Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging

Abstract

1. Introduction

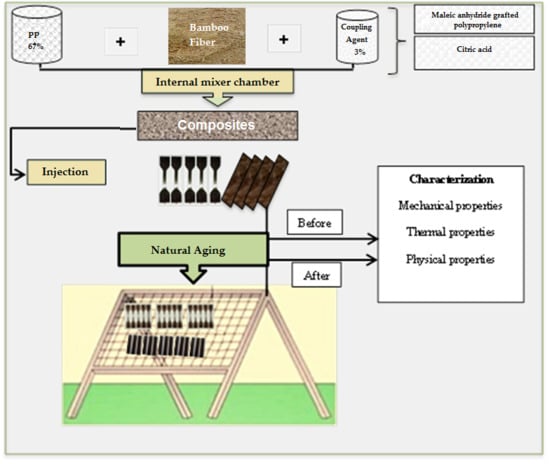

2. Materials and Methods

2.1. Materials

2.2. Processing Conditions

2.3. Natural Aging

3. Characterization

3.1. Mechanical Tests

3.2. Thermal Test

3.3. Physical Tests

3.3.1. Morphological Evaluation

3.3.2. Optical Analysis

3.3.3. Melt Flow Index

3.4. Statistical Analysis

4. Results and Discussion

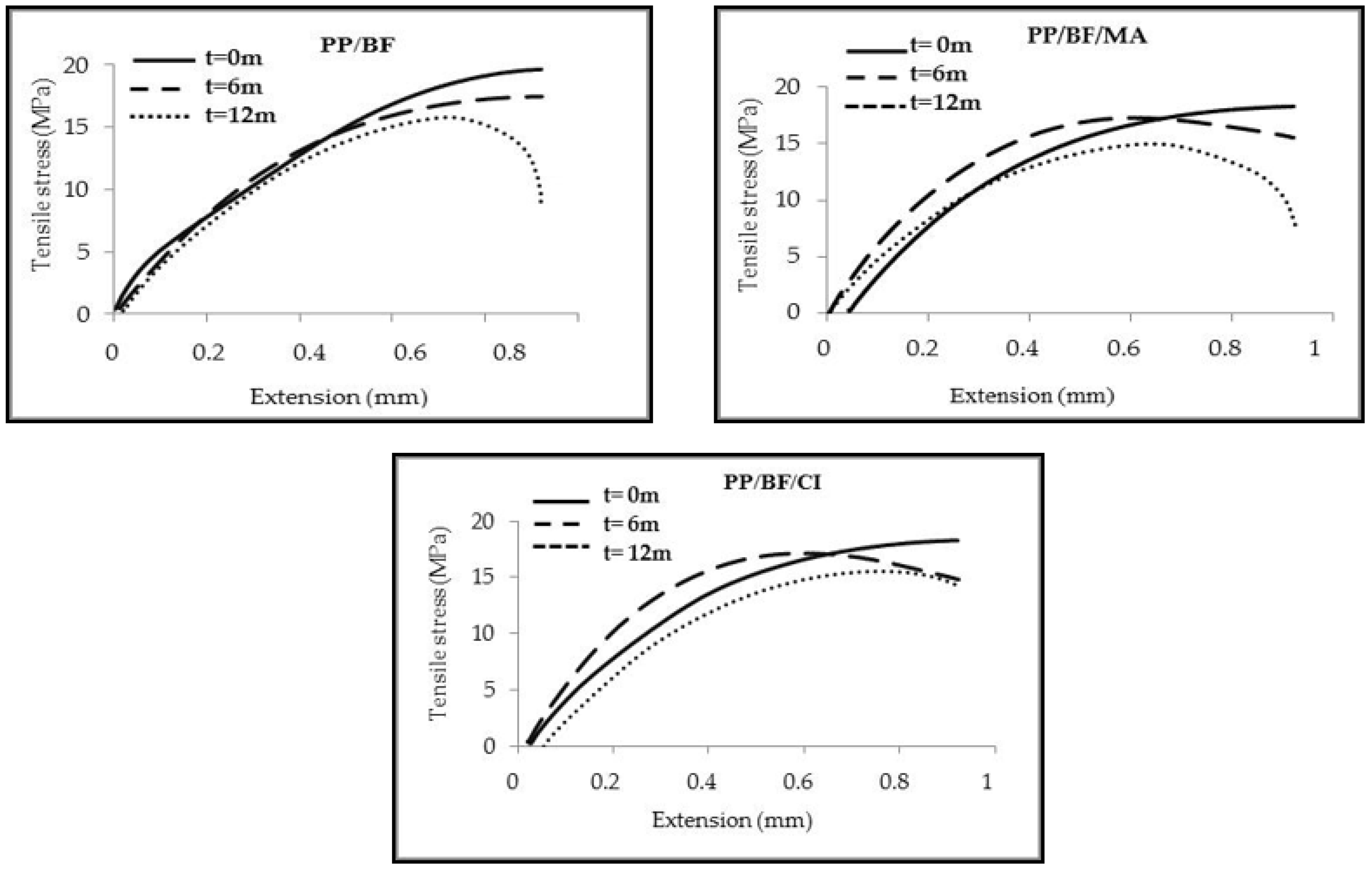

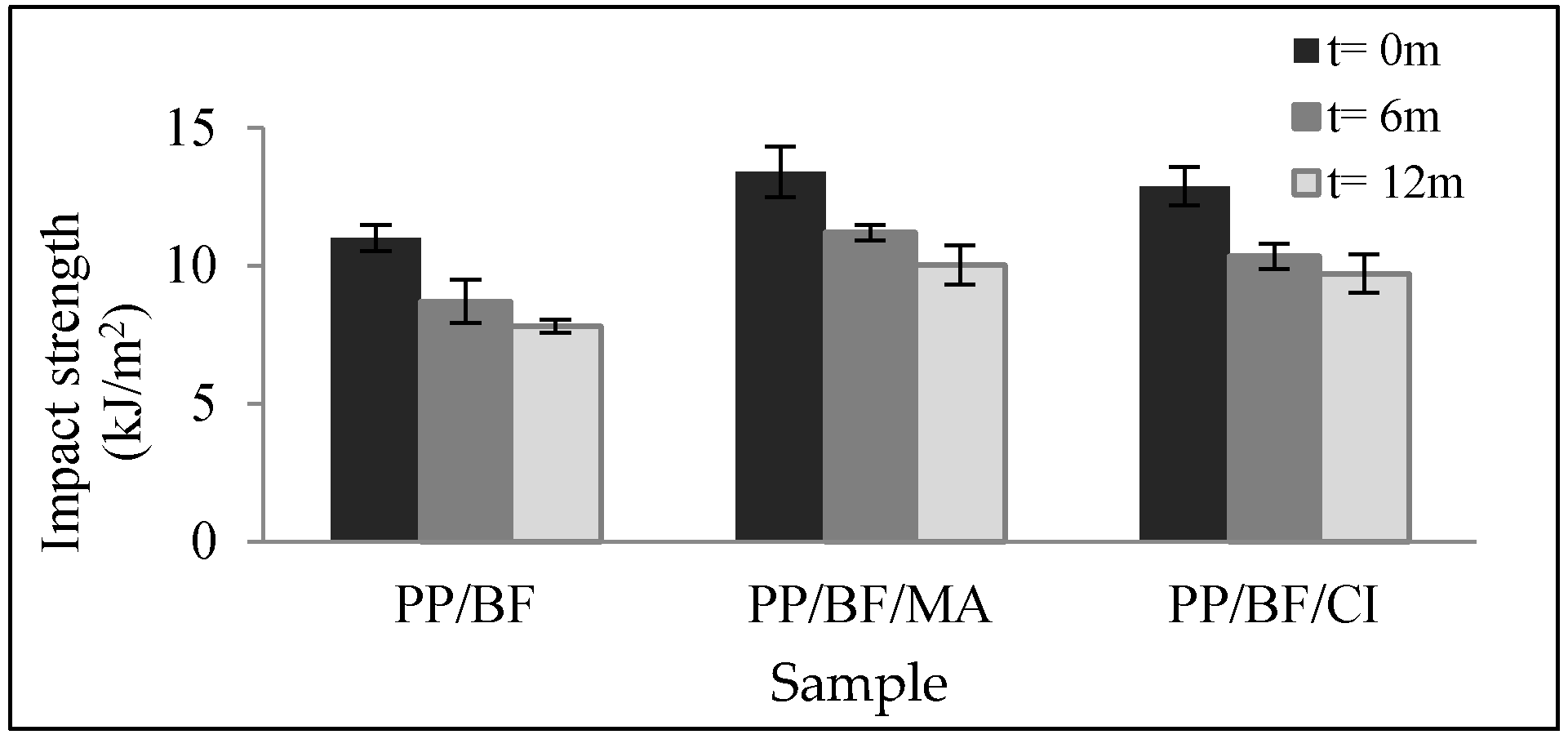

4.1. Mechanical Properties

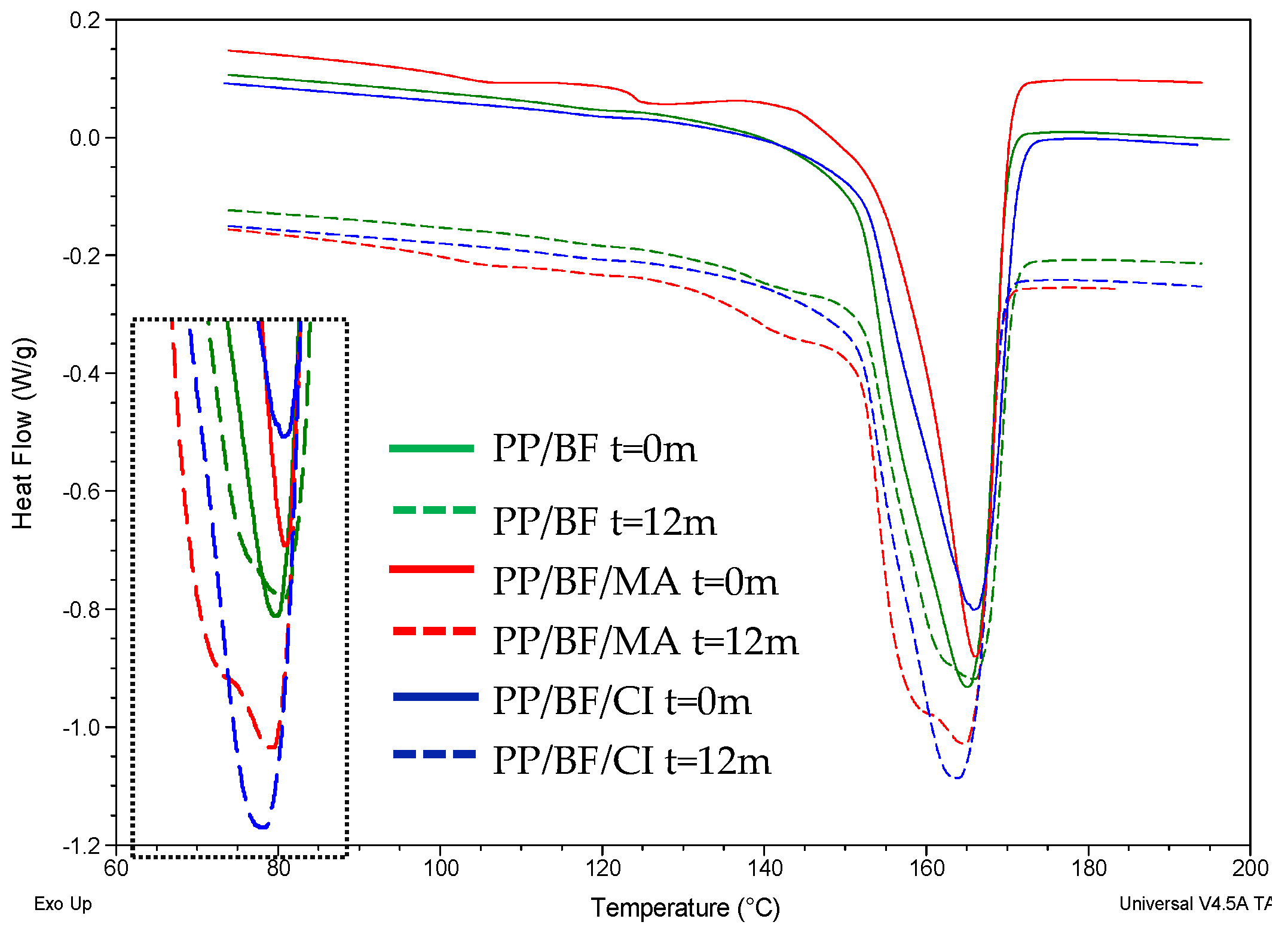

4.2. Thermal Properties

4.3. Morphological Properties

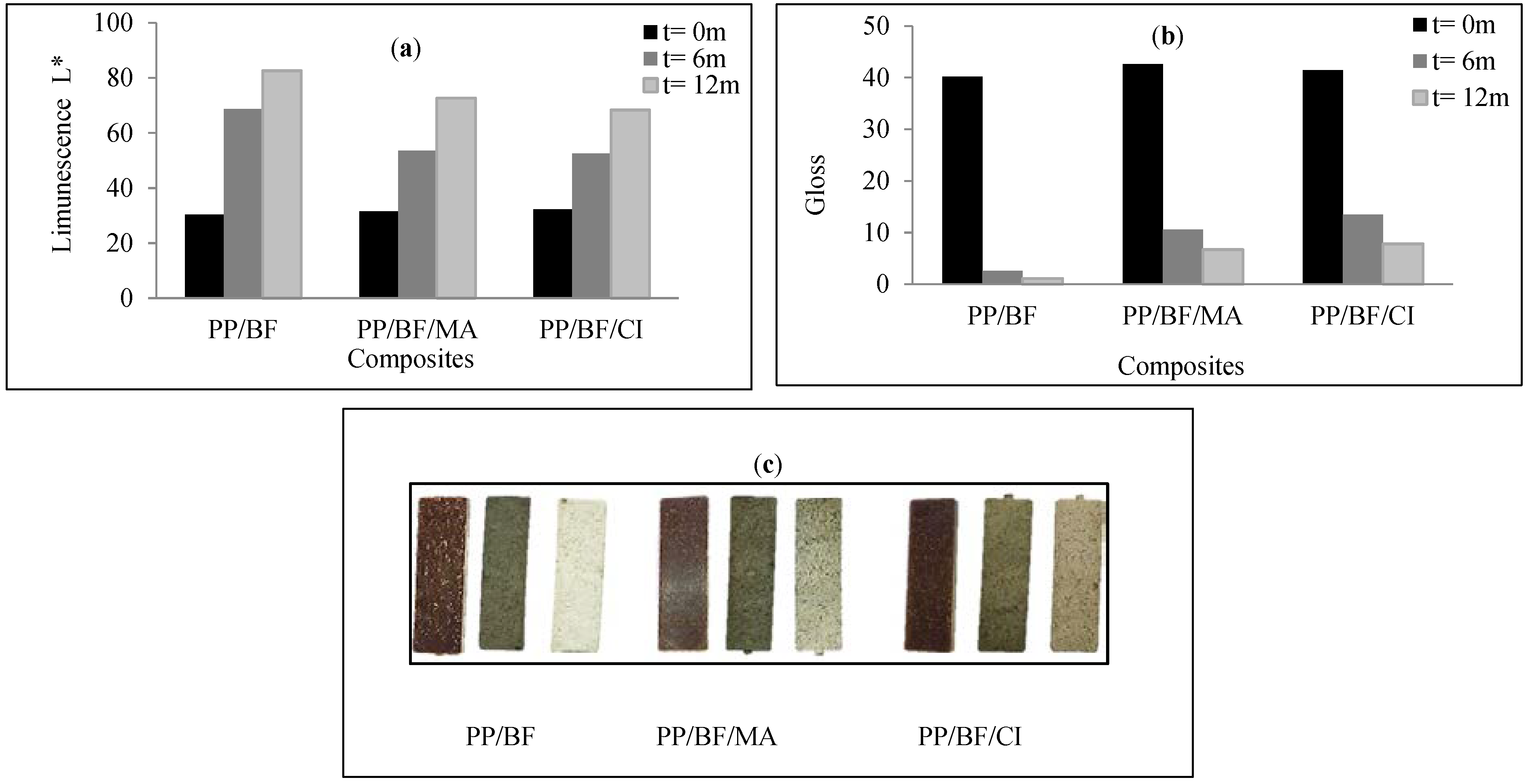

4.4. Optical Analysis: Luminescence and Gloss

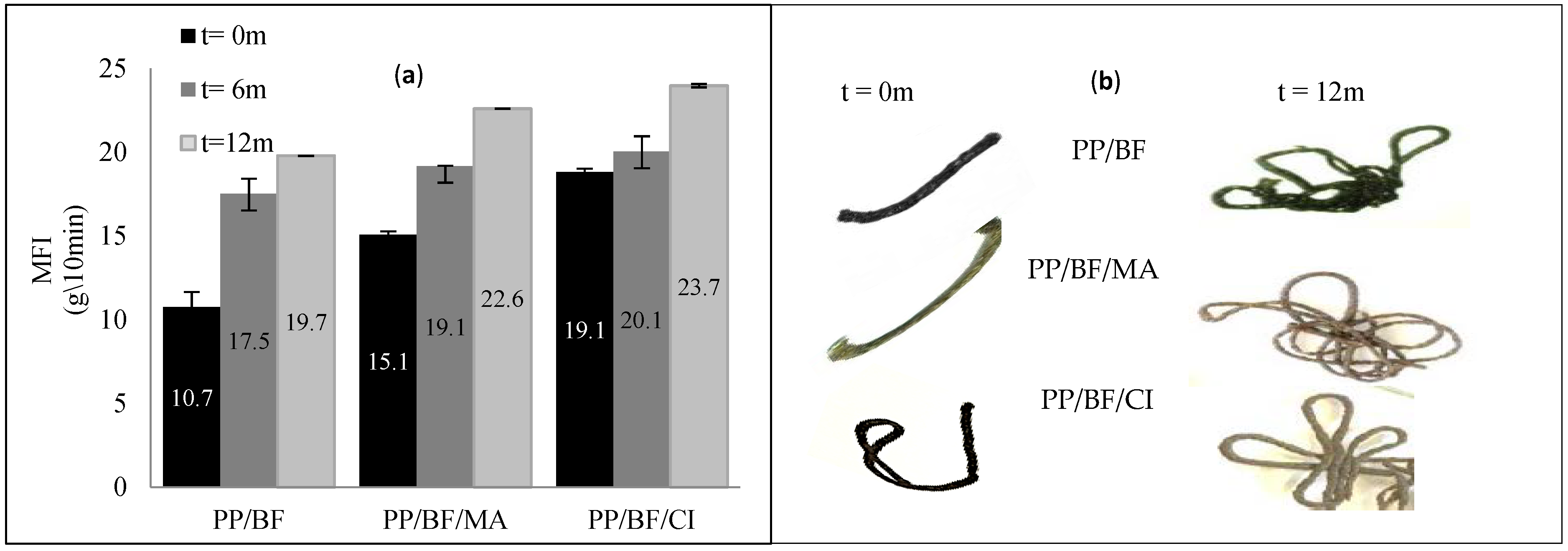

4.5. Rheological Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Bamboo fibre reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2011, 119, 1619–1626. [Google Scholar] [CrossRef]

- Chen, X.; Guo, Q.; Mi, Y. Bamboo fiber-reinforcedpolypropylene composites: A study of the mechanicalproperties. J. Appl. Polym. Sci. 1998, 69, 1891–1899. [Google Scholar] [CrossRef]

- Bledzki, A.; Letman, M.; Viksne, A.; Rence, L. A comparison of compounding and wood type for wood fiber—PP composites. Compos. Part A 2005, 36, 789–797. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Polyolefin-Based Plastic Lamber Decking Boards; ASTM D6662-13; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Portella, E.H.; Romanzini, D.; Angrizani, C.; Amico, S.; Zattera, A.J. Influence of sequence on the mechanical and dynamic mechanical properties of cotton/glass fiber reinforced polyester composites. Mater. Res. 2016, 19, 542–547. [Google Scholar] [CrossRef]

- Islam, M.N.; Rahman, M.R.; Haque, M.M. Physicomechanical properties of chemically trated coir reinforced polypropylene composites. Compos. Part A 2010, 41, 192–198. [Google Scholar] [CrossRef]

- Silva, R.; Haraguchi, S.K.; Muniz, E.C.; Rubira, A.F. Aplicações de fibras lignocelulósicas na química de polímeros e em compósitos. Quím. Nova 2009, 32, 661–671. [Google Scholar] [CrossRef]

- Martinz, A.; Silva, M.; Spiekermann, F.; Santana, R.M. Funcionalização do ácido mirístico em polipropileno (PP) e sua influência nas propriedades de blendas PP/amido termoplástico. In Proceedings of the 14th Congresso Brasileiro de Polimeros, Natal, Brasil, 22–26 October 2017. [Google Scholar]

- Khanoonkon, N.; Yoksan, R.; Ogale, A. Morphological characteristics of stearic acid-grafted starch-compatibilized linear low density polyethylene/thermoplastic starch blown film. Eur. Polym. J. 2016, 76, 266–277. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.; Santana, R. Effect of natural oils on the thermal stability and degradation kinetics of recycled polypropylene wood flour composites. Polym. Compos. 2014, 35, 1935–1942. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, Y.; Lin, Q.; Chen, L. Effects of Maleic Anhydride-Grafted Polypropylene (MAPP) on the physico-mechanical properties and rheological behavior of bamboo powder-polypropylene foamed composites. BioResources 2013, 8, 6263–6279. [Google Scholar] [CrossRef]

- Mi, Y.; Chen, X.; Guo, Q. Bamboo fiber-reinforced polypropylene composites: Cristallization and interfacial morphology. J. Appl. Polym. Sci. 1997, 64, 1267–1273. [Google Scholar] [CrossRef]

- Janssen, J. Designing and Building with Bamboo; INBAR Technical Report No. 20; Technical University of Eindhoven: Eindhoven, The Netherlands, 2006. [Google Scholar]

- Yeh, C.H.; Yang, T.C. Utilization of waste bamboo fibers in thermoplastic composites: Influence of the chemical composition and thermal decomposition behavior. Polymers 2020, 12, 636. [Google Scholar] [CrossRef]

- Catto, A.L. Estudo da Compatibilização da Matriz Poliolefinica em Compósitos Termoplásticos a Partir de Resíduos Pós-Uso. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brasil, 2012. [Google Scholar]

- Marek, A.; Kaprálkova, L.; Schmidt, P.; Pfleger, J.; Humlícek, J.; Pospísil, J.; Pilar, J. Spatial resolution of degradation in stabilized polystyrene and polypropylene plaques exposed to accelerated photodegradation of heat aging. Polym. Degrad. Stab. 2006, 91, 444–458. [Google Scholar] [CrossRef]

- Bertin, D.; Leblanc, M.; Sylvain, R.; Siri, D. Polypropylene degradation: Theoretical and experimental investigations. Polym. Degrad. Stab. 2010, 95, 782–791. [Google Scholar] [CrossRef]

- Decker, C. Photodegradation of PVC. In Degradation and Stabilization of PVC; Springer: Dordrecht, Netherlands, 1984; pp. 81–136. [Google Scholar]

- Santos, A.; Agnelli, J.; Trevisan, D.; Manrich, S. Degradation and stabilization of polyolefins from municipal plastic waste during multiple extrusions under different reprocessing conditions. Polym. Degrad. Stab. 2002, 77, 441–447. [Google Scholar] [CrossRef]

- Stark, N.M. Effect of weathering cycle and manufacturing method on performance of wood flour and high-density polyethylene composites. J. Appl. Polym. Sci. 2006, 100, 3131–3140. [Google Scholar] [CrossRef]

- White, J.; Turnbull, A. Review—Weathering of polymers: Mechanisms of degradation and stabilization, testing strategies and modeling. J. Mater. Sci. 1994, 29, 584–613. [Google Scholar] [CrossRef]

- Rabello, M.; White, J. Fotodegradação do polipropileno. Um processo essencialmente heterogêneo. Polím. Ciênc. Tecnol. 1997, 97, 47–57. [Google Scholar] [CrossRef]

- Mano, E.; Pacheco, E.; Bonelli, C. Meio Ambiente, Poluição e Reciclagem; Blucher: São Paulo, Brasil, 2005. [Google Scholar]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Rivaton, A.; Gardette, J.; Mailhot, B.; Therlas, S. Basics aspects of polymer degradation. Macromol. Symp. 2005, 225, 129–146. [Google Scholar] [CrossRef]

- Espi, E.; Salmerón, A.; Fontecha, A.; García, Y.; Real, A. The effect of different variables on the accelerated and natural weathering of agricultural films. Polym. Degrad. Stab. 2007, 92, 2150–2154. [Google Scholar] [CrossRef]

- Feldman, D. Polymer weathering: Photo-oxidation. J. Polym. Environ. 2002, 10, 163–173. [Google Scholar] [CrossRef]

- Montagna, L.; Santana, R. Influência da radiação na degradação do polipropileno. In Proceedings of the 3rd Congresso Internacional de Tecnologias para o Meio Ambiente, Bento Gonçalves, Brazil, 25–27 April 2012. [Google Scholar]

- American Society for Testing Materials. Standard Practice for Outdoor Weathering of Plastics; ASTM D1435-05; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Available online: www.inmet.gov.br (accessed on 10 January 2016).

- Available online: www.climatempo.com.br/previsao-do-tempo/cidade/363/portoalegre-rs (accessed on 10 January 2016).

- Available online: www.portoalegre.rs.gov.br/ceic/ (accessed on 30 January 2017).

- Grupo de Pesquisa de Geofísica Aplicada da Faculdade de Física da PUC RS. Available online: http://noticias.band.uol.com.br/cidades/rs/noticias/100000654252/capital-fica-sob-buraco-na-camada-de-ozonio.html (accessed on 30 August 2017).

- Canevarolo, S., Jr. Técnicas de Caracterização de Polímeros; Artliber: São Paulo, Brasil, 2007. [Google Scholar]

- Li, X.; Tabil, L.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Tensile properties of chemically treated hem fibres as reinforcement for composites. Compos. Part B 2013, 53, 362–368. [Google Scholar] [CrossRef]

- Domingos, Y.; Rocha, M.; Felipe, R.C.; Felipe, R.N. Avaliação do comportamento mecânico do compósito polimérico reforçado com fibras de vidro quando expostas a envelhecimento natural. In Proceedings of the 22nd Congresso Brasileiro de Engenharia e Ciência dos Materiais, Natal, Brazil, 6–10 November 2016. [Google Scholar]

- Joseph, P.V.; Rabello, M.; Mattoso, L.; Joseph, K.; Thomas, S. Environmental effects on the degradation behavior of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Bledzk, A.K.; Reihmaane, S.; Gassan, J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Krasowska, K.; Brzeska, J.; Rutkowska, M.; Janik, H.; Sadasivan, M.; Goda, K.; Thomas, S. Environmental degradation of ramie fibre reinforced biocomposites. Pol. J. Environ. Stud. 2010, 19, 937–945. [Google Scholar]

- Yew, G.H.; Chow, W.S.; Mohd, Z.A.; Ishak, Z.A.; Mohd, Y. Natural weathering of poly (lactic acid): Effects of rice starch and epoxidized natural rubber. J. Elastom. Plast. 2009, 41, 13–16. [Google Scholar] [CrossRef]

- Komuriah, A.; Shyam, N.; Durga, B. Determination of energy changes and length of micro cracks formed in cotton fiber reinforced natural composite laminate due to environmental degradation. APCBEE Procedia 2014, 9, 120–125. [Google Scholar] [CrossRef]

- Silva, C.; Martins, A.; Catto, A.; Santana, R. Effect of natural ageing on the properties of recycled polypropylene/ethylene vinyl acetate/wood flour composites. Rev. Mater. 2017, 22, e11835. [Google Scholar] [CrossRef]

- Moura, A.; Bolba, C.; Demori, R.; Lima, L.P.; Santana, R.M. Effect of rice rusk treatment with hot water on mechanical performance in poly(hydroxybutyrate)/rice rusk biocomposite. J. Polym. Environ. 2018, 26, 2632–2639. [Google Scholar] [CrossRef]

- Correa, C.; Fonseca, C.; Neves, S. Compósitos termoplásticos com madeira. Polím. Ciênc. Tecnol. 2003, 13, 154–165. [Google Scholar] [CrossRef]

- Machado, A.; Stuart, K. A comparison of process configuration for compounding wood-plastics composites. In Proceedings of the Wood-Plastic Conference, Baltimore, MD, USA, 5–6 December 2000; pp. 73–85. [Google Scholar]

- Araujo, J.; Waldman, W.; De Paoli, M. Polymer Degradation and Stability; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Poletto, M.; Zattera, A.; Santana, R.M. Natural oils improve interfacial adhesion between wood flour and matrix. Soc. Plast. Eng. 2014. [Google Scholar] [CrossRef]

- Poletto, M.; Zeni, M.; Zattera, A. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. J. Thermoplast. Compos. Mater. 2011, 25, 821–833. [Google Scholar] [CrossRef]

- Hee-Soo, K.; Sumin, K.; Hyun-Joong, K.; Han-Seung, Y. Thermal properties of bio-fluor-filler polyolefin composites with different compatibilizing agent type and contend. Thermochim. Acta 2006, 45, 181–188. [Google Scholar]

- De Paoli, M.A. Degradação e Estabilização de Polímeros. Capítulo 2: Tipos de Reações de Degradação, 2nd ed.; Atiliber: São Paulo, Brasil, 2008. [Google Scholar]

- Montagna, L.; Pezzini, A.; Forte, M.; Santana, R. Comparative study of degradation of PP modified with na organic pro-degradant subjected to natural and artificial ageing. Polyolefins J. 2016, 3, 93–111. [Google Scholar]

- Ribeiro, M.V. Procedimentos para Avaliação da Degradação de Reservatórios de Polietileno para Água Potável Expostos as Intempéries. Master’s Thesis, Polytechnic School of University of São Paulo, São Paulo, Brasil, 2004. [Google Scholar]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especyally polystyrene: Review. SpringerPlus J. 2013, 2, 398. [Google Scholar] [CrossRef]

- Poletto, M. Thermal degradation and morphologycal aspects of four wood species used in lumber industry. Rev. Árvore 2016, 40, 941–948. [Google Scholar] [CrossRef]

- Browning, B.L. The Chemistry of Wood; Interscience Publishers: New York, NY, USA, 1963; p. 689. [Google Scholar]

- Kass, A.; Wangaard, F.F.; Schroeder, H.A. Chemical degradation of wood: The relationship between strength retention and pentosan content. Wood Fiber 1970, 2, 31–39. [Google Scholar]

- Chang, J.K.-W.; Duret, X.; Berberi, V.; Duret, H.Z.; Lavoie, J.M. Two-step thermochemical cellulose hydrolysis with partial neutralization for glucose production. Front. Chem. 2018, 6, 1–11. [Google Scholar]

- Catto, A.L. Resistência ao Intemperismo Natural e Ataque Fúngico de Compósitos Polímero-Madera. Doctoral Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brasil, 2015. [Google Scholar]

- Butylina, S.; Hyvarinen, M.; Karki, T. A study of surface changes of wood-polypropylene composites as the result of exterior weathering. Polym. Degrad. Stab. 2012, 97, 337–345. [Google Scholar] [CrossRef]

- Mehrdad, A.; Mehdi, N.; Hamid, Y. Effect of the melt flow index and melt flow rate on the thermal degradation kinetics of commercial polyolefins. J. Appl. Polym. Sci. 2012, 126, 1739–1745. [Google Scholar]

- Gondak, M. Desenvolvimento de Compósito Termoplástico Farinha de Madeira/Amido de Milho para Moldagem por Injeção. Master’s Thesis, Technological Federal University of Parana, Curitiba, Brasil, 2005. [Google Scholar]

- Semkiw, L.; Araujo, M.; Bueno, E. Influência da distribuição de tamanho de partículas de farinha de pinus ellioti em compósitos de polipropileno. In Proceedings of the Congresso Anual da ABM, São Paulo, Brazil, 19–22 June 2004. [Google Scholar]

- Luppi, B.T.; Gadioli, R.; De Paoli, M.A. Lignina de Eucalyptus como antioxidante para polipropileno: Envelhecimento ambiental e acelerado. In Proceedings of the 12th Congresso Brasileiro de Polímeros, Florianópolis, Brazil, 22–26 September 2013. [Google Scholar]

| Composite | BF (wt %) | PP (wt %) | Coupling Agent (wt %) | |

|---|---|---|---|---|

| MA | CI | |||

| PP/BF | 30 | 70 | - | - |

| PP/BF/MA | 30 | 67 | 3 | - |

| PP/BF/CI | 30 | 67 | - | 3 |

| Climatological Variations Analyzed | 6 Months | 12 Months | |

|---|---|---|---|

| Exposure Period: 09/01/2016–09/07/2016 | Exposure Period: 09/01/2016–09/01/2017 | ||

| Temperature | Minimum average | 19.1 °C | 14.9 °C |

| Registered minimum | 11 °C | 6.4 °C | |

| Maximum average | 28.8 | 24.8 °C | |

| Maximum registered | 36 °C | 36 °C | |

| Medium daily variation | 9.3 °C | 9.6 °C | |

| Rainfall | Average rainfall | 6.6 m | 3.6 mm |

| Accumulated rainfall | 943 mm | 1224 mm | |

| PH | Medium | 3.7 | 5.7 |

| Minimum registered | 3.0 | 4 | |

| Maximum registered | 7.9 | 7.9 | |

| UV Index | Medium | 9.8 | 7.8 |

| Minimum registered | 4 | 2 | |

| Maximum registered | 14 | 14 | |

| Sample/Exposure Time (Months) | Elasticity Module (GPa) | Tensile Stress at Break (MPa) | Extension at Break (mm) | Impact Izod (kJ/m2) | |

|---|---|---|---|---|---|

| PP/BF | 0 | 1.40 ± 0.06 a | 12.45 ± 0.63 g | 0.99 ± 0.10 m | 11.00 ± 0.48 s |

| 6 | 1.16 ± 0.03 b | 10.00 ± 0.29 h | 1.00 ± 0.10 n | 8.70 ± 0.79 t | |

| 12 | 0.85 ± 0.01 c | 7.80 ± 0.15 i | 0.80 ± 0.12 o | 7.8 ± 0.23 u | |

| PP/BF/MA | 0 | 1.63 ± 0.10 d | 14.87 ± 0.55 j | 2.14 ± 0.31 p | 13.42 ± 0.92 v |

| 6 | 1.45 ± 0.12 e | 13.63 ± 0.15 k | 1.24 ± 0.12 q | 11.23 ± 0.27 w | |

| 12 | 1.34 ± 0.07 f | 11.66 ± 0.50 l | 1.09 ± 0.13 r | 10.02 ± 0.71 x | |

| PP/BF/CI | 0 | 1.58 ± 0.06 d | 15.17 ± 0.45 j | 2.27 ± 0.06 p | 12.89 ± 0.34 v |

| 6 | 1.41 ± 0.08 e | 12.40 ± 0.55 k | 1.16 ± 0.07 q | 10.40 ± 0.46 w | |

| 12 | 1.32 ± 0.03 f | 11.93 ± 0.79 l | 1.08 ± 0.04 r | 9.71 ± 0.70 x | |

| Sample | Time (Month) | TGA | DTG | ||||

|---|---|---|---|---|---|---|---|

| T (°C) 10% wt | Ash (%) | 1st Tp (°C) | 2nd Tp (°C) | 3rd Tp (°C) | 4th Tp (°C) | ||

| PP/BF | 0 | 310 | 7.5 | 84 | 259 | 330 | 475 |

| 12 | 316 | 2.3 | 86 | 265 | 333 | 457 | |

| PP/BF/MA | 0 | 320 | 6.1 | 90 | 286 | 348 | 464 |

| 12 | 319 | 4.8 | 92 | 299 | 357 | 467 | |

| PP/BF/CI | 0 | 333 | 1 | 96 | 295 | 357 | 451 |

| 12 | 328 | 1.6 | 98 | 289 | 357 | 461 | |

| Sample | Time (Month) | 2nd Heating | ||

|---|---|---|---|---|

| Tm (°C) | ∆Hm(J/g) | Xc (%) | ||

| PP/BF | 0 | 165 | 74.1 | 50.89 |

| 12 | 166 | 63.2 | 43.41 | |

| PP/BF/MA | 0 | 166 | 58.7 | 40.32 |

| 12 | 165 | 70.6 | 48.49 | |

| PP/BF/CI | 0 | 166 | 60.4 | 43.34 |

| 12 | 164 | 64.8 | 46.50 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fajardo Cabrera de Lima, L.d.P.; Santana, R.M.C.; Chamorro Rodríguez, C.D. Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers 2020, 12, 929. https://doi.org/10.3390/polym12040929

Fajardo Cabrera de Lima LdP, Santana RMC, Chamorro Rodríguez CD. Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers. 2020; 12(4):929. https://doi.org/10.3390/polym12040929

Chicago/Turabian StyleFajardo Cabrera de Lima, Lety del Pilar, Ruth Marlene Campomanes Santana, and Cristian David Chamorro Rodríguez. 2020. "Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging" Polymers 12, no. 4: 929. https://doi.org/10.3390/polym12040929

APA StyleFajardo Cabrera de Lima, L. d. P., Santana, R. M. C., & Chamorro Rodríguez, C. D. (2020). Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers, 12(4), 929. https://doi.org/10.3390/polym12040929