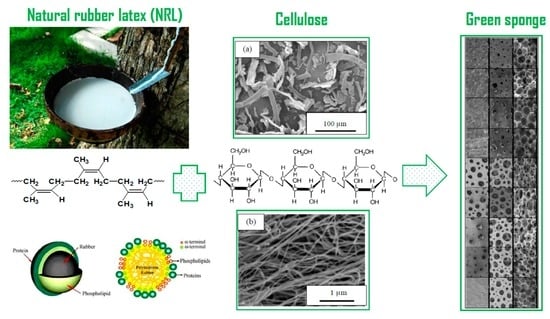

Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Cellulose Powder

2.3. Characterization of Cellulose

2.4. Preparation of NRLF and Reinforced NRLF

2.5. Characterization of NRLF, NRLF-MC and NRLF-NC

3. Results and Discussion

3.1. Characterization of Cellulose Fibers/Powders

3.2. Morphology of NRLF, NRLF-MC, and NRLF-NC

3.3. Foam Density

3.4. Crosslinking Density

3.5. Mechanical Properties

3.6. Compression Properties

3.7. Surface Wettability

3.8. Water Uptake

3.9. Thermal Degradation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bashir, A.S.; Munusamy, Y.; Chew, T.L.; Ismail, H.; Ramasamy, S. Mechanical, thermal, and morphological properties of (eggshell powder)-filled natural rubber latex foam. J. Vinyl Addit. Technol. 2015, 23, 3–12. [Google Scholar] [CrossRef]

- Zou, L.; Phule, A.D.; Sun, Y.; Zhu, T.Y.; Wen, S.; Zhang, Z. Superhydrophobic and superoleophilic polyethylene aerogel coated natural rubber latex foam for oil-water separation application. Polym. Test. 2020, 85, 106451. [Google Scholar] [CrossRef]

- Rathnayake, W.G.I.U.; Ismail, H.; Baharin, A.; Bandara, C.D.; Rajapakse, S. Enhancement of the antibacterial activity of natural rubber latex foam by the incorporation of zinc oxide nanoparticles. J. Appl. Polym. Sci. 2013, 131, 131. [Google Scholar] [CrossRef]

- Karim, A.F.A.; Ismail, H.; Ariff, Z.M. Properties and characterization of Kenaf-Filled natural rubber latex foam. Bioresources 2016, 11, 1080–1091. [Google Scholar]

- Ramasamy, S.; Ismail, H.; Munusamy, Y. Tensile and morphological properties of rice husk powder filled natural rubber latex foam. Polym. Technol. Eng. 2012, 51, 1524–1529. [Google Scholar] [CrossRef]

- Phomrak, S.; Phisalaphong, M. Reinforcement of natural rubber with bacterial cellulose via a latex aqueous Microdispersion process. J. Nanomater. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Ciechanska, D. Multifunctional bacterial cellulose/chitosan composite materials for medical applications. Fibres Text. East. Eur. 2004, 12, 69–72. [Google Scholar]

- Czaja, W.; Krystynowicz, A.; Bielecki, S.; Brown, R.M., Jr. Microbial cellulose—The natural power to heal wounds. Biomaterials 2006, 27, 145–151. [Google Scholar] [CrossRef]

- Deng, C.-M.; He, L.-Z.; Zhao, M.; Yang, D.; Liu, Y. Biological properties of the chitosan-gelatin sponge wound dressing. Carbohydr. Polym. 2007, 69, 583–589. [Google Scholar] [CrossRef]

- Bodhibukkana, C.; Srichana, T.; Kaewnopparat, S.; Tangthong, N.; Bouking, P.; Martin, G.P.; Suedee, R. Composite membrane of bacterially-derived cellulose and molecularly imprinted polymer for use as a transdermal enantioselective controlled-release system of racemic propranolol. J. Control. Release 2006, 113, 43–56. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Udhardt, U.; Marsch, S. Bacterial synthesized cellulose—Artificial blood vessels for microsurgery. Prog. Polym. Sci. 2001, 26, 1561–1603. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.; Martin, A., Jr.; Conrad, C. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Treloar, L.R.G. The Physics of Rubber Elasticity; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Najib, N.; Ariff, Z.M.; Bakar, A.; Sipaut, C. Correlation between the acoustic and dynamic mechanical properties of natural rubber foam: Effect of foaming temperature. Mater. Des. 2011, 32, 505–511. [Google Scholar] [CrossRef]

- Ariff, Z.; Zakaria, Z.; Tay, L.; Lee, S. Effect of foaming temperature and rubber grades on properties of natural rubber foams. J. Appl. Polym. Sci. 2008, 107, 2531–2538. [Google Scholar] [CrossRef]

- Abd-El-Messieh, S.; El-Nashar, D.; Khafagi, M. Compatibility investigation of microwave irradiated acrylonitrile butadiene/ethylene propylene diene rubber blends. Polym. Technol. Eng. 2004, 43, 135–158. [Google Scholar] [CrossRef]

- Zheng, Y.; Fu, Z.; Li, D.; Wu, M. Effects of ball milling processes on the microstructure and rheological properties of microcrystalline cellulose as a sustainable polymer additive. Materials 2018, 11, 1057. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, W.; Ji, G.; Zhang, Y.; Cao, Y.; Han, L. Regularity and mechanism of wheat straw properties change in ball milling process at cellular scale. Bioresour. Technol. 2017, 241, 214–219. [Google Scholar] [CrossRef]

- Zhou, L.; He, H.; Li, M.-C.; Song, K.; Cheng, H.; Wu, Q. Morphological influence of cellulose nanoparticles (CNs) from cottonseed hulls on rheological properties of polyvinyl alcohol/CN suspensions. Carbohydr. Polym. 2016, 153, 445–454. [Google Scholar] [CrossRef]

- Ling, Z.; Edwards, J.V.; Guo, Z.; Prevost, N.T.; Nam, S.; Wu, Q.; French, A.D.; Xu, F. Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: Micro and nano scale. Cellulose 2019, 26, 861–876. [Google Scholar] [CrossRef]

- Phisalaphong, M.; Suwanmajo, T.; Sangtherapitikul, P. Novel nanoporous membranes from regenerated bacterial cellulose. J. Appl. Polym. Sci. 2008, 107, 292–299. [Google Scholar] [CrossRef]

- Liu, M.; Wang, H.; Han, J.; Niu, Y. Enhanced hydrogenolysis conversion of cellulose to C2–C3 polyols via alkaline pretreatment. Carbohydr. Polym. 2012, 89, 607–612. [Google Scholar] [CrossRef]

- Nomura, S.; Kugo, Y.; Erata, T. 13C NMR and XRD studies on the enhancement of cellulose II crystallinity with low concentration NaOH post-treatments. Cellulose 2020, 27, 3553–3563. [Google Scholar] [CrossRef]

- Keshk, S.M.A.S.; Hamdy, M.S. Preparation and physicochemical characterization of zinc oxide/sodium cellulose composite for food packaging. Turk. J. Chem. 2019, 43, 94–105. [Google Scholar] [CrossRef]

- Williams, T.; Hosur, M.; Theodore, M.; Netravali, A.; Rangari, V.; Jeelani, S. Time effects on morphology and bonding ability in mercerized natural fibers for composite reinforcement. Int. J. Polym. Sci. 2011, 2011, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.-y.; Zhang, Z.-t.; Zhang, M.; Guo, M. Selective phase transformation behavior of titanium-bearing electric furnace molten slag during the molten NaOH treatment process. ISIJ Int. 2015, 55, 134–141. [Google Scholar] [CrossRef]

- Choi, S.-S.; Kim, E. A novel system for measurement of types and densities of sulfur crosslinks of a filled rubber vulcanizate. Polym. Test. 2015, 42, 62–68. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of various surface treatments on the performance of jute fibers filled natural rubber (NR) composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef]

- Dominic CD, M.; Joseph, R.; Begum, P.; Joseph, M.; Padmanabhan, D.; Morris, L.A.; Kumar, A.S.; Formela, K. Cellulose nanofibers isolated from the cuscuta reflexa plant as a green reinforcement of natural rubber. Polymers 2020, 12, 814. [Google Scholar] [CrossRef]

- Khimi, S.; Syamsinar, S.; Najwa, T. Effect of carbon black on self-healing efficiency of natural rubber. Mater. Today Proc. 2019, 17, 1064–1071. [Google Scholar] [CrossRef]

- Zheng, L.; Li, C.; Zhang, D.; Guan, G.; Xiao, Y.; Wang, D. Multiblock copolymers composed of poly (butylene succinate) and poly (1, 2-propylene succinate): Effect of molar ratio of diisocyanate to polyester-diols on crosslink densities, thermal properties, mechanical properties and biodegradability. Polym. Degrad. Stab. 2010, 95, 1743–1750. [Google Scholar] [CrossRef]

- Abdul Azam, F.A.; Rajendran Royan, N.R.; Yuhana, N.Y.; Mohd Radzuan, N.A.; Ahmad, S.; Sulong, A.B. Fabrication of porous recycled HDPE biocomposites foam: Effect of rice husk filler contents and surface treatments on the mechanical properties. Polymers 2020, 12, 475. [Google Scholar] [CrossRef]

- Tangpasuthadol, V.; Intasiri, A.; Nuntivanich, D.; Niyompanich, N.; Kiatkamjornwong, S. Silica-reinforced natural rubber prepared by the sol–gel process of ethoxysilanes in rubber latex. J. Appl. Polym. Sci. 2008, 109, 424–433. [Google Scholar] [CrossRef]

- Kemaloglu, S.; Ozkoc, G.; Aytac, A. Properties of thermally conductive micro and nano size boron nitride reinforced silicon rubber composites. Thermochim. Acta 2010, 499, 40–47. [Google Scholar] [CrossRef]

- Mohan, T.; Kuriakose, J.; Kanny, K. Effect of nanoclay reinforcement on structure, thermal and mechanical properties of natural rubber–styrene butadine rubber (NR–SBR). J. Ind. Eng. Chem. 2011, 17, 264–270. [Google Scholar] [CrossRef]

- Chong, E.; Ahmad, I.; Dahlan, H.; Abdullah, I. Reinforcement of natural rubber/high density polyethylene blends with electron beam irradiated liquid natural rubber-coated rice husk. Radiat. Phys. Chem. 2010, 79, 906–911. [Google Scholar] [CrossRef]

- Phomrak, S.; Phisalaphong, M. Lactic acid modified natural rubber–bacterial cellulose composites. Appl. Sci. 2020, 10, 3583. [Google Scholar] [CrossRef]

- Samaržija-Jovanović, S.; Jovanovic, V.; Markovic, G.; Zeković, I.; Marinović-Cincović, M. Properties of vulcanized polyisoprene rubber composites filled with opalized white tuff and precipitated silica. Sci. World J. 2014, 2014, 1–9. [Google Scholar]

- Ismail, H.; Edyham, M.; Wirjosentono, B. Bamboo fibre filled natural rubber composites: The effects of filler loading and bonding agent. Polym. Test. 2002, 21, 139–144. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.; Modak, J.M.; Chanda, M. Mechanical properties of wood–fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Thomas, M.G.; Abraham, E.; Jyotishkumar, P.; Maria, H.J.; Pothen, L.A.; Thomas, S. Nanocelluloses from jute fibers and their nanocomposites with natural rubber: Preparation and characterization. Int. J. Biol. Macromol. 2015, 81, 768–777. [Google Scholar] [CrossRef]

- Timothy, J.J.; Meschke, G. A cascade continuum micromechanics model for the effective elastic properties of porous materials. Int. J. Solids Struct. 2016, 83, 1–12. [Google Scholar] [CrossRef]

- Nascimento, R.M.D.; Ramos, S.M.; Bechtold, I.H.; Hernandes, A.N.C. Wettability study on natural rubber surfaces for applications as biomembranes. ACS Biomater. Sci. Eng. 2018, 4, 2784–2793. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Kirdponpattara, S.; Phisalaphong, M.; Newby, B.-m.Z. Applicability of Washburn capillary rise for determining contact angles of powders/porous materials. J. Colloid Interface Sci. 2013, 397, 169–176. [Google Scholar] [CrossRef]

- Frone, A.N.; Panaitescu, D.M.; Chiulan, I.; Nicolae, C.A.; Casarica, A.; Gabor, A.R.; Trusca, R.; Damian, C.M.; Purcar, V.; Alexandrescu, E. Surface treatment of bacterial cellulose in mild, eco-friendly conditions. Coatings 2018, 8, 221. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Mani, T.; Murugan, P.; Abedi, J.; Mahinpey, N. Pyrolysis of wheat straw in a thermogravimetric analyzer: Effect of particle size and heating rate on devolatilization and estimation of global kinetics. Chem. Eng. Res. Des. 2010, 88, 952–958. [Google Scholar] [CrossRef]

- Wang, Z.; McDonald, A.G.; Westerhof, R.J.; Kersten, S.R.; Cuba-Torres, C.M.; Ha, S.; Pecha, B.; Garcia-Perez, M. Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J. Anal. Appl. Pyrolysis 2013, 100, 56–66. [Google Scholar] [CrossRef]

- Pichayakorn, W.; Suksaeree, J.; Boonme, P.; Taweepreda, W.; Ritthidej, G.C. Preparation of deproteinized natural rubber latex and properties of films formed by itself and several adhesive polymer blends. Ind. Eng. Chem. Res. 2012, 51, 13393–13404. [Google Scholar] [CrossRef]

- Farhadinejad, Z.; Ehsani, M.; Khosravian, B.; Ebrahimi, G. Study of thermal properties of wood plastic composite reinforced with cellulose micro fibril and nano inorganic fiber filler. Eur. J. Wood Wood Prod. 2012, 70, 823–828. [Google Scholar] [CrossRef]

| Ingredient | Amount (phr) |

|---|---|

| 60% DRC HA-NRL | 100 |

| MC or NC | 5, 10, 15, 20 |

| 10 wt % Potassium oleate soap | 1.5 |

| 50 wt % Sulfur | 2.0 |

| 50 wt % Phenolic Adhesive Antioxidant | 1.0 |

| 50 wt % ZMBT | 1.0 |

| 50 wt % ZDEC | 1.0 |

| 50 wt % ZnO | 5.0 |

| 33 wt % DPG | 1.0 |

| 12.5 wt % SSF | 1.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phomrak, S.; Nimpaiboon, A.; Newby, B.-m.Z.; Phisalaphong, M. Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers 2020, 12, 1959. https://doi.org/10.3390/polym12091959

Phomrak S, Nimpaiboon A, Newby B-mZ, Phisalaphong M. Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers. 2020; 12(9):1959. https://doi.org/10.3390/polym12091959

Chicago/Turabian StylePhomrak, Sirilak, Adun Nimpaiboon, Bi-min Zhang Newby, and Muenduen Phisalaphong. 2020. "Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method" Polymers 12, no. 9: 1959. https://doi.org/10.3390/polym12091959

APA StylePhomrak, S., Nimpaiboon, A., Newby, B.-m. Z., & Phisalaphong, M. (2020). Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers, 12(9), 1959. https://doi.org/10.3390/polym12091959