Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

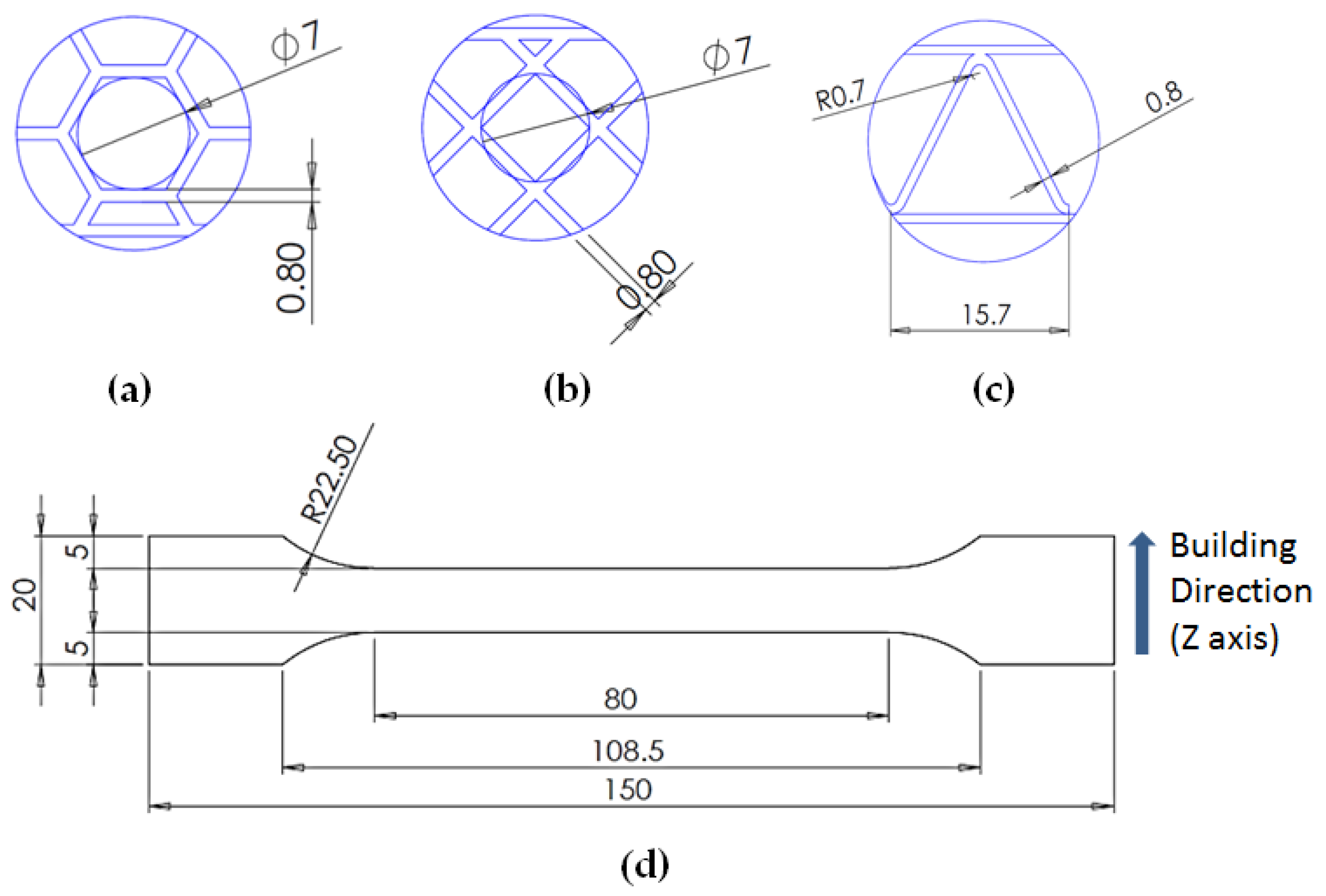

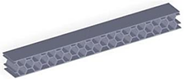

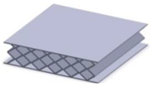

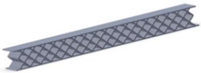

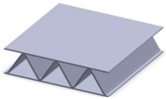

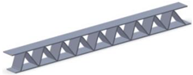

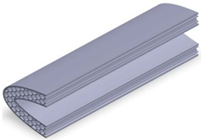

2.1. Design of Sandwich Structures

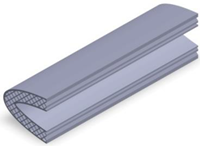

2.2. Design of Wing Leading Edges

2.3. Materials Properties and Manufacturing Conditions

2.4. Mechanical Testing

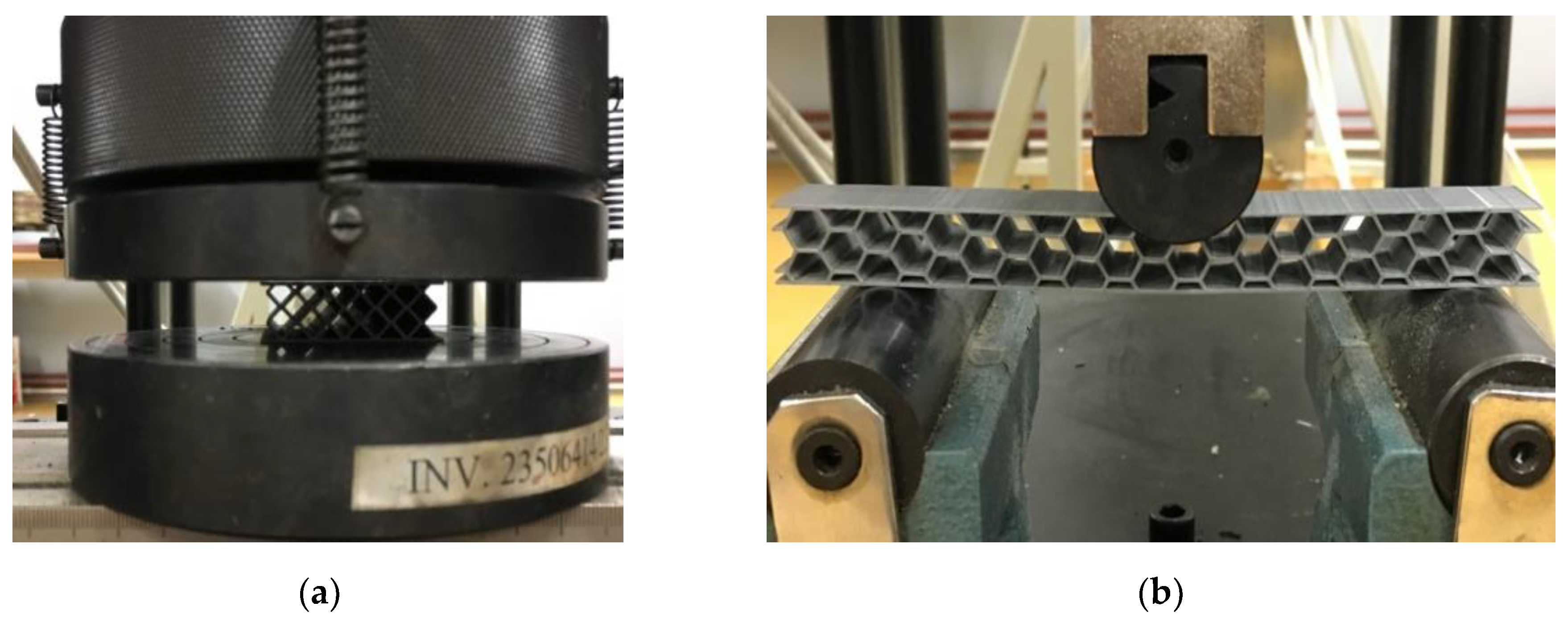

2.4.1. Compression Tests

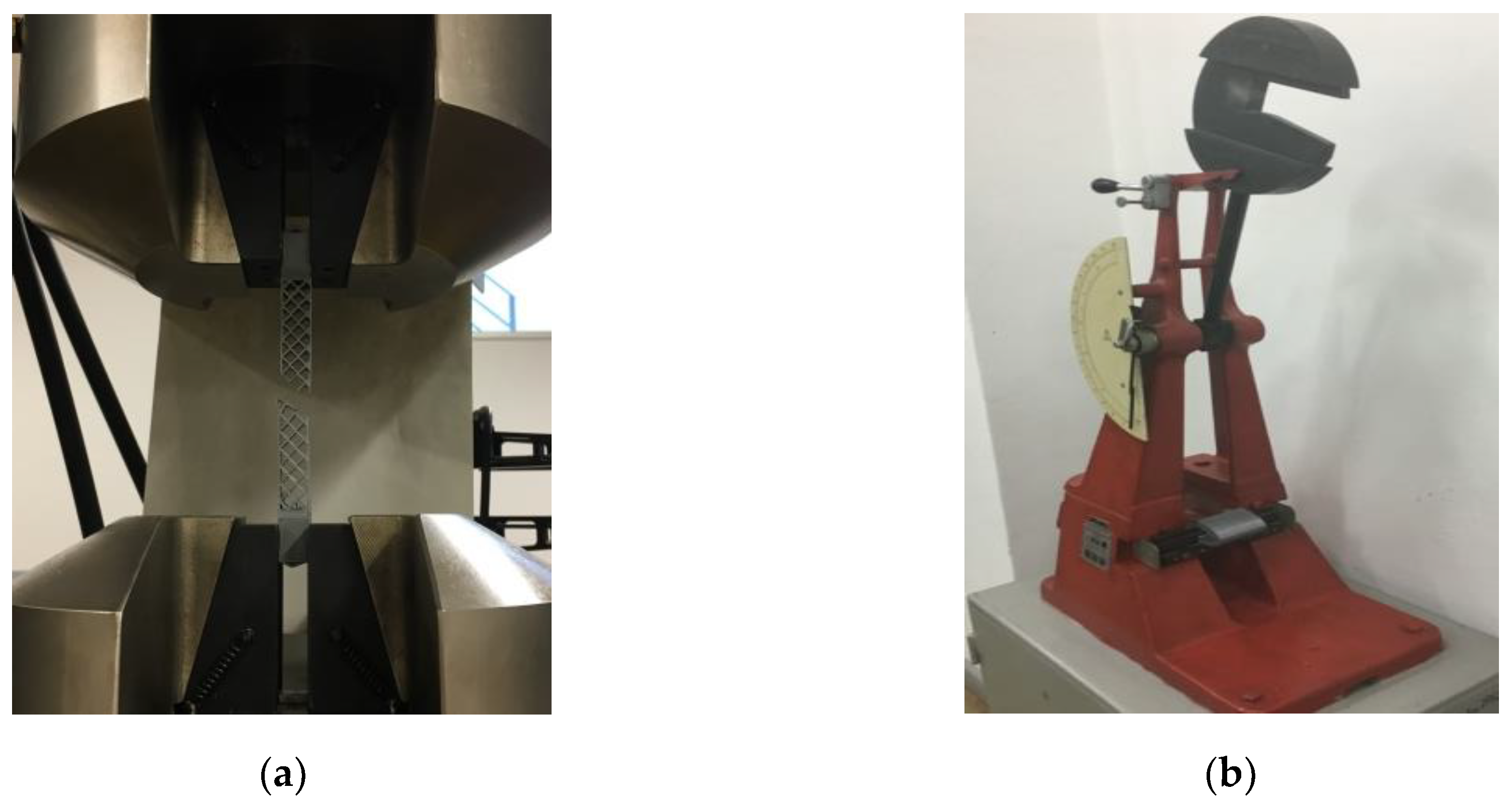

2.4.2. Three-Point Bending Tests

2.4.3. Tensile Tests

2.4.4. Impact Tests

3. Results and Discussion

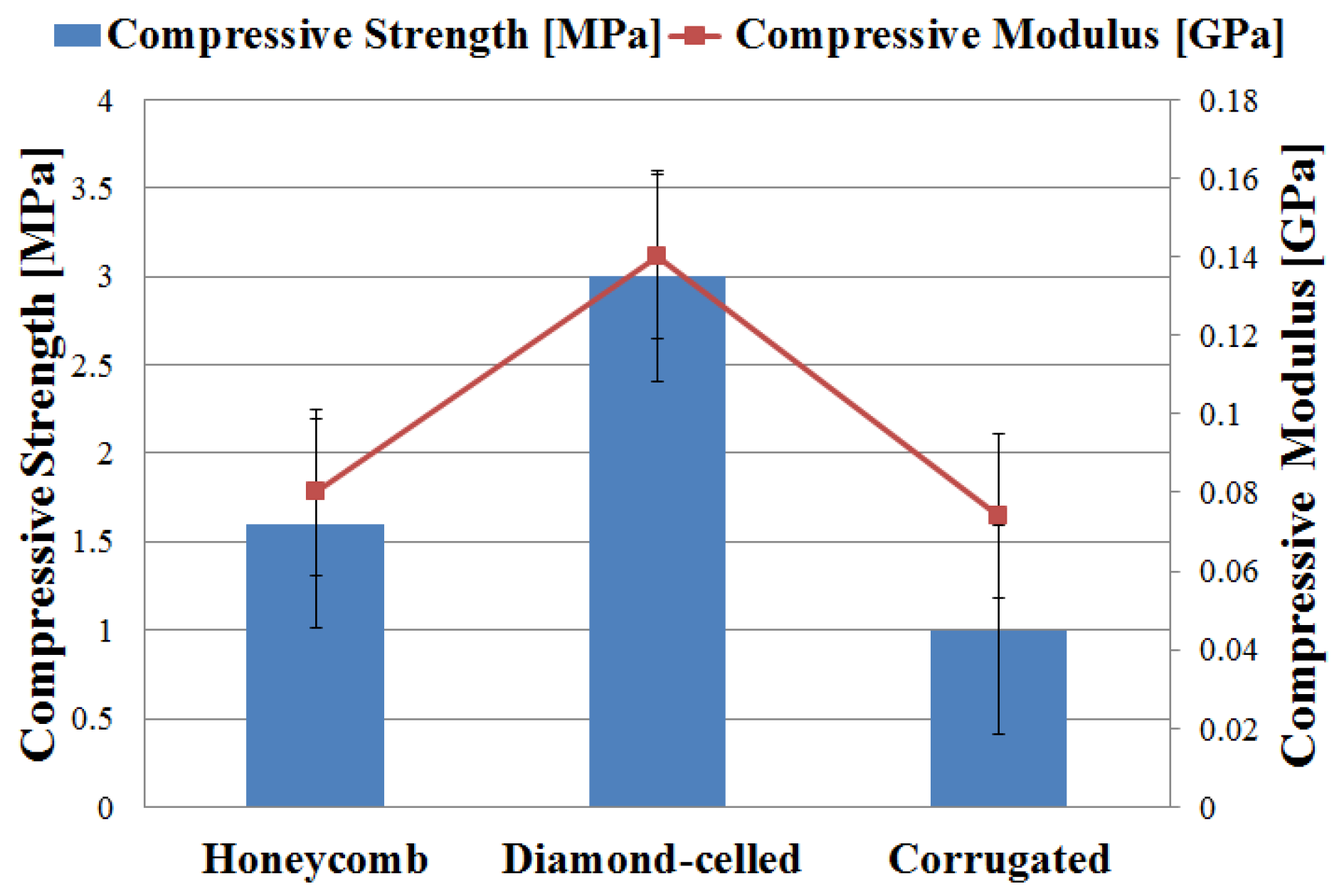

3.1. Compressive Performances of Sandwich Specimens

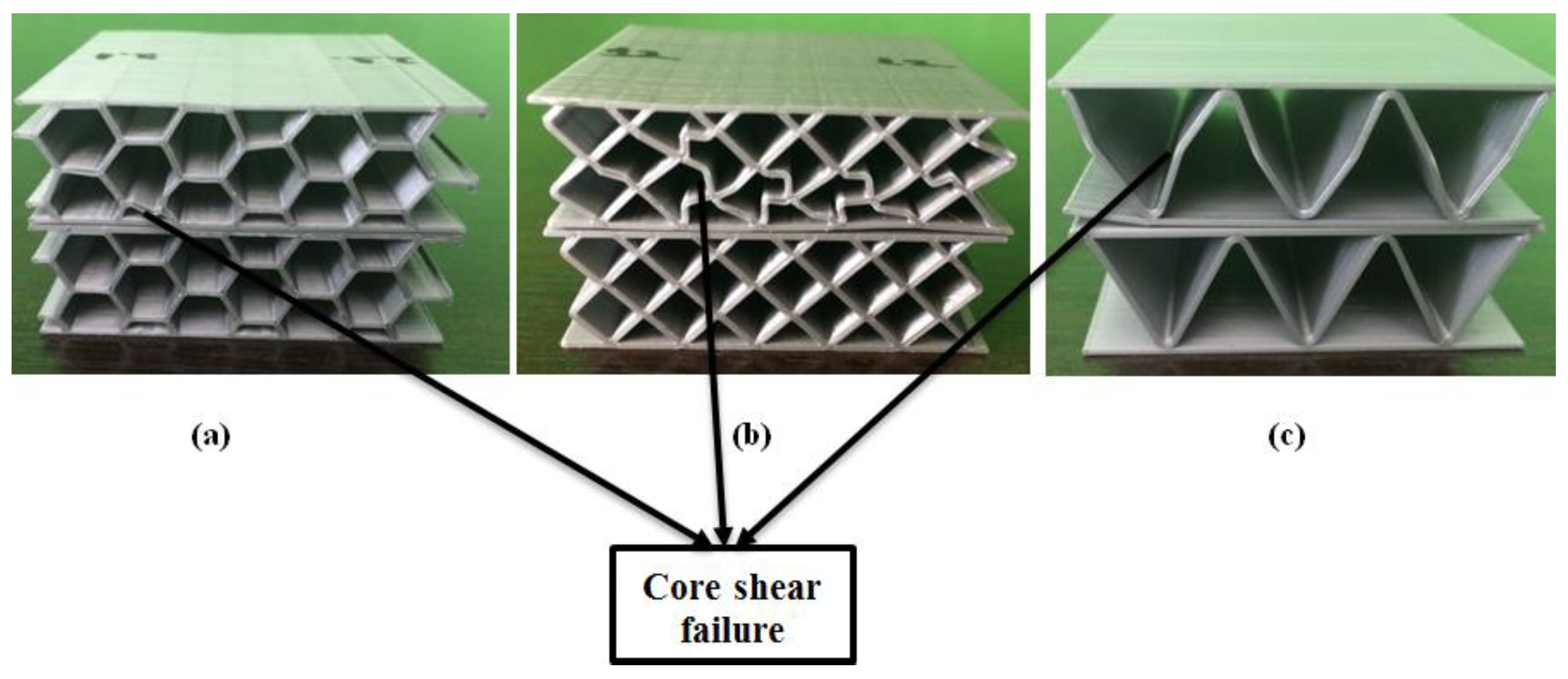

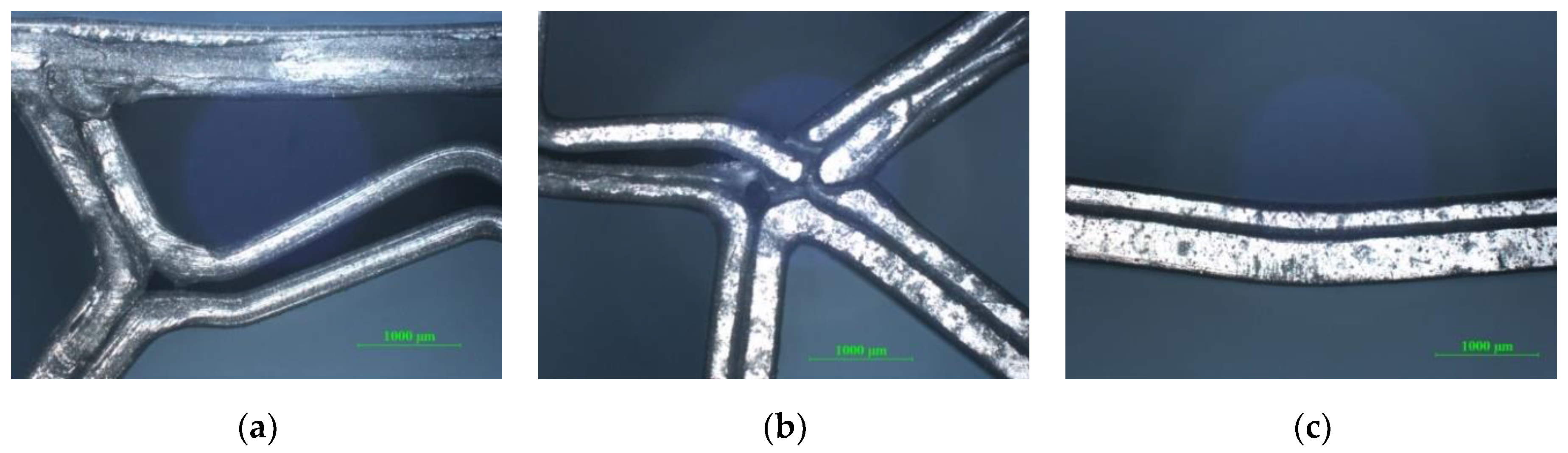

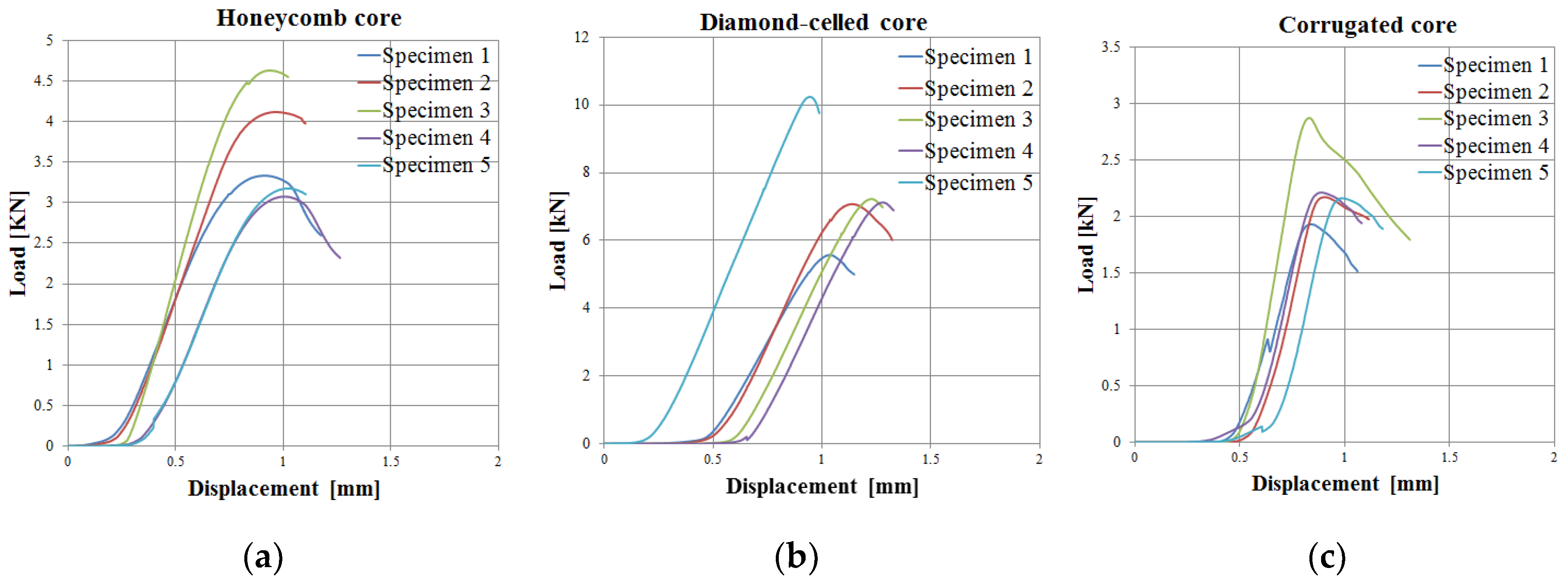

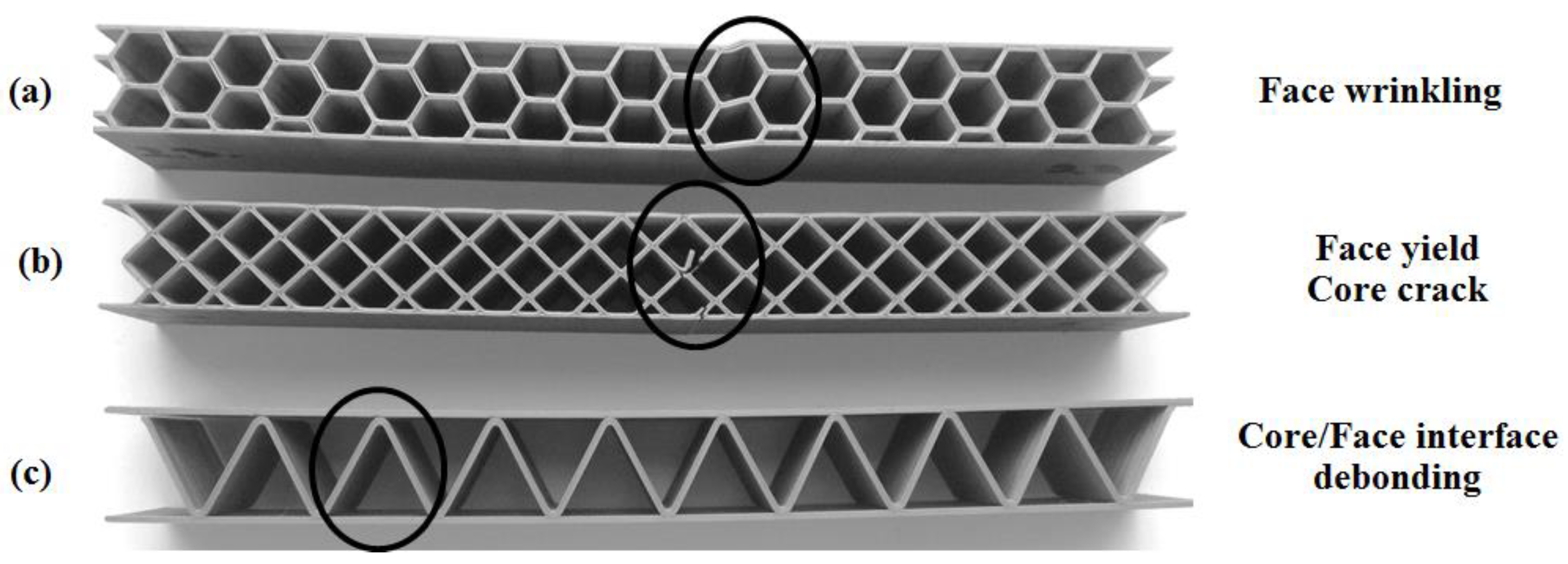

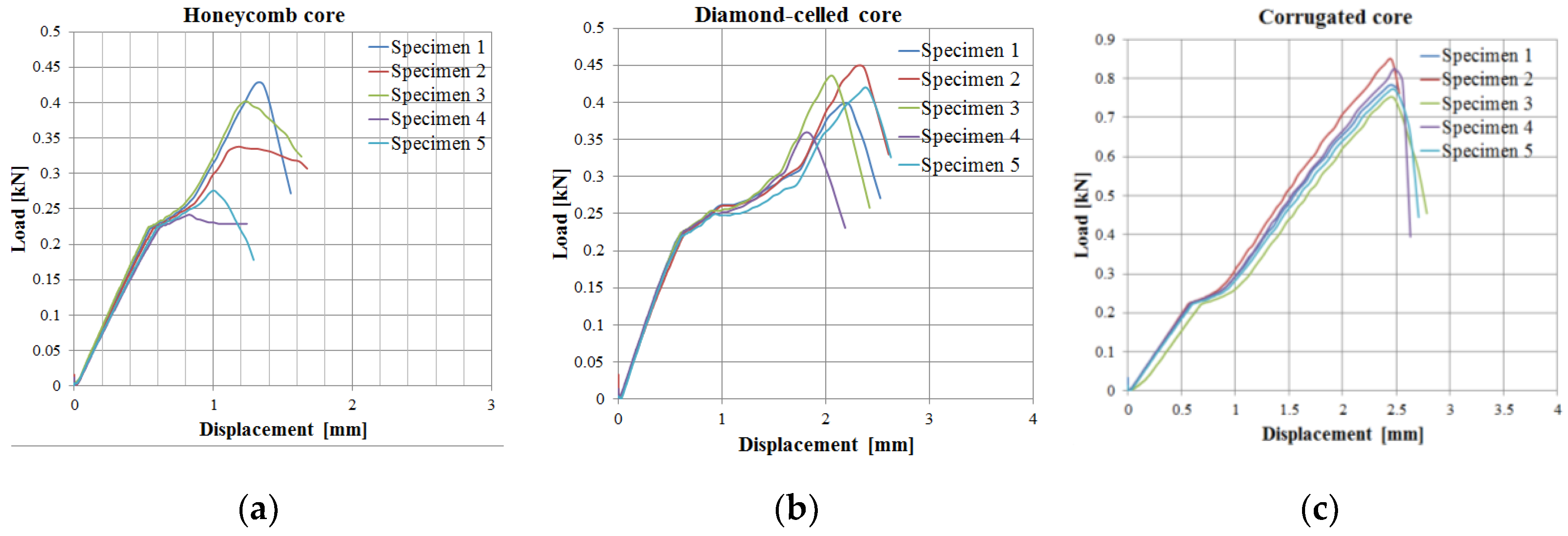

3.2. Mechanical Characteristics of Sandwich Structures under Three-Point Bending Tests

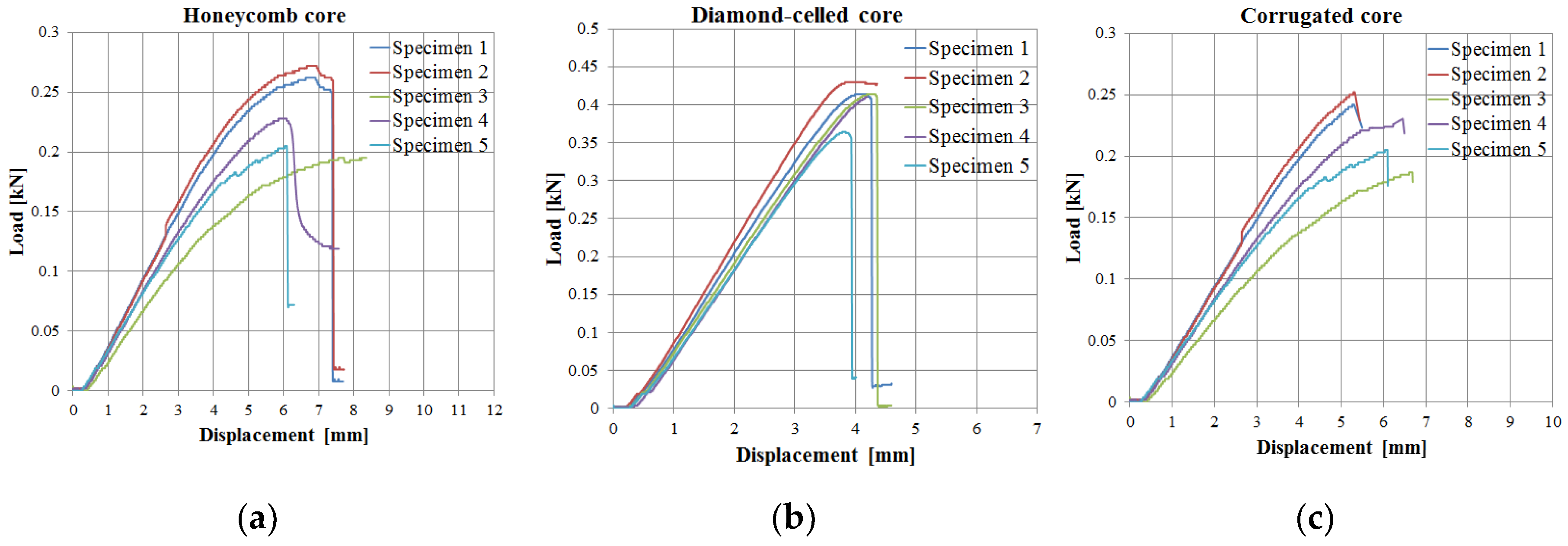

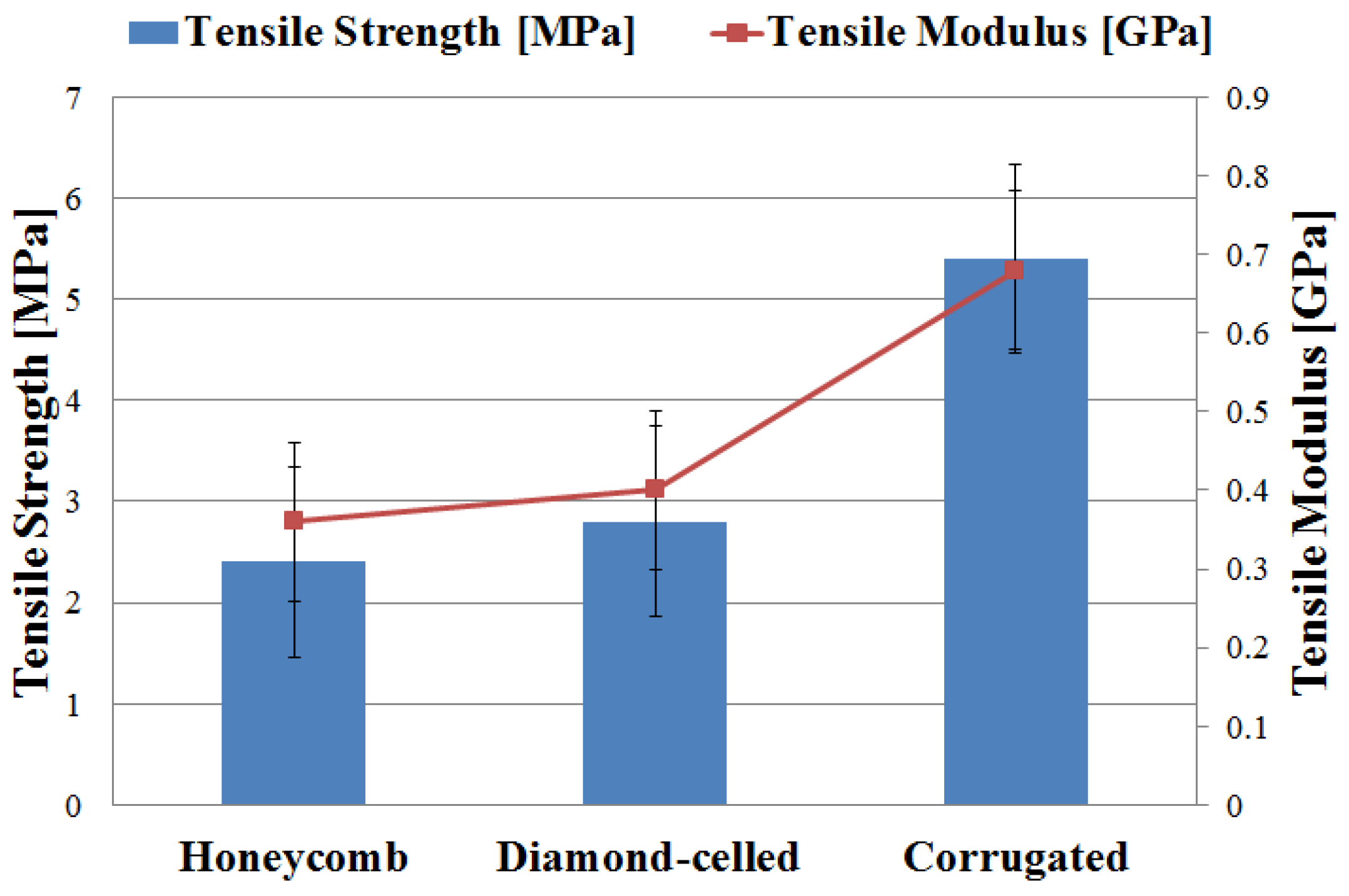

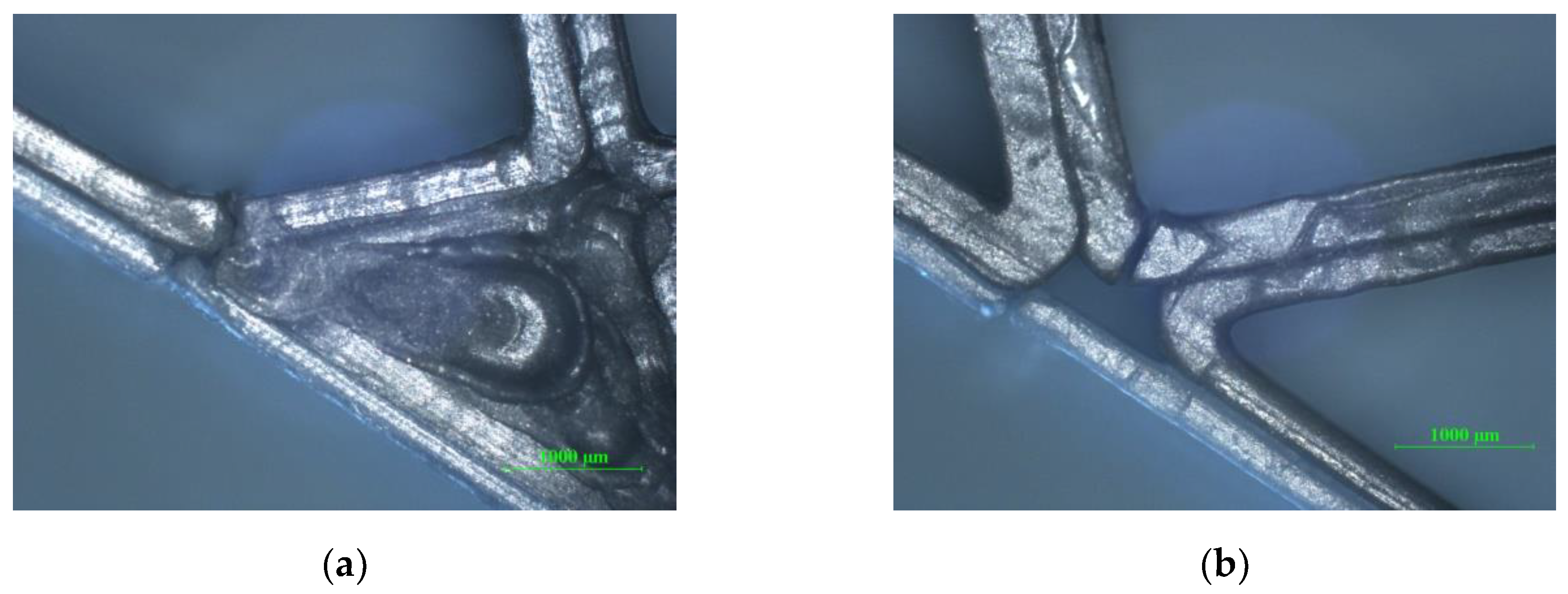

3.3. Tensile Behavior of Sandwich Specimens

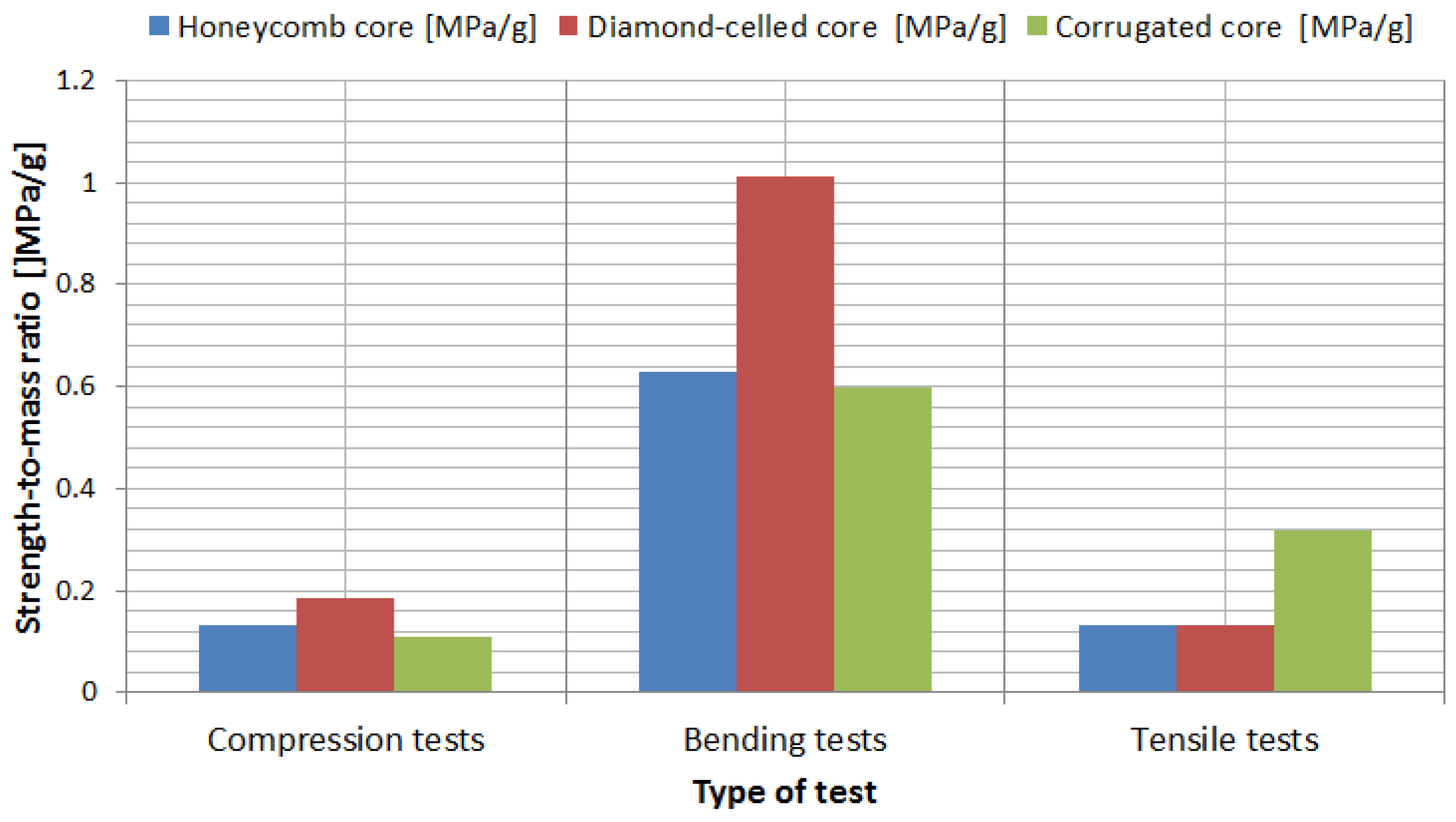

3.4. Strength-to-Mass Ratio Analysis of the Sandwich Specimens

- Based on the compression tests, the sandwich structures with a diamond-celled core presented the best performances;

- Based on the bending tests, the sandwich structures with a diamond-celled core showed the best performances, and the other two core configurations (honeycomb and corrugated) showed similar characteristics;

- Based on the tensile tests, the sandwich structures with a honeycomb core and the sandwich structures with a diamond-cell core showed identical performances, and the sandwich structures with a corrugated core presented the highest performances.

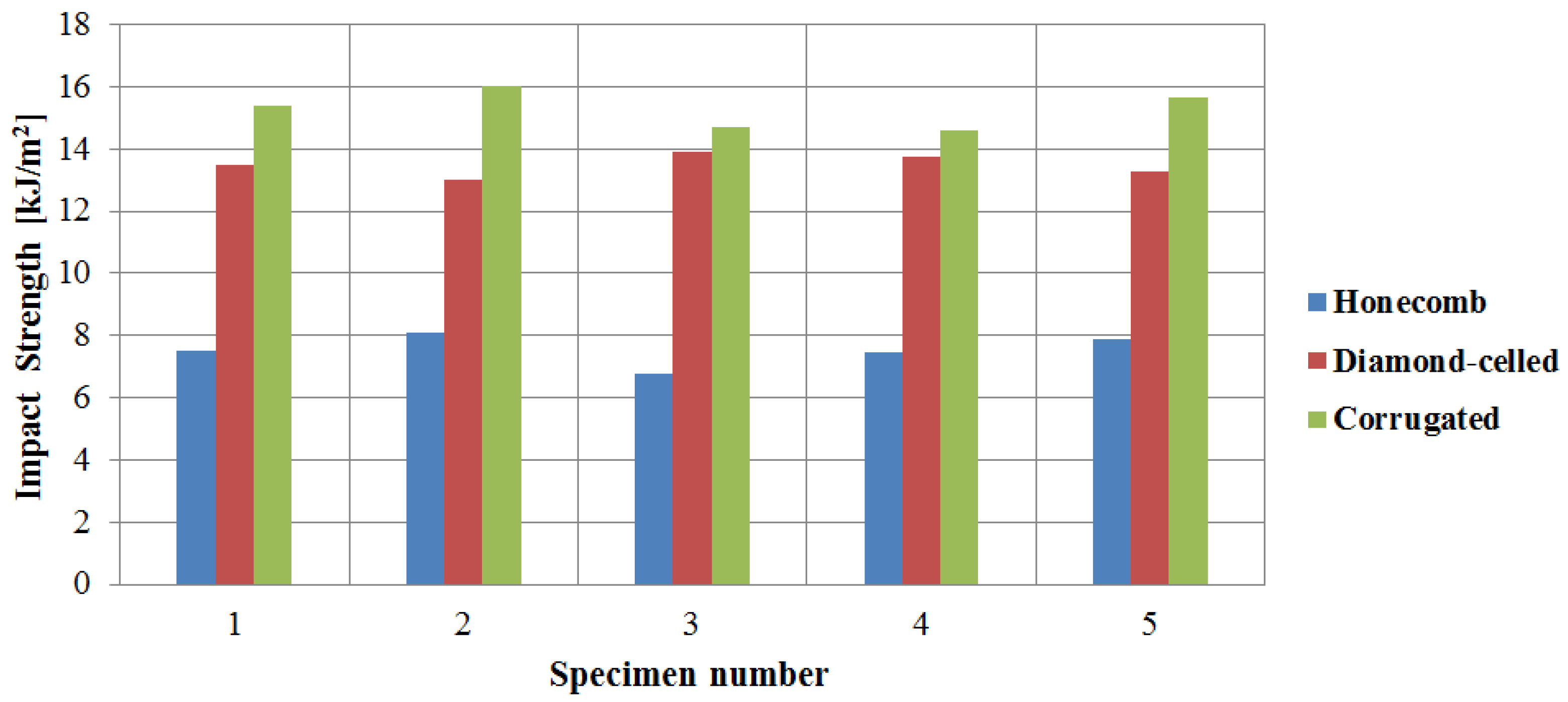

3.5. Impact Testing Properties of Wing Leading Edges

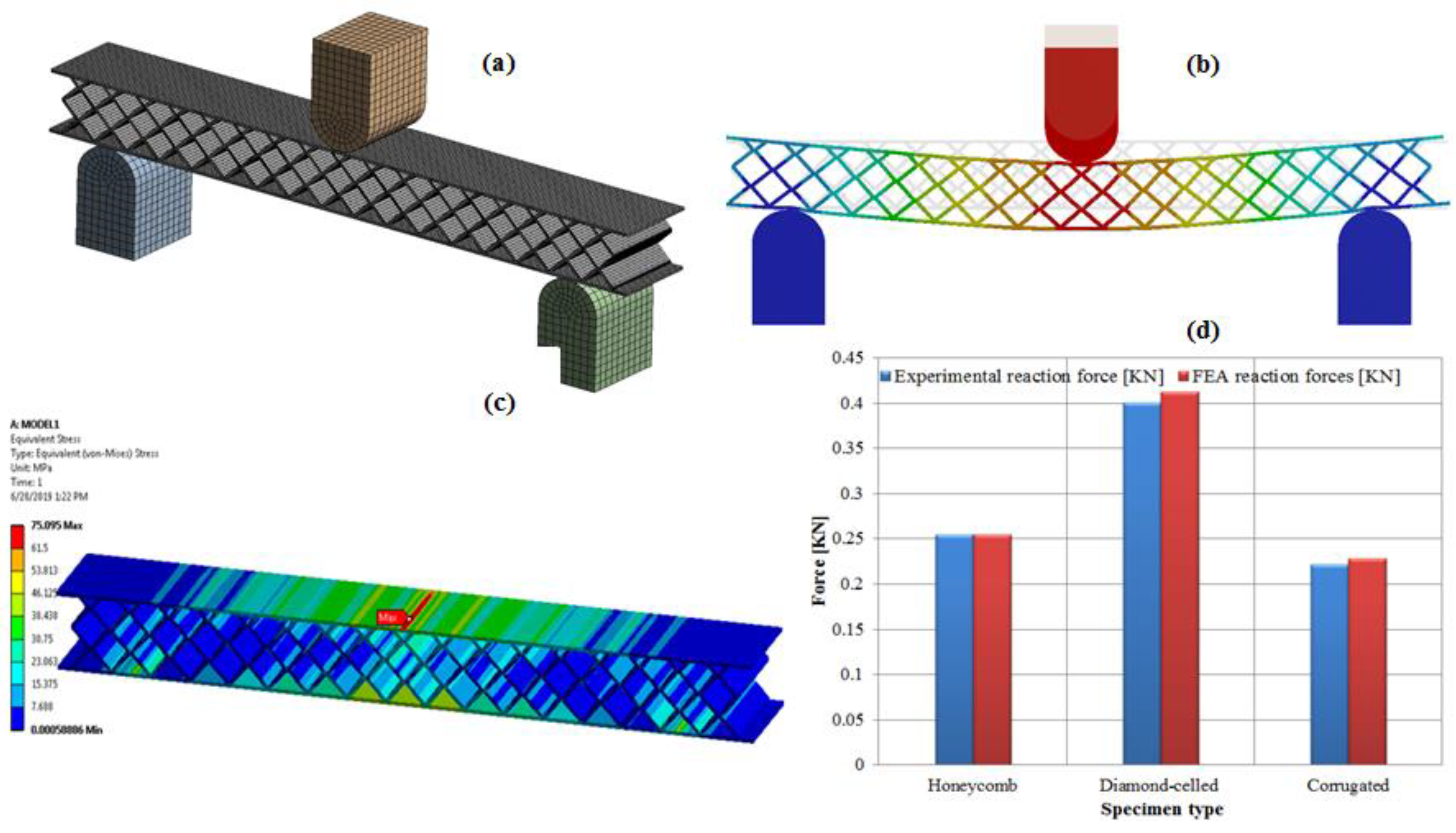

3.6. Results of Finite Element Analyses

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. 3D printed architected polymeric sandwich panels: Energy absorption and structural performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Herrmann, C.; Dewulf, W.; Hauschild, M.; Kaluza, A.; Kara, S.; Skerlos, S. Life cycle engineering of lightweight structures. CIRP Ann. -Manuf. Technol. 2018, 67, 651–672. [Google Scholar] [CrossRef]

- Lubombo, C.; Huneault, M.A. Effect of infill patterns on the mechanical performance of lightweight 3D-printed cellular PLA parts. Mater. Today Commun. 2018, 17, 214–228. [Google Scholar] [CrossRef]

- Baumann, F.W.; Roller, D. Additive Manufacturing, Cloud-Based 3D Printing and Associated Services—Overview. J. Manuf. Mater. Process. 2017, 1, 15. [Google Scholar]

- Singh, K. Experimental study to prevent the warping of 3D models in fused deposition modelling. Int. J. Plast. Technol. 2018, 22, 177–184. [Google Scholar] [CrossRef]

- Chen, Y.; Li, T.; Jia, Z.; Scarpa, F.; Yao, C.W.; Wang, L. 3D printed hierarchical honeycombs with shape integrity under large compressive deformations. Mater. Des. 2018, 137, 226–234. [Google Scholar] [CrossRef]

- Bates, S.R.G.; Farrow, I.R.; Trask, R.S. 3D printed polyurethane honeycombs for repeated tailored energy absorption. Mater. Des. 2016, 112, 172–183. [Google Scholar] [CrossRef]

- Yap, Y.L.; Yeong, W.Y. Shape recovery effect of 3D printed polymeric honeycomb. Virtual Phys. Prototyp. 2015, 10, 91–99. [Google Scholar] [CrossRef]

- Panda, B.; Leite, M.; Biswal, B.B.; Niu, X.; Garg, A. Experimental and numerical modelling of mechanical properties of 3D printed honeycomb structures. Measurement 2018, 116, 495–506. [Google Scholar] [CrossRef]

- Piekło, J.; Małysza, M.; Dańko, R. Modelling of the material destruction of vertically arranged honeycomb cellular structure. Arch. Civ. Mech. Eng. 2018, 18, 1300–1308. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Badwal, P.S.; Gibson, I. Design and fabrication considerations for three dimensional scaffold structures. In Proceedings of the International Conference on Design and Technology, KEG, Geelong, Australia, 5–8 December 2016; pp. 120–126. [Google Scholar]

- Jo, W.; Yoon, B.J.; Lee, H.; Moon, M.W. 3D Printed Hierarchical Gyroid Structure with Embedded Photocatalyst TiO2 Nanoparticles. 3D Print. Addit. Manuf. 2017, 4, 222–230. [Google Scholar] [CrossRef]

- Lu, C.; Qi, M.; Islam, S.; Chen, P.; Gao, S.; Xu, Y.; Yang, X. Mechanical performance of 3D-printing plastic honeycomb sandwich structure. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 47–54. [Google Scholar] [CrossRef]

- Eloy, F.S.; Gomes, G.F.; Ancelotti, J.R.A.C.; Cunha, J.R.S.S.; Bombard, A.J.F.; Junqueira, D.M. Experimental dynamic analysis of composite sandwich beams with magnetorheological honeycomb core. Eng. Struct. 2018, 176, 231–242. [Google Scholar] [CrossRef]

- Hou, S.; Li, T.; Jia, Z.; Wang, L. Mechanical properties of sandwich composites with 3d-printed auxetic and non-auxetic lattice cores under low velocity impact. Mater. Des. 2018, 160, 1305–1321. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef]

- Sarvestani, H.Y.; Akbarzadeh, A.; Mirbolghasemi, A.; Hermenean, K. 3D printed meta-sandwich structures: Failure mechanism, energy absorption and multi-hit capability. Mater. Des. 2018, 160, 179–193. [Google Scholar] [CrossRef]

- Rajpal, R.; Lijesh, K.P.; Gangadharan, K.V. Parametric studies on bending stiffness and damping ratio of sandwich structures. Addit. Manuf. 2018, 22, 583–591. [Google Scholar] [CrossRef]

- Brischetto, S.; Ferro, C.G.; Torre, R.; Maggiore, P. 3D FDM production and mechanical behavior of polymeric sandwich specimens embedding classical and honeycomb cores. Curved Layer Struct. 2018, 5, 80–94. [Google Scholar] [CrossRef]

- Saad, N.A.; Sabah, A. An investigation of new design of light weight structure of (ABS/PLA) by using of three dimensions printing. In Proceedings of the 13th International Conference “Standardization, Prototypes and Quality: A Means of Balkan Countries’ Collaboration”, Brasov, Romania, 3–4 November 2016; pp. 482–487. [Google Scholar]

- Baca Lopez, D.M.; Ahmad, R. Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 114–121. [Google Scholar] [CrossRef]

- Abuzaid, W.; Alkhader, M.; Omari, M. Experimental analysis of heterogeneous shape recovery in 4D printed honeycomb structures. Polym. Test. 2018, 68, 100–109. [Google Scholar] [CrossRef]

- ASTM C365-03. Standard Test Method for Flatwise Compressive Properties of Sandwich Core; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM C393-C393M-06. Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Zaharia, S.M.; Pop, M.A.; Udroiu, R. Reliability and Lifetime Assessment of Glider Wing’s Composite Spar through Accelerated Fatigue Life Testing. Materials 2020, 13, 2310. [Google Scholar] [CrossRef] [PubMed]

- ASTM D638–14. Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ISO 179-1:2010. Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Samali, B.; Nemati, S.; Sharafi, P.; Tahmoorian, F.; Sanati, F. Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art. J. Compos. Sci. 2019, 3, 40. [Google Scholar] [CrossRef]

- Dhakal, H.N.; MacMullen, J.; Zhang, Z.Y. Moisture measurement and effects on properties of marine composites. In Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Sawston/Cambridge, UK, 2016; pp. 103–124. [Google Scholar]

- Yu, J.; Wang, E.; Li, J.; Zheng, Z. Static and low-velocity impact behavior of sandwich beams with closed-cell aluminum-foam core in three-point bending. Int. J. Impact Eng. 2008, 35, 885–894. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Morariu, C.O.; Nedelcu, A.; Pop, M.A. Experimental Study of Static and Fatigue Behavior of CFRP-Balsa Sandwiches under Three-point Flexural Loading. BioResources 2017, 12, 2673–2689. [Google Scholar] [CrossRef]

- Hou, Z.; Fan, L.; Zhang, X.; Zhai, S.; Zhang, C.; Li, C.; Du, Y.; Zhao, H. Failure mechanism of brass with three V-notches characterized by acoustic emission in in situ three-point bending tests. Adv. Eng. Mater. 2016, 18, 1–10. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Chicoș, L.A.; Lancea, C.; Pop, M.A. Effects of Homogenization Heat Treatment on Mechanical Properties of Inconel 718 Sandwich Structures Manufactured by Selective Laser Melting. Metals 2020, 10, 645. [Google Scholar] [CrossRef]

| Compression Test Specimens | Tensile Test Specimens | Three-Point Bending Test Specimens | |

|---|---|---|---|

| Honeycomb |  |  |  |

| Diamond-celled |  |  |  |

| Corrugated |  |  |  |

| Honeycomb Core | Diamond-Celled Core | Corrugated Core | |

|---|---|---|---|

| Wing leading edges |  |  |  |

| Mechanical and Thermal Properties | PLA/PHA | Standard |

|---|---|---|

| Tensile strength [MPa] | 61.5 | ISO 527-1:2019 |

| Modulus of elasticity [MPa] | 2960 | ISO 527-1:2019 |

| Flexural stress [MPa] | 88.8 | ISO 178:2019 |

| Flexural modulus [MPa] | 3295 | ISO 178:2019 |

| Impact Strength [kJ/m²] | 30.8 | ISO 179-1:2010 |

| Density [g/cm³] | 1.24 | ISO 1183:2019 |

| Melting temperature [ºC] | >155 | ISO 3146-C:2000 |

| Parameter | Value |

|---|---|

| Layer height | 0.15 [mm] |

| Infill | 100 [%] |

| Print speed | 50 [mm/s] |

| Travel speed | 200 [mm/s] |

| Printing temperature | 200 [°C] |

| Building plate temperature | 60 [°C] |

| Hotend | 0.4 [mm] |

| Sandwich Specimens | Mean (m) | Standard Deviation (s) | Coefficient of Variation (CV)% |

|---|---|---|---|

| Honeycomb core– Compressive Strength (MPa) | 1.600 | 0.154 | 9.625 |

| Diamond-celled core– Compressive Strength (MPa) | 3.000 | 0.244 | 8.133 |

| Corrugated core– Compressive Strength (MPa) | 1.000 | 0.077 | 7.700 |

| Honeycomb core– Compressive Modulus (GPa) | 0.080 | 0.007 | 8.750 |

| Diamond-celled core– Compressive Modulus (GPa) | 0.140 | 0.014 | 10.000 |

| Corrugated core– Compressive Modulus (GPa) | 0.074 | 0.004 | 5.405 |

| Sandwich Specimens | Mean (m) | Standard Deviation (s) | Coefficient of Variation (CV)% |

|---|---|---|---|

| Honeycomb core– Bending Strength (MPa) | 8.800 | 0.836 | 9.500 |

| Diamond-celled core– Bending Strength (MPa) | 16.200 | 0.908 | 5.604 |

| Corrugated core– Bending Strength (MPa) | 5.400 | 0.547 | 10.129 |

| Honeycomb core– Bending Modulus (GPa) | 0.500 | 0.035 | 7.000 |

| Diamond-celled core– Bending Modulus (GPa) | 1.000 | 0.079 | 7.900 |

| Corrugated core– Bending Modulus (GPa) | 0.300 | 0.035 | 11.666 |

| Sandwich Specimens | Mean (m) | Standard Deviation (s) | Coefficient of Variation (CV)% |

|---|---|---|---|

| Honeycomb core– Tensile Strength (MPa) | 2.400 | 0.200 | 8.333 |

| Diamond-celled core– Tensile Strength (MPa) | 2.800 | 0.273 | 9.750 |

| Corrugated core– Tensile Strength (MPa) | 5.400 | 0.547 | 10.120 |

| Honeycomb core– Tensile Modulus (GPa) | 0.360 | 0.031 | 8.611 |

| Diamond-celled core– Tensile Modulus (GPa) | 0.400 | 0.028 | 7.000 |

| Corrugated core– Tensile Modulus (GPa) | 0.680 | 0.024 | 3.529 |

| Wing Leading Edges Specimens | Mean (m) | Standard Deviation (s) | Coefficient of Variation (CV)% |

|---|---|---|---|

| Honeycomb core– Impact Strength (kJ/m2) | 7.546 | 0.498 | 6.599 |

| Diamond-celled core– Impact Strength (kJ/m2) | 13.486 | 0.354 | 2.624 |

| Corrugated core– Impact Strength (kJ/m2) | 15.270 | 0.610 | 3.994 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaharia, S.M.; Enescu, L.A.; Pop, M.A. Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing. Polymers 2020, 12, 1740. https://doi.org/10.3390/polym12081740

Zaharia SM, Enescu LA, Pop MA. Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing. Polymers. 2020; 12(8):1740. https://doi.org/10.3390/polym12081740

Chicago/Turabian StyleZaharia, Sebastian Marian, Larisa Anamaria Enescu, and Mihai Alin Pop. 2020. "Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing" Polymers 12, no. 8: 1740. https://doi.org/10.3390/polym12081740

APA StyleZaharia, S. M., Enescu, L. A., & Pop, M. A. (2020). Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing. Polymers, 12(8), 1740. https://doi.org/10.3390/polym12081740