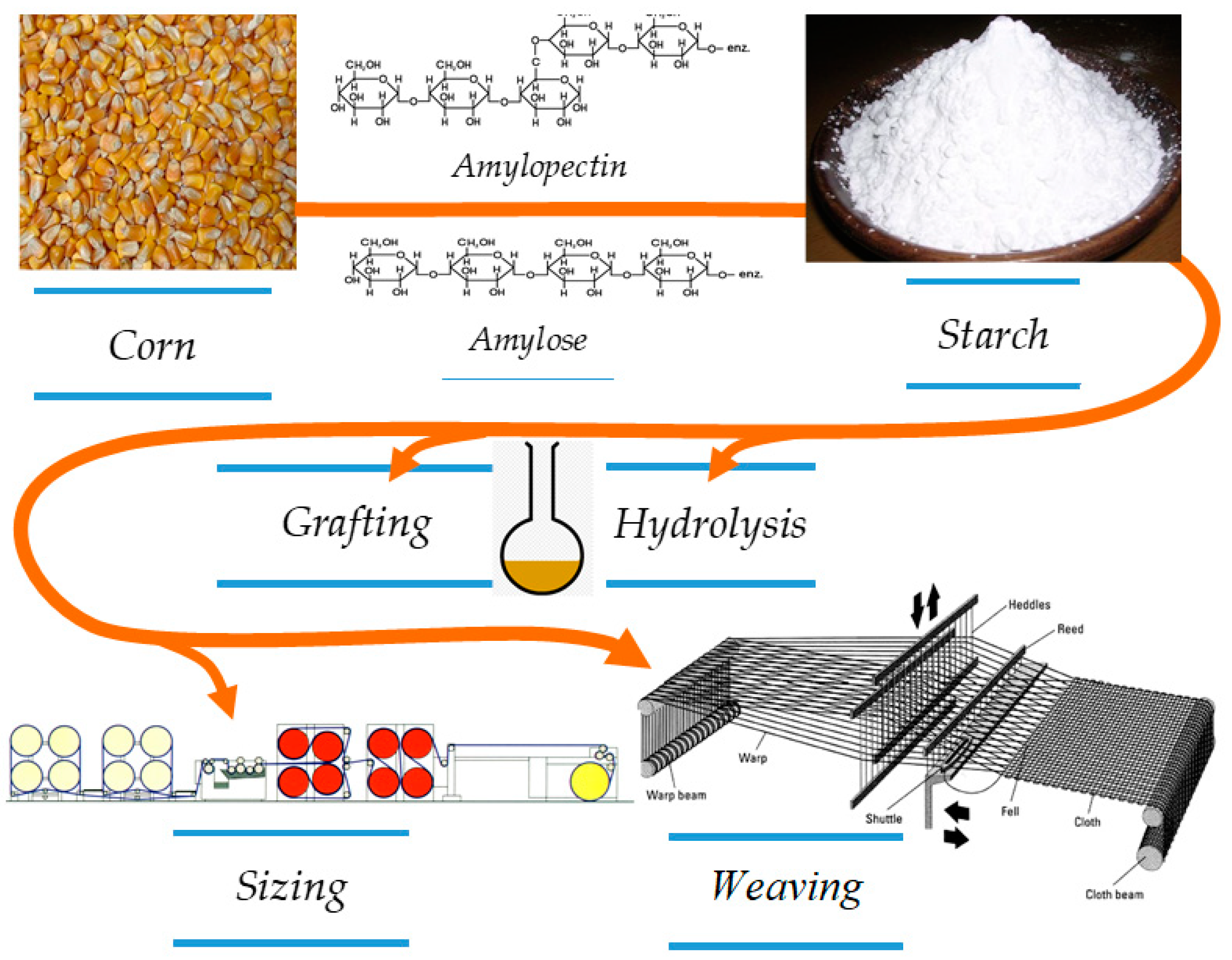

Synthesis of Corn Starch Derivatives and Their Application in Yarn Sizing

Abstract

1. Introduction

2. Experimental

2.1. Materials

- -

- acrylamide (AA) C3H5NO (Merck KG-aA, Darmstadt, Germany),

- -

- 2-hydroxy-ethyl methacrylate (HEMA) C6H10O3 (Sigma-Aldrich, St. Louis, MO, USA).

- -

- azobisisobutyronitrile (AIBN) i.e., (2,2′-azobis (2-methylpropionitrile)) 99% (Sigma-Aldrich, St. Louis, MO, USA),

- -

- potassium persulfate (KPS) K2S2O8 (Centrohem, Stara Pazova, Serbia),

- -

- benzoyl peroxide (BP) (C6H5CO)2O2 (Sigma-Aldrich, St. Louis, MO, USA) [36].

2.2. Methods and Testing Machines

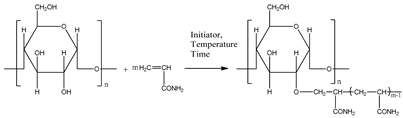

2.3. Graft Copolymer Synthesis Process

3. Results and Discussion

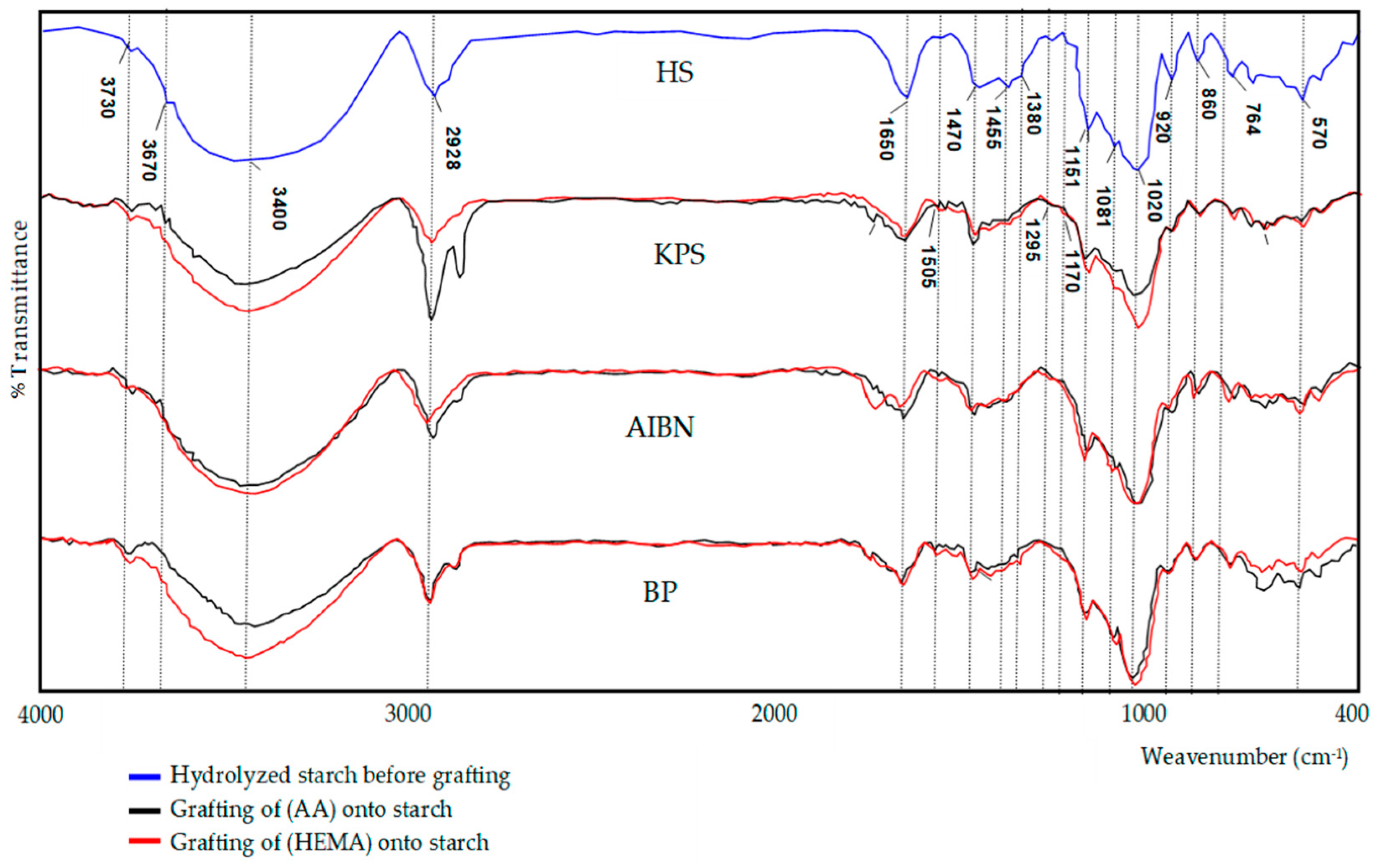

3.1. Characterization of HS-AA and HS-HEMA Copolymers

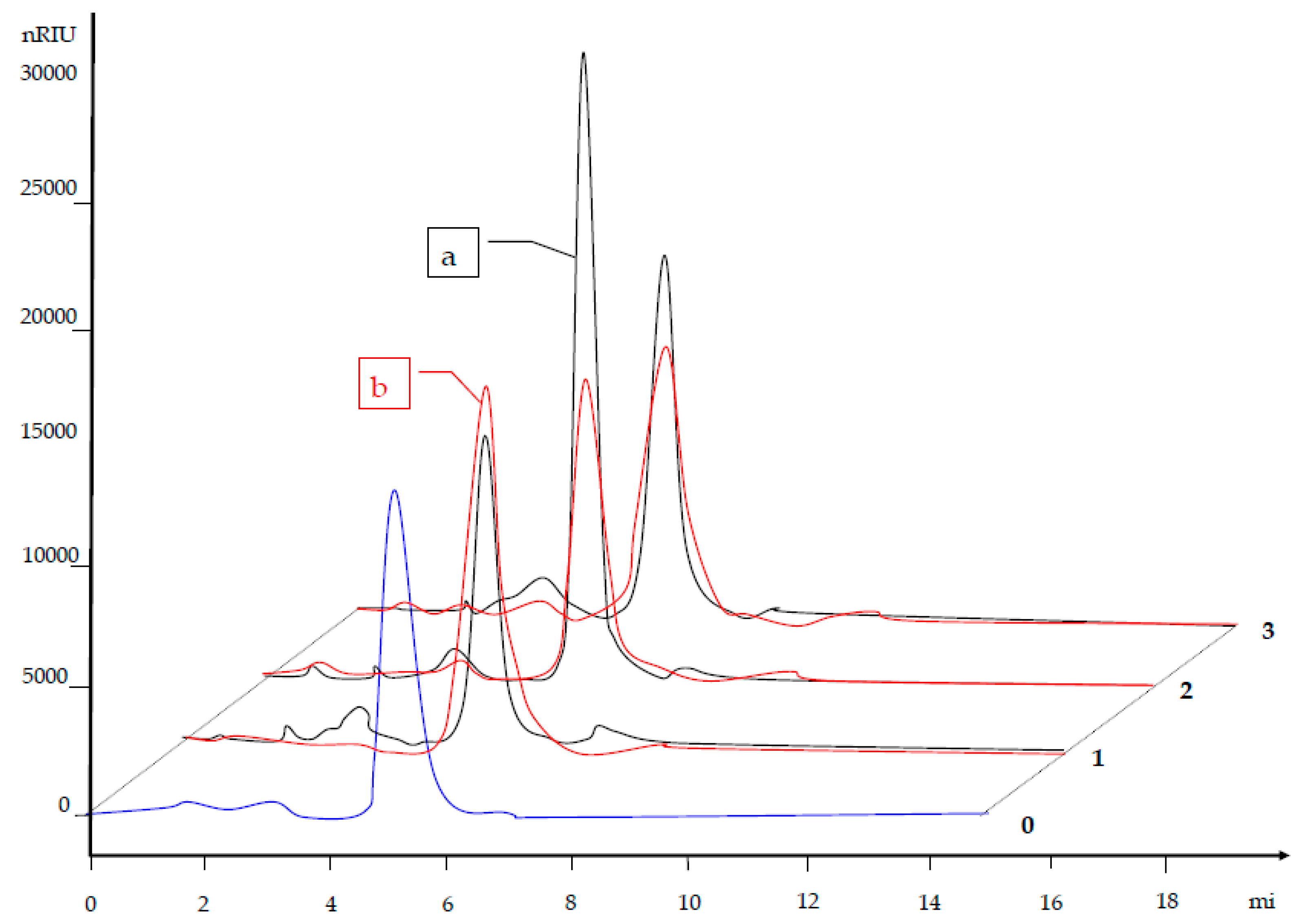

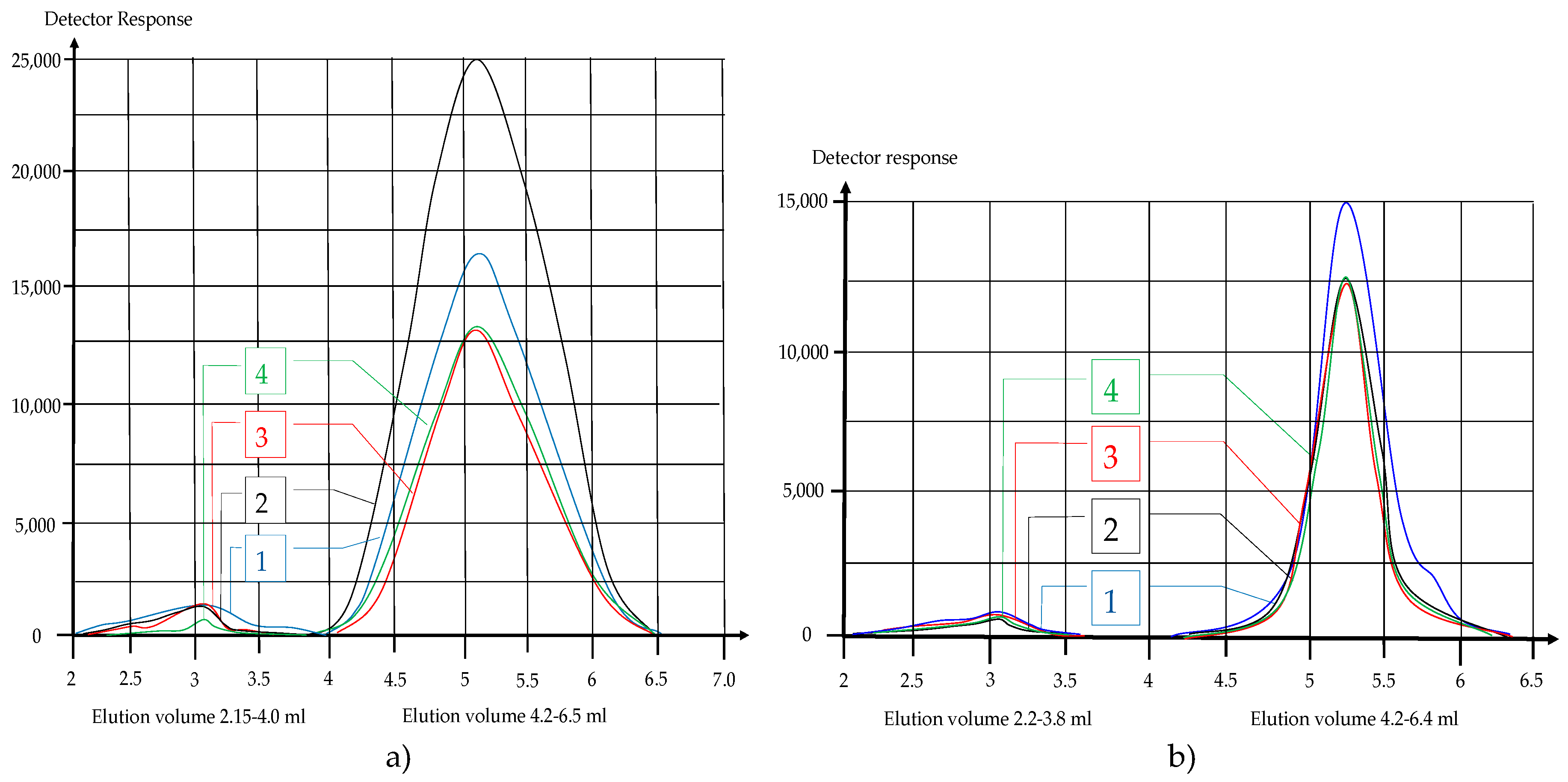

3.2. Molar Masses

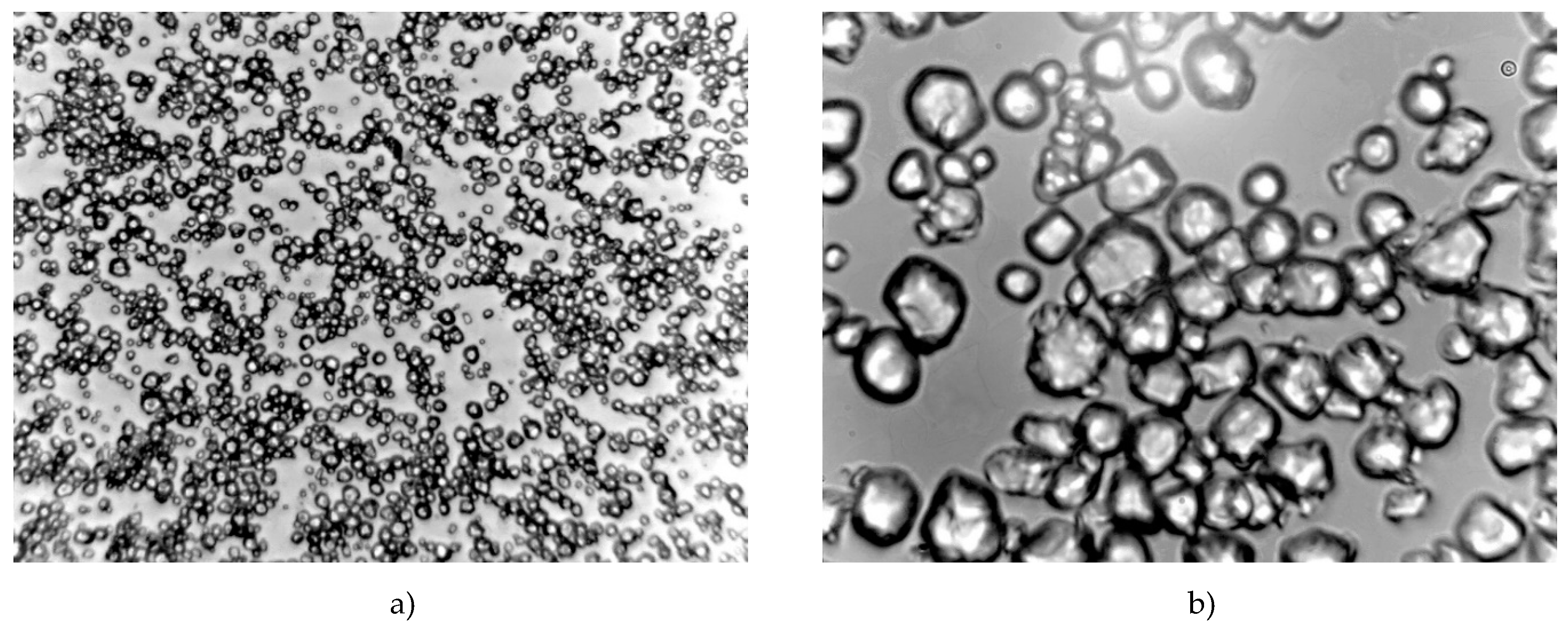

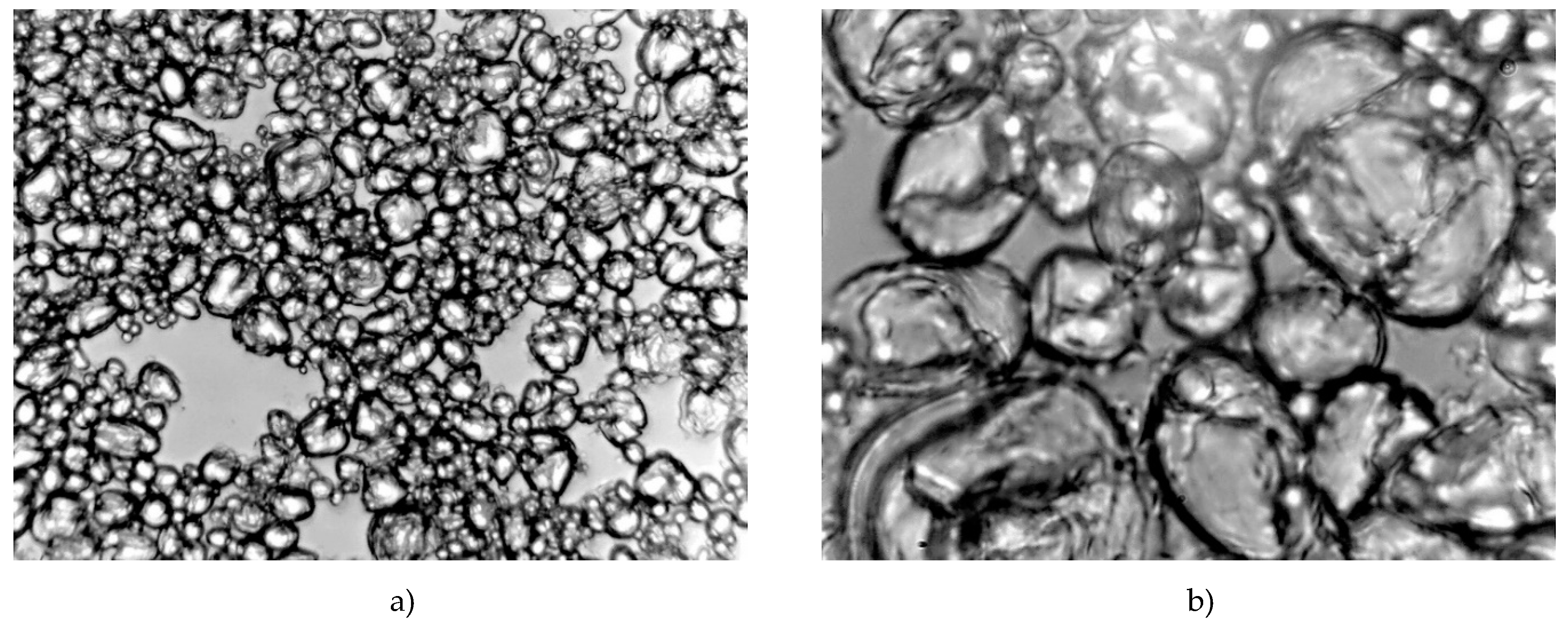

3.3. Microscopy of the Copolymer Solution

3.4. Viscosity

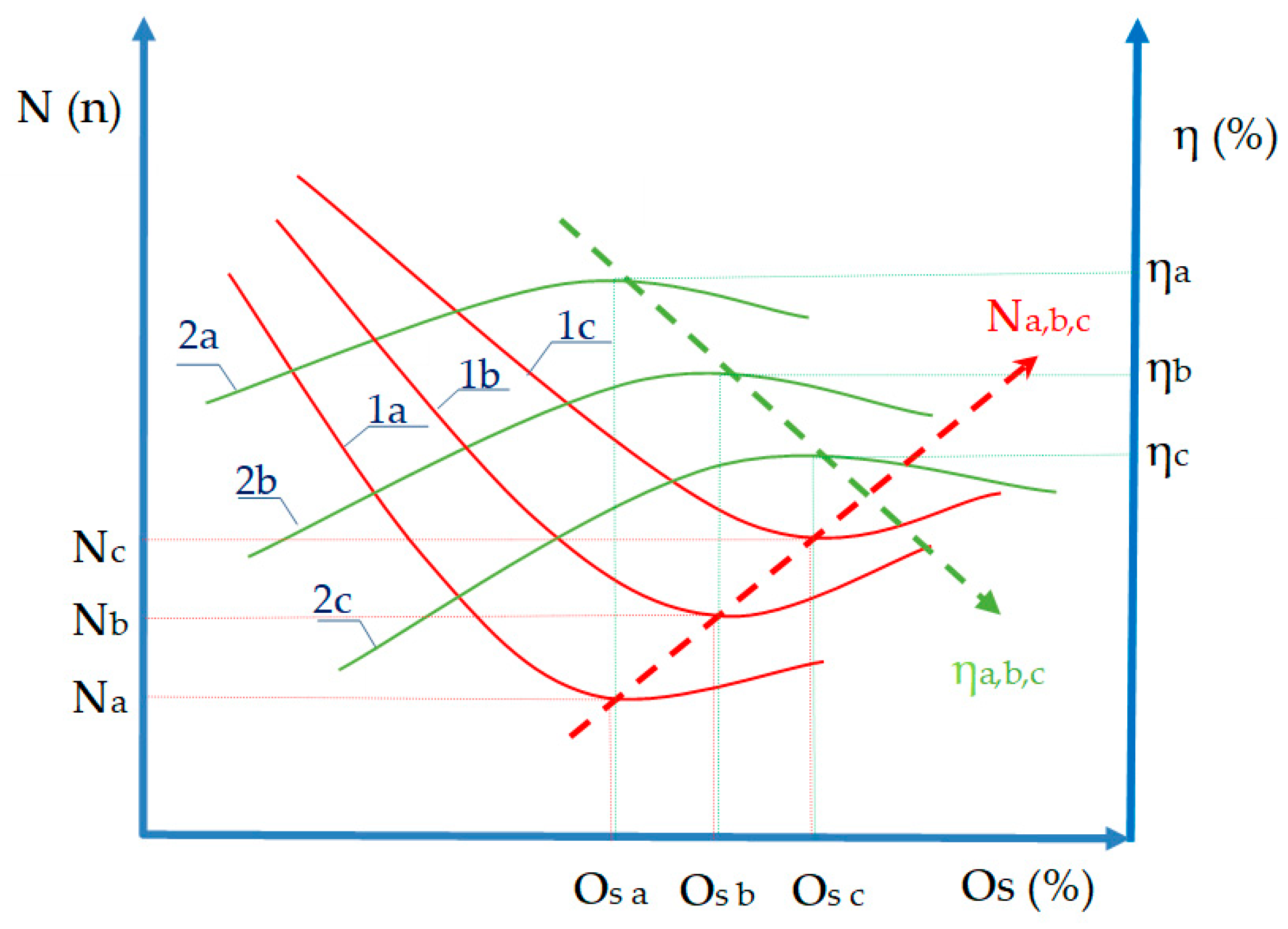

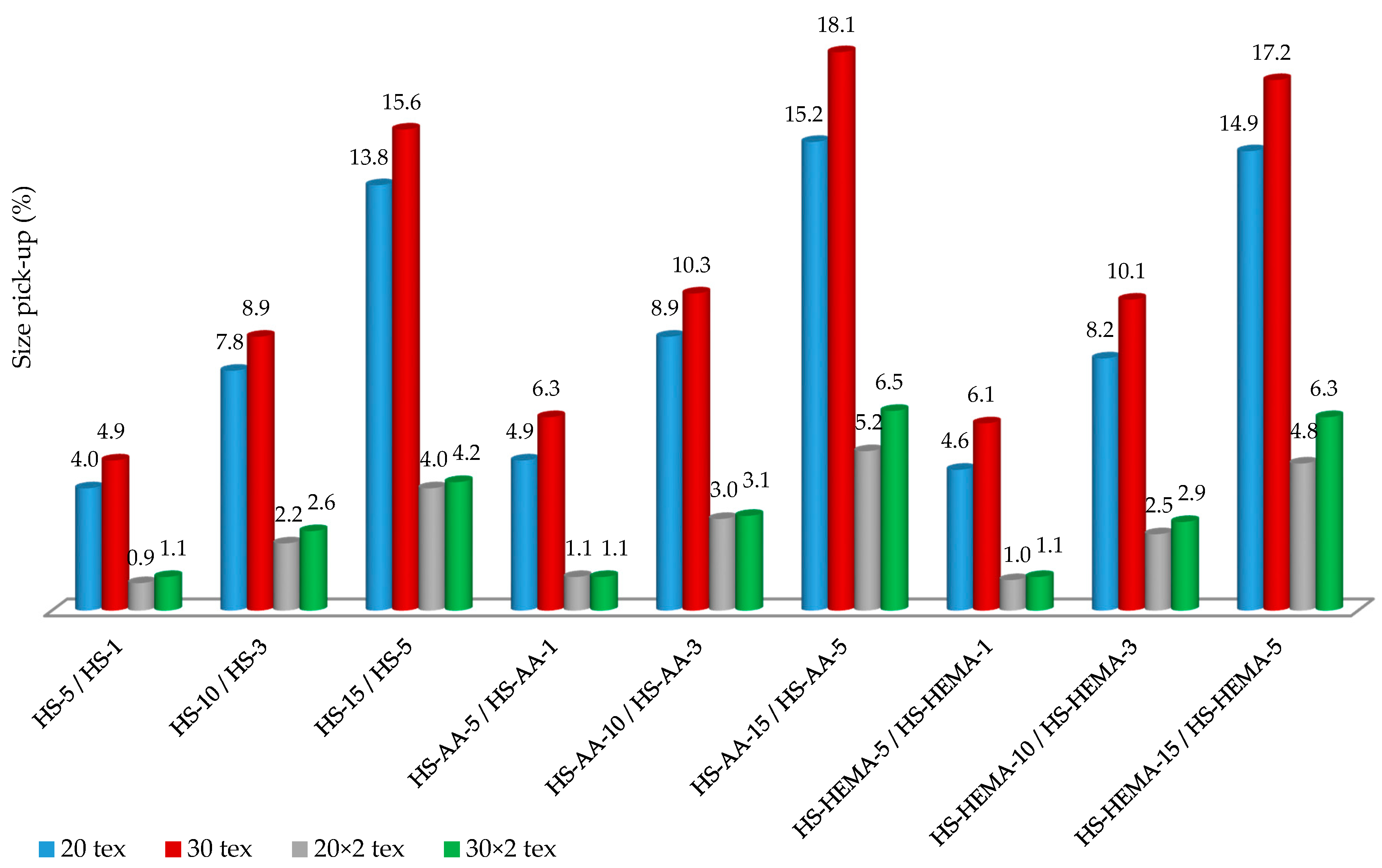

3.5. Size Pick-up

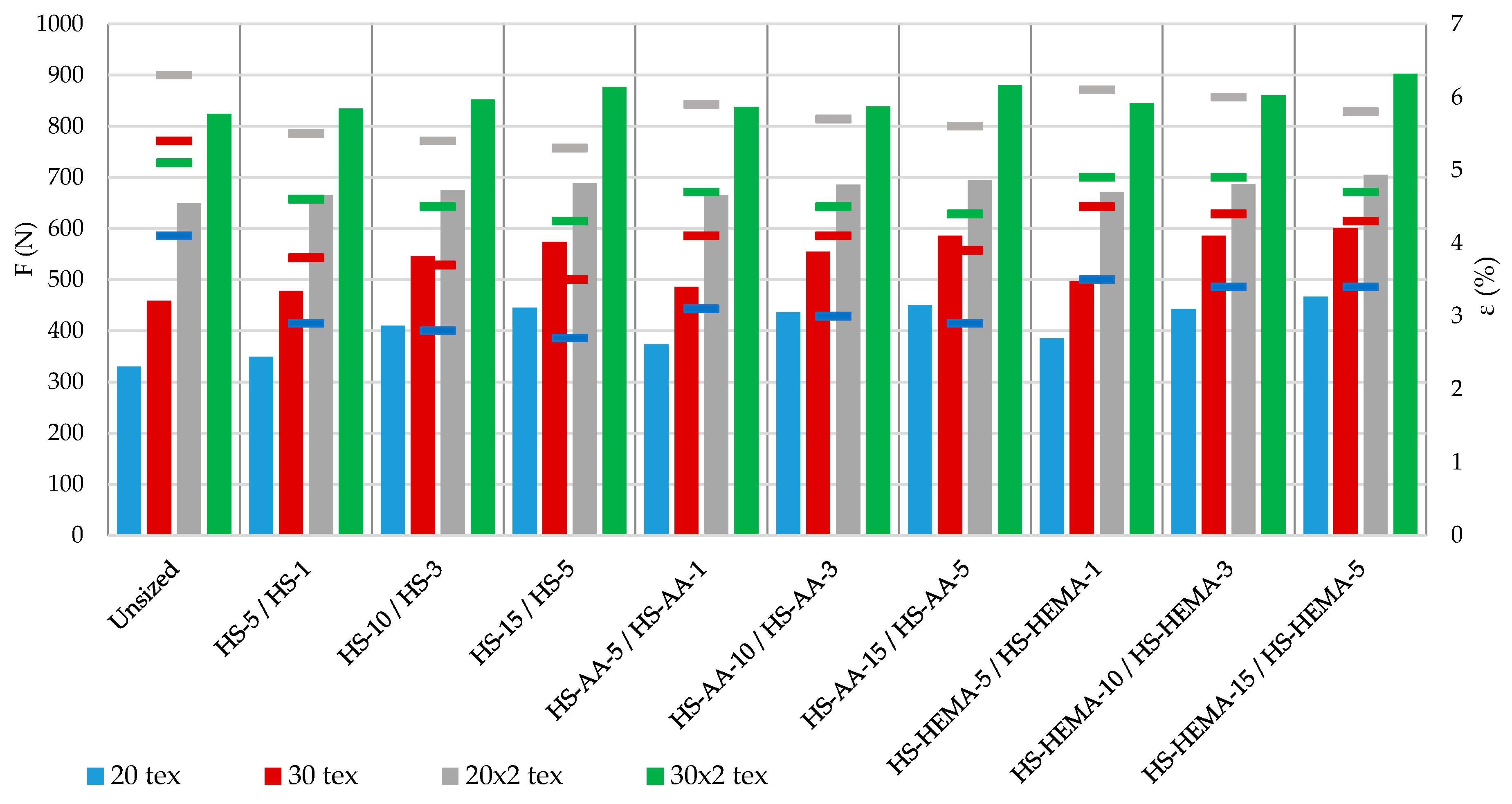

3.6. Breaking Strength and Elongation at Break

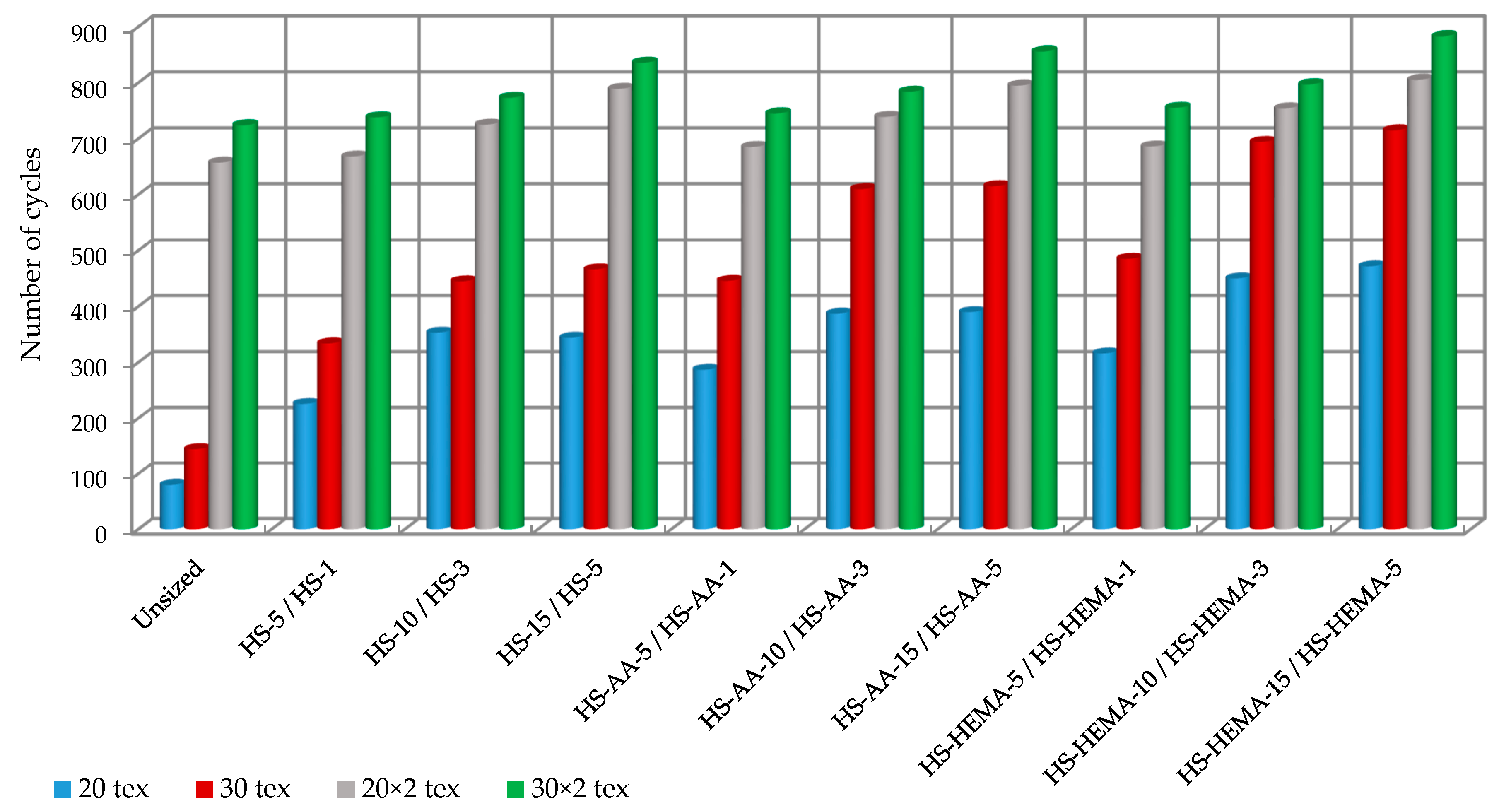

3.7. Yarn Abrasion

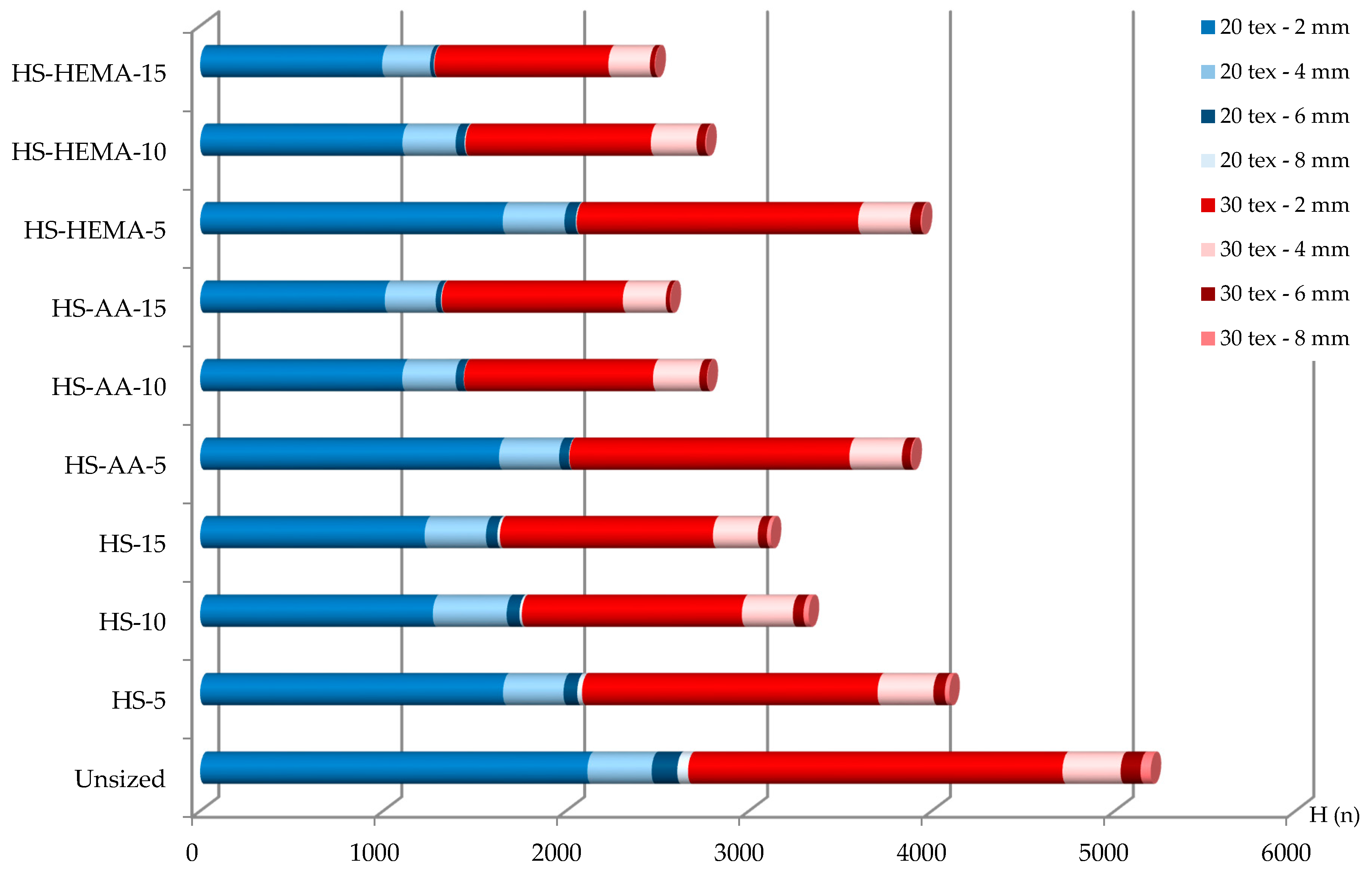

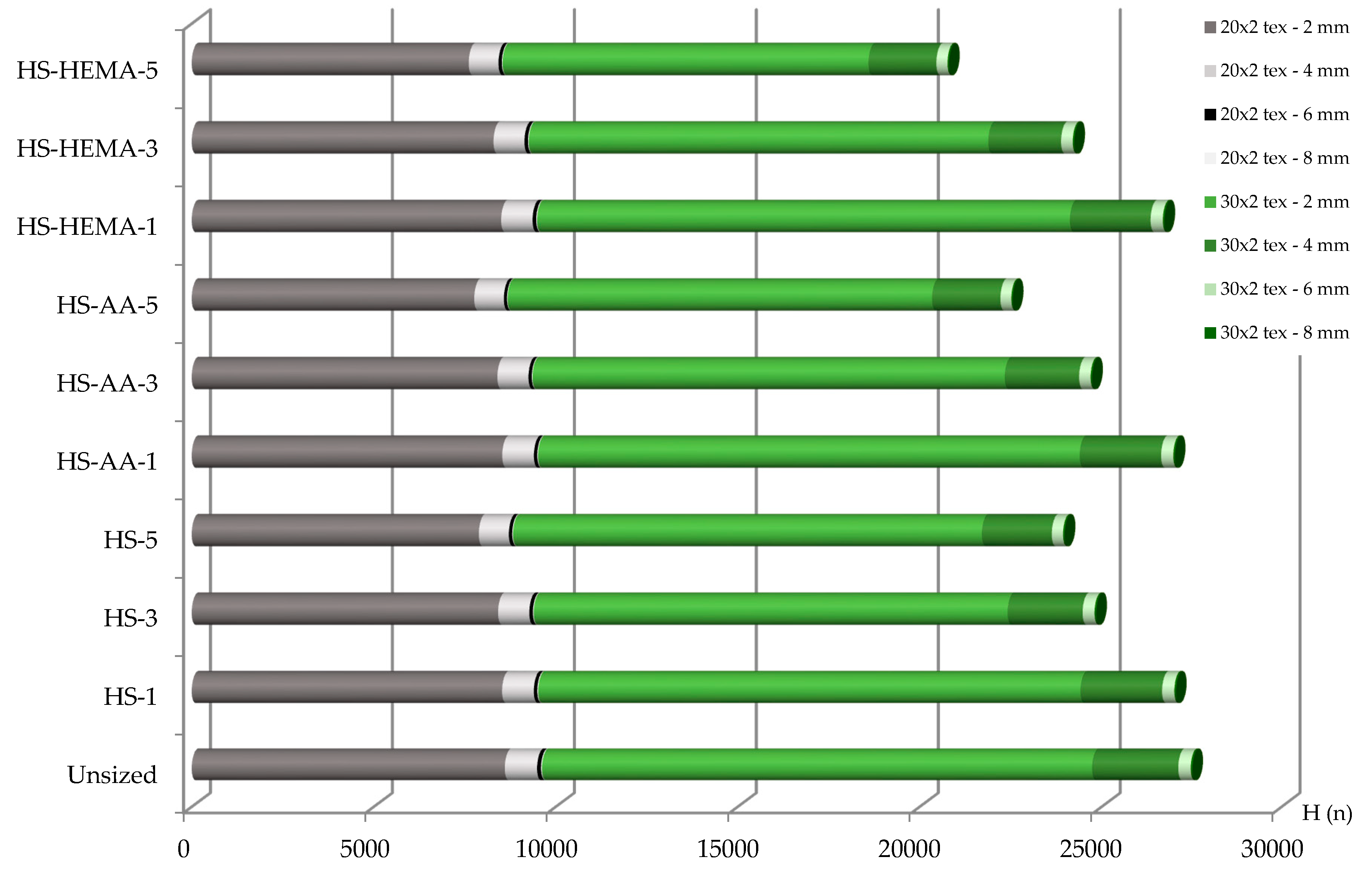

3.8. Yarn Hairiness

3.9. Degree of Desizing

4. Conclusions

- The modification of corn starch was carried out with the aim of producing an environmentally friendly and effective sizing agent that works better than starch.

- Acrylic monomers were grafted onto the starch structure using the initiators AIBN, BP, and KPS.

- The results of yield, percentage, and efficiency of grafting, and the data on BP initiator indicated that the grafting reactions of AA and HEMA to starch were successful.

- FTIR analysis confirmed that these were new products of starch and vinyl monomers.

- Most monomers remained in the sample HS-AA-KPS, followed by the sample HS-HEMA-BP, with the fewest in the samples HS-AA-BP and HS-HEMA-AIBN, which confirms a more successful graft polymerization in the presence of these initiators.

- HPLC chromatograms (RID signal) of aqueous extracts of synthesized starch copolymer samples (AA and HEMA) showed that, depending on the type of initiator used, AA BP has the highest peak height and the largest area under the diagram for monomers grafted with the initiator, while HEMA monomer grafted with the AIBIN initiator has the highest peak height and the KPS initiator has the largest surface area.

- The highest uniformity of molar mass was shown in samples of hydrolysed grafted starch, during an elution volume of 2.15–4.0 mL. The smaller molar masses of the grafted samples with an elution volume of 4.2–6.5 mL resulted in poorer homogeneity.

- The viscosity decreased with decreasing starch concentration. All grafted hydrolysed starches increased viscosity compared to non-grafted hydrolysed starches, indicating good stability of the potential starch.

- After impregnation of the yarn in sizing, the yarn mass yarn increased by the amount of the starch applied. Coarser single yarn as well as coarser plied yarn adsorbed or bound more starch, which is associated with a larger volume and more loose structure.

- The sizing process caused an increase in the breaking force. Before grafting, hydrolysed starch had a lower breaking force than grafted starch. The higher starch concentration had a higher breaking force. Starches with HEMA monomer gave better results than AA monomer in terms of breaking force of the yarn, which confirms their more homogenous distribution and good adhesion both on the surface and inside the yarn.

- Sizing reduced elongation at break of yarns and starches with HEMA monomer reduced elongation at break the least.

- Grafted starch proved to be a good agent for abrasion resistance, especially HS-HEMA, which can be ascribed to its good hydrophobicity, thus providing greater surface protection of the yarn. By the hydrolysis of corn starch and subsequent grafting, the yarn hairiness was significantly reduced in all yarns. An increase in the amount of starch caused less hairiness. Higher starch concentration had a better effect, as the number of fibres protruding in the direction of the measuring zones decreased considerably, especially in single yarns.

- Desizing of yarn using ultrasound gave better results than desizing by washing, even at lower size concentrations.

- Optical microscopy of the starch solution showed partially altered granules at different stages of swelling. Longer dormant starch state caused changes on the surface of acid hydrolysed starch granule, the granule surface became less smooth and the size increased.

- Tegewa numbers six and above generally occurred in all grafted starches, meaning that the desizing process was successful.

- On the basis of the analyses carried out, it can be concluded that there is an economic, qualitative, and ecological cost-effectiveness of the return of corn starch to the sizing process, but only by synthesizing and grafting with appropriate initiators, which significantly improves the properties.

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, Z.; Xiong, Z. Effect of starch/SiO2 nanoparticle blends on the adhesion of starch to fibers for warp sizing. AATCC Rev. 2008, 8, 45–48. [Google Scholar]

- Kovačević, S.; Dimitrovski, K.; Orešković, V. Optimization of size pick–up on yarn. In Book Of Proceedings Of The ITC&DC 2004, Proceedings of the 2nd International Textile, Clothing & Design Conference—Magic World of Textiles, Dubrovnik, Croatia, 3–6 October 2004; Dragčević, Z., Ed.; Faculty of Textile Technology, University of Zagreb: Zagreb, Croatia, 2004; pp. 210–215. [Google Scholar]

- Djordjević, S.; Kovacevic, S.; Djordjevic, D.; Konstantinovic, S. Sizing process of cotton yarn by size from a copolymer of methacrylic acid and hydrolysed potato starch. Text. Res. J. 2019, 89, 3457–3465. [Google Scholar] [CrossRef]

- Brockway, C.E. Sizing Hydrophobic Fibers With Acrylate Polymers And Gelatinized Starch Or Graft Copolymers Thereof (Staley Patent). US Patent 3,061,472, 30 October 1962. [Google Scholar]

- Wang, S.; Yu, J.; Gao, W.; Pang, J.; Liu, H.; Yu, J. Granule structural changes in native Chinese Yam (Dioscorea opposita Thunb var. Anguo) starch during acid hydrolysis. Carbohydr. Polym. 2007, 69, 286–292. [Google Scholar]

- Hebeish, A.; Hashem, M.; Abdel-Rahman, A.; El-Hilw, Z. Cationized Starch Derived From Pre-Oxidized Starch For Textile Sizing and Printing. Starch-Stärke 2005, 57, 616–623. [Google Scholar] [CrossRef]

- Zhang, Y.-R.; Wang, Y.; Zhang, S.-D.; Wang, X.-L. High Carbonyl Content Oxidized Starch Prepared by Hydrogen Peroxide and Its Thermoplastic Application. Starch-Stärke 2009, 61, 646–655. [Google Scholar] [CrossRef]

- Mikkonen, K.S.; Parikka, K.; Suuronen, J.-P.; Ghafar, A.; Serimaa, R.; Tenkanen, M. Enzymatic oxidation as a potential new route to produce polysaccharide aerogels. RSC Adv. 2014, 4, 11884. [Google Scholar] [CrossRef]

- Kalambur, S.; Rizvi, S. An Overview of Starch-Based Plastic Blends from Reactive Extrusion. J. Plast. Film Sheeting 2006, 22, 39–58. [Google Scholar] [CrossRef]

- Zakrajšek, N.; Knez, N.; Rravnjak, D.; Golob, J. Analysis of Modified Starch Adsorption Kinetics on Cellulose Fibers via the Modified Langmuir Adsorption Theory. Chem. Biochem. Eng. Q. 2009, 23, 461–470. [Google Scholar]

- Zhu, Z.; Chen, P. Carbamoyl ethylation of starch for enhancing the adhesion capacity to fibers. J. Appl. Polym. Sci. 2007, 106, 2763–2768. [Google Scholar] [CrossRef]

- Kenar, J.; Eller, F.J.; Felker, F.C.; Jackson, M.A.; Fanta, G.F. Starch aerogel beads obtained from inclusion complexes prepared from high amylose starch and sodium palmitate. Green Chem. 2014, 16, 1921–1930. [Google Scholar] [CrossRef]

- Biswas, A.; Willet, J.; Gordon, S.H.; Finkenstadt, V.; Cheng, H. Complexation and blending of starch, poly(acrylic acid), and poly(N-vinyl pyrrolidone). Carbohydr. Polym. 2006, 65, 397–403. [Google Scholar] [CrossRef]

- Pal, K.; Banthia, A.; Majumdar, D. Effect of heat treatment of starch on the properties of the starch hydrogels. Mater. Lett. 2008, 62, 215–218. [Google Scholar] [CrossRef]

- Kazimierczak, J.; Ciechanska, D.; Wawro, D.; Guzinska, K. Enzymatic Modification of Potato Starch. Fibres Text. East. Eur. 2007, 15, 100–104. [Google Scholar]

- Canché-Escamilla, G.; Canché-Canché, M.; Duarte-Aranda, S.; Cáceres-Farfán, M.; Borges-Argáez, R. Mechanical properties and biodegradation of thermoplastic starches obtained from grafted starches with acrylics. Carbohydr. Polym. 2011, 86, 1501–1508. [Google Scholar] [CrossRef]

- Mostafa, K.M.; Morsy, M.S. Modification of carbohydrate polymers via grafting of methacrylonitrile onto pregelled starch using potassium monopersulfate/Fe2+ redox pair. Polym. Int. 2004, 53, 885–890. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, Z. Monophosphorylation of Acid-thinned Starch to Enhance the Quality of Viscose Yarns Sized at Reduced Temperature. Starch-Stärke 2009, 61, 139–144. [Google Scholar] [CrossRef]

- Kaur, B.; Ariffin, F.; Bhat, R.; Karim, A.A. Progress in starch modification in the last decade. Food Hydrocoll. 2012, 26, 398–404. [Google Scholar] [CrossRef]

- Peng, X.; Song, J.-H.; Nesbitt, A.; Day, R. Microwave foaming of starch-based materials (I) dielectric performance. J. Cell. Plast. 2013, 49, 245–258. [Google Scholar] [CrossRef]

- Tucker, S.P.; Millson, M.B.; Dollberg, D.D. Determination of Polyacrylate Super Absorbent Polymers in Air. Anal. Lett. 1993, 26, 965–980. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, P.; Du, X.; Xue, Z.; Chen, S.; Yang, B. Effects of amylose content on property and microstructure of starch-graft-sodium acrylate copolymers. Carbohydr. Polym. 2014, 102, 453–459. [Google Scholar] [CrossRef]

- Shogren, R.; Willett, J.; Biswas, A. HRP-mediated synthesis of starch–polyacrylamide graft copolymers. Carbohydr. Polym. 2009, 75, 189–191. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.-K.; Liu, W.-J.; Li, F.-Y. Microwave-assisted synthesis, characterization, and textile sizing property of carboxymethyl corn starch. Fibers Polym. 2015, 16, 2308–2317. [Google Scholar] [CrossRef]

- Villalobos, F.J.; Fereres, E. Evaporation Measurements beneath Corn, Cotton, and Sunflower Canopies. Agron. J. 1907, 82, 1153–1159. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Goda, K.; Devi, P.V. Sorption characteristics of water, oil and diesel in cellulose nanofiber reinforced corn starch resin/ramie fabric composites. Compos. Interfaces 2008, 15, 281–299. [Google Scholar] [CrossRef]

- Abdelrahman, M.S.; Nassar, S.H.; Mashaly, H.; Mahmoud, S.; Maamoun, D.; Khattab, T.A. Polymerization products of lactic acid as synthetic thickening agents for textile printing. J. Mol. Struct. 2020, 1203, 127421. [Google Scholar] [CrossRef]

- Amani, A.; Montazer, M.; Rad, M.M. Synthesis of applicable hydrogel corn silk/ZnO nanocomposites on polyester fabric with antimicrobial properties and low cytotoxicity. Int. J. Boil. Macromol. 2019, 123, 1079–1090. [Google Scholar] [CrossRef]

- Sun, S.; Yu, H.; Williams, T.; Hicks, R.F.; Qiu, Y. Eco-friendly sizing technology of cotton yarns with He/O2 atmospheric pressure plasma treatment and green sizing recipes. Text. Res. J. 2013, 83, 2177–2190. [Google Scholar] [CrossRef]

- Utrilla-Coello, R.; Hernández-Jaimes, C.; Carrillo-Navas, H.; González, F.; Rodriguez, E.; Bello-Pérez, L.; Vernon-Carter, E.J.; Alvarez-Ramirez, J. Acid hydrolysis of native corn starch: Morphology, crystallinity, rheological and thermal properties. Carbohydr. Polym. 2014, 103, 596–602. [Google Scholar] [CrossRef]

- Zhu, Z.; Cao, S. Modifications to Improve the Adhesion of Crosslinked Starch Sizes to Fiber Substrates. Text. Res. J. 2004, 74, 253–258. [Google Scholar] [CrossRef]

- Hebeish, A.; Aly, A.; El-Shafei, A.; Zaghloul, S. Innovative Starch Derivatives as Textile Auxiliaries for Application in Sizing, Finishing and Flocculation. Starch-Stärke 2008, 60, 97–109. [Google Scholar] [CrossRef]

- Kovačević, S.; Đorđević, S.; Đorđević, D. Natural Modified Starch and Synthetic Sizes in Function of Characteristics of Sized Yarn. Fibres Text. East. Eur. 2016, 24, 56–66. [Google Scholar] [CrossRef]

- Maatoug, S.; Ladhari, N.; Sakli, F. Evaluation of the weavability of sized cotton warps. AUTEX Res. J. 2007, 8, 239–244. [Google Scholar]

- Stegmaier, T.; Wunderlich, W.; Hager, T.; Siddique, A.B.; Sarsour, J.; Planck, H. Chitosan—A Sizing Agent in Fabric Production—Development and Ecological Evaluation. CLEAN–Soil Air Water 2008, 36, 279–286. [Google Scholar] [CrossRef]

- Kovačević, S.; Schwarz, I.; Đorđević, S.; Đorđević, D. Synthetized Potato Starch-A New Eco Sizing Agent for Cotton Yarns. Polymers 2019, 11, 908. [Google Scholar] [CrossRef]

- Teli, M.D.; Chakrabarti, R. Use of statistical methods to understand the effect of yarn and fabric parameters on desizing efficiency. Fibres Text. East. Eur. 2008, 16, 95–100. [Google Scholar]

- Mostafa, K.M. Graft polymerization of methacrylic acid on starch and hydrolysed starches. Polym. Degrad. Stab. 1995, 50, 189–194. [Google Scholar] [CrossRef]

- Kiatkamjornwong, S.; Chomsaksakul, W.; Sonsuk, M. Radiation modification of water absorption of cassava starch by acrylic acid/acrylamide. Radiat. Phys. Chem. 2000, 59, 413–427. [Google Scholar] [CrossRef]

- Carvalho, A.J.F.; Curvelo, A.; Gandini, A. Surface chemical modification of thermoplastic starch: Reactions with isocyanates, epoxy functions and stearoyl chloride. Ind. Crop. Prod. 2005, 21, 331–336. [Google Scholar] [CrossRef]

- Kaewtatip, K.; Tanrattanakul, V. Preparation of cassava starch grafted with polystyrene by suspension polymerization. Carbohydr. Polym. 2008, 73, 647–655. [Google Scholar] [CrossRef]

- Işıklan, N.; Kurşun, F.; Inal, M. Graft copolymerization of itaconic acid onto sodium alginate using benzoyl peroxide. Carbohydr. Polym. 2010, 79, 665–672. [Google Scholar] [CrossRef]

- Mostafa, K.M. Synthesis of poly(acrylamide)-starch and hydrolysed starch graft copolymers as a size base material for cotton textiles. Polym. Degrad. Stabil. 1997, 55, 125–130. [Google Scholar] [CrossRef]

- Li, D.; Han, B.; Liu, Z. Grafting of 2-Hydroxyethyl Methacrylate onto Isotactic Poly(propylene) Using Supercritical CO2 as a Solvent and Swelling Agent. Macromol. Chem. Phys. 2001, 202, 2187–2194. [Google Scholar] [CrossRef]

- Xu, X.F.; Chen, H.; Ma, H.; Ma, B.; Peng, W. The Mechanism of Polymer Particles in Silicon Wafer CMP. Mater. Sci. Forum. 2009, 626, 231–236. [Google Scholar] [CrossRef]

- Lewis, R.J. Hawley’s Condensed Chemical Dictionary, 14th ed.; John Wiley&Sons, Inc.: New York, NY, USA, 2001; p. 127. [Google Scholar]

- Hoque, A.; Clarke, A.C. Greening of industries in Bangladesh: Pollution prevention practices. J. Clean. Prod. 2013, 51, 47–56. [Google Scholar] [CrossRef]

- Lanthong, P.; Nuisin, R.; Kiatkamjornwong, S. Graft copolymerization, characterization, and degradation of cassava starch-g-acrylamide/itaconic acid superabsorbents. Carbohydr. Polym. 2006, 66, 229–245. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, S.; Wang, G. Synthesis and physicochemical properties of graft copolymer of corn starch and acrylamide. Polym. Compos. 2007, 28, 47–56. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Kausch, H.H. Molecular Weight Distribution and Mechanical Properties. Plast. Addit. 1999, 3, 143–150. [Google Scholar]

- Guttman, C.M.; Wallace, W. MALDI Mass Spectrometry for the Quantitative Determination of Polymer Molecular Mass Distribution; Wiley: Hoboken, NJ, USA, 2009; Volume 175, pp. 187–204. [Google Scholar]

- Wang, Y.-J.; Truong, V.-D.; Wang, L. Structures and rheological properties of corn starch as affected by acid hydrolysis. Carbohydr. Polym. 2003, 52, 327–333. [Google Scholar] [CrossRef]

- Jenkins, P.J.; Donald, A.M. The effect of acid hydrolysis on native starch granule structure. Starch/Stärke 1997, 49, 262–267. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Singh, N.; Lim, S.-T. A comparison of native and oxidized normal and waxy corn starches: Physicochemical, thermal, morphological and pasting properties. LWT 2008, 41, 1000–1010. [Google Scholar] [CrossRef]

- Lee, J.S.; Kumar, R.N.; Rozman, H.D.; Azemi, B.M.N. Pasting, swelling and solubility properties of UV initiated starch-graft-poly(AA). Food Chem. 2005, 91, 203–211. [Google Scholar] [CrossRef]

- Gudlin Schwarz, I.; Kovačević, S.; Dimitrovski, K. Analysis of mechanical yarn properties in cyclic loads. Textil 2011, 60, 142–148. [Google Scholar]

- Schwarz, I.; Kovačević, S.; Dimitrovski, K. Analysis of changes in mechanical and deformation properties of yarn by sizing. Text. Res. J. 2010, 81, 545–555. [Google Scholar] [CrossRef]

- Chand, N.; Shams-Nateri, A.; Sajedi, R.; Mahdavi, A.; Rassa, M. Enzymatic desizing of cotton fabric using a Ca2+-independent α-amylase with acidic pH profile. J. Mol. Catal. B Enzym. 2012, 83, 46–50. [Google Scholar] [CrossRef]

- Li, X.; Qiu, Y. The effect of plasma pre-treatment on NaHCO3 desizing of blended sizes on cotton fabrics. Appl. Surf. Sci. 2012, 258, 4939–4944. [Google Scholar] [CrossRef]

- Ali, S.; Khatri, Z.; Khatri, A.; Tanwari, A. Integrated desizing–bleaching–reactive dyeing process for cotton towel using glucose oxidase enzyme. J. Clean. Prod. 2014, 66, 562–567. [Google Scholar] [CrossRef]

| Copolymer Designation | Meaning of Designations | Graft Schemes |

|---|---|---|

| HS | Hydrolysed starch | |

| HS-AA-AIBN | Hydrolysed starch grafted with acrylamide, initiator azobisisobutyronitrile |  |

| HS-AA-KPS | Hydrolysed starch grafted with acrylamide, initiator potassium persulfate | |

| HS-AA-BP | Hydrolysed starch grafted with acrylamide, initiator benzoyl peroxide | |

| HS-HEMA-AIBN | Hydrolysed starch grafted with 2-hydroxyethyl methacrylate, initiator azobisisobutyronitrile |  |

| HS-HEMA-KPS | Hydrolysed starch grafted with 2-hydroxyethyl methacrylate, initiator potassium persulfate | |

| HS-HEMA-BP | Hydrolysed starch grafted with 2-hydroxyethyl methacrylate, initiator benzoyl peroxide |

| Samples | PHS (%) | PriK (%) | PrpK (%) | PEK (%) | KMP (%) | |

|---|---|---|---|---|---|---|

| Hydrolysed starch | HS | 76.92 | - | - | - | - |

| Grafting of (AA) onto starch | HS-AA-AIBN | - | 79.33 a | 19.00 a | 38.31 a | 99.20 b |

| HS-AA-KPS | - | 80.00 a | 20.00 a | 40.65 a | 98.40 b | |

| HS-AA-BP | - | 81.33 | 22.00 | 44.49 | 98.90 | |

| Grafting of HEMA onto starch | HS-HEMA-AIBN | - | 84.67 | 27.00 | 54.88 | 98.40 |

| HS-HEMA-KPS | - | 81.33 a | 22.00 a | 44.81 a | 98.20 b | |

| HS-HEMA-BP | - | 83.33 a | 25.00 a | 50.71 a | 98.60 b | |

| Samples | Retention Time, min | Concentration of the Residual Monomer in the Copolymer, mg/g |

|---|---|---|

| HS-AA-BP | 2.505 | 4.46 |

| HS-AA-AIBN | 2.507 | 4.53 |

| HS-AA-KPS | 2.509 | 6.14 |

| HS-HEMA-BP | 2.602 | 5.75 |

| HS-HEMA-AIBN | 2.609 | 4.46 |

| HS-HEMA-KPS | 2.603 | 5.42 |

| Samples | Retention Time | Peak Surface Area | Peak Height |

|---|---|---|---|

| HS | 5.107 | 608,958.6 | 14,139.9 |

| HS-AA-AIBN | 5.199 | 521,071.8 | 16,214.7 |

| HS-AA-BP | 5.296 | 633,742.5 | 26,015.8 |

| HS-AA-KPS | 5.112 | 393,332.2 | 13,030.5 |

| HS-HEMA-AIBN | 5.167 | 522,475.4 | 15,776.7 |

| HS-HEMA-BP | 5.090 | 532,256.9 | 14,478.3 |

| HS-HEMA-KPS | 5.048 | 598,744.7 | 13,734.8 |

| Samples | Elution Volume 2.15—4.0 mL | Elution Volume 4.2—6.5 mL | ||||||

|---|---|---|---|---|---|---|---|---|

| Mn | Mw | Mz | D | Mn | Mw | Mz | D | |

| HS | 6.68 × 105 | 1.10 × 106 | 2.24 × 106 | 1.65 | 1.86 × 103 | 4.32 × 103 | 7.84 × 103 | 2.31 |

| HS-AA-AIBN | 7.19 × 105 | 1.54 × 106 | 3.06 × 106 | 2.15 | 2.12 × 103 | 4.41 × 103 | 7.90 × 103 | 2.08 |

| HS-AA-BP | 8.45 × 105 | 1.60 × 106 | 2.78 × 106 | 1.89 | 2.31 × 103 | 4.63 × 103 | 7.91 × 103 | 2.00 |

| HS-AA-KP | 7.59 × 105 | 1.24 × 106 | 2.32 × 106 | 1.64 | 1.99 × 103 | 4.49 × 103 | 7.85 × 103 | 2.26 |

| HS-HEMA-AIBN | 8.89 × 105 | 1.60 × 106 | 3.34 × 106 | 1.79 | 1.98 × 103 | 4.40 × 103 | 7.92 × 103 | 2.22 |

| HS-HEMA-BP | 6.81 × 105 | 1.25 × 106 | 2.31 × 106 | 1.83 | 1.95 × 103 | 4.43 × 103 | 7.89 × 103 | 2.27 |

| HS-HEMA-KP | 8.73 × 105 | 1.20 × 106 | 2.77 × 106 | 1.37 | 2.50 × 103 | 5.74 × 103 | 1.15 × 104 | 2.29 |

| Samples | Single Yarn (20 tex and 30 tex) | Plied Yarn (20 × 2 tex and 30 × 2 tex) | |||||

|---|---|---|---|---|---|---|---|

| 40 °C | 60 °C | 85 °C | 40 °C | 60 °C | 85 °C | ||

| HS 5/HS-1 | η (mPa·s) | 38.8 | 57.1 | 53.9 | 11.5 | 16.3 | 14.9 |

| Sd (mPa·s) | 0.34 | 0.82 | 1.52 | 1.46 | 2.21 | 1.53 | |

| CV (%) | 0.88 | 1.44 | 2.82 | 12.69 | 13.56 | 10.27 | |

| HS-10/HS-3 | η (mPa·s) | 46.2 | 65.2 | 61.9 | 22.6 | 37.1 | 35.5 |

| Sd (mPa·s) | 1.65 | 1.11 | 1.19 | 1.34 | 1.71 | 0.96 | |

| CV (%) | 3.57 | 1.70 | 1.92 | 5.93 | 4.61 | 2.70 | |

| HS-15/HS-5 | η (mPa·s) | 53.6 | 71.8 | 70.2 | 38.8 | 57.1 | 53.9 |

| Sd (mPa·s) | 1.31 | 1.32 | 1.43 | 1.18 | 0.90 | 1.25 | |

| CV (%) | 2.44 | 1.84 | 2.04 | 3.04 | 1.58 | 2.32 | |

| HS-AA-5/ HS-AA-1 | η (mPa·s) | 42.9 | 60.2 | 58.9 | 12.9 | 19.9 | 16.2 |

| Sd (mPa·s) | 1.54 | 1.27 | 1.01 | 1.70 | 1.25 | 1.70 | |

| CV (%) | 3.59 | 2.11 | 1.71 | 13.18 | 6.28 | 10.49 | |

| HS-AA-10/ HS-AA-3 | η (mPa·s) | 53.9 | 66.1 | 63.5 | 26.6 | 39.2 | 37.7 |

| Sd (mPa·s) | 1.65 | 1.44 | 1.22 | 1.57 | 1.26 | 1.27 | |

| CV (%) | 3.06 | 2.18 | 1.92 | 5.90 | 3.21 | 3.37 | |

| HS-AA-15/ HS-AA-5 | η (mPa·s) | 66.5 | 70.5 | 68.9 | 42.9 | 60.2 | 58.9 |

| Sd (mPa·s) | 0.82 | 1.63 | 1.25 | 1.25 | 1.37 | 1.54 | |

| CV (%) | 1.23 | 2.31 | 1.81 | 2.91 | 2.27 | 2.61 | |

| HS-HEMA-5/HS-HEMA-1 | η (mPa·s) | 44.8 | 62.0 | 60.0 | 14.3 | 21.7 | 20.1 |

| Sd (mPa·s) | 1.70 | 1.63 | 1.78 | 0.92 | 1.37 | 1.10 | |

| CV (%) | 3.79 | 2.63 | 2.97 | 6.43 | 6.31 | 5.47 | |

| HS-HEMA-10/HS-HEMA-3 | η (mPa·s) | 56.8 | 68.9 | 64.0 | 29.7 | 42.3 | 42.8 |

| Sd (mPa·s) | 1.53 | 1.2 | 1.35 | 1.31 | 1.65 | 1.26 | |

| CV (%) | 2.69 | 1.80 | 2.11 | 4.41 | 3.90 | 2.94 | |

| HS-HEMA-15/HS-HEMA-5 | η (mPa·s) | 69.3 | 72.9 | 70.6 | 44.8 | 62.0 | 60.0 |

| Sd (mPa·s) | 1.20 | 1.47 | 1.43 | 0.92 | 1.63 | 1.63 | |

| CV (%) | 1.73 | 2.02 | 2.02 | 2.05 | 2.63 | 2.72 | |

| Samples | Count of the Single Yarn | Count of the Plied Yarn | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 tex | 30 tex | 20 × 2 tex | 30 ×2 tex | |||||||||||||

| F20 (cN) | CV (%) | Ɛ20 (%) | CV (%) | F30 (cN) | CV (%) | Ɛ30 (%) | CV (%) | F20×2 (cN) | CV (%) | Ɛ20×2 (%) | CV (%) | F20×2 (cN) | CV (%) | Ɛ30×2 (%) | CV (%) | |

| Before sizing | 330 | 8.1 | 4.1 | 9.1 | 459 | 7.4 | 5.4 | 7.1 | 650 | 4.4 | 6.3 | 6.8 | 824 | 5.3 | 5.1 | 5.5 |

| HS-5/HS-1 | 349 | 9.2 | 2.9 | 8.8 | 478 | 6.6 | 3.8 | 6.5 | 665 | 4.8 | 5.5 | 7.5 | 835 | 4.5 | 4.6 | 6.2 |

| HS-10/HS-3 | 410 | 8.2 | 2.8 | 7.5 | 546 | 6.1 | 3.7 | 6.3 | 675 | 2.8 | 5.4 | 8.3 | 852 | 4.4 | 4.5 | 7.3 |

| HS-15/HS-5 | 445 | 7.8 | 2.7 | 7.9 | 574 | 7.2 | 3.5 | 5.5 | 688 | 5.2 | 5.3 | 9.6 | 877 | 3.5 | 4.3 | 5.8 |

| HS-AA-5/HS-AA-1 | 374 | 7.6 | 3.1 | 7.5 | 486 | 7.5 | 4.1 | 4.7 | 665 | 4.6 | 5.9 | 8.0 | 838 | 6.4 | 4.7 | 5.2 |

| HS-AA-10/HS-AA-3 | 436 | 7.9 | 3.0 | 7.8 | 555 | 7.3 | 4.1 | 3.9 | 686 | 4.1 | 5.7 | 7.3 | 839 | 5.4 | 4.5 | 8.0 |

| HS-AA-15/HS-AA-5 | 450 | 7.8 | 2.9 | 7.8 | 586 | 7.1 | 3.9 | 5.2 | 695 | 4.6 | 5.6 | 5.4 | 880 | 8.3 | 4.4 | 8.2 |

| HS-HEMA-5/HS-HEMA-1 | 385 | 8.5 | 3.5 | 8.8 | 497 | 8.1 | 4.5 | 5.7 | 671 | 6.0 | 6.1 | 10.2 | 845 | 4.7 | 4.9 | 10.0 |

| HS-HEMA-10/HS-HEMA-3 | 443 | 8.2 | 3.4 | 8.1 | 586 | 8.1 | 4.4 | 4.6 | 687 | 4.8 | 6.0 | 9.6 | 860 | 3.8 | 4.9 | 6.5 |

| HS-HEMA-15/HS-HEMA-5 | 467 | 7.4 | 3.4 | 8.2 | 601 | 8.2 | 4.3 | 7.3 | 705 | 3.8 | 5.8 | 6.7 | 903 | 5.4 | 4.7 | 9.8 |

| Samples | Degree of Yarn Desizing; by Using Washing off/ Ultrasound (%) | |||

|---|---|---|---|---|

| 20 tex | 30 tex | 20 × 2 tex | 30 × 2 tex | |

| HS-5/HS-1 | 80/90 | 70/78 | 85/90 | 75/83 |

| HS-10/HS-3 | 75/85 | 66/74 | 80/85 | 70/76 |

| HS-15/HS-5 | 72/82 | 65/72 | 77/83 | 65/70 |

| HS-AA-5/HS-AA-1 | 92/95 | 90/95 | 91/95 | 90/94 |

| HS-AA-10/HS-AA-3 | 90/92 | 89/91 | 90/93 | 88/92 |

| HS-AA-15/HS-AA-5 | 85/88 | 81/85 | 86/90 | 82/86 |

| HS-MK-5/HS-HEMA-1 | 91/97 | 93/98 | 92/97 | 93/97 |

| HS-MK-10/HS-HEMA-3 | 90/94 | 92/95 | 91/94 | 92/95 |

| HS-MK-15/HS-HEMA-5 | 86/88 | 88/90 | 85/90 | 88/92 |

| Samples | Tegewa Number by Using Washing/ultrasound | |||

|---|---|---|---|---|

| 20 tex | 30 tex | 20 × 2 tex | 30 × 2 tex | |

| HS-5/HS-1 | 6/6.5 | 5/7 | 6.5/7 | 6/7.5 |

| HS-10/HS-3 | 5.5/6 | 5/6.5 | 6/6 | 6/7 |

| HS-15/HS-5 | 5/6.5 | 4.5/6.5 | 6/7 | 5,5/7 |

| HS-AA-5/HS-AA-1 | 7.5/8 | 7/8 | 7/7 | 6.5/7.5 |

| HS-AA-10/HS-AA-3 | 7.5/8 | 6.5/8 | 7/8 | 6.5/8 |

| HS-AA-15/HS-AA-5 | 6/6.5 | 6/7.5 | 6/7 | 6/8 |

| HS-MK-5/HS-HEMA-1 | 8/8 | 8/8 | 7.5/8 | 7/8 |

| HS-MK-10/HS-HEMA-3 | 7.5/7.5 | 8/8 | 7.5/7.5 | 7/7.5 |

| HS-MK-15/HS-HEMA-5 | 7/7.5 | 7.5/8 | 7/7 | 7/7.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovačević, S.; Schwarz, I.; Đorđević, S.; Đorđević, D. Synthesis of Corn Starch Derivatives and Their Application in Yarn Sizing. Polymers 2020, 12, 1251. https://doi.org/10.3390/polym12061251

Kovačević S, Schwarz I, Đorđević S, Đorđević D. Synthesis of Corn Starch Derivatives and Their Application in Yarn Sizing. Polymers. 2020; 12(6):1251. https://doi.org/10.3390/polym12061251

Chicago/Turabian StyleKovačević, Stana, Ivana Schwarz, Suzana Đorđević, and Dragan Đorđević. 2020. "Synthesis of Corn Starch Derivatives and Their Application in Yarn Sizing" Polymers 12, no. 6: 1251. https://doi.org/10.3390/polym12061251

APA StyleKovačević, S., Schwarz, I., Đorđević, S., & Đorđević, D. (2020). Synthesis of Corn Starch Derivatives and Their Application in Yarn Sizing. Polymers, 12(6), 1251. https://doi.org/10.3390/polym12061251