Dynamic Mussel-Inspired Chitin Nanocomposite Hydrogels for Wearable Strain Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. TA-ChNFs Preparation

2.3. Hydrogel Preparation

2.4. Hydrogel Characterization

3. Results and Discussion

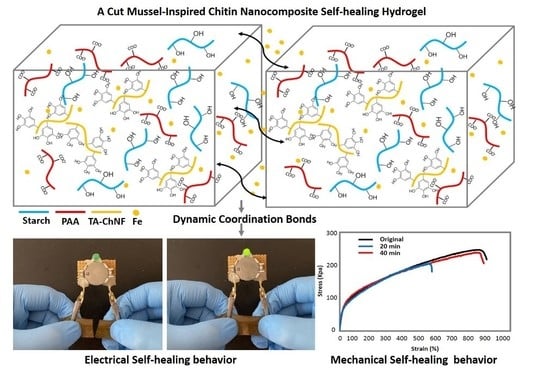

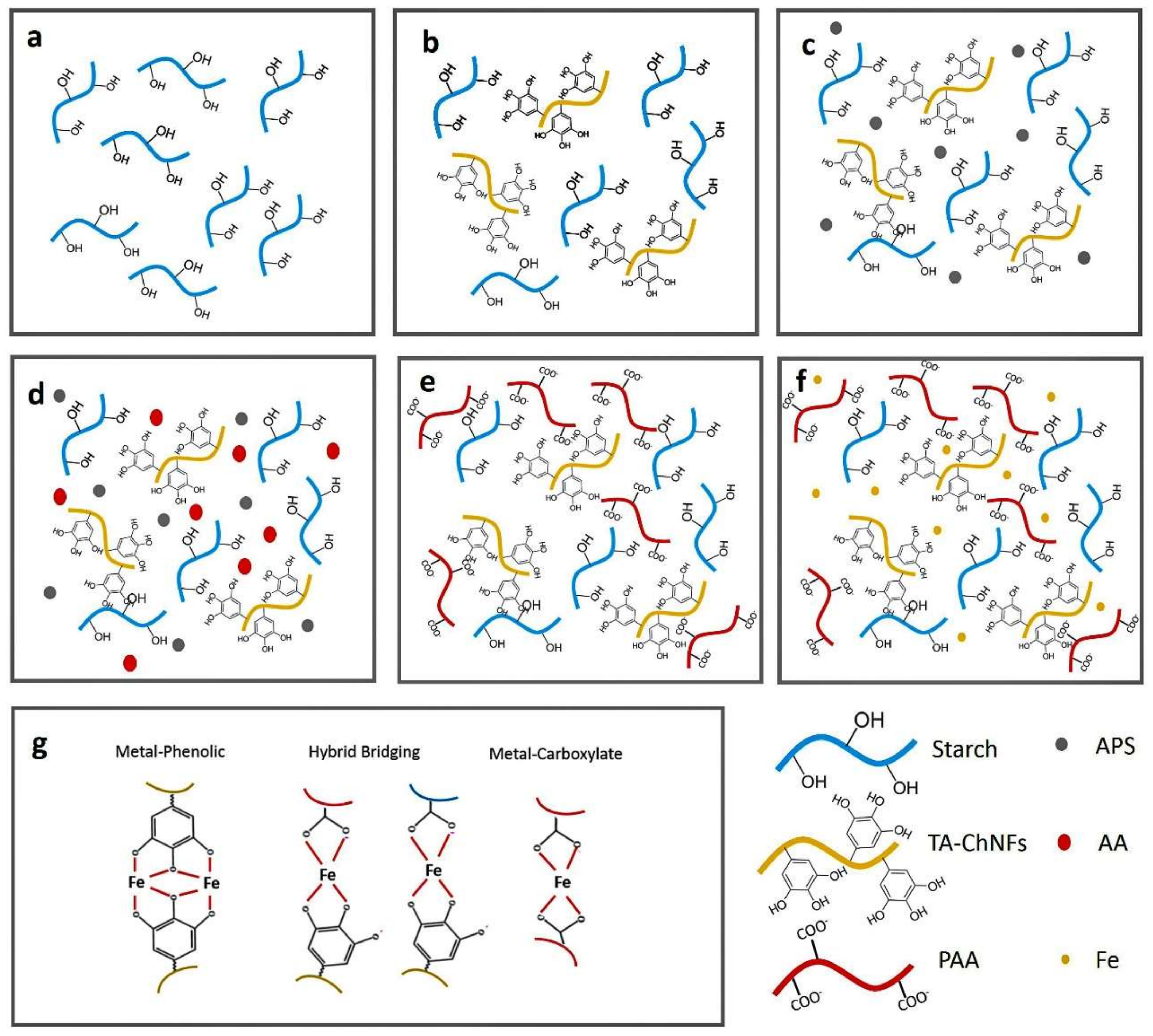

3.1. Tannic Acid Coated-Chitin Nanofiber-Assisted Hydrogels

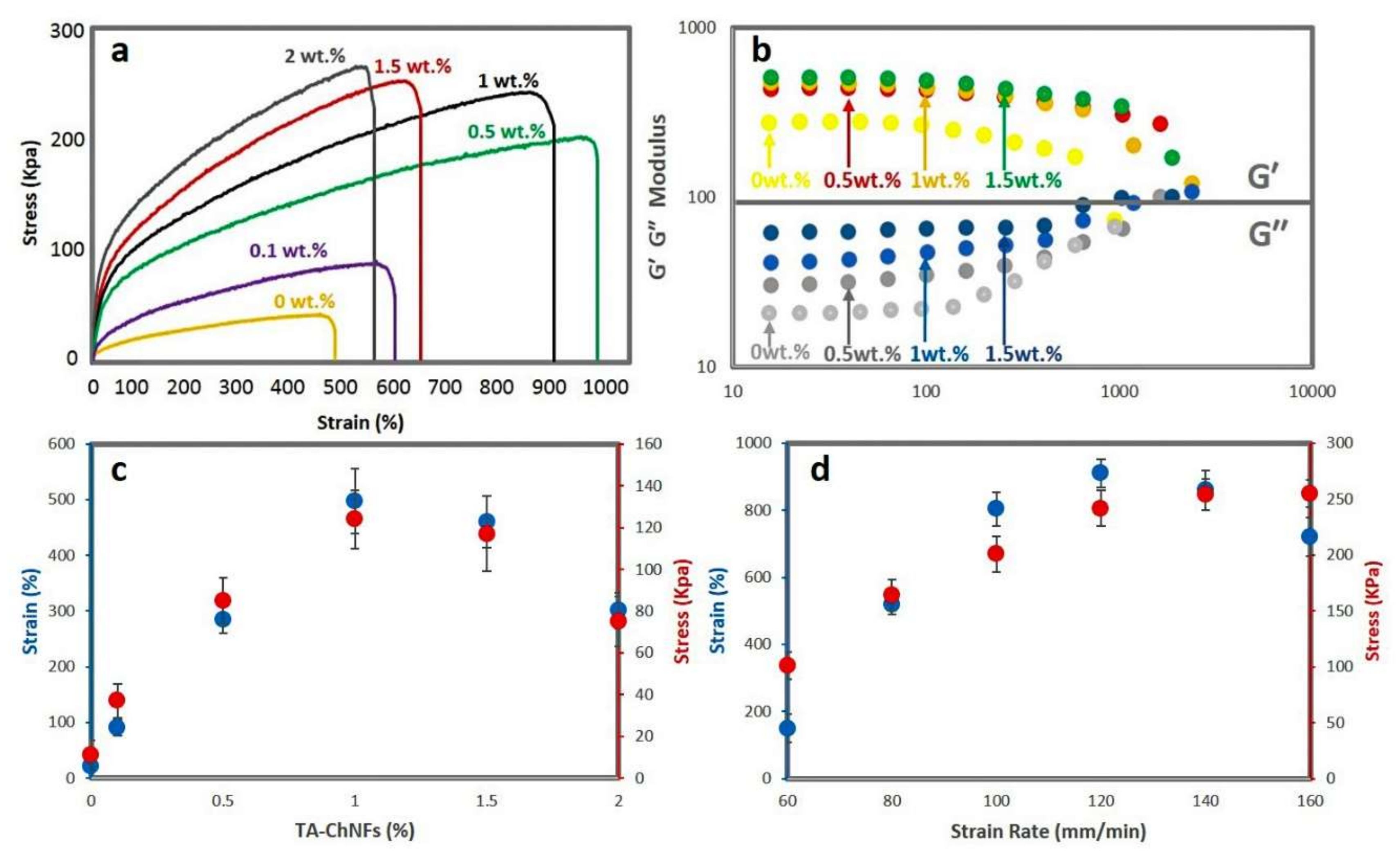

3.2. Mechanical and Rheological Properties

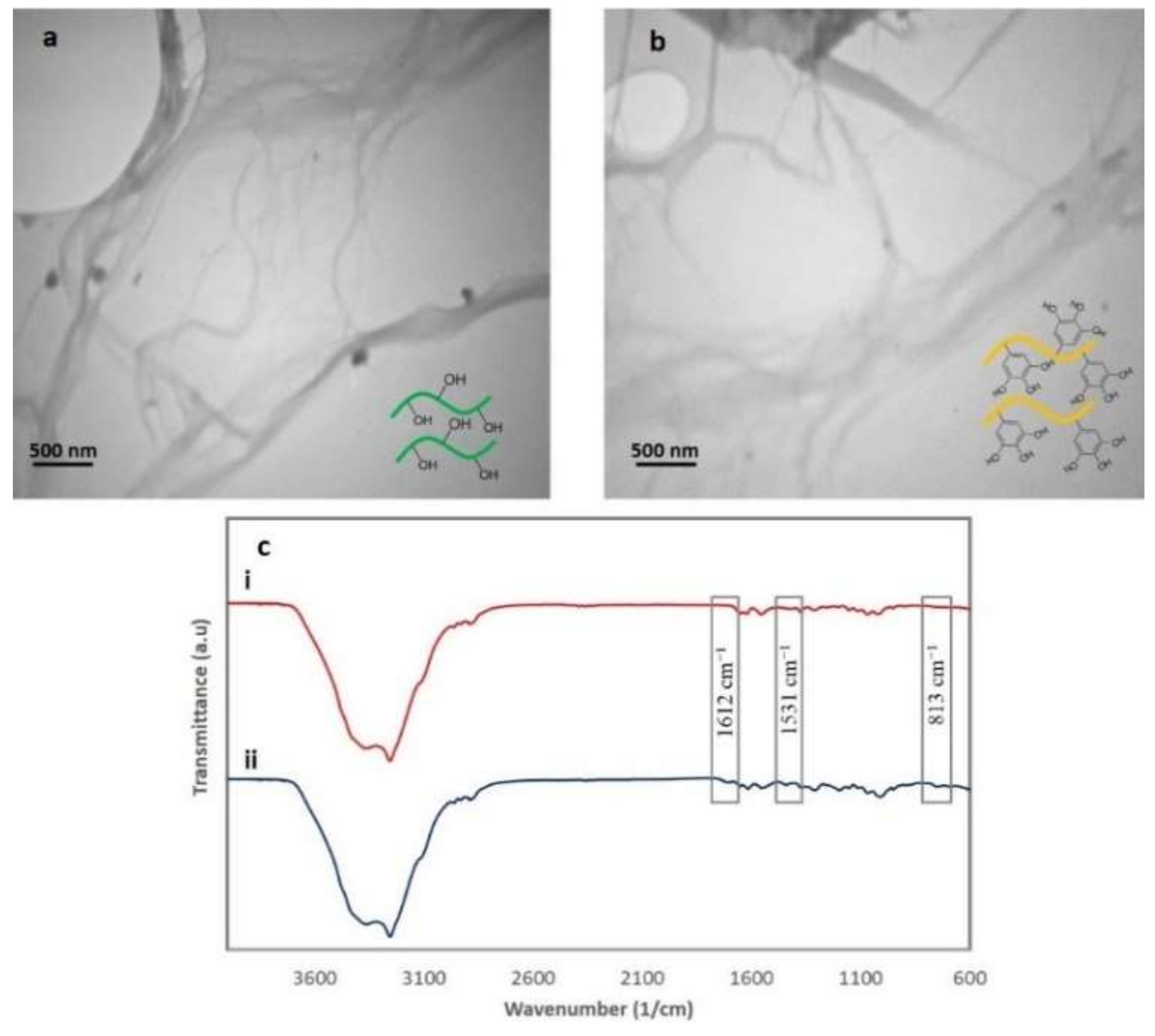

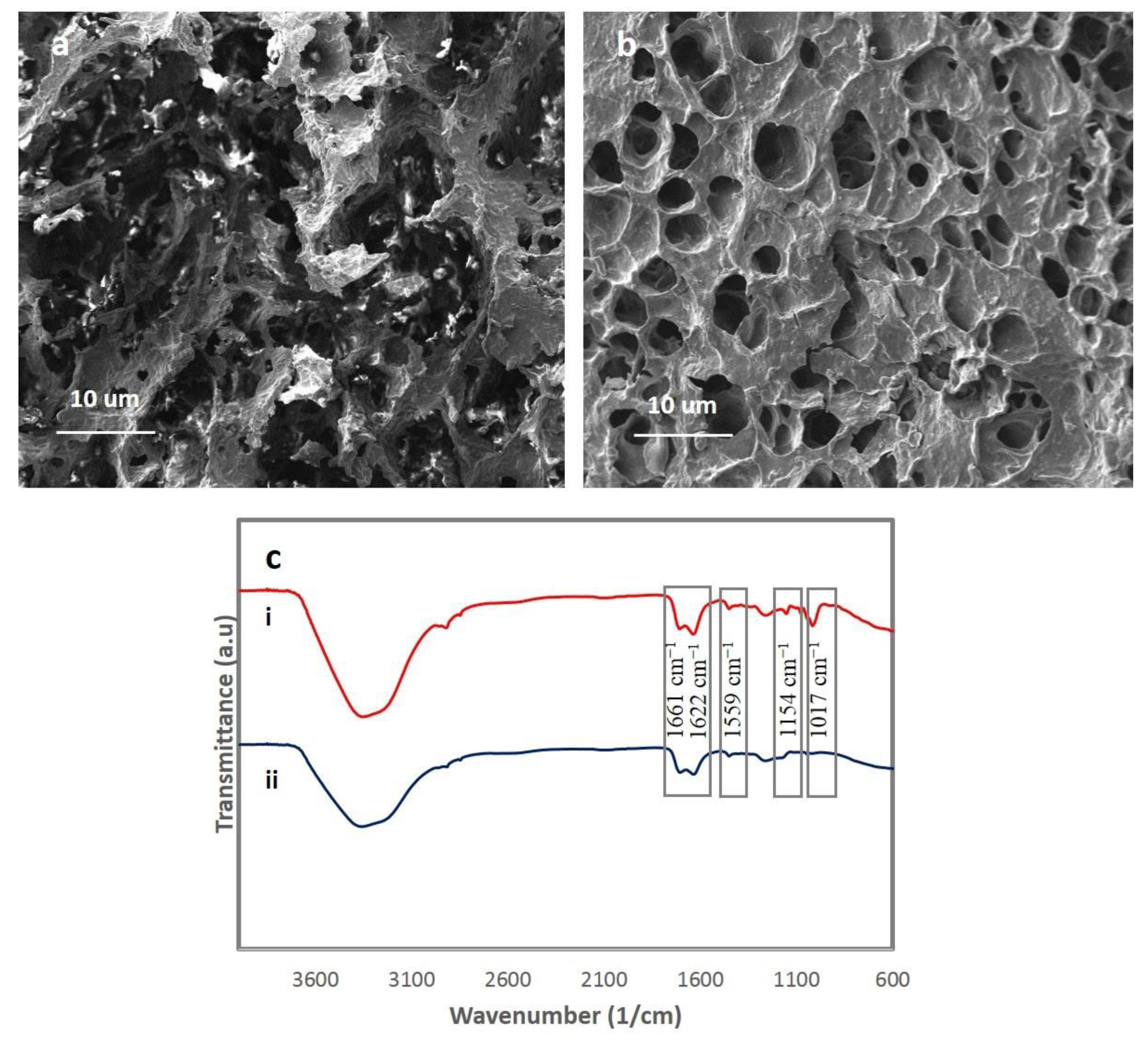

3.3. Morphological and FTIR Studies

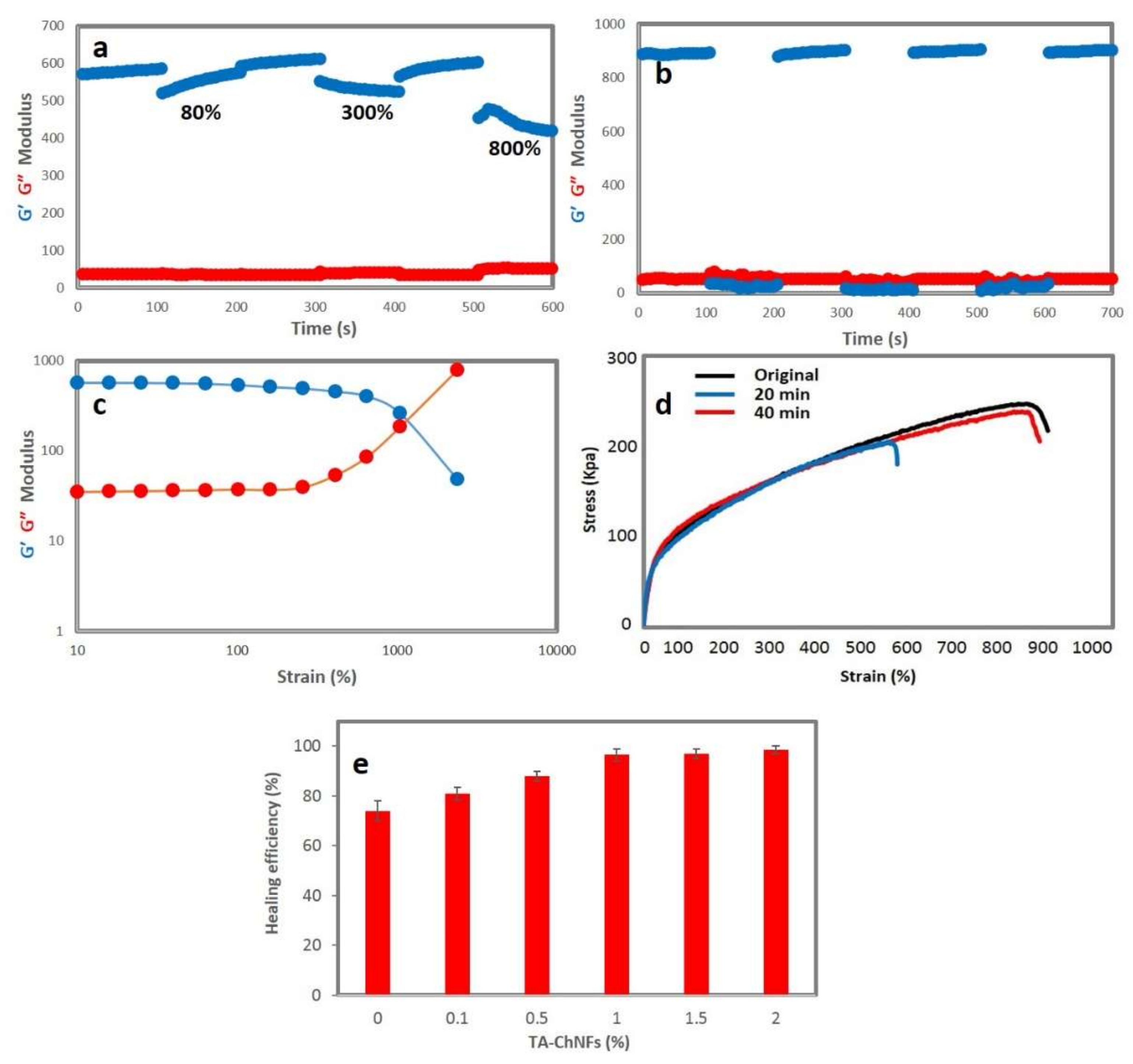

3.4. Self-Healing and Self-Recovery (SELF) Properties

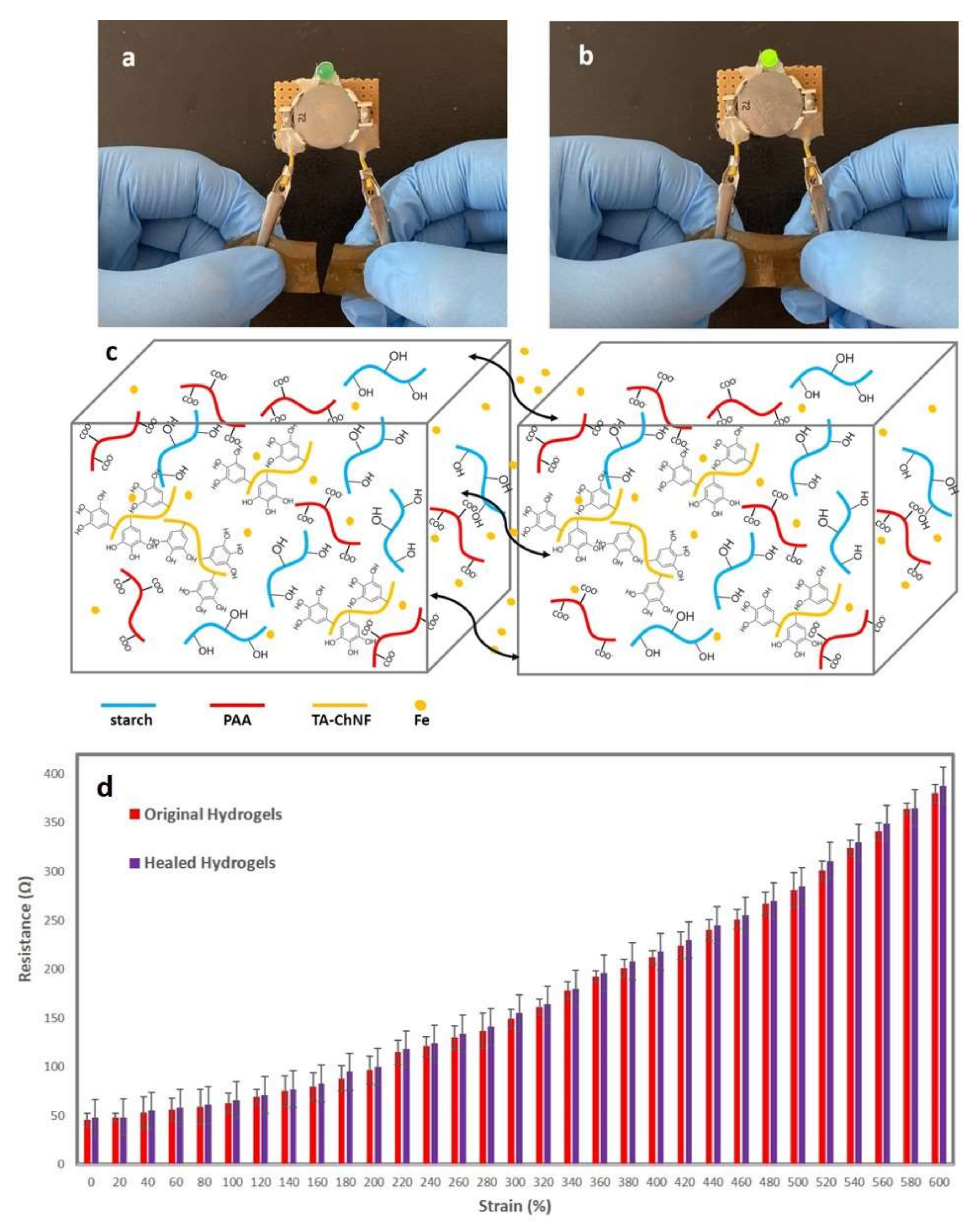

3.5. Self-Adhesiveness Properties

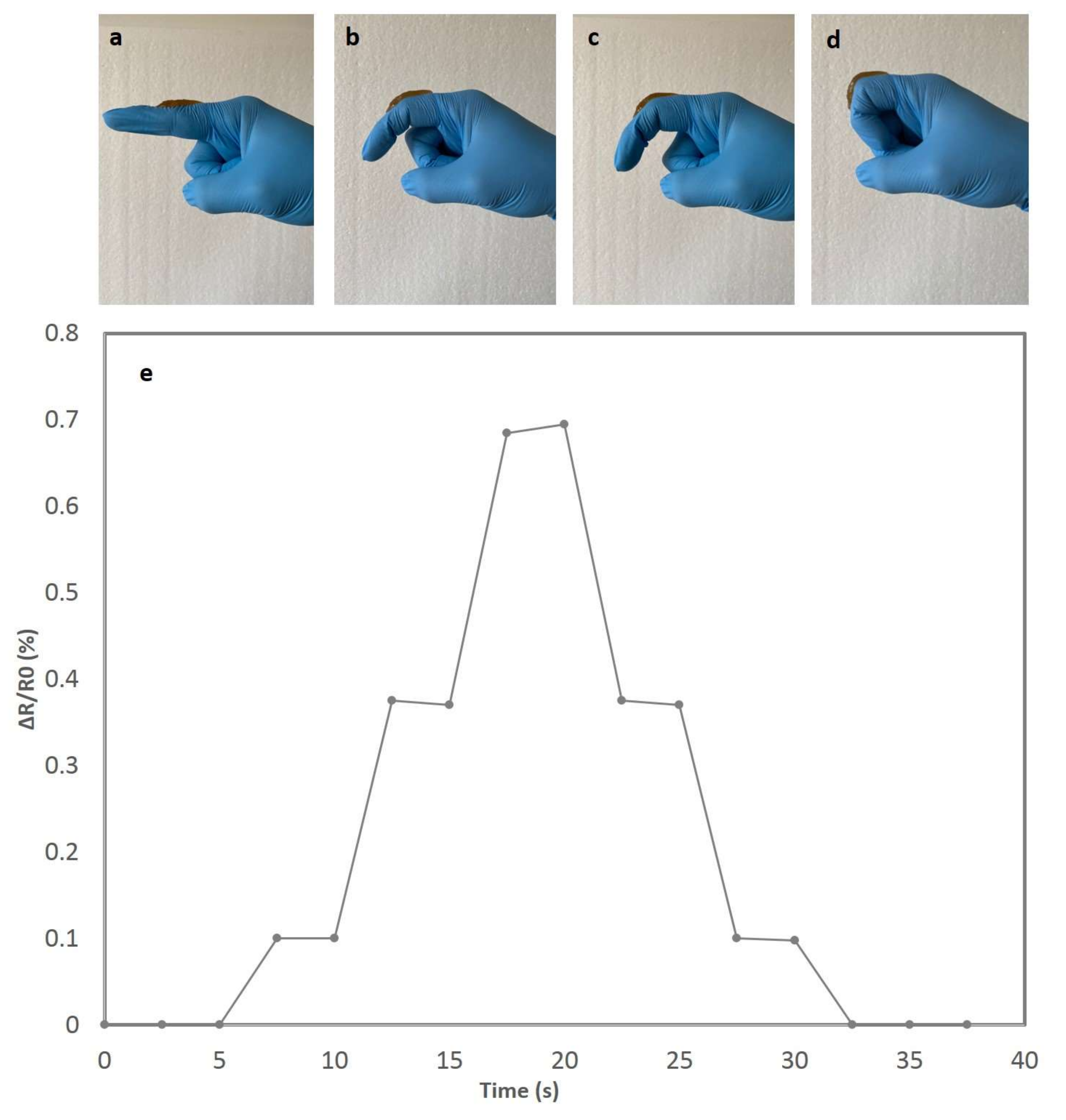

3.6. Electrical Conductivity and a Potential Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Heidarian, P.; Kouzani, A.Z.; Kaynak, A.; Paulino, M.; Nasri-Nasrabadi, B.; Zolfagharian, A.; Varley, R. Dynamic Plant-Derived Polysaccharide-Based Hydrogels. Carbohydr. Polym. 2020, 231, 115743. [Google Scholar] [CrossRef] [PubMed]

- Heidarian, P.; Kouzani, A.; Kaynak, A.; Paulino, M.; Nasri-Nasrabadi, B. Dynamic Hydrogels and Polymers as Inks for 3D Printing. ACS Biomater. Sci. Eng. 2019, 5, 2688–2707. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, H.; Ma, P.X.; Guo, B.J.N. Self-healing conductive hydrogels: Preparation, properties and applications. Nanoscale 2020, 12, 1224–1246. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.S.; Khademhosseini, A.J.S. Advances in engineering hydrogels. Science 2017, 356, eaaf3627. [Google Scholar] [CrossRef]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef]

- Nasri-Nasrabadi, B.; Kaynak, A.; Heidarian, P.; Komeily-Nia, Z.; Mehrasa, M.; Salehi, H.; Kouzani, A. Sodium alginate/magnesium oxide nanocomposite scaffolds for bone tissue engineering. Polym. Adv. Technol. 2018, 29, 2553–2559. [Google Scholar] [CrossRef]

- Basu, A.; Lindh, J.; Ålander, E.; Strømme, M.; Ferraz, N. On the use of ion-crosslinked nanocellulose hydrogels for wound healing solutions: Physicochemical properties and application-oriented biocompatibility studies. Carbohydr. Polym. 2017, 174, 299–308. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Nasri-Nasrabadi, B.; Kaynak, A. Development and analysis of a 3D printed hydrogel soft actuator. Sens. Actuators Phys. 2017, 265, 94–101. [Google Scholar] [CrossRef]

- Taylor, D.L.; in het Panhuis, M.J.A.M. Self-healing hydrogels. Adv. Mater. 2016, 28, 9060–9093. [Google Scholar] [CrossRef]

- Kowalski, P.S.; Bhattacharya, C.; Afewerki, S.; Langer, R. Smart biomaterials: Recent advances and future directions. ACS Biomater. Sci. Eng. 2018, 4, 3809–3817. [Google Scholar] [CrossRef]

- Ge, W.; Cao, S.; Shen, F.; Wang, Y.; Ren, J.; Wang, X. Rapid self-healing, stretchable, moldable, antioxidant and antibacterial tannic acid-cellulose nanofibril composite hydrogels. Carbohydr. Polym. 2019, 224, 115147. [Google Scholar] [CrossRef] [PubMed]

- Nadgorny, M.; Ameli, A. Functional polymers and nanocomposites for 3D printing of smart structures and devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Wang, J.; Qiu, C.; Xu, X.; Jin, Z. Dual Cross-Linked Strategy to Construct Moldable Hydrogels with High Stretchability, Good Self-Recovery, and Self-Healing Capability. J. Agric. Food Chem. 2019, 67, 3966–3980. [Google Scholar] [CrossRef]

- Wu, X.; Wang, J.; Huang, J.; Yang, S. Robust, stretchable, and self-healable supramolecular elastomers synergistically cross-linked by hydrogen bonds and coordination bonds. ACS Appl. Mater. Interfaces 2019, 11, 7387–7396. [Google Scholar] [CrossRef] [PubMed]

- Shao, C.; Meng, L.; Wang, M.; Cui, C.; Wang, B.; Han, C.-R.; Xu, F.; Yang, J. Mimicking dynamic adhesiveness and strain-stiffening behavior of biological tissues in tough and self-healable cellulose nanocomposite hydrogels. ACS Appl. Mater. Interfaces 2019, 11, 5885–5895. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhang, M.; Huang, L.; Li, Y.; Chen, J.; Li, C.; Shi, G. High-quality graphene ribbons prepared from graphene oxide hydrogels and their application for strain sensors. ACS Nano 2015, 9, 12320–12326. [Google Scholar] [CrossRef] [PubMed]

- Zhong, M.; Liu, Y.-T.; Xie, X. Self-healable, super tough graphene oxide–poly (acrylic acid) nanocomposite hydrogels facilitated by dual cross-linking effects through dynamic ionic interactions. J. Matter. Chem. B 2015, 3, 4001–4008. [Google Scholar] [CrossRef]

- Shao, C.; Wang, M.; Meng, L.; Chang, H.; Wang, B.; Xu, F.; Yang, J.; Wan, P. Mussel-inspired cellulose nanocomposite tough hydrogels with synergistic self-healing, adhesive, and strain-sensitive properties. Chem. Mater. 2018, 30, 3110–3121. [Google Scholar] [CrossRef]

- Jayakumar, R.; Nwe, N.; Tokura, S.; Tamura, H. Sulfated chitin and chitosan as novel biomaterials. Int. J. Biol. Macromol. 2007, 40, 175–181. [Google Scholar] [CrossRef]

- Dutta, P.K.; Dutta, J.; Tripathi, V. Chitin and chitosan: Chemistry, properties and applications. J. Sci. Ind. Res. 2004, 63, 20–31. [Google Scholar]

- Hejazi, M.; Behzad, T.; Heidarian, P.; Nasri-Nasrabadi, B. A study of the effects of acid, plasticizer, cross-linker, and extracted chitin nanofibers on the properties of chitosan biofilm. Compos. Part A-Appl. 2018, 109, 221–231. [Google Scholar] [CrossRef]

- Mohammadinejad, R.; Maleki, H.; Larrañeta, E.; Fajardo, A.R.; Nik, A.B.; Shavandi, A.; Sheikhi, A.; Ghorbanpour, M.; Farokhi, M.; Govindh, P. Status and future scope of plant-based green hydrogels in biomedical engineering. Appl. Mater. Today 2019, 16, 213–246. [Google Scholar] [CrossRef]

- Heidarian, P.; Kouzani, A.Z.; Kaynak, A.; Paulino, M.; Nasri-Nasrabadi, B.; Varley, R. Double dynamic cellulose nanocomposite hydrogels with environmentally adaptive self-healing and pH-tuning properties. Cellulose 2019, 27, 1407–1422. [Google Scholar] [CrossRef]

- Shen, X.; Nie, K.; Zheng, L.; Wang, Z.; Wang, Z.; Li, S.; Jin, C.; Sun, Q. Muscle-inspired capacitive tactile sensors with superior sensitivity in an ultra-wide stress range. J. Mater. Chem. C. 2020, 8, 5913–5922. [Google Scholar] [CrossRef]

- Chen, H.; Gao, Y.; Ren, X.; Gao, G. Alginate fiber toughened gels similar to skin intelligence as ionic sensors. Carbohydr. Polym. 2020, 235, 116018. [Google Scholar] [CrossRef]

- Hussain, I.; Sayed, S.M.; Liu, S.; Oderinde, O.; Yao, F.; Fu, G. Glycogen-based self-healing hydrogels with ultra-stretchable, flexible, and enhanced mechanical properties via sacrificial bond interactions. Int. J. Biol. Macromol. 2018, 117, 648–658. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Wang, J.; Jin, Z. Tough, Swelling-Resistant, Self-Healing, and Adhesive Dual-Cross-Linked Hydrogels Based on Polymer–Tannic Acid Multiple Hydrogen Bonds. Manromolecules 2018, 51, 1696–1705. [Google Scholar] [CrossRef]

- Heidarian, P.; Behzad, T.; Sadeghi, M. Investigation of cross-linked PVA/starch biocomposites reinforced by cellulose nanofibrils isolated from aspen wood sawdust. Cellulose 2017, 24, 3323–3339. [Google Scholar] [CrossRef]

- Ifuku, S.; Iwasaki, M.; Morimoto, M.; Saimoto, H. Graft polymerization of acrylic acid onto chitin nanofiber to improve dispersibility in basic water. Carbohydr. Polym. 2012, 90, 623–627. [Google Scholar] [CrossRef]

- Li, Q.; Liu, C.; Wen, J.; Wu, Y.; Shan, Y.; Liao, J. The design, mechanism and biomedical application of self-healing hydrogels. Chin. Chem. Lett. 2017, 28, 1857–1874. [Google Scholar] [CrossRef]

- Zhao, H.; An, H.; Xi, B.; Yang, Y.; Qin, J.; Wang, Y.; He, Y.; Wang, X. Self-healing hydrogels with both LCST and UCST through cross-linking induced thermo-response. Polymers 2019, 11, 490. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Wang, J.; Zhang, Q.; Jin, Z. Tannic acid-based multifunctional hydrogels with facile adjustable adhesion and cohesion contributed by polyphenol supramolecular chemistry. ACS Omega 2017, 2, 6668–6676. [Google Scholar] [CrossRef] [PubMed]

- Sahiner, N.; Butun Sengel, S.; Yildiz, M.J.J.o.C.C. A facile preparation of donut-like supramolecular tannic acid-Fe (III) composite as biomaterials with magnetic, conductive, and antioxidant properties. J. Coord. Chem. 2017, 70, 3619–3632. [Google Scholar] [CrossRef]

| Code | TA-ChNFs (wt.%) | TA-ChNFs (mg) | AA (g) | St (g) | APS (mg) | Water (cc) |

|---|---|---|---|---|---|---|

| St/PAA | 0 | 0 | 4 | 2 | 50 | 24 |

| St/PAA/TA-ChNF (0.1%) | 0.1 | 6 | 4 | 2 | 50 | 24 |

| St/PAA/TA-ChNF (0.5%) | 0.5 | 30 | 4 | 2 | 50 | 24 |

| St/PAA/TA-ChNF (1%) | 1 | 60 | 4 | 2 | 50 | 24 |

| St/PAA/TA-ChNF (1.5%) | 1.5 | 90 | 4 | 2 | 50 | 24 |

| St/PAA/TA-ChNF (2%) | 2 | 120 | 4 | 2 | 50 | 24 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidarian, P.; Kouzani, A.Z.; Kaynak, A.; Zolfagharian, A.; Yousefi, H. Dynamic Mussel-Inspired Chitin Nanocomposite Hydrogels for Wearable Strain Sensors. Polymers 2020, 12, 1416. https://doi.org/10.3390/polym12061416

Heidarian P, Kouzani AZ, Kaynak A, Zolfagharian A, Yousefi H. Dynamic Mussel-Inspired Chitin Nanocomposite Hydrogels for Wearable Strain Sensors. Polymers. 2020; 12(6):1416. https://doi.org/10.3390/polym12061416

Chicago/Turabian StyleHeidarian, Pejman, Abbas Z. Kouzani, Akif Kaynak, Ali Zolfagharian, and Hossein Yousefi. 2020. "Dynamic Mussel-Inspired Chitin Nanocomposite Hydrogels for Wearable Strain Sensors" Polymers 12, no. 6: 1416. https://doi.org/10.3390/polym12061416

APA StyleHeidarian, P., Kouzani, A. Z., Kaynak, A., Zolfagharian, A., & Yousefi, H. (2020). Dynamic Mussel-Inspired Chitin Nanocomposite Hydrogels for Wearable Strain Sensors. Polymers, 12(6), 1416. https://doi.org/10.3390/polym12061416