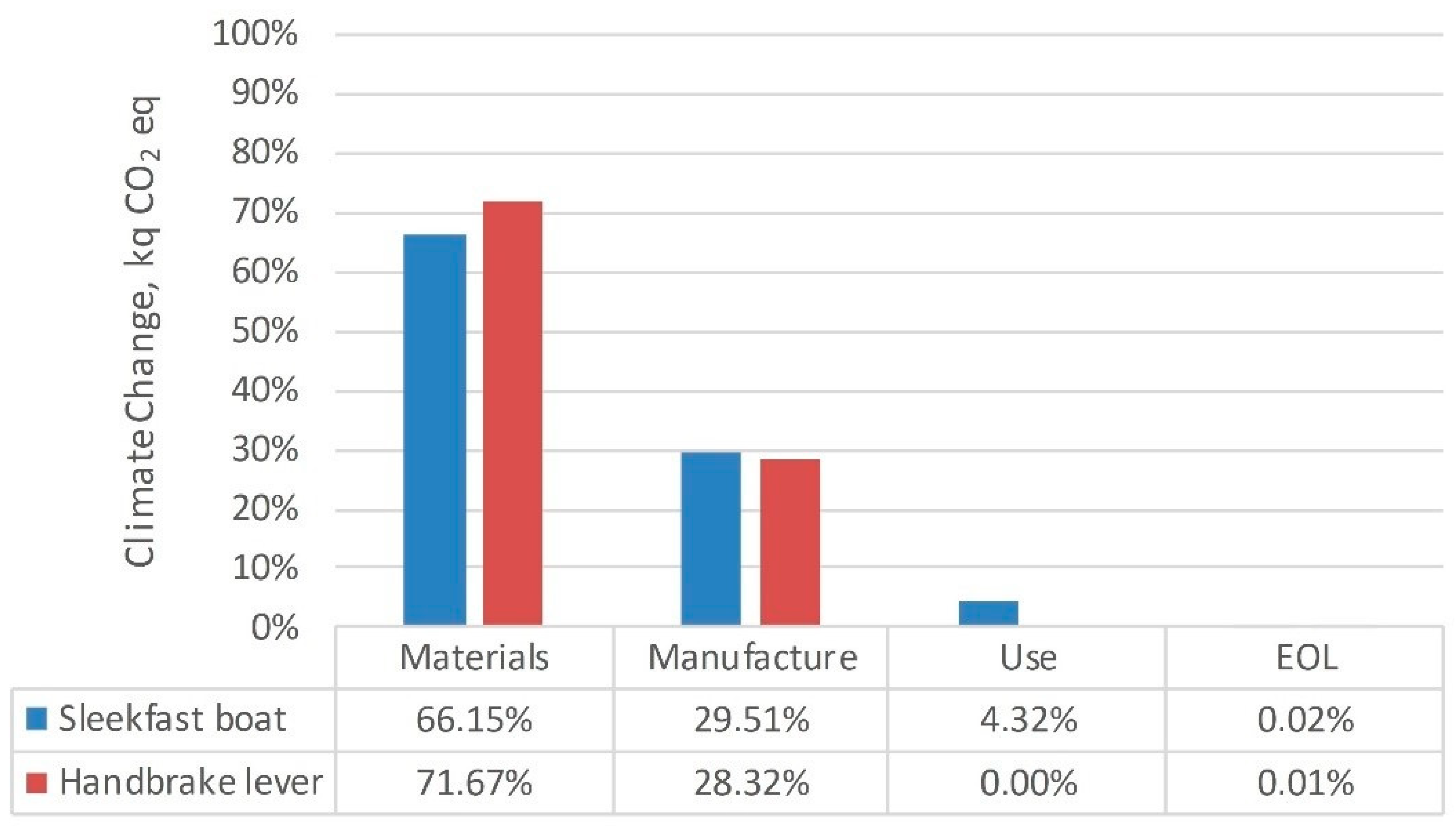

3. Results and Discussion

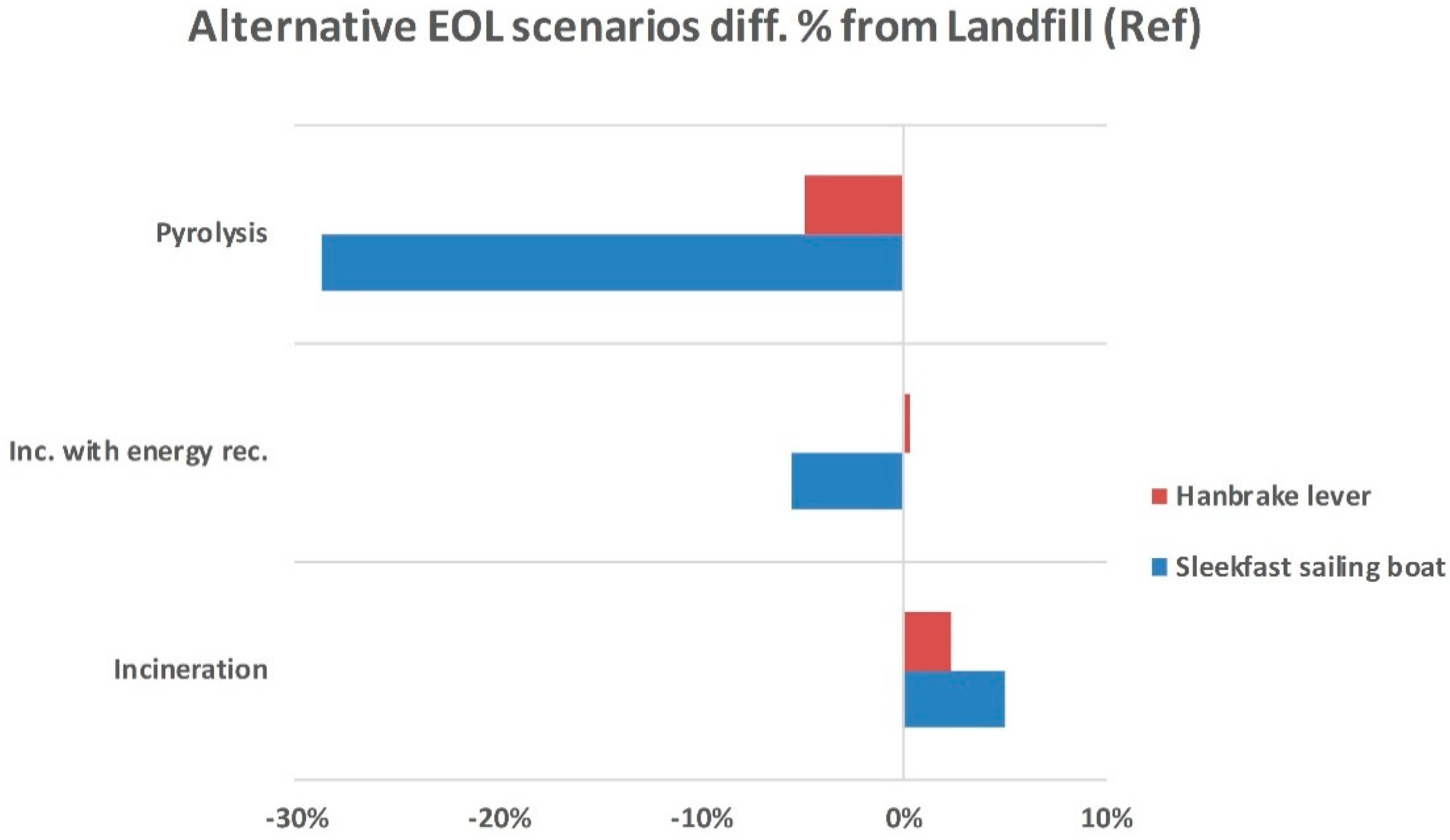

End of Life–The Most Uncertain Life Cycle Stage with the Highest Potential for Improvement

4. Discussion

5. Conclusions

- ‘Materials’ contribution dominates in the calculated 14 impact categories, with CF and CNTs being the environmental hotspots, both thanks to the high energy intensive production process. The laboratory production of CNTs required 1104 MJ/kg CNTs. While the upscale of CNT manufacturing becomes more mature reaching the industrial-scale, a reduction of approximately two to three orders of magnitude in manufacturing energy intensity can be expected [110].

- Recycling via pyrolysis can lead to significant impact savings due to material recovery (up to 40% for the case of Sleekfast boat).

- Incineration with energy recovery also leads to environmental savings, but much lower than recycling (~7 and ~4 times lower for the boat and the lever cases, respectively).

- Incineration without energy recovery contributes negatively by approximately 5% and 2% to climate change for the boat and lever, respectively. It is worth mentioning that this option accounts for around 1–2% of total municipal waste treated inside and outside Europe [111].

Author Contributions

Funding

Conflicts of Interest

Appendix A

| MATERIALS | ||

| Input (materials, energy, etc.) | Unit | Comment |

| Carbon fibre | 0.12 kg | [70] (updated 2014) |

| Epoxy resin {GLO} | 0.02 kg | Ecoinvent 3.3 |

| CNTs | 0.01 kg | Experimental Data |

| Electricity, medium voltage {GR} | 11.04 MJ | CNT production energy, experimental Data |

| Electricity, medium voltage {JP} | 45.631 MJ | CF production energy [70,112] |

| Output/Emissions to air | Unit | Comment |

| Ammonia | 0.0001 kg | [70] (updated 2014) |

| Hydrogen cyanide | 0.0019 kg | [70] (updated 2014) |

| Carbon monoxide | 0.0004 kg | [70] (updated 2014) |

| Carbon dioxide | 0.1216 kg | [70] (updated 2014) |

| Ethane | 1.2 × 10−6 kg | [70] (updated 2014) |

| Acrylonitrile | 0.0026 kg | [70] (updated 2014) |

| Nitrogen | 0.2144 kg | Experimental Data |

| VOC, volatile organic compounds | 0.0053 kg | Experimental Data |

| Soot | 0.0013 kg | Experimental Data |

| Ethyne | 0.0073 kg | Experimental Data |

| Output/Emissions to water | Unit | Comment |

| Sulfuric acid | 0.0024 kg | [70] (updated 2014) |

| N-N-Dimethylformamide | 0.0021 kg | [70] (updated 2014) |

| PAH, polycyclic aromatic hydrocarbons | 6.6 × 10−5 kg | Experimental Data |

| MANUFACTURE | ||

| Input (materials, energy, etc.) | Unit | Comment |

| Production scrap | 0.02 pc | Assumed 2% production scrap |

| Packaging materials | 1.272 kg | Experimental Data |

| Electricity, medium voltage {EU-27} | 18 MJ | Experimental Data |

| EOL DISPOSAL | ||

| Scenario 1: Landfill | Unit | Comment |

| Inert waste | 0.15 kg | [75] |

| Electricity, medium voltage {EU-27} | 0.0405 MJ | Industrial shredder energy [55] |

| Scenario 2: Incineration of Hazardous waste | Unit | Comment |

| Electricity, medium voltage {EU-27} | 0.0405 MJ | Industrial shredder [55] |

| Scenario 3: MSW incineration with energy recovery | Unit | Comment |

| Electricity, medium voltage {EU-27} | 0.0405 MJ | Industrial shredder [55] |

| Output/ avoided products | Unit | Comment |

| Electricity, medium voltage {EU-27} | 1.68 MJ | 35% efficiency [112] |

| Heat, for reuse in municipal waste incineration {EU-27} | 4.8 MJ | [81] [75] |

| Scenario 4: Thermal recycling via pyrolysis | Unit | Comment |

| Electricity, medium voltage {EU-27} | 0.0405 MJ | Industrial shredder [55] |

| Electricity, medium voltage {EU-27} | 4.5 MJ | [61] |

| Output/ avoided products | Unit | Comment |

| Carbon fibre | 0.0612 kg | 60% CF recovery [78] |

| Electricity, medium voltage {EU-27} | 5.94 MJ | [77] |

| MATERIALS | ||

| Input (materials, energy) | Unit | Comment |

| Carbon fibre | 10.5 kg | [70] (updated 2014) |

| SICOMIN 1500 (0,06 wt% MWCNTs) | 10 kg | Experimental Data |

| PVC foam | 1.5 kg | Ecoinvent 3.4 |

| Epoxy gelcoat | 4 kg | EuCIA - EcoImpact Calculator report v1.3, Ecoinvent 3.4 |

| Electricity, medium voltage {JP} | 3680 MJ | CF production energy [70,112] |

| Electricity, medium voltage {EU-27} | 6.48 MJ | Experimental Data |

| Electricity, medium voltage {PT} | 600 MJ | Experimental Data |

| Output/Emissions to air | Unit | Comment |

| Ammonia | 0.0122 kg | [70] (updated 2014) |

| Hydrogen cyanide | 0.1649 kg | [70] (updated 2014) |

| Carbon monoxide | 0.0340 kg | [70] (updated 2014) |

| Carbon dioxide | 10.636 kg | [70] (updated 2014) |

| Ethane | 0.0001 kg | [70] (updated 2014) |

| Acrylonitrile | 0.2243 kg | [70] (updated 2014) |

| Nitrogen | 0.1415 kg | Experimental Data |

| VOC, volatile organic compounds | 0.0035 kg | Experimental Data |

| Soot | 0.0009 kg | Experimental Data |

| Ethyne | 0.0048 kg | Experimental Data |

| VOC, volatile organic compounds | 0.0196 kg | Experimental Data |

| Carbon dioxide | 3.040 kg | Experimental Data |

| Output/Emissions to water | Unit | Comment |

| Sulfuric acid | 0.2089 kg | [70] (updated 2014) |

| N-N-Dimethylformamide | 0.1857 kg | [70] (updated 2014) |

| PAH, polycyclic aromatic hydrocarbons | 4.4 × 10−5 kg | Experimental Data |

| MANUFACTURE | ||

| Input (materials, energy) | Unit | Comment |

| Production scrap | 1.47 kg | Experimental Data |

| Packaging film, low density polyethylene {GLO} | 0.35 kg | Experimental Data |

| Acetone, liquid {GLO} | 2.37 kg | Experimental Data |

| Electricity, medium voltage {PT} | 230.4 MJ | Experimental Data |

| USE | ||

| Epoxy gelcoat | 30 kg | Assumed 2 kg biannually for 30 years operational life (EuCIA - EcoImpact Calculator report v1.3, Ecoinvent 3.4) |

| EOL DISPOSAL | ||

| Scenario 1: Landfill | Unit | Comment |

| Inert waste | 26 kg | [75] |

| Electricity, medium voltage {EU-27} | 7.02 MJ | Industrial shredder energy [55] |

| Scenario 2: Incineration of Hazardous waste | Unit | Comment |

| Electricity, medium voltage {EU-27} | 7.02 MJ | Industrial shredder [55], Incineration Haz. (Ecoinvent) |

| Scenario 3: MSW incineration with energy recovery | Unit | Comment |

| Electricity, medium voltage {EU-27} | 7.02 MJ | Industrial shredder [55] |

| Output/ avoided products | Unit | Comment |

| Electricity, medium voltage {EU-27} | 291 MJ | 35% efficiency |

| Heat, for reuse in municipal waste incineration {EU-27} | 832 MJ | [75,81] |

| Scenario 4: Thermal recycling via pyrolysis | Unit | Comment |

| Electricity, medium voltage {EU-27} | 7.02 MJ | Industrial shredder [55] |

| Electricity, medium voltage {EU-27} | 780 MJ | [61] |

| Output/ avoided products | Unit | Comment |

| Carbon fibre | 6.3 kg | 60% CF recovery [78] |

| Electricity, medium voltage {EU-27} | 396 MJ | [77] |

| Impact Category | Unit | Materials | Manufacturing | Use | EoL | CF in Materials |

|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 62% | 33% | 5% | 0% | 57% |

| Ozone depletion | kg CFC-11 eq | 54% | 24% | 22% | 0% | 53% |

| Human toxicity, cancer effects | CTUh | 53% | 38% | 9% | 0% | 44% |

| Human toxicity, non-cancer effects | CTUh | 57% | 31% | 11% | 0% | 52% |

| Particulate matter | kg PM2.5 eq | 48% | 30% | 22% | 0% | 39% |

| Ionizing radiation HH | kBq U235 eq | 70% | 27% | 3% | 0% | 69% |

| Ionizing radiation E (interim) | CTUe | 72% | 28% | 0% | 0% | 71% |

| Photochemical ozone formation | kg NMVOC eq | 53% | 34% | 12% | 0% | 45% |

| Acidification | molc H+ eq | 62% | 34% | 4% | 0% | 57% |

| Terrestrial eutrophication | molc N eq | 56% | 31% | 13% | 0% | 50% |

| Freshwater eutrophication | kg P eq | 62% | 35% | 4% | 0% | 59% |

| Marine eutrophication | kg N eq | 57% | 40% | 3% | 0% | 50% |

| Freshwater ecotoxicity | CTUe | 50% | 28% | 22% | 0% | 46% |

| Land use | kg C deficit | 59% | 29% | 12% | 0% | 57% |

| Water resource depletion | m3 water eq | 47% | 30% | 23% | 0% | 32% |

| Mineral, fossil, and ren resource depletion | kg Sb eq | 56% | 26% | 17% | 0% | 46% |

| Impact Category | Unit | Materials | Manufacturing | EoL | CF in Materials |

|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 72% | 28% | 0% | 51% |

| Ozone depletion | kg CFC-11 eq | 79% | 21% | 0% | 63% |

| Human toxicity, cancer effects | CTUh | 84% | 16% | 0% | 27% |

| Human toxicity, non-cancer effects | CTUh | 90% | 10% | 0% | 25% |

| Particulate matter | kg PM2.5 eq | 83% | 17% | 0% | 53% |

| Ionizing radiation HH | kBq U235 eq | 60% | 40% | 0% | 57% |

| Ionizing radiation E (interim) | CTUe | 59% | 41% | 0% | 56% |

| Photochemical ozone formation | kg NMVOC eq | 79% | 21% | 0% | 56% |

| Acidification | molc H+ eq | 86% | 14% | 0% | 60% |

| Terrestrial eutrophication | molc N eq | 82% | 18% | 0% | 65% |

| Freshwater eutrophication | kg P eq | 97% | 3% | 0% | 17% |

| Marine eutrophication | kg N eq | 79% | 21% | 0% | 33% |

| Freshwater ecotoxicity | CTUe | 79% | 21% | 0% | 28% |

| Land use | kg C deficit | 85% | 15% | 0% | 71% |

| Water resource depletion | m3 water eq | 62% | 38% | 0% | 31% |

| Mineral, fossil, and ren resource depletion | kg Sb eq | 74% | 26% | 0% | 60% |

References

- Koumoulos, E.P.; Trompeta, A.-F.; Santos, R.-M.; Martins, M.; Santos, C.M.; Iglesias, V.; Böhm, R.; Gong, G.; Chiminelli, A.; Verpoest, I.; et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. J. Compos. Sci. 2019, 3, 86. [Google Scholar] [CrossRef]

- Roy, M.; Tran, P.; Dickens, T.; Schrand, A. Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers. J. Compos. Sci. 2019, 4, 1. [Google Scholar] [CrossRef]

- Sahu, P.; Sharma, N.; Panda, S.K. Numerical prediction and experimental validation of free vibration responses of hybrid composite (Glass/Carbon/Kevlar) curved panel structure. Compos. Struct. 2020, 241, 112073. [Google Scholar] [CrossRef]

- Fausey, C.L.; Zucker, I.; Lee, D.E.; Shaulsky, E.; Zimmerman, J.B.; Elimelech, M. Tunable Molybdenum Disulfide-Enabled Fiber Mats for High-Efficiency Removal of Mercury from Water. ACS Appl. Mater. Interfaces 2020, 12, 18446–18456. [Google Scholar] [CrossRef]

- Johnson, S.; Faradilla, R.H.F.; Venditti, R.A.; Lucia, L.; Hakovirta, M. Hydrothermal Carbonization of Nanofibrillated Cellulose: A Pioneering Model Study Demonstrating the Effect of Size on Final Material Qualities. ACS Sustain. Chem. Eng. 2020, 8, 1823–1830. [Google Scholar] [CrossRef]

- Li, S.; Lv, R.; Wu, Y.; Huang, F.; Zhang, X.; Yue, T. Size-, Aggregation-, and Oxidization-Dependent Perturbation of Methane Hydrate by Graphene Nanosheets Revealed by Molecular Dynamics Simulations. J. Phys. Chem. C 2019, 123, 13154–13166. [Google Scholar] [CrossRef]

- Afreen, S.; Omar, R.A.; Talreja, N.; Chauhan, D.; Ashfaq, M. Carbon-Based Nanostructured Materials for Energy and Environmental Remediation Applications; Springer: Cham, Switzerland, 2018; pp. 369–392. [Google Scholar]

- Koniuszewska, A.G.; Kaczmar, J.W. Application of Polymer Based Composite Materials in Transportation. Prog. Rubber Plast. Recycl. Technol. 2016, 32, 1–24. [Google Scholar] [CrossRef]

- Bacakova, L.; Pajorova, J.; Tomkova, M.; Matejka, R.; Broz, A.; Stepanovska, J.; Prazak, S.; Skogberg, A.; Siljander, S.; Kallio, P. Applications of Nanocellulose/Nanocarbon Composites: Focus on Biotechnology and Medicine. Nanomaterials 2020, 10, 196. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Wang, X.; Wang, L.; Yu, J.; Zhang, Q.; Chen, R.; Yan, Y.; Sun, D. Graphene-Based Antibacterial Films with Enhanced Mechanical Properties. Integr. Ferroelectr. 2020, 206, 79–86. [Google Scholar] [CrossRef]

- Rajakumar, G.; Zhang, X.-H.; Gomathi, T.; Wang, S.-F.; Azam Ansari, M.; Mydhili, G.; Nirmala, G.; Alzohairy, M.A.; Chung, I.-M. Current Use of Carbon-Based Materials for Biomedical Applications—A Prospective and Review. Processes 2020, 8, 355. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Thakur, V.K. Carbon-Based Polymer Nanocomposite for High-Performance Energy Storage Applications. Polymers 2020, 12, 505. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, P.; Ma, T.; Zahiri, A.H.; Cao, L.; Wang, Y. Carbon-Based Materials for Thermoelectrics. Adv. Condens. Matter Phys. 2018, 2018, 3898479. [Google Scholar] [CrossRef]

- Yıldırım, G.; Öztürk, O.; Al-Dahawi, A.; Afşın Ulu, A.; Şahmaran, M. Self-sensing capability of Engineered Cementitious Composites: Effects of aging and loading conditions. Constr. Build. Mater. 2020, 231, 117132. [Google Scholar] [CrossRef]

- Trompeta, A.-F.; Koumoulos, E.; Stavropoulos, S.; Velmachos, T.; Psarras, G.; Charitidis, C. Assessing the Critical Multifunctionality Threshold for Optimal Electrical, Thermal, and Nanomechanical Properties of Carbon Nanotubes/Epoxy Nanocomposites for Aerospace Applications. Aerospace 2019, 6, 7. [Google Scholar] [CrossRef]

- Karnati, S.R.; Agbo, P.; Zhang, L. Applications of silica nanoparticles in glass/carbon fiber-reinforced epoxy nanocomposite. Compos. Commun. 2020, 17, 32–41. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, Y.; Liu, D.; Guo, J.; Zhang, J.; Chen, Z. Damage tolerance of 2-dimentional UHMWPE/CF hybrid woven laminates subjected to low-velocity impact. Mater. Des. 2020, 191, 108604. [Google Scholar] [CrossRef]

- Aly, N.M. A review on utilization of textile composites in transportation towards sustainability. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 42002. [Google Scholar] [CrossRef]

- Fekete, J.R.; Hall, J.N. 1—Design of Auto Body: Materials Perspective; Rana, R., Singh, S.B.B.T.-A.S., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 1–18. ISBN 978-0-08-100638-2. [Google Scholar]

- Composites Market Report. 2018. Available online: https://www.avk-tv.de/files/20181115_avk_ccev_market_report_2018_final.pdf (accessed on 22 January 2019).

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Hussain, C.M.; Mishra, A.K. Major Environmental Issues and New Materials. In New Polymer Nanocomposites for Environmental Remediation; Hussain, C.M., Mishra, A.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 77–97. [Google Scholar]

- Murphy, T. The New Face of CAFE. Ward’s AutoWorld. 2008. Available online: http://wardsautoworld.com/ar/auto_new_face_cafe/ (accessed on 22 January 2019).

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Meng, F.; Mckechnie, J.; Turner, T.A.; Pickering, S.j. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Duflou, J.; Deng, Y.; Van Acker, K.; Dewulf, W. Do fiber-reinforced polymer composites provide environmentally benign alternatives? A life-cycle-assessment-based study. MRS Bull. 2012, 37, 374–382. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Semitekolos, D.; Trompeta, A.-F.; Husarova, I.; Man’ko, T.; Potapov, A.; Romenskaya, O.; Liang, Y.; Li, X.; Giorcelli, M.; Dong, H.; et al. Comparative Physical–Mechanical Properties Assessment of Tailored Surface-Treated Carbon Fibres. Materials 2020, 13, 3136. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Li, X.; Semitekolos, D.; Charitidis, C.A.; Dong, H. Enhanced properties of PAN-derived carbon fibres and resulting composites by active screen plasma surface functionalisation. Plasma Process. Polym. 2020, 17, 1900252. [Google Scholar] [CrossRef]

- Semitekolos, D.; Kainourgios, P.; Jones, C.; Rana, A.; Koumoulos, E.P.; Charitidis, C.A. Advanced carbon fibre composites via poly methacrylic acid surface treatment; surface analysis and mechanical properties investigation. Compos. Part B Eng. 2018, 155, 237–243. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- The European Commission. The European Green Deal COM/2019/640 Final. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 22 May 2020).

- Jacob, A. Composites can be recycled. Reinf. Plast. 2011, 55, 45–46. [Google Scholar] [CrossRef]

- Initiative, L.C. New Report: The 2019 Annual Progress Report of the Life Cycle Initiative. 2019. Available online: https://www.lifecycleinitiative.org/ (accessed on 29 May 2020).

- ISO. ISO 14001:2015 Environmental Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Donnelly, K.; Beckett-Furnell, Z.; Traeger, S.; Okrasinski, T.; Holman, S. Eco-design implemented through a product-based environmental management system. J. Clean. Prod. 2006, 14, 1357–1367. [Google Scholar] [CrossRef]

- Singh, A.V.; Laux, P.; Luch, A.; Sudrik, C.; Wiehr, S.; Wild, A.-M.; Santomauro, G.; Bill, J.; Sitti, M. Review of emerging concepts in nanotoxicology: Opportunities and challenges for safer nanomaterial design. Toxicol. Mech. Methods 2019, 29, 378–387. [Google Scholar] [CrossRef]

- Kyriakidou, K.; Brasinika, D.; Trompeta, A.F.A.; Bergamaschi, E.; Karoussis, I.K.; Charitidis, C.A. In vitro cytotoxicity assessment of pristine and carboxyl-functionalized MWCNTs. Food Chem. Toxicol. 2020, 141, 111374. [Google Scholar] [CrossRef]

- EU. A Clean Planet for all A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52018DC0773&from=EN (accessed on 22 May 2020).

- SWD. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the Implementation of the Circular Economy Action Plan. 2019. Available online: https://ec.europa.eu/environment/circular-economy/pdf/report_implementation_circular_economy_action_plan.pdf (accessed on 22 May 2020).

- 1999/31/EC. 1999/31/EC on the Landfill of Waste. 1999. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31999L0031 (accessed on 22 May 2020).

- 94/62/EC. European Parliament and Council Directive 94/62/EC of 20 December 1994 on Packaging and Packaging Waste. 1994. Available online: http://eur-lex.europa.eu/legal-content/EN/NOT/?uri=celex:31994L0062 (accessed on 22 May 2020).

- 2000/53/EC. Directive 2000/53/EC on End-of Life Vehicles. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32000L0053 (accessed on 22 May 2020).

- 2006/66/EC. Directive 2006/66/ec of the European Parliament and of the Council on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC. 2006. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:266:0001:0014:en:PDF (accessed on 22 May 2020).

- 2012/19/EU. Directive 2012/19/eu of the European Parliament and of the Council on Waste Electrical and Electronic Equipment (WEEE). 2012. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2012:197:0038:0071:en:PDF (accessed on 22 May 2020).

- COM. Commission Staff Working Document Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions a European Strategy for Plastics in a Circular Economy. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52018SC0016&from=RO (accessed on 22 May 2020).

- 333/2014 Regulation (EU). No 333/2014 of the European Parliament and of the Council of 11 March 2014 Amending Regulation (EC) No 443/2009 to Define the Modalities for Reaching the 2020 Target to Reduce CO2 Emissions from New Passenger Cars. 2014. Available online: https://op.europa.eu/en/publication-detail/-/publication/5b971540-bc8f-11e3-86f9-01aa75ed71a1/language-en (accessed on 20 May 2020).

- Heuss, R.; Muller, N.; van Sintern, W.; Starke, A.; Tschiesner, A. Lightweight, Heavy Impact; McKinsey & Company. 2012. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/automotive (accessed on 22 May 2020).

- Gardiner, G. Recycled carbon fiber update: Closing the CFRP lifecycle loop. Compos. Technol. 2014, 20, 28–33. [Google Scholar]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Xiarchos, I.; Morozinis, A.K.; Charitidis, C. Life cycle assessment and possible impacts of CFRPs for space applications. MATEC Web Conf. 2019, 304, 07006. [Google Scholar] [CrossRef][Green Version]

- Meng, F.; Pickering, S.; McKechnie, J. An Environmental Comparison of Carbon Fibre Composite Waste End-of-life Options. In Proceedings of the SAMPE Europe Conference 2018, Southampton, UK, 13 September 2018. [Google Scholar]

- EC, Circular Economy Strategy. 2015. Available online: http://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 10 October 2016).

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Howarth, J.; Mareddy, S.S.R.; Mativenga, P.T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, W.; Jin, X.; Liang, X.; Sui, G.; Yang, X. Efficient reclamation of carbon fibers from epoxy composite waste through catalytic pyrolysis in molten ZnCl2. RSC Adv. 2019, 9, 377–388. [Google Scholar] [CrossRef]

- Hall, S. End-of-life recycling options for glass fibre reinforced polymers. Plymouth Student Sci. 2016, 9, 68–94. [Google Scholar]

- Hagnell, M.K.; Åkermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- Lee, C.-K.; Kim, Y.-K.; Pruitichaiwiboon, P.; Kim, J.-S.; Lee, K.-M.; Ju, C.-S. Assessing environmentally friendly recycling methods for composite bodies of railway rolling stock using life-cycle analysis. Transp. Res. Part. D Transp. Environ. 2010, 15, 197–203. [Google Scholar] [CrossRef]

- Khalil, Y.F. Comparative Environmental and Human Health Evaluations of Thermolysis and Solvolysis Recycling Technologies of Carbon Fiber Reinforced Polymer Waste. Waste Manag. 2018, 76, 767–778. [Google Scholar] [CrossRef] [PubMed]

- Keith, M.; Oliveux, G.; Leeke, G. Optimisation of Solvolysis for Recycling Carbon Fibre Reinforced Composites. 2016. Available online: http://dspace.lib.cranfield.ac.uk/handle/1826/10334 (accessed on 30 June 2016).

- Roux, M.; Eguémann, N.; Dransfeld, C.; Thiébaud, F.; Perreux, D. Thermoplastic carbon fibre-reinforced polymer recycling with electrodynamical fragmentation: From cradle to cradle. J. Thermoplast. Compos. Mater. 2015, 30, 381–403. [Google Scholar] [CrossRef]

- Shuaib, N.A.; Mativenga, P.T. Energy demand in mechanical recycling of glass fibre reinforced thermoset plastic composites. J. Clean. Prod. 2016, 120, 198–206. [Google Scholar] [CrossRef]

- Nakagawa Mitsutoshi, S.K. CFRP Recycling Technology Using Depolymerization Under Ordinary Pressure. 2014. Available online: https://www.hitachi-chem.co.jp/english/report/056/56.pdf#page=5 (accessed on 22 May 2020).

- EC-JRC. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment–Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, 2010; ISBN 978-92-79-19092-6. [Google Scholar]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. The Ecoinvent Database: Overview and Methodology, Data Quality Guideline for the Ecoinvent Database Version 3. 2013. Available online: https://www.ecoinvent.org (accessed on 22 May 2020).

- Kainourgios, P.; Kartsonakis, I.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Goulis, P.; Charitidis, C.A. Electrochemical surface functionalization of carbon fibers for chemical affinity improvement with epoxy resins. Appl. Surf. Sci. 2017, 416, 593–604. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.; Elgowainy, A. Material Efficiencies and Recycling of Aluminum and Carbon Fiber Reinforced Plastics for Automotive Applications. Energy Syst. 2016. Available online: https://greet.es.anl.gov/publication-materials-automotive-2016 (accessed on 22 May 2020).

- Griffing, E. Chemical Life Cycle Database. 2010. Available online: https://environmentalgenome.org/wp-content/uploads/2017/09/ES_V4_triethylaluminum_2016-11-10_15-48.pdf (accessed on 22 May 2020).

- Sidorina, A.I.; Gunyaeva, A.G. Market for Carbon Fibres and Composites Based on them. A review. Fibre Chem. 2016, 48, 306–310. [Google Scholar] [CrossRef]

- Prakashkumar, P.; Chauhan, E.C.; Shah, D.S.N. Basics of Carbon Fiber—Business Opportunities; Lulu Publications: Raleigh, NC, US, 2019; Chapter 2; ISBN 978-0-359-87231-2. [Google Scholar]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Seghini, M.C. Investigation into the Mechanical Properties and Fibre/Matrix Interface Optimization for Next Generation of Basalt-Plant Fibre Hybrid Composites, Sapienza; University of Rome: Rome, Italy, 2020. [Google Scholar]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Dong, P.A. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Khalil, Y.F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain. Prod. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef]

- Pickering, S. Recycling Thermoset Composite Materials. In Wiley Encyclopedia of Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; Volume 42, ISBN 9781118097298. [Google Scholar]

- Dauguet, M.; Mantaux, O.; Perry, N.; Zhao, Y.F. Recycling of CFRP for High Value Applications: Effect of Sizing Removal and Environmental Analysis of the SuperCritical Fluid Solvolysis. Procedia CIRP 2015, 29, 734–739. [Google Scholar] [CrossRef]

- Lee, S.; Norman, J.; Gunasekaran, S.; van Laack, R.L.J.; Kim, B.; Kauffman, R. Use of electrical conductivity to predict water-holding capacity in post-rigor pork. Meat Sci. 2000, 55, 385–389. [Google Scholar] [CrossRef]

- Prinçaud, M.; Aymonier, C.; Loppinet-Serani, A.; Perry, N.; Sonnemann, G. Environmental Feasibility of the Recycling of Carbon Fibers from CFRPs by Solvolysis Using Supercritical Water. ACS Sustain. Chem. Eng. 2014, 2, 1498–1502. [Google Scholar] [CrossRef]

- Leu, S.-Y.; Yang, T.-H.; Lo, S.-F.; Yang, T.-H. Optimized material composition to improve the physical and mechanical properties of extruded wood–plastic composites (WPCs). Constr. Build. Mater. 2012, 29, 120–127. [Google Scholar] [CrossRef]

- Doka, G. Life Cycle Inventories of Waste Treatment Services, Dübendorf. 2003. Available online: https://www.doka.ch/13_I_WasteTreatmentGeneral.pdf (accessed on 22 May 2020).

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.; Haywood, J.; Lean, J.; Lowe, D.; Myhre, G.; et al. Changes in atmospheric constituents and in radiative forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K., Tignor, M., Miller, H., Eds.; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, M.; De Schryver, A.; Humbert, S.; Laurent, A.; et al. Identifying best existing practice for characterization modeling in life cycle impact assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar] [CrossRef]

- Bonou, A.O.S.I. Decision Uncertainties in LCA: Database, Software & LCIA Methodology Choice. In Proceedings of the 23th SETAC Europe Annual Meeting, Glasgow, UK, 12–16 May 2013. [Google Scholar]

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?—A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Behrens, A. The Climate Change Impact of Material Use. Intereconomics 2016, 51, 209–212. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Svanström, M. Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J. Clean. Prod. 2019, 223, 946–956. [Google Scholar] [CrossRef]

- Zoghi, M. The International Handbook of FRP Composites in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Chua, M.H. Understanding Aerospace Composite Components Supply Chain Carbon Emissions. In Proceedings of the Irish Manufacturing Conference (IMC32), Belfast, UK, 3 September 2015. [Google Scholar]

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Pickering, S.J. Environmental Aspects of Use of Recycled Carbon Fiber Composites in Automotive Applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef]

- Trompeta, A.-F.; Koklioti, M.A.; Perivoliotis, D.K.; Lynch, I.; Charitidis, C.A. Towards a holistic environmental impact assessment of carbon nanotube growth through chemical vapour deposition. J. Clean. Prod. 2016, 129, 384–394. [Google Scholar] [CrossRef]

- EEA. CO2 Intensity of Electricity Generation. 2017. Available online: https://www.eea.europa.eu/data-and-maps/data/co2-intensity-of-electricity-generation (accessed on 1 June 2020).

- SBI50. Japan’s Current Progress of GHG Reduction. 2019. Available online: https://unfccc.int/sites/default/files/resource/Japan_MA2019_presentation.pdf (accessed on 1 June 2020).

- IEA. Key Energy Statistics. 2019. Available online: https://www.iea.org/countries/japan (accessed on 1 June 2020).

- EEA. European Union Emission Inventory Report 1990–2017 under the UNECE Convention on Long-range Transboundary Air Pollution (LRTAP). EEA Technical Report No 9/2019. Copenhagen. 2019. Available online: https://www.eea.europa.eu/data-and-maps/indicators/eea32-persistent-organic-pollutant-pop-emissions-1/eea-2010-.-european-union (accessed on 22 May 2020).

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fibre in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Job, S.; Mativenga, P.; Shuaib, N.A.; Oliveux, G.; Leeke, G.; Pickering, S. Composites Recycling—Where Are We Now? Composites UK Ltd.: Berkhamsted, UK, 2016. [Google Scholar]

- Miseljic, M.; Olsen, S.I. LCA of Nanomaterials. In Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2018; pp. 817–833. [Google Scholar]

- Miseljic, M.; Olsen, S.I. Life-cycle assessment of engineered nanomaterials: A literature review of assessment status. J. Nanoparticle Res. 2014, 16, 2427. [Google Scholar] [CrossRef]

- Thangadurai, T.D.; Manjubaashini, N.; Thomas, S.; Maria, H.J. Nanomaterials Research and Development; Springer: Cham, Switzerland, 2020; pp. 203–210. [Google Scholar]

- Upreti, G.; Rajive, D.; Naidu, S.; Atuahene, I.; Sawhney, R. Life Cycle Assessment of Nanomaterials. In Green Processes for Nanotechnology: From Inorganic to Bioinspired Nanomaterials; Springer: Cham, Switzerland, 2015; pp. 393–408. [Google Scholar]

- OECD. Incineration of Waste Containing Nanomaterials. In Nanomaterials in Waste Streams: Current Knowledge on Risks and Impacts; OECD Publishing: Paris, France, 2016. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- OECD. Waste: Municipal Waste. In OECD Environmental Statistics (Database); OECD: Paris, France, 2020. [Google Scholar]

- Duflou, J.R.; De Moor, J.; Verpoest, I.; Dewulf, W. Environmental impact analysis of composite use in car manufacturing. CIRP Ann. 2009, 58, 9–12. [Google Scholar] [CrossRef]

| CFRP Recycling Routes | Energy Consumption MJ/kg CFRP | Reference |

|---|---|---|

| Mechanical | 0.17–1.93 | [64] |

| Mechanical | 0.27–2.03 | [55] |

| Pyrolysis | 3–30 | [64] |

| Solvolysis | 19.2 | [62] |

| Chemical | 60–90 | [65] |

| Materials | Manufacture | Use | End-of-life | |

|---|---|---|---|---|

| Sleekfast sailing boat | Input CF = 10.5 kg Sicomin SR1500 (0.06 wt% MWCNTs) = 10 kg PVC foam = 1.5 kg Epoxy gelcoat = 4 kg Electricity = 368 MJ/kg CF Electricity = 1104 MJ/kg CNTs Output/emissions to air/water (see Table A2 in Appendix A) | Input Auxiliaries = 2.72 kg Scraps = 1.47 kg (6%) Electricity = 230 MJ (curing) Manufacture waste

| Input Epoxy gelcoat = 30 kg (for maintenance, 2 kg biannually for 30 years’ lifetime) | Scenario 1: Landfill Input 100% inert waste [75] Electricity = 0.27 MJ/kg Scenario 2: Hazardous waste incineration Input Electricity = 0.27 MJ/kg Scenario 3: MSW incineration with energy recovery Input Electricity = 0.27 MJ/kg Avoided products Electricity = 3.1 kWh [76] Heat for reuse = 32 MJ/kg [77] Scenario 4: Recyclingvia pyrolysis Input Electricity = 0.27 MJ/kg Electricity = 30 MJ/kg [61] Avoided products CF recovery 60% [78] Heating oil = 30 MJ/kg [77] |

| Handbrake lever | Input CF = 0.12 kg Epoxy resin = 0.02 kg CNTs = 0.01 kg Electricity = 368 MJ/kg CF Electricity = 1.1 MJ/kg CNTs Output/emissions to air/water (see Table A1 in Appendix) | Input Pack. mat. = 1.272 kg Electricity = 18 MJ (curing) Manufacture waste

| Assumptions:

|

| Scenario | Waste Management | Waste Treatment Technology | Comments |

|---|---|---|---|

| Scenario 1 | Landfill | Sanitary landfill | 100% inert waste [75,86] |

| Scenario 2 | Incineration of hazardous waste | Rotary kiln (>1100 °C) | 100% bottom ash sent to hazardous landfill |

| Scenario 3 | Incineration with energy recovery | MSW incinerator (850 °C–1200 °C) | 35% heat recovery convert to electricity [75] |

| Scenario 4 | Thermal recycling | Pyrolysis (450 °C and 700 °C) | 60% CF recovery and retrieved energy of 40 MJ/kg matrix [75] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrakli, F.; Gkika, A.; Bonou, A.; Karayannis, P.; Koumoulos, E.P.; Semitekolos, D.; Trompeta, A.-F.; Rocha, N.; Santos, R.M.; Simmonds, G.; et al. End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective. Polymers 2020, 12, 2129. https://doi.org/10.3390/polym12092129

Petrakli F, Gkika A, Bonou A, Karayannis P, Koumoulos EP, Semitekolos D, Trompeta A-F, Rocha N, Santos RM, Simmonds G, et al. End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective. Polymers. 2020; 12(9):2129. https://doi.org/10.3390/polym12092129

Chicago/Turabian StylePetrakli, Fotini, Anastasia Gkika, Alexandra Bonou, Panagiotis Karayannis, Elias P. Koumoulos, Dionisis Semitekolos, Aikaterini-Flora Trompeta, Nuno Rocha, Raquel M. Santos, Guy Simmonds, and et al. 2020. "End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective" Polymers 12, no. 9: 2129. https://doi.org/10.3390/polym12092129

APA StylePetrakli, F., Gkika, A., Bonou, A., Karayannis, P., Koumoulos, E. P., Semitekolos, D., Trompeta, A.-F., Rocha, N., Santos, R. M., Simmonds, G., Monaghan, G., Valota, G., Gong, G., & Charitidis, C. A. (2020). End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle Perspective. Polymers, 12(9), 2129. https://doi.org/10.3390/polym12092129