Reinforcement of Epoxy Composites with Application of Finely-ground Ochre and Electrophysical Method of the Composition Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

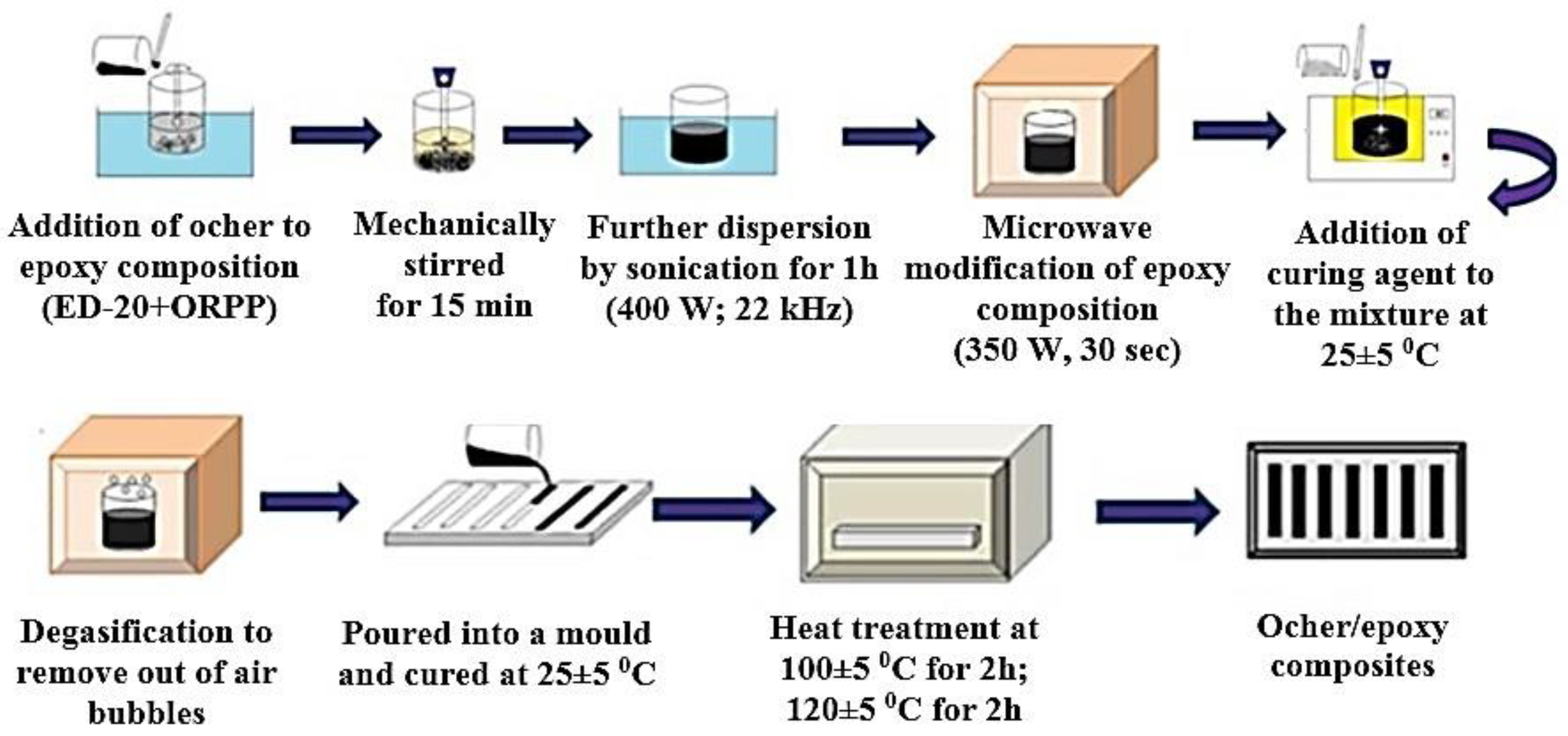

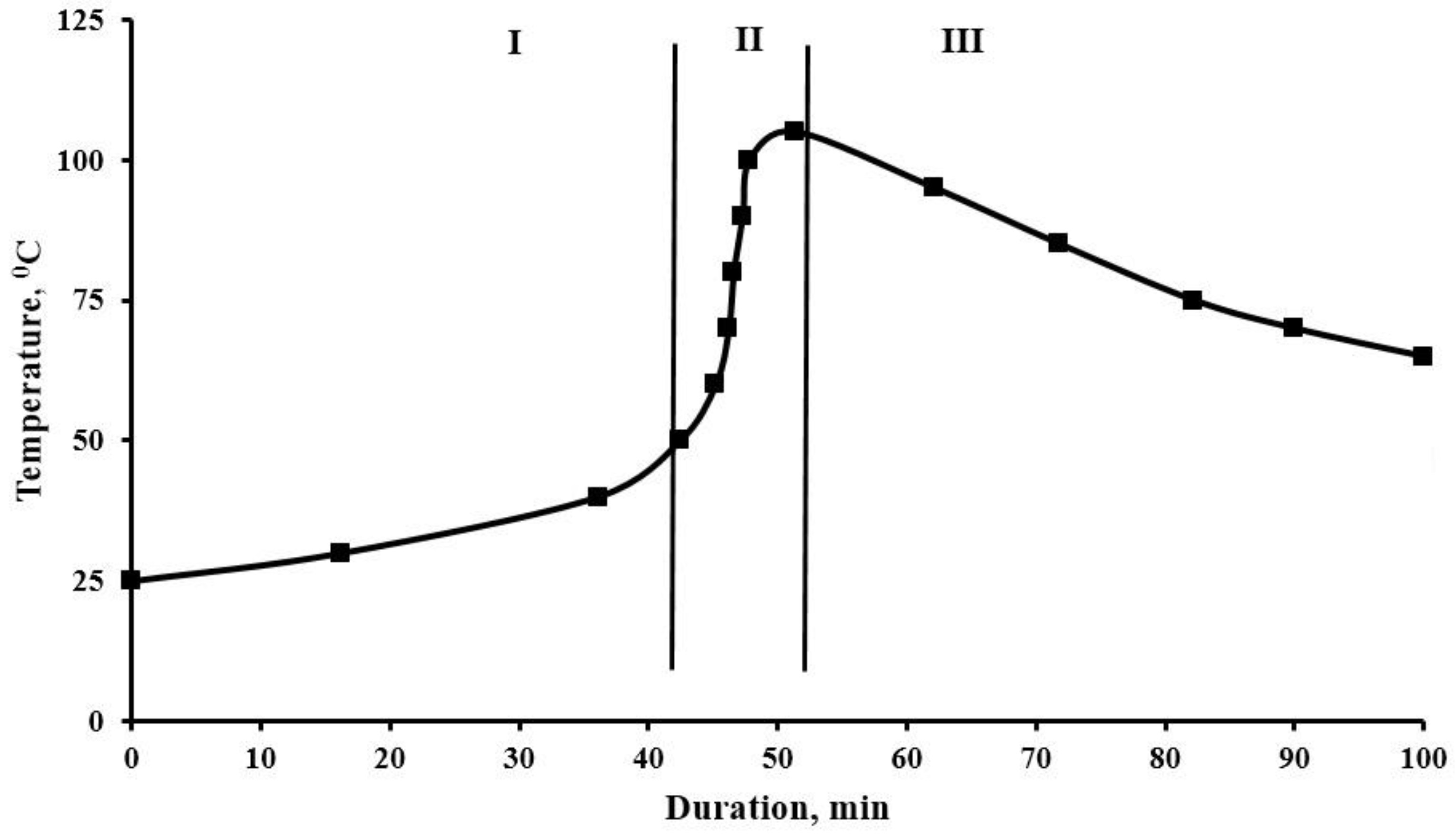

2.2. Preparation of Epoxy Composites

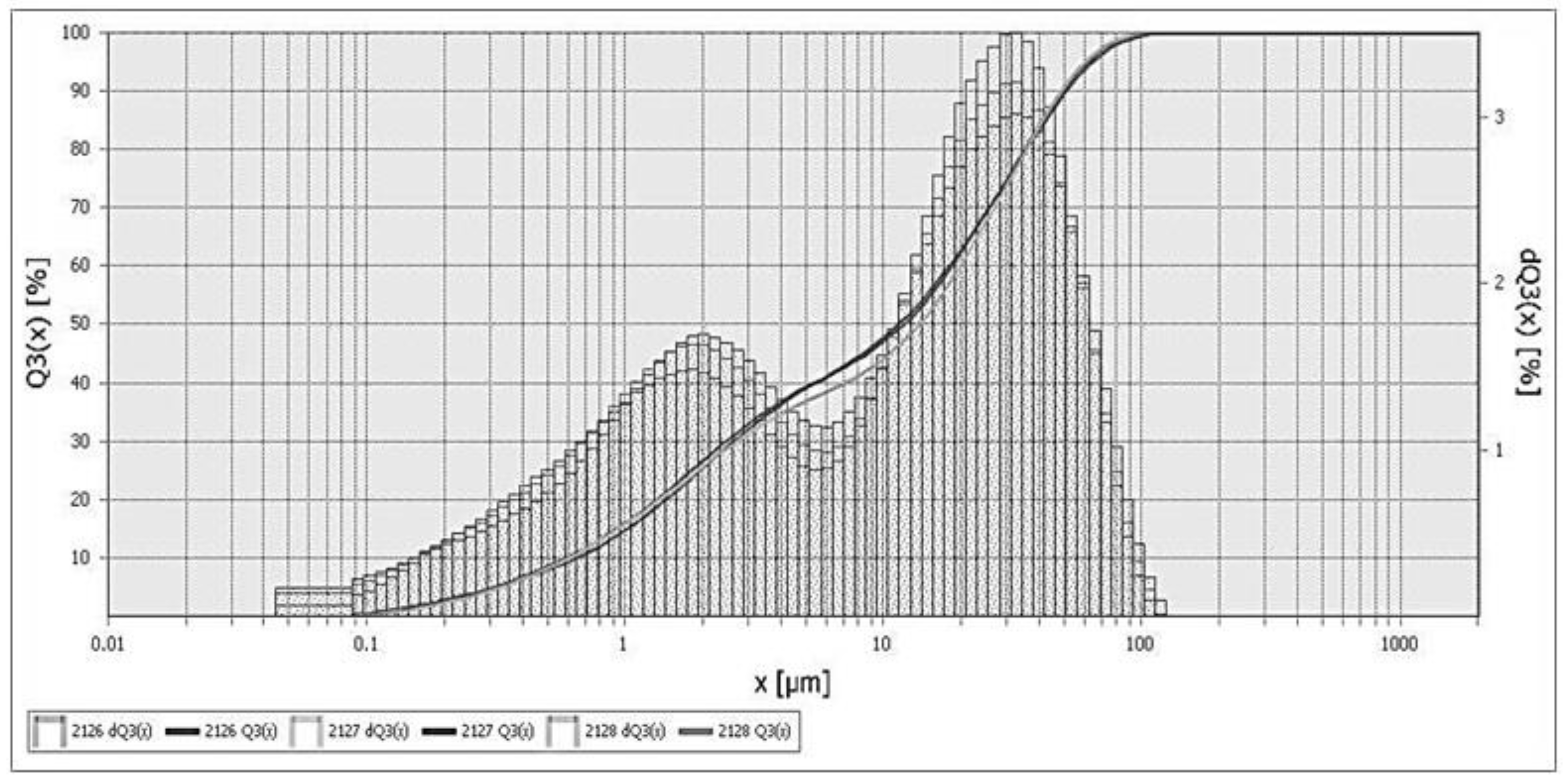

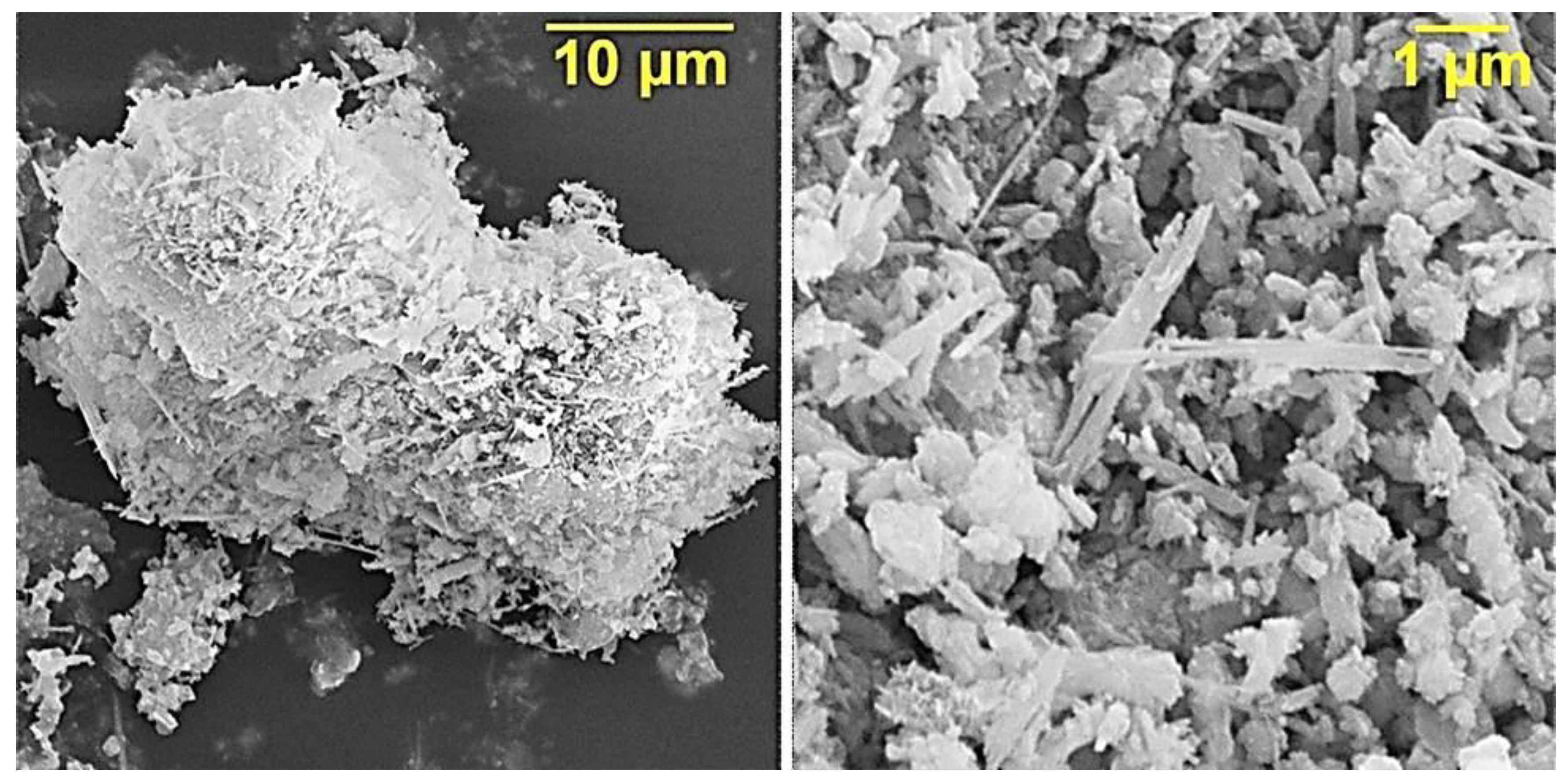

2.3. Characterization of Finely Ground Ochre

2.4. Testing of the Composites

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Starokadomskii, D.L. Epoxy composites with 10 and 50 wt% micronanoiron: Strength, microstructure, and chemical and thermal resistance. Russ. J. Appl. Chem. 2017, 90, 1337–1345. [Google Scholar] [CrossRef]

- Amirbeygi, H.; Khosravi, H.; Tohidlou, E. Reinforcing effects of aminosilane-functionalized graphene on the tribological and mechanical behaviors of epoxy nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47410. [Google Scholar] [CrossRef]

- Moaseri, E.; Bazubandi, B.; Baniadam, M.; Maghrebi, M. Enhancement in mechanical properties of multiwalled carbon nanotube-reinforced epoxy composites: Crosslinking of the reinforcement with the matrix via diamines. Polym. Eng. Sci. 2019, 59, 1905–1910. [Google Scholar] [CrossRef]

- Radoman, T.S.; Dzunuzovic, J.V.; Jeremic, K.B.; Grgur, B.N.; Milicevic, D.S.; Popovic, I.G.; Dzunuzovic, E.S. Improvement of epoxy resin properties by incorporation of TiO2 nanoparticles surface modified with gallic acid esters. Mater. Des. 2014, 62, 158–167. [Google Scholar] [CrossRef]

- Qian, L.; Qiu, Y.; Sun, N.; Xu, M.; Xu, G.; Xin, F.; Chen, Y. Pyrolysis route of a novel flame retardant constructed by phosphaphenanthrene and triazine-trione groups and its flame-retardant effect on epoxy resin. Polym. Degrad. Stab. 2014, 107, 98–105. [Google Scholar] [CrossRef]

- Hu, J.H.; Shan, J.Y.; Wen, D.H.; Liu, X.X.; Zhao, J.Q.; Tong, Z. Flame retardant, mechanical properties and curing kinetics of DOPO-based epoxy resins. Polym. Degrad. Stab. 2014, 109, 218–225. [Google Scholar] [CrossRef]

- Mostovoi, A.S.; Yakovlev, E.A.; Burmistrov, I.N.; Panova, L.G. Use of modified nanoparticles of potassium polytitanate and physical methods of modification of epoxy compositions for improving their operational properties. Russ. J. Appl. Chem. 2015, 88, 129–137. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Kadykova, Y.A.; Bekeshev, A.Z.; Tastanova, L.K. Epoxy composites modified with microfibers of potassium polytitanates. J. Appl. Polym. Sci. 2018, 135, 46651. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Nurtazina, A.S.; Kadykova, Y.A.; Bekeshev, A.Z. Highly Efficient Plasticizers-Antipirenes for Epoxy Polymers. Inorg. Mater. Appl. Res. 2019, 10, 1135–1139. [Google Scholar] [CrossRef]

- Mukbaniani, O.; Aneli, J.; Markarashvili, E.; Titvinidze, G.; Katsitadze, M.; Gogesashvili, N. Effect of Modification of Bentonite by Tetraethoxysilane on the Properties of Composites Based on Epoxy Resin. Oxid. Commun. 2010, 33, 555–560. [Google Scholar]

- Syugaev, A.V.; Maratkanova, A.N.; Shakov, A.A.; Nelyubov, A.V.; Lomayeva, S.F. Surface modification of iron particles with polystyrene and surfactants under high-energy ball milling. Surf. Coat. Technol. 2013, 236, 429–437. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Nurtazina, A.S.; Burmistrov, I.N.; Kadykova, Y.A. Effect of Finely Dispersed Chromite on the Physicochemical and Mechanical Properties of Modified Epoxy Composites. Russ. J. Appl. Chem. 2018, 91, 1758–1766. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, H.; He, X.; Zhao, Y.; Gou, L.; Wang, Y. Synthesis and self-healing behavior of thermoreversible epoxy resins modified with nitrile butadiene rubber. Polym. Eng. Sci. 2019, 59, 1603–1610. [Google Scholar] [CrossRef]

- Kulkarni, S.M. Kishore. Effect of filler–fiber interactions on compressive strength of fly ash and short-fiber epoxy composites. J. Appl. Polym. Sci. 2003, 87, 836–841. [Google Scholar] [CrossRef]

- Ahmetli, G.; Kocak, N.; Dag, M.; Kurbanli, R. Mechanical and thermal studies on epoxy toluene oligomer-modified epoxy resin/marble waste composites. Polym Compos. 2012, 33, 1455–1463. [Google Scholar] [CrossRef]

- Pati, P.R.; Satpathy, M.P. Investigation on red brick dust filled epoxy composites using ant lion optimization approach. Polym. Compos. 2019, 40, 3877–3885. [Google Scholar] [CrossRef]

- Mostovoi, A.S.; Kurbatova, E.A. Controlling the properties of epoxy composites filled with brick dust. Russ. J. Appl. Chem. 2017, 90, 267–276. [Google Scholar] [CrossRef]

- Kumara, R.; Kumarb, K.; Sahooc, P.; Bhowmika, S. Study of mechanical properties of wood dust reinforced epoxy composite. Procedia Mater. Sci. 2014, 6, 551–556. [Google Scholar] [CrossRef] [Green Version]

- Vahedi, H.; Pasbakhsh, P. Instrumented impact properties and fracture behaviour of epoxy/modified halloysite nanocomposites. Polym. Test. 2014, 39, 101–114. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Yakovlev, A.V. Reinforcement of Epoxy Composites with Graphite-Graphene Structures. Sci. Rep. 2019, 9, 16246. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.J.; Zhao, L.H.; Zhang, L.; Li, J. Surface modification of magnesium aluminum hydroxide nanoparticles with poly(methyl methacrylate) via one-pot in situ polymerization. Appl. Surf. Sci. 2012, 258, 2404–2409. [Google Scholar] [CrossRef]

- Wang, X.; Song, L.; Pornwannchai, W.; Hu, Y.; Kandola, B. The effect of graphene presence in flame retarded epoxy resin matrix on the mechanical and flammability properties of glass fiber-reinforced composites. Compos. Part A 2013, 53, 88–96. [Google Scholar] [CrossRef]

- Ning, R.; Chen, D.; Zhang, Q.; Bian, Z.; Dai, H.; Zhang, C. Surface modification of titanium hydride with epoxy resin via microwave-assisted ball milling. Appl. Surf. Sci. 2014, 316, 632–636. [Google Scholar] [CrossRef]

- Mandrino, D.; Paulin, I.; Skapin, S.D. Scanning electron microscopy, X-ray diffraction and thermal analysis study of the TiH2 foaming agent. Mater. Charact. 2012, 72, 87–93. [Google Scholar] [CrossRef]

- Wong, T.; Lau, K.-T.; Tam, W.-U.; Etches, J.A.; Kim, J.-K.; Wu, Y. Effects of silane surfactant on Nano-ZnO and rheology properties of nano-ZnO/epoxy on the UV absorbability of nano-ZnO/epoxy/micron-HGF composite. Compos. Part B 2016, 90, 378–385. [Google Scholar] [CrossRef]

- Li, W.; Song, B.; Zhang, S.; Zhang, F.; Liu, C.; Zhang, N.; Yao, H.; Shi, Y. Using 3-Isocyanatopropyltrimethoxysilane to Decorate Graphene Oxide with Nano-Titanium Dioxide for Enhancing the Anti-Corrosion Properties of Epoxy Coating. Polymers 2020, 12, 837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meisak, D.; Macutkevic, J.; Plyushch, A.; Kuzhir, P.; Selskis, A.; Banys, J. Dielectric Relaxation in the Hybrid Epoxy/MWCNT/MnFe2O4 Composites. Polymers 2020, 12, 697. [Google Scholar] [CrossRef] [Green Version]

- Zavrazhin, D.; Zavrazhina, C. Microwave Modification of Polymer-Carbon Materials. Mater. Sci. Forum. 2019, 945, 443–447. [Google Scholar] [CrossRef]

- Zlobina, I.; Bekrenev, N. The Influence of Electromagnatic Field Microwave on Physical and Mechanical Characteristics of CFRP (Carbon Fiber Reinforced Polymer) Structural. Mater. Sci. Forum. 2016, 870, 101–106. [Google Scholar] [CrossRef]

- Al-Harthi, M.A. Influence of applying microwave radiation on the LDPE/MWCNTs nanocomposite. Polym. Compos. 2014, 35, 2036–2042. [Google Scholar] [CrossRef]

- Zhang, Q.; Bai, G.; Xiao, W.; Sui, G.; Yang, X. Effect of amine functionalized MWCNT-epoxy interfacial interaction on MWCNT dispersion and mechanical properties of epoxy-amine composites. Polym. Compos. 2018, 39, E2552–E2561. [Google Scholar] [CrossRef]

| Component | Concentration, % |

|---|---|

| FeO(OH) Fe2O3 Fe3O4 | 85.95 |

| Al2O3 | 4.63 |

| Cr2O3 | 2.80 |

| SiO2 | 2.31 |

| NiO | 2.88 |

| TiO2 | 0.38 |

| CuO | 0.66 |

| CaO | 0.24 |

| S | 0.08 |

| P | 0.07 |

| The Composition, Parts by Mass Cured by 15 Parts by Mass of PEPA | Gben, MPa | Eben, MPa | Gcom, MPa | Gten, MPa | Eten, MPa | aim, kJ/m2 |

|---|---|---|---|---|---|---|

| 100 ED-20 + 40 ORPP | 80 ± 3.2 | 2210 ± 88 | 100 ± 4.0 | 30 ± 1.5 | 1896 ± 75 | 6 ± 0.3 |

| 100 ED-20 + 40 ORPP + 0.1 ocher | 87 ± 3.5 | 3206 ± 120 | 102 ± 4.1 | 41 ± 2.0 | 2113 ± 84 | 7 ± 0.3 |

| 100 ED-20 + 40 ORPP + 0.5 ocher | 105 ± 4.2 | 3500 ± 140 | 105 ± 4.1 | 53 ± 2.6 | 2317 ± 92 | 11 ± 0.5 |

| 100 ED-20 + 40 ORPP + 1.0 ocher | 75 ± 3.0 | 4073 ± 152 | 110 ± 4.4 | 43 ± 2.2 | 3040 ± 121 | 5 ± 0.2 |

| 100 ED-20 + 40 ORPP + 10 ocher | 80 ± 3.2 | 4373 ± 164 | 114 ± 4.5 | 53 ± 2.6 | 3242 ± 122 | 5 ± 0.2 |

| 100 ED-20 + 40 ORPP + 30 ocher | 76 ± 2.8 | 5568 ± 220 | 125 ± 5.0 | 36 ± 1.8 | 3512 ± 140 | 7 ± 0.3 |

| 100 ED-20 + 40 ORPP + 50 ocher | 74 ± 2.2 | 7462 ± 240 | 145 ± 5.6 | 41 ± 2.0 | 4000 ± 156 | 5 ± 0.2 |

| 100 ED-20 + 40 ORPP + 75 ocher | 102 ± 4.1 | 10163 ± 350 | 156 ± 5.8 | 45 ± 2.3 | 4110 ± 160 | 9 ± 0.4 |

| 100 ED-20 + 40 ORPP + 100 ocher | 55 ± 2.0 | 12120 ± 445 | 95 ± 4.0 | 32 ± 1.6 | 4860 ± 184 | 4 ± 0.2 |

| Composition, Parts by Mass, Cured by 15 Parts by Mass of PEPA | τgel, Min | τcur, Min | Tmax, °C |

|---|---|---|---|

| 100ED-20 + 40ORPP | 27 | 38 | 88 |

| 100ED-20+40ORPP+0.5 ocher | 21 | 30 | 99 |

| 100ED-20+40ORPP +75 ocher | 17 | 29 | 96 |

| Composition, Parts by Mass, Cured by 15 Parts by Mass of PEPA | Tin, °C | Tf °C | Yield of CS at Tf,% Mass | Tv, °C | OI, % vol. |

|---|---|---|---|---|---|

| 100ED-20 | 200 | 390 | 40 (390 °C) | 86 | 19 |

| 100ED-20 + 40ORPP | 230 | 370 | 54 (370 °C) | 132 | 28 |

| 100ED-20 + 40ORPP + 0.5 ocher | 240 | 360 | 58 (360 °C) | 148 | 28 |

| 100ED-20 + 40ORPP + 50 ocher | 242 | 370 | 69 (370 °C) | 170 | 30 |

| 100ED-20 + 40ORPP + 75 ocher | 245 | 370 | 72 (370 °C) | 190 | 31 |

| 100ED-20 + 40ORPP + 100 ocher | 245 | 370 | 76 (370 °C) | 210 | 32 |

| Parameters of Microwave Modification of Composition in parts by Mass: 100ED-20 + 40ORPP + 0.5 Ocher + 15PEPA | Gben, MPa | Eben, MPa | Gt, MPa | Et, MPa | aim, kJ/m2 |

|---|---|---|---|---|---|

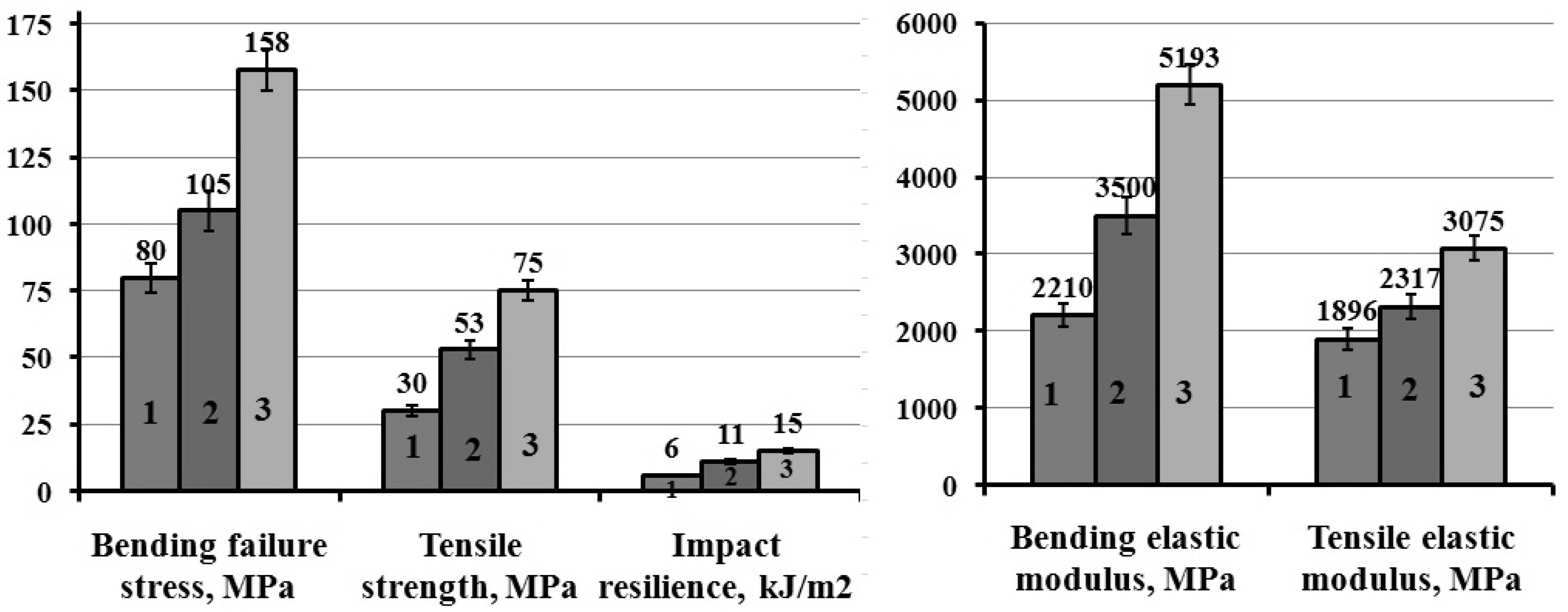

| Without microwave modification | 105 ± 4.2 | 3500 ± 140 | 58 ± 2.6 | 2317 ± 92 | 11 ± 0.5 |

| 200 W, 15 s | 108 ± 4.3 | 4192 ± 165 | 57 ± 2.3 | 2804 ± 112 | 11 ± 0.5 |

| 200 W, 30 s | 128 ±4.5 | 4438 ± 168 | 63 ± 2.8 | 2889 ± 115 | 13 ± 0.6 |

| 200 W, 45 s | 100 ± 4.0 | 4101 ± 145 | 55 ± 2.0 | 2039 ± 81 | 7 ± 0.4 |

| 250 W, 30 s | 130 ± 4.5 | 4892 ± 175 | 59 ±2.4 | 3162 ± 125 | 13 ±0.6 |

| 300 W, 30 s | 132 ± 4.6 | 3861 ± 145 | 75 ± 3.0 | 2674 ± 110 | 12 ± 0.5 |

| 350 W, 30 s | 158 ± 6.0 | 5193 ± 200 | 75 ± 3.0 | 3075 ± 123 | 15 ± 0.7 |

| 400 W, 30 s | 121 ± 4.8 | 3685 ± 142 | 58 ± 2.3 | 2628 ± 105 | 10 ± 0.5 |

| 500 W, 30 s | 115 ± 4.6 | 3470 ± 135 | 45 ± 1.8 | 2031 ± 81 | 8 ± 0.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekeshev, A.; Mostovoy, A.; Tastanova, L.; Kadykova, Y.; Kalganova, S.; Lopukhova, M. Reinforcement of Epoxy Composites with Application of Finely-ground Ochre and Electrophysical Method of the Composition Modification. Polymers 2020, 12, 1437. https://doi.org/10.3390/polym12071437

Bekeshev A, Mostovoy A, Tastanova L, Kadykova Y, Kalganova S, Lopukhova M. Reinforcement of Epoxy Composites with Application of Finely-ground Ochre and Electrophysical Method of the Composition Modification. Polymers. 2020; 12(7):1437. https://doi.org/10.3390/polym12071437

Chicago/Turabian StyleBekeshev, Amirbek, Anton Mostovoy, Lyazzat Tastanova, Yulia Kadykova, Svetlana Kalganova, and Marina Lopukhova. 2020. "Reinforcement of Epoxy Composites with Application of Finely-ground Ochre and Electrophysical Method of the Composition Modification" Polymers 12, no. 7: 1437. https://doi.org/10.3390/polym12071437

APA StyleBekeshev, A., Mostovoy, A., Tastanova, L., Kadykova, Y., Kalganova, S., & Lopukhova, M. (2020). Reinforcement of Epoxy Composites with Application of Finely-ground Ochre and Electrophysical Method of the Composition Modification. Polymers, 12(7), 1437. https://doi.org/10.3390/polym12071437