High-Yield Lignocellulosic Fibers from Date Palm Biomass as Reinforcement in Polypropylene Composites: Effect of Fiber Treatment on Composite Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

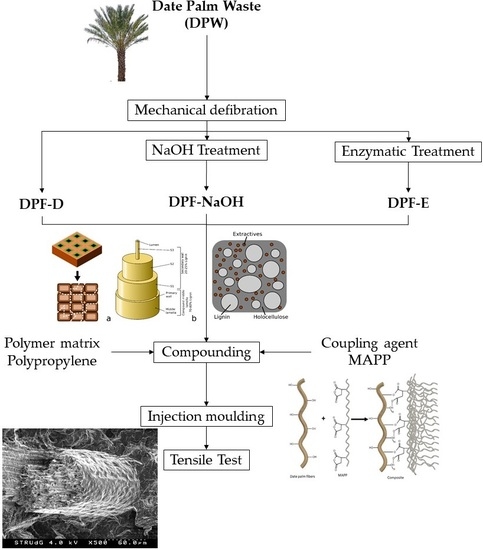

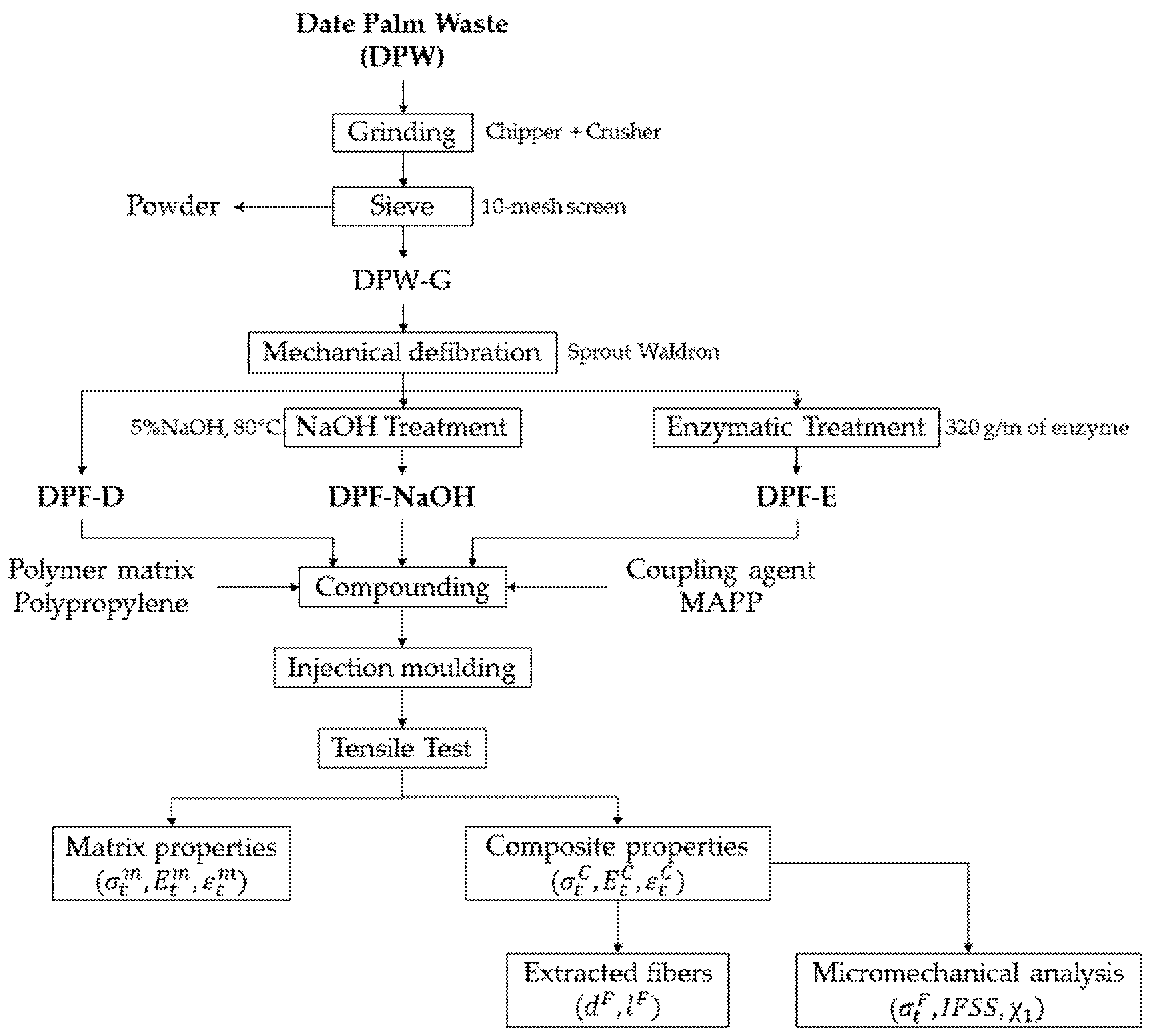

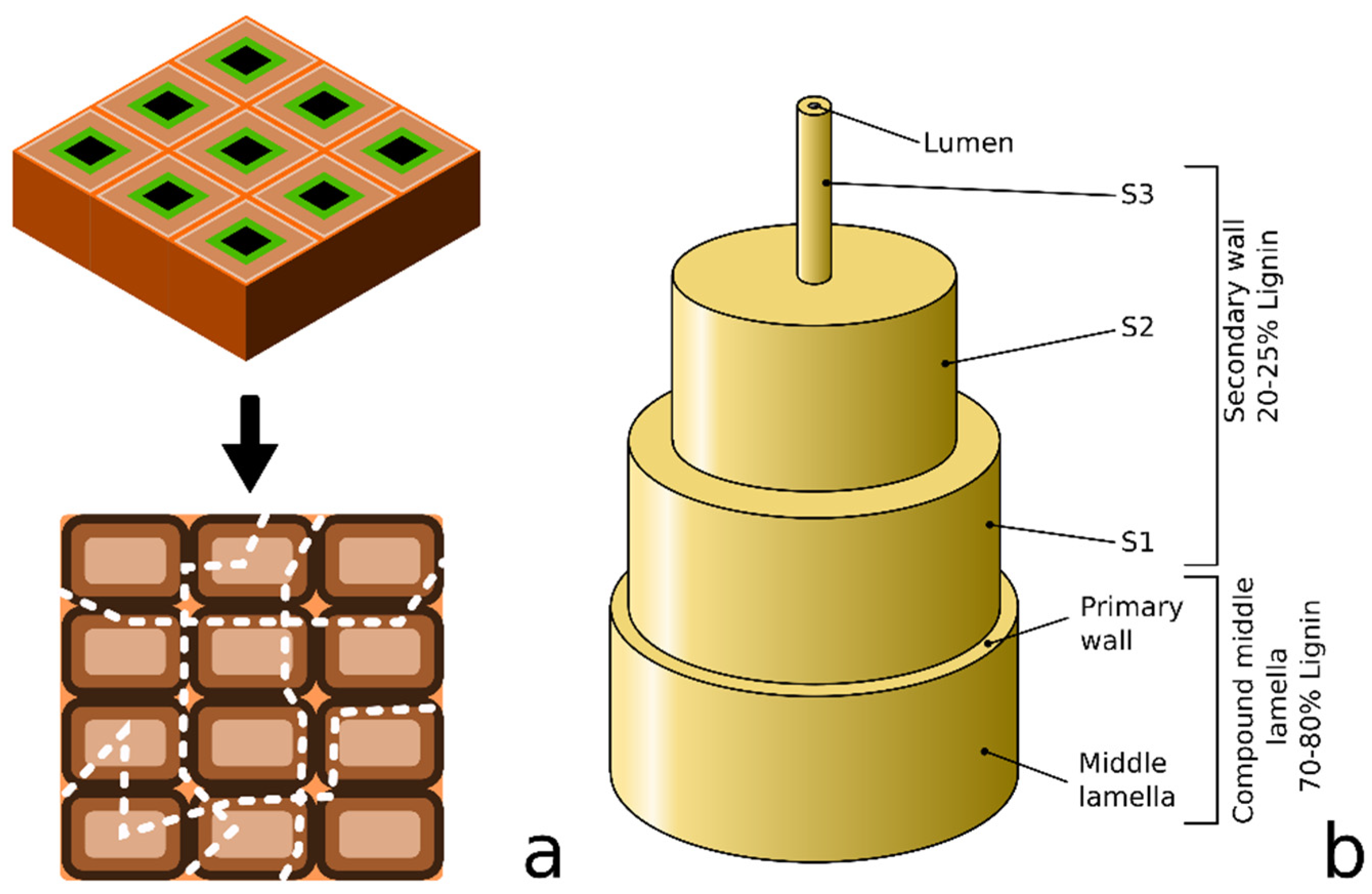

2.2.1. Preparation of the DPF

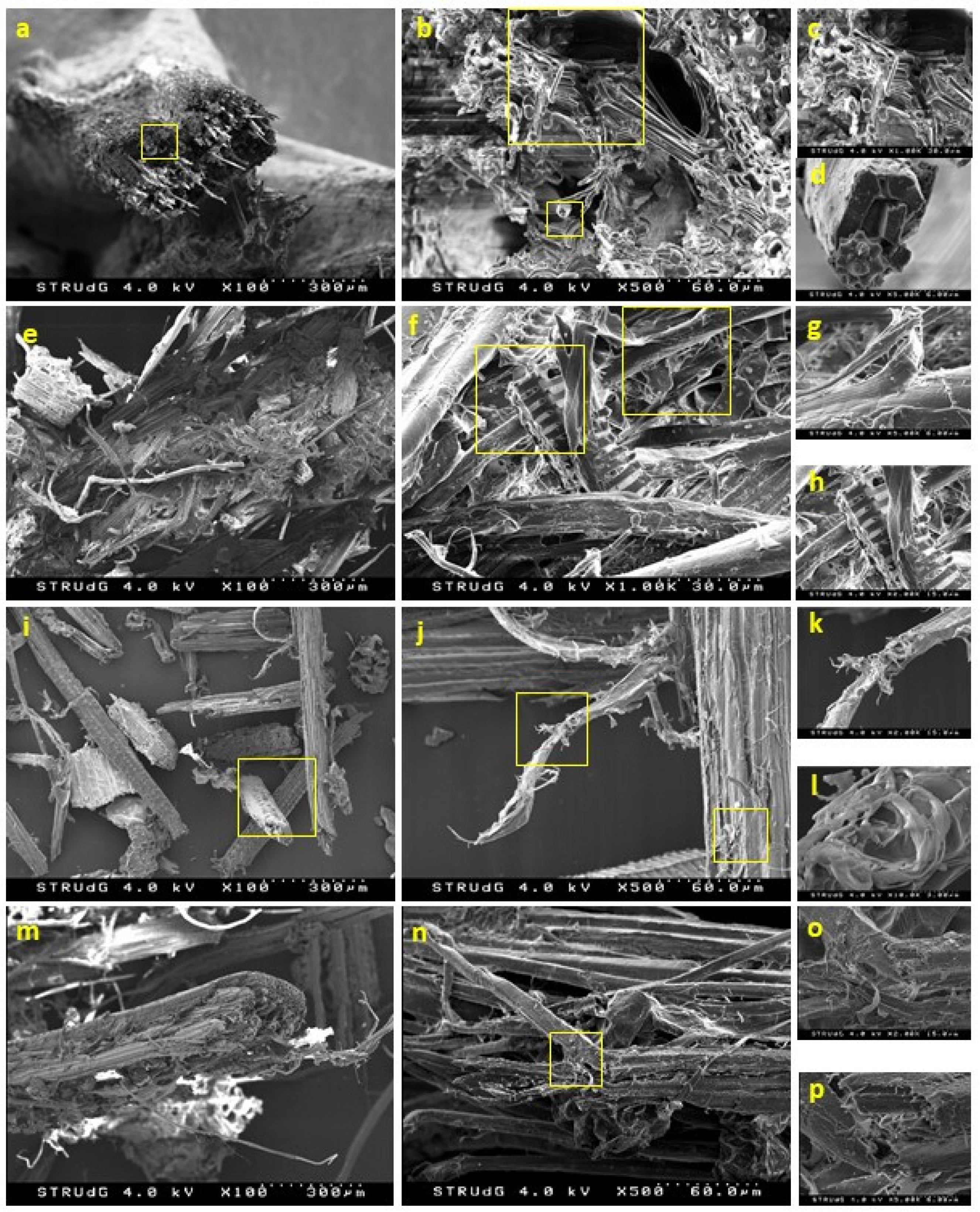

2.2.2. Fiber Characterization

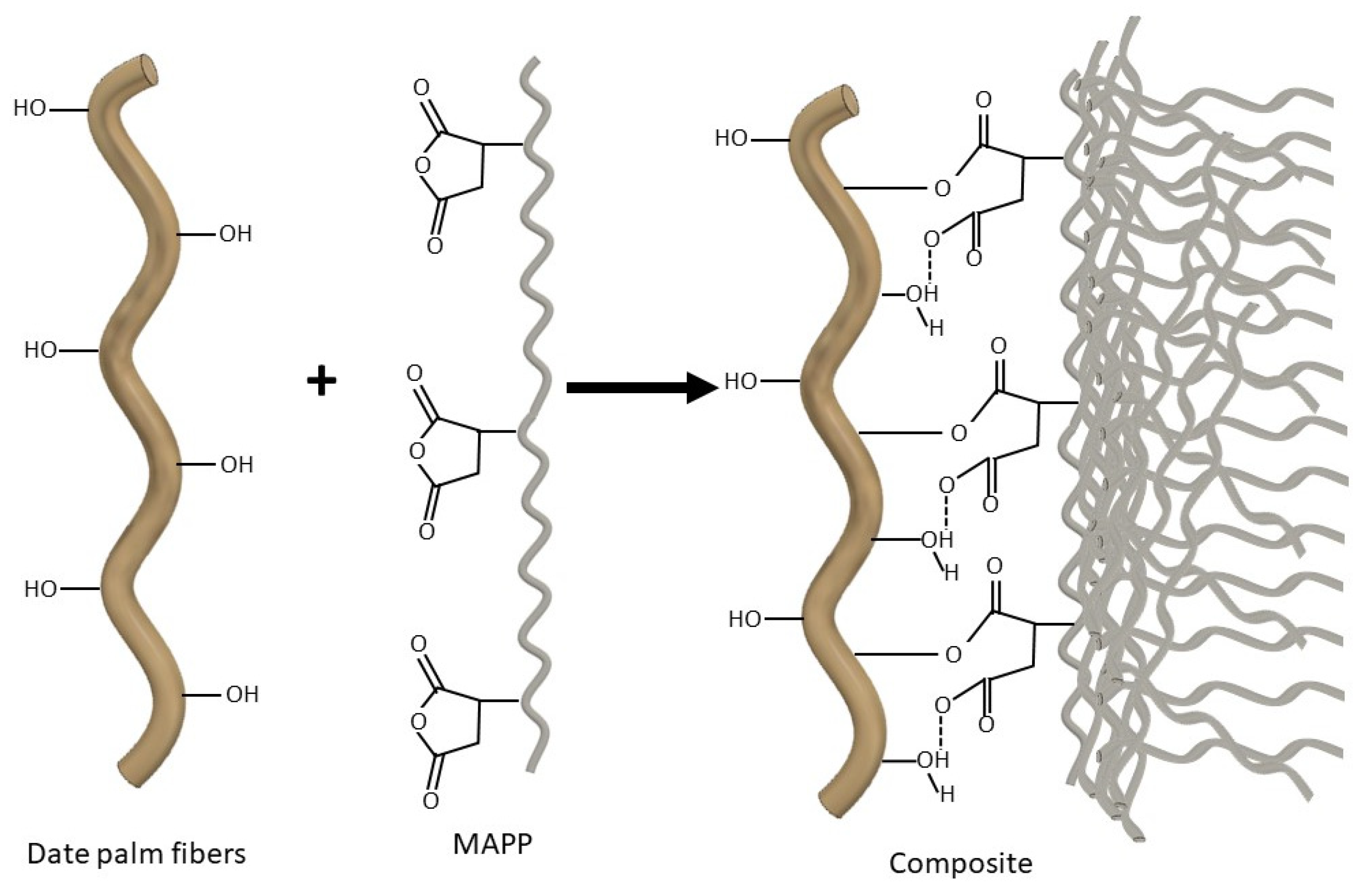

2.2.3. Preparation of the Composite Materials

2.2.4. Composites Characterization

3. Results and Discussion

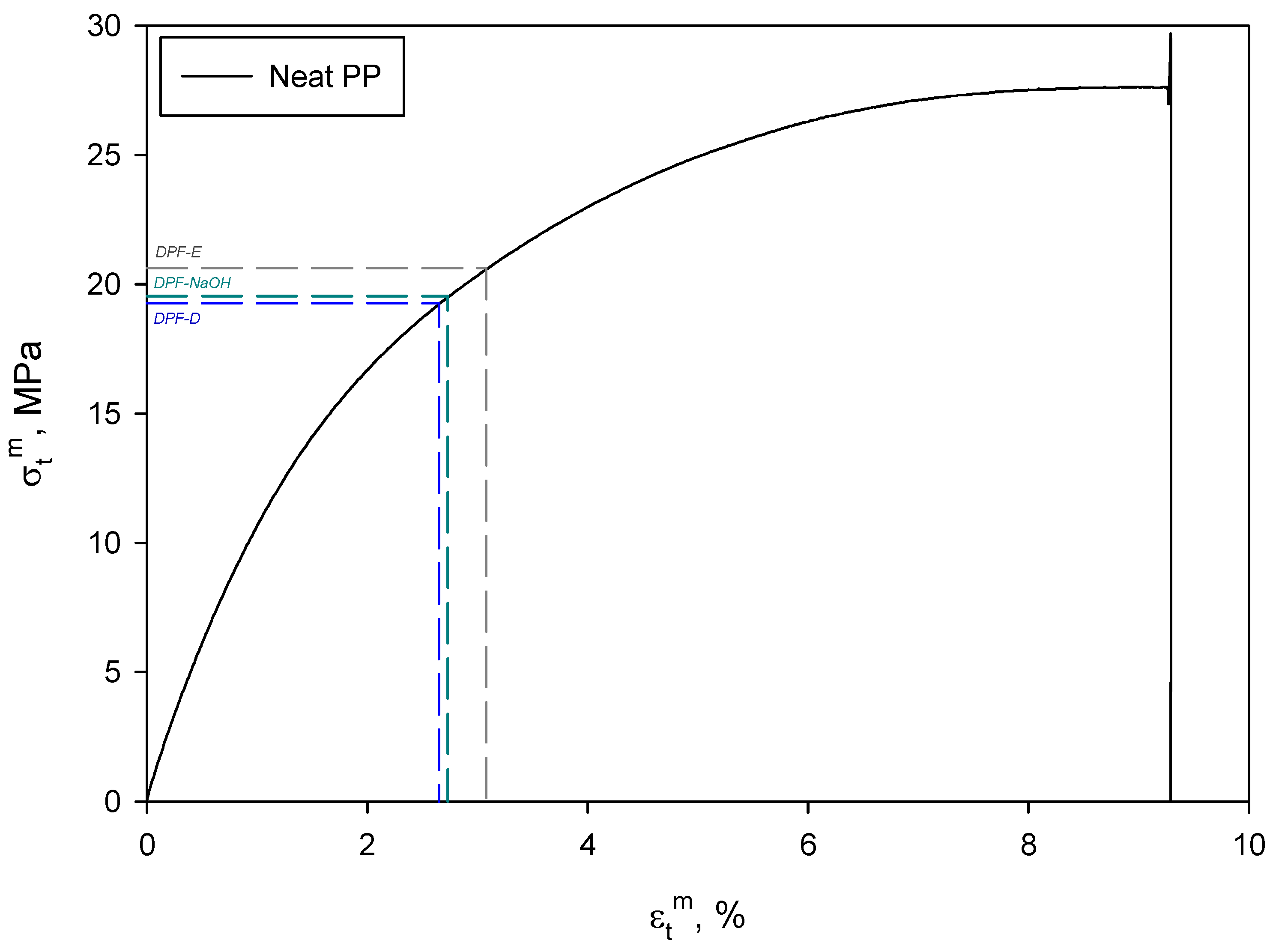

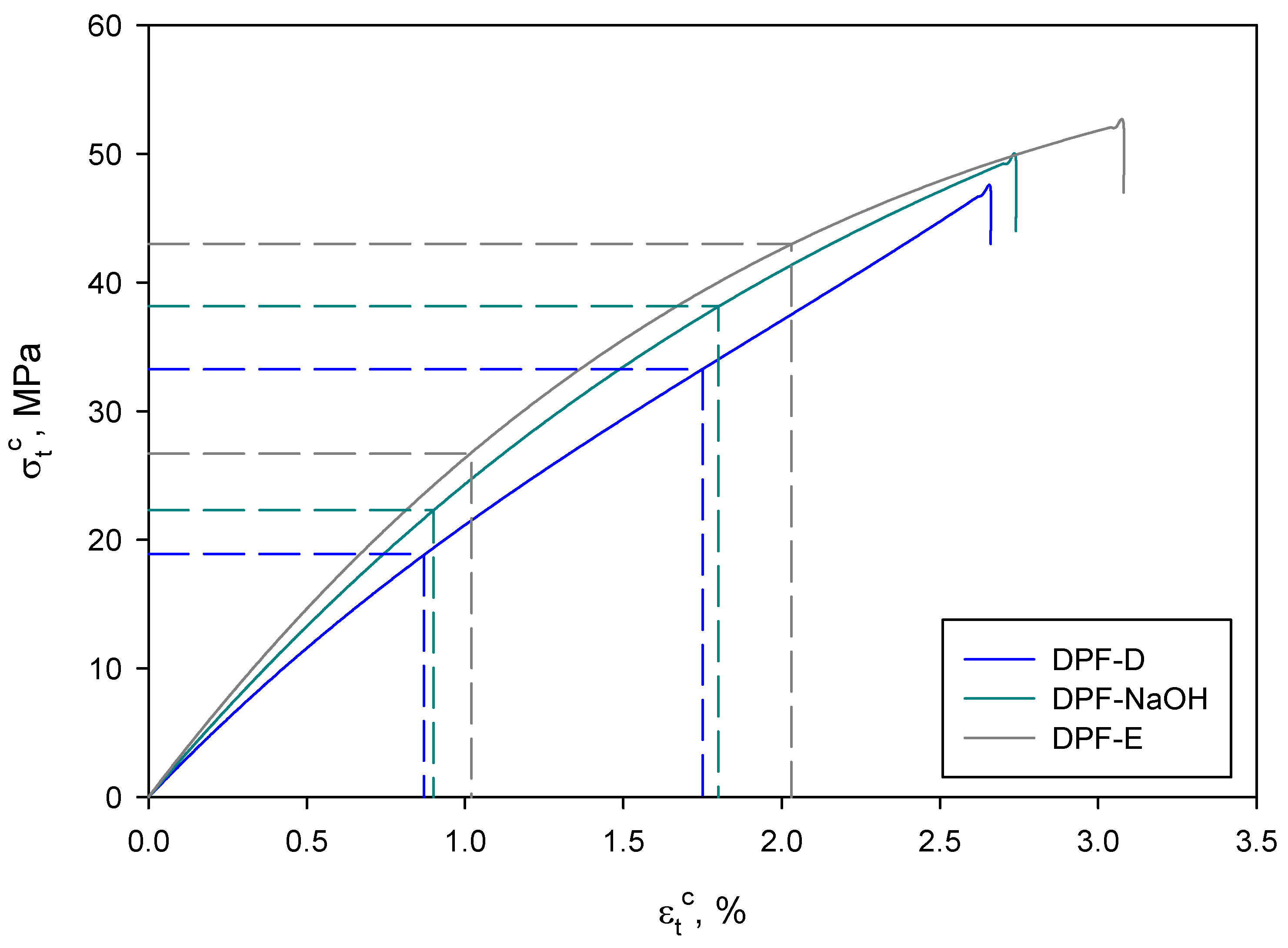

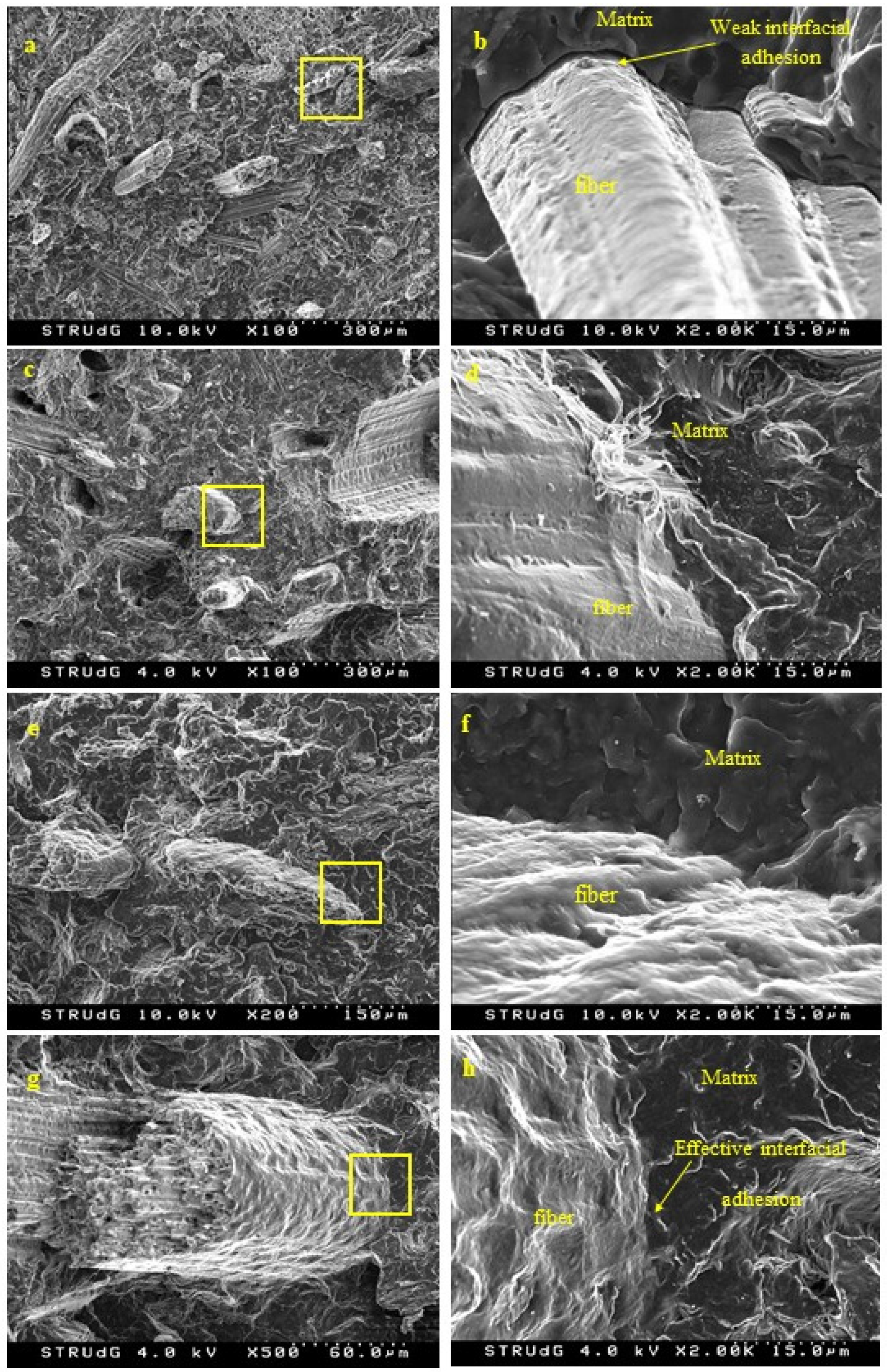

3.1. Tensile Properties of Date Palm Fibers—PP Composites

3.2. Micromechanical Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ashori, A. Wood-plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Olive stones flour as reinforcement in polypropylene composites: A step forward in the valorization of the solid waste from the olive oil industry. Ind. Crops Prod. 2014, 72, 183–191. [Google Scholar] [CrossRef]

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, L.; Essel, R.; Breitmayer, E.; Barth, M. WPC/NFC Market Study 2014-10 (Update 2015-06): Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends in Automotive and Construction. Bio-based.eu/markets 2015, 6, 1–14. [Google Scholar]

- Chandrasekaran, M.; Bahkali, A.H. Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology—Review. Saudi J. Biol. Sci. 2013, 20, 105–120. [Google Scholar] [CrossRef] [PubMed]

- Borchani, C.; Besbes, S.; Blecker, C.; Masmoudi, M.; Baati, R.; Attia, H. Chemical properties of 11 date cultivars and their corresponding fiber extracts. African J. Biotechnol. 2010, 9, 4096–4105. [Google Scholar]

- Hamza, H.; Elbekkay, M.; Ben Abederrahim, M.A.; Ferchichi Ali, A. Molecular and morphological analyses of date palm (Phoenix dactylifera L.) subpopulations in southern Tunisia. Spanish J. Agric. Res. 2011, 9, 484. [Google Scholar] [CrossRef]

- Elseify, L.A.; Midani, M.; Shihata, L.A.; El-Mously, H. Review on cellulosic fibers extracted from date palms (Phoenix Dactylifera L.) and their applications. Cellulose 2019, 26, 2209–2232. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Saadaoui, N.; Rouilly, A.; Fares, K.; Rigal, L. Characterization of date palm lignocellulosic by-products and self-bonded composite materials obtained thereof. Mater. Des. 2013, 50, 302–308. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Abu-Sharkh, B.F.; Hamid, H. Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis. Polym. Degrad. Stab. 2004, 85, 967–973. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Nógellová, Z.; Mičušík, M.; Novák, I.; Krupa, I. Mechanical, sorption and adhesive properties of composites based on low density polyethylene filled with date palm wood powder. Mater. Des. 2014, 53, 29–37. [Google Scholar] [CrossRef]

- Sbiai, A.; Kaddami, H.; Fleury, E.; Maazouz, A.; Erchiqui, F.; Koubaa, A.; Soucy, J.; Dufresne, A. Effect of the fiber size on the physicochemical and mechanical properties of composites of epoxy and date palm tree fibers. Macromol. Mater. Eng. 2008, 293, 684–691. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Oudrhiri Hassani, F.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Dhakal, H.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crops Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef]

- Mirmehdi, S.M.; Zeinaly, F.; Dabbagh, F. Date palm wood flour as filler of linear low-density polyethylene. Compos. Part B Eng. 2014, 56, 137–141. [Google Scholar] [CrossRef]

- López, J.P.; Méndez, J.A.; El Mansouri, N.-E.; Mutjé, P.; Vilaseca, F. Mean intrinsic tensile properties of stone groundwood fibers from softwood. BioResources 2011, 6, 5037–5049. [Google Scholar]

- López, J.P.; Méndez, J.A.; Espinach, F.X.; Julián, F.; Mutjé, P.; Vilaseca, F. Tensile strength characteristics of polypropylene composites reinforced with stone groundwood fibers from softwood. BioResource 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Dehghani, A.; Madadi Ardekani, S.; Al-Maadeed, M.A.; Hassan, A.; Wahit, M.U. Mechanical and thermal properties of date palm leaf fiber reinforced recycled poly (ethylene terephthalate) composites. Mater. Des. 2013, 52, 841–848. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Sautereau, H.; Raihane, M.; Erchiqui, F.; Dufresne, A. Short palm tree fibers poly olefin composites: Effect of filler content and coupling agent on physical properties. Macromol. Mater. Eng. 2008, 293, 140–148. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Pèlach, M.A.; Pastor, F.J.; Puig, J.; Vilaseca, F.; Mutjé, P. Enzymic deinking of old newspapers with cellulase. Process Biochem. 2003, 38, 1063–1067. [Google Scholar] [CrossRef]

- Collins, T.; Gerday, C.; Feller, G. Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol. Rev. 2005, 29, 3–23. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Applications of Enzymes in the Pulp and Paper Industry. Biotechnol. Prog. 1999, 15, 147–157. [Google Scholar]

- Hassan, M.; Berglund, L.; Hassan, E.; Abou-Zeid, R.; Oksman, K. Effect of xylanase pretreatment of rice straw unbleached soda and neutral sulfite pulps on isolation of nanofibers and their properties. Cellulose 2018, 25, 2939–2953. [Google Scholar] [CrossRef]

- Hassan, M.L.; Bras, J.; Hassan, E.A.; Silard, C.; Mauret, E. Enzyme-assisted isolation of microfibrillated cellulose from date palm fruit stalks. Ind. Crops Prod. 2014, 55, 102–108. [Google Scholar] [CrossRef]

- Tarrés, Q.; Ehman, N.V.; Vallejos, M.E.; Area, M.C.; Delgado-Aguilar, M.; Mutjé, P. Lignocellulosic nanofibers from triticale straw: The influence of hemicelluloses and lignin in their production and properties. Carbohydr. Polym. 2017, 163. [Google Scholar] [CrossRef]

- Hausser, N.; Marinkovic, S.; Estrine, B. Improved sulfuric acid decrystallization of wheat straw to obtain high yield carbohydrates. Cellulose 2011, 18, 1521–1525. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A.; Schipper, G.; Krikor, H.G.L.T. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: Part 3. Strength and strain at failure. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1075–1084. [Google Scholar] [CrossRef]

- Shibata, M.; Takachiyo, K.I.; Ozawa, K.; Yosomiya, R.; Takeishi, H. Biodegradable polyester composites reinforced with short abaca fiber. J. Appl. Polym. Sci. 2002, 85, 129–138. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Faruk, O. Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites. Express Polym. Lett. 2007, 1, 755–762. [Google Scholar] [CrossRef]

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.D.F.M.; De Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled Newspaper Fibers as Reinforcing Fillers in Thermoplastics: Part I-Analysis of Tensile and Impact Properties in Polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Marais, A.; Wågberg, L. The use of polymeric amines to enhance the mechanical properties of lignocellulosic fibrous networks. Cellulose 2012, 19, 1437–1447. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Nadji, H.; Riedl, B.; Zhang, S.Y.; Deng, J. Medium-density fiberboard produced using pulp and paper sludge from different pulping processes. Wood Fiber Sci. 2010, 42, 292–303. [Google Scholar]

- McDonald, D.; Miles, K.; Amiri, R. The nature of the mechanical pulping process. Pulp Pap. Canada 2004, 105, 27–32. [Google Scholar]

- Liu, X.; Jiang, Y.; Yang, S.; Meng, X.; Song, X.; Wu, M. Effects of pectinase treatment on pulping properties and the morphology and structure of bagasse fiber. BioResources 2017, 12, 7731–7743. [Google Scholar]

- De Prez, J.; Van Vuure, A.W.; Ivens, J.; Aerts, G.; Van de Voorde, I. Effect of enzymatic treatment of flax on ease of fiber extraction and chemical composition. BioResources 2019, 14, 1–16. [Google Scholar]

- Böras, L.; Gatenholm, P. Surface composition and morphology of CTMP fibers. Holzforschung 1999, 53, 188–194. [Google Scholar] [CrossRef]

- Zimmerman, M.H.; Brown, C.L. Trees: Structure and Function; Springer: New York, NY, USA, 1971. [Google Scholar]

- Zimmerman, M.H. Xylem Structure and the Ascent of Sap; Springer Series in Wood Science: New York, NY, USA, 2013. [Google Scholar]

- Tarrés, Q.; Saguer, E.; Pèlach, M.A.; Alcalà, M.; Delgado-Aguilar, M.; Mutjé, P. The feasibility of incorporating cellulose micro/nanofibers in papermaking processes: The relevance of enzymatic hydrolysis. Cellulose 2016, 23, 1433–1445. [Google Scholar] [CrossRef]

- Pääkko, M.; Ankerfors, M.; Kosonen, H.; Nykänen, a.; Ahola, S.; Österberg, M.; Ruokolainen, J.; Laine, J.; Larsson, P.T.; Ikkala, O.; et al. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 2007, 8, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- Henriksson, M.; Henriksson, G.; Berglund, L.A.; Lindström, T. An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur. Polym. J. 2007, 43, 3434–3441. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals-copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, H.G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Rodriguez, M.; Rodriguez, A.; R, J.B.; Vilaseca, F.; Girones, J.; Mutje, P. Determination of corn stalk fibers’ strength through modeling of the mechanical properties of its composites. BioResources 2010, 5, 2535–2546. [Google Scholar]

- Delgado-Aguilar, M.; Reixach, R.; Tarrés, Q.; Espinach, F.X.; Mutjé, P.; Méndez, J.A. Bleached kraft eucalyptus fibers as reinforcement of poly(lactic acid) for the development of high-performance biocomposites. Polymers 2018, 10, 699. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Espinach, F.X.; Julian, F.; Torres, L.; Vilaseca, F.; Mutje, P. Micromechanics of hemp strands in polypropylene composites. Compos. Sci. Technol. 2012, 72, 1209–1213. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Méndez, J.A.; Julian, F.; Mutjé, P. Tensile properties and micromechanical analysis of stone groundwood from softwood reinforced bio-based polyamide11 composites. Compos. Sci. Technol. 2016, 132, 123–130. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a Coupling Agent on the Performance of Jute-PP Composites. J. Reinf. Plast. Compos. 2004, 23, 625–637. [Google Scholar] [CrossRef]

- Osman, H.; Ismail, H.; Mustapha, M. Effects of maleic anhydride polypropylene on tensile, water absorption, and morphological properties of recycled newspaper filled polypropylene/natural rubber composites. J. Compos. Mater. 2010, 44, 1477–1491. [Google Scholar] [CrossRef]

- Franco-Marquès, E.; Méndez, J.; Pèlach, M.A.; Vilaseca, F.; Bayer, J.; Mutjé, P. Influence of coupling agents in the preparation of polypropylene composites reinforced with recycled fibers. Chem. Eng. J. 2011, 166, 1170–1178. [Google Scholar] [CrossRef]

- Vilaseca, F.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Pelach, M.; Lopez, J.P.; Mutje, P. Biocomposites from abaca strands and polypropylene. Part I: Evaluation of the tensile properties. Bioresour. Technol. 2010, 101, 387–395. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber ( NR ) Composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef]

- Templeton, P.A. Strength Predictions of Injection Molding Compounds. J. Reinf. Plast. Compos. 1990, 9, 210–225. [Google Scholar] [CrossRef]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-I-Palmer, P.; Mutjé, P. Mechanical and micromechanical tensile strength of eucalyptus bleached fi bers reinforced polyoxymethylene composites. Compos. Part B Eng. 2016, 116, 1–7. [Google Scholar]

- Reixach, R.; Franco-Marquès, E.; El Mansouri, N.-E.; de Cartagena, F.R.; Arbat, G.; Espinach, F.X.; Mutjé, P. Micromechanics of Mechanical, Thermomechanical, and Chemi-Thermomechanical Pulp from Orange Tree Pruning as Polypropylene Reinforcement: A Comparative Study. Bioresources 2013, 8, 3231–3246. [Google Scholar] [CrossRef]

- Mittal, R.K.; Gupta, V.B.; Sharma, P. The effect of fibre ortientation on the interfacial shear stress in short fibre-reinforced polypropylene. J. Mater. Sci. 1987, 22, 1949–1955. [Google Scholar] [CrossRef]

| Composite | VF | (MPa) | (GPa) | (%) | (MPa) | (µm) | (µm) | |

|---|---|---|---|---|---|---|---|---|

| PP | 0 | 27.60 ± 0.13 | 1.50 ± 0.06 | 9.3 ± 0.2 | 27.6 | - | - | - |

| PP-40DPF-D | 0.315 | 47.17 ± 0.21 | 3.92 ± 0.04 | 2.65 ± 0.4 | 16.98 | 29.8 | 682 | 22.9 |

| PP-40DPF-NaOH | 0.307 | 49.55 ± 0.19 | 4.35 ± 0.09 | 2.73 ± 0.2 | 17.31 | 27.4 | 650 | 23.7 |

| PP-40DPF-E | 0.291 | 52.33 ± 0.17 | 4.57 ± 0.03 | 3.08 ± 0.5 | 18.63 | 18.0 | 435 | 24.2 |

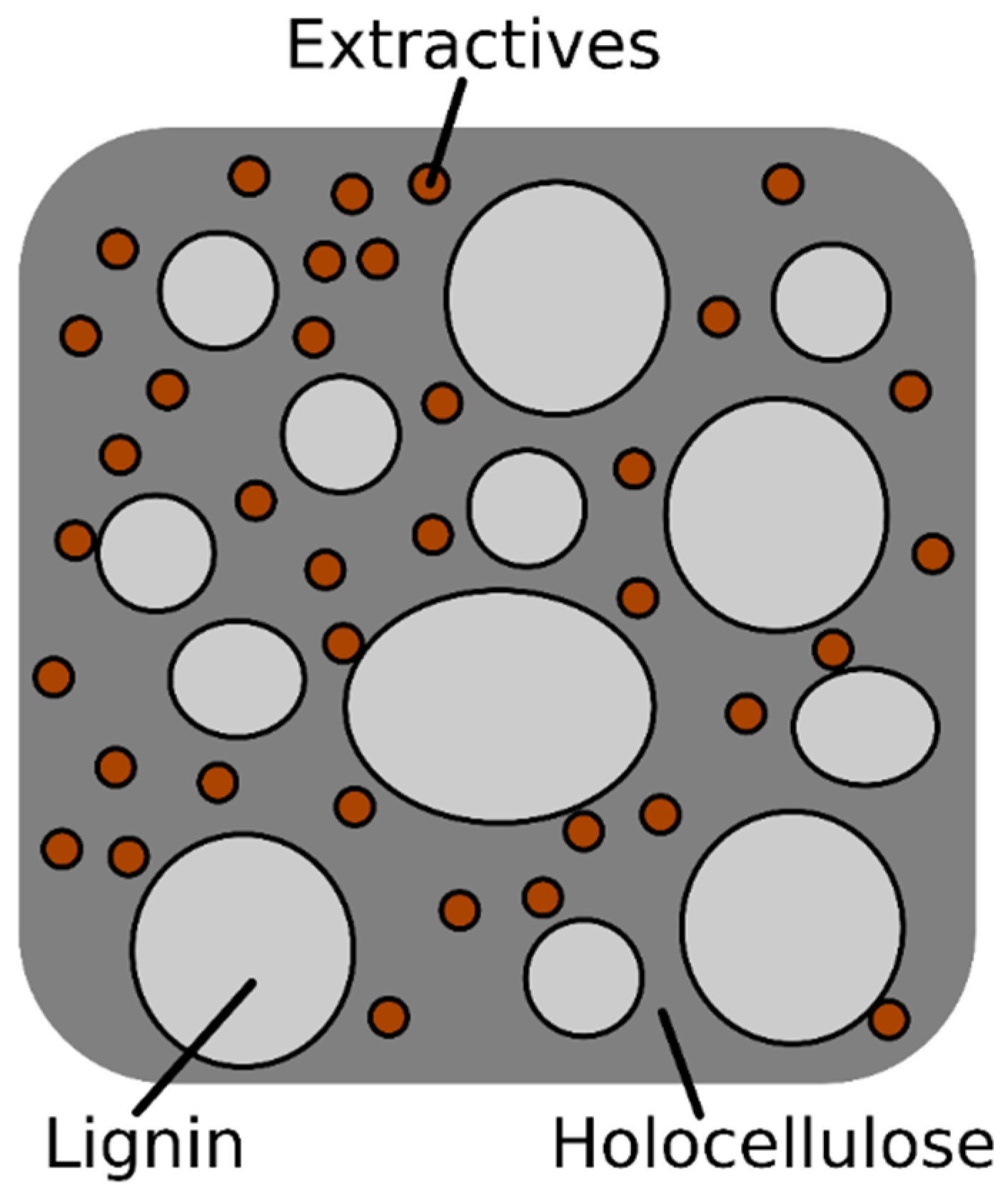

| Reinforcement | Extractives (%) | Ash (%) | Lignin (%) | Holocellulose (%) | Kappa Number |

|---|---|---|---|---|---|

| DPF-D | 2.59 ± 0.12 | 7.41 ± 0.16 | 26.50 ± 0.31 | 63.50 | 87.5 |

| DPF-NaOH | 1.98 ± 0.08 | 5.70 ± 0.24 | 24.63 ± 0.22 | 67.69 | 66.6 |

| DPF-E | 0.72 ± 0.07 | 1.97 ± 0.14 | 19.86 ± 0.17 | 77.45 | 43.9 |

| Reinforcement | (µm) | (MPa) | ||

|---|---|---|---|---|

| DPF-D | 537 | 541 | 15.01 | 0.323 |

| DPF-NaOH | 543 | 607 | 15.32 | 0.331 |

| DPF-E | 412 | 719 | 15.70 | 0.333 |

| Reinforcement | FTSF | |

|---|---|---|

| DPF-D | 112.8 | 113.6 |

| DPF-NaOH | 122.3 | 121.4 |

| DPF-E | 134 | 136.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belgacem, C.; Tarres, Q.; Espinach, F.X.; Mutjé, P.; Boufi, S.; Delgado-Aguilar, M. High-Yield Lignocellulosic Fibers from Date Palm Biomass as Reinforcement in Polypropylene Composites: Effect of Fiber Treatment on Composite Properties. Polymers 2020, 12, 1423. https://doi.org/10.3390/polym12061423

Belgacem C, Tarres Q, Espinach FX, Mutjé P, Boufi S, Delgado-Aguilar M. High-Yield Lignocellulosic Fibers from Date Palm Biomass as Reinforcement in Polypropylene Composites: Effect of Fiber Treatment on Composite Properties. Polymers. 2020; 12(6):1423. https://doi.org/10.3390/polym12061423

Chicago/Turabian StyleBelgacem, Chihaoui, Quim Tarres, Francesc Xavier Espinach, Pere Mutjé, Sami Boufi, and Marc Delgado-Aguilar. 2020. "High-Yield Lignocellulosic Fibers from Date Palm Biomass as Reinforcement in Polypropylene Composites: Effect of Fiber Treatment on Composite Properties" Polymers 12, no. 6: 1423. https://doi.org/10.3390/polym12061423

APA StyleBelgacem, C., Tarres, Q., Espinach, F. X., Mutjé, P., Boufi, S., & Delgado-Aguilar, M. (2020). High-Yield Lignocellulosic Fibers from Date Palm Biomass as Reinforcement in Polypropylene Composites: Effect of Fiber Treatment on Composite Properties. Polymers, 12(6), 1423. https://doi.org/10.3390/polym12061423