Long-Term Formaldehyde Emission Potential from UF- and NAF-Bonded Particleboards

Abstract

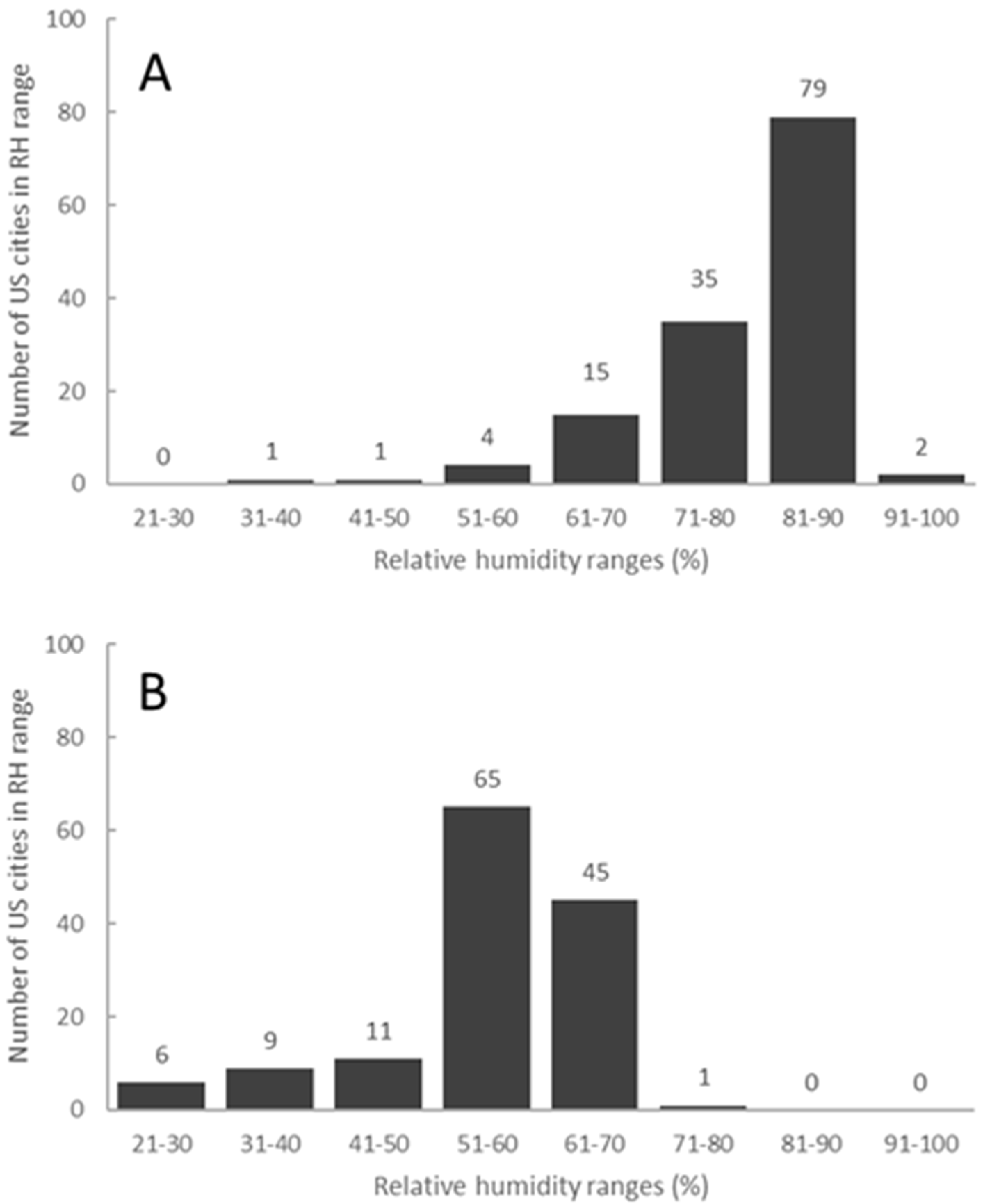

1. Introduction

2. Methods

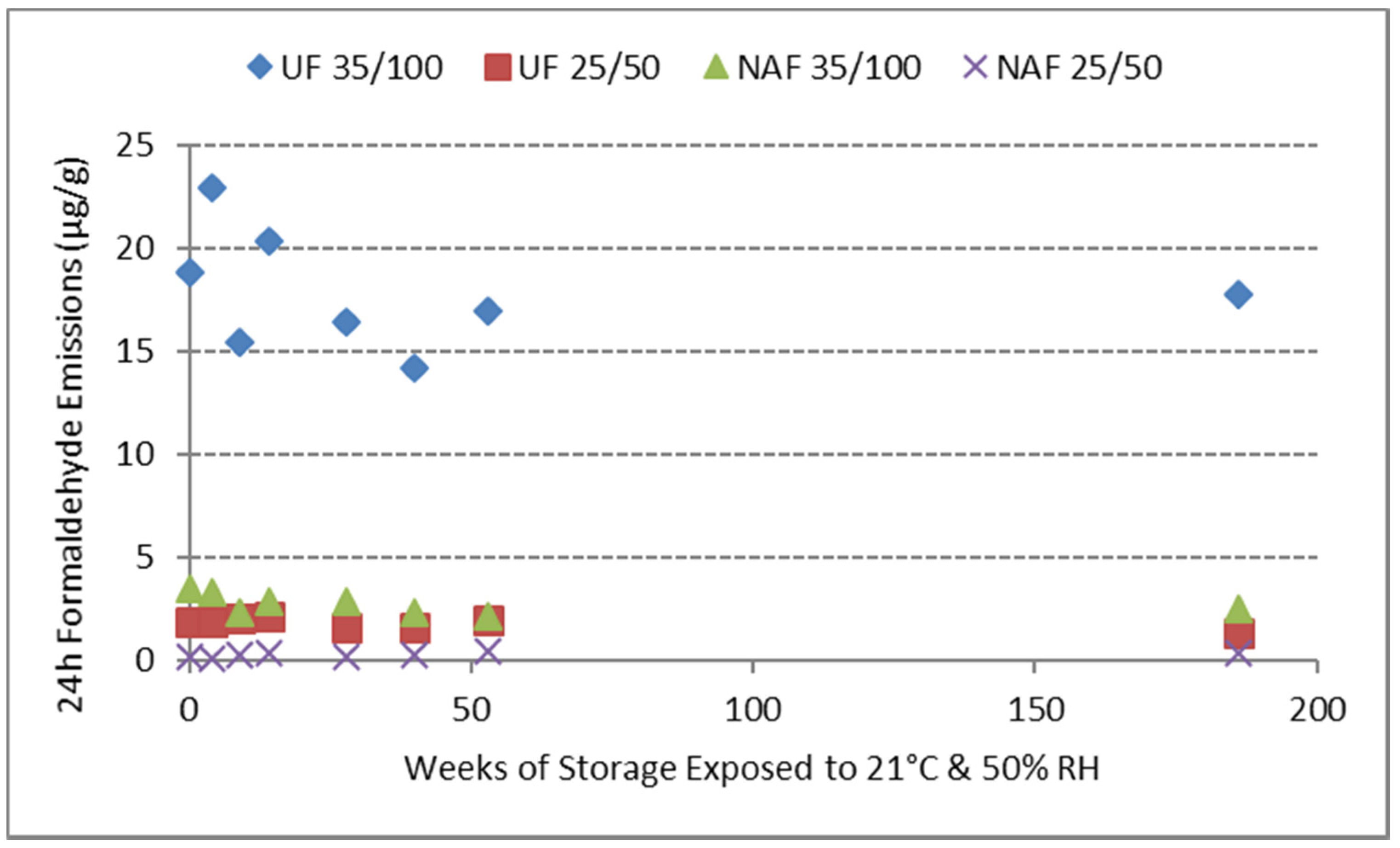

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pizzi, A.; Papadopoulos, A.N.; Policardi, F. Wood composites and their polymer binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef] [PubMed]

- Frihart, C.R.; Wescott, J.M.; Chaffee, T.L.; Gonner, K.M. Formaldehyde emissions from urea-formaldehyde- and no-added-formaldehyde- bonded particleboard as influenced by temperature and relative humidity. For. Prod. J. 2012, 62, 551–558. [Google Scholar] [CrossRef]

- Pizzi, A. Urea-Formaldehyde Adhesives. In Handbook of Adhesive Technology; Pizzi, A., Mittal, K., Eds.; Marcel Dekker: New York, NY, USA, 2003; pp. 635–652. [Google Scholar]

- Myers, G.E. Effects of post-manufacture board treatments on formaldehyde emission: A literature review (1960–1985). For. Prod. J. 1986, 36, 41–51. [Google Scholar]

- Myers, G.E. Effects of temperature and humidity on formaldehyde emission from UFbonded boards: A literature critique. For. Prod. J. 1985, 35, 20–31. [Google Scholar]

- Colombo, A.; Jann, O.; Marutzky, R. The Estimate of the Steady State Formaldehyde Concentration in Large Chamber Tests; Springer: Heidelberg, Germany, 1994; Volume 54, pp. 143–146. [Google Scholar]

- Myers, G.E. How mole ratio of UF resin affects formaldehyde emission and other properties: A literature critique. For. Prod. J. 1984, 34, 35–41. [Google Scholar]

- Kelly, T.S. Determination of Formaldehyde and Toluene Diisocyanate Emissions from Indoor Residential Sources; California Air Resources Board: Sacramento, CA, USA, 1996; p. 119. [Google Scholar]

- Berge, A.; Mellegaard, B.; Hanetho, P.; Ormstad, E.B. Formaldehyde release from particleboard—Evaluation of a mathematical model. Holz als Roh-und Werkstoff 1980, 38, 251–255. [Google Scholar] [CrossRef]

- Dunky, M. Urea-formaldehyde glues —Influence of molar ratio on the properties of glues and the obtainable bond strength with gluing of plywood. Holzforsch. Holzverwert. 1985, 37, 75–82. [Google Scholar]

- Myers, G.E.; Nagaoka, M. Emission of formaldehyde by particleboard: Effect of ventilation rate and loading on air-contamination levels. For. Prod. J. 1981, 31, 39–44. [Google Scholar]

- Myers, G.E.; Nagaoka, M. Formaldehyde from UF-Bonded Panels—Its Measurement and Its Relation to Air Contamination, in Wood Adhesives—Research, Application and Needs Symposium; Noyes Publication: Madison, WI, USA, 1980. [Google Scholar]

- Huang, S.; Xiong, J.; Cai, C.; Xu, W.; Zhang, Y. Influence of humidity on the initial emittable concentration of formaldehyde and hexaldehyde in building materials: Experimental observation and correlation. Sci. Rep. 2016, 6, 23388. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, Y. Impact of temperature on the initial emittable concentration of formaldehyde in building materials: Experimental observation. Indoor Air 2010, 20, 523–529. [Google Scholar] [CrossRef]

- Xiong, J.; Yao, Y.; Zhang, Y. C-History method: Rapid measurement of the initial emittable concentration, diffusion and partition coefficients for formaldehyde and VOCs in building materials. Environ. Sci. Technol. 2011, 45, 3584–3590. [Google Scholar] [CrossRef] [PubMed]

- Roffael, E. Formaldehyde Release from Particleboard and Other Wood Based Panels; Forest Research Institute Malaysia: Kuala Lumpur, Malaysia, 1993. [Google Scholar]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- ANSI. American National Standard for Particleboard; The Composite Panel Association: Gaithersburg, Maryland, 2016. [Google Scholar]

- ANSI. American National Standard for Medium Density Fiberboard (MDF) for Interior Applications; The Composite Panel Association: Gaithersburg, Maryland, 2016. [Google Scholar]

- HPVA. American National Standard for Hardwood Plywood and Decorative Plywood; Hardwood Plywood and Veneer Association: Reston, Virginia, 2016. [Google Scholar]

- Spear, M. Formaldehyde and Standards in Board Products. COST Action FP1303 Training School, Danish Technological Institute, Taastrup, Denmark 15–17 March 2017. Available online: http://costfp1303.iam.upr.si/en/resources/files//past-events/training-school-4/formaldehyde-training-school.pdf (accessed on 19 January 2017).

- Zeleniuc, O. Standards and regulations concerning the formaldehyde emissions from wood panels. In Proceedings of the 13th International Conference “Standardization, Protypes and Quality: A Means of Balkan Countries Collaboration”, Transilvania University of Brasov, Brasov, Romania, 3–4 November 2016; pp. 266–271. [Google Scholar]

- Gatlin, C.G. IARC classifies formaldehyde as carcinogenic. Oncol. Times 2004, 26, 72. [Google Scholar]

- International Agency for Research on Cancer. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. Available online: http://www.inchem.org/documents/iarc/vol88/volume88.pdf (accessed on 21 February 2019).

- CARB. Airborne toxic control measure to reduce formaldehyde emissions from composite wood products. In Health and Safety Code: Title 17, California Code of Regulations; California Air Resources Board: Sacramento, CA, USA, 2009. [Google Scholar]

- US Congress. Formaldehyde Standards for Composite Wood Products Act amended to the Toxic Substances Control Act of 1976. In Proceedings of the 111th Congress 111–199, Washington, DC, USA, 7 July 2010. [Google Scholar]

- Dunky, M. Resins for ultra-low formaldehyde emission according to the Japanese F**** quality. In Proceedings of the International Conference on Wood Adhesives 2005, San Diego, CA, USA, 2–4 November 2005; Forest Products Society: Madison, WI, USA, 2005. [Google Scholar]

- Allen, A.J.; Spraul, B.K.; Wescott, J.M. Improved CARB II-Compliant soy adhesives for laminates. In Proceedings of the International Conference on Wood Adhesives 2009, South Lake Tahoe, NV, USA, 28–30 September 2009; Forest Products Society: Madison, WI, USA, 2010. [Google Scholar]

- Wescott, J.M.; Birkeland, J.; Yarvoski, B.R. Recent advances in soy containing PB and MDF. In Proceedings of the International Conference on Wood Adhesives 2009, South Lake Tahoe, CA, USA, 28–30 September 2009; Forest Products Society: Madison, WI, USA, 2010. [Google Scholar]

- Dunky, M. Adhesives in the Wood Industry. In Handbook of Adhesive Technology; Pizzi, A., Mittal, K., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2017; pp. 511–574. [Google Scholar]

- Myers, G.E. Resin hydrolysis and mechanisms of formaldehyde release from bonded wood products. In Proceedings of the Wood Adhesives in 1985: Status and Needs, Madison, WI, USA, 14–16 May 1985; Forest Products Research Society: Madison, WI, USA, 1985. [Google Scholar]

- Winter, S.; Kreuzinger, H. The Bad Reichenhall Ice-Arena Collapse and The Necessary Consequences for Wide Span Timber Structures. 2008. Available online: http://www.support.sbcindustry.com/Archive/2008/june/Paper_271.pdf (accessed on 16 December 2019).

- Roffael, E. Volatile organic compounds and formaldehyde in nature, wood and wood based panels. Holz Roh Werkstatt 2006, 64, 144–149. [Google Scholar] [CrossRef]

- Schäfer, M.; Roffael, E. On the formaldehyde release of wood. Holz Roh Werkstatt 2000, 58, 259–264. [Google Scholar] [CrossRef]

- Birkeland, M.J.; Lorenz, L.; Wescott, J.M.; Frihart, C.R. Significance of native formaldehyde in particleboards generated during wood composite panel production. In Proceedings of the Wood Adhesives 2009, South Lake Tahoe, CA, USA, 28–30 September 2009; Forest Products Society: Madison, WI, USA, 2010. [Google Scholar]

- Birkeland, M.J.; Lorenz, L.; Wescott, J.M.; Frihart, C.R. Determination of native (wood derived) formaldehyde by the desiccator method in particleboards generated during panel production. Holzforschung 2010, 64, 429–433. [Google Scholar] [CrossRef]

- Salthammer, T. Formaldehyde sources, formaldehyde concentrations and air exchange rates in European housings. Build. Environ. 2019, 150, 219–232. [Google Scholar] [CrossRef]

- Fredriksson, M.; Thybring, E.E. On sorption hysteresis in wood: Separating hysteresis in cell wall water and capillary water in the full moisture range. PLoS ONE 2019, 14, e0225111. [Google Scholar] [CrossRef]

- ASTM International. E1333-14. Standard Test Method for Determining Formaldehyde Concentrations in Air and Emission Rates from Wood Products Using a Large Chamber; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Riedlinger, D.A.; Martin, P.; Holloway, T. Particleboard formaldehyde emissions and decay under elevated temperature and humidity conditions. Tech. Rep. Arclin 2012. [Google Scholar]

- Cai, Z.; Birkeland, M.; Wescott, J.M.; O’Dell, J.; Winandy, J.E. Effects of press sizes on internal steam pressure during particleboard hot-pressing process. Forest Prod. J. 2009, 59, 40–44. [Google Scholar]

- Marutzky, R. Release of formaldehyde by wood products. In Wood Adhesives Chemistry and Technology; Pizzi, A., Ed.; Marcel Dekker: New York, NY, USA, 1989. [Google Scholar]

- Wexler, A. Humidity standards. TAPPI J. 1961, 44, 180A–191A. [Google Scholar]

- CEN EN 717-3:1996. Wood-based panels—Determination of formaldehyde release. In Part 3: Formaldehyde Release by the Flask Method; European Committee for Standardization: Brussels, Belgium, 1996. [Google Scholar]

- CPA. NAF/ULEF Manufactures. Available online: https://www.compositepanel.org/sustainability/ecc/naf-ulef.html (accessed on 18 February 2020).

| Internal Bond (psi) [MPa] | Modulus of Rupture (psi) [MPa] | Apparent Density (lb/ft3) [kg/m3] | |

|---|---|---|---|

| Commercial UF-bonded | 86.5 ± 9.0 [0.59 ± 0.06] | 1999 ± 179 [13.78 ± 1.23] | 44.6 ± 1.3 [714 ± 21] |

| Laboratory NAF-bonded | 91.2 ± 10.1 [0.63 ± 0.07] | 1973 ± 111 [13.60 ± 0.77] | 46.8 ± 1.1 [750 ± 18] |

| EN-717-3 | Our Method | |

|---|---|---|

| Temperature | 40 °C | 25 °C and 35 °C |

| Test duration | 3 h | 24 h |

| Relative humidity | 100% | 50% and 100% |

| Weeks of Storage at 21 °C and 50% RH | UF | NAF | ||

|---|---|---|---|---|

| 25 °C and | 35 °C and | 25 °C and | 35 °C and | |

| 50% RH | 100% RH | 50% RH | 100% RH | |

| 0 | 1.9 | 19 | 0.19 | 3.5 |

| 4 | 1.8 | 23 | 0.10 | 3.3 |

| 9 | 2.0 | 15 | 0.28 | 2.4 |

| 14 | 2.2 | 20 | 0.34 | 2.9 |

| 28 | 1.6 | 16 | 0.18 | 2.8 |

| 40 | 1.6 | 14 | 0.25 | 2.3 |

| 53 | 2.0 | 17 | 0.47 | 2.1 |

| 186 | 1.4 | 18 | 0.38 | 2.5 |

| Overall Average | 1.8 | 18 | 0.27 | 2.7 |

| X-increase | 10 | 10 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frihart, C.R.; Chaffee, T.L.; Wescott, J.M. Long-Term Formaldehyde Emission Potential from UF- and NAF-Bonded Particleboards. Polymers 2020, 12, 1852. https://doi.org/10.3390/polym12081852

Frihart CR, Chaffee TL, Wescott JM. Long-Term Formaldehyde Emission Potential from UF- and NAF-Bonded Particleboards. Polymers. 2020; 12(8):1852. https://doi.org/10.3390/polym12081852

Chicago/Turabian StyleFrihart, Charles R., Timothy L. Chaffee, and James M. Wescott. 2020. "Long-Term Formaldehyde Emission Potential from UF- and NAF-Bonded Particleboards" Polymers 12, no. 8: 1852. https://doi.org/10.3390/polym12081852

APA StyleFrihart, C. R., Chaffee, T. L., & Wescott, J. M. (2020). Long-Term Formaldehyde Emission Potential from UF- and NAF-Bonded Particleboards. Polymers, 12(8), 1852. https://doi.org/10.3390/polym12081852