Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites

Abstract

1. Introduction

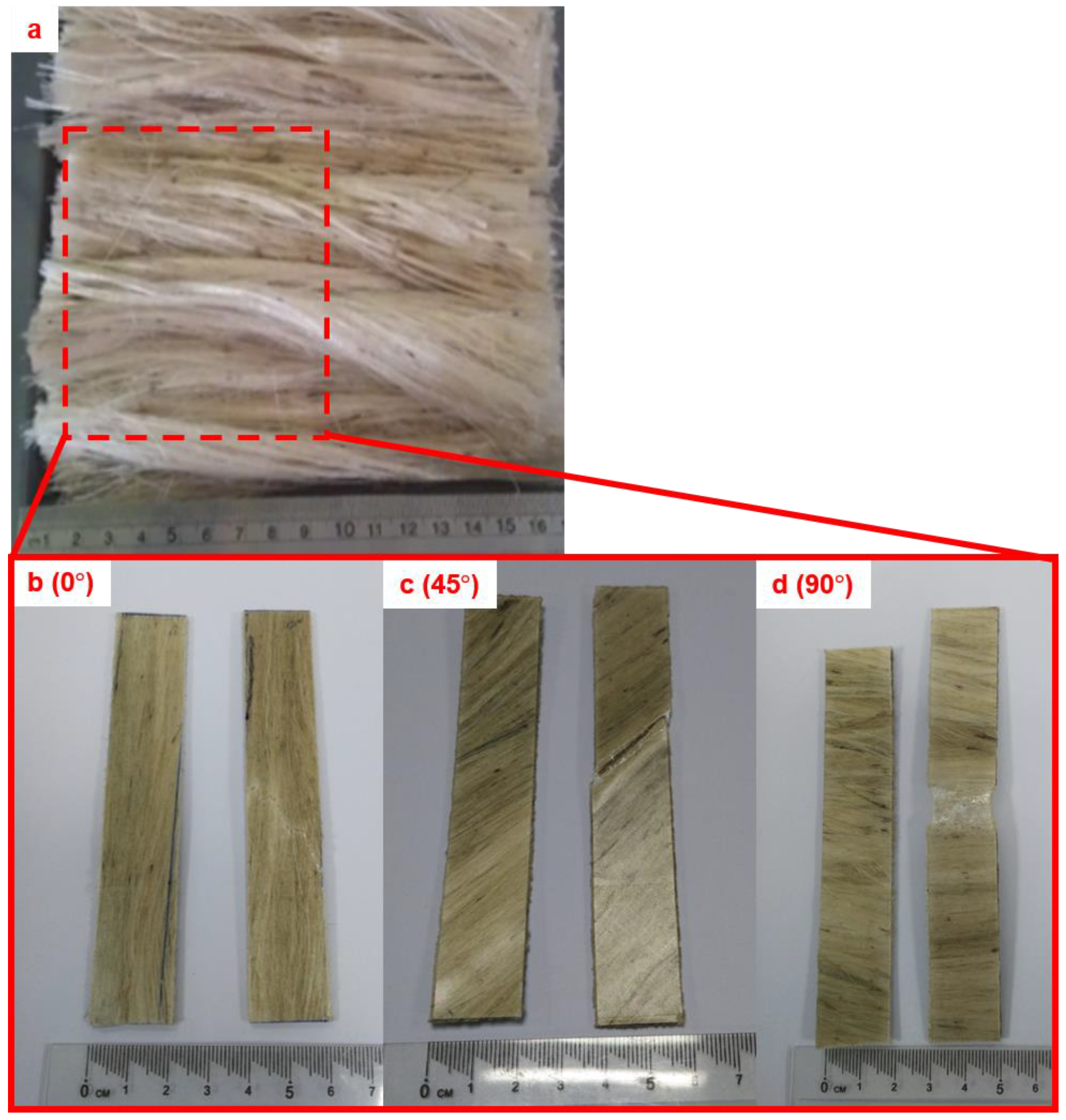

2. Methodology

2.1. Materials

2.2. Fabrication Process

2.3. Characterization

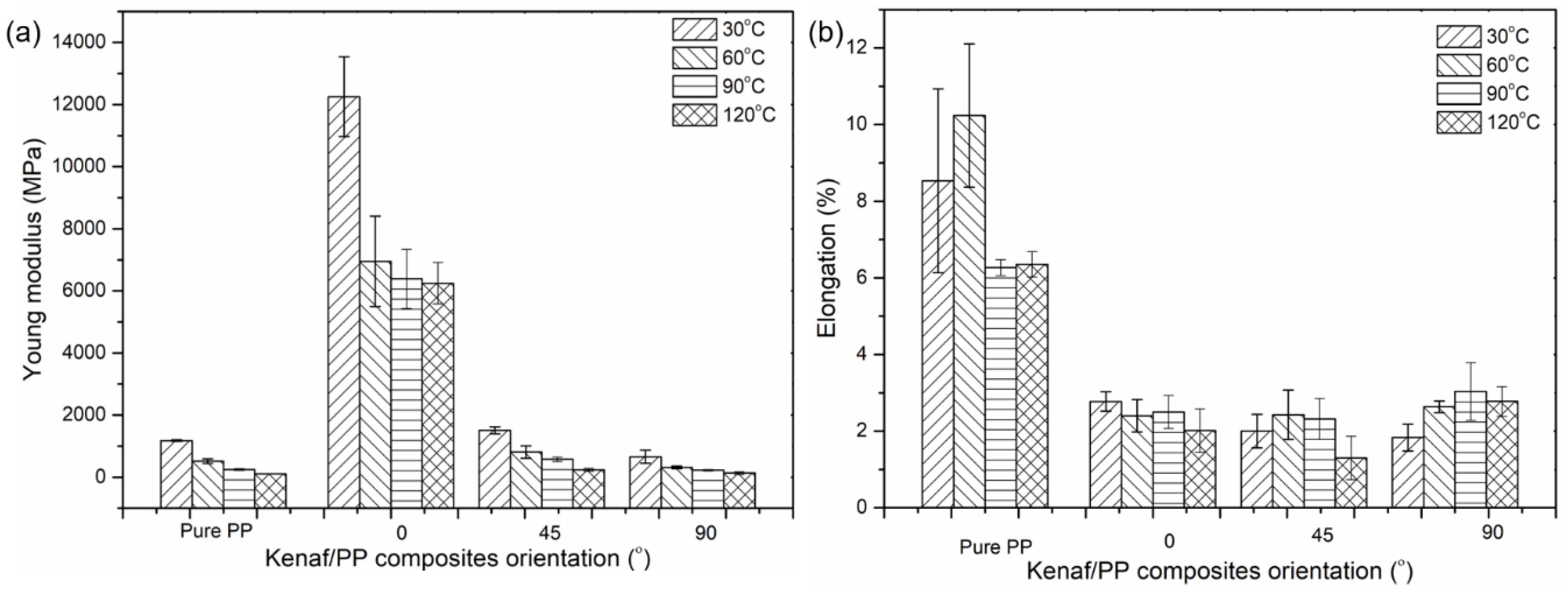

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yahya, M.N.; Daniel, D.; Chin, V.S.; Kamarudin, S.H.; Chuah, L. The potential of natural fibres for automotive sector-review. In Proceedings of CAR2017 International Congress of Automotive and Transport Engineering-Mobility Engineering and Environment, Pitesti, Romania, 8–10 November 2017; IOP Conference Series: Materials Science and Engineering. IOPScience: Bristol, UK, 2017; pp. 1–11. [Google Scholar]

- Sanyang, M.L.; Ilyas, R.A.; Sapuan, S.M.; Jumaidin, R. Sugar palm starch-based composites for packaging applications. Bionanocompos. Packag. Appl. 2017, 125–147. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int. J. Biol. Macromol. 2019, 123, 379–388. [Google Scholar] [CrossRef] [PubMed]

- D’Urso, L.; Spadaro, S.; Bonsignore, M.; Santangelo, S.; Compagnini, G.; Neri, F.; Fazio, E. Zinc oxide nanocolloids prepared by picosecond pulsed laser ablation in water at different temperatures. EPJ Web Conf. 2018, 167, 1–5. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Ilyas Rushdana, A.; Sapuan Salit, M.; Lamin Sanyang, M.; Ridzwan Ishak, M. Nanocrystalline Cellulose As Reinforcement For Polymeric Matrix Nanocomposites And Its Potential Applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Ariawan, D.; Salim, M.S.; Mat, R.; Ahmad, M.Z.; Zainal, T.; Ishak, A.M. Durability of alkali and heat treated kenaf fiber/unsaturated polyester composite fabricated by resin transfer molding under natural weathering exposure. Adv. Polym. Technol. 2018, 37, 1420–1434. [Google Scholar] [CrossRef]

- Zampaloni, M.; Pourboghrat, F.; Yankovich, S.A.; Rodgers, B.N.; Moore, J.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1569–1580. [Google Scholar] [CrossRef]

- Prakash, V.A.; Viswanthan, R. Fabrication and Characterization of Echinoidea spike Particles and Kenaf Natural Fibre-Reinforced Azadirachta-Indica Blended Epoxy Multi-hybrid Bio Composite. Compos. Part A 2019, 118, 317–326. [Google Scholar] [CrossRef]

- Ramesh, M. Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: A review on processing and properties. Prog. Mater. Sci. 2016, 78, 1–92. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Fairuz, A.M.; Sapuan, S.M.; Marliana, N.M.; Sahari, J. 5. Fabrication and Effect of Immersion in Various Solutions on Mechanical Properties of Pultruded Kenaf Fiber Composites: A Review; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021606. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef]

- Razak, Z.; Bakar, A.; Muhamad, N.; Hassan, C.; Haron, C.; Khairul, M.; Radzi, F.; Farhani, N.; Tholibon, D.; Tharazi, I. Effects of thermal cycling on physical and tensile properties of injection moulded kenaf/carbon nanotubes/polypropylene hybrid composites. Compos. Part B 2019, 168, 159–165. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A.; Hambali, A. Conceptual design of kenaf fiber polymer composite automotive parking brake lever using integrated TRIZ-Morphological Chart-Analytic Hierarchy Process method. Mater. Des. 2014, 54, 473–482. [Google Scholar] [CrossRef]

- Tholibon, D.; Sulong, A.B.; Muhammad, N.; Ismail, N.F.; Tharazi, I.; Radzi, M.K.F.M. Tensile properties of unidirectional kenaf fiber polypropylene composite. J. Teknol. 2016, 78, 101–106. [Google Scholar] [CrossRef][Green Version]

- Sulong, A.B.S.; Radzuan, N.A.M.; Mamat, M.R.; Tharazi, I.; Tholibon, D.; Dweiri, R.; Hammadi, M.S. Kenaf Reinforced PLA Composite Thermoforming: A Numerical Simulation. Int. J. Integr. Eng. 2019, 10, 15–20. [Google Scholar] [CrossRef]

- Barton, R.L.; Keith, J.M.; King, J.A. Development and modeling of electrically conductive carbon filled liquid crystal polymer composites for fuel cell bipolar plate applications. J. New Mater. Electrochem. Syst. 2007, 10, 225. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Effect of delignification on the physical, thermal, chemical, and structural properties of sugar palm fibre. BioResources 2017, 12, 8734–8754. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Somalu, M.R. Influence the filler orientation on the performance of bipolar plate. Sains Malays. 2019, 48, 669–676. [Google Scholar] [CrossRef]

- Asumani, O.M.L.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali-silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Hao, A.; Zhao, H.; Chen, J.Y. Kenaf/polypropylene nonwoven composites: The influence of manufacturing conditions on mechanical, thermal, and acoustical performance. Compos. Part B Eng. 2013, 54, 44–51. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Zakaria, M.Y.; Sulong, A.B.; Sahari, J. The effect of milled carbon fibre filler on electrical conductivity in highly conductive polymer composites. Compos. Part B Eng. 2017, 110, 153–160. [Google Scholar] [CrossRef]

- Kiran, E.; Gillham, J.K. Pyrolysis-molecular weight chromatography: A new on-line system for analysis of polymers. II. Thermal decomposition of polyolefins: Polyethylene, polypropylene, polyisobutylene. J. Appl. Polym. Sci. 1976, 20, 2045–2068. [Google Scholar] [CrossRef]

- Mariod, A.A.; Mirghani, M.E.S.; Hussein, I.H. Hibiscus cannabinus. In Unconventional Oilseeds and Oil Sources; Academic Press: Cambridge, MA, USA; International Islamic University: Selangor, Malaysia, 2017; pp. 45–51. ISBN 9780128094358. [Google Scholar]

- Placet, V. Characterization of the thermo-mechanical behaviour of Hemp fibres intended for the manufacturing of high performance composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1111–1118. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Långström, R.; Nyström, B.; Joseph, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1847–1853. [Google Scholar] [CrossRef]

- Jespersen, K.M.; Zangenberg, J.; Lowe, T.; Withers, P.J.; Mikkelsen, L.P. Fatigue damage assessment of uni-directional non-crimp fabric reinforced polyester composite using X-ray computed tomography. Compos. Sci. Technol. 2016, 136, 94–103. [Google Scholar] [CrossRef]

- Pötschke, P.; Bhattacharyya, A.R.; Janke, A. Melt mixing of polycarbonate with multiwalled carbon nanotubes: Microscopic studies on the state of dispersion. Eur. Polym. J. 2004, 40, 137–148. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 339–345. [Google Scholar] [CrossRef]

- Taufiq, M.J.; Mansor, M.R.; Mustafa, Z. Characterisation of wood plastic composite manufactured from kenaf fibre reinforced recycled-unused plastic blend. Compos. Struct. 2018, 189, 510–515. [Google Scholar] [CrossRef]

- Afiqah, N.; Radzuan, M.; Sulong, A.B.; Irwan, M.; Firdaus, M.; Husaini, T.; Majlan, E.H. Fabrication of multi-filler MCF/MWCNT/SG-based bipolar plates. Ceram. Int. 2019, 45, 7413–7418. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Somalu, M.R.; Majlan, E.H.; Husaini, T.; Rosli, M.I. Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate. Polymers 2018, 10, 558. [Google Scholar] [CrossRef]

- Tungjitpornkull, S.; Sombatsompop, N. Processing technique and fiber orientation angle affecting the mechanical properties of E-glass fiber reinforced wood/PVC composites. J. Mater. Process. Technol. 2009, 209, 3079–3088. [Google Scholar] [CrossRef]

- Abral, H.; Basri, A.; Muhammad, F.; Fernando, Y.; Hafizulhaq, F.; Mahardika, M.; Sugiarti, E.; Sapuan, S.M.; Ilyas, R.A.; Stephane, I. A simple method for improving the properties of the sago starch films prepared by using ultrasonication treatment. Food Hydrocoll. 2019, 93, 276–283. [Google Scholar] [CrossRef]

- Huang, M.; Tai, C. The effective factors in the warpage problem of an injection-molded part with a thin shell feature. J. Mater. Process. Technol. 2001, 110, 1–9. [Google Scholar] [CrossRef]

- Chen, C.-P.; Chuang, M.-T.; Hsiao, Y.-H.; Yang, Y.-K.; Tsai, C.-H. Simulation and experimental study in determining injection molding process parameters for thin-shell plastic parts via design of experiments analysis. Expert Syst. Appl. 2009, 36, 10752–10759. [Google Scholar] [CrossRef]

- Karian, H.G. Handbook of Polypropylene and Polypropylene Composites, Revised and Expanded, 2nd ed.; CRC Press: Boca Raton, NY, USA, 2003; ISBN 0-8247-4064-5. [Google Scholar]

- Bachtiar, D.; Sapuan, S.M.; Hamdan, M.M. Flexural properties of alkaline treated sugar palm fibre reinforced epoxy composites. Int. J. Automot. Mech. Eng. 2010, 1, 79–90. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Sulong, A.B.; Radzi, M.K.F.; Ismail, N.F.; Raza, M.R.; Muhamad, N.; Khan, M.A. Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog. Nat. Sci. Mater. Int. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Houshyar, S.; Shanks, R.A.; Hodzic, A. Effect of Fibre-Orientation on Mechanical Properties of Polypropylene Composites. In Composite Technologies for 2020; Ye, L., Mai, Y.W., Su, Z., Eds.; Woodhead Publishing: Melbourne, Australia, 2004; pp. 41–45. ISBN 978-1-85573-831-7. [Google Scholar]

- Mutasher, S.A.; Poh, A.; Than, A.M.; Law, J. The Effect of Alkali Treatment Mechanical Properties of Kenaf Fiber Epoxy Composite. Key Eng. Mater. 2011, 471–472, 191–196. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Mohd Radzuan, N.A.; Tholibon, D.; Sulong, A.B.; Muhamad, N.; Haron, C.H.C. New processing technique for biodegradable kenaf composites: A simple alternative to commercial automotive parts. Compos. Part B Eng. 2020, 184, 107644. [Google Scholar] [CrossRef]

- El-Shekeil, Y.A.; Sapuan, S.M.; Abdan, K.; Zainudin, E.S. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Pandini, S.; Pegoretti, A. Time, Temperature, and Strain Effects on Viscoelastic Poisson’s Ratio of Epoxy Resins. Polym. Eng. Sci. 2008, 48, 1434–1441. [Google Scholar] [CrossRef]

| Composition | Percentage (%) |

|---|---|

| Extractive | 5.88 |

| Holocellulose (cellulose +hemicellulose) | 96.17 |

| α-Cellulose | 61.02 |

| Hemicellulose | 35.15 |

| Lignin | 12.5 |

| Mechanical Properties | Kenaf/PP (0°) at 120 °C | Product T |

|---|---|---|

| Tensile strength (MPa) | ~90 | 30.52 |

| Flexural strength (MPa) | ~50 | 39.4 |

| Young’s modulus (GPa) | ~7.5 | 2.56 |

| Flexural modulus (GPa) | ~6.0 | 4.51 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radzuan, N.A.M.; Tholibon, D.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers 2020, 12, 1643. https://doi.org/10.3390/polym12081643

Radzuan NAM, Tholibon D, Sulong AB, Muhamad N, Che Haron CH. Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers. 2020; 12(8):1643. https://doi.org/10.3390/polym12081643

Chicago/Turabian StyleRadzuan, Nabilah Afiqah Mohd, Dulina Tholibon, Abu Bakar Sulong, Norhamidi Muhamad, and Che Hassan Che Haron. 2020. "Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites" Polymers 12, no. 8: 1643. https://doi.org/10.3390/polym12081643

APA StyleRadzuan, N. A. M., Tholibon, D., Sulong, A. B., Muhamad, N., & Che Haron, C. H. (2020). Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers, 12(8), 1643. https://doi.org/10.3390/polym12081643