Molecular Dynamics Simulation on the Interfacial Behavior of Over-Molded Hybrid Fiber Reinforced Thermoplastic Composites

Abstract

1. Introduction

2. Simulation Model and Methodology

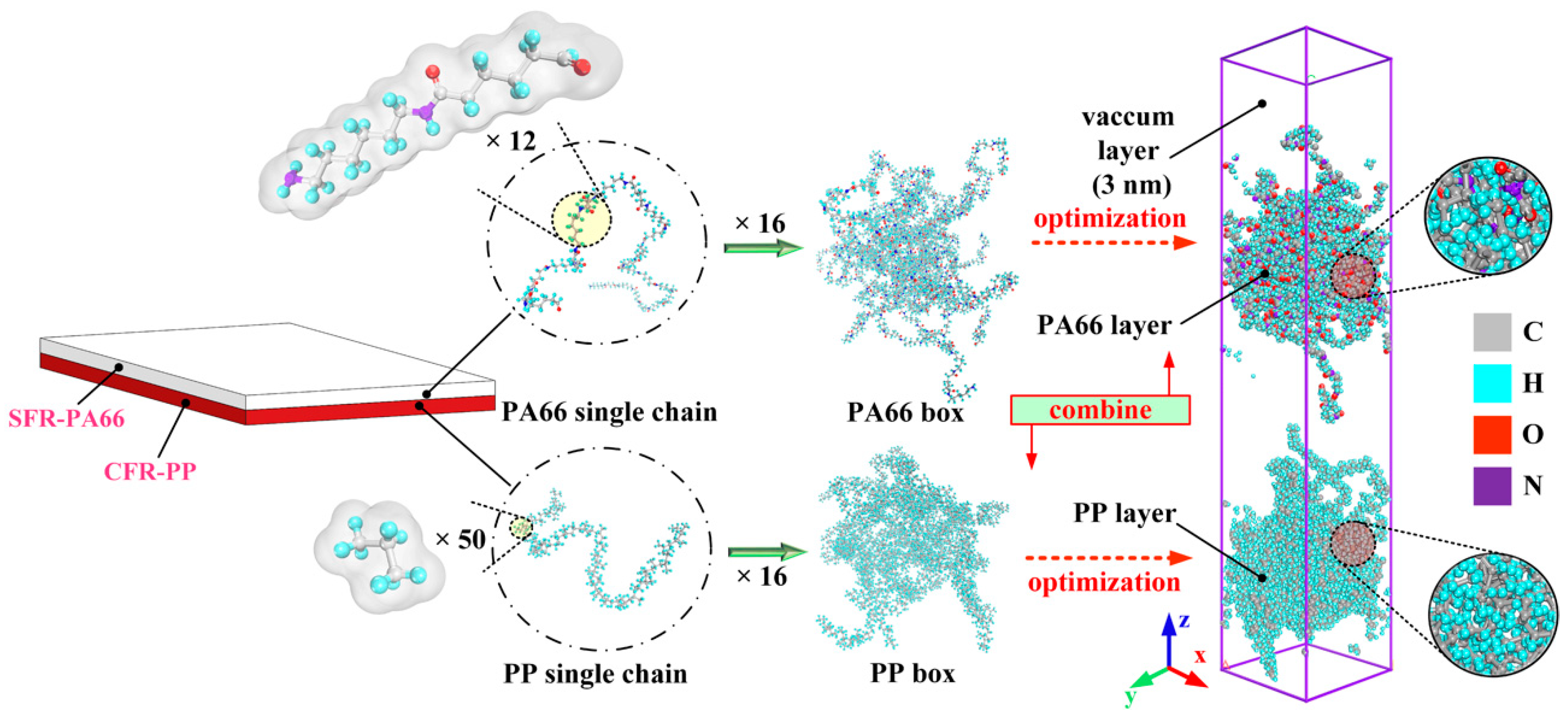

2.1. Model Construction

2.2. Simulation Procedure

3. Results and Discussion

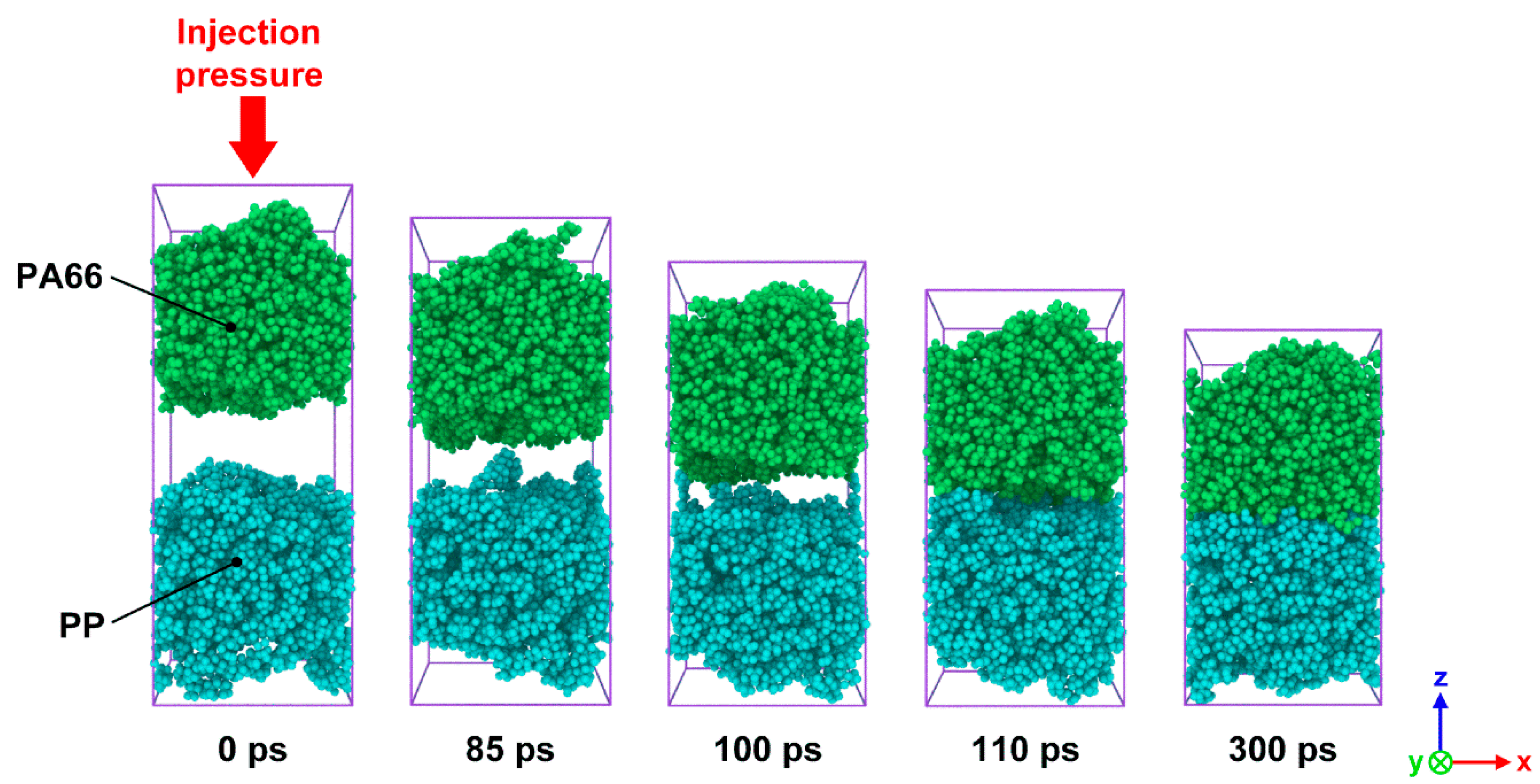

3.1. PA66–PP Interface Forming Process

3.2. Effect of Processing Parameters on Bonding Behavior

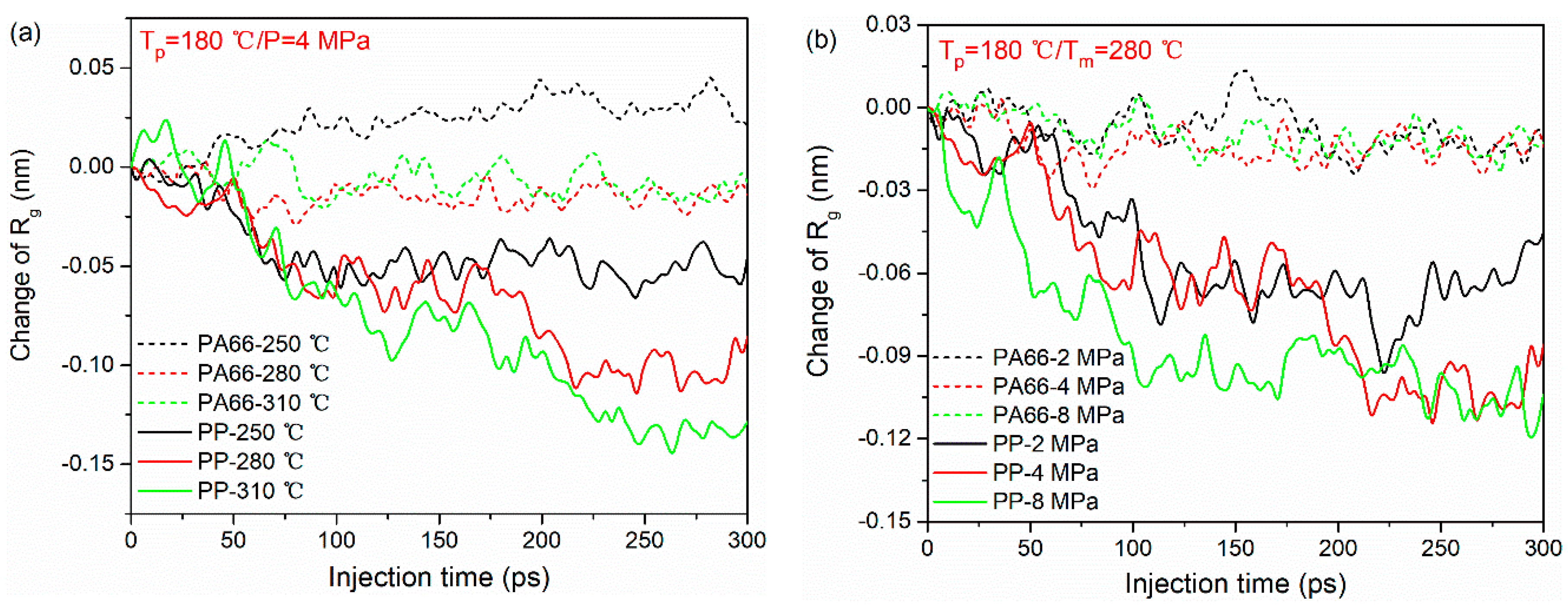

3.2.1. Radius of Gyration

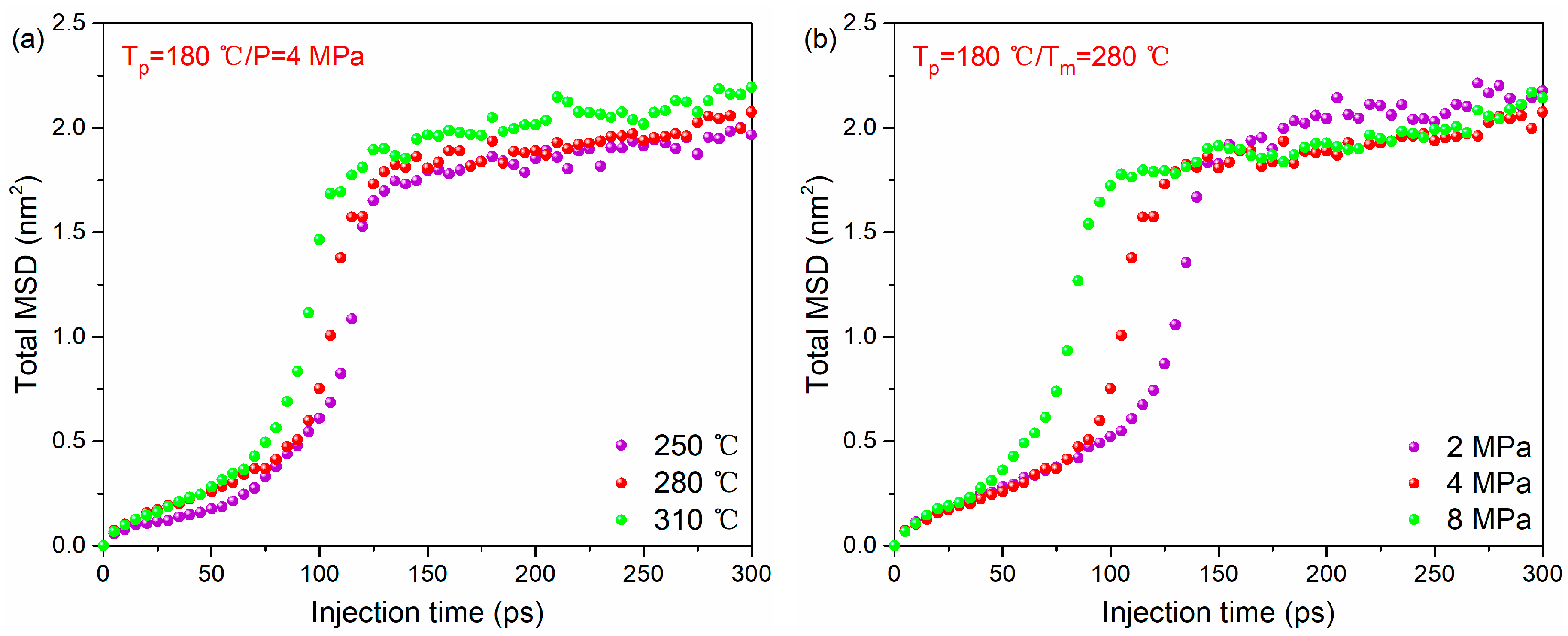

3.2.2. Interfacial Bonding Energy and Diffusion Coefficient

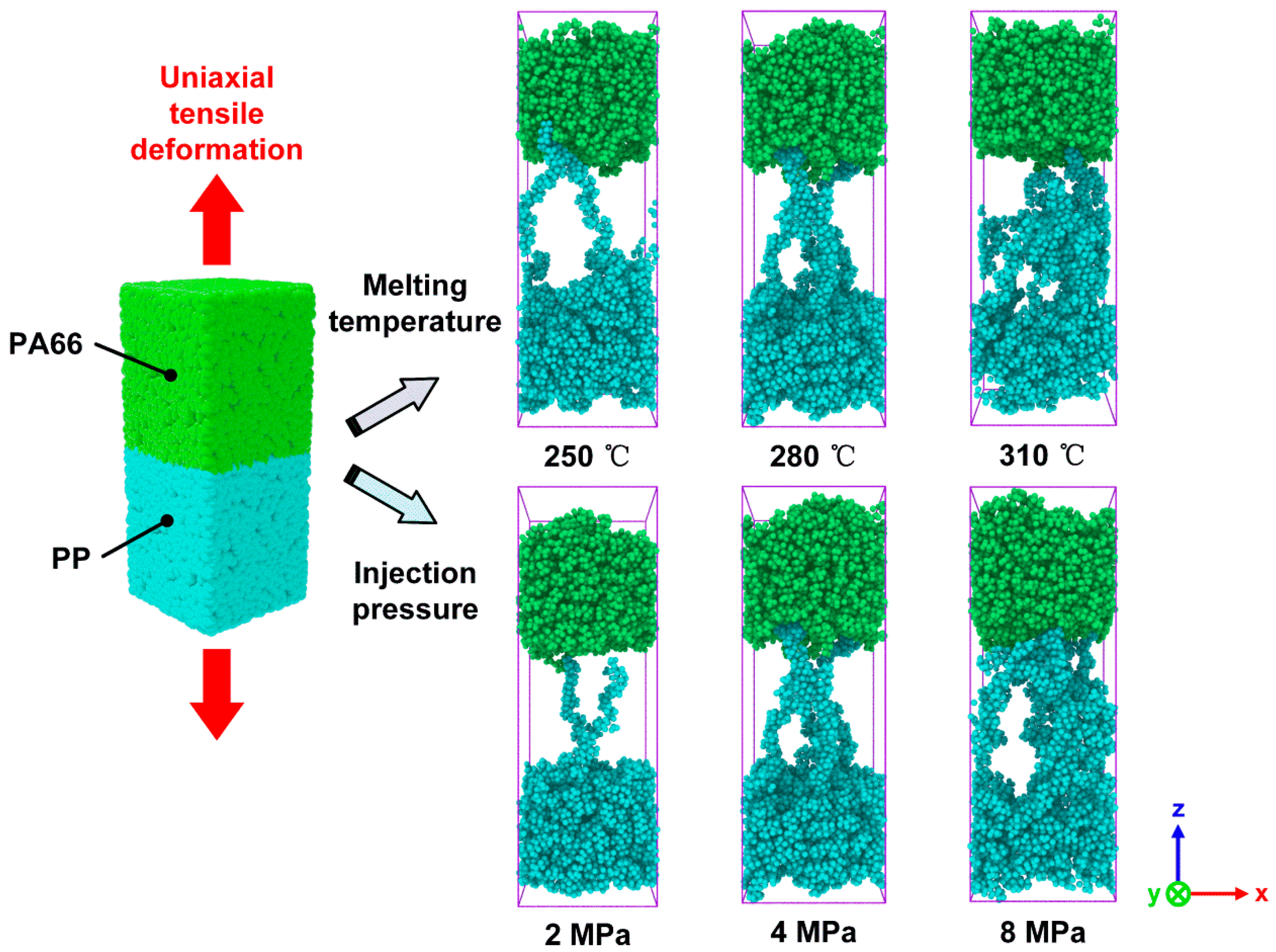

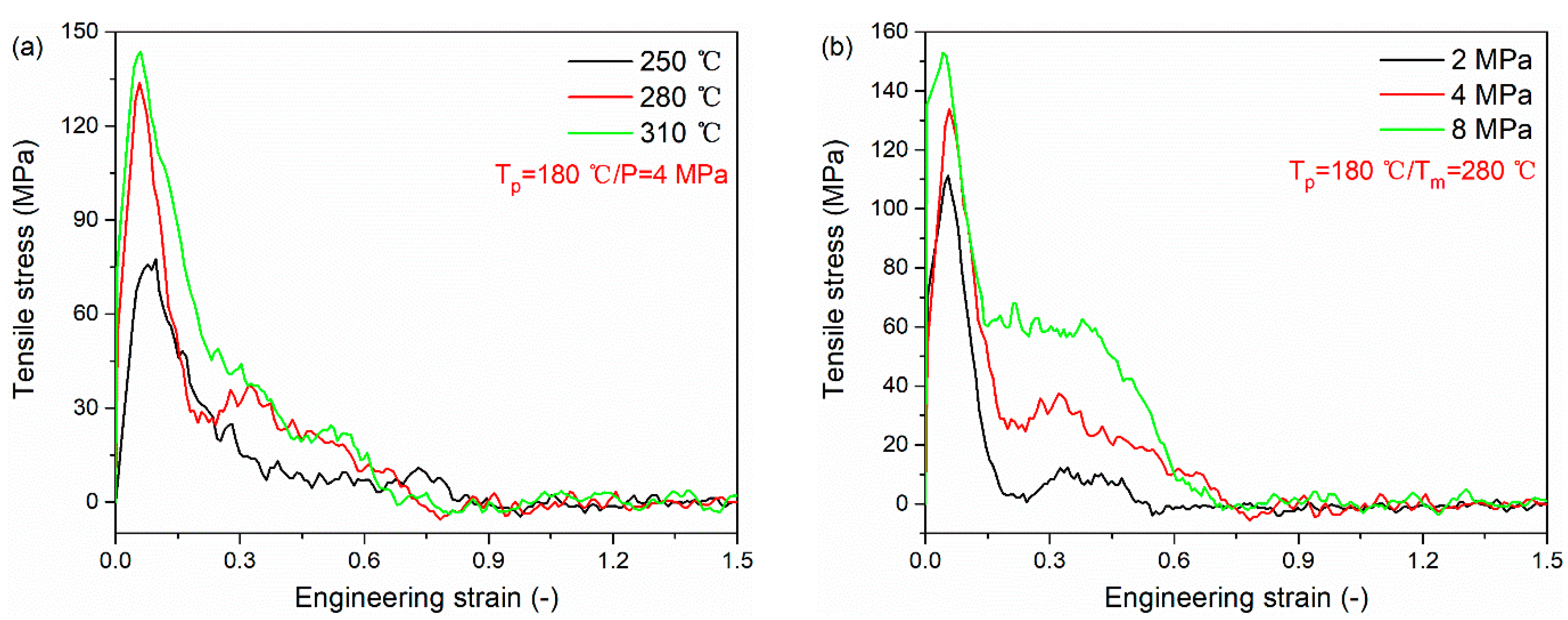

3.3. Unixial Tensile Deformation Process

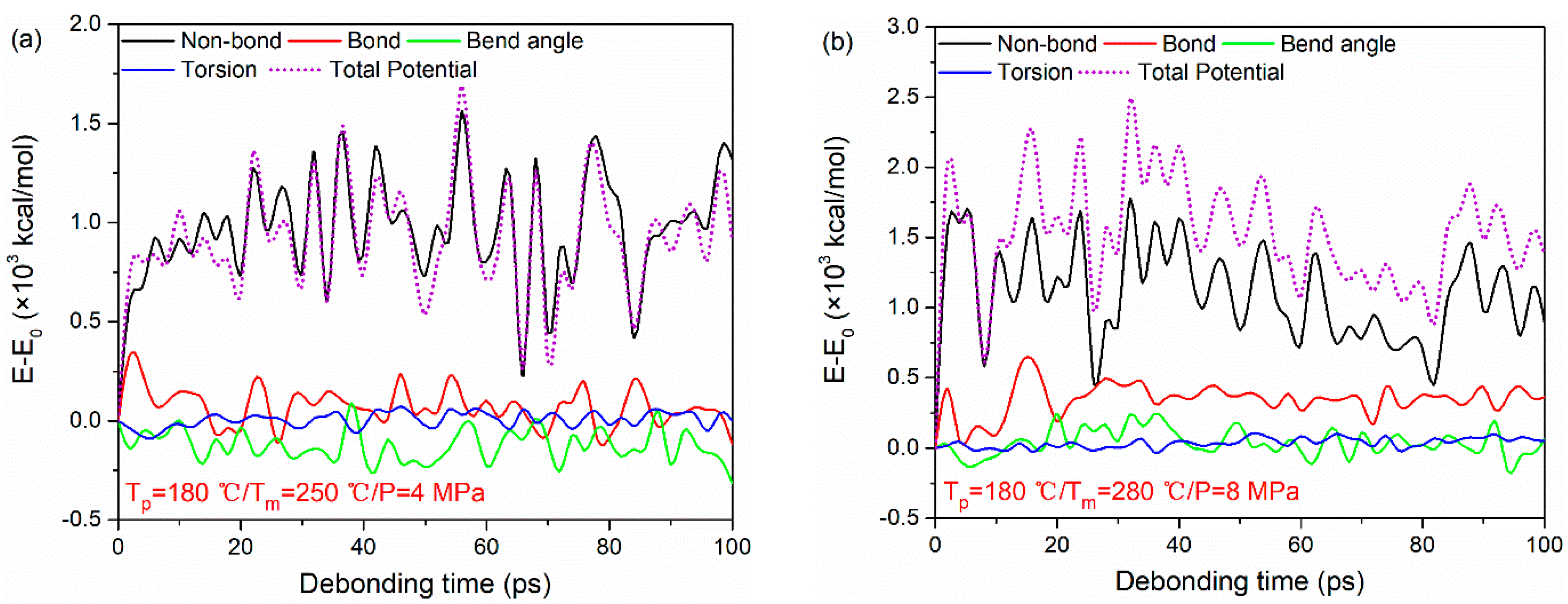

3.4. Sliding Deformation Process

4. Conclusions

- (1)

- During TCO process, the molecules from both PA66 and PP layers gradually accumulated near the final interface. A few molecules get across the interface, and tangle with the molecules from the other layer. Thus, it can be concluded that the interfacial bonding mechanism of hybrid composites is caused by molecules diffusion.

- (2)

- Both melting temperature and injection pressure have a positive effect on the interfacial properties of PA66–PP interface. The diffusion coefficient and interfacial bonding energy of interface increase with the melting temperature and the injection pressure. Thus, a higher melting temperature and injection pressure lead to a higher tensile stress. While, the shear stress does not exhibit an obvious increase with increasing melting temperature because of the loss of orientation of polymer chains at high temperatures.

- (3)

- Tensile failure modes of PA66–PP system are composed of adhesive failure and cohesive failure. The diffusion of polymer molecules is directly related to the interfacial failure. At higher melting temperature, more damage events in PP layers can be found because of strong interface. With increasing injection pressure, the failure mode changes from the adhesive failure to the mixing mode of adhesive and cohesive failures. The non-bonded interaction energy plays a crucial role during the tensile and sliding deformations of the PA66–PP interface.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valverde, M.A.; Kupfer, R.; Kawashita, L.; Gude, M.; Hallett, S. Influence of geometry on component quality and properties in overmoulded thermoplastic composite parts. In Proceedings of the 14th International Conference on Flow Processing in Composite Materials, Norrbottena Lan, Sweden, 30 May–1 June 2018. [Google Scholar]

- Matsumoto, K.; Ishikawa, T.; Tanaka, T. A novel joining method by using carbon nanotube-based thermoplastic film for injection over-molding process. J. Reinf. Plast. Compos. 2019, 38, 616–627. [Google Scholar] [CrossRef]

- Sealy, C. Molding the future: ENGEL takes composite approach to composites. Reinf. Plast. 2016, 60, 138–141. [Google Scholar] [CrossRef]

- Cetin, M.; Herrmann, C.; Fenske, S. Automation concepts for manufacturing fibre-reinforced thermoplastic components. Lightweight Des. Worldw. 2017, 10, 30–35. [Google Scholar] [CrossRef][Green Version]

- Harte, A.M.; Mc Namara, J.F. Overinjection of thermoplastic composites: I. Processing and testing of components. J. Mater. Process. Technol. 2007, 182, 12–20. [Google Scholar] [CrossRef]

- Tanaka, K.; Fujita, Y.; Katayama, T. Press and injection hybrid molding of glass fiber reinforced thermoplastics. Mater. Charact. 2015, 90, 225–232. [Google Scholar] [CrossRef]

- Fiorotto, M.; Lucchetta, G. Experimental investigation of a new hybrid molding process to manufacture high-performance composites. Int. J. Mater. Form. 2011, 6, 179–185. [Google Scholar] [CrossRef]

- Joppich, T.; Menrath, A.; Henning, F. Advanced molds and methods for the fundamental analysis of process induced interface bonding properties of hybrid, thermoplastic composites. Procedia CIRP 2017, 66, 137–142. [Google Scholar] [CrossRef]

- Iwasaki, T. Molecular dynamics study of diffusion and atomic configuration in layered structures for Al circuit interconnects. Comput. Mech. 1999, 24, 148–154. [Google Scholar] [CrossRef]

- Iwasaki, T.; Miura, H. Molecular dynamics analysis of adhesion strength of interfaces between thin films. J. Mater. Res. 2001, 16, 1789–1794. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Interfacial interaction and joining property of direct injection-molded polymer-metal hybrid structures: A molecular dynamics simulation study. Appl. Surf. Sci. 2019, 478, 680–689. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation and experimental investigation of the geometrical morphology development of injection-molded nanopillars on polymethylmethacrylate surface. Comput. Mater. Sci. 2018, 149, 208–216. [Google Scholar] [CrossRef]

- Wong, C.K.Y.; Leung, S.Y.Y.; Poelma, R.H.; Jansen, K.; Yuan, C.C.A.; Van Driel, W.D.; Zhang, G.Q. Molecular dynamics study of the traction-displacement relations of epoxy-copper interfaces. In Proceedings of the 2010 11th International Thermal, Mechanical & Multi-Physics Simulation, and Experiments in Microelectronics and Microsystems, Linz, Austria, 18–20 April 2011; pp. 1/5–5/5. [Google Scholar] [CrossRef]

- Cheng, C.-Y.; Lee, K.-J.; Li, Y.; Wang, B.-C. Molecular dynamics simulation of polymers adsorbed onto an alumina surface. J. Adhes. Sci. Technol. 1998, 12, 695–712. [Google Scholar] [CrossRef]

- Zhang, X.; Du, L.; Xu, Z. The effect of soft bake on adhesion property between SU-8 photoresist and Ni substrate by molecular dynamics simulation. J. Appl. Polym. Sci. 2012, 127, 4456–4462. [Google Scholar] [CrossRef]

- Liu, D.; Pourrahimi, A.; Olsson, R.; Hedenqvist, M.; Gedde, U.W. Influence of nanoparticle surface treatment on particle dispersion and interfacial adhesion in low-density polyethylene/aluminium oxide nanocomposites. Eur. Polym. J. 2015, 66, 67–77. [Google Scholar] [CrossRef]

- Bedair, T.M.; Cho, Y.; Kim, T.J.; Kim, Y.-D.; Park, B.J.; Joung, Y.K.; Han, D.K. Reinforcement of interfacial adhesion of a coated polymer layer on a cobalt–chromium surface for drug-eluting stents. Langmuir 2014, 30, 8020–8028. [Google Scholar] [CrossRef]

- Iwasaki, T. Molecular dynamics study on the effect of lattice mismatch on adhesion strength between ceramics and organic materials. J. Soc. Mater. Sci. Jpn. 2010, 59, 165–170. [Google Scholar] [CrossRef][Green Version]

- Wei, Q.; Wang, Y.; Chai, W.; Zhang, Y.; Chen, X. Molecular dynamics simulation and experimental study of the bonding properties of polymer binders in 3D powder printed hydroxyapatite bioceramic bone scaffolds. Ceram. Int. 2017, 43, 13702–13709. [Google Scholar] [CrossRef]

- Niuchi, T.; Koyanagi, J.; Inoue, R.; Kogo, Y. Molecular dynamics study of the interfacial strength between carbon fiber and phenolic resin. Adv. Compos. Mater. 2017, 26, 569–581. [Google Scholar] [CrossRef]

- Demir, B.; Henderson, L.C.; Walsh, T.R. Design rules for enhanced interfacial shear response in functionalized carbon fiber epoxy composites. ACS Appl. Mater. Interfaces 2017, 9, 11846–11857. [Google Scholar] [CrossRef]

- Tam, L.-H.; He, L.; Wu, C. Molecular dynamics study on the effect of salt environment on interfacial structure, stress, and adhesion of carbon fiber/epoxy interface. Compos. Interfaces 2018, 26, 431–447. [Google Scholar] [CrossRef]

- Xiao, Y.; Xian, G. Effects of moisture ingress on the bond between carbon fiber and epoxy resin investigated with molecular dynamics simulation. Polym. Compos. 2017, 39, E2074–E2083. [Google Scholar] [CrossRef]

- Randall, J.D.; Eyckens, D.J.; Servinis, L.; Stojcevski, F.; O’Dell, L.A.; Gengenbach, T.R.; Demir, B.; Walsh, T.R.; Henderson, L.C. Designing carbon fiber composite interfaces using a ‘graft-to’ approach: Surface grafting density versus interphase penetration. Carbon 2019, 146, 88–96. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, L.; Li, L.; Yang, W.; Zhang, Y.; Dai, Z.; Xiong, Z. Experimental and numerical investigations on microstructures and mechanical properties of hybrid fiber reinforced thermoplastic polymer. Polym. Test. 2018, 70, 215–225. [Google Scholar] [CrossRef]

- Frankland, S.J.V.; Clancy, T.C.; Hinkley, J.; Gates, T.S. Molecular dynamics simulation of adhesion at epoxy interfaces. In Proceedings of the American Society for Composites—23rd Technical Conference of the American Society for Composites, Memphis, TN, USA, 9–11 September 2008; Volume 1, pp. 336–345. [Google Scholar]

- Clancy, T.; Mattice, W. Computer simulation of polyolefin interfaces. Comput. Theor. Polym. Sci. 1999, 9, 261–270. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation on the effect of bonding pressure on thermal bonding of polymer microfluidic chip. Polymers 2019, 11, 557. [Google Scholar] [CrossRef]

- Demir, B.; Chan, K.-Y.; Yang, D.; Mouritz, A.; Lin, H.; Jia, B.; Lau, K.-T.; Walsh, T.R. Epoxy-Gold nanoparticle nanocomposites with enhanced thermo-mechanical properties: An integrated modelling and experimental study. Compos. Sci. Technol. 2019, 174, 106–116. [Google Scholar] [CrossRef]

- Laurien, M.; Demir, B.; Büttemeyer, H.; Herrmann, A.S.; Walsh, T.R.; Ciacchi, L.C. Atomistic modeling of the formation of a thermoset/thermoplastic interphase during co-curing. Macromolecules 2018, 51, 3983–3993. [Google Scholar] [CrossRef]

- LAMMPS Molecular Dynamics Simulation. Available online: http://lammps.sandia.gov/ (accessed on 16 March 2018).

- Fox, R.F. Contributions to non-equilibrium thermodynamics. I. Theory of hydrodynamical fluctuations. Phys. Fluids 1873, 13. [Google Scholar] [CrossRef]

- Hahn, P.O. Chemical bonding at the polyimide surface. J. Vac. Sci. Technol. A 1984, 2, 756–760. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Ishiaku, U.; Leong, Y.; Hamada, H.; Tsujii, T. Effect of heat-Sealing temperature on the failure criteria of oriented polypropylene/cast polypropylene heat seal. Polym. Eng. Sci. 2005, 46, 205–214. [Google Scholar] [CrossRef]

| Material | Number of Chains | Degree of Polymerization | Total Amount of Atoms | Initial Density (g/cm3) | Box Size (nm3) |

|---|---|---|---|---|---|

| PP | 16 | 50 | 7232 | 0.92 | 4.5 × 4.5 × 3.0 |

| PA66 | 16 | 12 | 7328 | 1.14 | 4.5 × 4.5 × 3.1 |

| Serial Number | Melting Temperature (Tm) | Injection Pressure (P) | Preheating Temperature (Tp) |

|---|---|---|---|

| 1 | 250 °C | 4 MPa | 180 °C |

| 2 | 280 °C | ||

| 3 | 310 °C | ||

| 4 | 280 °C | 2 MPa | |

| 5 | 4 MPa | ||

| 6 | 8 MPa |

| Processing Parameters | 250 °C/4 MPa | 280 °C/4 MPa | 310 °C/4 MPa | 280 °C/2 MPa | 280 °C/4 MPa | 280 °C/8 MPa |

|---|---|---|---|---|---|---|

| Peak tensile stress (MPa) | 75.9 | 133.7 | 143.8 | 111.2 | 133.7 | 152.9 |

| Average shear stress (MPa) | 15.1 | 53.0 | 52.9 | 46.9 | 53.0 | 75.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Zhang, M.; Fu, L.; Zhou, M.; Zhai, Z. Molecular Dynamics Simulation on the Interfacial Behavior of Over-Molded Hybrid Fiber Reinforced Thermoplastic Composites. Polymers 2020, 12, 1270. https://doi.org/10.3390/polym12061270

Jiang B, Zhang M, Fu L, Zhou M, Zhai Z. Molecular Dynamics Simulation on the Interfacial Behavior of Over-Molded Hybrid Fiber Reinforced Thermoplastic Composites. Polymers. 2020; 12(6):1270. https://doi.org/10.3390/polym12061270

Chicago/Turabian StyleJiang, Bingyan, Muhan Zhang, Liang Fu, Mingyong Zhou, and Zhanyu Zhai. 2020. "Molecular Dynamics Simulation on the Interfacial Behavior of Over-Molded Hybrid Fiber Reinforced Thermoplastic Composites" Polymers 12, no. 6: 1270. https://doi.org/10.3390/polym12061270

APA StyleJiang, B., Zhang, M., Fu, L., Zhou, M., & Zhai, Z. (2020). Molecular Dynamics Simulation on the Interfacial Behavior of Over-Molded Hybrid Fiber Reinforced Thermoplastic Composites. Polymers, 12(6), 1270. https://doi.org/10.3390/polym12061270