Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis

Abstract

:1. Introduction

2. Description of the Constitutive Model

2.1. Description of the Viscoelastic Part

2.2. Description of the Viscoplastic Part

2.3. Yield Criterion and Subsequent Yield Behavior

3. Mechanical Tests

3.1. Low-Strain Rate Tests

3.2. High-Strain Rate Tests

3.3. Test Results

4. Taylor Impact Research

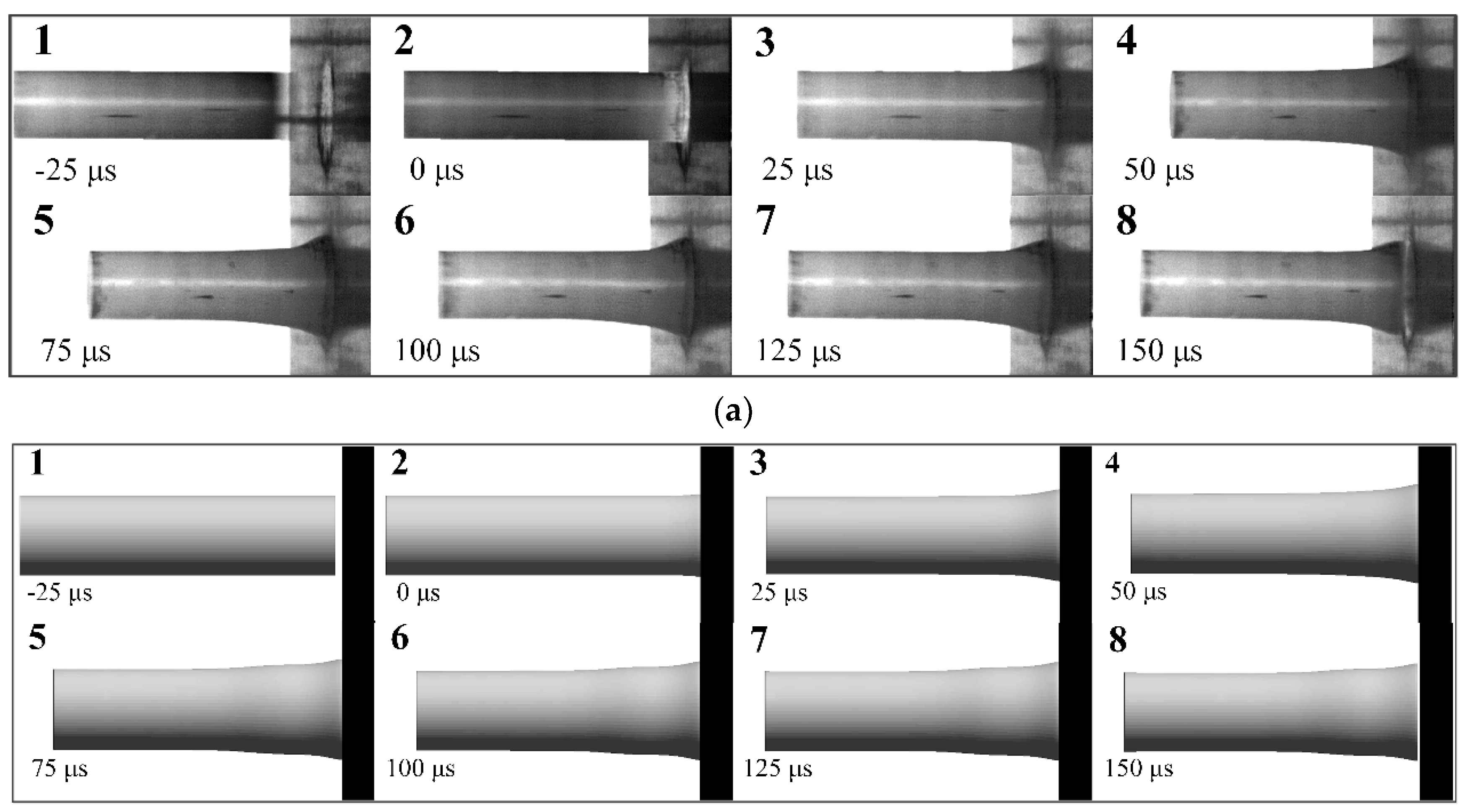

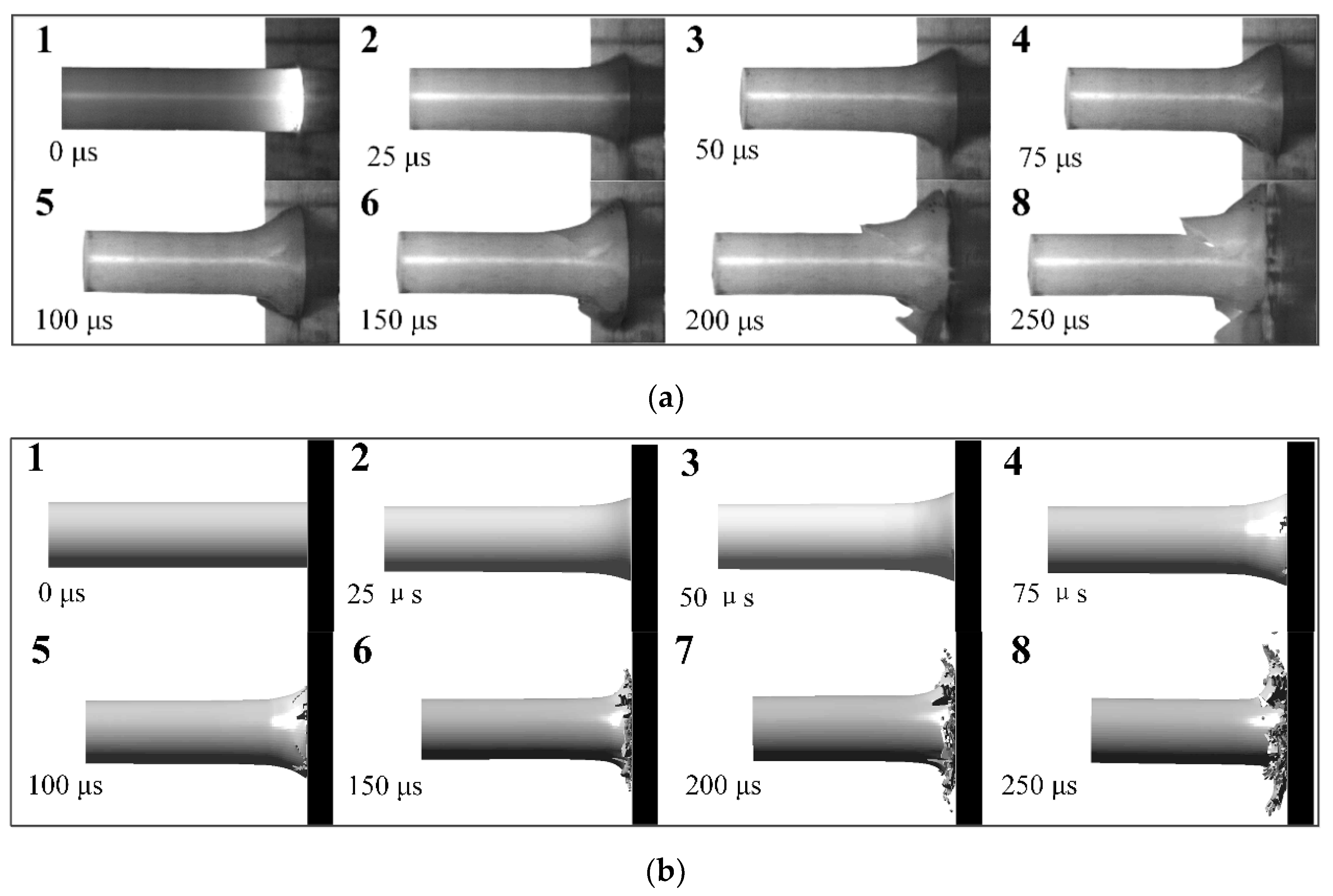

4.1. Taylor Impact Test

4.2. Taylor Impact Simulation

4.3. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dasari, A.; Misra, R.D.K. On the strain rate sensitivity of high density polyethylene and polypropylenes. Mater. Sci. Eng. A. 2003, 358, 1–2. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Y.; Mallick, P.K. Effects of temperature and strain rate on the tensile behavior of short fibre reinforced polyamide-6. Polym. Composit. 2002, 23, 5. [Google Scholar] [CrossRef]

- Torres, J.P.; Frontini, P.M. Mechanics of polycarbonate in biaxial impact loading. Int. J. Solids Struct. 2016, 85, 125–133. [Google Scholar] [CrossRef]

- Xu, M.M.; Huang, G.Y.; Feng, S.S.; McShane, G.; Stronge, W. Static and dynamic properties of semi-crystalline polyethylene. Polymers 2016, 8, 4. [Google Scholar] [CrossRef] [PubMed]

- Omar, M.F.; Akil, H.M.; Ahmad, Z.A. Effect of molecular structures on dynamic compression properties of polyethylene. Mater. Sci. Eng. A. 2012, 538, 125–134. [Google Scholar] [CrossRef]

- Duan, Y.; Saigal, A.; Greif, R.; Zimmerman, M.A. A uniform phenomenological constitutive model for glassy and semicrystalline polymers. Polym. Eng. Sci. 2001, 41, 8. [Google Scholar] [CrossRef]

- Pouriayevali, H.; Arabnejad, S.; Guo, Y.B.; Shim, V.P.W. A constitutive description of the rate-sensitive response of semi-crystalline polymers. Int. J. Impact Eng. 2013, 62, 35–47. [Google Scholar] [CrossRef]

- Bowden, P.B.; Jukes, J.A. The plastic flow of isotropic polymers. J. Mater. Sci. 1972, 7, 1. [Google Scholar] [CrossRef]

- Raghava, R.; Caddell, R.M.; Yeh, G.S.Y. The macroscopic yield behaviour of polymers. J. Mater. Sci. 1973, 8, 2. [Google Scholar] [CrossRef] [Green Version]

- Silano, A.A.; Bhateja, S.K.; Pae, K.D. Effects of hydrostatic pressure on the mechanical behavior of polymers: Polyurethane, polyoxymethylene, and branched polyethylene. Inter. J. Polym.Mater. Polym. Biomater. 1974, 3, 2. [Google Scholar] [CrossRef]

- Pae, K.D. The macroscopic yielding behaviour of polymers in multiaxial stress fields. J. Mater. Sci. Technol. 1977, 12, 6. [Google Scholar] [CrossRef]

- Ghorbel, E. A viscoplastic constitutive model for polymeric materials. Int. J. Plast. 2008, 24, 11. [Google Scholar] [CrossRef]

- Farrokh, B.; Khan, A.S. A strain rate dependent yield criterion for isotropic polymers: Low to high rates of loading. Eur. J. Mech. A Solids. 2010, 29, 274–282. [Google Scholar] [CrossRef]

- Xu, L.; Du, Z.; Wang, J.; Cheng, C.; Du, C.; Gao, G. A viscoelastoplastic constitutive model of semi-crystalline polymers under dynamic compressive loading: Application to PE and PA66. Mech. Adv. Mater.Struc. 2018, 1, 11. [Google Scholar] [CrossRef]

- Li, Y.C. Introduction of Tensor analysis and Modern Continuum Mechanics; China University of Science and Technology: Hefei, China, 2016; Volume 5, pp. 231, 240. [Google Scholar]

- Yu, P.; Yao, X.H.; Han, Q.; Zang, S.G.; Gu, Y.B. A visco-elastoplastic constitutive model for large deformation response of polycarbonate over a wide range of strain rates and temperatures. Polymer 2014, 55, 25. [Google Scholar] [CrossRef]

- Fu, S.Q.; Wang, Y.; Wang, Y. Tension testing of polycarbonate at high strain rates. Polym. Test. 2009, 28, 7. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.W.; Shu, X.F.; Wang, Z.H.; Wu, G.Y.; Zhao, L.M. Investigation on the yield behaviour and macroscopic phenomenological constitutive law of PA66. Polym. Test. 2018, 69, 563–582. [Google Scholar] [CrossRef]

- Dar, U.A.; Zhang, W.H.; Xu, Y.J.; Wang, J. Thermal and strain rate sensitive compressive behavior of polycarbonate polymer—Experimental and constitutive analysis. J. Polym. Res. 2014, 21, 8. [Google Scholar] [CrossRef]

- Tang, Z.P. Optimum size of transversal isotropic specimen in dynamic testing using the split hopkinson pressure bar. Explos. Shock Waves 1985, 2, 54–57. [Google Scholar]

- Shemirani, A.B.; Naghdabadi, R.; Ashrafi, M.J. Experimental and numerical study on choosing proper pulse shapers for testing concrete specimens by split Hopkinson pressure bar apparatus. Constr. Build. Mater. 2016, 125, 326–336. [Google Scholar] [CrossRef]

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear finite elements for continua and structures; John Wiley & Sons Inc.: New York, NY, USA, 2014; pp. 112–120. [Google Scholar]

- Gao, Y.F. An implicit finite element method for simulating inhomogeneous deformation and shear bands of amorphous alloys based on the free-volume model. Model. Simul. Mater. Sci. Eng. 2006, 14, 8. [Google Scholar] [CrossRef]

| Number | Formula | References | Polymer |

|---|---|---|---|

| R1 | Bowden and Jukes (1972) | PS | |

| R2 | Bowden and Jukes (1972) | PMMA | |

| R3 | Raghava et al. (1973) | PC, PVC | |

| R4 | Silano et al. (1974) Pae (1977) | PP, POM | |

| R5 | Ghorbel (2008) | PMMA, PC, PS | |

| R6 | Farrokh (2010) | Nylon 101 |

(MPa) | s−1 | (MPa) | (MPa) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2300 | 0.665 | 0.175 | 1 | 3.852 | 1.790 | 90 | 0.51 | 2665.47 | 1.42 | 0.25 | 0.28 | 40.1 | −0.1 |

| Test Number | v (m/s) | L (mm) | D (mm) | Lt1 (mm) | Lt2 (mm) | Dtm (mm) | Ls1 (mm) | Ls2 (mm) | Dsm (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 104 | 48.04 | 11.70 | 47.06 | 33.50 | 13.04 | 45.90 | 30.94 | 13.61 |

| 2 | 128 | 48.01 | 11.88 | 46.24 | 27.70 | 14.26 | 44.50 | 25.71 | 14.80 |

| 3 | 168 | 48.01 | 11.88 | 31.32 | - | - | - | 30.28 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Cheng, C.; Du, C.; Jiang, Z.; Du, Z.; Gao, G. Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis. Polymers 2020, 12, 1615. https://doi.org/10.3390/polym12071615

Xu L, Cheng C, Du C, Jiang Z, Du Z, Gao G. Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis. Polymers. 2020; 12(7):1615. https://doi.org/10.3390/polym12071615

Chicago/Turabian StyleXu, Lizhi, Chun Cheng, Chengxin Du, Zhaoxiu Jiang, Zhonghua Du, and Guangfa Gao. 2020. "Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis" Polymers 12, no. 7: 1615. https://doi.org/10.3390/polym12071615

APA StyleXu, L., Cheng, C., Du, C., Jiang, Z., Du, Z., & Gao, G. (2020). Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis. Polymers, 12(7), 1615. https://doi.org/10.3390/polym12071615