Potential Natural Fiber Polymeric Nanobiocomposites: A Review

Abstract

1. Introduction

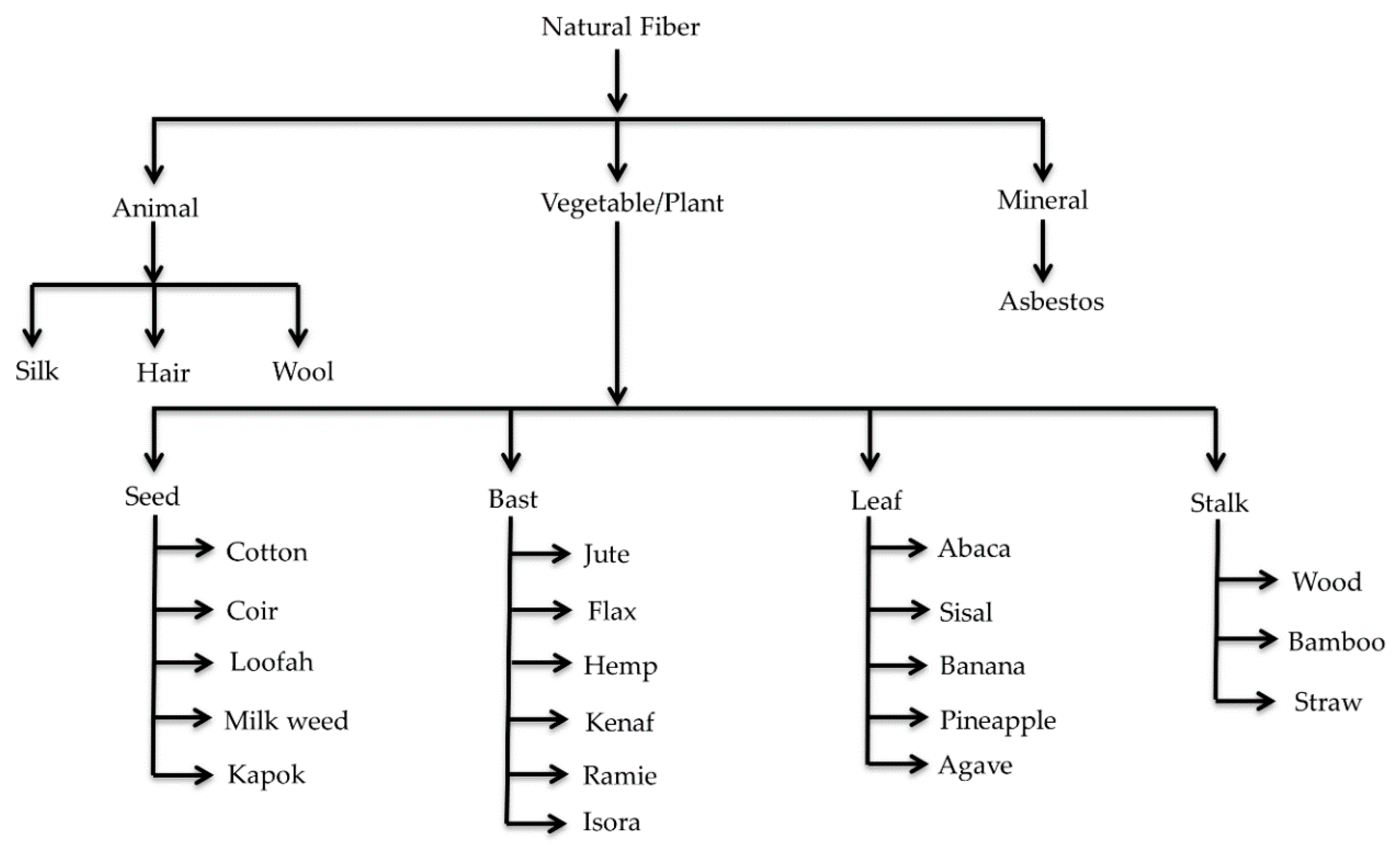

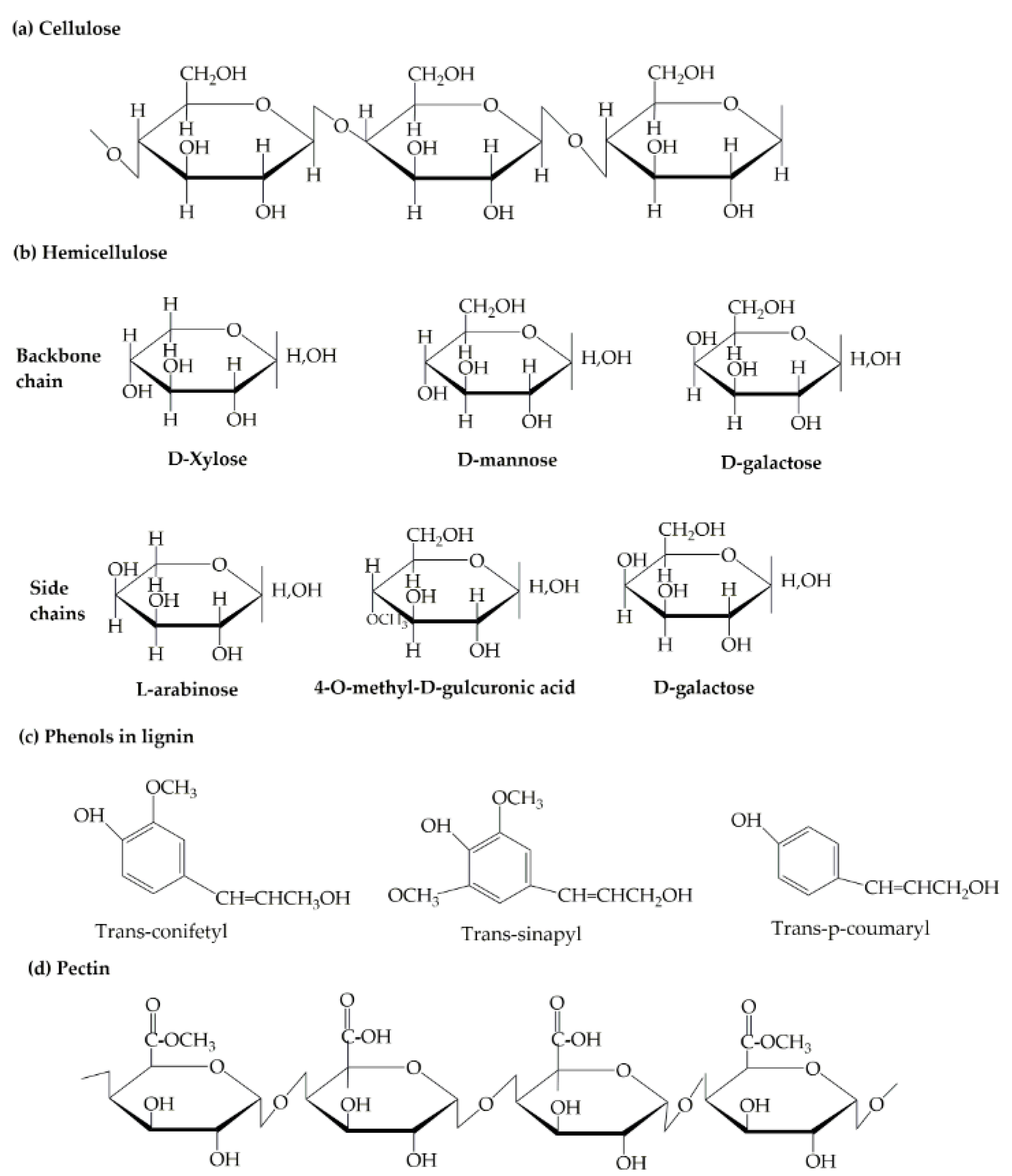

2. Natural Fibers

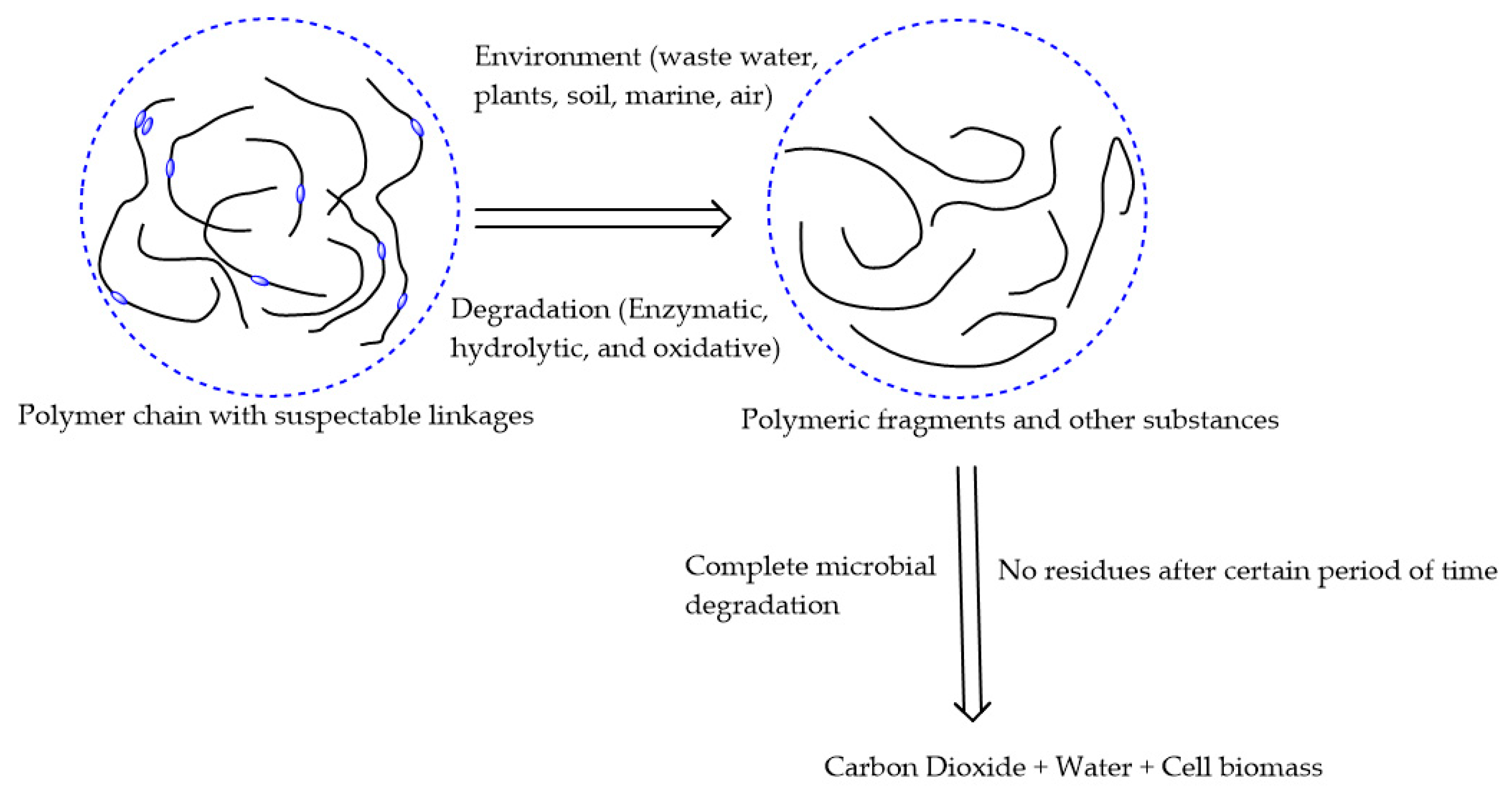

3. Polymer/Matrix

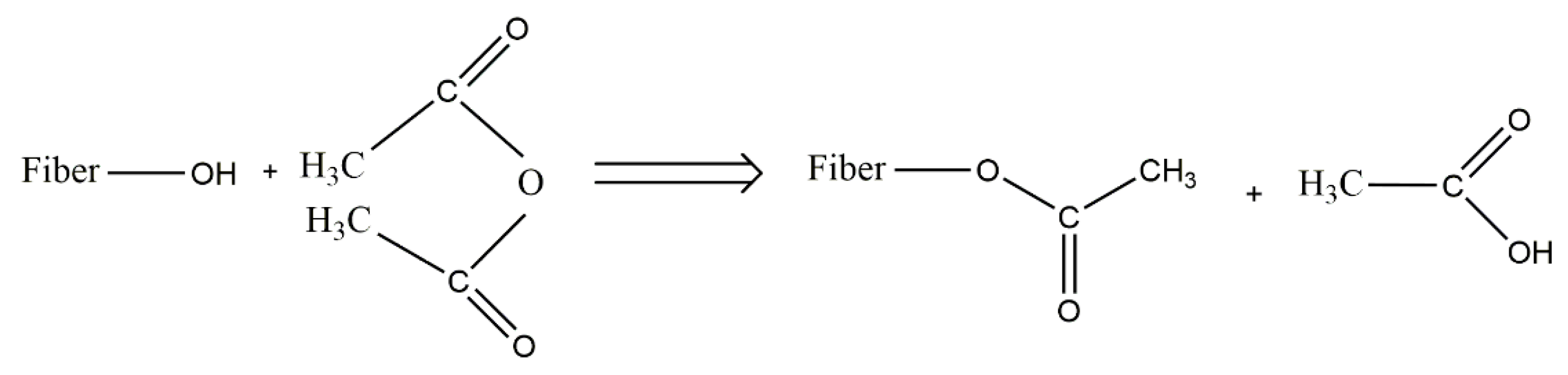

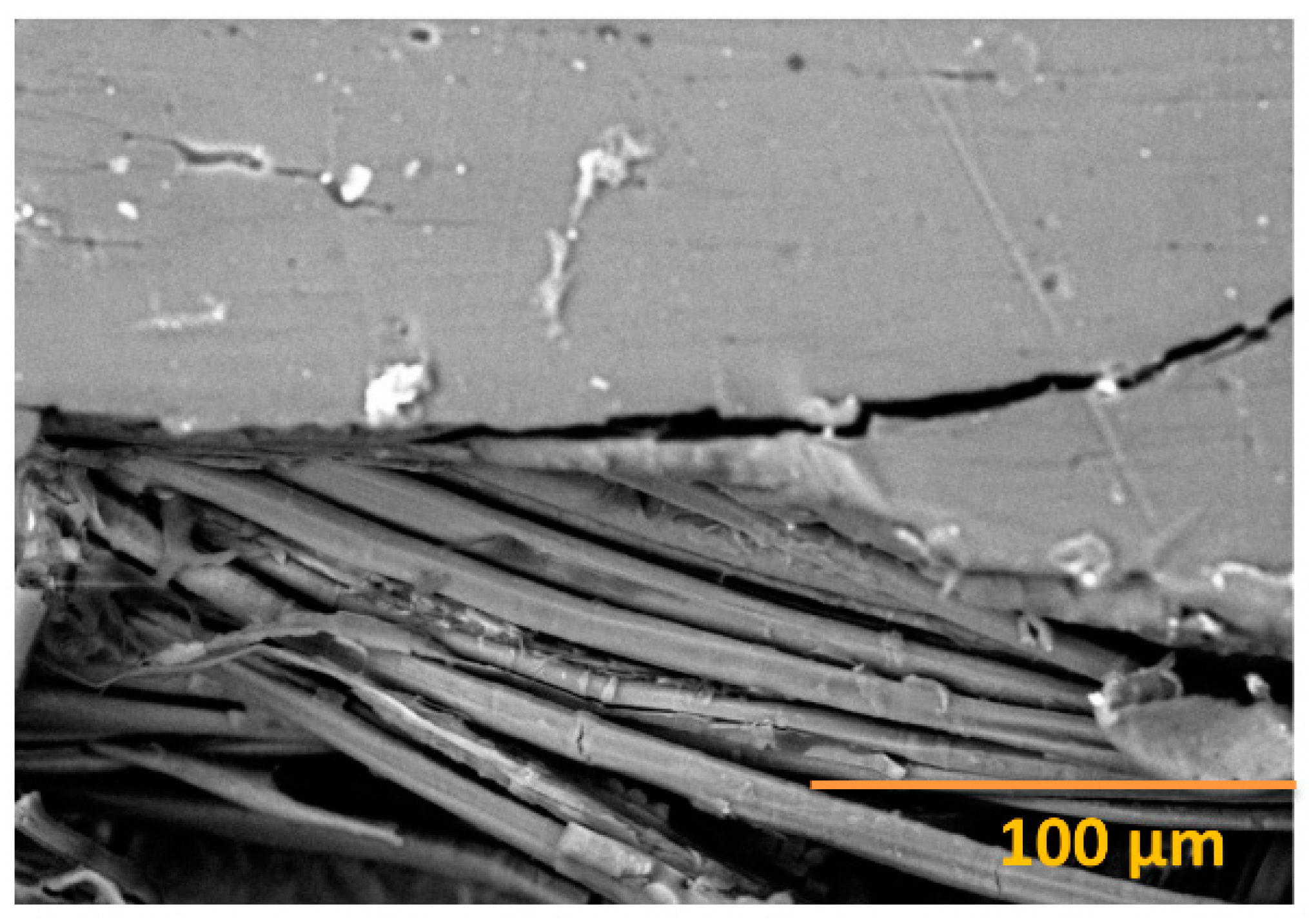

4. Surface Treatment of Biofibers before Composite Formation

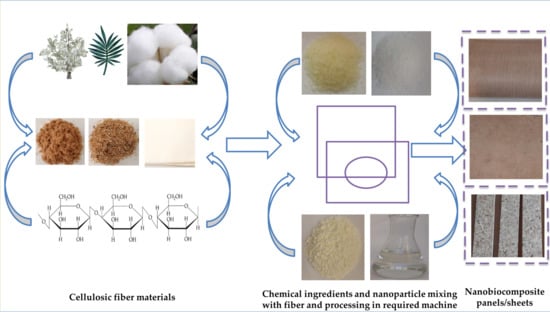

5. Preparation of BCs and NBCs

6. Natural Filler Reinforced Polymeric NBC

7. Nanoparticle-Based BCs (NBCs)

7.1. TiO2-Based NBC

7.2. Silica-Based NBC

7.3. Graphene-Based NBC

7.4. Carbon Nanotube-Based NBC

7.5. ZnO-Based NBC

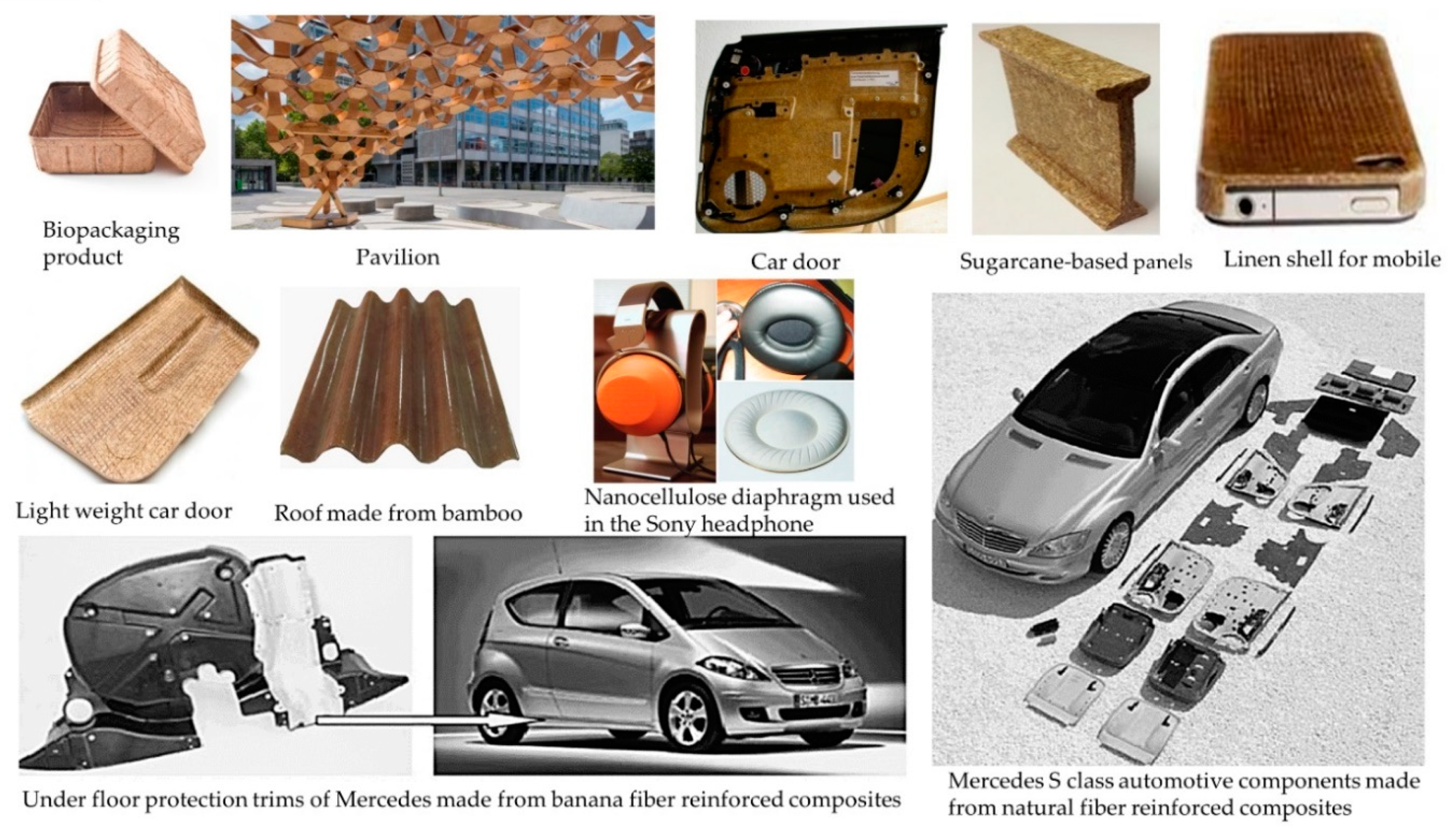

8. Application of BCs and NBCs

9. Marketing Aspects of NBCs

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zagho, M.M.; Hussein, E.A.; Elzatahry, A.A. Recent Overviews in Functional Polymer Composites for Biomedical Applications. Polymers 2018, 10, 739. [Google Scholar] [CrossRef] [PubMed]

- Sherif, G.; Chukov, D.I.; Tcherdyntsev, V.V.; Torokhov, V. Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers. Polymers 2019, 11, 1364. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.; Bin Abdollah, M.F.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using Weighted Decision Matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Mashkour, M.; Ranjbar, Y. Superparamagnetic Fe3O4@ wood flour/polypropylene nanocomposites: Physical and mechanical properties. Ind. Crop. Prod. 2018, 111, 47–54. [Google Scholar] [CrossRef]

- Sun, G.; Liang, R.; Lu, Z.; Shi, T.; Geng, P.; Li, Z. Remarkable mechanical enhancement achieved by interfacial strengthening of organic/inorganic/fiber composites. Constr. Build. Mater. 2017, 142, 7–10. [Google Scholar] [CrossRef]

- Sun, Z.; Mingming, W. Effects of sol-gel modification on the interfacial and mechanical properties of sisal fiber reinforced polypropylene composites. Ind. Crop. Prod. 2019, 137, 89–97. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Boulos, L.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. The Effect of cellulose oxidation on interfacial bonding of nano-TiO2 coating to flax fibers. Cellulose 2017, 24, 1529–1542. [Google Scholar] [CrossRef]

- Narayan, R. Biodegradability. Bioplastics Magazine 2009, 4, 28–31. Available online: https://bpiworld.org/resources/Documents/Narayan%20Bioplastics%20Article%202009.pdf (accessed on 20 December 2019).

- Rahman, R.; Putra, S.Z.F.S. Tensile properties of natural and synthetic fiber-reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier BV: Woodhead Publishing: Duxford, UK, 2019; pp. 81–102. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Man. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2019, 55, 829–892. [Google Scholar] [CrossRef]

- Davoodi, M.; Sapuan, S.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M.; Sapuan, S.M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Tshai, K.Y.; Kong, I. Advancement in flame retardancy of natural fibre reinforced composites with macro to nanoscale particulates additives. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier BV: Woodhead Publishing: Duxford, UK, 2020; pp. 311–342. [Google Scholar]

- Wu, H.; Fahy, W.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 100638. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Al-Oqla, F.M.; Sapuan, S.; Anwer, T.; Jawaid, M.; Hoque, E.; Sapuan, S.M. Natural fiber reinforced conductive polymer composites as functional materials: A review. Synth. Met. 2015, 206, 42–54. [Google Scholar] [CrossRef]

- Kord, B.; Ghalehno, M.D.; Movahedi, F. Effect of Surface Functionalization of SiO2 Nanoparticles on the Dynamic Mechanical, Thermal and Fire Properties of Wheat Straw/LDPE Composites. J. Polym. Environ. 2019, 28, 304–316. [Google Scholar] [CrossRef]

- Mousa, M.; Dong, Y. A critical role of interphase properties and features on mechanical properties of poly(vinyl alcohol) (PVA) bionanocomposites. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier BV: Woodhead Publishing: Duxford, UK, 2020; pp. 115–136. [Google Scholar]

- Saba, N.; Paridah, M.T.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Islam, S.; Ahmad, M.B.; Hasan, M.; Aziz, S.A.; Jawaid, M.; Haafiz, M.K.M.; Zakaria, S.A.H. Natural Fiber-Reinforced Hybrid Polymer Nanocomposites: Effect of Fiber Mixing and Nanoclay on Physical, Mechanical, and Biodegradable Properties. Bioresources 2015, 10, 1394–1407. [Google Scholar] [CrossRef]

- Ching, Y.C.; Rahman, A.; Ching, K.Y.; Sukiman, N.L.; Cheng, H.C. Preparation and Characterization of Polyvinyl Alcohol-Based Composite Reinforced with Nanocellulose and Nanosilica. Bioresources 2015, 10, 3364–3377. [Google Scholar] [CrossRef]

- Sharma, A.; Bhojak, V.; Kukshal, V.; Biswas, S.K.; Patnaik, A.; Patnaik, T.K. Mechanical and Erosion Characteristics of Natural Fiber Reinforced Polymer Composite: Effect of Filler Size. Automotive Tribology. In Energy, Environment, and Sustainability; Springer Science and Business Media LLC: Singapore, 2019; pp. 101–116. [Google Scholar]

- Arjmandi, R.; Hassan, A.; Zakaria, Z. Polylactic Acid Green Nanocomposites for Automotive Applications. In Global Warming; Springer Science and Business Media LLC: Cham, Switzerland, 2017; pp. 193–208. [Google Scholar]

- Kong, J.; Tan, B.H.; Lu, X.; Li, Z.; He, C. Hybrid POSS Nanocomposites. In Silicon Containing Hybrid Copolymers; John Wiley and Sons: Weinheim, Germany, 2020; pp. 201–237. [Google Scholar]

- Chen, H.; Cui, Y.; Liu, X.; Zhang, M.; Hao, S.; Yin, Y. Study on depositing SiO 2 nanoparticles on the surface of jute fiber via hydrothermal method and its reinforced polypropylene composites. J. Vinyl Addit. Technol. 2019, 26, 43–54. [Google Scholar] [CrossRef]

- Spinella, A.; Bondioli, F.; Nasillo, G.; Renda, V.; Caponetti, E.; Messori, M.; Morselli, D. Organic-inorganic nanocomposites prepared by reactive suspension method: Investigation on filler/matrix interactions and their effect on the nanoparticles dispersion. Colloid Polym. Sci. 2017, 295, 695–701. [Google Scholar] [CrossRef]

- Bansal, S.A.; Singh, A.P.; Kumar, A.; Kumar, S.; Kumar, N.; Goswamy, J.K. Improved mechanical performance of bisphenol-A graphene-oxide nano-composites. J. Compos. Mater. 2017, 52, 2179–2188. [Google Scholar] [CrossRef]

- Genix, A.-C.; Oberdisse, J. Nanoparticle self-assembly: From interactions in suspension to polymer nanocomposites. Soft Matter 2018, 14, 5161–5179. [Google Scholar] [CrossRef] [PubMed]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Amiandamhen, S.; Meincken, M.; Tyhoda, L. Natural Fibre Modification and Its Influence on Fibre-matrix Interfacial Properties in Biocomposite Materials. Fiber. Polym. 2020, 21, 677–689. [Google Scholar] [CrossRef]

- Markó, G.; Halász, K.; Alpár, T. Natural fibre reinforced PLA composite. In Proceedings of the International Conference on Bio-Friendly Polymers and Polymer Additives: From Scientific Aspects to Processing and Applications, Budapest, Hungary, 19–21 May 2014; p. 23. [Google Scholar]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Kamaraj, M.; Dodson, E.A.; Datta, S. Effect of graphene on the properties of flax fabric reinforced epoxy composites. Adv. Compos. Mater. 2019, 1–16. [Google Scholar] [CrossRef]

- Shea, A.; Lawrence, M.; Walker, P.; Walker, P. Hygrothermal performance of an experimental hemp–lime building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Ansell, M.P.; Jiang, Y.; Schorr, D.; Blanchet, P. Development of novel building composites based on hemp and multi-functional silica matrix. Compos. Part B Eng. 2019, 156, 266–273. [Google Scholar] [CrossRef]

- Bajpai, P. Biermann’s Handbook of Pulp and Paper: Paper and Board Making, 3rd ed.; Marinakis, K.K., Fisher, M.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Azeez, M.A.; Orege, J.I. Bamboo, Its Chemical Modification and Products. Bamboo Curr. Fut. Prosp. 2018, 25–48. [Google Scholar]

- Li, X.; Tabil, L.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P.; White, R.H. Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym. 2011, 12, 919–926. [Google Scholar] [CrossRef]

- Muzyczek, M. The use of flax and hemp for textile applications. In Handbook of Natural Fibres; Elsevier BV: Woodhead Publishing: Duxford, UK, 2020; pp. 147–167. [Google Scholar]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Battegazzore, D.; Frache, A.; Abt, T.; Maspoch, M.L. Epoxy coupling agent for PLA and PHB copolymer-based cotton fabric bio-composites. Compos. Part B Eng. 2018, 148, 188–197. [Google Scholar] [CrossRef]

- Holt, G.; Chow, P.; Wanjura, J.; Pelletier, M.; Wedegaertner, T. Evaluation of thermal treatments to improve physical and mechanical properties of bio-composites made from cotton byproducts and other agricultural fibers. Ind. Crop. Prod. 2014, 52, 627–632. [Google Scholar] [CrossRef]

- Shibata, M.; Teramoto, N.; Nakamura, T.; Saitoh, Y. All-cellulose and all-wood composites by partial dissolution of cotton fabric and wood in ionic liquid. Carbohydr. Polym. 2013, 98, 1532–1539. [Google Scholar] [CrossRef]

- Shen, M.; Wang, L.; Long, J.-J. Biodegumming of ramie fiber with pectinases enhanced by oxygen plasma. J. Clean. Prod. 2015, 101, 395–403. [Google Scholar] [CrossRef]

- Roy, S.; Lutfar, L. Bast fibres: Ramie. In Handbook of Natural Fibres; Elsevier BV: Woodhead Publishing: Duxford, UK, 2012; pp. 47–55. [Google Scholar]

- Mahmud, S.; Pervez, N.; Hasan, K.M.F.; Abu Taher, M.; Liu, H.; Mahmud, S. In situ synthesis of green AgNPs on ramie fabric with functional and catalytic properties. Emerg. Mater. Res. 2019, 8, 623–633. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly (lactic acid)/ramie composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Verma, D.; Senal, I. Natural fiber-reinforced polymer composites: Feasibiliy study for sustainable automotive industries. In Biomass, Biopolymer-Based Materials, and Bioenergy, 1st ed.; Verma, D., Fortunati, E., Jain, S., Zhang, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–122. [Google Scholar]

- Menezes, P.L.; Rohatgi, P.; Lovell, M.R. Studies on the Tribological Behavior of Natural Fiber Reinforced Polymer Composite; Springer Science and Business Media LLC: Berlin, Germany, 2012; pp. 329–345. [Google Scholar]

- Razali, N.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Lazim, Y. A Study on Chemical Composition, Physical, Tensile, Morphological, and Thermal Properties of Roselle Fibre: Effect of Fibre Maturity. Bioresources 2015, 10, 1803–1824. [Google Scholar] [CrossRef]

- Pereira, J.F.; Ferreira, D.; Bessa, J.; Matos, J.; Cunha, F.; Araújo, I.; Silva, L.F.; Pinho, E.; Fangueiro, R. Mechanical performance of thermoplastic olefin composites reinforced with coir and sisal natural fibers: Influence of surface pretreatment. Polym. Compos. 2019, 40, 3472–3481. [Google Scholar] [CrossRef]

- Essabir, H.; Bensalah, M.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E.K. Structural, mechanical and thermal properties of bio-based hybrid composites from waste coir residues: Fibers and shell particles. Mech. Mater. 2016, 93, 134–144. [Google Scholar] [CrossRef]

- Zhu, Z.; Hao, M.; Zhang, N. Influence of contents of chemical compositions on the mechanical property of sisal fibers and sisal fibers reinforced PLA composites. J. Nat. Fibers 2018, 17, 1–12. [Google Scholar] [CrossRef]

- Hempalaya. The Difference between Hemp and Linen Fibers. Available online: https://hempalaya.com/blogs/news/der-unterschied-zwischen-hanf-und-leinen-fasern (accessed on 20 December 2019).

- Sunstrands. The Basics of Kenaf Fiber and Hurd. Available online: https://www.sunstrands.com/2019/the-uses-of-kenaf-fiber/ (accessed on 20 December 2019).

- Swadesh. Indira Gandhi Krishi Vishvavidyalaya (IGKV) Achieves a Breakthrough in Getting Linen Yarn Using the Flax Plant. Available online: https://www.unnatisilks.com/blog/indira-gandhi-krishi-vishvavidyalaya-igkv-achieves-a-breakthrough-in-getting-linen-yarn-using-the-flax-plant/ (accessed on 20 January 2020).

- Textiles School. Sampling from Cotton Bales. Available online: https://www.textileschool.com/164/cotton-fibers-and-its-properties (accessed on 20 January 2020).

- Fatema Jute Fibers. Raw Jute. Available online: http://fatemajutefibers.com (accessed on 20 January 2020).

- Always Fresh. Why We Use Coconut Coir Not Soil. Available online: http://www.alwaysfresh2u.com/uncategorized/use-coconut-coir-not-soil (accessed on 20 January 2020).

- Tintsaba. The Sesal Plant. Available online: https://www.tintsaba.com/sisal (accessed on 20 December 2019).

- Leiden, T. Ramie. Available online: https://trc-leiden.nl/trc-needles/materials/fibres/ramie (accessed on 20 January 2020).

- Fan, R.; Ma, W.; Liu, S.; Huang, Q. Integrated analysis of four new sequenced fern Chloroplast Genomes: Genome structure and Comparative Analysis. Plant Physiol. Morphol. 2019. [Google Scholar] [CrossRef]

- Dreamstime. Sugarcane Juice Gabasse. Available online: https://www.dreamstime.com/photos-images/sugarcane-juice-bagasse.html (accessed on 20 December 2019).

- Cisneros-López, E.; Pérez-Fonseca, A.A.; Fuentes-Talavera, F.; Anzaldo, J.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Rotomolded polyethylene-agave fiber composites: Effect of fiber surface treatment on the mechanical properties. Polym. Eng. Sci. 2016, 56, 856–865. [Google Scholar] [CrossRef]

- Langhorst, A.E.; Burkholder, J.; Long, J.; Thomas, R.; Kiziltas, A.; Mielewski, D. Blue-Agave Fiber-Reinforced Polypropylene Composites for Automotive Applications. Bioresources 2017, 13, 820–835. [Google Scholar] [CrossRef]

- Annandarajah, C.; Li, P.; Michel, M.; Chen, Y.; Jamshidi, R.; Kiziltas, A.; Hoch, R.; Grewell, D.; Montazami, R. Study of Agave Fiber-Reinforced Biocomposite Films. Materials 2018, 12, 99. [Google Scholar] [CrossRef]

- Mahdi, E.; Dean, A. The Effect of Filler Content on the Tensile Behavior of Polypropylene/Cotton Fiber and poly (vinyl chloride)/Cotton Fiber Composites. Materials 2020, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Ng, W.; Johar, M.; Israr, H.; Wong, K. A review on the interfacial characteristics of natural fibre reinforced polymer composites. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier BV: Woodhead Publishing: Duxford, UK, 2020; pp. 163–198. [Google Scholar]

- Farahbakhsh, N.; Shahbeigi-Roodposhti, P.; Sadeghifar, H.; Venditti, R.A.; Jur, J.S. Effect of isolation method on reinforcing capability of recycled cotton nanomaterials in thermoplastic polymers. J. Mater. Sci. 2017, 52, 4997–5013. [Google Scholar] [CrossRef]

- Battegazzore, D.; Abt, T.; Maspoch, M.L.; Frache, A. Multilayer cotton fabric bio-composites based on PLA and PHB copolymer for industrial load carrying applications. Compos. Part B Eng. 2019, 163, 761–768. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Zwawi, M.; Mehran, M.T.; Kanthasamy, R.; Bahadar, A. Jute Based Bio and Hybrid Composites and Their Applications. Fibers 2019, 7, 77. [Google Scholar] [CrossRef]

- Dinesh, S.; Kumaran, P.; Mohanamurugan, S.; Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.; Siengchin, S.; Bhat, K.S. Influence of wood dust fillers on the mechanical, thermal, water absorption and biodegradation characteristics of jute fiber epoxy composites. J. Polym. Res. 2019, 27, 9. [Google Scholar] [CrossRef]

- Tanasă, F.; Zănoagă, M.; Teacă, C.; Nechifor, M.; Shahzad, A. Modified hemp fibers intended for fiber-reinforced polymer composites used in structural applications—A review. I. Methods of modification. Polym. Compos. 2019, 41, 5–31. [Google Scholar] [CrossRef]

- Del Borrello, M.; Mele, M.; Campana, G.; Secchi, M. Manufacturing and characterization of hemp-reinforced epoxy composites. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. Three-Dimensional Printing of Continuous Flax Fiber-Reinforced Thermoplastic Composites by Five-Axis Machine. Materials 2020, 13, 1678. [Google Scholar] [CrossRef]

- Munde, Y.S.; Ingle, R.B.; Siva, I. Investigation to appraise the vibration and damping characteristics of coir fibre reinforced polypropylene composites. Adv. Mater. Process. Technol. 2018, 4, 1–12. [Google Scholar] [CrossRef]

- Mishra, S.; Nayak, C.; Sharma, M.K.; Dwivedi, U.K. Influence of Coir Fiber Geometry on Mechanical Properties of SiC Filled Epoxy Composites. Silicon 2020, 1–7. [Google Scholar] [CrossRef]

- Saxena, M.; Pappu, A.; Haque, R.; Sharma, A. Sisal Fiber Based Polymer Composites and Their Applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer Science and Business Media LLC: Berlin, Germany, 2011; pp. 589–659. [Google Scholar]

- Chaitanya, S.; Singh, I.; Song, J.-I. Recyclability analysis of PLA/Sisal fiber biocomposites. Compos. Part B Eng. 2019, 173, 106895. [Google Scholar] [CrossRef]

- Manral, A.; Bajpai, P.K. Static and dynamic mechanical analysis of geometrically different kenaf/PLA green composite laminates. Polym. Compos. 2019, 41, 691–706. [Google Scholar] [CrossRef]

- Asumani, O.; Paskaramoorthy, R. Fatigue and impact strengths of kenaf fibre reinforced polypropylene composites: Effects of fibre treatments. Adv. Compos. Mater. 2020, 1–13. [Google Scholar] [CrossRef]

- Sitticharoen, W.; Chainawakul, A.; Sangkas, T.; Kuntham, Y. Rheological and Mechanical Properties of Silica-Based Bagasse-Fiber-Ash-Reinforced Recycled HDPE Composites. Mech. Compos. Mater. 2016, 52, 421–432. [Google Scholar] [CrossRef]

- Wirawan, R.; Sapuan, S. Sugarcane Bagasse-Filled Poly(Vinyl Chloride) Composites. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier BV: Woodhead Publishing: Duxford, UK, 2018; pp. 157–168. [Google Scholar]

- Das, M. Bamboo Fiber-Based Polymer Composites. In Polymer-Engineered Nanostructures for Advanced Energy Applications; Springer Science and Business Media LLC: Cham, Switzerland, 2016; pp. 627–645. [Google Scholar]

- Lokesh, P.; Kumari, T.S.; Gopi, R.; Loganathan, G.B. A study on mechanical properties of bamboo fiber reinforced polymer composite. Mater. Today Proc. 2020, 22, 897–903. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, J.-S. Effects of surface treatment of ramie fibers in a ramie/poly(lactic acid) composite. Fibers Polym. 2012, 13, 217–223. [Google Scholar] [CrossRef]

- Djafar, Z.; Renreng, I.; Jannah, M. Tensile and Bending Strength Analysis of Ramie Fiber and Woven Ramie Reinforced Epoxy Composite. J. Nat. Fibers 2020, 1–12. [Google Scholar] [CrossRef]

- Chandar, J.V.; Shanmugan, S.; Murugan, P.; Mutharasu, D.; Sudesh, K. Structural Analysis of ZnO Nanoparticles Reinforced P(3HB-co-15 mol% 3HHx) Bioplastic Composite. J. Polym. Environ. 2016, 25, 1251–1261. [Google Scholar] [CrossRef]

- Karakoti, A.; Biswas, S.; Aseer, J.R.; Sindhu, N.; Sanjay, M. Characterization of microfiber isolated from Hibiscus sabdariffa var. altissima fiber by steam explosion. J. Nat. Fibers 2018, 17, 189–198. [Google Scholar] [CrossRef]

- Phanthong, P.; Karnjanakom, S.; Reubroycharoen, P.; Hao, X.; Abudula, A.; Guan, G. A facile one-step way for extraction of nanocellulose with high yield by ball milling with ionic liquid. Cellulose. 2017, 24, 2083–2093. [Google Scholar] [CrossRef]

- Souza, S.; Ferreira, F.; Cherian, B.; Silva, V.; Manzato, L.; Pinheiro, I. Processing of nanocellulose-based composites. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 431–448. [Google Scholar]

- Miyashiro, D.; Hamano, R.; Umemura, K. A Review of Applications Using Mixed Materials of Cellulose, Nanocellulose and Carbon Nanotubes. Nanomaterials 2020, 10, 186. [Google Scholar] [CrossRef] [PubMed]

- Martin-Martinez, F.J. Designing nanocellulose materials from the molecular scale. Proc. Natl. Acad. Sci. USA 2018, 115, 7174–7175. [Google Scholar] [CrossRef] [PubMed]

- Dixit, S.; Goel, R.; Dubey, A.; Shivhare, P.R.; Bhalavi, T. Natural Fibre Reinforced Polymer Composite Materials - A Review. Polym. Renew. Resour. 2017, 8, 71–78. [Google Scholar] [CrossRef]

- Nassar, A.; Nassar, E. Effect of fiber orientation on the mechanical properties of multi layers laminate nanocomposites. Heliyon 2020, 6, e03167. [Google Scholar] [CrossRef] [PubMed]

- Crosky, A.; Soatthiyanon, N.; Ruys, D.; Meatherall, S.; Potter, S. Thermoset matrix natural fibre-reinforced composites. In Natural Fibre Composites; Elsevier BV: Woodhead Publishing: Oxford, Uk, 2014; pp. 233–270. [Google Scholar]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Dwivedi, M. Processability in Open Mould Processing of Polymeric Composites. In Processability of Polymeric Composites; Springer Science and Business Media LLC: New Delhi, India, 2019; pp. 179–203. [Google Scholar]

- Hosseini, S.B. Natural fiber polymer nanocomposites. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 279–299. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Alharbi, M.A.H.; Hirai, S.; Tuan, H.A.; Akioka, S.; Shoji, W. Effects of chemical composition, mild alkaline pretreatment and particle size on mechanical, thermal, and structural properties of binderless lignocellulosic biopolymers prepared by hot-pressing raw microfibrillated Phoenix dactylifera and Cocos nucifera fibers and leaves. Polym. Test. 2020, 84, 106384. [Google Scholar] [CrossRef]

- Verma, A.; Parashar, A.; Jain, N.; Singh, V.K.; Rangappa, S.M.; Siengchin, S. Surface Modification Techniques for the Preparation of Different Novel Biofibers for Composites. In Biofibers and Biopolymers for Biocomposites; Springer Science and Business Media LLC: Cham, Switzerland, 2020; pp. 1–34. [Google Scholar]

- Franco-Marquès, E.; Méndez, J.A.; Pèlach, M.; Àngels; Vilaseca, F.; Bayer, J.; Mutjé, P. Influence of coupling agents in the preparation of polypropylene composites reinforced with recycled fibers. Chem. Eng. J. 2011, 166, 1170–1178. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Composites Part B: Engineering. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G. Natural Fiber Composites; CRC Press, Taylor & Francis: Boca Raton, FL, USA, 2015. [Google Scholar]

- DiTommaso, G.; Gaff, M.; Kačík, F.; Sikora, A.; Sethy, A.; Corleto, R.; Razaei, F.; Kaplan, L.; Kubš, J.; Das, S.; et al. Interaction of technical and technological factors on qualitative and energy/ecological/economic indicators in the production and processing of thermally modified merbau wood. J. Clean. Prod. 2020, 252, 119793. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Omari, M.A. Sustainable biocomposites: Challenges, potential and barriers for development. In Green biocomposites; Springer: Cham, Switzerland, 2017; pp. 13–29. [Google Scholar]

- Navaneethakrishnan, G.; Karthikeyan, T.; Saravanan, S.; Selvam, V.; Parkunam, N.; Sathishkumar, G.; Jayakrishnan, S. Structural analysis of natural fiber reinforced polymer matrix composite. Mater. Today: Proc. 2020, 21, 7–9. [Google Scholar] [CrossRef]

- Jaafar, J.; Siregar, J.P.; Tezara, C.; Hamdan, M.H.M.; Rihayat, T. A review of important considerations in the compression molding process of short natural fiber composites. Int. J. Adv. Manuf. Technol. 2019, 105, 3437–3450. [Google Scholar] [CrossRef]

- Sarikaya, E.; Çallioğlu, H.; Demirel, H. Production of epoxy composites reinforced by different natural fibers and their mechanical properties. Compos. Part B Eng. 2019, 167, 461–466. [Google Scholar] [CrossRef]

- Avella, M.; Buzarovska, A.; Errico, M.; Gentile, G.; Grozdanov, A. Eco-Challenges of Bio-Based Polymer Composites. Materials 2009, 2, 911–925. [Google Scholar] [CrossRef]

- Crawford, B.; Pakpour, S.; Kazemian, N.; Klironomos, J.; Stoeffler, K.; Rho, D.; Denault, J.; Milani, A.S. Effect of Fungal Deterioration on Physical and Mechanical Properties of Hemp and Flax Natural Fiber Composites. Materials 2017, 10, 1252. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized Vegetable Oils Plasticized Poly(lactic acid) Biocomposites: Mechanical, Thermal and Morphology Properties. Moleluces 2014, 19, 16024–16038. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, H.; Zhang, J.; Zhang, S.; Li, J. Improvement of Interfacial Adhesion by Bio-Inspired Catechol-Functionalized Soy Protein with Versatile Reactivity: Preparation of Fully Utilizable Soy-Based Film. Polymers 2017, 9, 95. [Google Scholar] [CrossRef]

- Liu, W.; Fei, M.-E.; Ban, Y.; Jia, A.; Qiu, R. Preparation and Evaluation of Green Composites from Microcrystalline Cellulose and a Soybean-Oil Derivative. Polymers 2017, 9, 541. [Google Scholar] [CrossRef]

- Alpár, T.; Markó, G.; Koroknai, L. Natural Fiber Reinforced PLA Composites: Effect of Shape of Fiber Elements on Properties of Composites. In Handbook of Composites from Renewable Materials; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 287–312. [Google Scholar]

- Getme, A.S.; Patel, B. A Review: Bio-fiber’s as reinforcement in composites of polylactic acid (PLA). Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. Cellulose reinforced polymer composites and nanocomposites: A critical review. Cellulose 2013, 20, 2221–2262. [Google Scholar] [CrossRef]

- Cótica, L.F.; Garcia, A.; Polli, A.D.; Bini, R.D.; De Chaves, T.; Junior, V.A.D.O.; Pamphile, J.A. Nanobiocomposites: Synthesis and Environmental Applications. In Fungal Nanobionics: Principles and Applications; Springer Science and Business Media LLC: Singapore, 2018; pp. 1–19. [Google Scholar]

- Iozzino, V.; Haroutioun, A.; Fabrice, L.; Vincent, V.; Pantani, R. Poly(Lactic Acid)-Based Nanobiocomposites with Modulated Degradation Rates. Materials 2018, 11, 1943. [Google Scholar] [CrossRef]

- Kausar, A. Progress in green nanocomposites for high-performance applications. Mater. Res. Innov. 2020, 1–13. [Google Scholar] [CrossRef]

- Adamu, M.; Rahman, M.R.; Hamdan, S. Bamboo Nanocomposite: Impact of Poly (Ethylene-alt-Maleic Anhydride) and Nanoclay on Physicochemical, Mechanical, and Thermal Properties. BioResources 2020, 15, 331–346. [Google Scholar]

- Saba, N.; Paridah, M.; Abdan, K.; Ibrahim, N. Physical, structural and thermomechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Mater. Chem. Phys. 2016, 184, 64–71. [Google Scholar] [CrossRef]

- Sinha, R.K.; Sridhar, K.; Purohit, R.; Malviya, R.K. Effect of nano SiO2 on properties of natural fiber reinforced epoxy hybrid composite: A review. Mater. Today: Proc. 2020. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.A.; Lvov, Y.M. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Blanco, I. The Rediscovery of POSS: A Molecule Rather than a Filler. Polymers 2018, 10, 904. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Kurmus, H.; Milas, J.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A.; Kadir, A.A. Nanoparticles in Construction Materials and Other Applications, and Implications of Nanoparticle Use. Materials 2019, 12, 3052. [Google Scholar] [CrossRef]

- Marquis, D.M.; Guillaume, E.; Chivas-Joly, C. Properties of Nanofillers in Polymer. In Nanocomposites and Polymers with Analytical Methods; IntechOpen: London, UK, 2011; pp. 261–284. [Google Scholar]

- Nguyen, T.A.; Han, B.; Sharma, S.; Longbiao, L.; Bhat, K.S. Fiber-reinforced nanocomposites: An introduction. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 3–6. [Google Scholar]

- Sharma, R.K.; Sharma, S.; Dutta, S.; Zboril, R.; Gawande, M.B. Silica-nanosphere-based organic–inorganic hybrid nanomaterials: Synthesis, functionalization and applications in catalysis. Green Chem. 2015, 17, 3207–3230. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Lai, C.; Zeng, G.; Huang, D.; Cheng, M.; Wang, J.; Chen, F.; Zhou, C.; Xiong, W. BiOX (X = Cl, Br, I) photocatalytic nanomaterials: Applications for fuels and environmental management. Adv. Colloid Interface Sci. 2018, 254, 76–93. [Google Scholar] [CrossRef] [PubMed]

- Rajini, N.; Jappes, J.W.; Siva, I.; Rajulu, A.V.; Rajakarunakaran, S. Fire and thermal resistance properties of chemically treated ligno-cellulosic coconut fabric–reinforced polymer eco-nanocomposites. J. Ind. Text. 2016, 47, 104–124. [Google Scholar] [CrossRef]

- Ramu, P.; Kumar, C.J.; Palanikumar, K. Mechanical Characteristics and Terminological Behavior Study on Natural Fiber Nano reinforced Polymer Composite—A Review. Mater. Today Proc. 2019, 16, 1287–1296. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Gries, T.; Veit, D.; Quadflieg, T.; Mohr, B.; Kolloch, M. Effect of nanomaterial on mode I and mode II interlaminar fracture toughness of woven carbon fabric reinforced polymer composites. Eng. Fract. Mech. 2017, 180, 73–86. [Google Scholar] [CrossRef]

- Prasad, V.; Sekar, K.; Varghese, S.; Joseph, M. Enhancing Mode I and Mode II interlaminar fracture toughness of flax fibre reinforced epoxy composites with nano TiO2. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105505. [Google Scholar] [CrossRef]

- Jujjavarapu, S.E.; Poluri, K.M. Green Polymeric Nanocomposites; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Pinto, D.; Bernardo, L.; Amaro, A.; Lopes, S.M.R. Mechanical properties of epoxy nanocomposites using titanium dioxide as reinforcement—A review. Constr. Build. Mater. 2015, 95, 506–524. [Google Scholar] [CrossRef]

- Catauro, M.; Barrino, F.; Blanco, I.; Piccolella, S.; Pacifico, S. Use of the Sol–Gel Method for the Preparation of Coatings of Titanium Substrates with Hydroxyapatite for Biomedical Application. Coatings 2020, 10, 203. [Google Scholar] [CrossRef]

- Jiang, Q.; Pei, X.; Wu, L.; Li, T.-T.; Lin, J.-H. UV resistance and water barrier properties of PP/PLA/MAH/TiO2 functional hybrid biocomposite films for packaging application. Adv. Polym. Technol. 2018, 37, 2971–2980. [Google Scholar] [CrossRef]

- Brandrup, J.; Immergut, E.H.; Grulke, E.A.; Abe, A.; Bloch, D.R. Polymer Handbook; Wiley and Sons: New York, NY, USA, 1999. [Google Scholar]

- Battegazzore, D. Crystallization kinetics of poly(lactic acid)-talc composites. Express Polym. Lett. 2011, 5, 849–858. [Google Scholar] [CrossRef]

- Nomai, J.; Suksut, B.; Schlarb, A.K. Crystallization behavior of poly (lactic acid)/titanium dioxide nanocomposites. KMUTNB. Int. J. Appl. Sci. Technol. 2015, 8, 251–258. [Google Scholar]

- Prasad, V.; Joseph, M.; Sekar, K. Investigation of mechanical, thermal and water absorption properties of flax fibre reinforced epoxy composite with nano TiO2 addition. Compos. Part A Appl. Sci. Manuf. 2018, 115, 360–370. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Jahandideh, S.; Baseri, S.; Zarei, M.; Azadi, S. Modification of Phenol Novolac Epoxy Resin and Unsaturated Polyester Using Sasobit and Silica Nanoparticles. Polym. Renew. Resour. 2017, 8, 117–132. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Mousavi, S.M. Effect of bubble based degradation on the physical properties of Single Wall Carbon Nanotube/Epoxy Resin composite and new approach in bubbles reduction. Compos. Part A Appl. Sci. Manuf. 2016, 90, 457–469. [Google Scholar] [CrossRef]

- Rahman, M.R.; Rahman, M.; Hamdan, S.; Lai, J.C.H. Impact of Maleic Anhydride, Nanoclay, and Silica on Jute Fiber-reinforced Polyethylene Biocomposites. Bioresources 2016, 11, 5905–5917. [Google Scholar] [CrossRef][Green Version]

- Chang, H.; Sun, S.-Q.; Huan, C.; Sun, S. Silicon nanoparticles: Preparation, properties, and applications. Chin. Phys. B 2014, 23, 088102. [Google Scholar] [CrossRef]

- Catauro, M.; Barrino, F.; Blanco, I.; Dal Poggetto, G.; Piccolella, S.; Crescente, G.; Pacifico, S. Bioactivity of chlorogenic acid/SiO2/PEG composite synthesized via sol-gel. Mater. Today. 2020. [Google Scholar] [CrossRef]

- Siengchin, S.; Dangtungee, R. Polyethylene and polypropylene hybrid composites based on nano silicon dioxide and different flax structures. J. Thermoplast. Compos. Mater. 2014, 27, 1428–1447. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, M.; He, C.; Li, S.; Fan, X.; Nie, C.; Luo, H.; Qiu, L.; Cheng, C. Graphene-based advanced nanoplatforms and biocomposites from environmentally friendly and biomimetic approaches. Green Chem. 2019, 21, 4887–4918. [Google Scholar] [CrossRef]

- Kumar, D.; Babu, G.; Krishnan, S. Study on mechanical & thermal properties of PCL blended graphene biocomposites. Polímeros 2019, 29, 29. [Google Scholar] [CrossRef]

- Idumah, C.I.; Hassan, A. Hibiscus Cannabinus Fiber/PP based Nano-Biocomposites Reinforced with Graphene Nanoplatelets. J. Nat. Fibers 2017, 14, 691–706. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, S.; Zhang, Q.; Ming, P.; Wan, S.; Peng, J.; Jiang, L.; Cheng, Q. Graphene-based artificial nacre nanocomposites. Chem. Soc. Rev. 2016, 45, 2378–2395. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Ni, H.; Jiang, L.; Cheng, Q. Learning from nature: Constructing high performance graphene-based nanocomposites. Mater. Today 2017, 20, 210–219. [Google Scholar] [CrossRef]

- Razak, Z.; Sulong, A.B.; Muhamad, N.; Haron, C.H.C.; Radzi, M.K.F.M.; Ismail, N.F.; Tholibon, D.; Tharazi, I. Effects of thermal cycling on physical and tensile properties of injection moulded kenaf/carbon nanotubes/polypropylene hybrid composites. Compos. Part B Eng. 2019, 168, 159–165. [Google Scholar] [CrossRef]

- Fu, S.; Song, P.; Yang, H.; Jin, Y.; Lu, F.; Ye, J.; Wu, Q. Effects of carbon nanotubes and its functionalization on the thermal and flammability properties of polypropylene/wood flour composites. J. Mater. Sci. 2010, 45, 3520–3528. [Google Scholar] [CrossRef]

- Russo, P.; Vitiello, L.; Sbardella, F.; Santos, J.I.; Tirillò, J.; Bracciale, M.P.; Rivilla, I.; Sarasini, F. Effect of Carbon Nanostructures and Fatty Acid Treatment on the Mechanical and Thermal Performances of Flax/Polypropylene Composites. Polymers 2020, 12, 438. [Google Scholar] [CrossRef]

- Montazeri, A.; Javadpour, J.; Khavandi, A.; Tcharkhtchi, A.; Mohajeri, A. Mechanical properties of multi-walled carbon nanotube/epoxy composites. Mater. Des. 2010, 31, 4202–4208. [Google Scholar] [CrossRef]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Li, Y.; Cai, S.; Huang, X. Multi-scaled enhancement of damping property for carbon fiber reinforced composites. Compos. Sci. Technol. 2017, 143, 89–97. [Google Scholar] [CrossRef]

- Turlybekuly, A.; Pogrebnjak, A.; Sukhodub, L.; Sukhodub, L.; Kistaubayeva, A.; Savitskaya, I.; Shokatayeva, D.; Bondar, O.; Shaimardanov, Z.; Plotnikov, S.; et al. Synthesis, characterization, in vitro biocompatibility and antibacterial properties study of nanocomposite materials based on hydroxyapatite-biphasic ZnO micro- and nanoparticles embedded in Alginate matrix. Mater. Sci. Eng. C 2019, 104, 109965. [Google Scholar] [CrossRef]

- Al Abdullah, K.; Awad, S.; Zaraket, J.; Salame, C.-T. Synthesis of ZnO Nanopowders By Using Sol-Gel and Studying Their Structural and Electrical Properties at Different Temperature. Energy Procedia 2017, 119, 565–570. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A. Green Composites for Automotive Applications; Woodhead Publishing: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Less by Design. CocoForm-a Sustainable Packaging Alternative. 2015. Available online: https://lessbydesign.org/2015/02/06/cocoform-a-sustainable-packaging-alternative (accessed on 20 January 2020).

- Architonic. Biocomposites Experimental Pavilion, Stuttgart, Germany. 2018. Available online: https://www.architonic.com/en/project/biomat-group-at-itke-biocomposites-experimental-pavilion/20013658 (accessed on 20 January 2020).

- Treehugger. Cannabis in Your Car Doors, but Not to Smuggle It. Available online: https://www.treehugger.com/sustainable-agriculture/cannabis-your-car-doors-not-smuggle-it.html (accessed on 20 January 2020).

- Godavari. Natural Fiber Biocomposite. Available online: https://www.somaiya.com/naturomer-%C2%AE-natural-fiber-biocomposite (accessed on 20 January 2020).

- Composites World. Six Candidates Nominated for “Biocomposite of the Year 2019”. Available online: https://www.compositesworld.com/news/six-candidates-nominated-for-biocomposite-of-the-year-2019 (accessed on 20 January 2020).

- Siti, S.; Abdul, H.; Wan, W.; Jawai, M. Bamboo Based Biocomposites Material, Design and Applications. In Materials Science—Advanced Topics; IntechOpen: London, UK, 2013. [Google Scholar]

- Reddy, T.R.K.; Kim, H.; Park, J.-W. Renewable Biocomposite Properties and their Applications. In Composites from Renewable and Sustainable Materials; IntechOpen: London, UK, 2016; pp. 177–197. [Google Scholar]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-Based Bio- and Nanocomposites: A Review. Int. J. Polym. Sci. 2011, 2011. [Google Scholar] [CrossRef]

- Christy, P.N.; Basha, S.K.; Kumari, V.S.; Bashir, A.; Maaza, M.; Kaviyarasu, K.; Arasu, M.V.; Al-Dhabi, N.A.; Ignacimuthu, S. Biopolymeric nanocomposite scaffolds for bone tissue engineering applications—A review. J. Drug Deliv. Sci. Technol. 2020, 55, 101452. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.-H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2016, 38, 2553–2569. [Google Scholar] [CrossRef]

- Arora, B.; Bhatia, R.; Attri, P. Bionanocomposites: Green materials for a sustainable future. In New Polymer Nanocomposites for Environmental Remediation; Elsevier BV: Woodhead Publishing: Duxford, UK, 2018; pp. 699–712. [Google Scholar]

- Dicker, M.; Duckworth, P.F.; Baker, A.B.; François, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Malviya, R.K.; Singh, R.K.; Purohit, R.; Sinha, R. Natural fibre reinforced composite materials: Environmentally better life cycle assessment—A case study. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Ita-Nagy, D.; Vázquez-Rowe, I.; Kahhat, R.; Quispe, I.; Chinga-Carrasco, G.; Clauser, N.M.; Area, M.C. Life cycle assessment of bagasse fiber reinforced biocomposites. Sci. Total. Environ. 2020, 137586. [Google Scholar] [CrossRef]

- Sarkar, S.; Gulati, K.; Poluri, K.M. Life Cycle Assessment and Future Perspectives of Green Polymeric Nanocomposites. In Green Polymeric Nanocomposites; CRC Press: Boca Raton, FL, USA, 2020; pp. 251–280. [Google Scholar]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef]

| Number | Merits | Demerits |

|---|---|---|

| (a) | Comparatively lighter | Higher moisture absorption |

| (b) | Low cost | Low impact strength |

| (c) | Biodegradability | Poor flame retardancy |

| (d) | Renewability | Not suitable with a higher processing temperature |

| (e) | Better insulation and thermal performances | Poor resistance to microbial attack |

| (f) | Nontoxicity | Variation in quality |

| (g) | Environment-friendly | Complex supply chain of natural fibers for geographic locations and availability |

| (h) | No irritations with physical contact | / |

| (i) | Low energy consumption | / |

| (j) | Best alternatives for replacing synthetic fibers | / |

| Fibers | Cellulose (%) | Hemi- cellulose (%) | Lignin (%) | Pectin (%) | Waxes (%) | Moisture Content/ Extractive (%) | Ash (%) |

|---|---|---|---|---|---|---|---|

| Cotton | 89 | 4 | 0.75 | 6 | 0.6 | -- | -- |

| Jute | 45 to 71.5 | 13.6 to 21 | 12 to 26 | 0.2 | -- | 12 | 0.5 to 2.0 |

| Hemp | 57 to 77 | 14 to 22.4 | 3.7 to 13 | 0.9 | -- | 9 | 0.8 |

| Flax | 71 | 18.6 to 20.6 | 2.2 | 2.3 | 1.7 | 8 to 12 | 5 to 10 |

| Coir | 32 to 43 | 0.15 to 0.25 | 40 to 45 | 3 to 4 | -- | 8 | |

| Sisal | 47 to 77 | 10 to 24 | 7 to 11 | 10 | -- | 11 | 0.6 to 1.0 |

| Kenaf | 53.5 | 21 | 17 | 2 | -- | -- | 2 to 5 |

| Sugarcane Bagasse | 32 to 34 | 19 to 24 | 25 to 32 | -- | -- | 6 to 12 | 2 to 6 |

| Bamboo | 73.83 | 12.49 | 10.15 | 0.37 | -- | 3.16-8.9 | -- |

| Ramie | 68.6 to 91 | 5 to 16.7 | 0.6 to 0.7 | 1.9 | -- | 9 | -- |

| Fibers | Elongation (%) | Density (g/cm3) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Decomposition Temperature (°C) |

|---|---|---|---|---|---|

| Cotton | 3 to 10 | 1.5 to 1.6 | 5.5 to 12.6 | 287 to 597 | 232 |

| Jute | 1.5 to 1.8 | 1.3 to 1.46 | 10 to 30 | 393 to 800 | 215 |

| Hemp | 1.6 | 1.48 | 70 | 550 to 900 | 215 |

| Flax | 1.2 to 3.2 | 1.4 to 1.5 | 27.6 to 80 | 345 to 1500 | 220 |

| Coir | 15 to 30 | 1.2 | 4 to 6 | 175 to 220 | 285 to 465 |

| Sisal | 2 to 14 | 1.33 to 1.5 | 9 to 38 | 400 to 700 | 205 to 220 |

| Kenaf | 1.6 to 4.3 | 0.6 to 1.5 | 11 to 60 | 223 to 1191 | 229 |

| Sugarcane Bagasse | 6.3 to 7.9 | 1.1 to 1.6 | 5.1 to 6.2 | 170 to 350 | 232 |

| Bamboo | 1.9 to 3.2 | 1.2 to 1.5 | 27 to 40 | 500 to 575 | 214 |

| Ramie | 2.3 to 3.8 | 1.5 | 44 to 128 | 220 to 938 | 240 |

| Reinforcing Fibers | Polymeric Matrix | Manufacturing Method | Application | Ref. |

|---|---|---|---|---|

| Cotton | Polylactic acid (PLA), silane, and low-density polyethylene (LDPE) | Extrusion and injection molding | Building, automotive, furniture, and food packaging | [72,73,74,75] |

| Jute | Polyester and PP | Compression/injection molding and hand lay-up | Door panels, ropes, roofing, durable chairs, kitchen sinks, sanitary latrines (slab and rings), helmets, and chest guards | [76,77] |

| Hemp | Polyethylene (PE), polyurethane (PU), and PP | Compression molding and resin transfer molding (RTM) | Automotives and furniture | [78,79] |

| Flax | Epoxy, PLA, polyester, and PP | Vacuum infusion, RTM, and hand lay-up | Textile, automotive and structural | [80,81] |

| Coir | PE, PP, and epoxy resin | Extrusion and injection molding | Building boards, insulation boards, roofing sheets, and automotive structural components | [82,83] |

| Sisal | Polystyrene(PS), PP, and epoxy resin | Compression molding and hand lay-up | Body parts of automobiles and roofing sheets | [84,85] |

| Kenaf | Epoxy resin, PLA, and PP | Pultrusion and compression molding | Bearings, automotive parts, and tooling | [86,87] |

| Sugarcane Bagasse | HDPE and poly (vinyl chloride) (PVC) | Compression molding, injection molding, and extrusion | Interior of automotives (side panels, seat frames, and central consuls) | [88,89] |

| Bamboo | Epoxy resin and PLA | Compression molding | Hardware for electronics, furniture, and toys | [90,91] |

| Ramie | PLA, PP, and polyolefin | Injection molding through extrusion | Civil and bulletproof vests | [92,93] |

| Resin | Melting Temperature (Tm) in °C | Glass Transition Temperature (Tg) in °C |

|---|---|---|

| PLA | 150 to 162 | 58 |

| PP | 160 to 176 | 0.9 to 1.55 |

| Nylon 6 | 22 | 40 |

| Polyester | 250 to 300 | 60 |

| LDPE | 105 to 116 | 120 |

| HDPE | 120 to 140 | 80 |

| Epoxy | - | 70 to 67 |

| Starch | 110 to 115 | 60 |

| Polystyrene | - | 110–135 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. https://doi.org/10.3390/polym12051072

Hasan KMF, Horváth PG, Alpár T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers. 2020; 12(5):1072. https://doi.org/10.3390/polym12051072

Chicago/Turabian StyleHasan, K. M. Faridul, Péter György Horváth, and Tibor Alpár. 2020. "Potential Natural Fiber Polymeric Nanobiocomposites: A Review" Polymers 12, no. 5: 1072. https://doi.org/10.3390/polym12051072

APA StyleHasan, K. M. F., Horváth, P. G., & Alpár, T. (2020). Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers, 12(5), 1072. https://doi.org/10.3390/polym12051072