Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives

Abstract

1. Introduction

2. Experimental Details

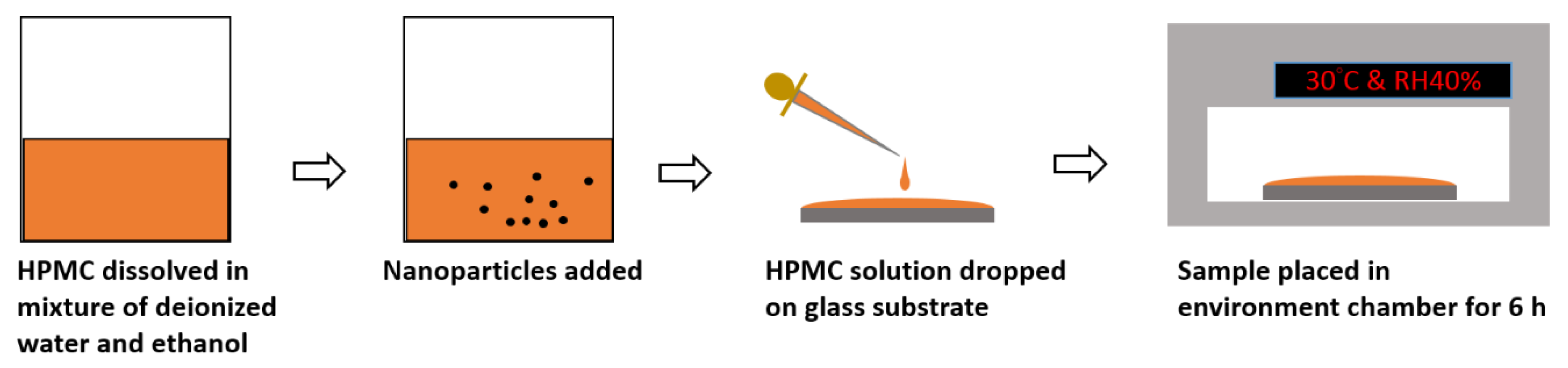

2.1. Film Preparation

2.2. Evaluation of the Mechanical Properties

2.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.4. Tribology Behavior of the HPMC Composites

2.5. Third-Body Velocity Accommodation Mode

3. Results and Discussion

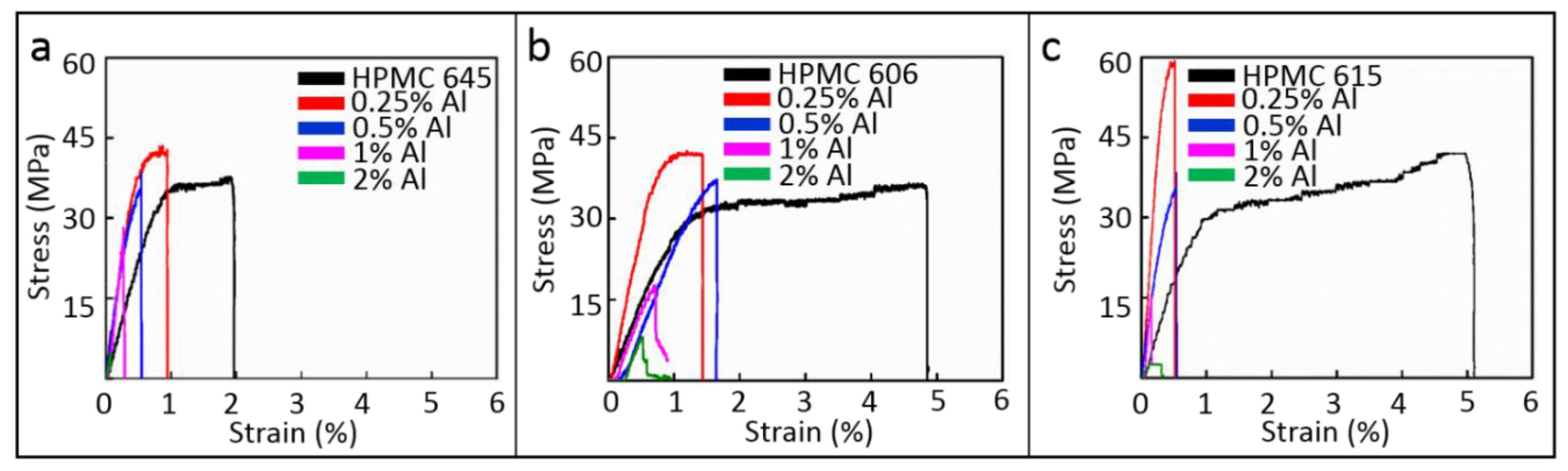

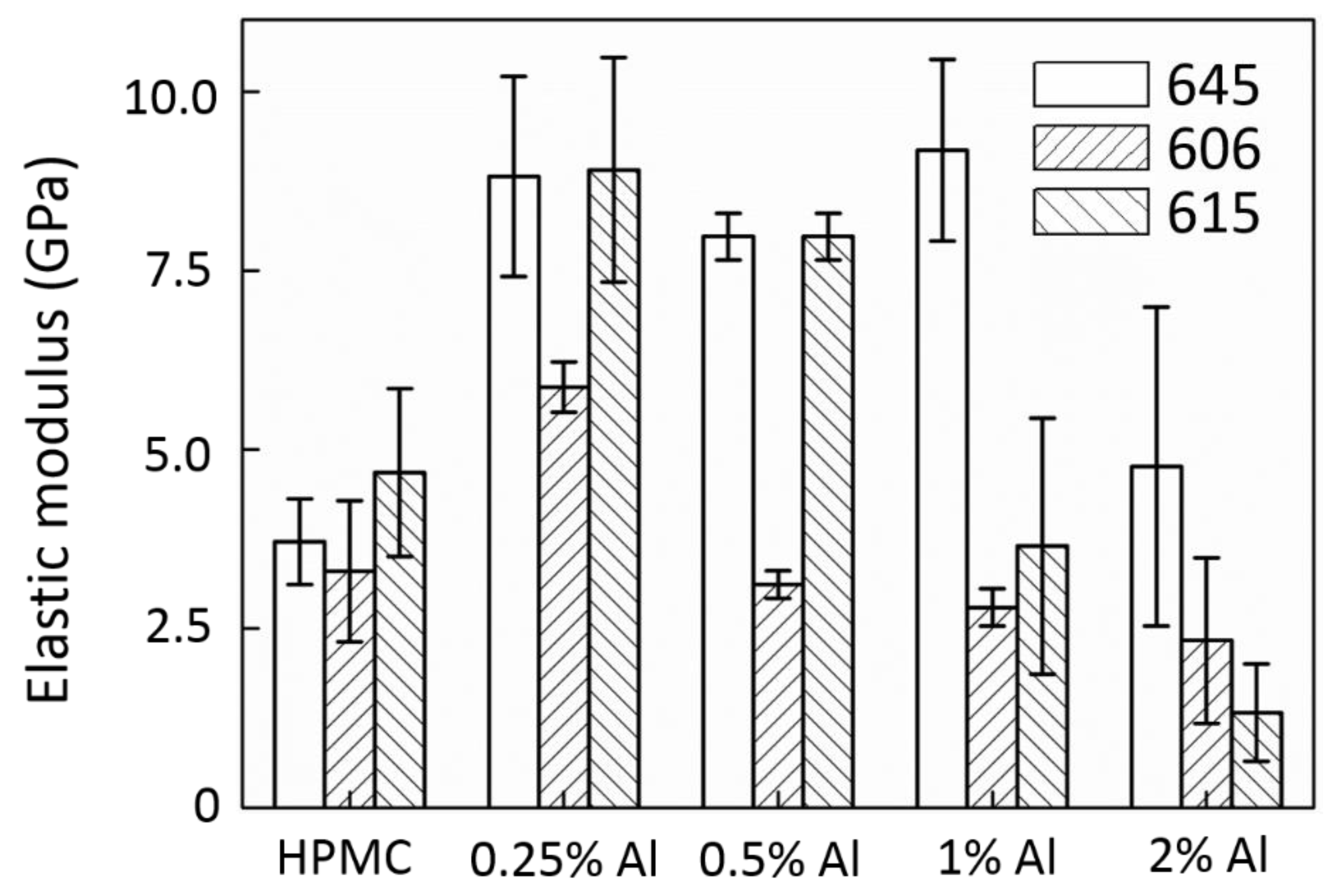

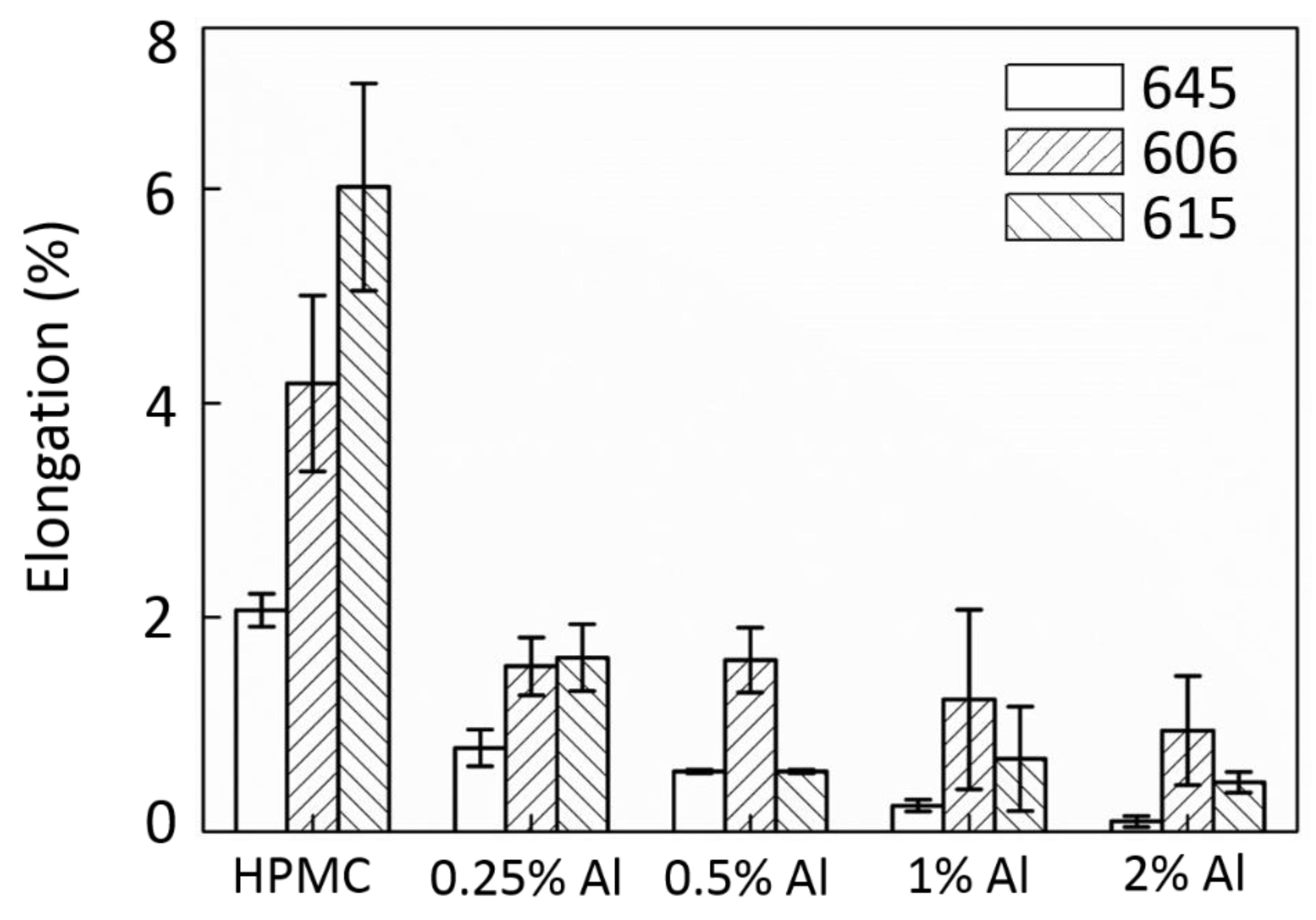

3.1. Mechanical Properties of the Nanocomposite Films

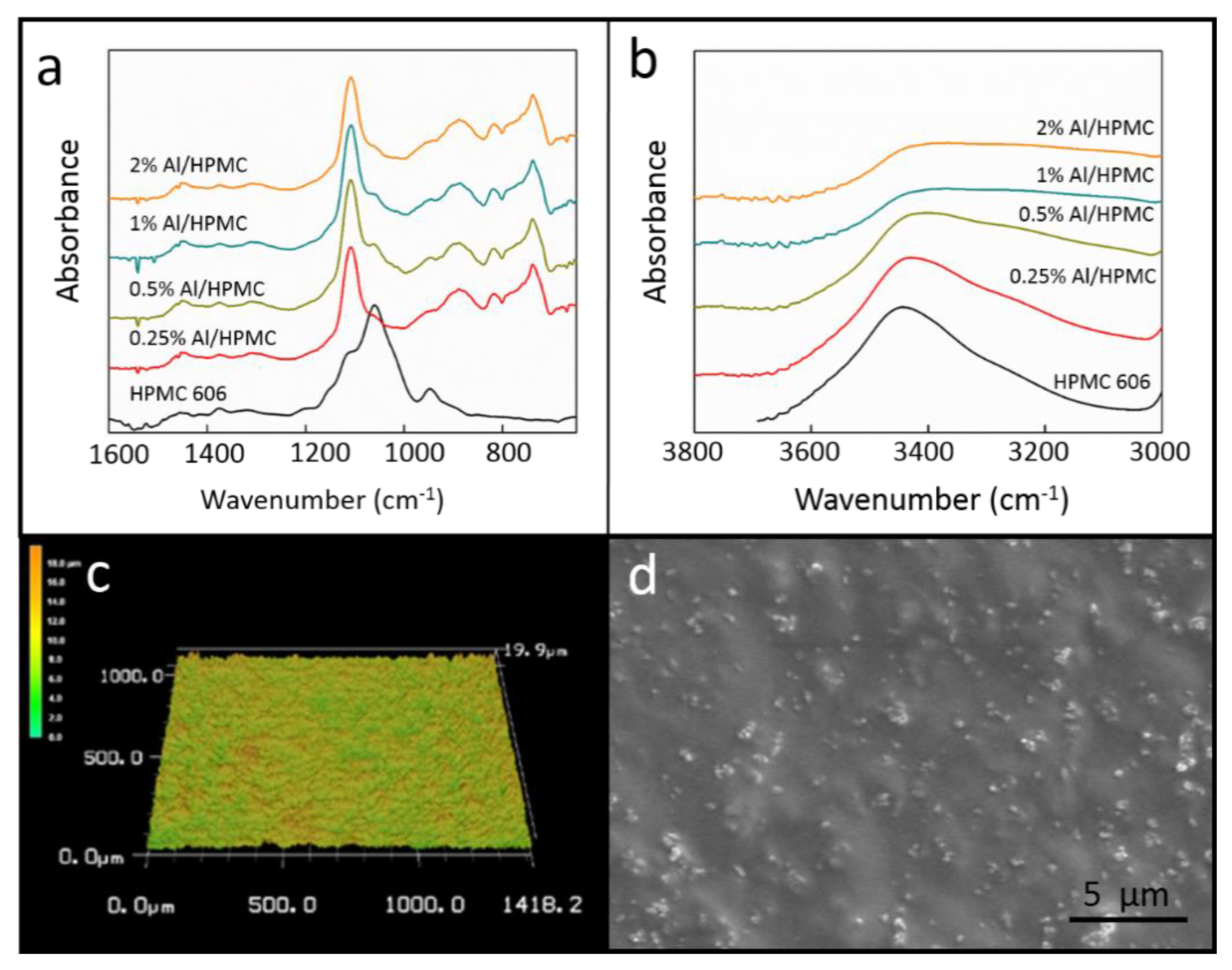

3.2. FTIR Evidence of Intermolecular Bonding

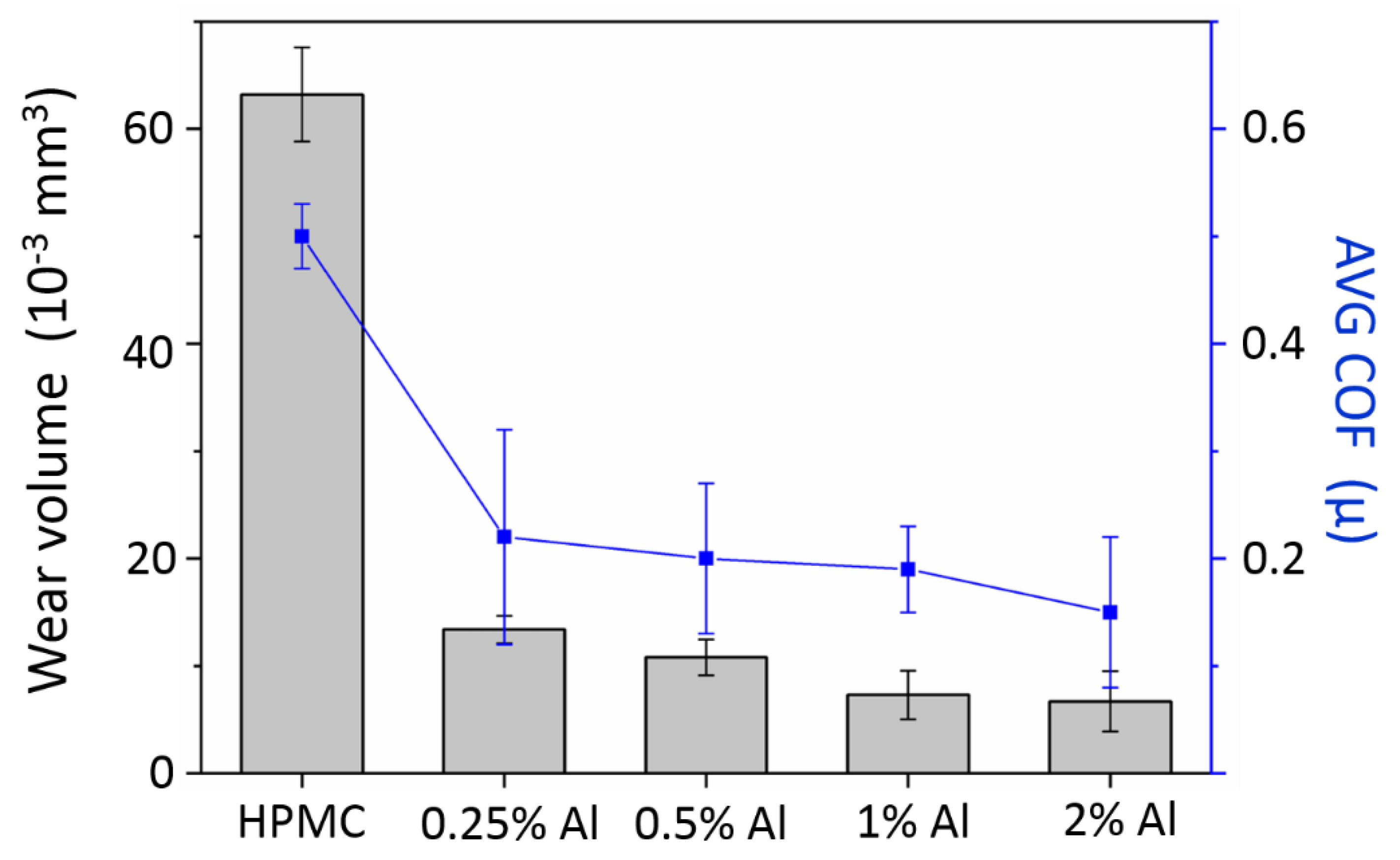

3.3. Tribology Behavior of the Al/HPMC Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hamberg, I.; Granqvist, C.G. Optical properties of transparent and heat-reflecting indium tin oxide films: Refinements of a model for ionized impurity scattering. J. Appl. Phys. 1986, 59, 2950–2952. [Google Scholar]

- Wang, B.-L.; Mai, Y.-W.; Zhang, X.-H. Thermal shock resistance of functionally graded materials. Acta Mater. 2004, 52, 4961–4972. [Google Scholar]

- Yu, C.; Ke, Y.; Hu, X.; Zhao, Y.; Deng, Q.; Lu, S. Effect of bifunctional montmorillonite on the thermal and tribological properties of polystyrene/montmorillonite nanocomposites. Polymers 2019, 11, 834. [Google Scholar] [CrossRef] [PubMed]

- Vaezi, K.; Asadpour, G.; Sharifi, H. Bio nanocomposites based on cationic starch reinforced with montmorillonite and cellulose nanocrystals: Fundamental properties and biodegradability study. Int. J. Biol. Macromol. 2020, 146, 374–386. [Google Scholar] [CrossRef]

- Minami, T. Present status of transparent conducting oxide thin-film development for Indium-Tin-Oide (ITO) substitutes. Thin Solid Film. 2008, 516, 5822–5828. [Google Scholar] [CrossRef]

- Chopra, K.; Major, S.; Pandya, D. Transparent conductors—A status review. Thin Solid Film. 1983, 102, 1–46. [Google Scholar] [CrossRef]

- Hay, W.T.; Fanta, G.F.; Peterson, S.C.; Thomas, A.; Utt, K.D.; Walsh, K.A.; Boddu, V.M.; Selling, G.W. Improved hydroxypropyl methylcellulose (HPMC) films through incorporation of amylose-sodium palmitate inclusion complexes. Carbohydr. Polym. 2018, 188, 76–84. [Google Scholar] [CrossRef]

- Shi, S.-C.; Wu, J.-Y. MoS2 additives for enhancing tribological performance of hydroxypropyl methylcellulose biopolymer. Smart Sci. 2017, 5, 167–172. [Google Scholar]

- Shi, S.-C.; Wu, J.-Y.; Huang, T.-F.; Peng, Y.-Q. Improving the tribological performance of biopolymer coating with MoS2 additive. Surf. Coat. Technol. 2016, 303, 250–255. [Google Scholar]

- Shi, S.-C.; Lu, F.-I. Biopolymer green lubricant for sustainable manufacturing. Materials 2016, 9, 338. [Google Scholar]

- Shi, S.-C. Tribological performance of green lubricant enhanced by sulfidation IF-MoS2. Materials 2016, 9, 856. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.-C.; Huang, T.-F. Self-healing materials for ecotribology. Materials 2017, 10, 91. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.-C.; Huang, T.-F. Effects of temperature and humidity on self-healing behaviour of biopolymer hydroxylpropyl methylcellulose for ecotribology. Surf. Coat. Technol. 2018, 350, 997–1002. [Google Scholar] [CrossRef]

- Shi, S.-C.; Su, C.-C. Corrosion inhibition of high speed steel by biopolymer HPMC derivatives. Materials 2016, 9, 612. [Google Scholar] [CrossRef]

- Shi, S.-C.; Su, C.-C. Electrochemical behavior of hydroxypropyl methylcellulose acetate succinate as novel biopolymeric anticorrosion coating. Mater. Chem. Phys. 2020, 248, 122929. [Google Scholar] [CrossRef]

- Shi, S.-C.; Wu, J.-Y.; Huang, T.-F. Raman, FTIR, and XRD study of MoS2 enhanced hydroxypropyl methylcellulose green lubricant. Opt. Quantum Electron. 2016, 48, 474. [Google Scholar] [CrossRef]

- Shi, S.-C.; Huang, T.-F. Raman study of HPMC biopolymer transfer layer formation under tribology test. Opt. Quantum Electron. 2016, 48, 532. [Google Scholar] [CrossRef]

- Fahs, A.; Brogly, M.; Bistac, S.; Schmitt, M. Hydroxypropyl methylcellulose (HPMC) formulated films: Relevance to adhesion and friction surface properties. Carbohydr. Polym. 2010, 80, 105–114. [Google Scholar] [CrossRef]

- Ghosh, T.K.; Gope, S.; Mondal, D.; Bhowmik, B.; Mollick, M.M.R.; Maity, D.; Roy, I.; Sarkar, G.; Sadhukhan, S.; Rana, D. Assessment of morphology and property of graphene oxide-hydroxypropylmethylcellulose nanocomposite films. Int. J. Biol. Macromol. 2014, 66, 338–345. [Google Scholar] [CrossRef]

- Vijayashree, K.; Rai, K.S.; Demappa, T. Investigation on nanosized CuO incorporated hydroxypropyl methylcellulose polymer nanocomposite films. Indian J. Adv. Chem. Sci. S1 2016, 1, 5. [Google Scholar]

- Wang, Y.; Zhang, L.; Liu, H.; Yu, L.; Simon, G.P.; Zhang, N.; Chen, L. Relationship between morphologies and mechanical properties of hydroxypropyl methylcellulose/hydroxypropyl starch blends. Carbohydr. Polym. 2016, 153, 329–335. [Google Scholar] [CrossRef]

- Shi, S.-C.; Jiang, S.-Z. Influence of graphene/copper hybrid nanoparticle additives on tribological properties of solid cellulose lubricants. Surf. Coat. Technol. 2020, 389, 125655. [Google Scholar] [CrossRef]

- Shi, S.-C.; Tsai, X.-N.; Pek, S.-S. Tribological behavior and energy dissipation of hybrid nanoparticle-reinforced HPMC composites during sliding wear. Surf. Coat. Technol. 2020, 389, 125617. [Google Scholar] [CrossRef]

- Abanto-Bueno, J.; Lambros, J. Investigation of crack growth in functionally graded materials using digital image correlation. Eng. Fract. Mech. 2002, 69, 1695–1711. [Google Scholar] [CrossRef]

- Jedamzik, R.; Neubrand, A.; Rödel, J. Functionally graded materials by electrochemical processing and infiltration: Application to tungsten/copper composites. J. Mater. Sci. 2000, 35, 477–486. [Google Scholar] [CrossRef]

- Shi, S.-C.; Peng, Y.-Q. Preparation and tribological studies of stearic acid-modified biopolymer coating. Prog. Org. Coat. 2020, 138, 105304. [Google Scholar] [CrossRef]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Berthier, Y. Experimental evidence for friction and wear modelling. Wear 1990, 139, 77–92. [Google Scholar] [CrossRef]

- Shi, S.-C.; Pek, S.-S. Third-body and dissipation energy in green tribology film. Appl. Sci. 2019, 9, 3787. [Google Scholar] [CrossRef]

- Shi, S.-C.; Huang, T.-F.; Wu, J.-Y. Preparation and tribological study of biodegradable lubrication films on Si substrate. Materials 2015, 8, 1738–1751. [Google Scholar] [CrossRef]

- Kausch, H.; Michler, G. Effect of nanoparticle size and size-distribution on mechanical behavior of filled amorphous thermoplastic polymers. J. Appl. Polym. Sci. 2007, 105, 2577–2587. [Google Scholar] [CrossRef]

- Shi, S.-C.; Yang, J.H.C. Preparation of stable biopolymer composite suspension with metal/metal-oxide nanoparticles. Mod. Phys. Lett. B 2020, 34, 2040028. [Google Scholar] [CrossRef]

- Olea-Mejia, O.; Brostow, W.; Buchman, E. Wear resistance and wear mechanisms in polymer+ metal composites. J. Nanosci. Nanotechnol. 2010, 10, 8254–8259. [Google Scholar] [CrossRef]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides: Structure, Properties, Reactions, Occurrences and Uses; Wiley: New York, NY, USA, 2003. [Google Scholar]

- Lutz, B.T.; Astarloa, G.; van der Maas, J.H.; Janssen, R.G.; Verboom, W.; Reinhoudt, D.N. Conformational isomerism and self-association of calixarene building blocks in non-polar solution studied by fourier transform infrared spectrometry. Vib. Spectrosc. 1995, 10, 29–40. [Google Scholar] [CrossRef]

- Sözügeçer, S.; Bayramgil, N.P. Activity of glucose oxidase immobilized onto Fe3+ attached hydroxypropyl methylcellulose films. Colloids Surf. B Biointerfaces 2013, 101, 19–25. [Google Scholar] [CrossRef] [PubMed]

| Grade | Molecular Weight (g/mol) | Viscosity (mPa·s) @ 20 °C, 2 wt.% |

|---|---|---|

| HPMC 645 | 20,000 | 4.5 |

| HPMC 606 | 35,600 | 6 |

| HPMC 615 | 60,000 | 15 |

| Al (g) | 0 | 0.259 | 0.518 | 1.041 | 2.103 |

| Al (wt.%) | 0 | 0.25 | 0.5 | 1 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.-C.; Chen, T.-H.; Mandal, P.K. Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives. Polymers 2020, 12, 1246. https://doi.org/10.3390/polym12061246

Shi S-C, Chen T-H, Mandal PK. Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives. Polymers. 2020; 12(6):1246. https://doi.org/10.3390/polym12061246

Chicago/Turabian StyleShi, Shih-Chen, Tao-Hsing Chen, and Pramod Kumar Mandal. 2020. "Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives" Polymers 12, no. 6: 1246. https://doi.org/10.3390/polym12061246

APA StyleShi, S.-C., Chen, T.-H., & Mandal, P. K. (2020). Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives. Polymers, 12(6), 1246. https://doi.org/10.3390/polym12061246