Visualizing Polymer Damage Using Hyperspectral Imaging

Abstract

1. Introduction

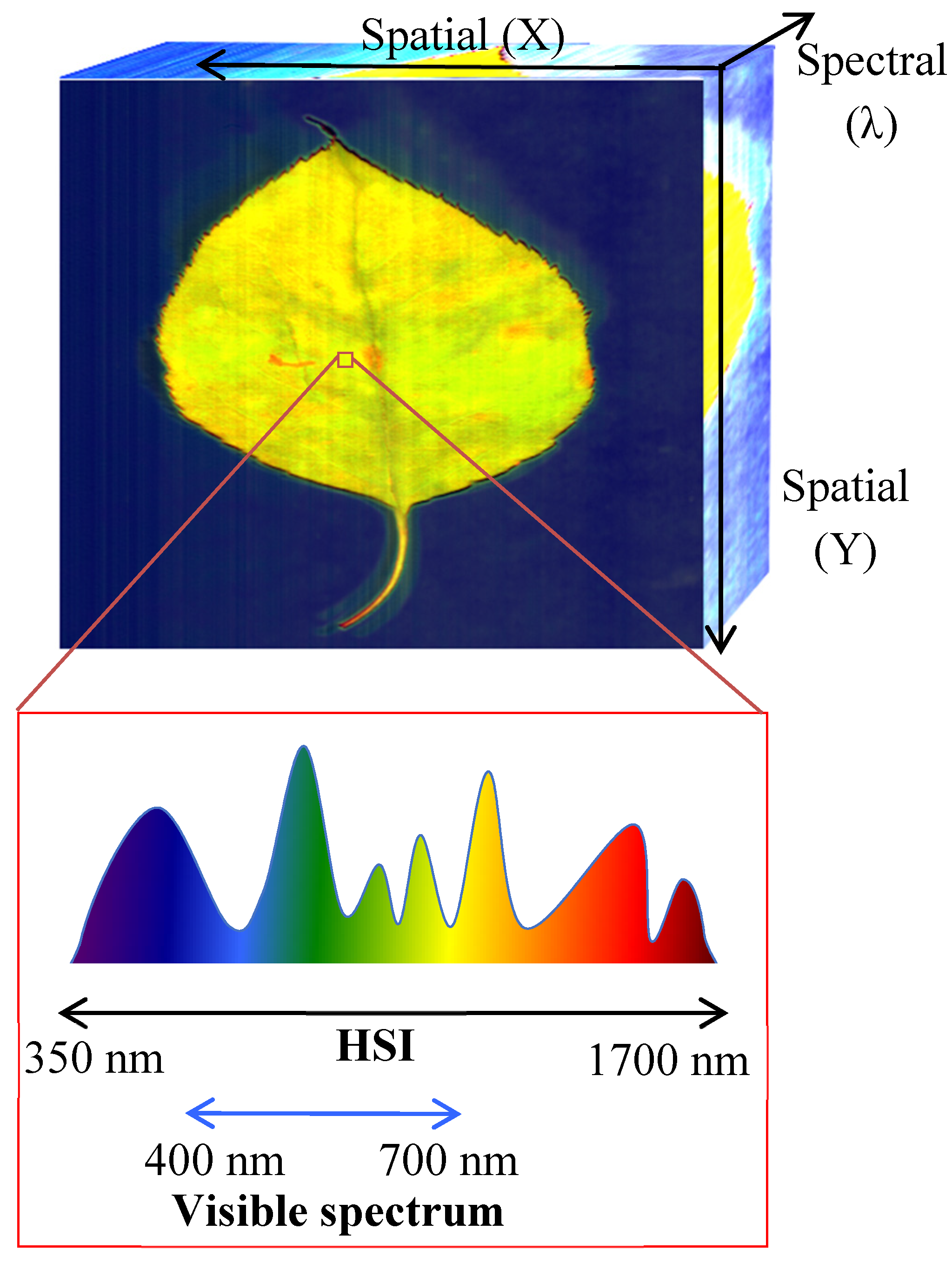

2. Hyperspectral Imaging

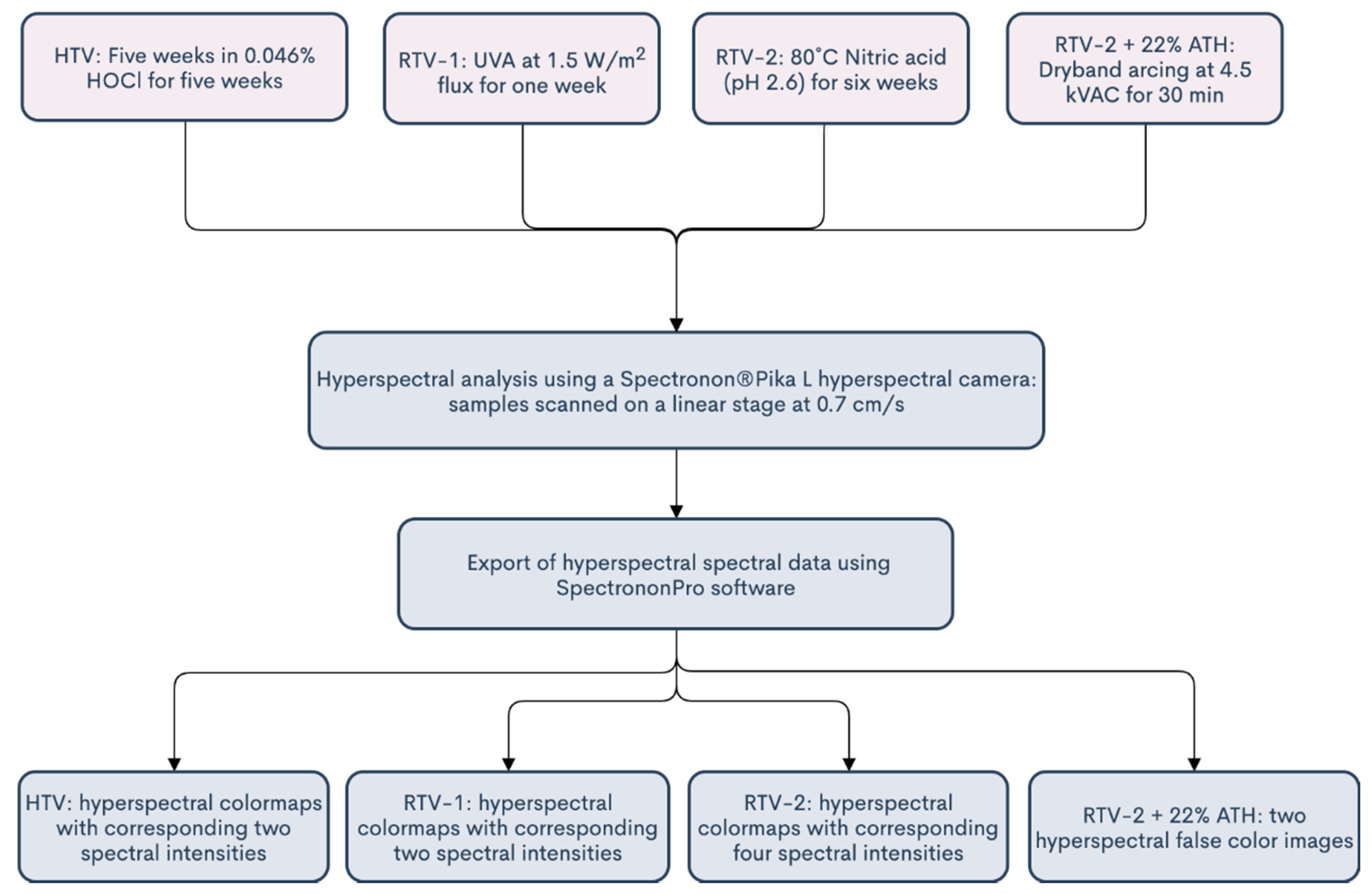

3. Materials and Methods

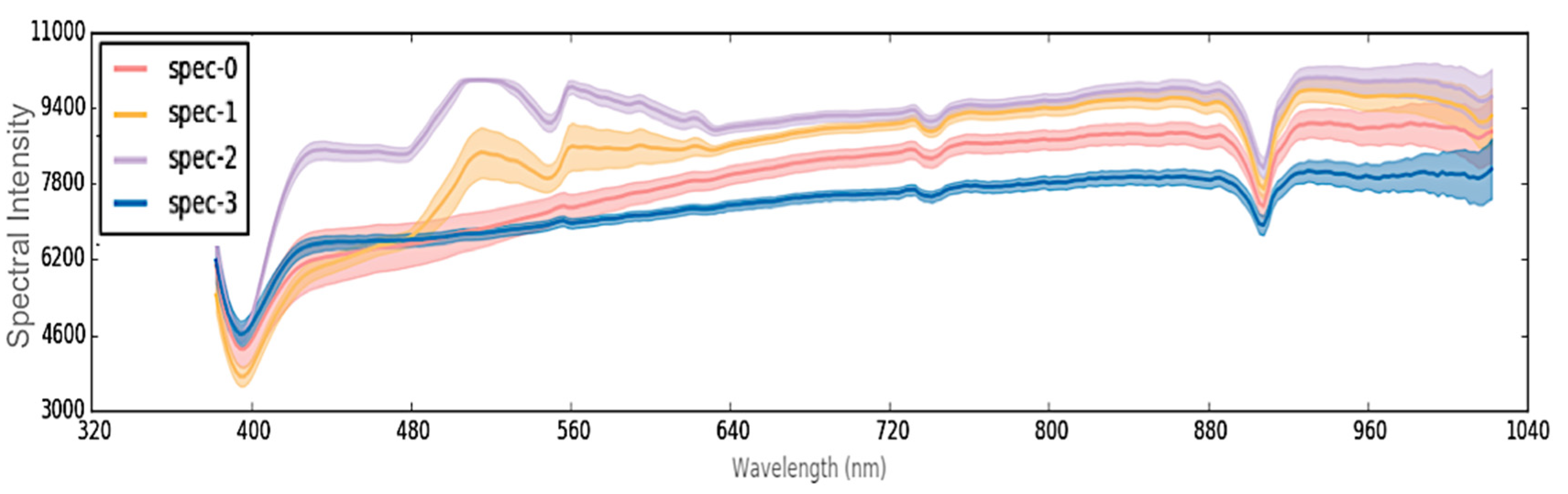

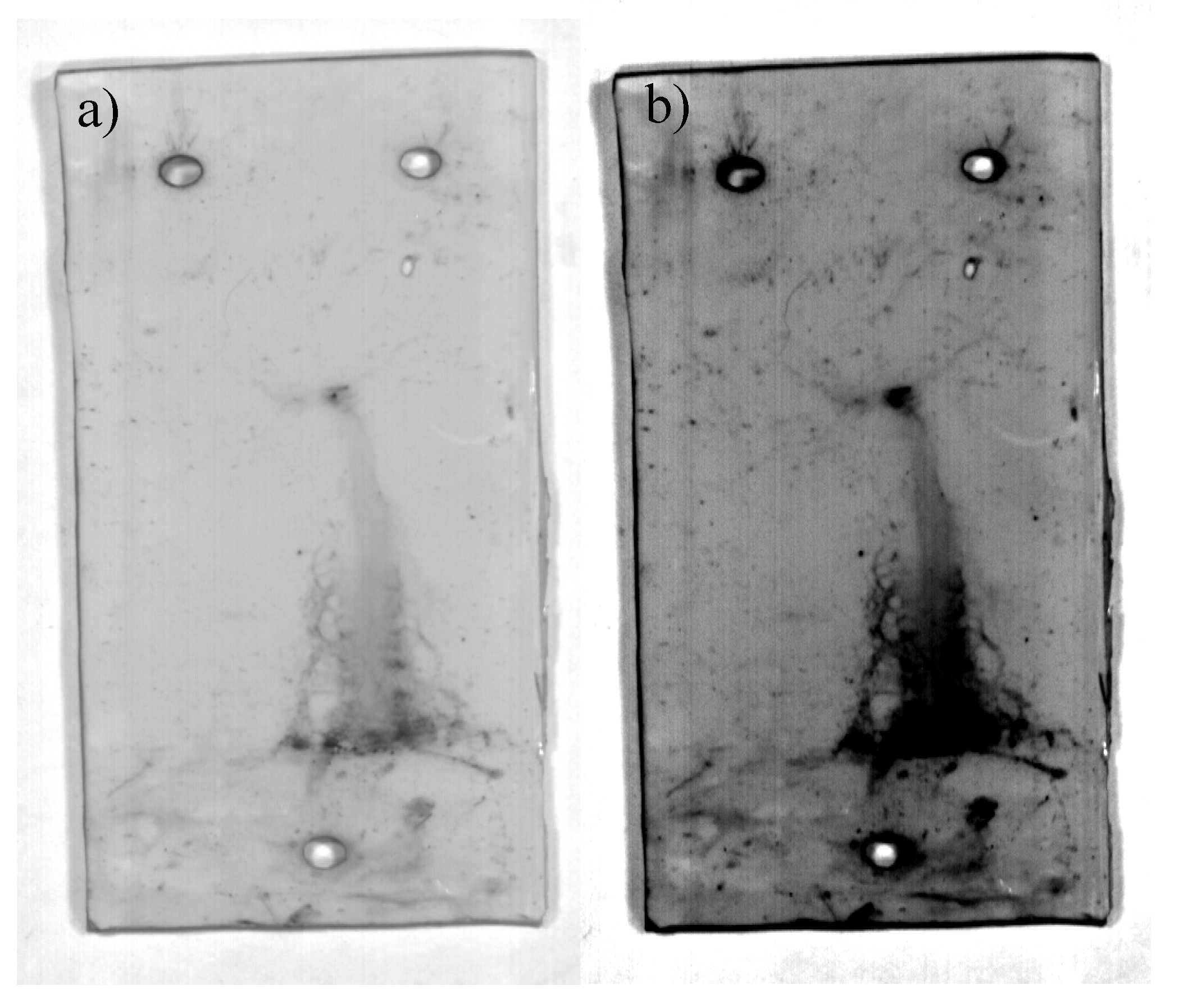

4. Results and Discussion

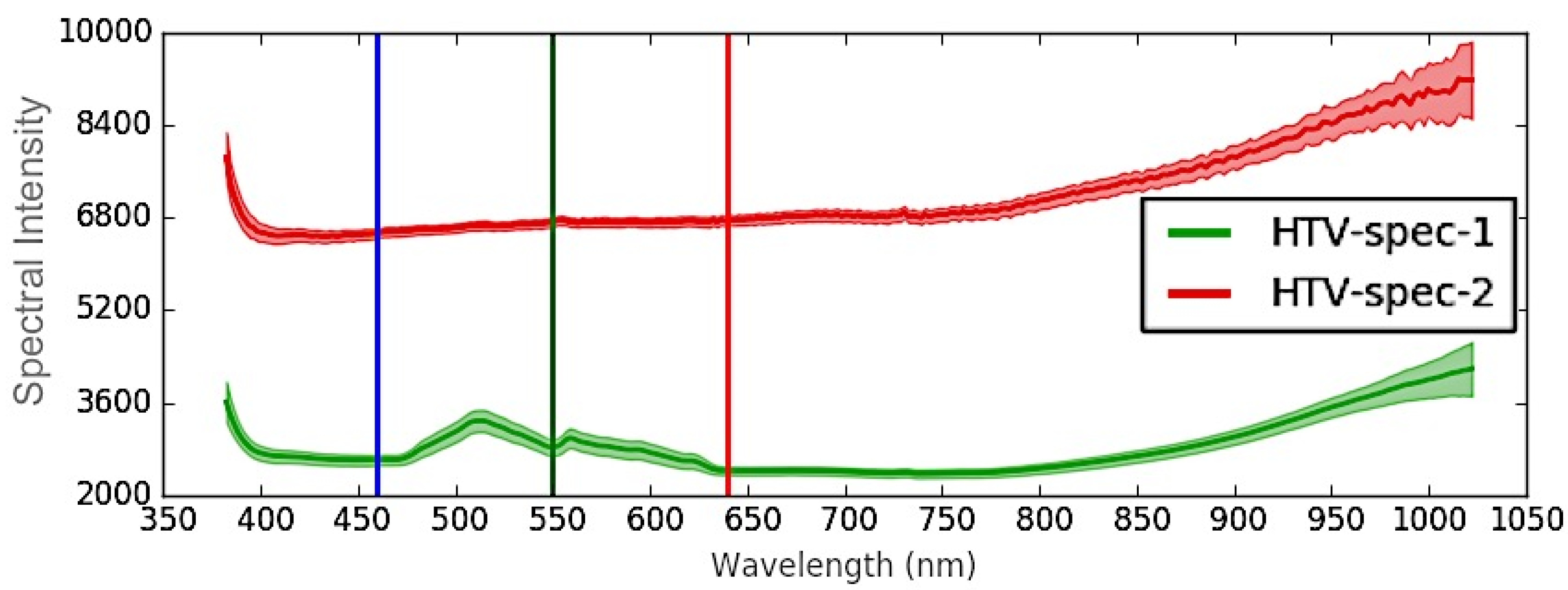

4.1. HTV

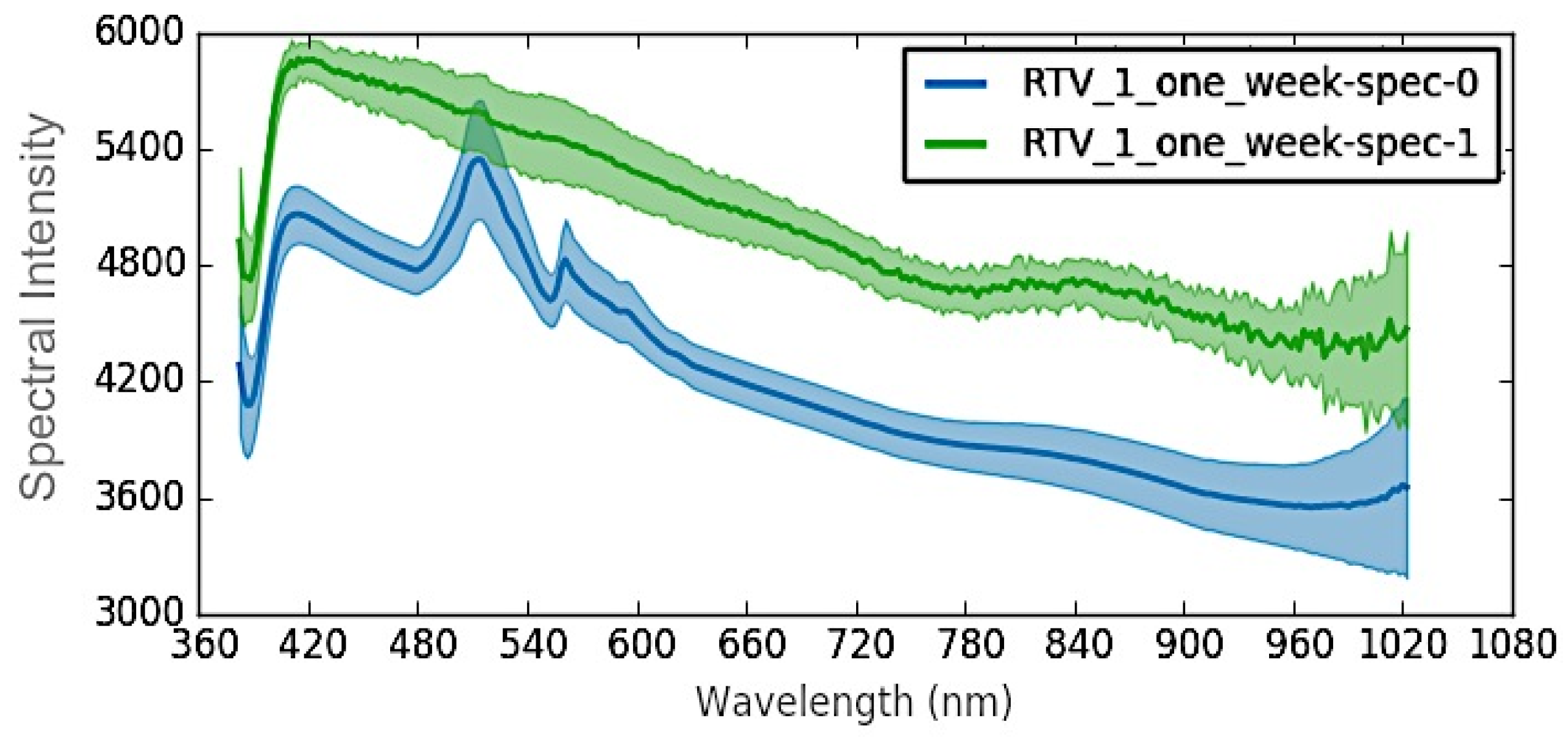

4.2. RTV-1

4.3. RTV-2

4.4. RTV-2 + 22% ATH

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Noll, W. Chemistry and Technology of Silicones; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Bernstorf, R.A.; Randall, K.N.; David, S.W. Polymer Compounds Used in High Voltage Insulators. Hubbell Power Syst. 2000. Available online: https://www.semanticscholar.org/paper/Polymer-Compounds-Used-In-High-Voltage-Insulators-Bernstorf-Niedermier/e3368cfac67f6a93aaeff2579d18951471ca43ca?p2df (accessed on 12 September 2020).

- Amin, M.; Salman, M. Aging of polymeric insulators (an overview). Rev. Adv. Mater. Sci. 2006, 13, 93–116. [Google Scholar]

- Allen, B.; Bleszynski, M.; Kumosa, M.; Willis, E. Investigation into the effects of environmental stresses on RTV-1 silicone-based caulk materials. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2978–2986. [Google Scholar] [CrossRef]

- Bleszynski, M.; Kumosa, M. Silicone rubber aging in electrolyzed aqueous salt environments. Polym. Degrad. Stab. 2017, 146, 61–68. [Google Scholar] [CrossRef]

- Bleszynski, M.; Kumosa, M. Aging resistant TiO2/silicone rubber composites. Compos. Sci. Technol. 2018, 164, 74–81. [Google Scholar] [CrossRef]

- Homma, H.; Mirley, C.; Ronzello, J.; Boggs, S. Field and laboratory aging of RTV silicone insulator coatings. IEEE Trans. Power Deliv. 2000, 15, 1298–1303. [Google Scholar] [CrossRef]

- Kaneko, T.; Ito, S.; Minakawa, T.; Hirai, N.; Ohki, Y. Degradation mechanisms of silicone rubber under different aging conditions. Polym. Degrad. Stab. 2019, 168, 108936. [Google Scholar] [CrossRef]

- Sundhar, S.; Bernstorf, A.; Goch, W.; Linson, D.; Huntsman, L. Polymer Insulating Materials and Insulators for High Voltage Outdoor Applications. In Proceedings of the Conference Record of the 1992 IEEE International Symposium on Electrical Insulation (ISEI), Baltimore, MD, USA, 7–10 June 1992; Available online: https://ieeexplore.ieee.org/abstract/document/247015 (accessed on 12 September 2020).

- Jahromi, A.; Cherney, E.; Jayaram, S. Aging Characteristics of RTV Silicone Rubber Insulator Coatings. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 444–452. [Google Scholar] [CrossRef]

- Cherney, E.; Hackam, R.; Kim, S. Porcelain insulator maintenance with RTV silicone rubber coatings. IEEE Trans. Power Deliv. 1991, 6, 1177–1181. [Google Scholar] [CrossRef]

- Abdollahian, A.; El-Hag, A.H.; Jahromi, A.N.; Farahani, M.; Ranjbar, G.A. A study on the aging characteristics of RTV insulator coatings. In Proceedings of the 2008 Canadian Conference on Electrical and Computer Engineering, Niagara Falls, ON, Canada, 4–7 May 2008. [Google Scholar]

- Resonon Hyperspectral Cameras. Available online: https://resonon.com/hyperspectral-cameras (accessed on 11 September 2020).

- Manolakis, D.; Shaw, G. Detection algorithms for hyperspectral imaging applications. IEEE Signal Process. Mag. 2002, 19, 29–43. [Google Scholar] [CrossRef]

- Schlerf, M.; Rock, G.; Lagueux, P.; Ronellenfitsch, F.; Gerhards, M.; Hoffmann, L.; Udelhoven, T.A. Hyperspectral Thermal Infrared Imaging Instrument for Natural Resources Applications. Remote Sens. 2012, 4, 3995–4009. [Google Scholar] [CrossRef]

- Chang, C.-I. Hyperspectral Imaging: Techniques for Spectral Detection and Classification; Springer Science & Business Media: Berlin, Germany, 2003. [Google Scholar]

- Ballanti, L.; Blesius, L.; Hines, E.; Kruse, B. Tree Species Classification Using Hyperspectral Imagery: A Comparison of Two Classifiers. Remote Sens. 2016, 8, 445. [Google Scholar] [CrossRef]

- Clark, M.L.; Roberts, D.; Ewel, J.J.; Clark, D.B. Estimation of tropical rain forest aboveground biomass with small-footprint lidar and hyperspectral sensors. Remote Sens. Environ. 2011, 115, 2931–2942. [Google Scholar] [CrossRef]

- Näsi, R.; Honkavaara, E.; Blomqvist, M.; Lyytikäinen-Saarenmaa, P.; Hakala, T.; Viljanen, N.; Kantola, T.; Holopainen, M. Remote sensing of bark beetle damage in urban forests at individual tree level using a novel hyperspectral camera from UAV and aircraft. Urban For. Urban Green. 2018, 30, 72–83. [Google Scholar] [CrossRef]

- Ji-Yong, S.; Zou, X.; Jie-Wen, Z.; Kai-Liang, W.; Zheng-Wei, C.; Xiao-Wei, H.; De-Tao, Z.; Holmes, M. Nondestructive diagnostics of nitrogen deficiency by cucumber leaf chlorophyll distribution map based on near infrared hyperspectral imaging. Sci. Hortic. 2012, 138, 190–197. [Google Scholar] [CrossRef]

- Khan, M.H.; Saleem, Z.; Ahmad, M.; Sohaib, A.; Ayaz, H.; Mazzara, M. Hyperspectral Imaging for Color Adulteration Detection in Red Chili. Appl. Sci. 2020, 10, 5955. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Makino, Y.; Oshita, S. Rapid and non-destructive detection of chicken adulteration in minced beef using visible near-infrared hyperspectral imaging and machine learning. J. Food Eng. 2016, 170, 8–15. [Google Scholar] [CrossRef]

- Gutiérrez, S.; Wendel, A.; Underwood, J. Spectral filter design based on in-field hyperspectral imaging and machine learning for mango ripeness estimation. Comput. Electron. Agric. 2019, 164, 104890. [Google Scholar] [CrossRef]

- Sanz, J.A.A.; Fernandes, A.; Barrenechea, E.; Silva, S.; Santos, V.A.C.; Gonçalves, N.J.; Paternain, D.; Jurio, A.; Melo-Pinto, P. Lamb muscle discrimination using hyperspectral imaging: Comparison of various machine learning algorithms. J. Food Eng. 2016, 174, 92–100. [Google Scholar] [CrossRef]

- Zhang, J.; Dai, L.; Cheng, F. Classification of Frozen Corn Seeds Using Hyperspectral VIS/NIR Reflectance Imaging. Molecules 2019, 24, 149. [Google Scholar] [CrossRef]

- Serranti, S.; Gargiulo, A.; Bonifazi, G. Characterization of post-consumer polyolefin wastes by hyperspectral imaging for quality control in recycling processes. Waste Manag. 2011, 31, 2217–2227. [Google Scholar] [CrossRef]

- Karlsson, T.M.; Grahn, H.; Van Bavel, B.; Geladi, P. Hyperspectral Imaging and Data Analysis for Detecting and Determining Plastic Contamination in Seawater Filtrates. J. Near Infrared Spectrosc. 2016, 24, 141–149. [Google Scholar] [CrossRef]

- Serranti, S.; Gargiulo, A.; Bonifazi, G. Hyperspectral imaging for process and quality control in recycling plants of polyolefin flakes. J. Near Infrared Spectrosc. 2012, 20, 573. [Google Scholar] [CrossRef]

- Bonifazi, G.; Di Maio, F.; Potenza, F.; Serranti, S. FT-IR Analysis and Hyperspectral Imaging Applied to Postconsumer Plastics Packaging Characterization and Sorting. IEEE Sens. J. 2015, 16, 3428–3434. [Google Scholar] [CrossRef]

- Potenza, M.A.C.; Nazzari, D.; Cremonesi, L.; Denti, I.; Milani, P. Hyperspectral imaging with deformable gratings fabricated with metal-elastomer nanocomposites. Rev. Sci. Instrum. 2017, 88, 113105. [Google Scholar] [CrossRef] [PubMed]

- Brodie, C.H.; Devasagayam, J.; Collier, C.M. A Hyperspectral Imaging Instrumentation Architecture Based on Accessible Optical Disc Technology and Frequency-Domain Analyses. IEEE Trans. Instrum. Meas. 2019, 68, 2531–2538. [Google Scholar] [CrossRef]

- Castillo-Lopez, E.; Dominguez, J.A.; Pereda, R.; De Luis, J.M.; Pérez-Álvarez, R.; Piña, F. The importance of atmospheric correction for airborne hyperspectral remote sensing of shallow waters: Application to depth estimation. Atmos. Meas. Tech. 2017, 10, 3919–3929. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.M.; Kang, Y.I. Field identification and spatial determination of hazardous chemicals by Fourier transform infrared imaging. Instrum. Sci. Technol. 2016, 44, 504–520. [Google Scholar] [CrossRef]

- Elmasry, G.; Wang, N.; Vigneault, C.; Qiao, J.; Elsayed, A. Early detection of apple bruises on different background colors using hyperspectral imaging. LWT 2008, 41, 337–345. [Google Scholar] [CrossRef]

- Cochrane, H.; Lin, C.S. The effect of fumed silica in RTV-1 silicone rubber sealants. Rubber World 1985, 192, 29–36. [Google Scholar]

- Alumina (Aluminum Oxide)—The Different Types of Commercially Available Grades. Available online: https://www.azom.com/article.aspx?ArticleID=1389 (accessed on 11 September 2020).

- Shen, H.; Li, X.; Zhang, L.; Tao, D.; Zeng, C. Compressed Sensing-Based Inpainting of Aqua Moderate Resolution Imaging Spectroradiometer Band 6 Using Adaptive Spectrum-Weighted Sparse Bayesian Dictionary Learning. IEEE Trans. Geosci. Remote Sens. 2013, 52, 894–906. [Google Scholar] [CrossRef]

- Camps-Valls, G.; Gomez-Chova, L.; Muñoz-Marí, J.; Vila-Frances, J.; Calpe-Maravilla, J. Composite Kernels for Hyperspectral Image Classification. IEEE Geosci. Remote Sens. Lett. 2006, 3, 93–97. [Google Scholar] [CrossRef]

- Stancil, D.D. Theory of Magnetostatic Waves; Springer Science and Business Media LLC: Berlin, Germany, 1993. [Google Scholar]

- Ferguson, B.G. Minimum variance distortion-less response beamforming of acoustic array data. JASA 1998, 104, 947–954. [Google Scholar] [CrossRef]

- Introduction to FTIR Spectroscopy. Available online: https://www.newport.com/n/introduction-to-ftir-spectroscopy (accessed on 11 September 2020).

| Material | Aging Mechanism | Aging Time |

|---|---|---|

| HTV | 0.046% Hypochlorous acid | 5 weeks |

| RTV-1 | UVA | 1 week |

| RTV-2 | 80 °C Nitric acid (pH = 2.6) | 6 weeks |

| RTV-2 + 22% ATH | Dry band arcing at 4.5 kVAC | 30 min |

| Material | Aging Mechanism/Time | Measured STRI Hydrophobicity before Aging | Measured STRI Hydrophobicity after Aging | Measured Shore A Hardness before Aging | Measured Shore A Hardness after Aging |

|---|---|---|---|---|---|

| HTV | 0.046% Hypochlorous acid for 5 weeks | HC 1 | HC 7 | 92 | 88 |

| RTV-1 | UVA for 1 week | HC 1 | HC 2 | 21 | 17.5 |

| RTV-2 | Nitric acid (pH 2.6) for 6 weeks | HC 1 | HC 6 | 23 | 12 |

| RTV-2 + 22% ATH | Dry band arcing at 4.5 kVAC for 30 min | HC 1 | HC 1 | 34 | 34 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bleszynski, M.; Mann, S.; Kumosa, M. Visualizing Polymer Damage Using Hyperspectral Imaging. Polymers 2020, 12, 2071. https://doi.org/10.3390/polym12092071

Bleszynski M, Mann S, Kumosa M. Visualizing Polymer Damage Using Hyperspectral Imaging. Polymers. 2020; 12(9):2071. https://doi.org/10.3390/polym12092071

Chicago/Turabian StyleBleszynski, Monika, Shaun Mann, and Maciej Kumosa. 2020. "Visualizing Polymer Damage Using Hyperspectral Imaging" Polymers 12, no. 9: 2071. https://doi.org/10.3390/polym12092071

APA StyleBleszynski, M., Mann, S., & Kumosa, M. (2020). Visualizing Polymer Damage Using Hyperspectral Imaging. Polymers, 12(9), 2071. https://doi.org/10.3390/polym12092071