Flammability Characteristics and Mechanical Properties of Casein Based Polymeric Composites

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

2.2. Composites Fabrication

2.3. Differential Scanning Calorimetery

2.4. Thermogravimetric Analysis

2.5. Flammability Tests

2.5.1. Vertical Burn Test (UL-94)

2.5.2. Cone Calorimeter Experiment

2.6. Mechanical Tests

2.7. Environmental Scanning Electron Microscope

3. Results and Discussion

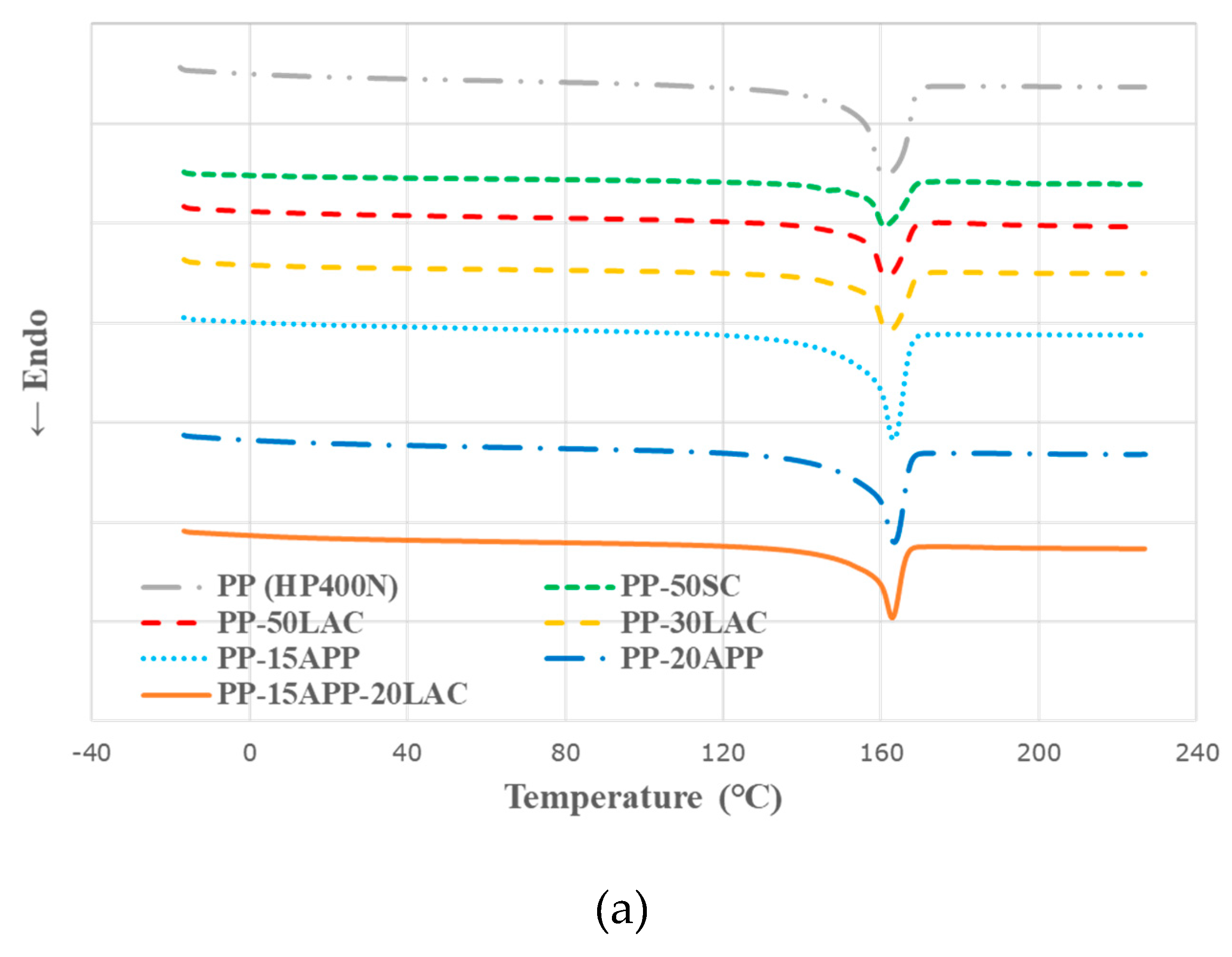

3.1. Differential Scanning Calorimetry

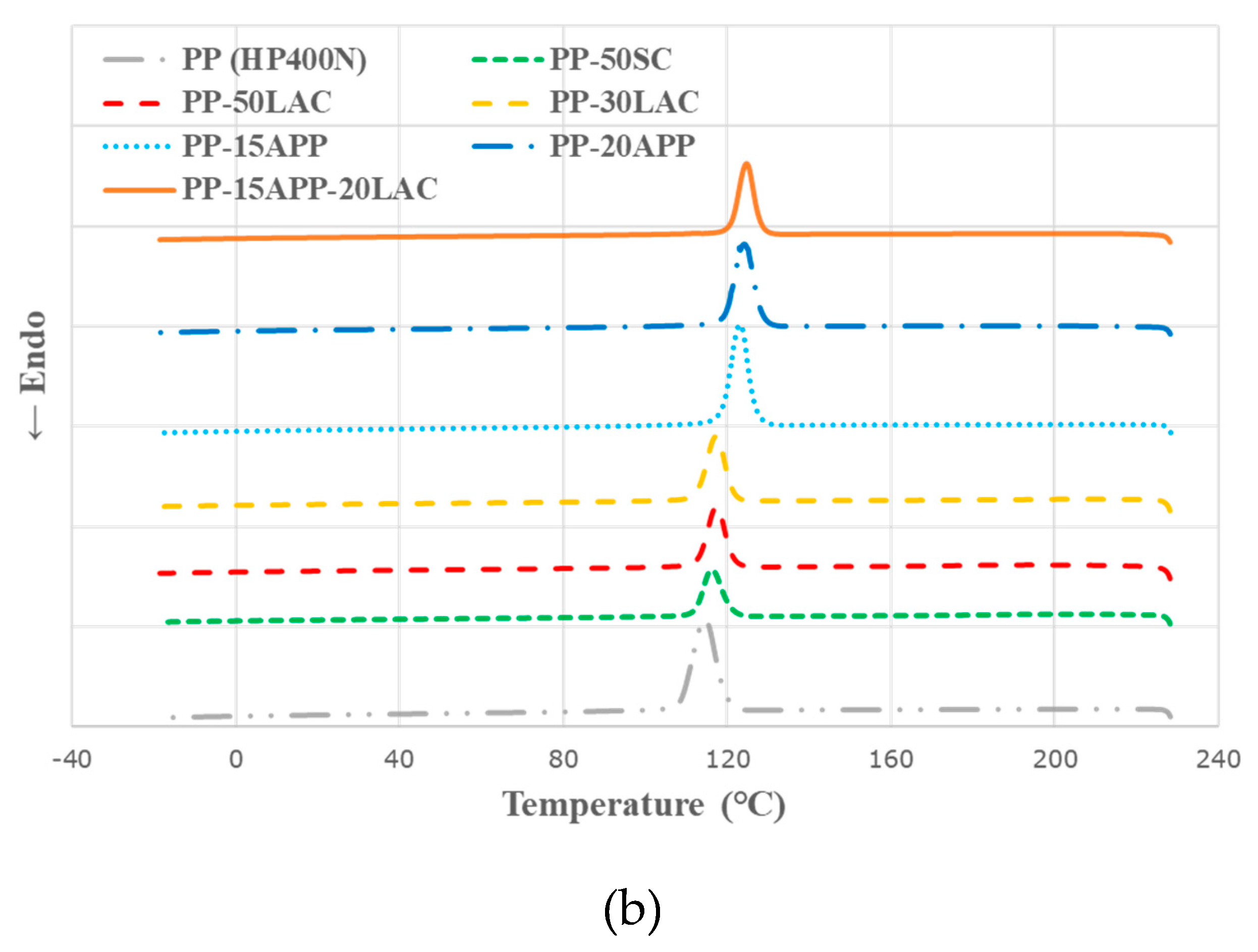

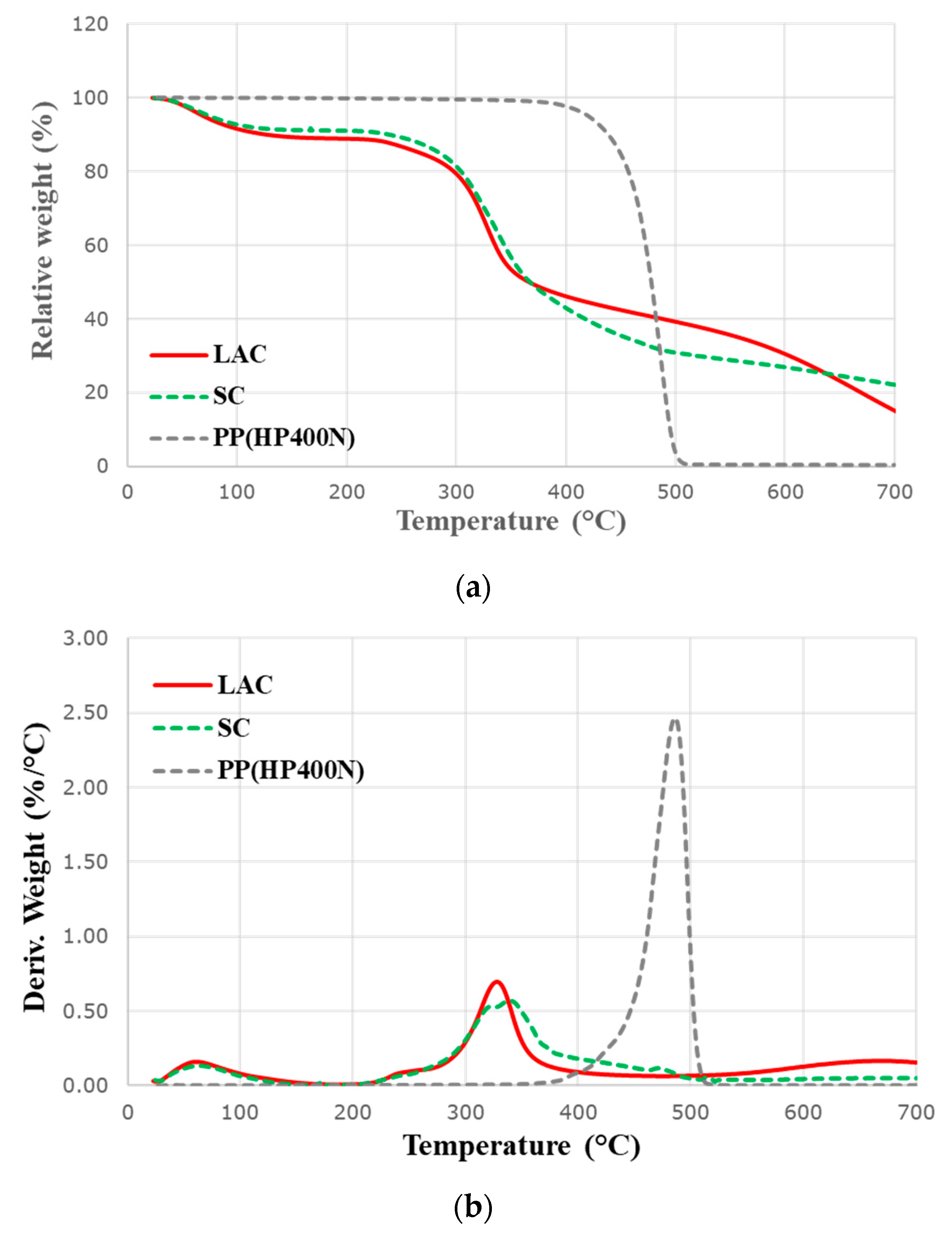

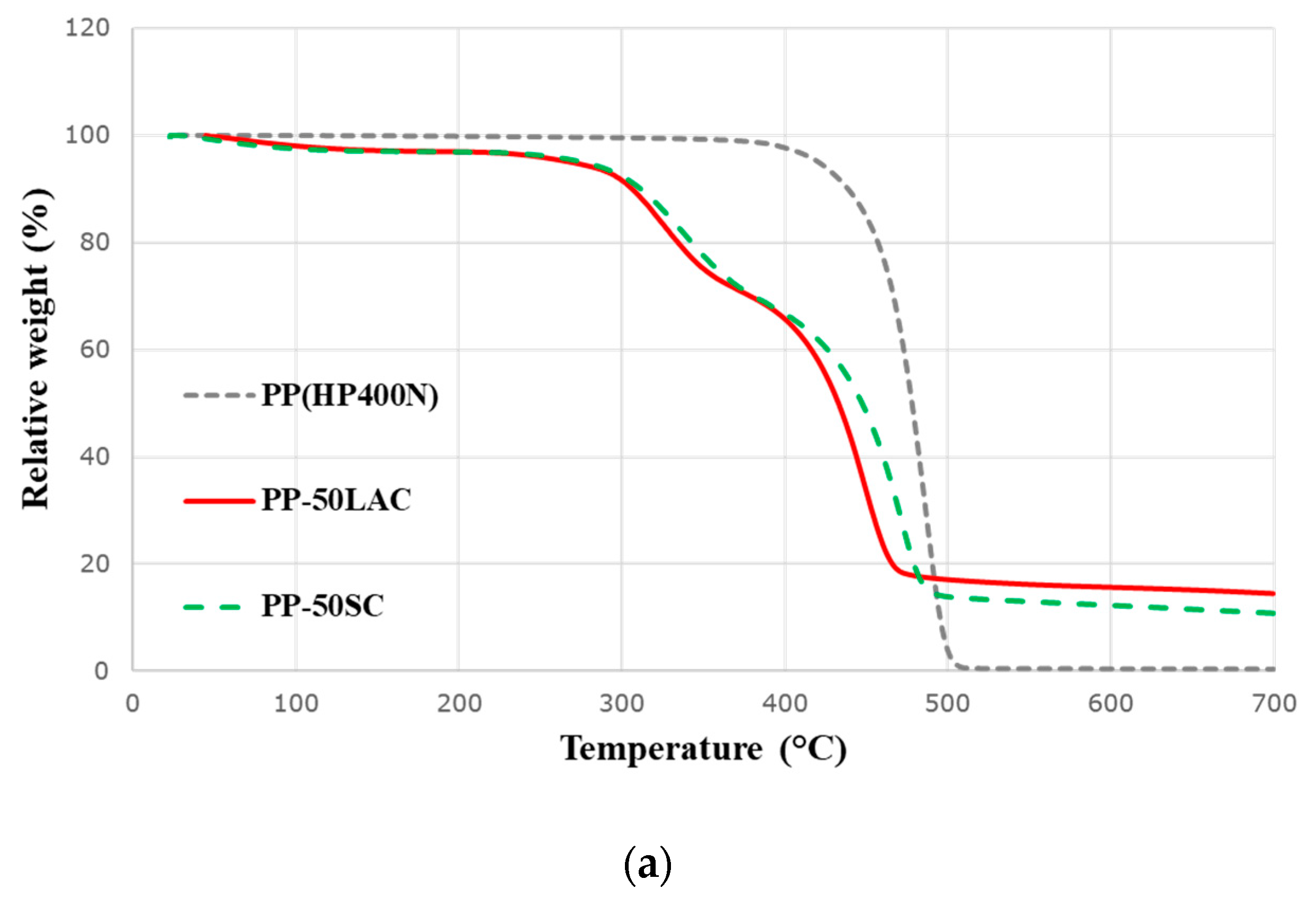

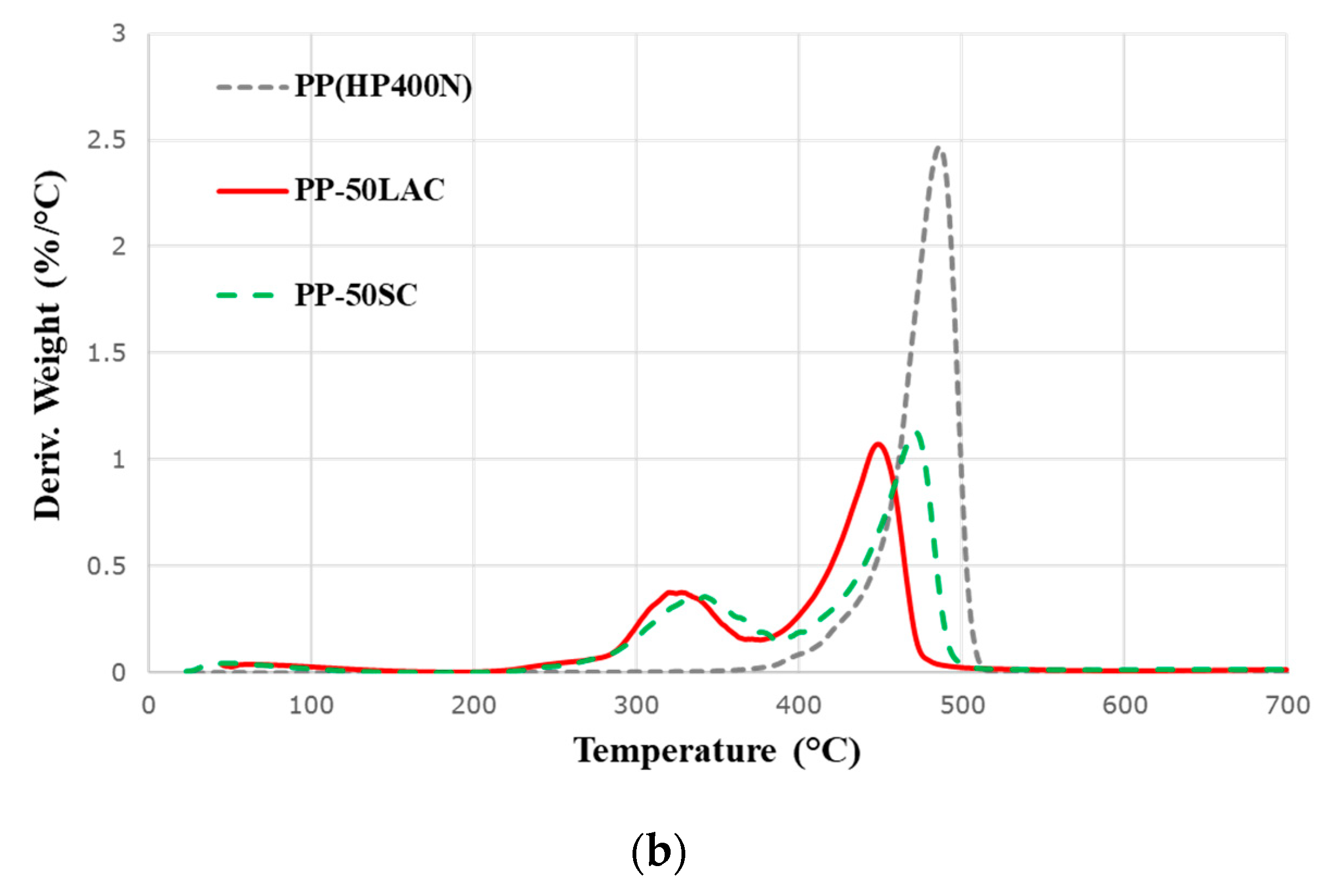

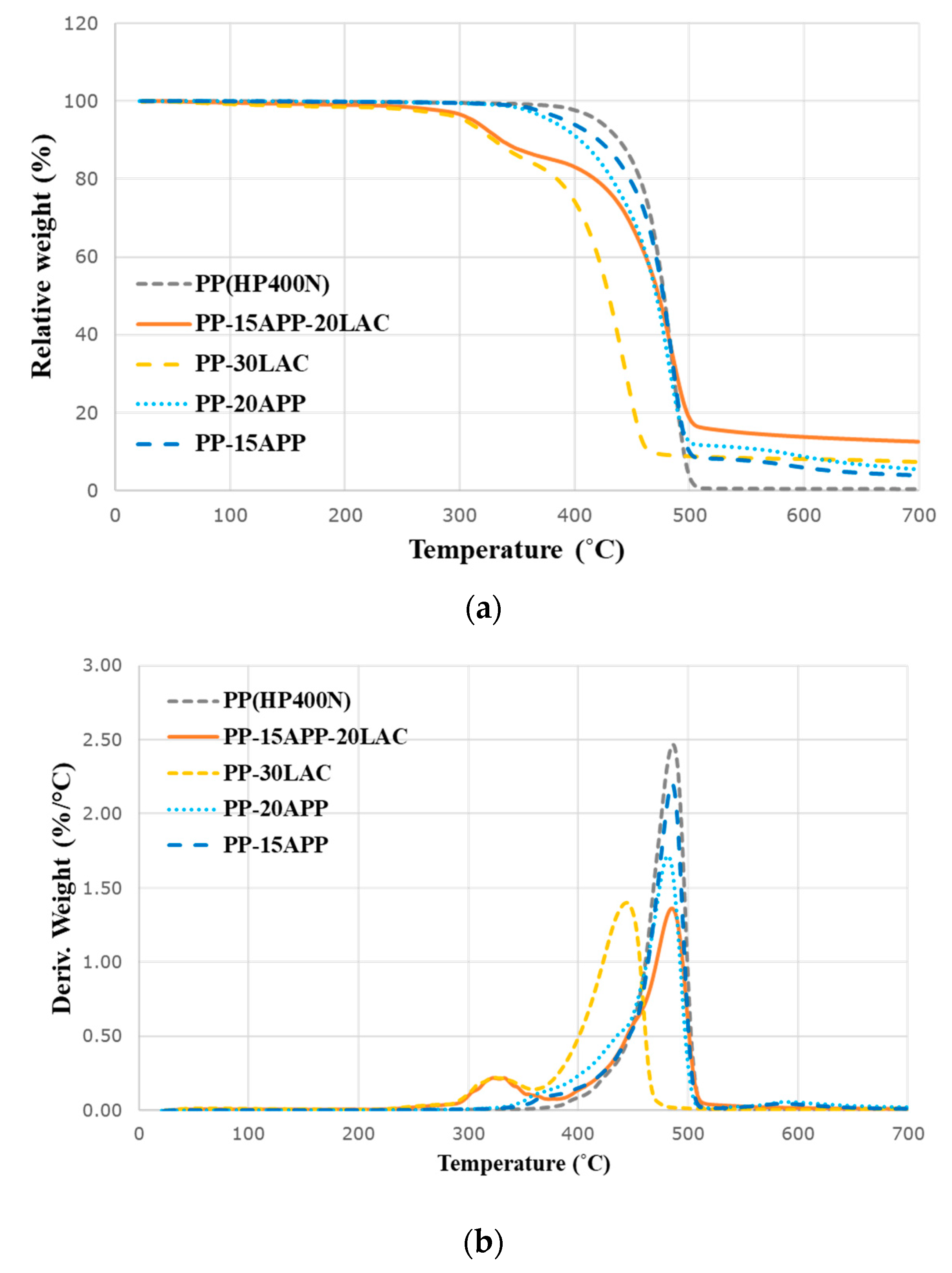

3.2. Thermogravimetric Analysis

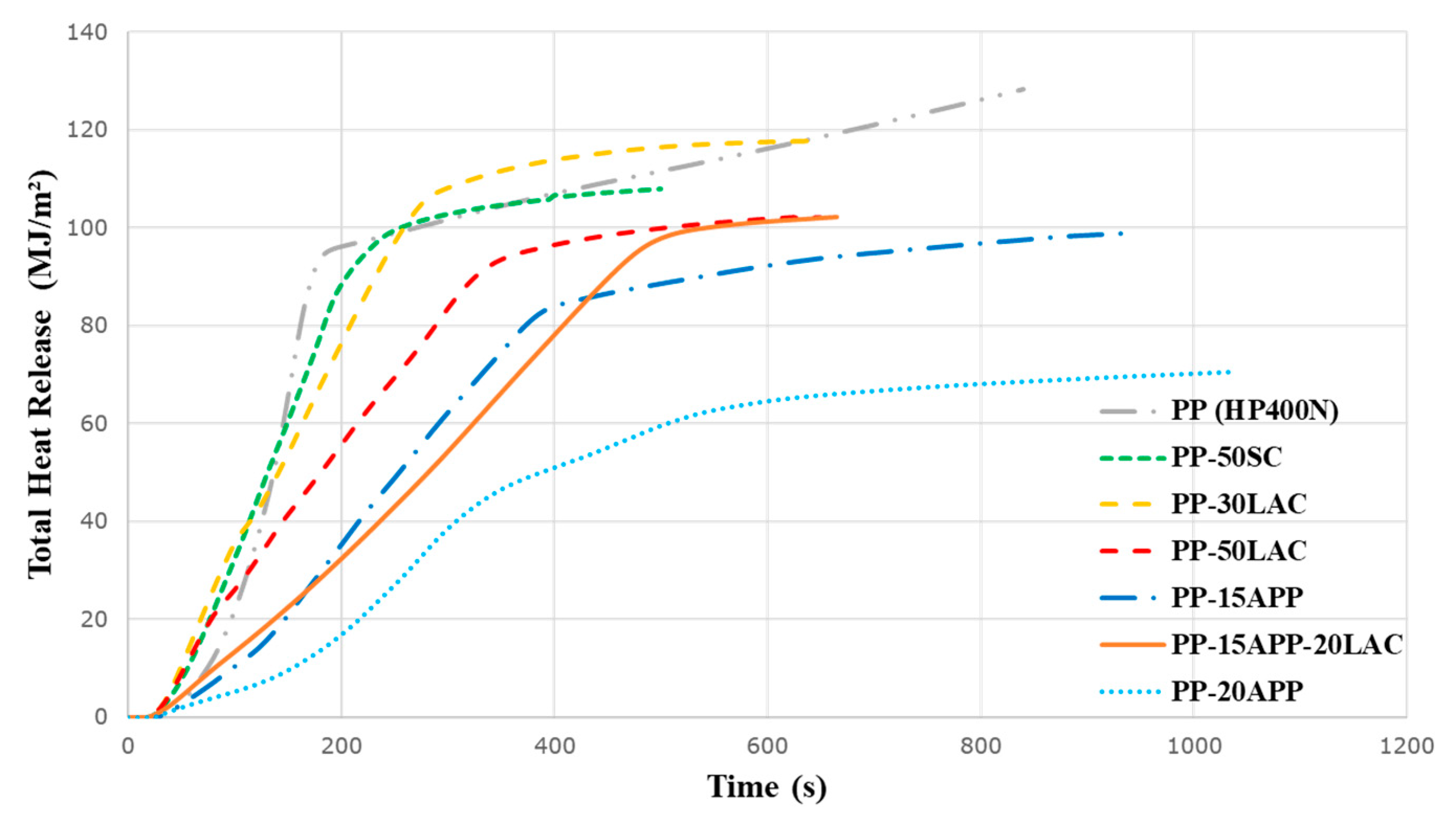

3.3. Cone Calorimeter Results

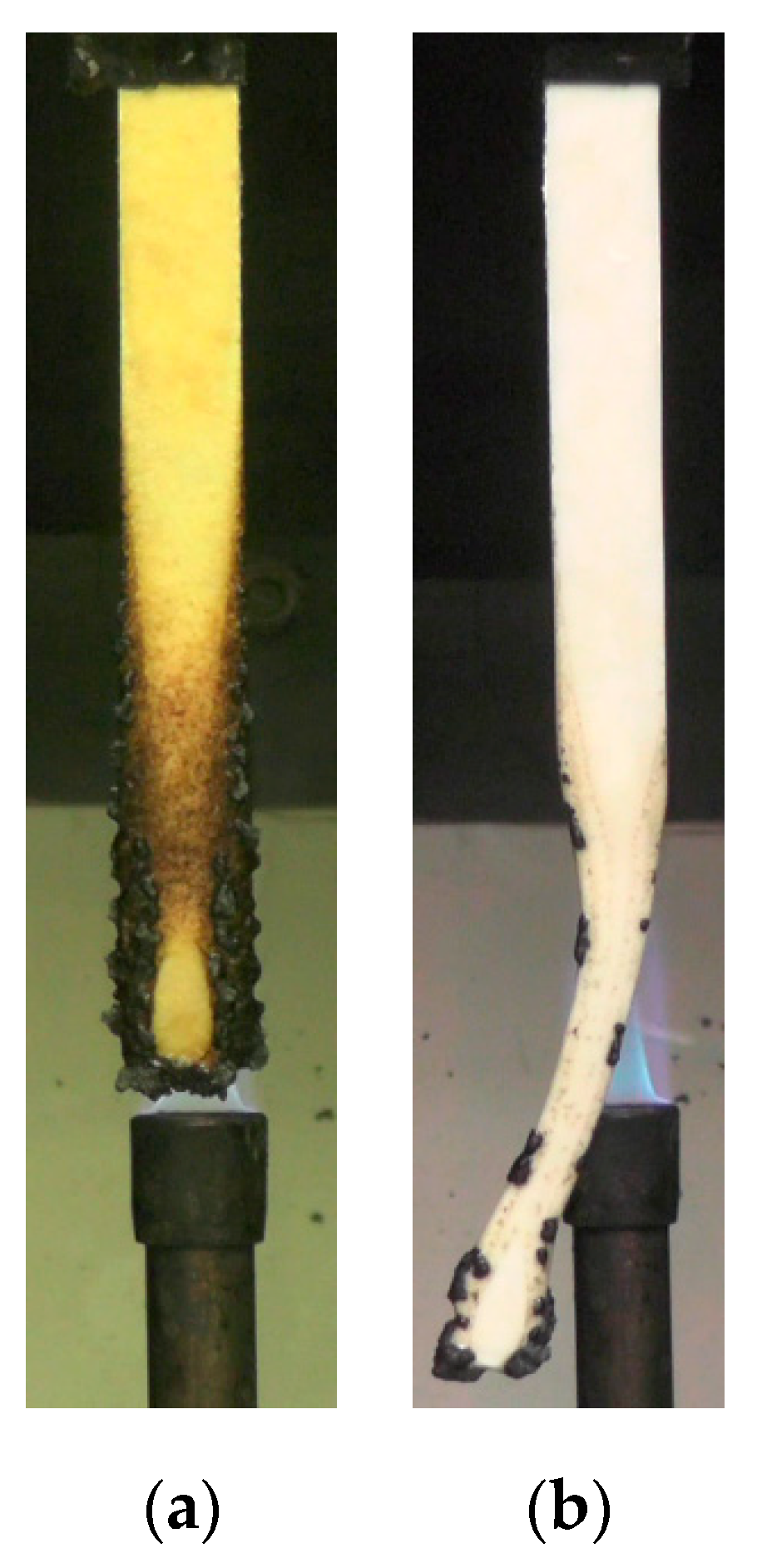

3.4. Char Formation

3.5. Vertical Burn Test (UL-94)

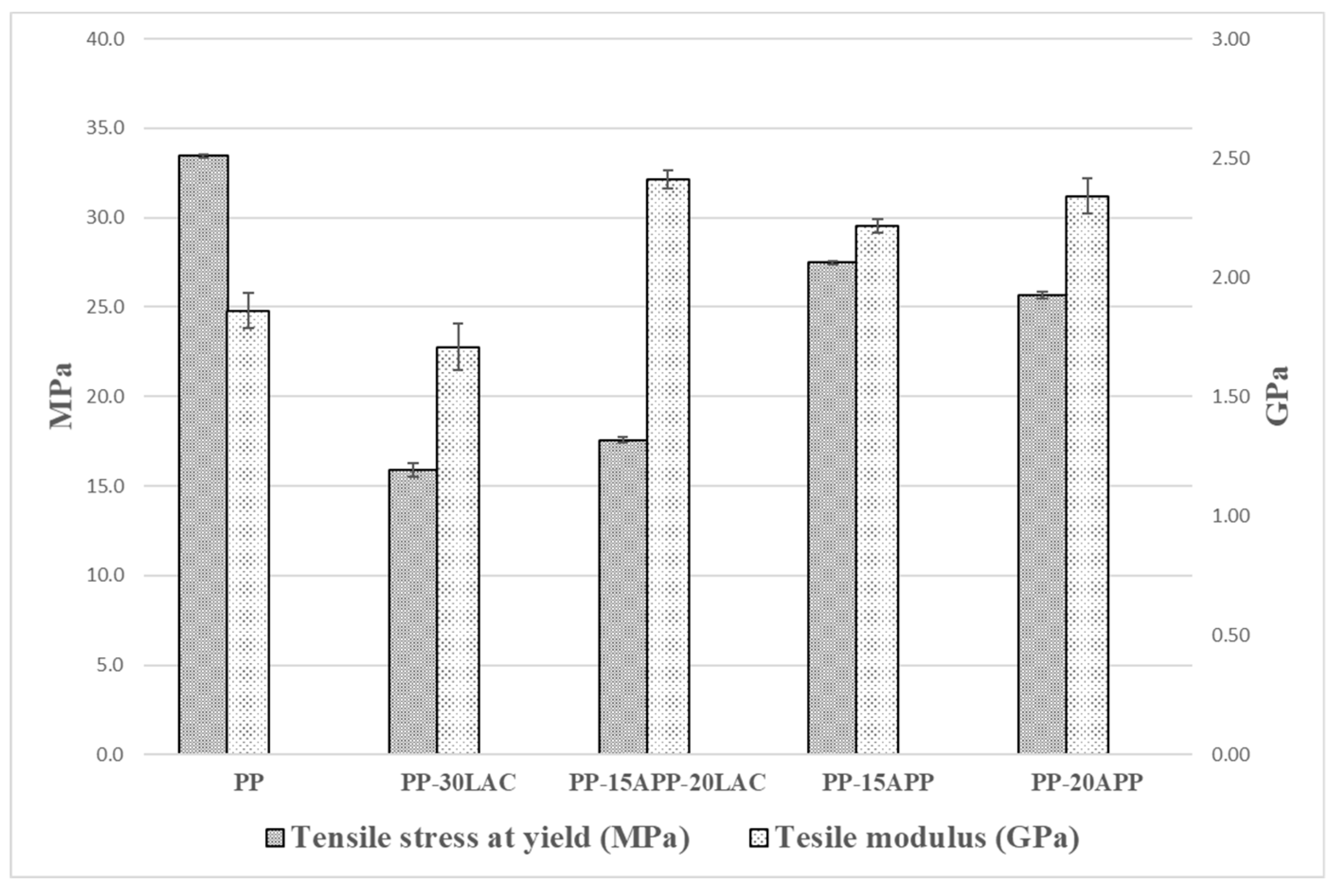

3.6. Tensile Properties

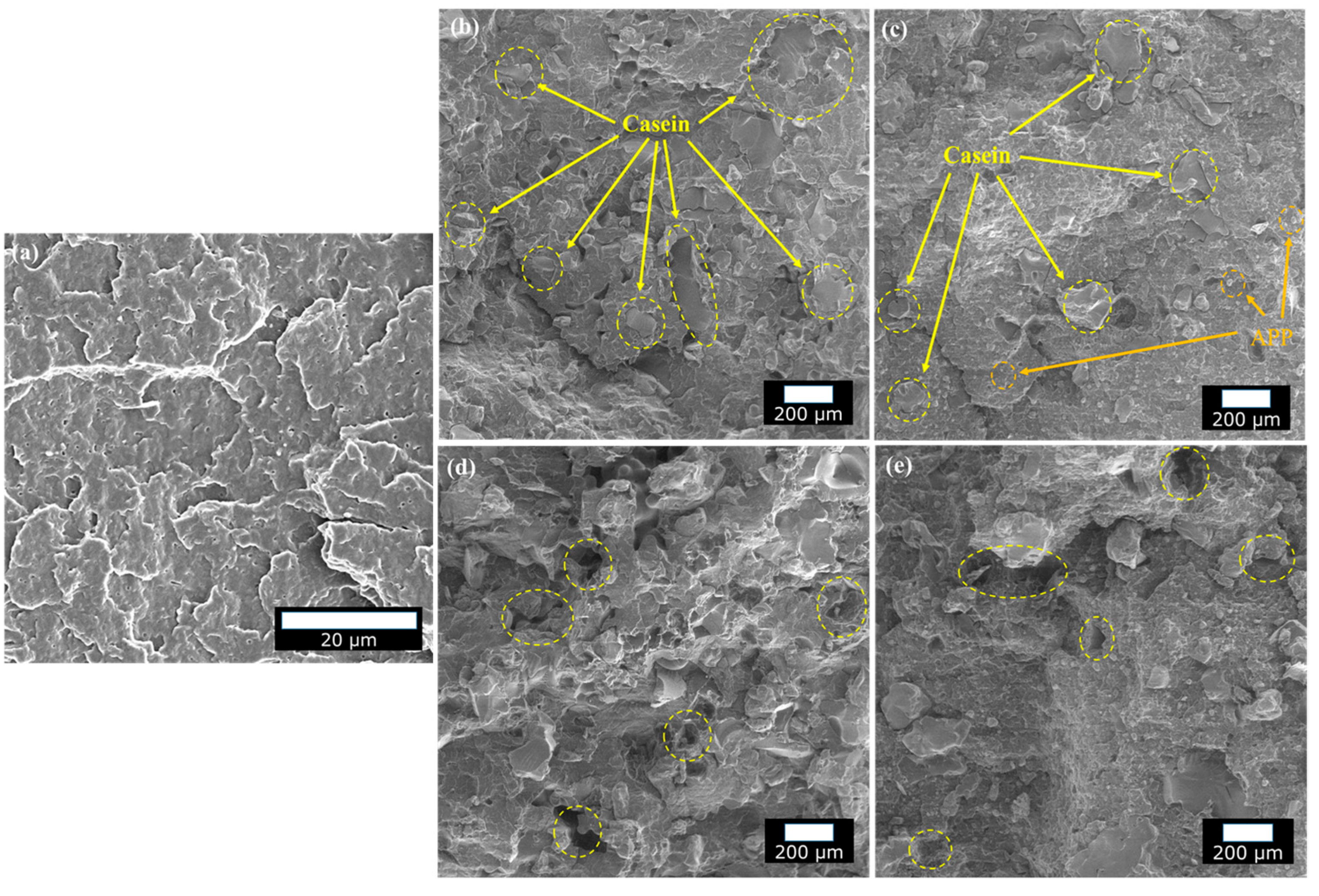

3.7. Morphology

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Das, O.; Rasheed, F.; Kim, N.K.; Johansson, E.; Capezza, A.J.; Kalamkarov, A.L.; Hedenqvist, M.S. The Development of Fire and Microbe Resistant Sustainable Gluten Plastics. J. Clean. Prod. 2019, 222, 163–173. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. A Review of Flammability of Natural Fibre Reinforced Polymeric Composites. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A Review of Stimuli-Responsive Polymers for Smart Textile Applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Alongi, J.; Bosco, F.; Carosio, F.; Di Blasio, A.; Malucelli, G. A New Era for Flame Retardant Materials? Mater. Today 2014, 17, 152–153. [Google Scholar] [CrossRef]

- Kim, N.K.; Bhattacharyya, D.; Lin, R. Multi-Functional Properties of Wool Fibre Composites. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; pp. 8–11. [Google Scholar]

- Subasinghe, A.D.L.; Das, R.; Bhattacharyya, D. Parametric Analysis of Flammability Performance of Polypropylene/Kenaf Composites. J. Mater. Sci. 2016, 51, 2101–2111. [Google Scholar] [CrossRef]

- Özmen, U.; Baba, B.O. Thermal Characterization of Chicken Feather/PLA Biocomposites. J. Therm. Anal. Calorim. 2017, 129, 347–355. [Google Scholar] [CrossRef]

- Wrześniewska-Tosik, K.; Zajchowski, S.; Bryśkiewicz, A.; Ryszkowska, J. Feathers as a Flame-Retardant in Elastic Polyurethane Foam. Fibres Text. East. Eur. 2014, 103, 119–128. [Google Scholar]

- Jung, D.; Bhattacharyya, D. Keratinous Fiber Based Intumescent Flame Retardant with Controllable Functional Compound Loading. ACS Sustain. Chem. Eng. 2018, 6, 13177–13184. [Google Scholar]

- Holt, C.; Sawyer, L. Caseins as Rheomorphic Proteins: Interpretation of Primary and Secondary Structures of the As1-, β- and κ-Caseins. J. Chem. Soc. Faraday Trans. 1993, 89, 2683–2692. [Google Scholar] [CrossRef]

- Snoeren, T.H.M.; Van Markwijk, B.; Van Montfort, R. Some Physicochemical Properties of Bovine As2-Casein. BBA—Protein Struct. 1980, 622, 268–276. [Google Scholar] [CrossRef]

- Shepherd, R.; Robertson, A.; Ofman, D. Dairy Glycoconjugate Emulsifiers: Casein-Maltodextrins. Food Hydrocoll. 2000, 14, 281–286. [Google Scholar] [CrossRef]

- de Kruif, C.G. Chapter VI Caseins. Prog. Biotechnol. 2003, 23, 219–269. [Google Scholar]

- Chang, I.; Im, J.; Chung, M.K.; Cho, G.C. Bovine Casein as a New Soil Strengthening Binder from Diary Wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Wormell, R.L. 18—Regenerated Protein Fibres from Wool and Casein. J. Text. Inst. Trans. 1948, 39, T219–T224. [Google Scholar] [CrossRef]

- Alongi, J.; Cuttica, F.; Blasio, A. Di; Carosio, F.; Malucelli, G. Intumescent Features of Nucleic Acids and Proteins. Thermochim. Acta 2014, 591, 31–39. [Google Scholar] [CrossRef]

- Alongi, J.; Carletto, R.A.; Bosco, F.; Carosio, F.; Di Blasio, A.; Cuttica, F.; Antonucci, V.; Giordano, M.; Malucelli, G. Caseins and Hydrophobins as Novel Green Flame Retardants for Cotton Fabrics. Polym. Degrad. Stab. 2014, 99, 111–117. [Google Scholar] [CrossRef]

- Horne, D.S. Casein Micelle Structure and Stability, Second Edition; Elsevier Inc.: Amsterdam, The Netherlands, 2008; pp. 133–162. [Google Scholar]

- Broyard, C.; Gaucheron, F. Modifications of Structures and Functions of Caseins: A Scientific and Technological Challenge. Dairy Sci. Technol. 2015, 95, 831–862. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y.; Chai, Z.; Leng, X. Study of the Physical Properties of Whey Protein Isolate and Gelatin Composite Films. J. Agric. Food Chem. 2010, 58, 5100–5108. [Google Scholar] [CrossRef]

- Mi, Y.; Chen, X.; Guo, Q. Bamboo Fiber--reinforced Polypropylene Composites: Crystallization and Interfacial Morphology. J. Appl. Polym. Sci. 1997, 64, 1267–1273. [Google Scholar] [CrossRef]

- Mocanu, A.M.; Moldoveanu, C.; Odochian, L.; Paius, C.M.; Apostolescu, N.; Neculau, R. Study on the Thermal Behavior of Casein under Nitrogen and Air Atmosphere by Means of the TG-FTIR Technique. Thermochim. Acta 2012, 546, 120–126. [Google Scholar] [CrossRef]

- Capelle, H.A.; Britcher, L.G.; Morris, G.E. Sodium Stearate Adsorption onto Titania Pigment. J. Colloid Interface Sci. 2003, 268, 293–300. [Google Scholar] [CrossRef] [PubMed]

- Dutta, S.; Kim, N.K.; Das, R.; Bhattacharyya, D. Effects of Sample Orientation on the Fire Reaction Properties of Natural Fibre Composites. Compos. Part B Eng. 2019, 157, 195–206. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Dumazert, L.; Lopez-Cuesta, J.M.; Brohez, S.; Delvosalle, C.; Dubois, P. Metallic Phytates as Efficient Bio-Based Phosphorous Flame Retardant Additives for Poly(Lactic Acid). Polym. Degrad. Stab. 2015, 119, 217–227. [Google Scholar] [CrossRef]

- Grand, A.F.; Wilkie, C.A. Fire Retardancy of Polymeric Materials; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Dasari, A.; Yu, Z.Z.; Cai, G.P.; Mai, Y.W. Recent Developments in the Fire Retardancy of Polymeric Materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Hermansson, A.; Hjertberg, T.; Sultan, B.Å. The Flame Retardant Mechanism of Polyolefins Modified with Chalk and Silicone Elastomer. Fire Mater. 2003, 27, 51–70. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R. Development of Fire-Retardant Materials-Interpretation of Cone Calorimeter Data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Kim, N.K.; Lin, R.J.T.; Bhattacharyya, D. Effects of Wool Fibres, Ammonium Polyphosphate and Polymer Viscosity on the Flammability and Mechanical Performance of PP/Wool Composites. Polym. Degrad. Stab. 2015, 119, 167–177. [Google Scholar] [CrossRef]

- Jung, D.; Persi, I.; Bhattacharyya, D. Synergistic Effects of Feather Fibers and Phosphorus Compound on Chemically Modified Chicken Feather/Polypropylene Composites. ACS Sustain. Chem. Eng. 2019, 7, 19072–19080. [Google Scholar] [CrossRef]

- Wang, C.; Wei, P.; Qian, Y.; Liu, J. The Synthesis of a Novel Flame Retardant and Its Synergistic Efficiency in Polypropylene/Ammonium Polyphosphate System. Polym. Adv. Technol. 2011, 22, 1108–1114. [Google Scholar] [CrossRef]

- Stec, A.A.; Hull, T.R. Assessment of Fire Toxicity from Polymer Nanocomposites. In Fire Retardancy of Polymers; RSC Publishing: Cambridge, UK, 2008; pp. 405–417. [Google Scholar]

- Jayakody, C.; Nelson, G.L.; Sorathia, U.; Lewandowski, S. A Cone Calorimetric Study of Flame Retardant Elastomeric Polyurethanes Modified with Siloxanes and Commercial Flame Retardant Additives. J. Fire Sci. 1998, 16, 351–380. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, Y.; Jiao, C. Smoke Suppression Properties of Ferrite Yellow on Flame Retardant Thermoplastic Polyurethane Based on Ammonium Polyphosphate. J. Hazard. Mater. 2014, 266, 114–121. [Google Scholar] [CrossRef]

- Almeras, X.; Le Bras, M.; Hornsby, P.; Bourbigot, S.; Marosi, G.; Keszei, S.; Poutch, F. Effect of Fillers on the Fire Retardancy of Intumescent Polypropylene Compounds. Polym. Degrad. Stab. 2003, 82, 325–331. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate-Polymer Composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Pukanszky, B.; VÖRÖS, G. Mechanism of Interfacial Interactions in Particulate Filled Composites. Compos. Interfaces 1993, 1, 411–427. [Google Scholar] [CrossRef]

- Kim, S.J.; Moon, J.B.; Kim, G.H.; Ha, C.S. Mechanical Properties of Polypropylene/Natural Fiber Composites: Comparison of Wood Fiber and Cotton Fiber. Polym. Test. 2008, 27, 801–806. [Google Scholar] [CrossRef]

| Samples | PP (%) | LAC (%) | SC (%) | APP (%) |

|---|---|---|---|---|

| PP(HP400N) | 100 | - | - | - |

| PP-50SC | 50 | - | 50 | - |

| PP-50LAC | 50 | 50 | - | - |

| PP-30LAC | 70 | 30 | - | - |

| PP-15APP | 85 | - | - | 15 |

| PP-20APP | 80 | - | - | 20 |

| PP-15APP-20LAC | 65 | 20 | - | 15 |

| Samples | Tg (°C) | Tm (°C) | Tc (°C) |

|---|---|---|---|

| PP(HP400N) | - | 154.7 | 119.6 |

| SC | 197.58 | - | - |

| LAC | 193.94 | - | - |

| PP-50SC | - | 156.1 | 121.1 |

| PP-50LAC | - | 156.3 | 121.4 |

| PP-30LAC | - | 156.5 | 121.4 |

| PP-15APP | - | 158.1 | 126.8 |

| PP-20APP | - | 157.9 | 128.4 |

| PP-15APP-20LAC | - | 158.2 | 128.1 |

| Samples | Tonset | Tmax1 | Tmax2 | Residue at Tmax1 (wt%) | Residue at Tmax2 (wt%) | Residue at 700 °C (wt%) |

|---|---|---|---|---|---|---|

| PP(HP400N) | 385.6 | 487.2 | - | 30.4 | - | 0 |

| SC | 277.4 | 337.2 | - | 63.8 | - | 22.3 |

| LAC | 279.1 | 328.6 | 667.2 | 64.7 | 20.0 | 15.3 |

| PP-50SC | 276.4 | 334.3 | 471.0 | 82.4 | 29.8 | 10.8 |

| PP-50LAC | 271.2 | 323.1 | 448.7 | 84.2 | 34.9 | 14.5 |

| PP-30LAC | 302.4 | 325.1 | 443.7 | 91.9 | 32.7 | 7.4 |

| PP-15APP | 388.9 | 485.9 | - | 33.4 | - | 3.9 |

| PP-20APP | 377.6 | 483.3 | - | 33.1 | - | 5.5 |

| PP-15APP-20LAC | 308.5 | 324.4 | 484.6 | 91.6 | 34.1 | 12.6 |

| Samples | TTI (s) | PHRR (kW/m2) | TPHRR (s) | THR (MJ/m2) | CO (kg/kg) (± 0.002) | CO2 (kg/kg) (± 0.06) |

|---|---|---|---|---|---|---|

| PP(HP400N) | 27.5 ± 1 | 1253.91 ± 27 | 150 ± 7 | 128.50 ± 3 | 0.029 | 2.52 |

| PP-50SC | 18.6 ± 2 | 652.49 ± 9 | 185 ± 0 | 105.26 ± 3 | 0.023 | 2.06 |

| PP-50LAC | 18.0 ± 1 | 421.70 ± 4 | 57 ± 6 | 101.23 ± 1 | 0.035 | 1.95 |

| PP-30LAC | 16.3 ± 1 | 529.34 ± 5 | 60 ± 5 | 118.27 ± 1 | 0.033 | 2.22 |

| PP-15APP | 22.3 ± 2 | 298.32 ± 6 | 258 ± 79 | 96.10 ± 8 | 0.032 | 2.08 |

| PP-20APP | 19.0 ± 0 | 243.14 ± 28 | 273 ± 4 | 70.25 ± 5 | 0.036 | 1.53 |

| PP-15APP-20LAC | 14.7 ± 1 | 248.00 ± 12 | 355 ± 35 | 101.75 ± 1 | 0.043 | 1.94 |

| Samples | T1 a (s) | T2 a (s) | Tt b(s) | Ta c (s) | AAh d | CId e | Classification |

|---|---|---|---|---|---|---|---|

| PP(HP400N) | 112.2 | - | - | - | Yes | Yes | NR |

| PP-50SC | 67.2 | - | - | - | Yes | Yes | NR |

| PP-50LAC | 80.6 | - | - | - | Yes | Yes | NR |

| PP-30LAC | 66.2 | - | - | - | Yes | Yes | NR |

| PP-15APP | 4.6 | 66.0 | 70.6 | - | Yes | Yes | NR |

| PP-20APP | 0 | 0 | 0 | - | No | No drips | V-0 |

| PP-15APP-20LAC | 0 | 0 | 0 | - | No | No drips | V-0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Kim, N.K.; Jung, D.; Bhattacharyya, D. Flammability Characteristics and Mechanical Properties of Casein Based Polymeric Composites. Polymers 2020, 12, 2078. https://doi.org/10.3390/polym12092078

Lee H, Kim NK, Jung D, Bhattacharyya D. Flammability Characteristics and Mechanical Properties of Casein Based Polymeric Composites. Polymers. 2020; 12(9):2078. https://doi.org/10.3390/polym12092078

Chicago/Turabian StyleLee, Hanbin, Nam Kyeun Kim, Daeseung Jung, and Debes Bhattacharyya. 2020. "Flammability Characteristics and Mechanical Properties of Casein Based Polymeric Composites" Polymers 12, no. 9: 2078. https://doi.org/10.3390/polym12092078

APA StyleLee, H., Kim, N. K., Jung, D., & Bhattacharyya, D. (2020). Flammability Characteristics and Mechanical Properties of Casein Based Polymeric Composites. Polymers, 12(9), 2078. https://doi.org/10.3390/polym12092078