1. Introduction

When a customer requests the development of a new product, a small quantity of the prototype is usually prepared for validation. Rapid tooling (RT) methods provide a quick way to satisfy this requirement. In general, the volume shrinkage of most polymer-based RT materials occurs when the material state changes from a melted state to a solid state. The volume of a gypsum block expands after the gypsum paste becomes solidified and the gypsum mold does not suffer from the volume shrinkage that is a known processing issue for many polymer-based RT materials. This specific material property improves the replication capability. The excellent replication capability of microstructures makes gypsum molds good candidates for precision molding, for example, gypsum molds are frequently used in denture application. Gypsum (calcium sulfate dihydrate) is a well-known mineral obtained from natural resources. However, gypsum molds are often used in low-pressure molding, e.g., casting [

1,

2,

3], due to the weak mechanical strength of gypsum material. In our previous work [

1], we developed gypsum inserts and gypsum molds for the RT method to be used in plastic injection molding. Since gypsum is a natural material and can be easily recycled, gypsum molds provide an ecofriendly approach for producing a limited quantity of prototypes made by using thermoplastic materials, with the injection molding method as the intended production line.

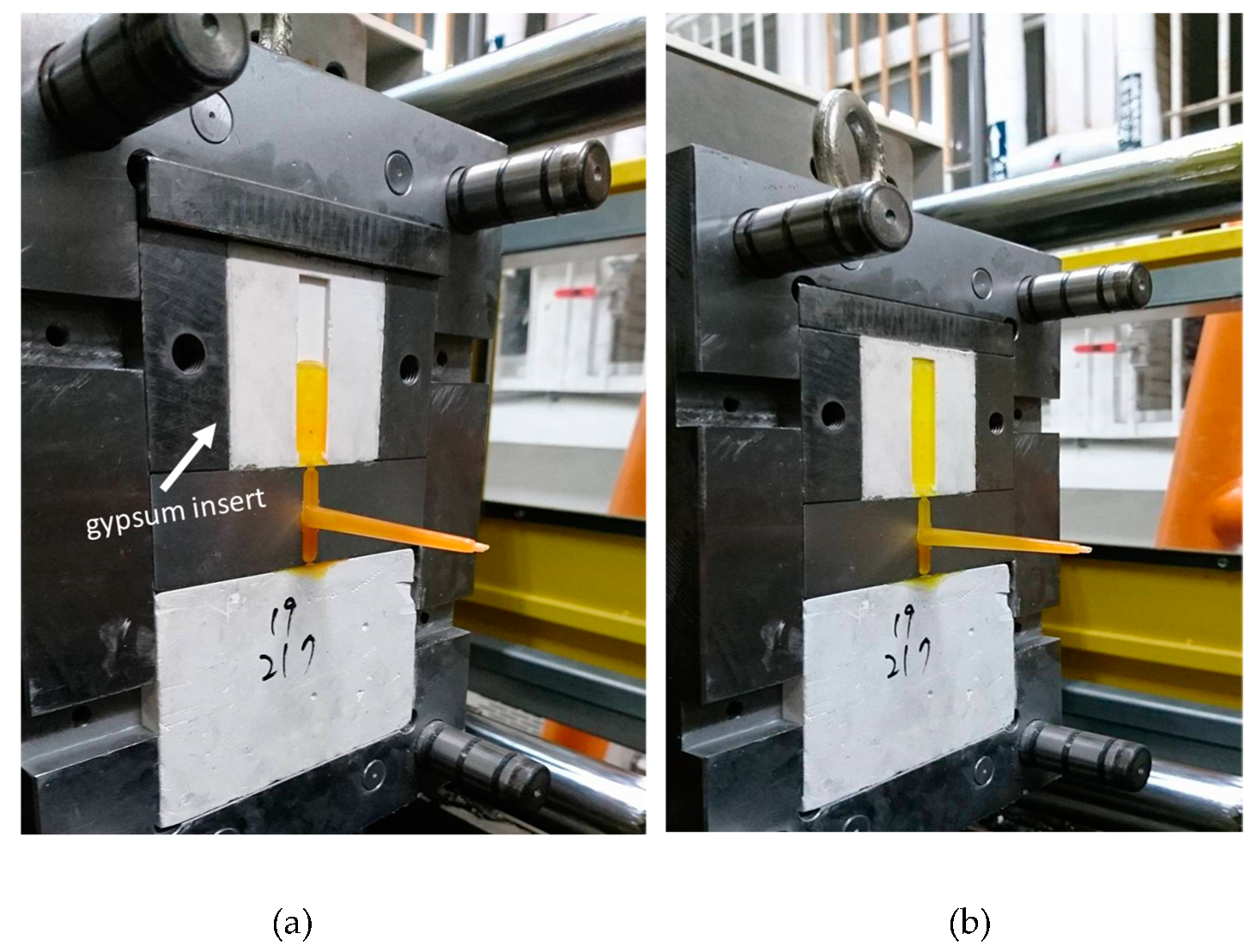

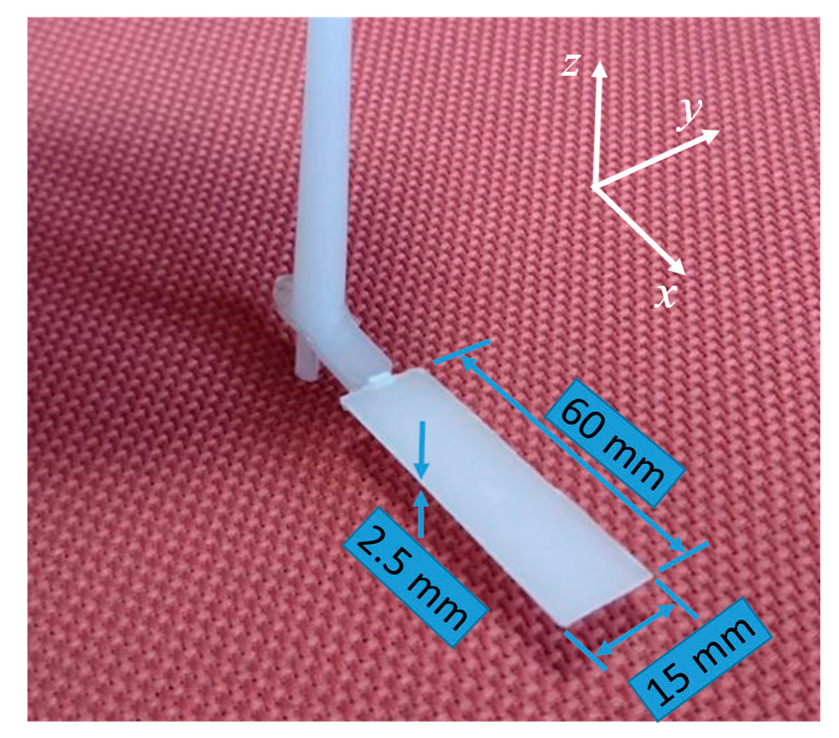

Figure 1a,b show examples of parts molded using a gypsum mold in plastic injection molding.

Injection molding is a sequential manufacturing process that produces products one by one periodically. The resin is heated and transformed into molten polymer, and then, the injection pressure and speed force the molten polymer into a mold cavity. As the molten polymer continues to cool and becomes strong enough, the mold opens and the cooled product is then stripped from the cavity. The qualities of the molded product, such as dimensional stability, appearance, and mechanical properties, are highly dependent on the processing conditions. One of the most critical variables determining the final quality of the product is the mold temperature [

2,

3,

4,

5,

6]. The mold temperature is dynamic during the injection molding process. To lessen the mold temperature variation, the mold is usually designed with a cooling system to keep the mold temperature as constant as possible. An unsuitable mold temperature not only influences the quality of the molded product, but it may also increase production costs [

7,

8,

9]. An RT mold is used only for a small number of productions and the problem resulting from the mold temperature in the injection process is often neglected. Nevertheless, Segal and Campbell [

10] pointed out that engineers making use of the RT method to produce technical prototypes must be aware of the effect of the mold temperature on the properties of the final part. Mendible et al. [

11] evaluated three different inserts: (PolyJet) 3D printing using digital ABS, direct metal laser sintering (DMLS) using bronze, and machining using stainless steel. Without a cooling system in the inserts, they found that the shrinkage value of the molded part using PolyJet was the largest. Wu et al. [

12] proposed the optimization of the conformal cooling design for a uniform mold temperature of the RT mold. Hopkinson and Dickens [

13] tried to predict the ejection force and the tool lifetime of an RT mold because of their poor heat transfer characteristics. Aluru et al. [

14] also studied the effect of the thermal conductivity of RT molds on final-part distortions using a simulation tool. They compared the molding performance of the RT mold and the conventional steel mold using simulation results and actual molding experiments. All of their studies indicated that the cooling system within the mold insert was important, and its effect should be evaluated in the application of the RT mold. In addition, they pointed out that an analytical approach was still required. How to analyze the design parameters of a cooling system, such as the location or the diameter of the channel, still need to be addressed.

In general, the design of the cooling system is usually implemented by the designers’ experiences or the use of commercial software, which may be time-consuming in respect to computation and the lack of the physical essence of an active system. Pignon et al. [

15] provided an analytical approach for choosing thermal conditions during thermoplastic injection molding. The proposed models allowed quick determinations of the cooling/solidifying time, the mold surface temperature variation, and the heat flux densities exchanged between the polymer and the mold. Zarkadas and Xanthos [

16] developed a simplified semi-analytical method to predict the cooling time of the part in an injection molding process. Their study demonstrated that the determination of an engineering problem can be more efficient if an analytical model can be established in advance.

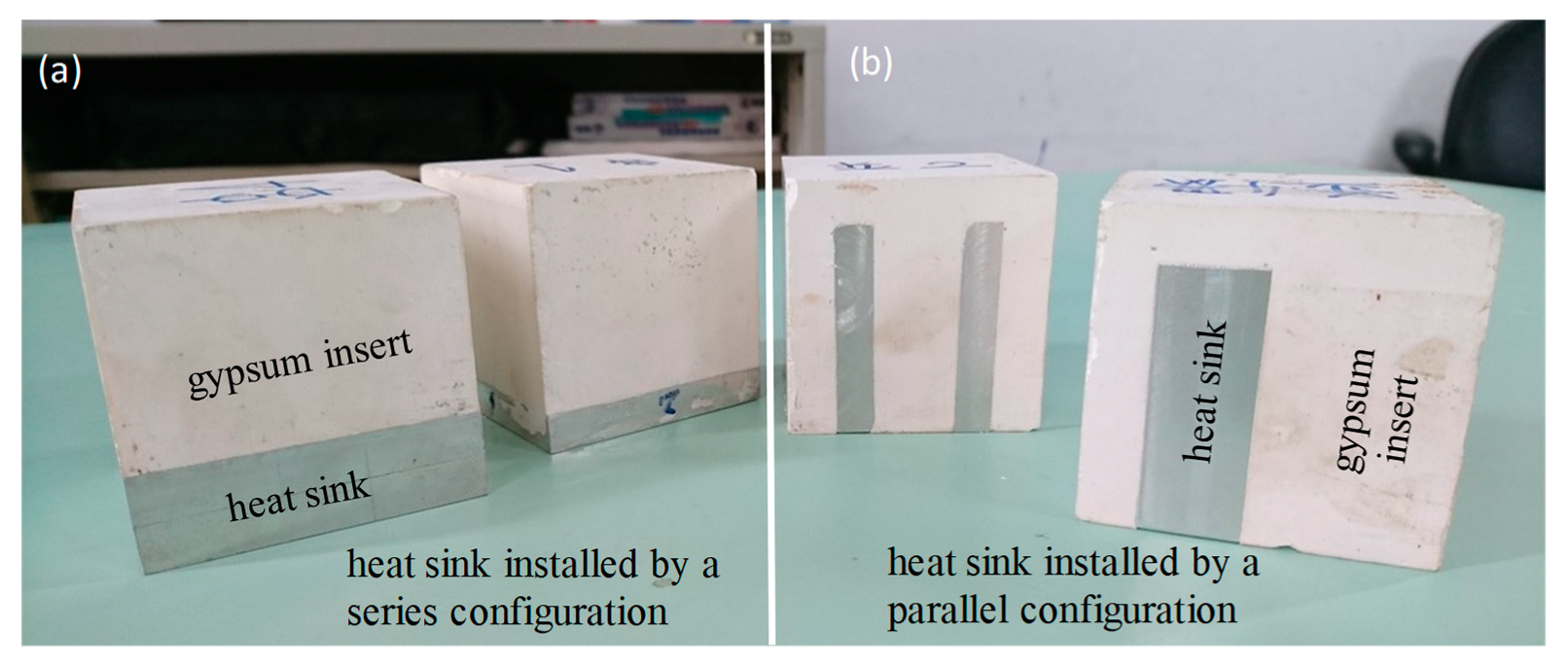

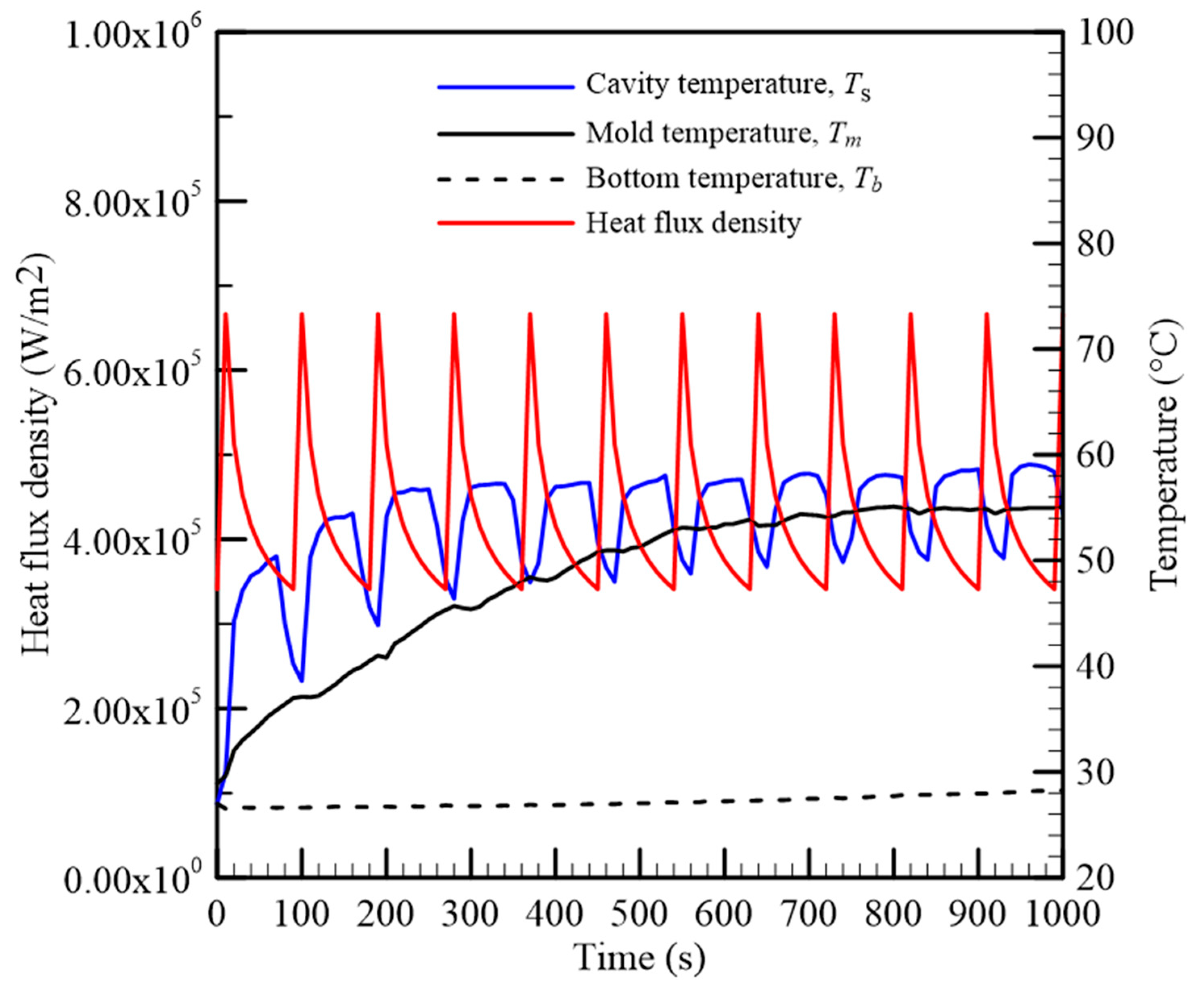

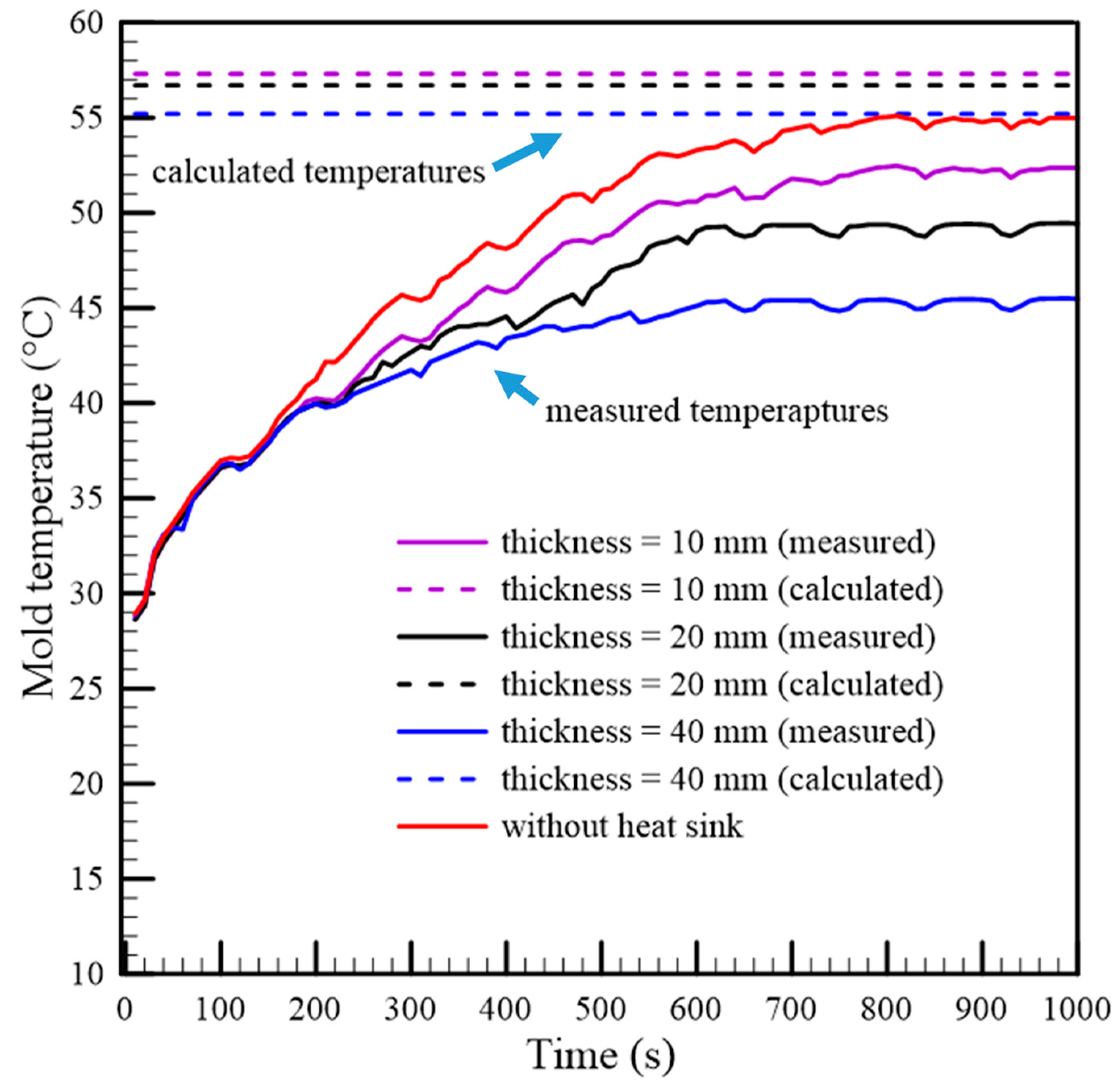

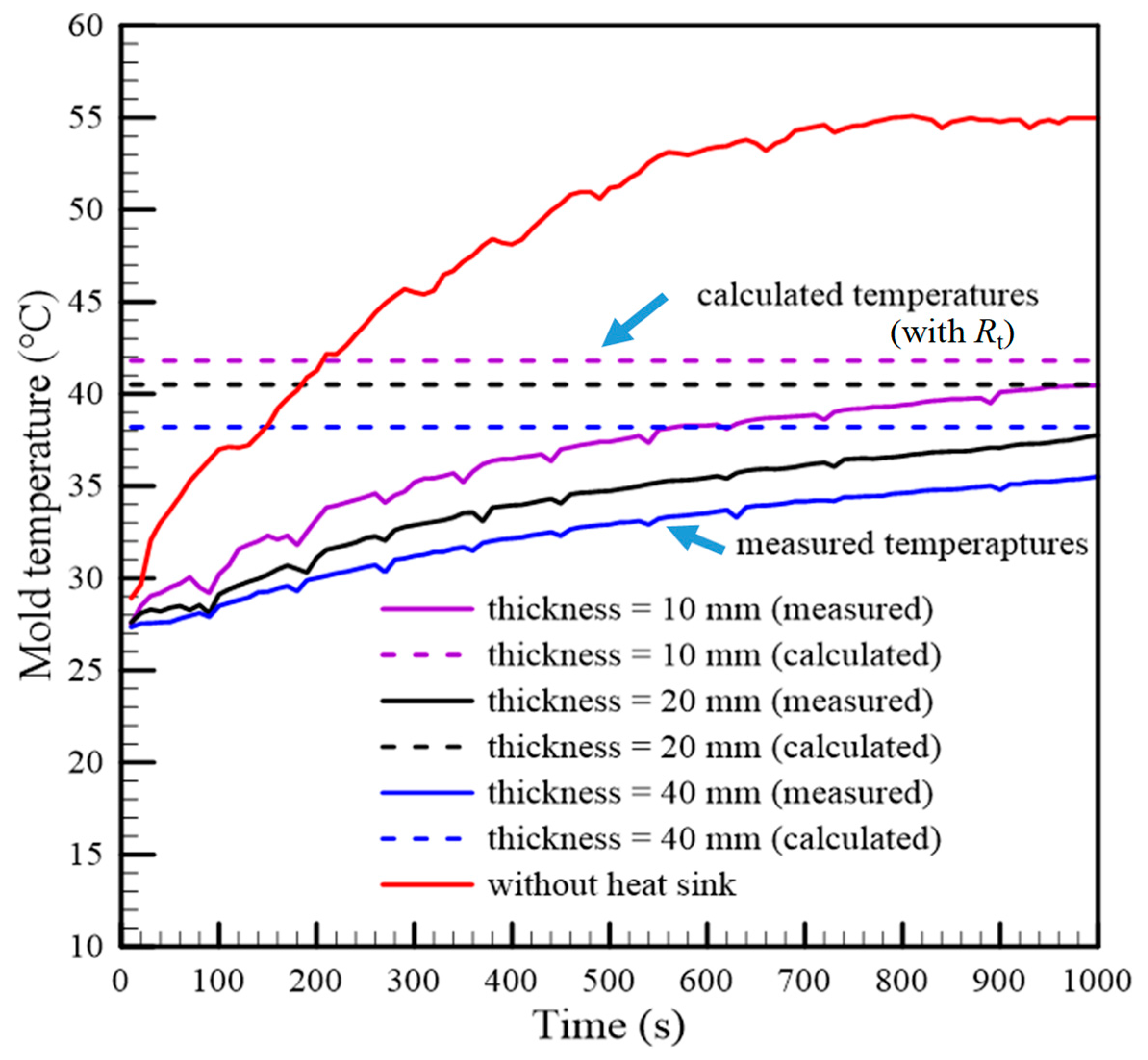

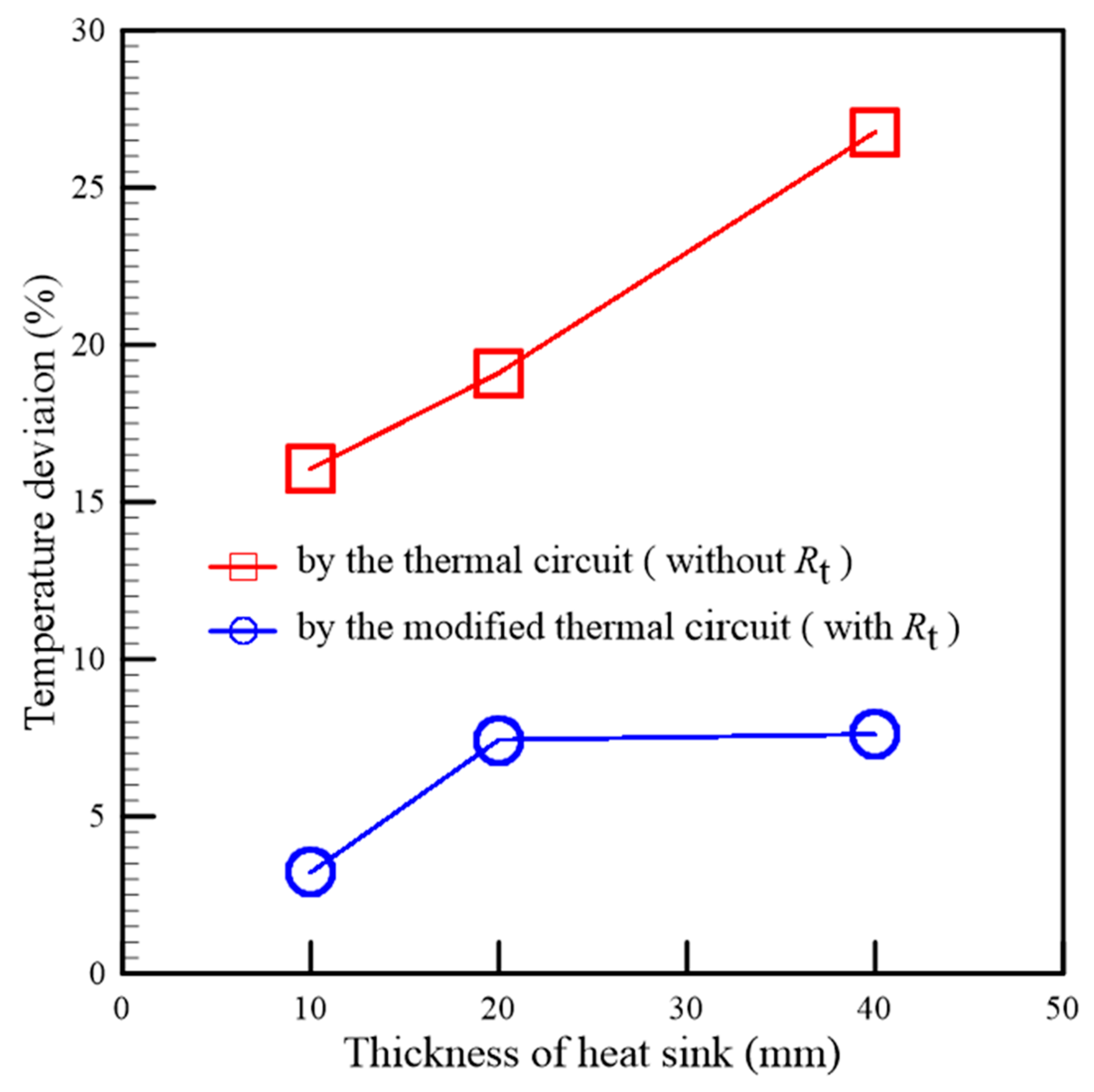

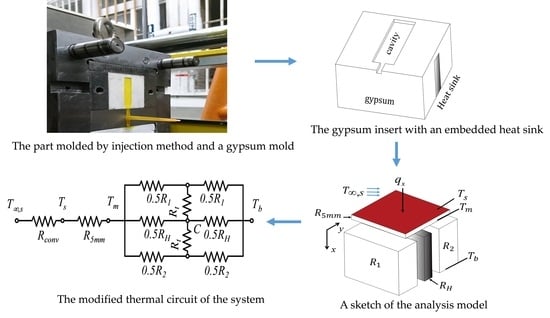

Materials used in RT methods are characterized by low thermal conductivity, and this represents an issue of the thermal effect for processing. A coolant system can improve the heat transfer capability but increases the cost and complexity as well. In our work, we introduced a heat sink made of aluminum as the cooling system when forming the gypsum inserts and, thus, improved the heat transfer capability. We also developed a methodology based on the thermal circuit concept [

17] to easily determine the design parameters of the heat sink, such as the thickness and installation configuration (e.g., series or parallel) of the heat sink. The influences of the design parameters on the gypsum mold temperature were investigated with thermal circuits and validated by experiments. In addition, a modified thermal circuit considering transverse heat conduction was proposed, which extended a 1D model to a 2D heat transfer. It provided a more accurate model to predict the mold temperature. Finally, the influence of the mold temperature on the deflection of the molded parts was also investigated in this work.

2. Formulation to Analyze Mold Temperature

When the shape of the molded part was symmetrical and the mold cavity was located in the center of the mold, the heat transfer process inside the mold was assumed to be symmetrical and could be modeled using the 1D heat transfer equation [

17]. Heat convection can be neglected due to the very high viscosity of the molten polymer (more than 1000 Pa·s), and the molded part was cooled mainly by conduction [

18]. Two mold halves (the fixed side and the mobile side) constructed the mold cavity, and the heat transfer happened on each side of the mold insert. Suppose the dimensions of the mold insert for both mold halves were the same, and the heat transfer process in each mold insert was regarded identically. The heat conduction started from the surface of the insert, and the heat flow direction was assumed to be normal to this surface. All of the thermal properties, such as thermal conductivity of the gypsum and heat sink, were considered constant during the heat diffusion process. The 1D heat transfer equation, through the thickness of the mold insert in the

x-direction, was given by [

15]:

where

k,

ρm, and

Cm are the thermal conductivity, density, and specific heat capacity of the mold insert material, respectively. At the initial time of the injection process, the mold cavity was instantaneously filled, and the temperature field on the mold cavity surface was assumed to be uniform and equal to the melting temperature

Tp. The initial condition was defined by:

In addition, since the heat transfer equation is second order in the spatial coordinate, two boundary conditions need to be specified to determine the temperature distribution in the mold insert. Heat flux densities,

φ1(

t) and

φ2(

t), were imposed on the top and bottom surfaces of the mold insert. They were expressed by:

in which

h represents the thickness of the mold insert. Both of them were to be determined using the experimental data. Hence, the temperature

T could be calculated by using the finite difference method [

19].

At the beginning of the injection process, the mold temperature rises gradually and then achieves a plateau with the increase in the injection molding cycle. In this stage, the mold temperature is supposed to be in a periodic stable state. A semi-empirical equation based on the assumption of a linear evolution of the mold temperature [

15] provides an efficient way to determine the cavity temperature,

Ts, in the steady state.

Ts was determined by:

where

Tc was the thermal contact temperature as the molten polymer contacted the cavity’s surface at the end of the filling stage, and

Tmi represented the mold temperature before injection molding. Note that

Tc can be calculated from Equation (1).

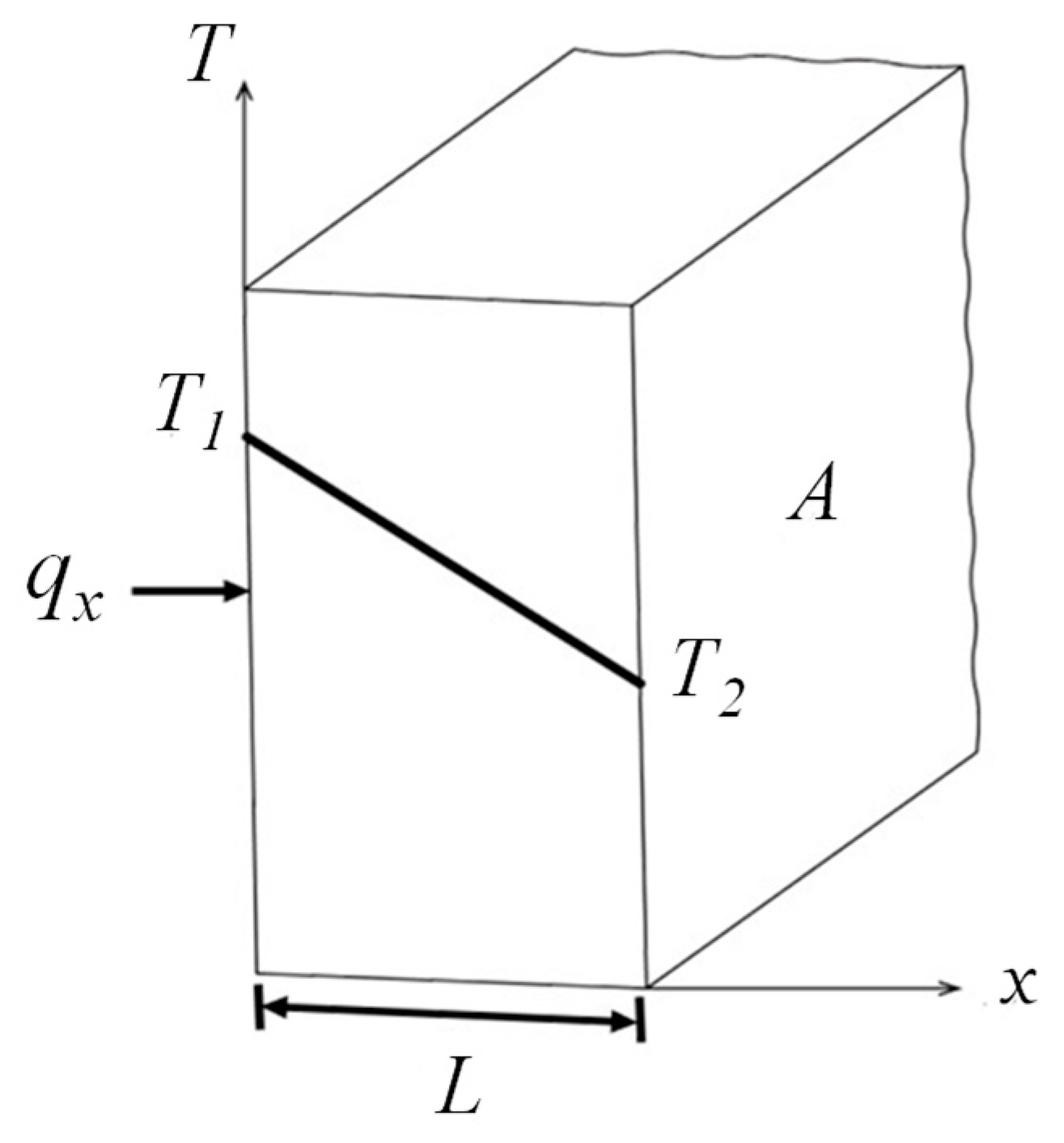

For a steady-state condition with no extra source or sink of energy within the wall, the heat flux density is a constant and independent of a transfer path [

17]. The appropriate form of the heat equation is given by:

Fourier’s law implies that the 1D heat transfer rate,

qx, is directly proportional to the temperature difference, Δ

T = (

T1 −

T2), and cross-sectional area

A, as well as varying inversely with Δ

x. Therefore, for 1D steady-state conduction in a plane wall with no heat generation, the temperature varies linearly with

x, as shown in

Figure 2. The simplified heat transfer rate equation of the wall can be expressed by:

2.1. Thermal Resistance

The concept of thermal resistance is referred to as the electrical circuit. There exists an analogy between the diffusion of heat and the movement of electrical charge. Just as an electrical resistance is associated with the conduction of electricity, a thermal resistance may be associated with the conduction of heat. The resistance is defined by the ratio of the driving potential to the corresponding transfer rate [

20]. Therefore, the thermal resistance for conduction

R can be derived from Equation (7) and defined ideally by the ratio of the temperature difference Δ

T to the heat transfer rate

qx. In fact, any material defects, such as a small void or non-uninform structure resulting from manufacture process, may influence the accuracy of the thermal resistance. A modified thermal resistance with a correction factor is proposed and defined by:

where

x is the measurement location, and the coefficients

c1 and

c0 can be determined by the experimental data.

Similarly, a thermal resistance may also be associated with heat transfer by convection at a surface. The thermal resistance for convection is then given by:

where

hcv is the convection heat transfer coefficient.

When a gypsum insert is installed with a heat sink for heat transfer improvement, it can be regarded as an assembly of different layers of materials. Therefore, the heat diffusion of a gypsum insert can be modeled using several thermal resistances in a thermal circuit. As the equivalent thermal resistance of the circuit is determined, the heat transfer rate can be calculated, and then, the temperature on each layer of the insert can be calculated analytically.

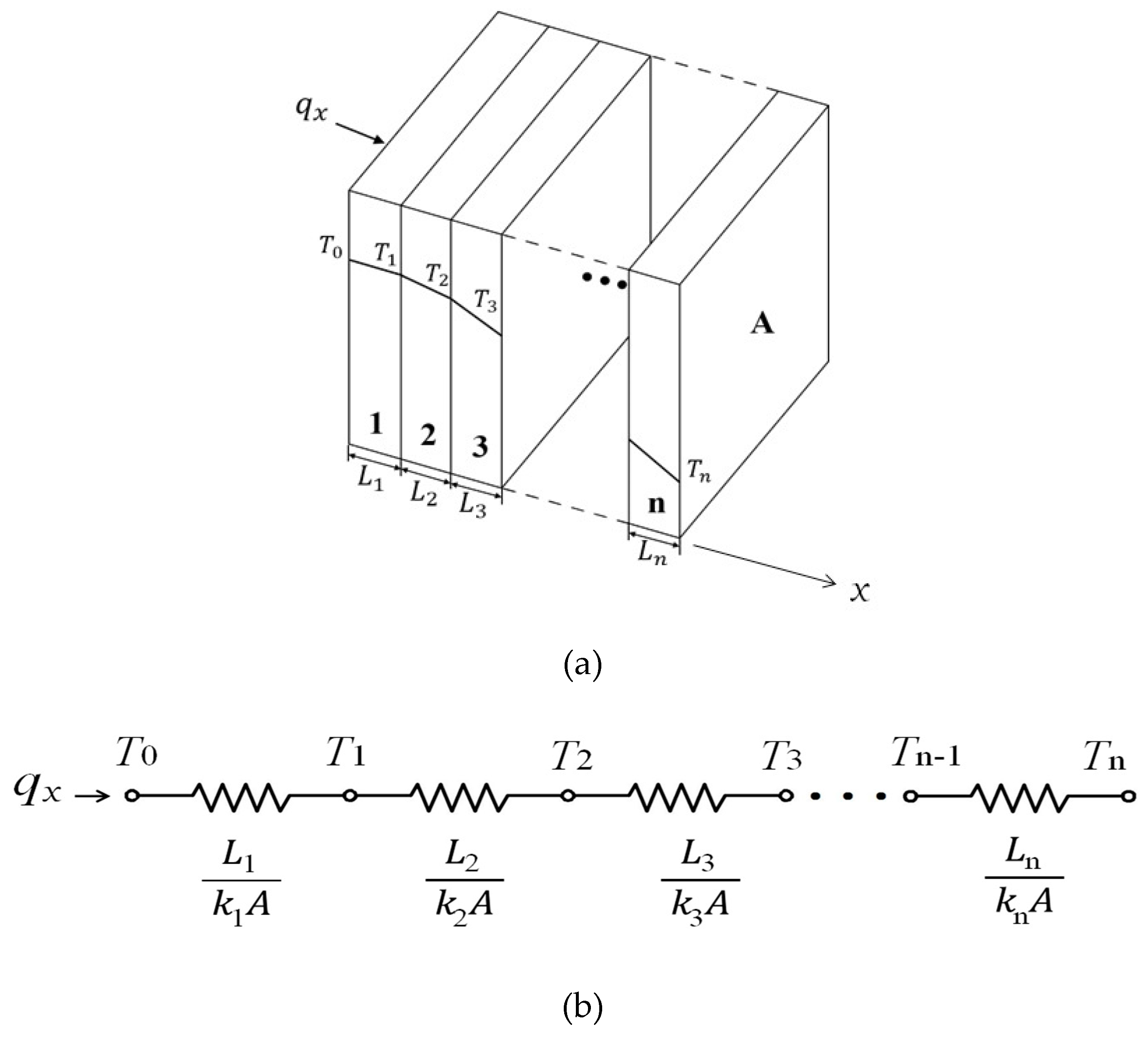

2.2. A Series Configuration of the Composite Wall

Suppose that

n pieces of wall have thicknesses and thermal conductivity of

Li, and

ki,

i = 1, 2, …,

n, respectively, and are assembled in a series configuration, as shown in

Figure 3a. Assume that the material of each piece of wall is uniform, and each adjacent wall comes into contact with each other perfectly. Hence, the heat loss between their interfaces can be neglected. The heat is conducted from the first wall to the last wall, sequentially. The thermal circuit of the composite wall can be sketched using

Figure 3b. The node in the circuit represents the temperature of the location. In accordance with the electrical circuit concept for a series configuration, the heat transfer rate,

qx, may be determined by separate consideration of each element in the circuit. That is:

where the nodes in the circuit,

T0,

T1, …, and

Tn are the surface temperatures for each layer. The equivalent thermal resistance of the thermal circuit,

, is the sum of the resistances of each wall and is expressed by:

In terms of overall temperature difference,

T0-

Tn, the heat transfer rate is determined by:

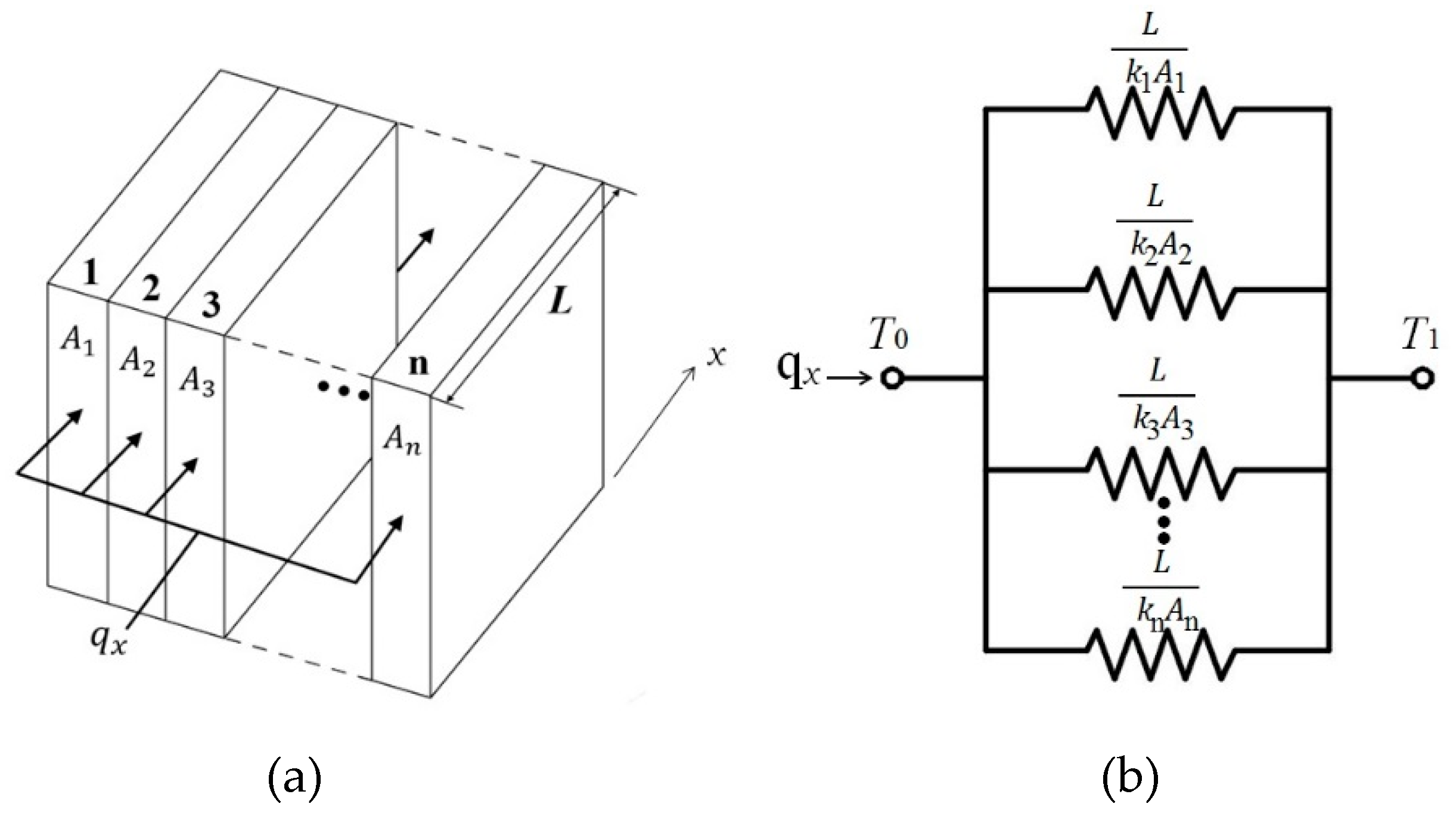

2.3. A Parallel Configuration of the Composite Wall

When the walls are characterized by a parallel configuration, as shown in

Figure 4a, heat transfer occurs simultaneously on the contact surfaces of all the walls. The heat flow is now two-dimensional; however, it is often reasonable to assume one-dimensional conditions as the thickness of the heat sink is small [

17]. The thermal circuit can be sketched as shown in

Figure 4b. All of the surfaces normal to the

x-direction where the heat is delivered are assumed to be the same temperature. Therefore, the equivalent thermal resistance of the thermal circuit,

, is calculated by:

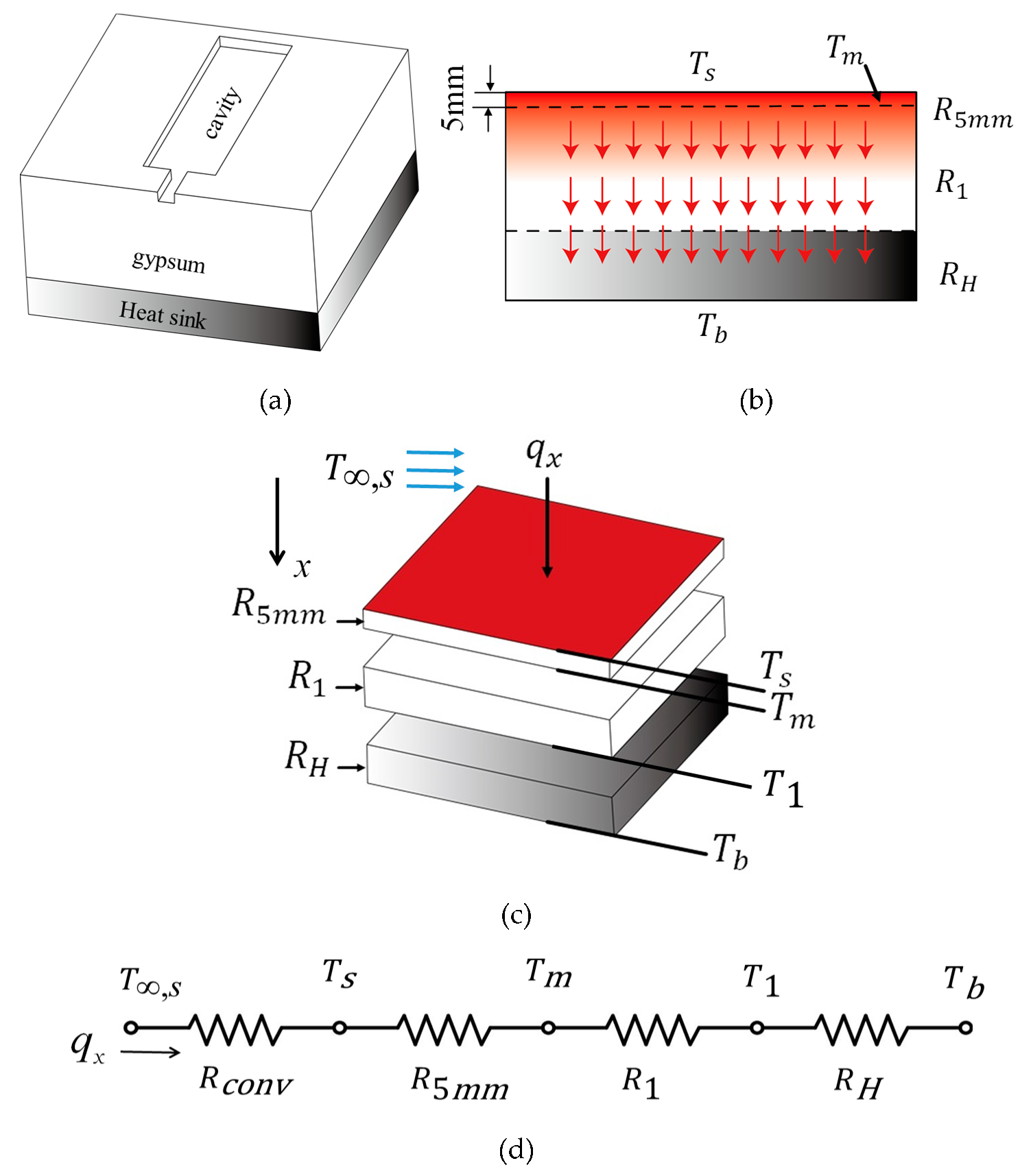

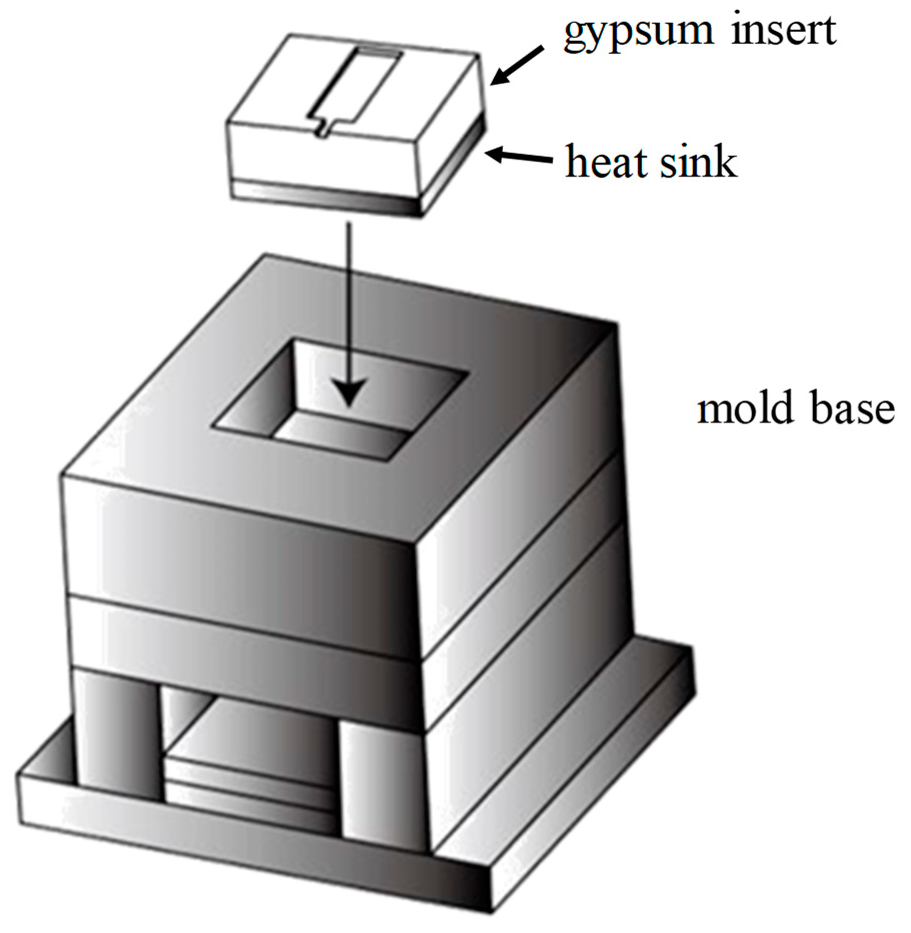

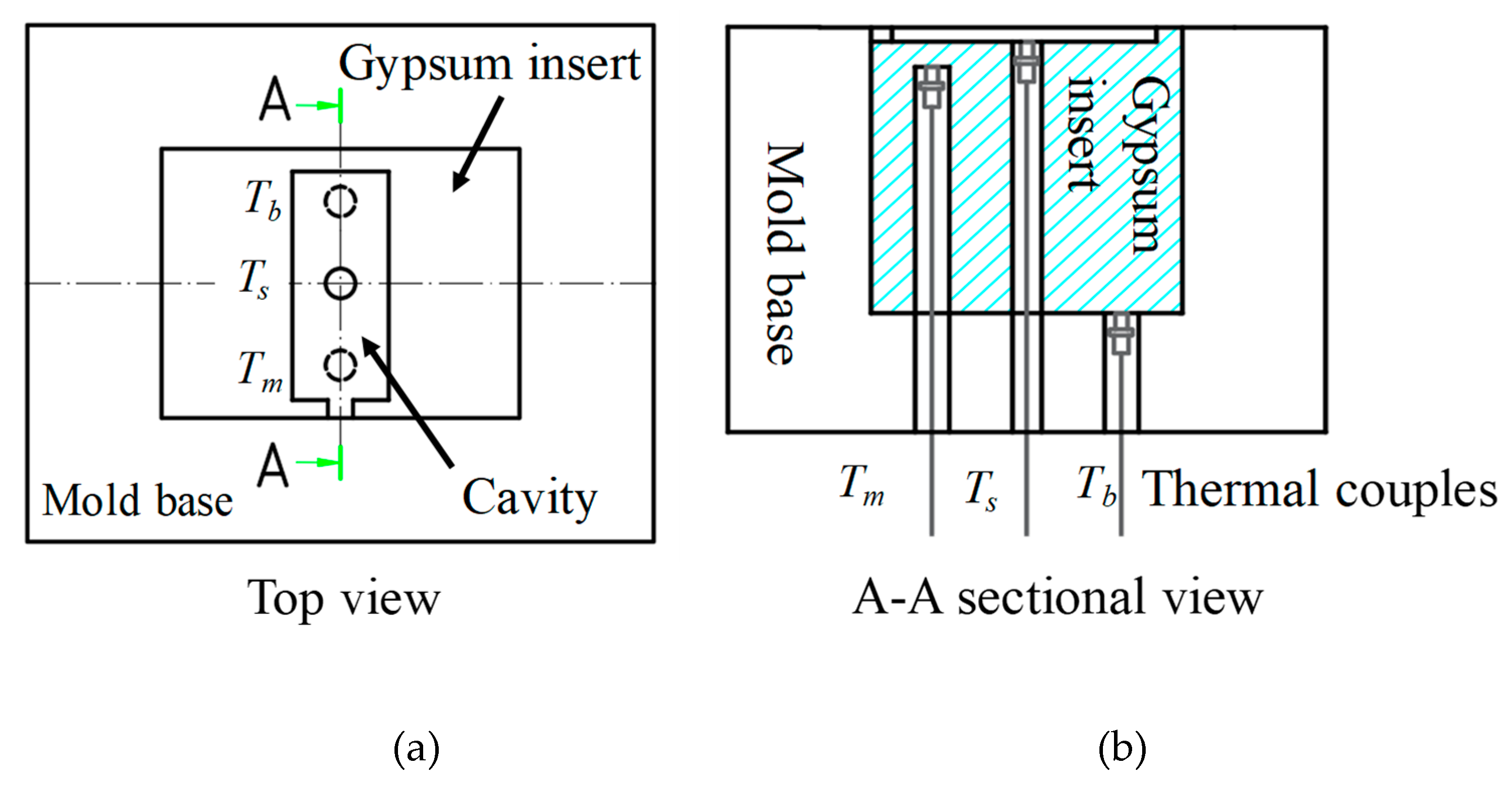

2.4. Thermal Circuit of the Gypsum Insert

When molten polymer is injected into the mold, the duration of the filling stage is usually very short, and the whole temperature on the mold cavity can be assumed to be the same during this stage. Suppose the mold cavity is located in the center of the gypsum insert with a heat sink, as shown in

Figure 5a. The heat conduction starts from the top of the gypsum insert and passes through different layers, such as the gypsum layer and heat sink and the bottom of the gypsum insert, sequentially. The heat diffusion process in the central cross-sectional plane of the insert can be referred to in

Figure 5b. The mold temperature,

Tm, is defined by the temperature measured at a depth of 5 mm below the cavity’s surface of the gypsum insert [

21,

22].

Ts, and

Tb stand for the cavity temperature and the bottom temperatures of the gypsum insert, respectively.

T∞,s represents the room air temperatures on top surface of the insert. The discrete components of the insert and its thermal circuit are constructed as shown in

Figure 5c,d, respectively. For a series configuration of the gypsum insert, the equivalent resistance,

of this circuit can be calculated by:

where

R5mm,

R1, and

RH, represent the thermal resistances of each layer where the heat is conducted.

Rconv is the thermal resistance for environmental convection.

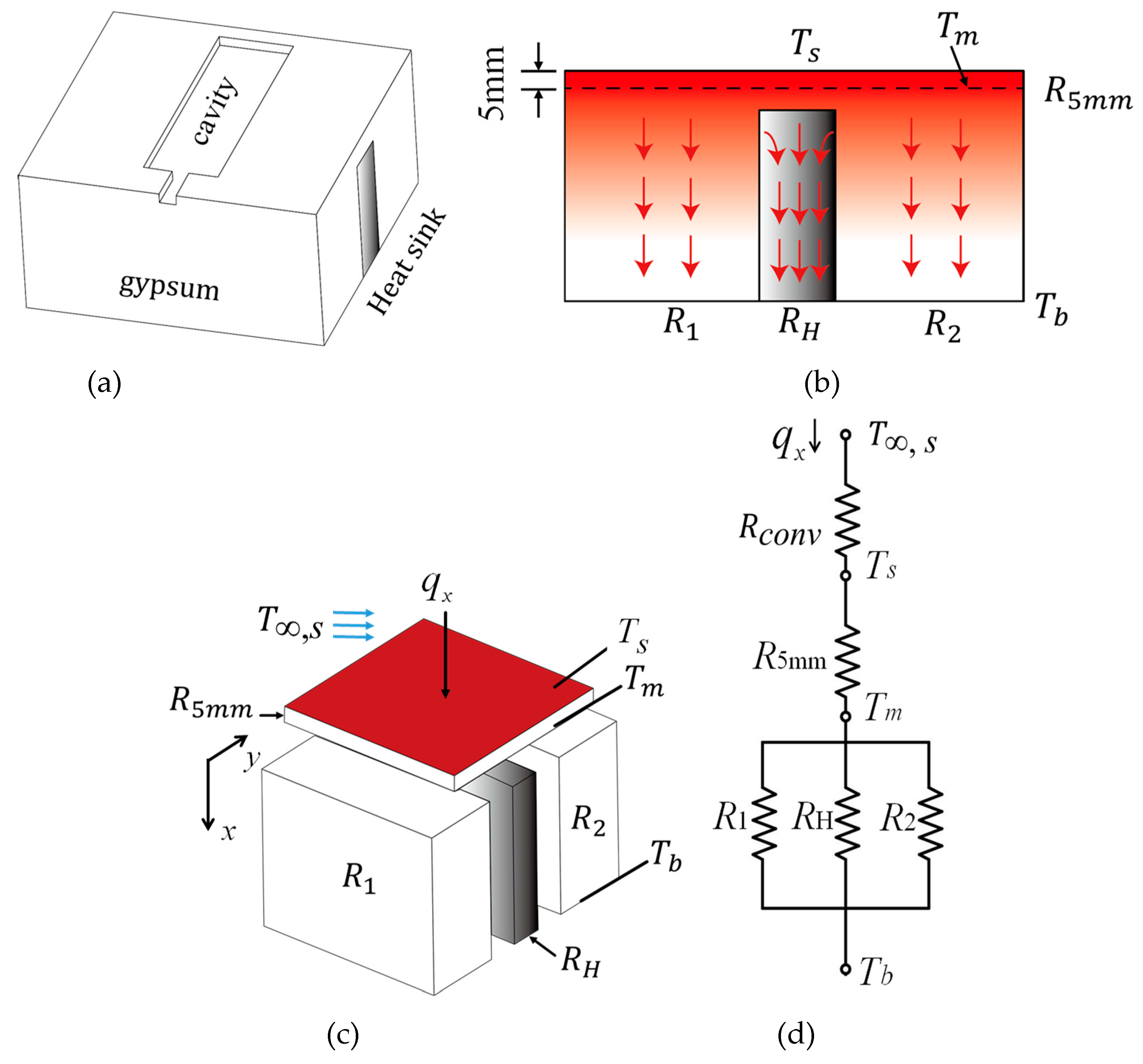

Similarly, if a heat sink is installed into the gypsum insert in accordance with

Figure 6a, a sketch of the heat conduction process is illustrated in

Figure 6b. The heat in the cavity is first conducted through the top layer, and then, the heat passes through both the gypsum layer and the heat sink simultaneously. The discrete components of the insert and the corresponding thermal circuit are illustrated as in

Figure 6c,d. The process of heat conduction in this case can be regarded as heat transfer mainly in a parallel configuration of the thermal circuit.

R1,

R2,

RH, and

Rconv represent the thermal resistances of the gypsum material, heat sink, as well as the thermal resistance for convection, respectively.

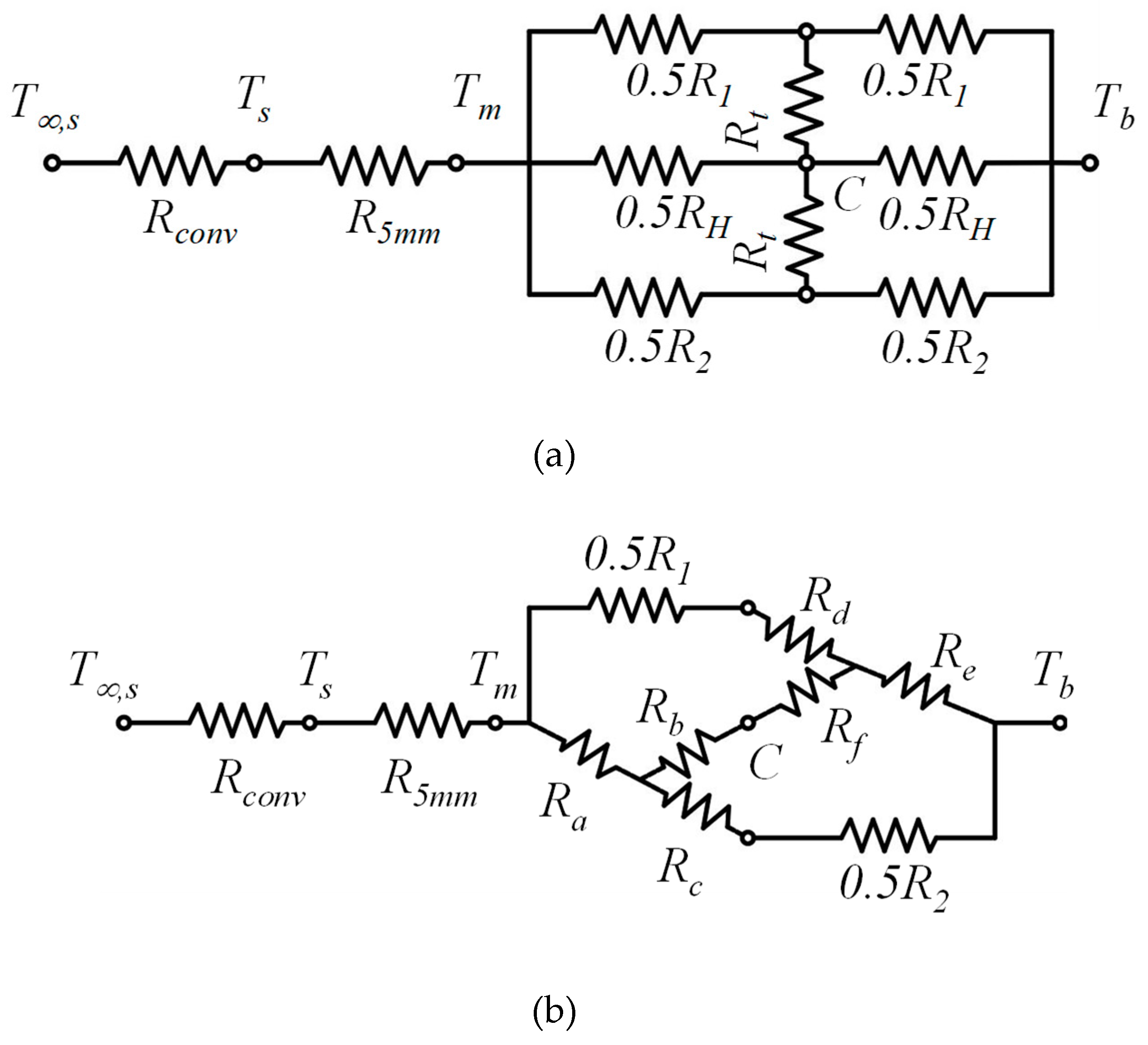

2.5. A Modified Thermal Circuit Including Transverse Thermal Resistance

When the heat sink is too thick, it is inappropriate to assume that the heat diffusion is only in the

x-direction, as shown in

Figure 6c. In fact, the heat diffusion in the transverse direction (the

y-direction) needs to be considered. A node

C is added at the center of the heat diffusion path of the circuit shown in

Figure 6d, and the temperature can be assumed to be the average of

Tm and

Tb. Two transverse thermal resistances

Rt are connected to both side paths of

R1 and

R2 when considering transverse heat diffusion. The modified thermal circuit is sketched in

Figure 7a.

Solving the modified thermal circuit problem, as shown in

Figure 7a, the transformation of Δ and Y circuits [

20] should be utilized to calculate the equivalent resistance of the circuit. Two Y-shaped resistance circuits are added into the upper right and the bottom left loops of the modified thermal circuit, and thus, the equivalent circuit is shown in

Figure 7b. The resistances on the border of the loops are replaced by (

Ra,

Rb,

Rc) and (

Rd,

Re,

Rf) and expressed by:

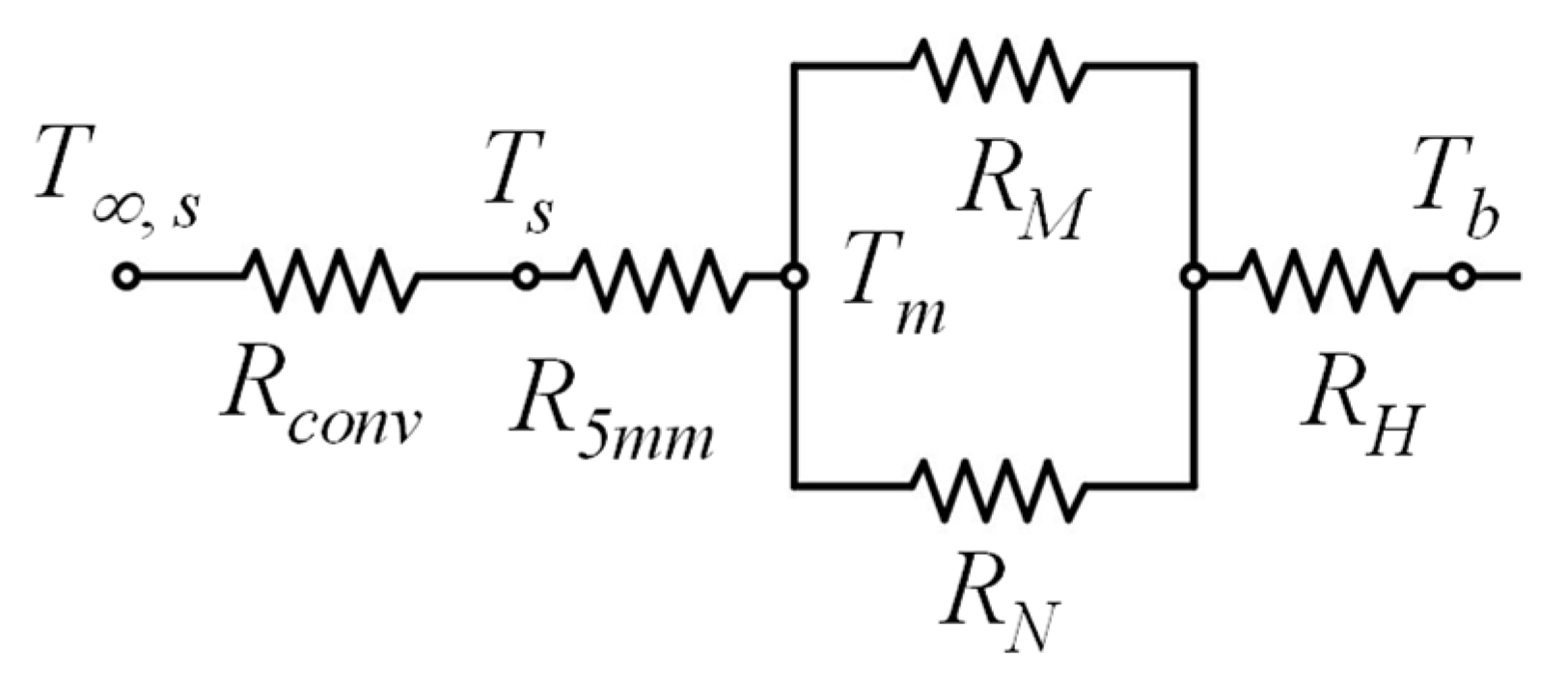

Furthermore, a sequential calculation of the transformation skill of Δ and Y circuits is implemented, and finally, the circuit shown in

Figure 7a is simplified and illustrated in

Figure 8. The equivalent resistance of the modified thermal circuit with transverse thermal resistance can be determined by:

where:

Equations (21) and (22) provide a modified approach to treating the heat conduction of the gypsum insert, including the transverse heat diffusion.

2.6. Calculation of Mold Temperature Based on Thermal Circuit

Suppose that a gypsum insert is assembled into the mold base firmly.

Ts and

Tb are the cavity temperature and the bottom temperature of the gypsum insert. According to the methodology developed in the previous section, the theoretical mold temperature,

Tm, in a steady state can be calculated by:

where

(

i =

s for a series configuration,

i =

p for a parallel configuration) is an equivalent resistance of the thermal circuit.

5. Conclusions

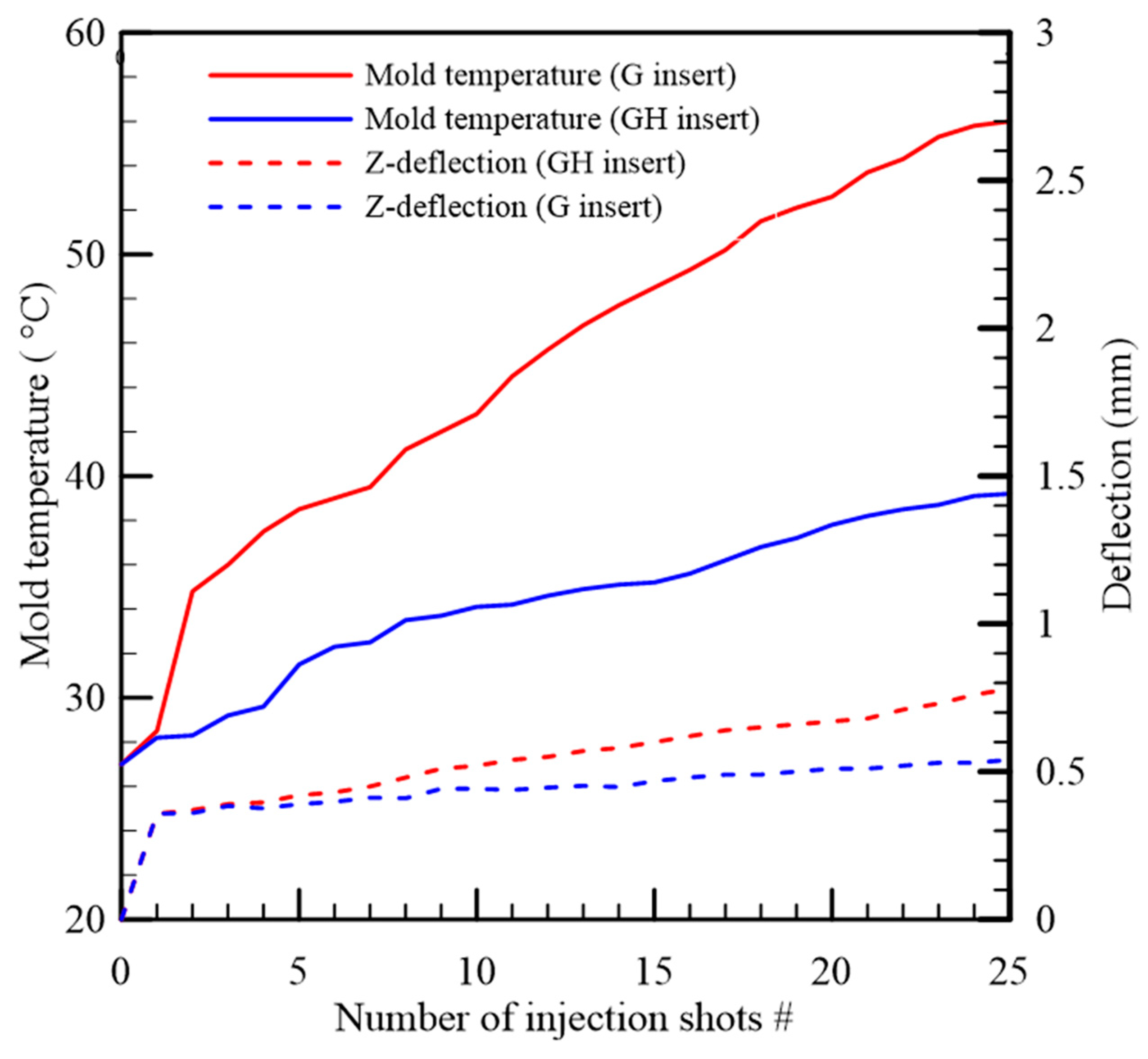

A mold insert made of gypsum with an embedded heat sink to improve the mold temperature, has been demonstrated in this work. A methodology based on the thermal circuit concept was developed as well to provide a systematical approach to analyze the influences of the design parameters on the mold temperature. After the thermal resistances of all the components were determined either theoretically or experimentally, the thermal circuit of the mold was constructed, and then, the heat transfer rate was calculated. Based on this model, one could quickly gain the understanding of the physical essence behind the functionality of the heat sink. This helps us to determine quickly what design and engineering elements govern the mold temperature. In addition, we also provided a modified thermal circuit including the transverse heat transfer process and expanded the system to a 2D heat transfer model in this work. The results showed that the mold temperature was reduced more efficiently when the heat sink was embedded by a parallel configuration rather than by a series configuration. In this study, the mold temperature was reduced by 16.8 °C, while the deflection of the molded part was improved from 0.78 mm to 0.54 mm if the insert included a heat sink 40 mm thick in a parallel configuration. This method is very helpful to determine the arrangement of a cooling system at the very early design stages during the development of new molds. If detailed information is needed for further confirmation, the commercial simulation tool may be introduced cooperatively.