1. Introduction

Polylactic acid (PLA) is a polymer obtained by polymerization of lactic acid as the main raw material. Lactic acid is derived from raw materials such as corn and cassava. It has sufficient sources and is renewable. The production process of polylactic acid is pollution-free, and the product can be biodegraded to achieve circulation in nature, so it is an ideal green polymer material. Acrylonitrile butadiene styrene (ABS) is a terpolymer of acrylonitrile (A), butadiene (B), and styrene (S). The relative content of the three monomers can be arbitrarily changed to make various resins. ABS has the common properties of three components: A makes it resistant to chemical corrosion and heat, and has a certain surface hardness; B makes it have high elasticity and toughness; S makes it have the characteristics of thermoplastic molding and improves electrical properties. Therefore, ABS is a material with easy access to raw materials, good comprehensive performance, low price, and a wide range of uses.

ABS has been widely used in manufacturing industries such as the machinery, electrical, textile, automobile, aircraft, ship, and chemical industries. Polylactic acid (PLA) is widely used in agriculture, forestry, medical, and food industries, as well as packaging and other fields. Unique functions such as cleaning, anti-icing, anti-corrosion, water-reducing oil separation, liquid transport, and water collection [

1,

2,

3,

4,

5,

6] are needed in these fields. In daily life, the surfaces of automobiles, home appliances, and packaging with anti-fouling properties, as well as kitchen appliances with anti-fouling properties, are expected. For wind turbines and the power grid, at low temperatures, ice coating will occur on the surface of transmission lines, insulators, and wind turbines, which affect their performance. Therefore, the ability to resist ice coating is required in these fields [

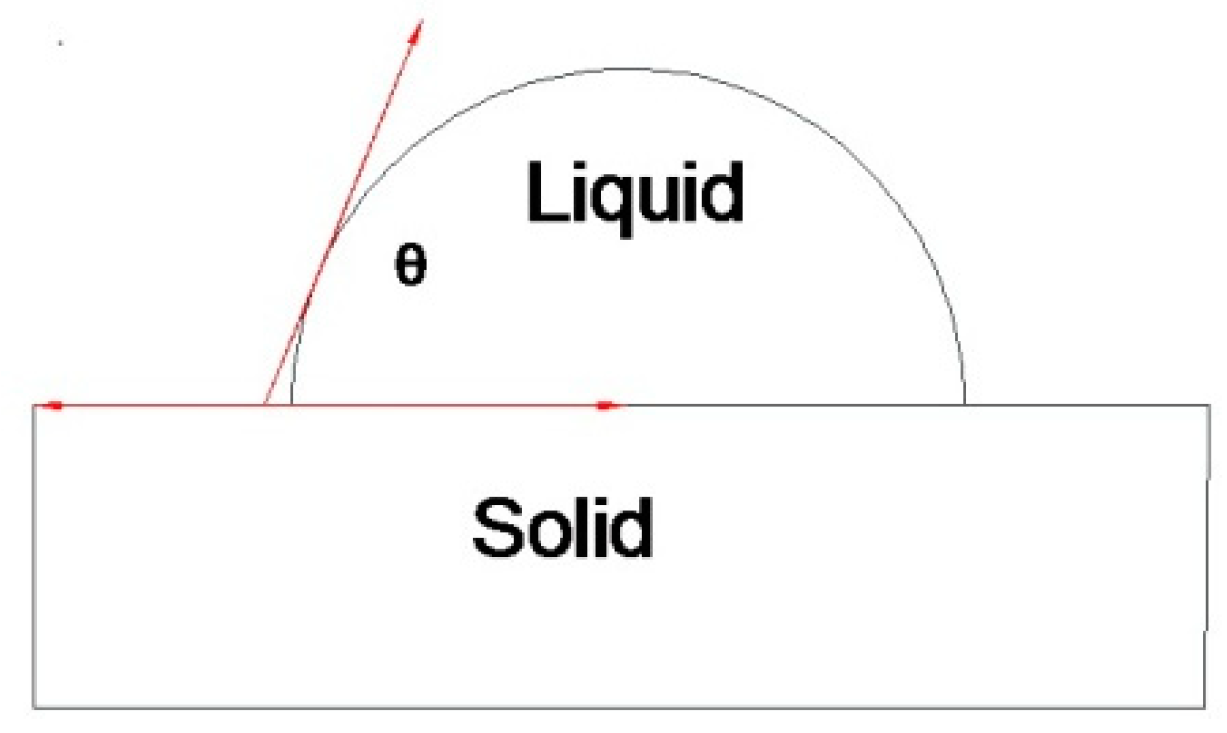

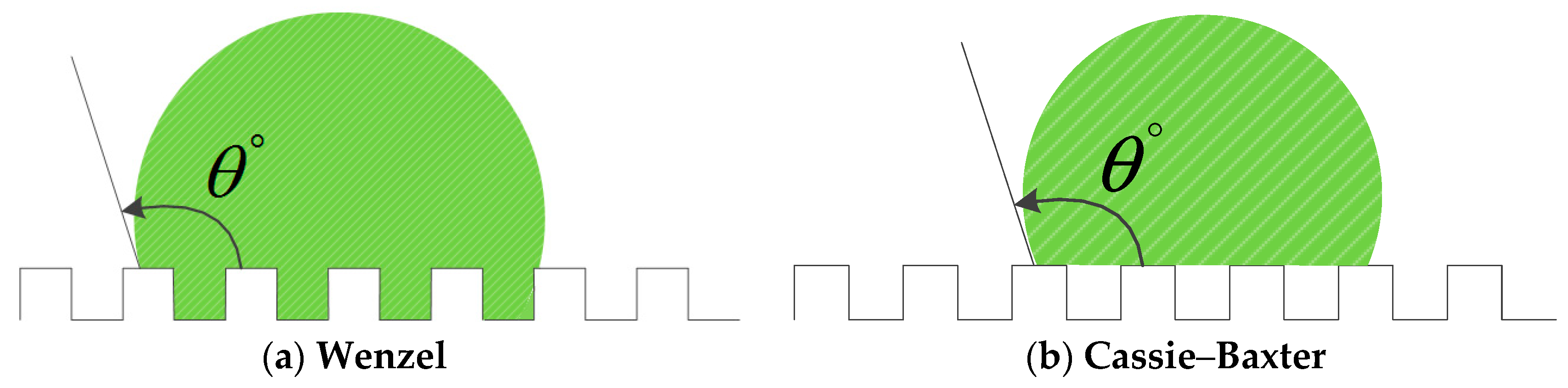

7]. The realization of these functions can be solved by constructing a hydrophobic layer, as wettability is a dominant factor for ice formation on a specific surface. Hydrophobic surfaces can tend to repel water [

8]; however, hydrophilic surfaces have more affinity to water [

9]. These functions can be obtained by coating a hydrophobic film on PLA and ABS surfaces.

Hydrophobic surfaces can be fabricated by modifying low-surface-energy materials on rough surfaces or constructing micro-nano rough structures on surfaces with low surface energy [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19]. Many methods have been developed for the preparation of hydrophobic coatings, such as electrochemical deposition, photolithography, chemical etching, phase separation, spraying, sol–gel, self-assembly, and electro-spinning. However, these preparation methods of hydrophobic surfaces are complicated and costly.

3D printing is an emerging additive manufacturing technology that is developing rapidly [

20], and has been widely used in rapid prototyping and customized products. Among the 3D printers on the market, fused deposition modeling (FDM) printers are popular because of their open source and simple system configuration, which have been widely used in the polymers field. In addition, a variety of materials can be applied for FDM printing, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), thermoplastic polyurethane (TPU), high-density polystyrene (HIPS), and polyamide (nylon) [

21,

22,

23,

24,

25]. Studies have shown that the surface properties of parts affect their wettability, and the surface quality is affected by process parameters of FDM 3D-printed parts [

26,

27,

28,

29,

30,

31,

32]. Jiang [

33] analyzed the FDM forming process by a numerical model and experiment, and obtained the mechanism of dimensional error, and the function of specific surface accuracy error was constructed. Xue [

34] analyzed the effect of layer thickness on forming quality. The results showed that if the layer thickness was smaller, excellent forming quality will be obtained; however, it will reduce the printing speed. Feng [

35] studied the problems of nozzle clogging and substrate deformation that affected the dimensional accuracy during the 3D printing. The results show that the selection of high-quality materials and the use of optimized process parameters have a significant effect.

Based on the construction of the process parameters and objective function of fused deposition modeling, the application of artificial neural networks and genetic algorithms for process optimization of fused deposition modeling was discussed. According to the idea of converting the multi-objective optimization problem into the single-objective, the optimal single-objective was decomposed and the precision and warpage of the part under the optimal condition were obtained [

36]. Based on the fused deposition modeling (FDM) technology, the influence of building orientation on surface roughness and supporting area is studied. The surface roughness of parts made by polylactic acid (PLA) at different building orientations is tested in experiments, and combined with the theoretical and empirical formula, a novel model for surface roughness prediction is established, which conforms to the actual situation in manufacturing [

37].

In the current research, much research has been implemented to analyze the effect of the layer thickness and building orientation on the forming quality, but the research on the influence of the filling method on surface quality and mechanical properties is not enough, and further discussion is needed. The preparation of coatings on the surface of printed parts also requires in-depth research to explore the relationship between process parameters and surface wettability.

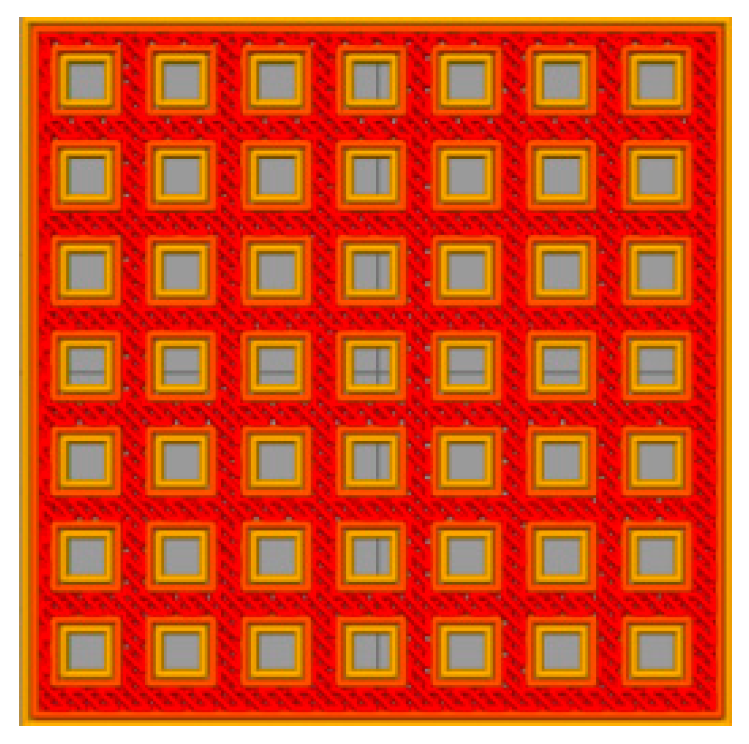

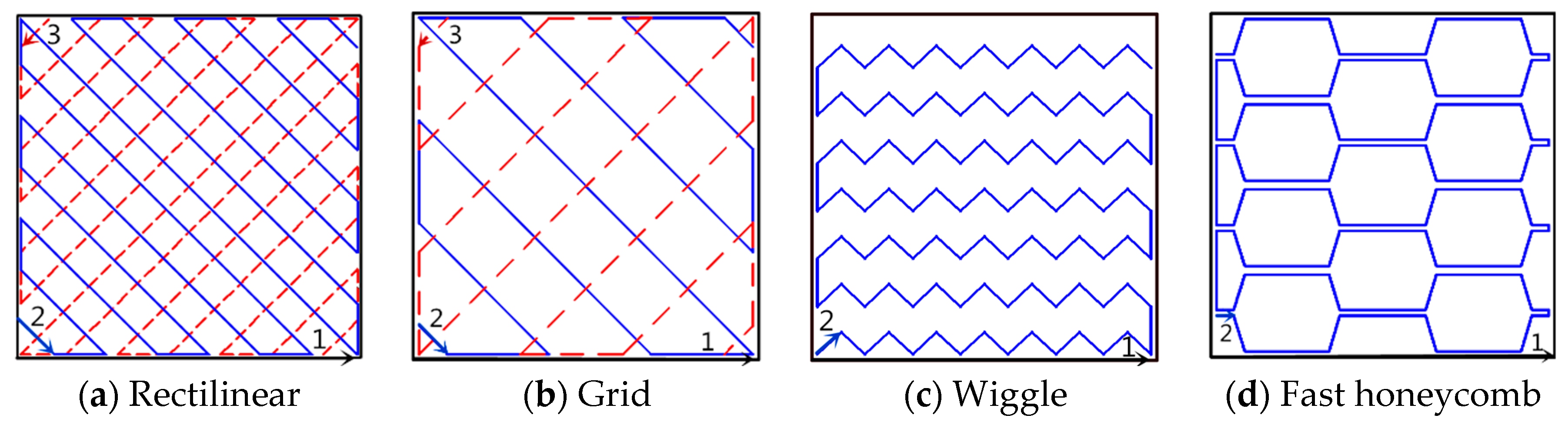

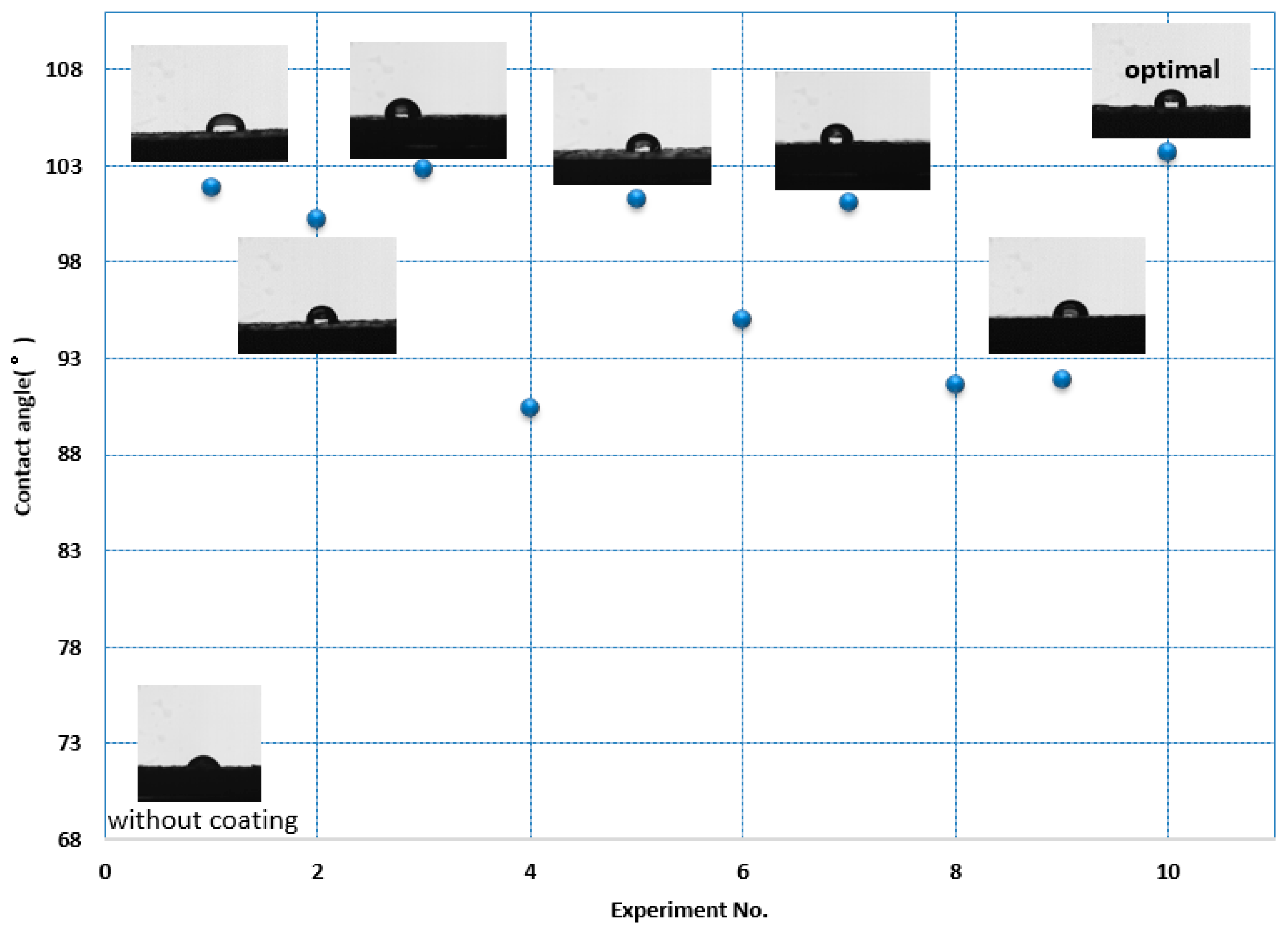

In this paper, a commercial FDM 3D printer was applied to print parts by using PLA and ABS filaments. By modifying the printing process parameters, multiple sets of test pieces were prepared, and the relationship between the process parameters and surface roughness of the test pieces was explored. Then, the preparation method of hydrophobic coatings on FDM test pieces was studied. Finally, the corresponding relationship between process parameters and surface hydrophobic properties was discussed. The surface quality and the surface roughness were observed and measured by using a light-cut microscope, and the effect of different printing parameters on the surface quality of the tested part was analyzed and optimized. Then, hydrophobic GF-2200 self-drying nano-ceramic fluorine paint was used to achieve a nano-structured hydrophobic coating surface. The contact angle measuring instrument was used to measure the static contact angle of the surface coating, and the wettability changes of the 3D-printed parts under different process parameters were evaluated and analyzed. The effect of different process parameters on the hydrophobic properties of the coatings on the 3D-printed part was studied.

4. Conclusions

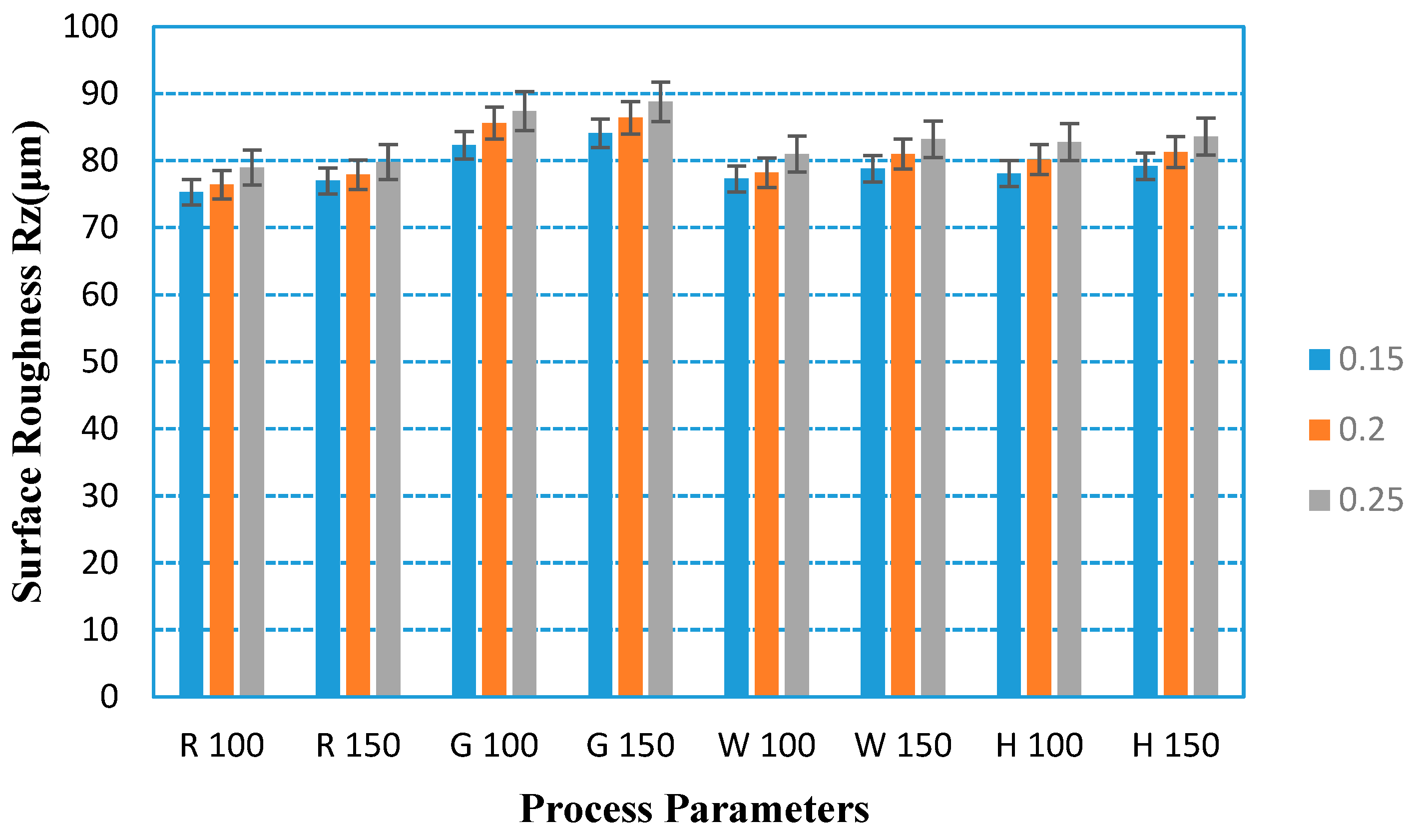

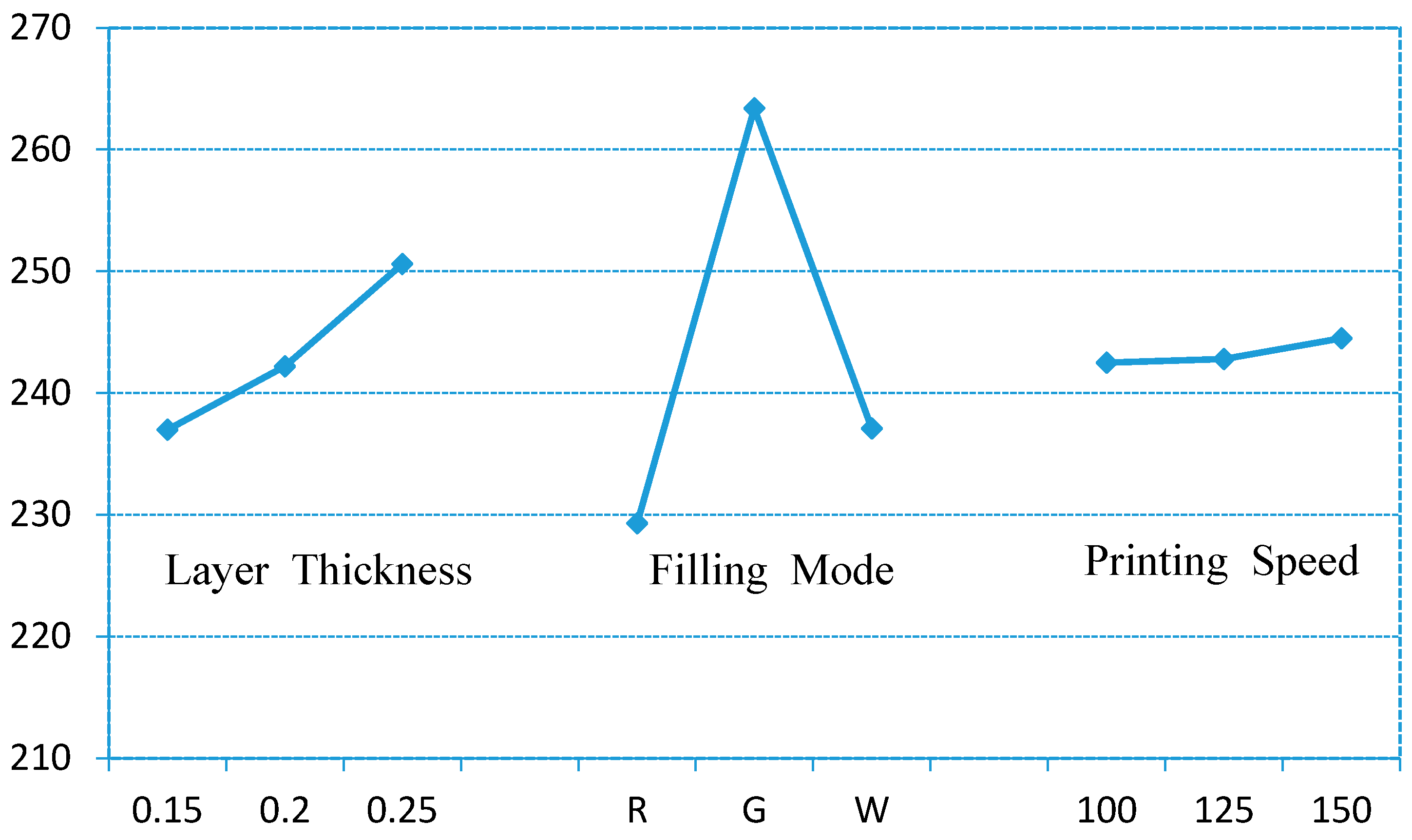

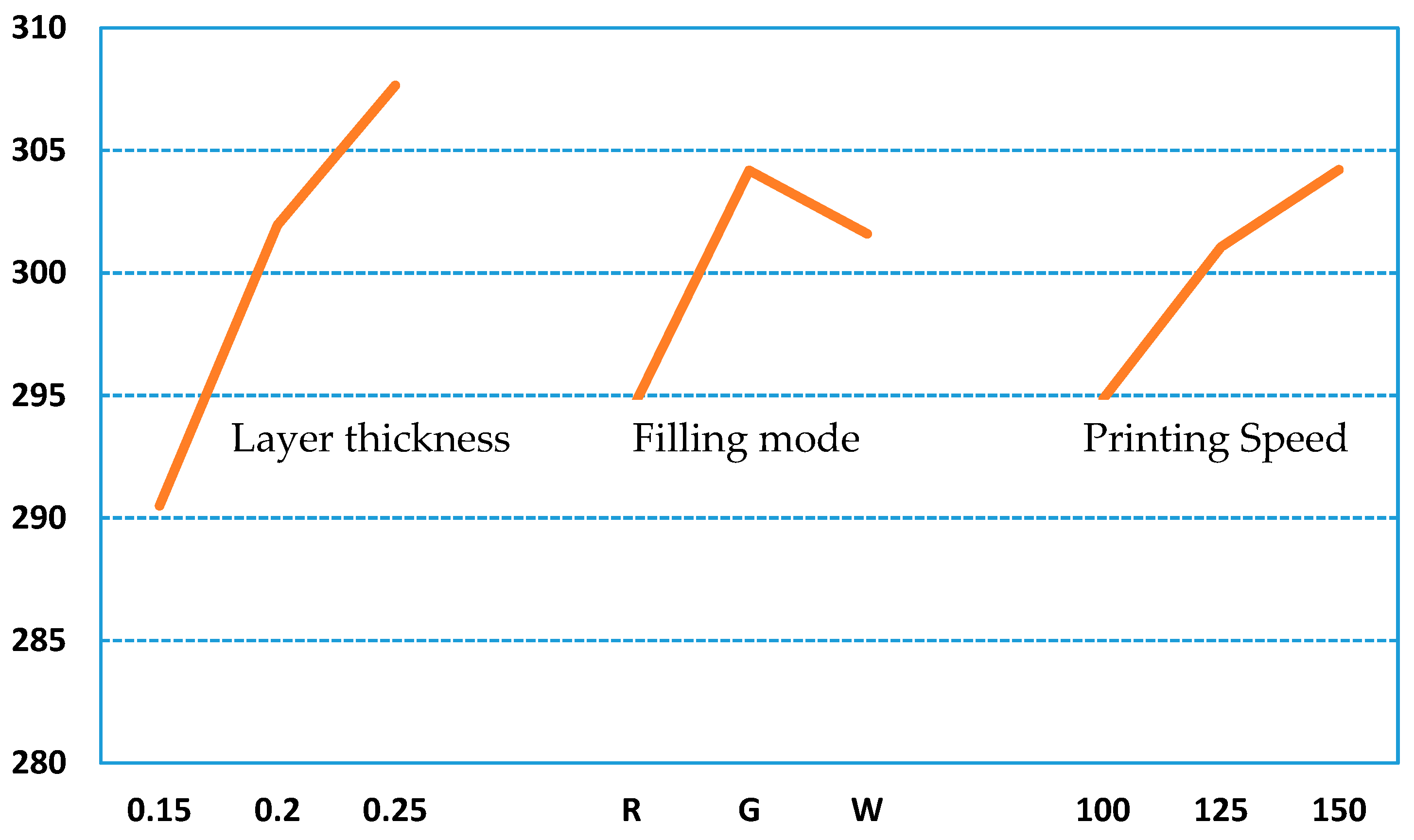

For PLA and ABS materials, the surface roughness distribution under different printing process parameters (layer thickness, filling method, and printing speed) was analyzed. Experimental results show that the layer thickness and filling method have a significant effect on the surface roughness. The effect of the filling method on the roughness should be of concern, but the effect of the printing speed on the surface roughness is not obvious.

The orthogonal test method was used to evaluate the wettability. The research results show that the 3D printing method can be used to prepare parts with low cost and a convenient method. The choice of dip coating method can effectively prepare a hydrophobic coating, which significantly improves the hydrophobicity of PLA and ABS performance. At the same time, it can be found that the printing parameters have a very significant effect on the wettability, and it is necessary to pay attention to optimize the selection of the process parameter combination of layer thickness, filling method, and printing speed.

If FDM 3D printing is applied to prepare a hydrophobic coating, the layer thickness and filling method should be optimized because these process parameters significantly affect the surface wettability. In this experiment, the process parameters combination such as the grid filling method and 0.25 mm layer thickness can be used to fabricate the parts with maximum contact angle.