Numerical Simulation of Coupled Pyrolysis and Combustion Reactions with Directly Measured Fire Properties

Abstract

1. Introduction

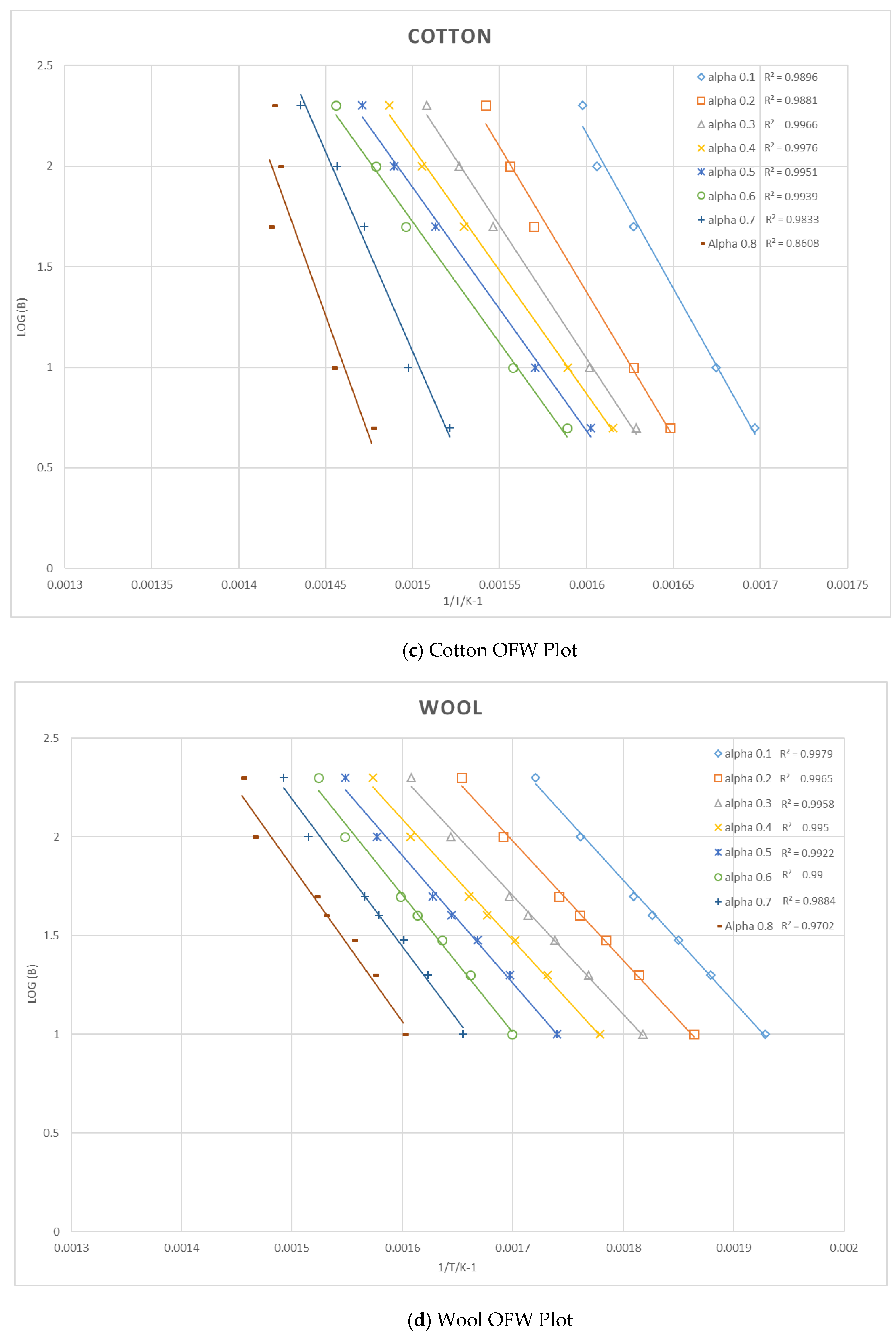

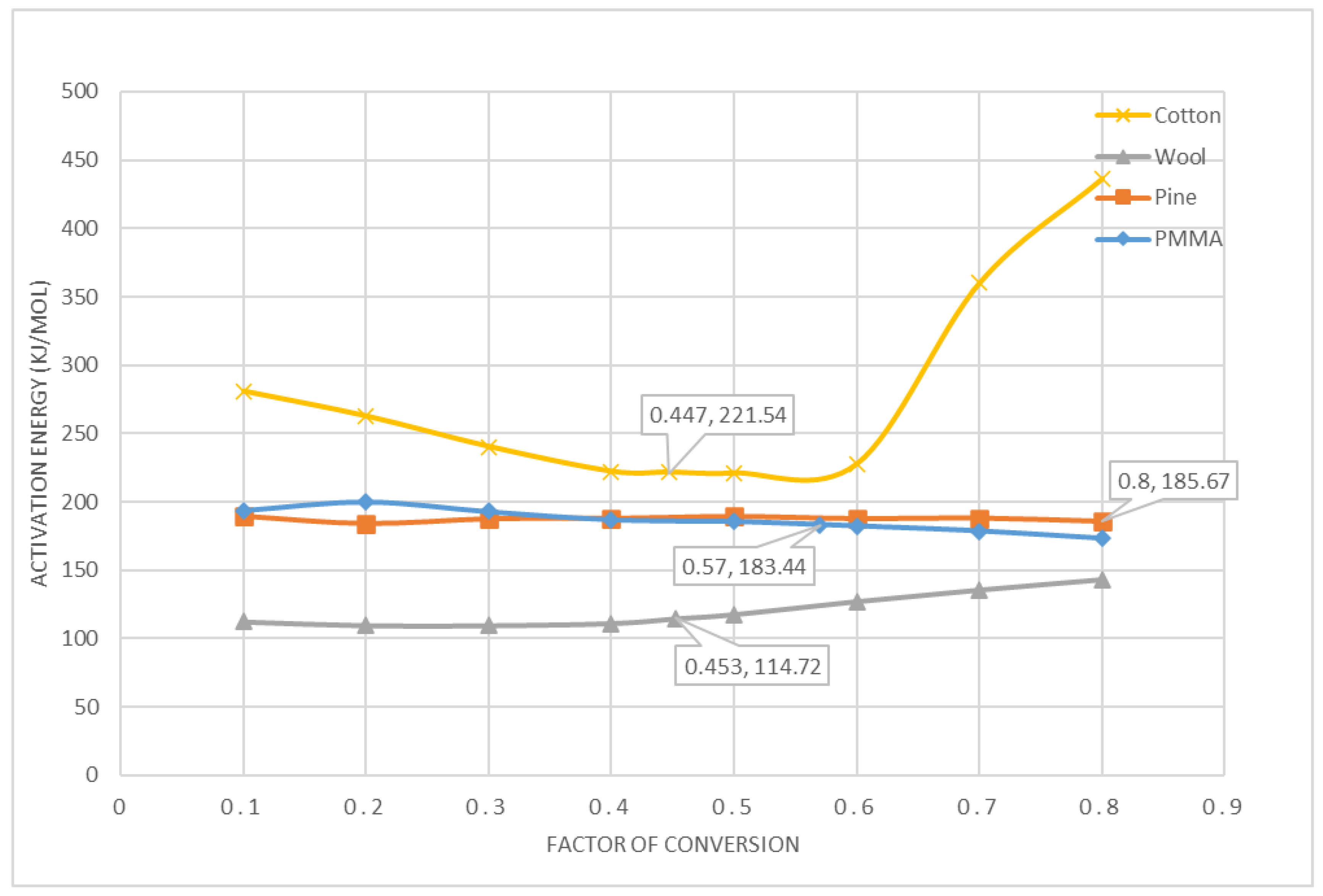

2. Fire Properties

3. Kinetic Parameters of PMMA, Pine, Cotton and Wool

4. Flammability and Thermo-Physical Parameters

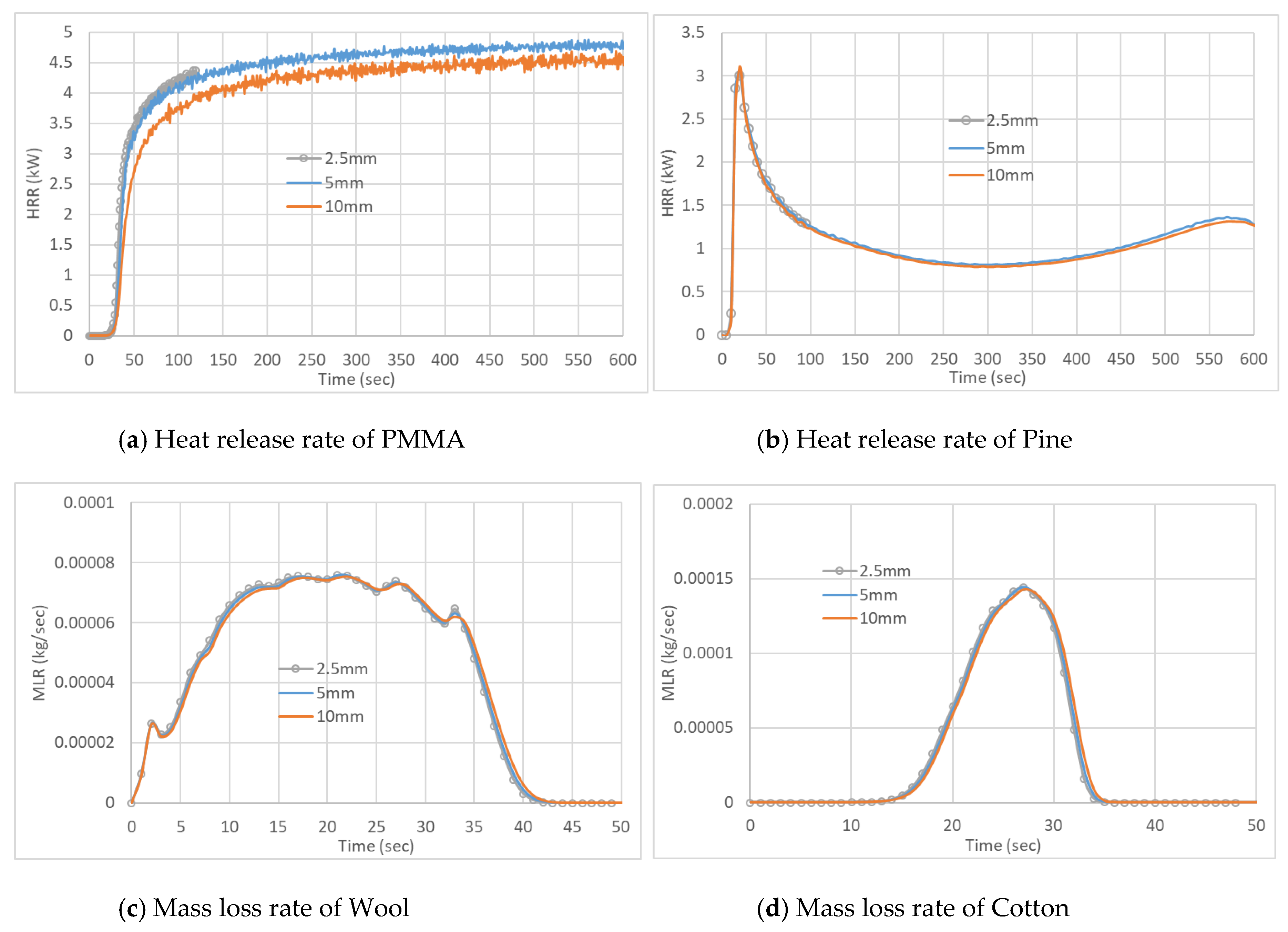

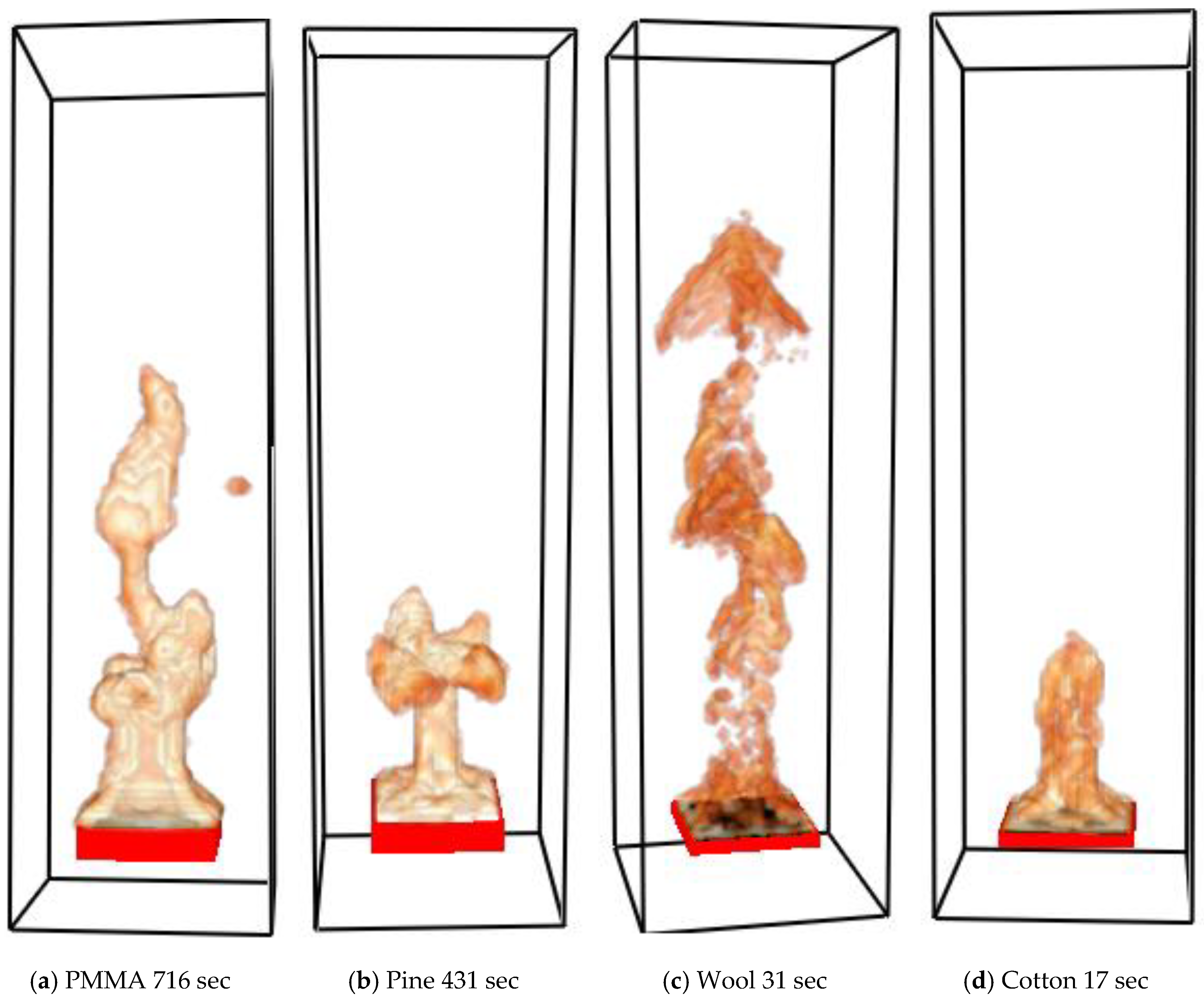

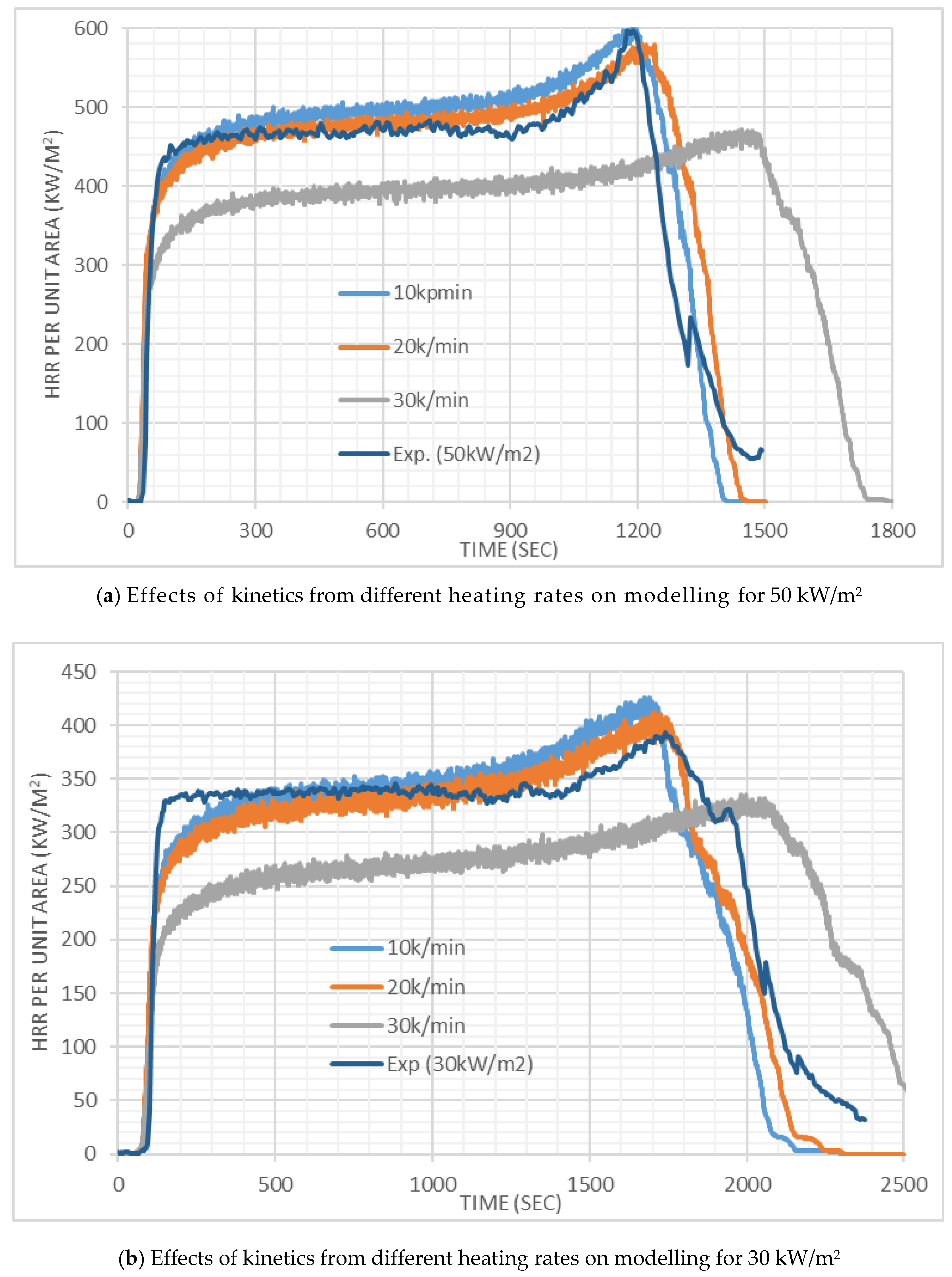

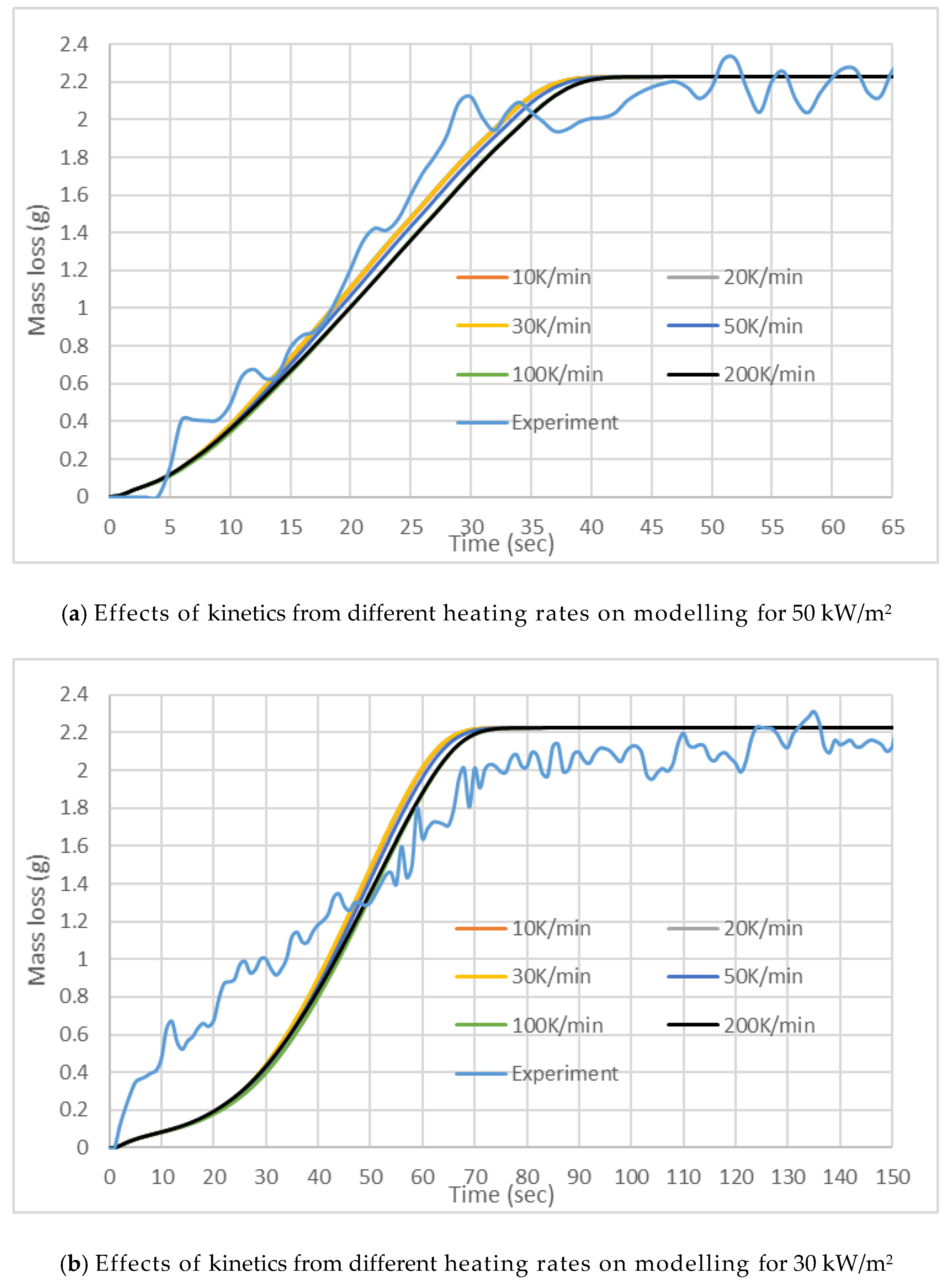

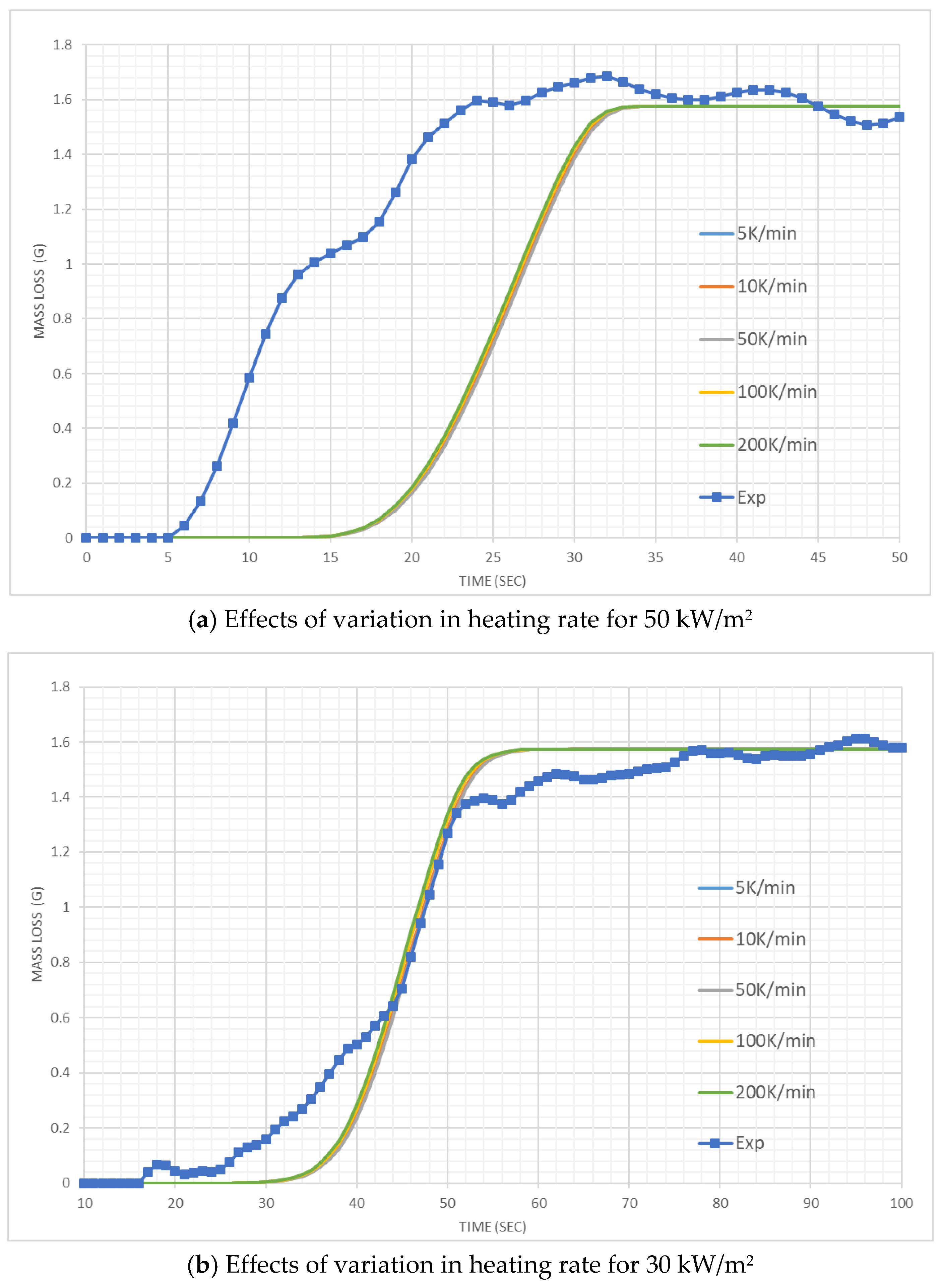

5. Numerical Analysis of Pyrolysis

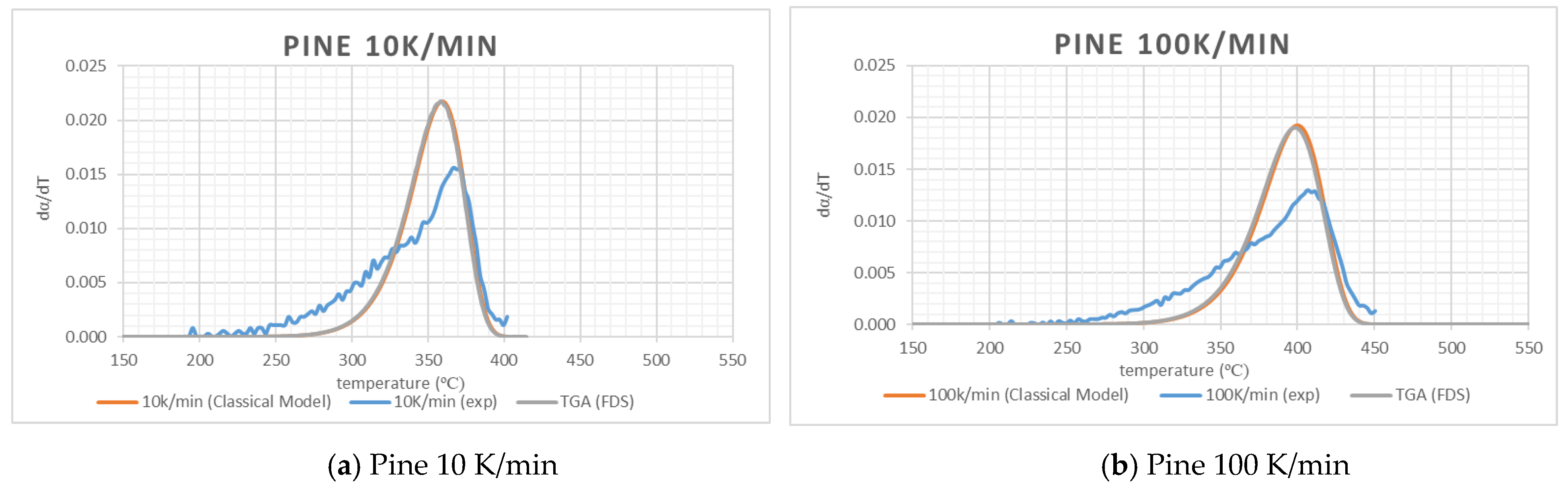

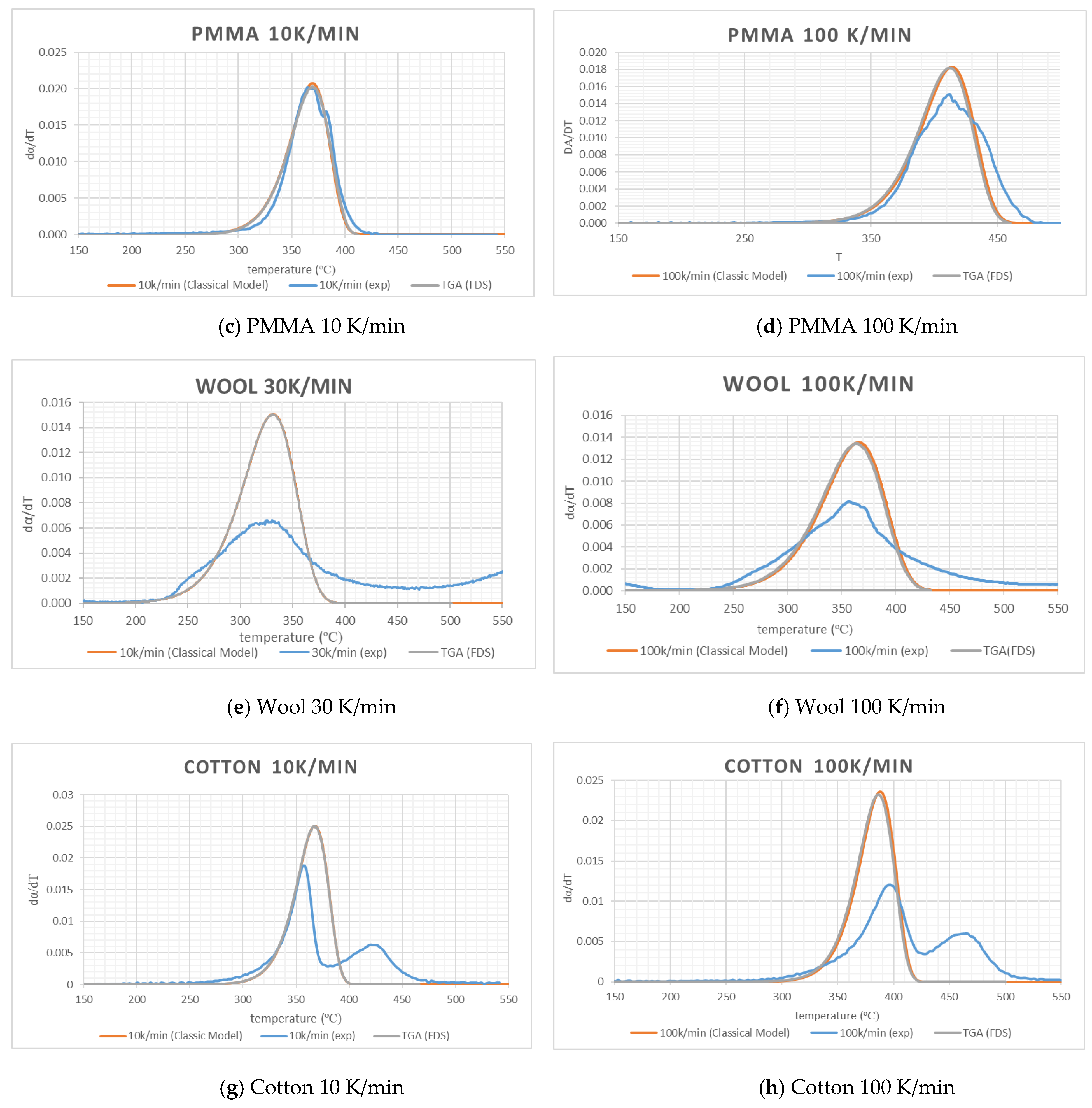

5.1. Classical Theory (Arrhenius Equation)

5.2. TGA Modelling Using FDS

6. Numerical Simulation of Cone Calorimeter

6.1. Model Set-Up

6.2. Results

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Board, A.B.C. National Construction Code Series Volume 1, Building Code of Australia 2019, Class. 2 to 9 Buildings; Australian Building Codes Board: Canberra, Australia, 2019. [Google Scholar]

- Standard, I. 834: Fire Resistance Tests-Elements of Building Construction; International organisation for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator Technical Reference Guide Volume 1: Mathematical Model, 6th ed.; National Institute of Standards and Technology Special Publication 1018: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Di Blasi, C. Modeling chemical and physical processes of wood and biomass pyrolysis. Prog. Energy Combust. Sci. 2008, 34, 47–49. [Google Scholar] [CrossRef]

- Li, J.; Gong, J.; Stoliarov, S.I. Development of pyrolysis models for charring polymers. Polym. Degrad. Stab. 2015, 115, 138–152. [Google Scholar] [CrossRef]

- Ferriola, M.; Gentilhomme, A.; Cochez, M.; Oget, N.; Mieloszynski, J.L. Thermal degradation of Poly(methyl methacrylate) (PMMA): Modelling of DTG and TG Curves. Polym. Degrad. Stab. 2003, 79, 271–281. [Google Scholar] [CrossRef]

- Linteris, T.G.; Lyon, R.E.; Stoliarov, S.I. Prediction of the Gasification Rate of POM, PP, PA66 and PET in Fire-Like Environments. Fire Mater. 2013, 60, 14–24. [Google Scholar]

- Li, J.; Stoliarov, S.I. Measurement of kinetics and thermodynamics of the thermal degradation for charring polymers. Polym. Degrad. Stab. 2014, 106, 2–15. [Google Scholar]

- Wu, W.; Mei, Y.; Zhang, L.; Liu, R.; Cai, J. Effective activation energies of lignocellulosic biomass pyrolysis Energy Fuels. Energy Fuels 2014, 28, 3916–3923. [Google Scholar] [CrossRef]

- Yousef Haseli, Y.; van Oijen, J.A.; de Goey, L.P.H. Modeling Biomass Particle Pyrolysis with Temperature-dependent Heat of Reactions. J. Anal. Appl. Pyrolysis 2011, 90, 140–154. [Google Scholar] [CrossRef]

- Oztekin, S.E.; Crowley, B.S.; Lyon, E.R.; Stoliarov, I.S.; Patel, P.; Hull, R.T. Sources of Variability in Fire Test. Data: A Case Study on Poly(aryl ether ether ketone) (PEEK). Combust. Flame 2012, 159, 1720–1731. [Google Scholar] [CrossRef]

- McKinnon, M.B.; Stoliarov, S.I.; Witkowski, A. Development of a pyrolysis model for corrugated cardboard. Combust. Flame 2013, 160, 2595–2607. [Google Scholar] [CrossRef]

- Moinuddin, K.; Nguyen, T.; Mahmud, H. Designing an experimental rig for developing a fire severity model using numerical simulation. Fire Mater. 2017, 41, 871–883. [Google Scholar] [CrossRef]

- Riccio, A.; Damiano, M.; Zarrelli, M.; Scaramuzzino, F. Three-dimensional modeling of composites fire behaviour. J. Reinf. Plast. Compos. 2014, 33, 619–629. [Google Scholar] [CrossRef]

- Marquis, M.; Pavageau, M.; Guillaume, E.; Chivas-Joly, C. Modelling decomposition and fire behaviour of small samples of a glass-fibre-reinforced polyester/balsa-cored sandwich material. Fire Mater. 2013, 37, 413–439. [Google Scholar] [CrossRef]

- Nguyen, Q.; Ngo, T.; Tran, P.; Mendis, P.; Zobec, M.; Aye, L. Fire performance of prefabricated modular units using organoclay/glass fibre reinforced polymer composite. Constr. Build. Mater. 2016, 129, 204–215. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Dréan, V.; Girardin, B.; Guillaume, E.; Fateh, T. Numerical simulation of the fire behaviour of facade equipped with aluminium composite material-based claddings-Model. validation at intermediate scale. Fire Mater. 2019, 43, 839–856. [Google Scholar] [CrossRef]

- Lautenberger, C.; Rein, G.; Fernandez-Pello, C. The application of a genetic algorithm to estimate material properties for fire modeling from bench-scale fire test data. Fire Saf. J. 2006, 41, 204–214. [Google Scholar] [CrossRef]

- Lautenberger, C.; Fernandez-Pello, A. Optimization algorithms for material pyrolysis property estimation. Fire Saf. Sci. 2011, 10, 751–764. [Google Scholar] [CrossRef]

- Chaos, M.; Khan, M.M.; Krishnamoorthy, N.; de Ris, J.L.; Dorofeev, S.B. Evaluation of optimization schemes and determination of solid fuel properties for CFD fire models using bench-scale pyrolysis tests. Proc. Combust. Inst. 2011, 33, 2599–2606. [Google Scholar] [CrossRef]

- Yuen, A.; Chen, T.; Wang, C.; Wei, W.; Kabir, I.; Vargas, J.; Chan, Q.; Kook, S.; Yeoh, G. Utilising genetic algorithm to optimise pyrolysis kinetics for fire modelling and characterisation of chitosan/graphene oxide polyurethane composites. Compos. Part. B 2020, 182, 107619. [Google Scholar] [CrossRef]

- Abu-Bakar, A.S.; Cran, M.J.; Moinuddin, K.A.M. Moinuddin Experimental investigation of effects of variation in heating rate, temperature and heat flux on fire properties of a non-charring polymer. J. Therm. Anal. Calorim. 2019, 137, 447–459. [Google Scholar] [CrossRef]

- Abu-Bakar, A.; Cran, M.; Wadhwani, R.; Khalid, A. Characterisation of pyrolysis and combustion parameters of charring materials most frequently found in buildings. J. Therm. Anal. Calorim. 2020, 139, 2985–2999. [Google Scholar] [CrossRef]

- Witkowski, A.; Stec, A.A.; Hull, T.R. SFPE Handbook in Thermal Decomposition of Polymeric Materials; Springer: New York, NY, USA, 2016; p. 167. [Google Scholar]

- Stephen, W.; Bigger, M.; Intan, S.T. Two novel algorithms for the thermogravimetric assessment of polymer degredation under non-isothermal conditions. Polym. Test. 2015, 43, 139–146. [Google Scholar]

- Wadhwani, R.; Sutherland, D.; Moinuddin, K.; Joseph, P. Kinetics of pyrolysis of litter materials from pine and eucalyptus forests. J. Therm. Anal. Calorim. 2017, 130, 2035–2046. [Google Scholar] [CrossRef]

- Ozawa, T. A New Method of Analysing Thermogravimetric Data. Bull. Chem. Soc. Jpn. 1965, 11, 1881–1886. [Google Scholar] [CrossRef]

- Flynn, H.; Leo, A.W. General Treatment of the Thermogravimetry of Polymers. J. Res. Natl. Bur. Stand. Phys. Chem. 1966, 70, 487. [Google Scholar] [CrossRef]

- Mamleev, V.; Bourbigot, S.; Bras, M.; Lefebvre, J. Three model-free methods for calculation of activation energy in TG. J. Therm. Anal. Calorim. 2004, 78, 1009–1027. [Google Scholar] [CrossRef]

- Abu-Bakar, S.A.; Cran, M.; Wadhwani, R.; Moinuddin, K. Correction to: Characterisation of pyrolysis and combustion parameters of charring materials most frequently found in buildings. J. Therm. Anal. Calorim. 2020, 139, 3001. [Google Scholar] [CrossRef]

- Abu-Bakar, A.S. Characterization of Fire Properties for Coupled Pyrolysis and Combustion Simulation and Their Optimised Use. Ph.D. Thesis, Victoria University, Melbourne, Australia, 2015. [Google Scholar]

- Pooley, L.I.; Abu-Bakar, A.S.; Cran, M.J.; Wadhwani, R.; Moinuddin, K.A. Measurements of specific heat capacity of common building materials at elevated temperatures: A comparison of DSC and HDA. J. Therm. Anal. Calorim. 2019, 141, 1279–1289. [Google Scholar] [CrossRef]

- Hallman, J.R. Polymer Surface Reflectance-absorptance Characteristics. Polym. Eng. Sci. 1974, 14, 717–723. [Google Scholar] [CrossRef]

- Tsilingiris, P.T. Comparative Evaluation of the Infrared Transmission of Polymer Films. Energy Convers. Manag. 2003, 44, 2839–2856. [Google Scholar] [CrossRef]

- DeWitt, D.P.; Incropera, F.P. Fundamentals of Heat and Mass Transfer, 3rd ed.; John Wiley & Sons: Chichester, UK, 1990. [Google Scholar]

- Khan, N.; Sutherland, D.; Wadhwani, R.; Moinuddin, K.A.M. Physics-based simulation of heat load on structures for improving construction standards for bushfire prone areas. Front. Mech. Eng. 2019, 5, 35. [Google Scholar] [CrossRef]

- Parker, W.J. Prediction of the heat release rate of wood. Fire Saf. Sci. 1986, 1, 207–216. [Google Scholar] [CrossRef]

- Brown, J.E.; Braun, E.; Twilley, W.H. Cone Calorimeter Evaluation of the Flammability of Composite Materials; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1988; pp. 88–3733. [Google Scholar]

- Moinuddin, K.A.; Thomas, I.R. An experimental study of fire development in deep enclosures and a new HRR–time–position model for a deep enclosure based on ventilation factor. Fire Mater. 2009, 33, 157–185. [Google Scholar] [CrossRef]

| Sl. No. | Kinetic Model | Equation (1/df(α)/dα) |

|---|---|---|

| 1 | P1 Power Law | α1/n |

| 2 | E1 Exponential law | ln(α) |

| 3 | A2 Avrami–Erofeev Model | [−ln(1 − α)]1/2 |

| 4 | A3 Avrami–Erofeev Model | [−ln(1 − α)]1/3 |

| 5 | A4 Avrami–Erofeev Model | [–ln(1 − α)]1/4 |

| 6 | B1 Prout–Tompkins | [−ln(α/(1 − α))] + C |

| 7 | R1 Contracting area | 1 − (1 − α)1/2 |

| 8 | R3 Contracting volume | 1 − (1 − α)1/3 |

| 9 | D1 One dimensional | α2 |

| 10 | D2 Two dimensional | (1 − α)ln(1 − α) + α |

| 11 | D3 Three dimensional | [1 − (1 − α)1/3]2 |

| 12 | D4 Ginstling–Brounshtein | (1 − 2α/3) − (1 − α)2/3 |

| 13 | F1 First order | −ln(1 − α) |

| 14 | F2 Second order | 1/(1 − α) |

| 15 | F3 Third order | 1/(1 − α)2 |

| Material | Heating Rate | E (kJ/mol) | A (1/s) | HoR (kJ/kg) | Material | Heating Rate | E (kJ/mol) | A (1/s) | HoR (kJ/kg) |

|---|---|---|---|---|---|---|---|---|---|

| Pine | 10 K/min | 185.67 | 2.05 × 1013 | 97.4 | Cotton | 5 K/min | 221.54 | 2.06 × 1016 | 385 |

| 20 K/min | 2.09 × 1013 | 137.2 | 10 K/min | 1.84 × 1016 | |||||

| 30 K/min | 2.04 × 1013 | 172.5 | 50 K/min | 1.76 × 1016 | |||||

| 50 K/min | 2.13 × 1013 | 254.3 | 100 K/min | 2.05 × 1016 | |||||

| 100 K/min | 2.13 × 1013 | 357.8 | 200 K/min | 2.16 × 1016 | |||||

| 200 K/min | 2.55 × 1013 | 461.4 | Wool | 10 K/min | 114.72 | 1.45 × 108 | 314.8 | ||

| PMMA | 10 K/min | 183.44 | 7.25 × 1012 | 1747.2 | 20 K/min | 1.53 × 108 | 346.3 | ||

| 20 K/min | 7.79 × 1012 | 2019.9 | 30 K/min | 1.57 × 108 | 377.7 | ||||

| 30 K/min | 7.94 × 1012 | 2335.1 | 40 K/min | 1.45 × 108 | 409.2 | ||||

| 50 K /min | 7.6 × 1012 | 3120.6 | 50 K/min | 1.45 × 108 | 440.7 | ||||

| 100 K/min | 6.9 × 1012 | 6443.3 | 100 K min | 1.36 × 108 | 598.2 | ||||

| 200 K/min | 6.26 × 1012 | 27468.4 | 200 K/min | 1.84 × 108 | 913.2 |

| Material | Irradiation | EHoC (kJ/kg) | CO Yield (kg/kg) | Soot Yield (kg/kg) | Moisture (Fraction) | Char Residue (Fraction) |

|---|---|---|---|---|---|---|

| Pine | 30 kW/m2 | 11,210 | 0.007 | 0.006 | 0.035 | 0.105 |

| 50 kW/m2 | 11,210 | 0.007 | 0.006 | 0.035 | 0.126 | |

| PMMA | 30 kW/m2 | 21,295 | 0.007 | 0.14 | - | - |

| 50 kW/m2 | 21,295 | 0.007 | 0.14 | - | - | |

| Cotton | 30 kW/m2 | 8927 | 0.013 | 0.022 | 0.012 | 0.025 |

| 50 kW/m2 | 5363 + 40% 1 | 0.013 | 0.022 | 0.012 | 0.025 | |

| Wool | 30 kW/m2 | 6300 + 28% 1 | 0.01 | 0.039 | 0.06 | 0.038 |

| 50 kW/m2 | 7687 + 5% 1 | 0.01 | 0.039 | 0.06 | 0.038 |

| Material | Properties | Value | Unit | Value | Material |

|---|---|---|---|---|---|

| Pine | Thermal Conductivity | 0.168; 20 > T 0.0002T + 0.1649; 20 ≤ T ≤ 225 0.2; T > 225 | W/m/K | 0.1945 | PMMA |

| Specific heat | 0.756; 25 > T 0.004T + 0.6544; 25 ≤ T≤240 1.614; T > 240 | kJ/kg/K | 1.47 | ||

| Emissivity | 1 | 0.85 [34] | |||

| Absorption Coefficient | Default | m−1 | 2700 [35] | ||

| Density | 403 | kg/m3 | 1210 | ||

| Char 1 | Thermal Conductivity | 0.069; 20 > T 0.0001T + 0.0661; 20 ≤ T ≤ 225 0.102; T > 225 | W/m/K | 48; 20 > T −23.107T + 1139; 20 ≤ T ≤ 677 30; T > 677 | Steel [36] |

| Specific Heat | 0.927; 25 > T 0.0028T + 0.8587; 25 ≤ T ≤300 1.697; T > 300 | kJ/kg/K | 0.45; 20 > T 6 × 10−07 T2 + 0.0002T + 4463; 20 ≤ T ≤ 200 0.85; T > 677 | ||

| Emissivity | 1 | 0.9 | |||

| Density | 110 | kg/m3 | 7850 | ||

| Wool | Thermal Conductivity | 0.0846; 20 > T 1× 10−06 T2 − 0.0002T + 0.0882; 20 ≤ T ≤ 200 0.0882; T > 200 | W/m/K | 0.142; 20 > T 0.0002T + 0.1378; 20 ≤ T ≤ 200 0.178; T > 200 | Cotton |

| Specific Heat | 1.773; 20 > T 9 × 10−06 T3 − 0.000355T2 + 0.04237T − 0.06137; 20 ≤ T ≤ 275 3.583; T > 275 | kJ/kg/K | 1.672; 20 > T 0.0024T + 1.6238; 20 ≤ T ≤ 300 2.344; T > 300 | ||

| Emissivity | 1 | 1 | |||

| Absorption Coefficient | 50000 | m−1 | 50000 | ||

| Density | 220 | kg/m3 | 254 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moinuddin, K.; Razzaque, Q.S.; Thomas, A. Numerical Simulation of Coupled Pyrolysis and Combustion Reactions with Directly Measured Fire Properties. Polymers 2020, 12, 2075. https://doi.org/10.3390/polym12092075

Moinuddin K, Razzaque QS, Thomas A. Numerical Simulation of Coupled Pyrolysis and Combustion Reactions with Directly Measured Fire Properties. Polymers. 2020; 12(9):2075. https://doi.org/10.3390/polym12092075

Chicago/Turabian StyleMoinuddin, Khalid, Qazi Samia Razzaque, and Ananya Thomas. 2020. "Numerical Simulation of Coupled Pyrolysis and Combustion Reactions with Directly Measured Fire Properties" Polymers 12, no. 9: 2075. https://doi.org/10.3390/polym12092075

APA StyleMoinuddin, K., Razzaque, Q. S., & Thomas, A. (2020). Numerical Simulation of Coupled Pyrolysis and Combustion Reactions with Directly Measured Fire Properties. Polymers, 12(9), 2075. https://doi.org/10.3390/polym12092075