1. Introduction

Asphalt pavement has been widely used in road engineering construction due to its high strength, durability, and impermeability. As the primary material in road construction, asphalt is a non-renewable energy source [

1]. At the same time, the demand for asphalt increases year by year with the rapid development of road construction. Therefore, it is urgent to find materials that can replace part of the asphalt [

2]. Waste oil and waste plastic are two wastes in industrial production and daily life. Waste oil can cause harm to the environment and waste plastic becomes the primary source of “white pollution” because of hard degradation. To make things worse, the waste plastic releases a large amount of harmful gas during incineration treatment.

Recently, many pieces of research have been focused on using waste oil or waste plastic to modify asphalt [

3,

4]. They found that the main component of waste engine oil (WEO) is similar to the lightweight component of asphalt. According to the principle of “like dissolves like”, WEO can be used to modify asphalt [

5]. Jia et al. [

6] used WEO residues to partially replace asphalt. They found that the addition of WEO improves low-temperature performance. However, it also impaired the high-temperature resistance of the asphalt and its resilience at the same time. Liu et al. [

7] used WEO to modify asphalt. They found that the addition of WEO is beneficial to prevent asphalt aging and improving fatigue performance, but WEO has a negative effect on the rutting resistance of asphalt. Villanueva et al. [

8] prepared the modified asphalt with used lubricating oil (or engine oil). They found that used lubricating oil improves the anti-cracking performance at low-temperatures and reduces the quality loss of asphalt after rolling thin film oven test (RTFOT). Liu et al. [

9] mixed WEO with the matrix asphalt and styrene–butadiene–styrene (SBS) modified asphalt, respectively. They revealed that the appropriate contents of WEO increase the fatigue resistance and temperature sensitivity of asphalt. In addition, WEO affects the matrix asphalt more significantly than SBS modified asphalt. Qurashi et al. [

10] studied the aging performance of WEO as a rejuvenator when it is incorporated into asphalt. They discovered that 2–4 wt % of WEO eliminates the negative influence of aging on asphalt performance and improves the flexibility and elasticity of asphalt. DeDene et al. [

11,

12] added WEO into the reclaimed asphalt binder (RAB) and found that WEO can restore the performance of RAP. Meanwhile, WEO can also improve the low-temperature properties of asphalt mixtures blended with RAB.

Waste polyethylene (WPE), as another asphalt modifier, has also been investigated by many researchers. Polacco et al. [

13] used several polyethylenes and polyethylene-based polymers to modify vacuum-distilled asphalt. They found that linear low-density polyethylene had good compatibility with asphalt and enhances the mechanical properties of asphalt. Attaelmanan et al. [

14] used high-density polyethylene (HDPE) as an asphalt modifier. They discovered that HDPE and asphalt are compatible to a certain extent and HDPE improves the high-temperature shear resistance of asphalt. By adding HDPE, the moisture sensitivity and temperature sensitivity of asphalt can be reduced. Hu et al. [

15] used WPE from packaging as a modifier of matrix asphalt and found that WPE modified asphalt has better deformation resistance than matrix asphalt. Fang et al. [

16] blended WPE with the matrix asphalt. They found that WPE does not react with asphalt and WPE modified asphalt still had excellent high-temperature stability after the oxidation aging test. Priyansh et al. [

17] incorporated the pulverized WPE into the asphalt by the dry mixing method and used a dynamic shear rheometer to evaluate the viscoelasticity of WPE modified asphalt. They found that WPE improves the adhesion of the asphalt in the short heating time during the mixing process. Fuentes-Auden et al. [

18] used recycled polyethylene (RPE) to modify 150/200 penetration grade asphalt and discovered that RPE can improve rutting and the fatigue cracking resistance of asphalt binder.

Based on the above research related to WEO and WPE applications, it reveals that WEO is beneficial for the low-temperature performance of asphalt and WPE improves the high-temperature stability of asphalt. However, the high- or low-temperature properties of asphalt modified by the WEO and WPE mixture (WEO/WPE) are still unknown.

During the service life of asphalt pavement, asphalt surface aging is vulnerable to take place due to the ultraviolet (UV) radiation from the sunlight. UV can change the chemical composition and chemical structure of asphalt and weaken the performance of asphalt pavement [

19,

20,

21,

22]. Bocci et al. [

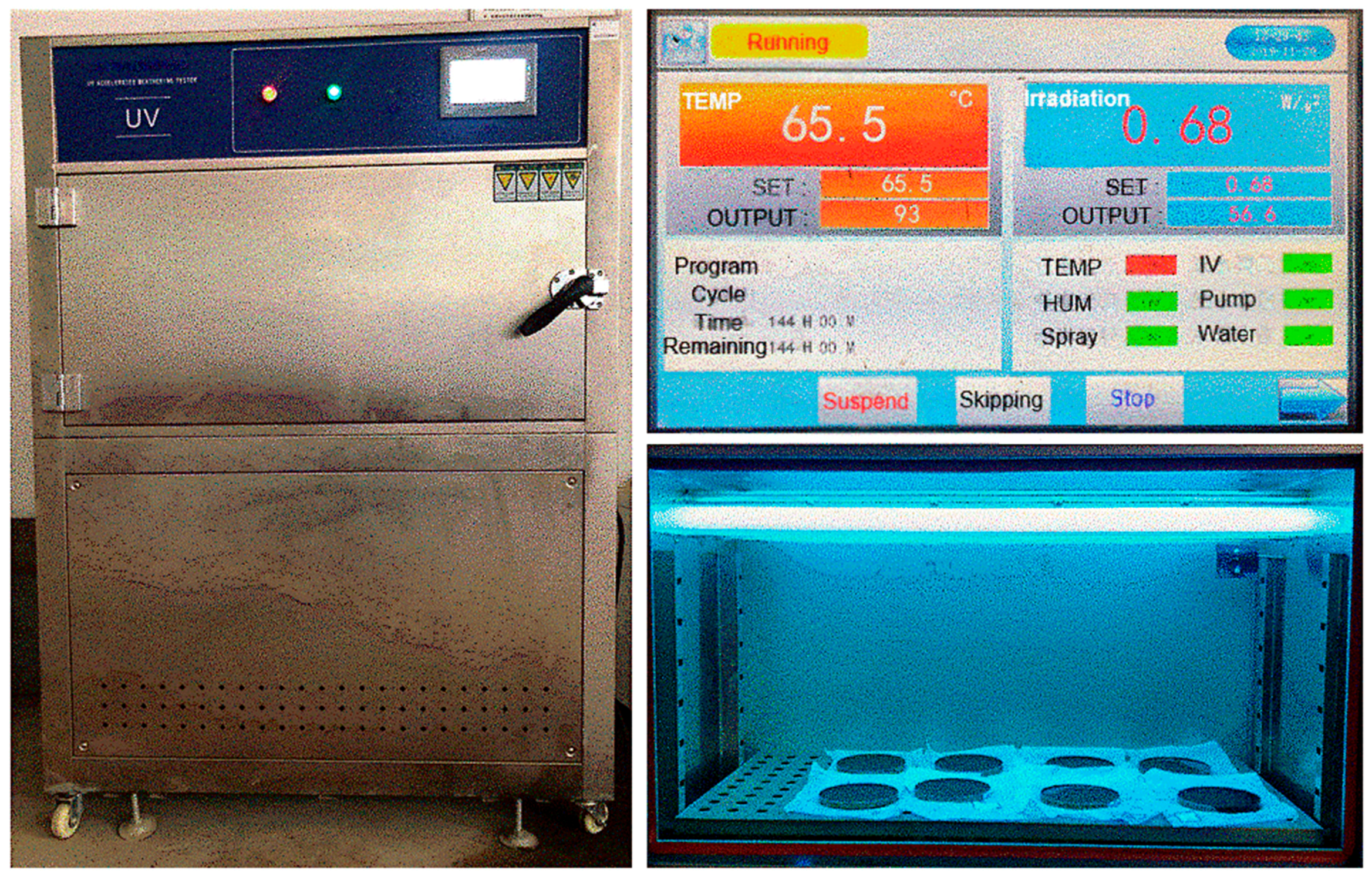

23] designed a UV aging simulation experiment in the laboratory. They found that increasing UV radiation intensity aging time has a similar effect on asphalt with prolonging UV aging time. Peng et al. [

24,

25,

26] studied the effect of layered double hydroxides (LDH) containing p-methyl cinnamic acid anions (Zn-Al-PMCA-LDH), LDH containing 4,4′-stilbene dicarboxylic acid anions (Zn/Al-SA-LDH), and LDH containing 2-hydroxy-4-n-octoxy-benzophenone anions (Zn/Al-HNOB--LDH) on asphalt UV aging resistance. The results show that Zn-Al-PMCA-LDH, Zn/Al-SA-LDH, and Zn/Al-HNOB--LDH have a synergistic effect on reflecting and absorbing UV light. Cao et al. [

27] used nitric acid to etch layered double hydroxides (LDHs) and discovered that LDHs after etching treatment enhances the anti-UV aging properties of asphalt much more than LDHs without etching treatment. From the above studies, it can be seen that increasing UV aging resistance of asphalt is essential to prolong the service life of asphalt pavement. To our best knowledge, the UV aging resistance of asphalts modified by the WEO/WPE mixture has not been investigated.

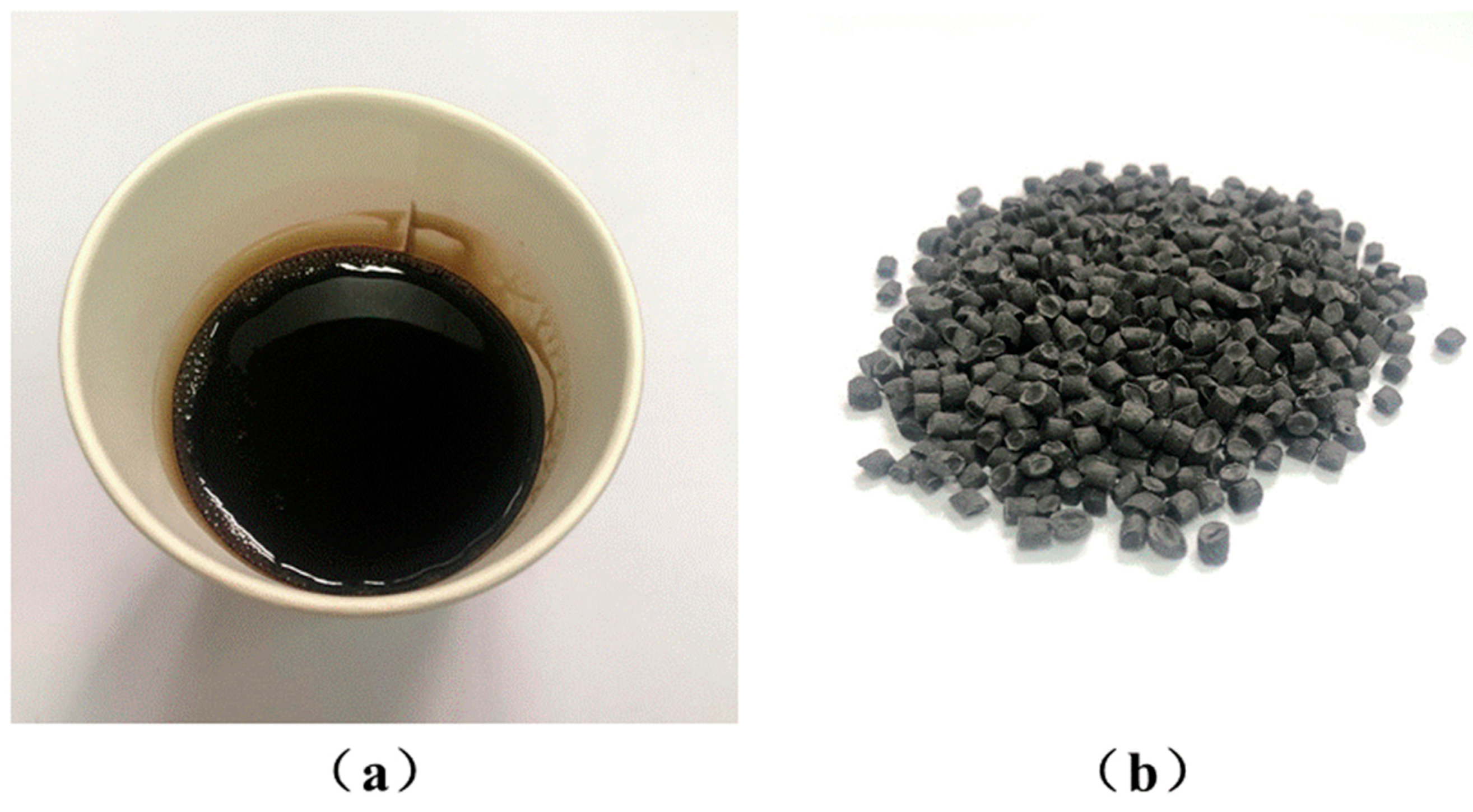

In this work, the physical parameters of asphalts modified by WEO, WPE, and WEO/WPE mixture were tested. Then, the molecular weight distribution characteristics of asphalts were analyzed by gel permeation chromatography (GPC). The compatibility between the modifiers and the matrix asphalt was evaluated by the storage stability test. Subsequently, an ultraviolet aging simulation experiment of asphalts was carried out. The functional groups of asphalts before and after UV aging were analyzed by Fourier transform infrared spectroscopy (FTIR). Finally, the micro-morphology of asphalts before and after UV aging was observed by atomic force microscopy (AFM).

4. Conclusions

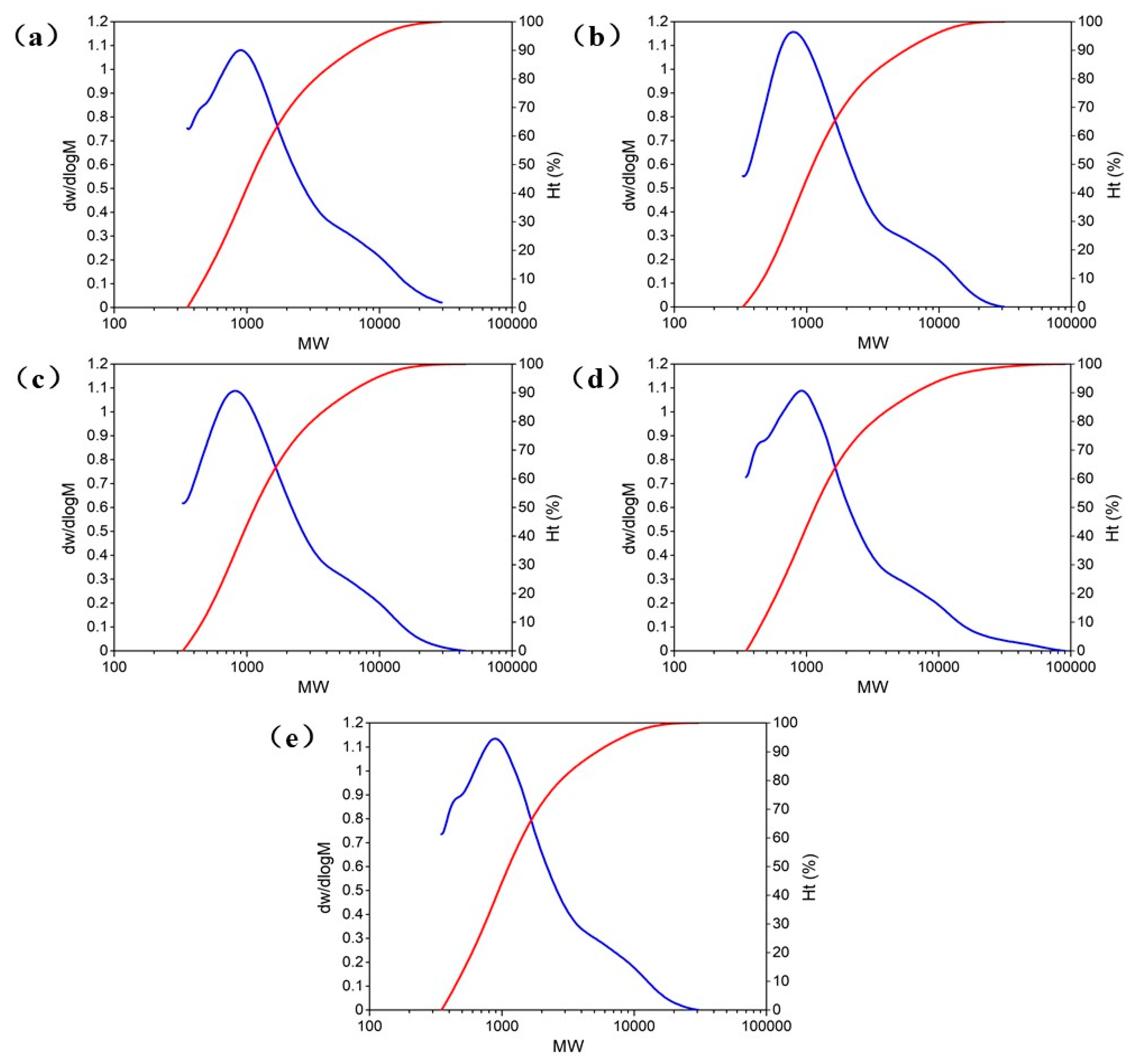

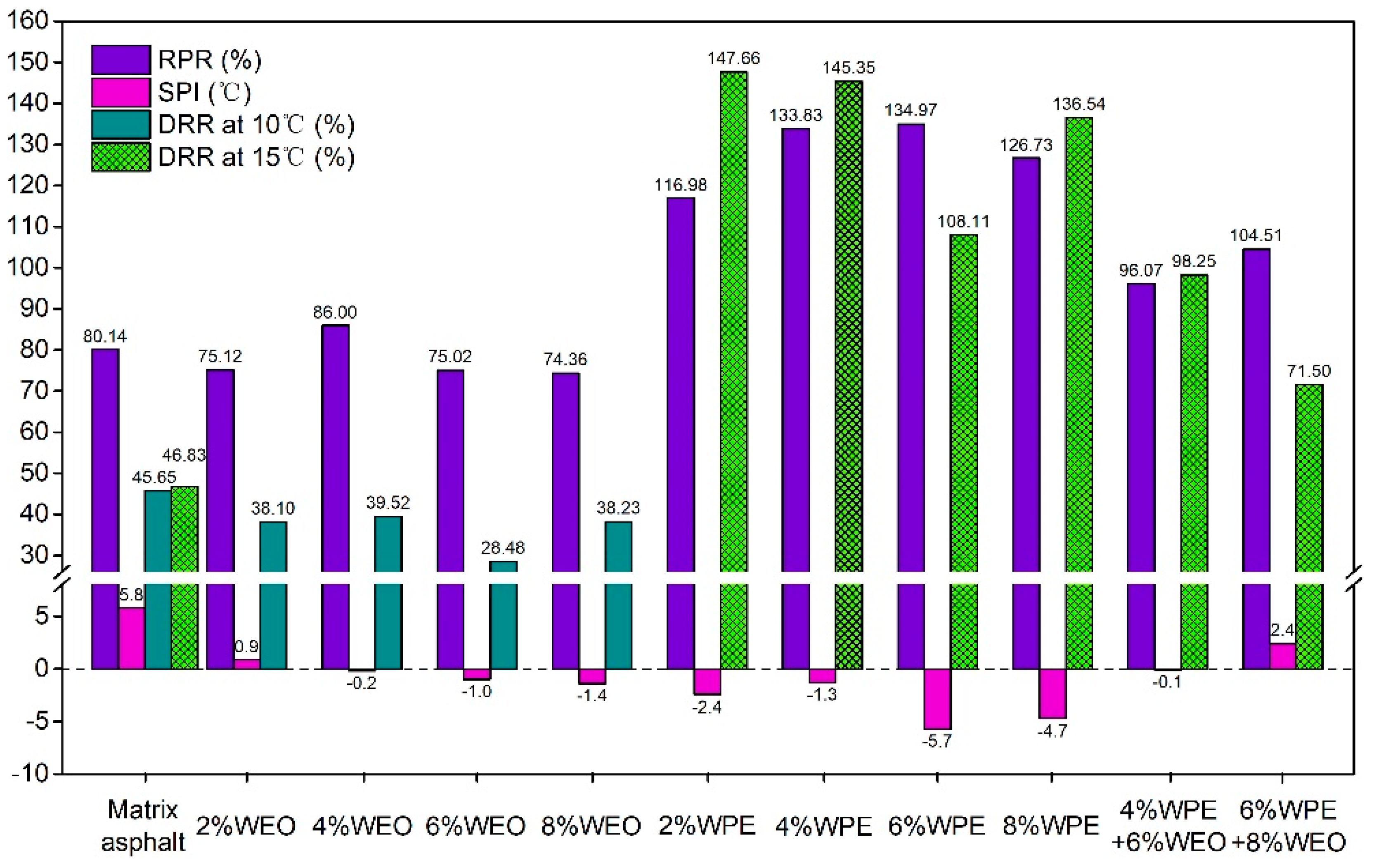

(1) Physical property results show that WEO can soften the matrix asphalt and enhance low-temperature crack resistance of asphalt. The WPE can make the matrix asphalt hard and increase the deformation resistance of asphalt at high temperatures. Physical properties of 4%WPE + 6%WEO and 6%WPE + 8%WEO are similar to those of the matrix asphalt. GPC experiments display that WEO increases the molecular weight of asphalt in the low molecular weight range, while WPE raises the molecular weight of asphalt in the high molecular weight range. The molecular weight distribution characteristic of 4%WPE + 6%WEO is most similar to that of the matrix asphalt and can effectively replace part of the matrix asphalt. The storage stability test indicates that 4%WPE + 6%WEO has satisfactory compatibility with the matrix asphalt.

(2) The physical aging indexes of asphalts reveal that 4%WEO or 6%WPE has better UV aging resistance than other WEO modified asphalts or WPE modified asphalts. Considering DRR and SPI, the UV aging resistance of 4%WPE + 6%WEO is superior to that of the matrix asphalt or 6%WPE + 8%WEO.

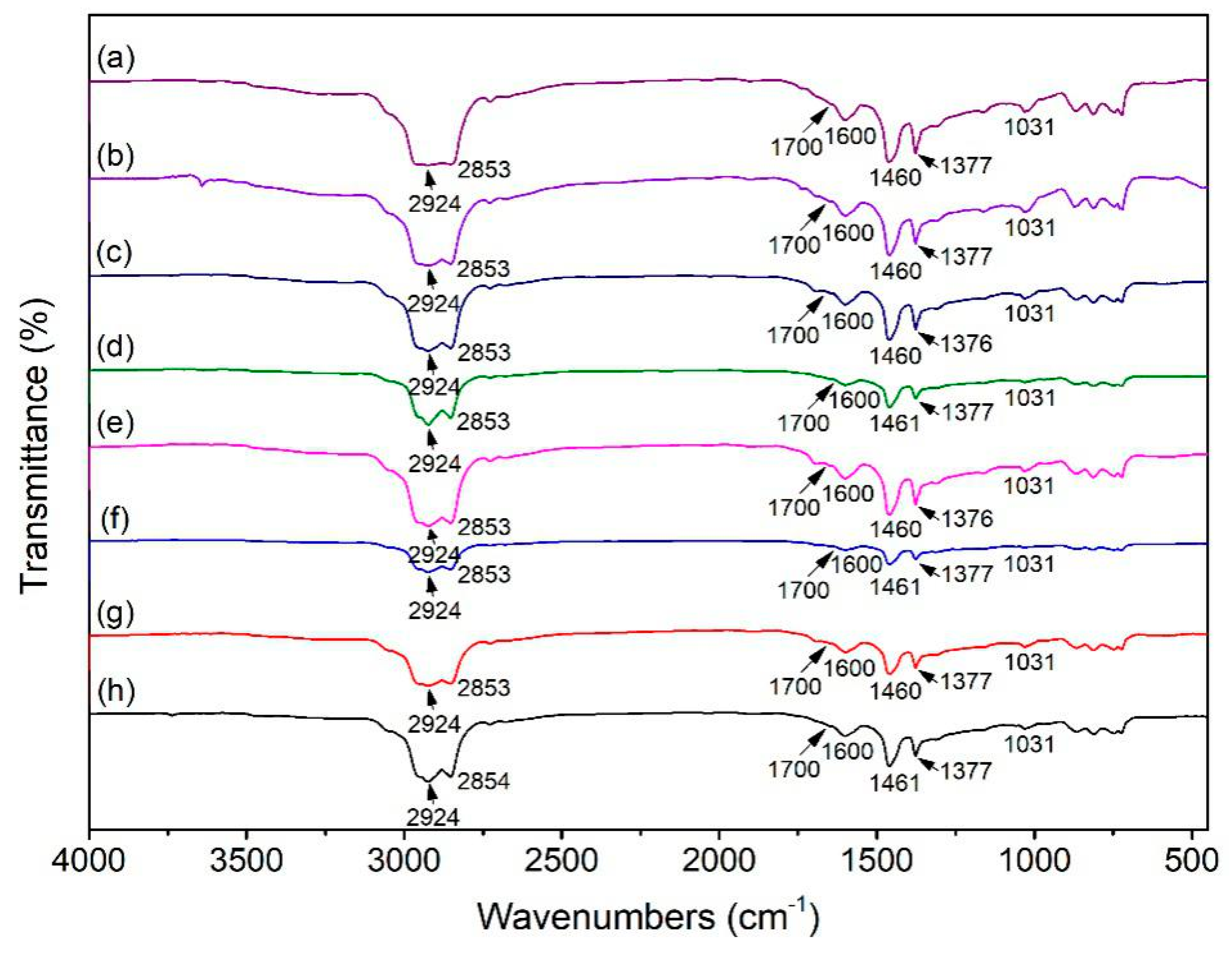

(3) The FTIR shows that WEO and WPE are physical blending modifications for asphalt. The contents of carboxyl and sulfoxide groups in matrix asphalt, WEO modified asphalt, and WPE modified asphalt after the UV aging experiment are increased, while the contents of carboxyl and sulfoxide groups in 4%WPE + 6%WEO after the UV aging experiment are decreased. The WEO and WPE in asphalt provide small molecules under the action of UV light, preventing the conversion of saturates and aromatics components in asphalt.

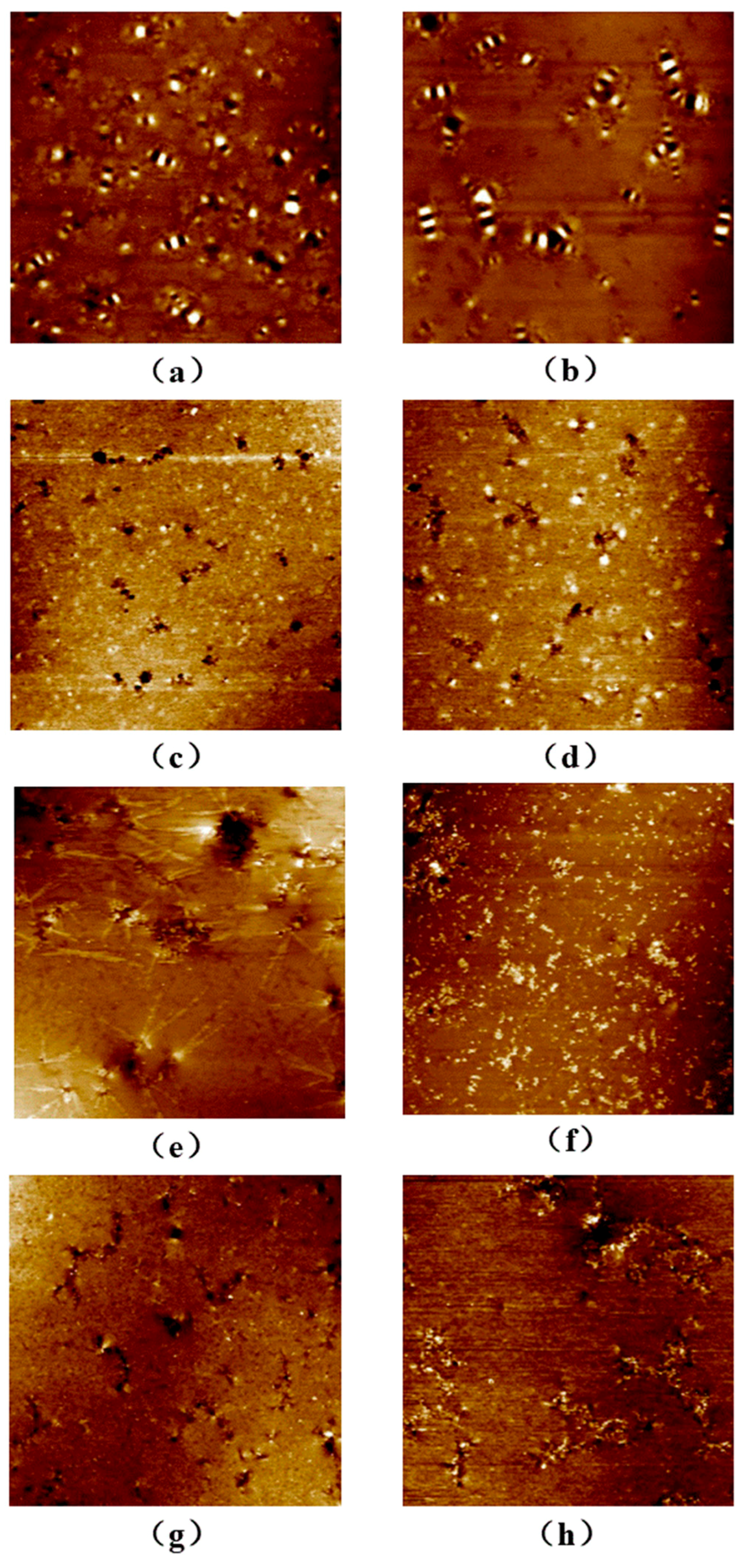

(4) The AFM morphologies exhibit that WEO and WPE can change the components of asphalt and reduce the formation of a “bee-like” structure. Finally, 4%WPE + 6%WEO can also reduce the formation of a “bee-like” structure after the UV aging experiment. The combined effect of WEO and WPE in asphalt can slow down the conversion of micromolecules to macromolecules during the UV aging process and thereby improve the UV aging resistance of asphalt.