The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Pasting Characteristics

2.2.2. Rheological Measurements

2.2.3. Textural Properties of Gels

2.2.4. Statistics

3. Results and Discussion

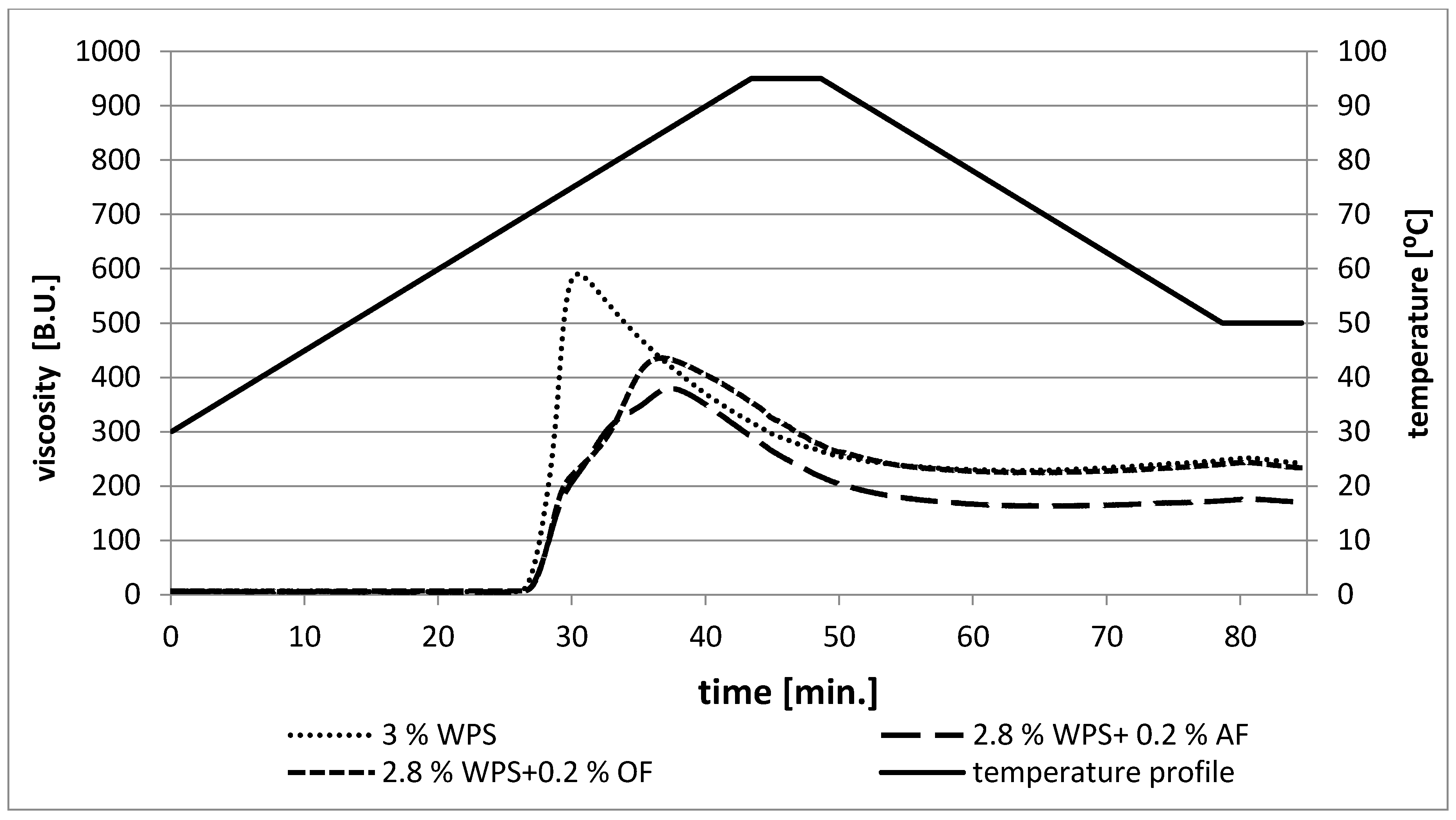

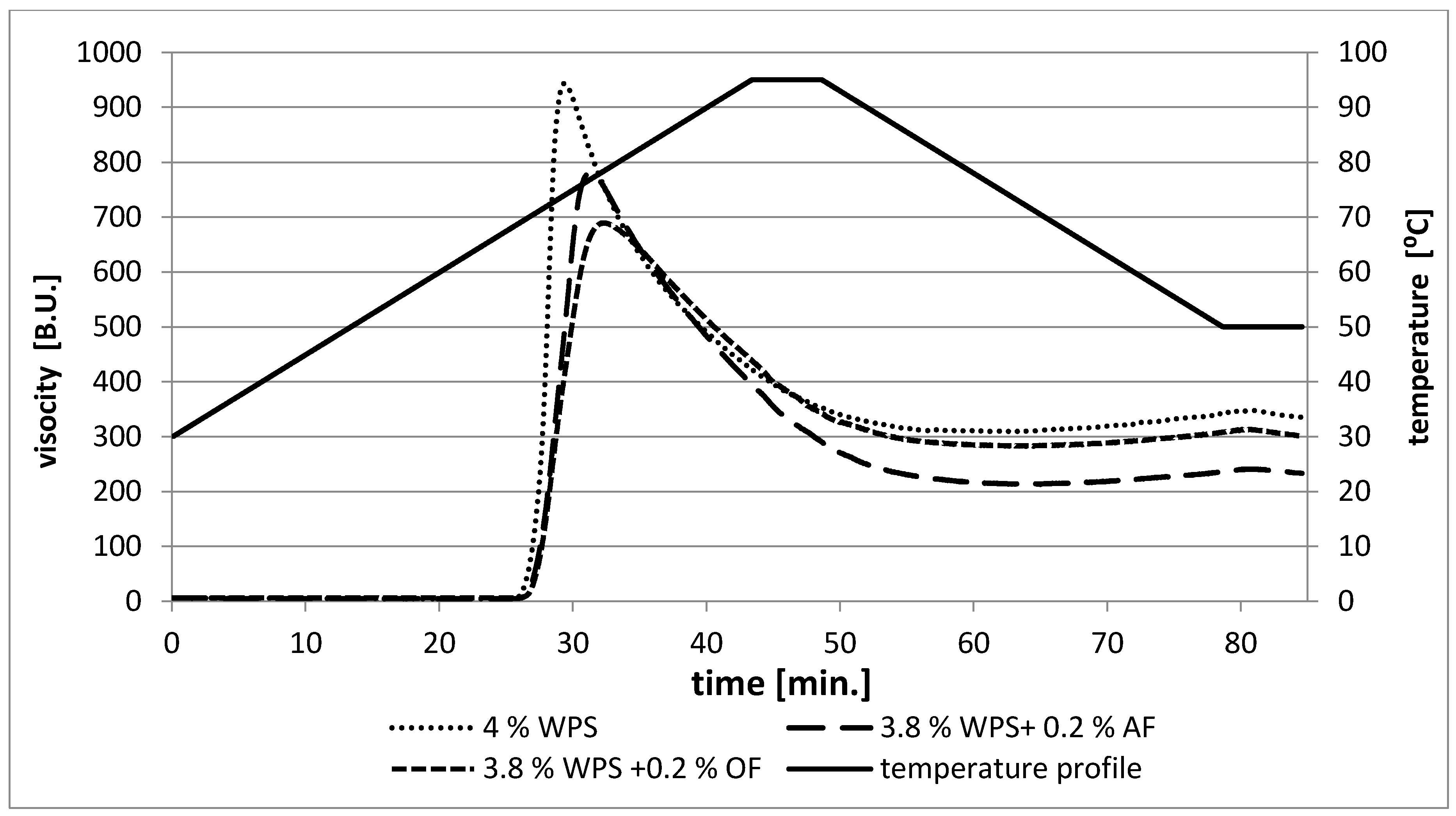

3.1. Pasting Characteristics

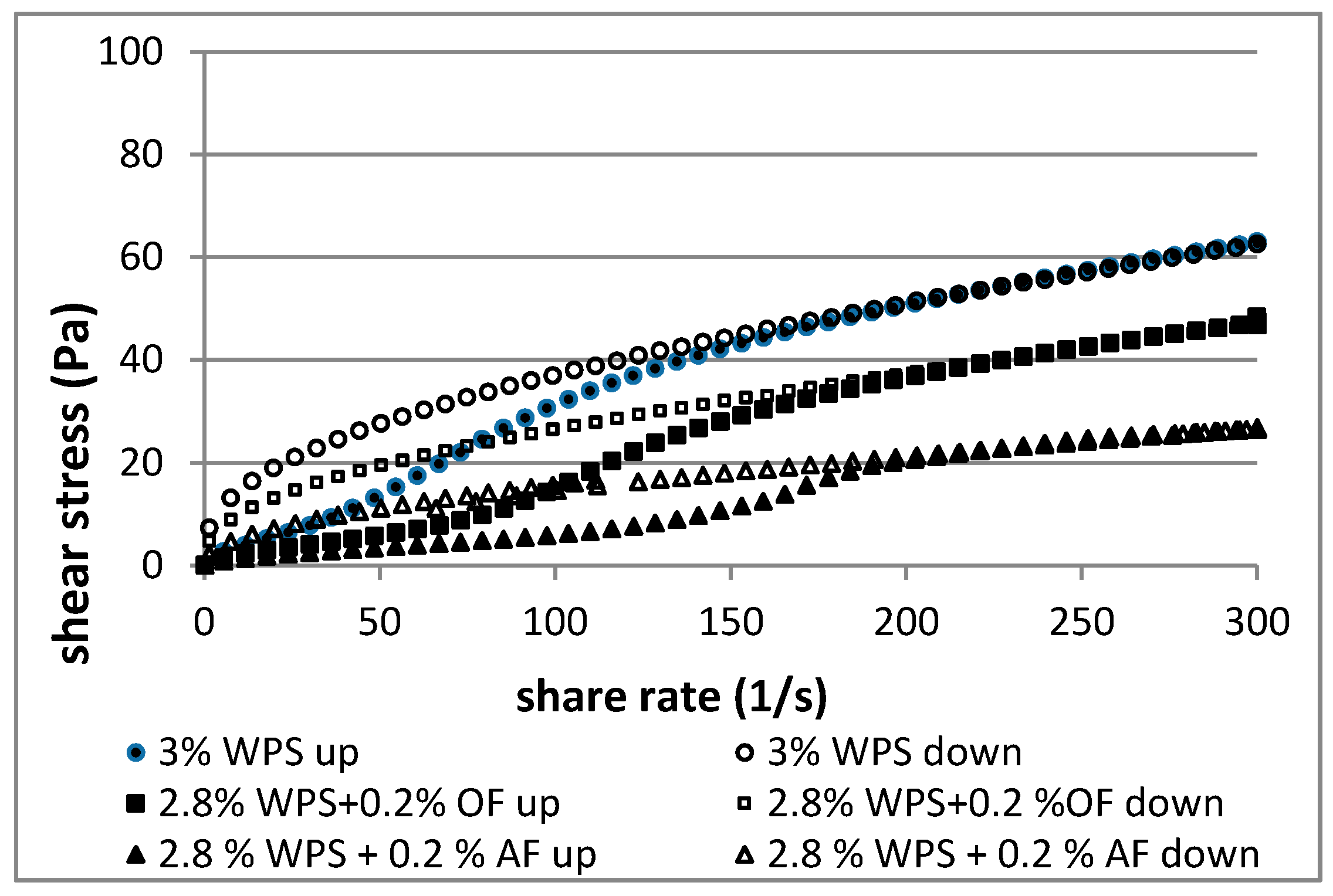

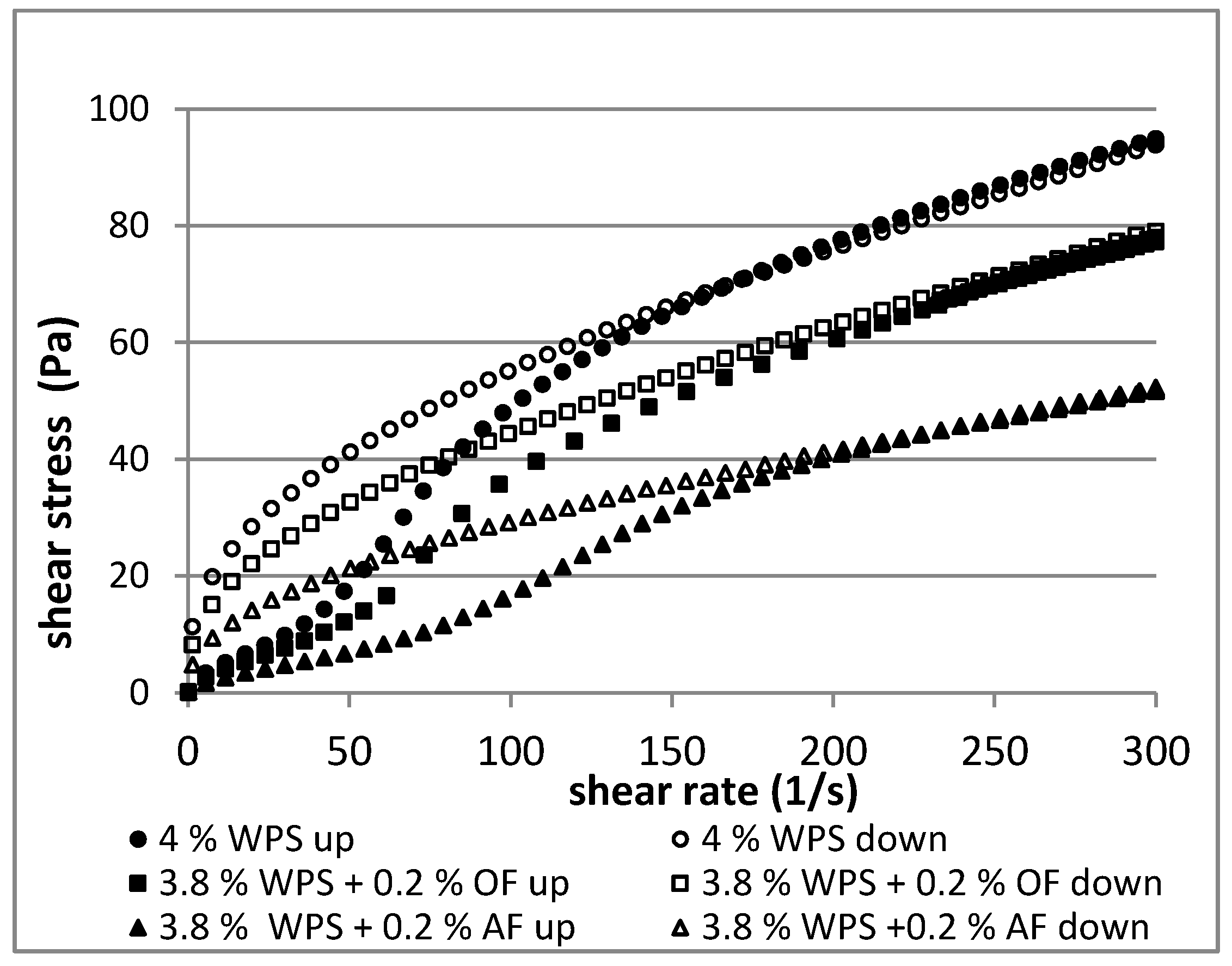

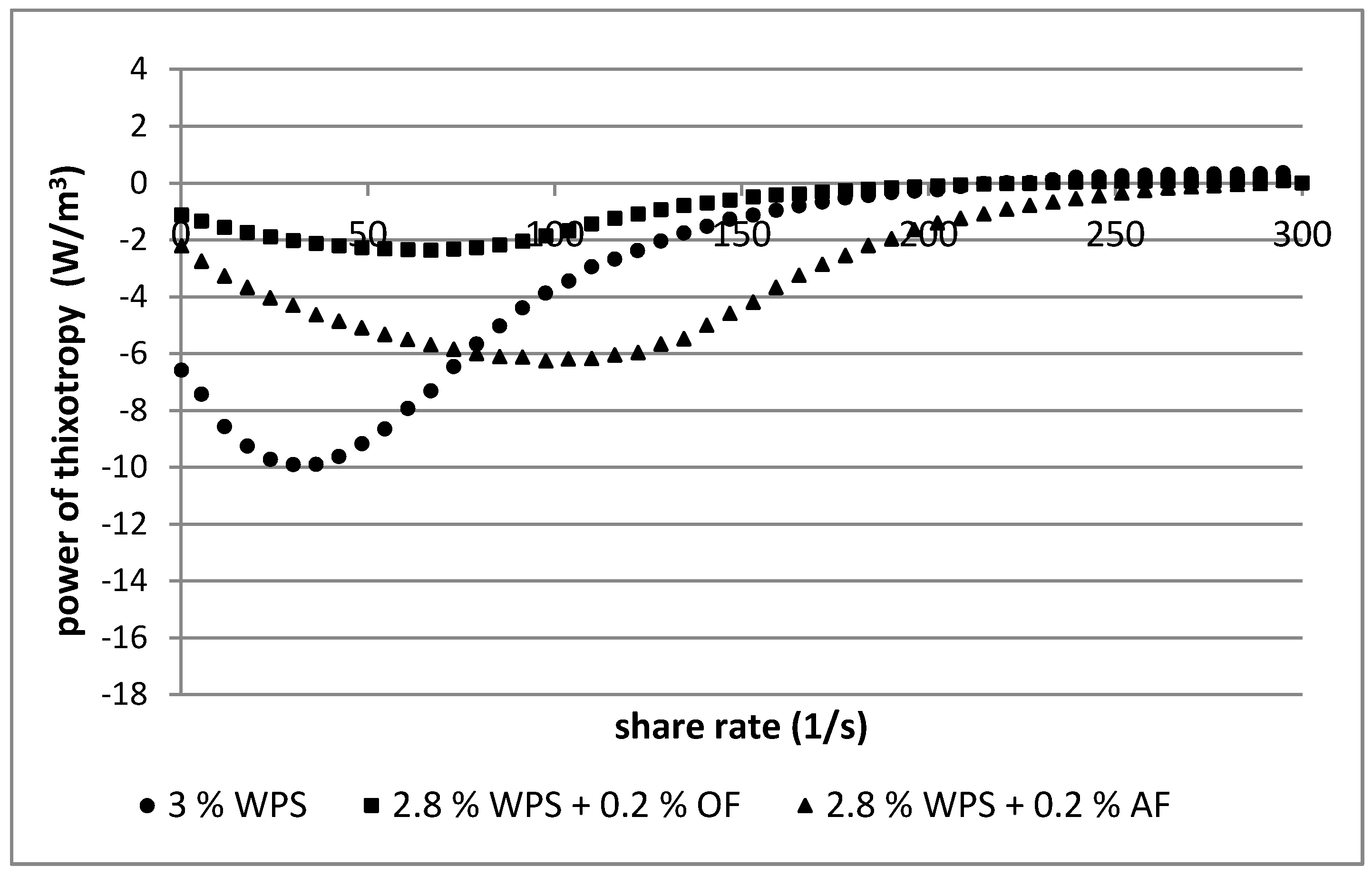

Rheological Measurements

3.2. Textural Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abdul-Hamid, A.; Luan, Y.S. Functional properties of dietary fibre prepared from deffated rice bran. Food Chem. 2000, 68, 15–19. [Google Scholar] [CrossRef]

- Mann, J.I.; Cummings, J.H. Possible implications for health of the different definitions of dietary fibre. Nutr. Metab. Cardiovasc. Dis. 2009, 19, 226–229. [Google Scholar] [CrossRef] [PubMed]

- Gallaher, D.D. Dietary fibre and its physiological effects. In Essentials of Functional Foods; Schmidl, M.K., Labuza, T.P., Eds.; Springer: Berlin, Germany, 2000; pp. 273–292. [Google Scholar]

- Lattimer, J.M.; Haub, M.D. Effects of dietary fibre and its components on metabolic health. Nutrients 2010, 2, 1266–1289. [Google Scholar] [CrossRef] [PubMed]

- AACC Report. The definition of dietary fibre. Cereal Foods World 2001, 46, 112–131.

- Chen, H.; Rubenthaler, G.L.; Leung, H.K.; Baranowski, J.D. Chemical, Physical, and Baking Properties of Apple Fibre Compared with Wheat and Oat Bran. Cereal Chem. 1988, 65, 244–247. [Google Scholar]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The impact of resistant starch on characteristics of gluten-free dough and bread. Food Hydrocoll. 2009, 23, 988–995. [Google Scholar] [CrossRef]

- Ellis, R.P.; Cochrane, M.P.; Dale, M.; Duffus, C.; Lynn, A.; Morrison, I.M.; Derek, R.; Prentice, M.; Swanston, J.R.; Tiller, S.A. Starch production and industrial use. J. Sci. Food Agric. 1998, 77, 289–311. [Google Scholar] [CrossRef]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary fibres: Nutritional and technological interest. Trends Food Sci. Technol. 1997, 8, 41–49. [Google Scholar] [CrossRef]

- Gelroth, J.; Ranhotra, G.R. Food uses of fiber. In Handbook of Dietary Fibre; Cho, S.S., Dreher, M.L., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2001. [Google Scholar]

- Biliaderis, C.G.; Arvanitoyannis, I.; Izydorczyk, M.S.; Prokopowich, D.J. Effect of hydrocolloids on gelatinization and structure formation in concentrated waxy maize and wheat starch gels. Starch/Starke 1997, 49, 278–283. [Google Scholar] [CrossRef]

- Bonnand-Ducasse, M.; Della Valle, G.; Lefebvre, J.; Saulnier, L. Effect of wheat dietary fibres on bread dough development and rheological properties. J. Cereal Sci. 2010, 52, 200–206. [Google Scholar] [CrossRef]

- Adamczyk, G.; Sikora, M.; Krystyjan, M. Methods of measuring thixotropic food products. Zywnosc-Nauka Technol. Jakosc. 2012, 3, 19–34. [Google Scholar] [CrossRef]

- Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Sikora, M. Thixotropic properties of starch. Zywnosc-Nauka Technol. Jakosc. 2013, 6, 16–31. [Google Scholar]

- Sasaki, T.; Kohyama, K.; Yasui, T. Effect of water-soluble and insoluble non-starch polysaccharides isolated from wheat flour on the rheological properties of wheat starch gel. Carboh. Polym. 2004, 57, 451–458. [Google Scholar] [CrossRef]

- Cornejo-Villegas, M.A.; Acosta-Osorio, A.A.; Rojas-Molina, I.; Gutiérrez-Cortéz, E.; Quiroga, M.A.; Gaytán, M.; Herrera, G.; Rodríguez-García, M.E. Study of the physicochemical and pasting properties of instant corn flour added with calcium and fibers from nopal powder. J. Food Eng. 2010, 96, 401–409. [Google Scholar] [CrossRef]

- Lai, P.; Li, K.Y.; Lu, S.; Chen, H.H. Physicochemical characteristics of rice starch supplemented with dietary fibre. Food Chem. 2011, 127, 153–158. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Yildiz, Ö.; Yurt, B.; Baştürk, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S.; Dağlıoğlu, O. Pasting properties, texture profile and stress–relaxation behaviour of wheat starch/dietary fibre systems. Food Res. Int. 2013, 53, 278–290. [Google Scholar] [CrossRef]

- International Starch Institute Science Park Aarhus, Denmark. ISI 19-6e Determination of Viscosity of Starch by Brabender—Comments. Available online: http://www.starch.dk/isi/methods/19brabenderNotes.htm (accessed on 24 December 2019).

- Małyszek, Z.; Makowska, A.; Smentek, J.; Kubiak, P.; Le Thanh-Blicharz, J.; Lewandowicz, G. Assessment of factors determining accuracy in measuring rheological properties of modified starches. Zywnosc-Nauka Technol. Jakosc. 2015, 3, 160–175. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: East Lansing, MI, USA, 1996; pp. 1–91. [Google Scholar]

- Sikora, M.; Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Tomasik, P.; Berski, W.; Łukasiewicz, M.; Izak, P. Thixotropic properties of normal potato starch depending on the degree of the granules pasting. Carboh. Polym. 2015, 121, 254–264. [Google Scholar] [CrossRef]

- McPherson, A.E.; Jane, J. Comparison of waxy potato starch with other root and tuber starches. Carboh. Polym. 1999, 40, 57–70. [Google Scholar] [CrossRef]

- Hong, Y.; Zhang, Y.; Zhu, L.; Gu, Z. Study on physicochemical characteristics of waxy potato starch in comparison with other waxy starches. Starch/Stärke 2011, 63, 754–759. [Google Scholar]

- Krystyjan, M.; Sikora, M.; Adamczyk, G.; Dobosz, A.; Tomasik, P.; Berski, W.; Łukasiewicz, M.; Izak, P. Thixotropic properties of waxy potato starch depending on the degree of the granules pasting. Carboh. Polym. 2016, 141, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Krystyjan, M.; Ciesielski, W.; Khachatryan, G.; Sikora, M.; Tomasik, P. Structure, rheological, textural and thermal properties of potato starch—Inulin gels. LWT—Food Sci. Technol. 2015, 60, 131–136. [Google Scholar] [CrossRef]

- Ragaee, S.; Abdel-Aal, E.M. Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem. 2006, 95, 9–18. [Google Scholar] [CrossRef]

- Collar, C.; Santos, E.; Rosell, C.M. Significance of dietary fibre on the viscometric pattern of pasted and gelled flour-fibre blends. Cereal Chem. 2006, 83, 370–376. [Google Scholar] [CrossRef]

- Goldstein, A.; Ashrafi, L.; Seetharaman, K. Effects of cellulosic fibre on physical and rheological properties of starch, gluten and wheat flour. Int. J. Food Sci. Technol. 2010, 45, 1641–1646. [Google Scholar] [CrossRef]

- Tester, R.F.; Morrison, W.R. Swelling and Gelatinization of Cereal Starches. I. Effects of Amylopectin, Amylose, and Lipids. Cereal Chem. 1990, 67, 551–557. [Google Scholar]

- Thirathumthavorn, D.; Charoenrein, S. Thermal and pasting properties of native and acid-treated starches derivatized by 1-octenyl succinic anhydride. Carboh. Polym. 1996, 66, 258–265. [Google Scholar] [CrossRef]

- Kaushal, P.; Kumar, V.; Sharma, H.K. Comparative study of physicochemical, functional, antinutritional and pasting properties of taro (Colocasia esculenta), rice (Oryza sativa) flour, pigeonpea (Cajanus cajan) flour and their blends. LWT—Food Sci. Technol. 2012, 48, 59–68. [Google Scholar] [CrossRef]

- Sikora, M.; Kowalski, S.; Tomasik, P. Binary hydrocolloids from starches and xanthan gum. Food Hydrocoll. 2008, 22, 943–952. [Google Scholar] [CrossRef]

- Gumul, D.; Krystyjan, M.; Buksa, K.; Ziobro, R.; Zięba, T. The influence of oxidation, extrusion and oxidation/extrusion on physico-chemical properties of potato starch. Starch/Starke 2014, 66, 190–198. [Google Scholar] [CrossRef]

- Krystyjan, M.; Ciesielski, W.; Gumul, D.; Buksa, K.; Ziobro, R.; Sikora, M. Physico-chemical and rheological properties of gelatinized/freeze-dried cereal starches. Int. Agroph. 2017, 31, 357–365. [Google Scholar] [CrossRef][Green Version]

- Achayuthakan, P.; Suphantharika, M. Pasting and rheological properties of waxy corn starch as affected by guar gum and xanthan gum. Carboh. Polym. 2008, 31, 9–17. [Google Scholar] [CrossRef]

- Barnes, H.A. Thixotropy—A review. J. Fluid Mech. 1997, 70, 1–33. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Thixotropy. Adv. Colloid Interfaces 2009, 147–148, 214–227. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Li, D.; Özkan, N.; Li, S.-J.; Mao, Z.-H. Rheological properties of waxy maize starch and xanthan gum mixtures in the presence of sucrose. Carboh. Polym. 2009, 77, 472–481. [Google Scholar] [CrossRef]

| Samples | T0 [°C] | ηmax. [BU] | Tη max. [°C] | η95°C [BU] | η95°C after 5 min [BU] | ηmin. [BU] | Tη min. [°C] | BD | η50°C [BU] |

|---|---|---|---|---|---|---|---|---|---|

| 3% WPS | 68.7 ± 0.00 b | 590.0 ± 0.49 b | 75.1 ± 0.14 b | 309.5 ± 2.12 b | 260.0 ± 1.41 b | 228.0 ± 2.83 b | 75.1 ± 0.92 b | 330.0 ± 7.07 b | 250.0 ± 2.83 b |

| 2.8% WPS + 0.2% OF | 69.5 ± 0.14 c | 436.5 ± 23.3 a | 83.9 ± 0.28 d | 345.0 ± 8.49 c | 270.5 ± 4.95 b,c | 190.5 ± 14.85 a | 70.8 ± 0.28 a | 166.0 ± 18.38 a | 241.5 ± 6.36 b |

| 2.8% WPS + 0.2% AF | 69.6 ± 0.07 c | 372.5 ± 28.9 a | 85.1 ± 0.85 d | 266.5 ± 9.19 a | 187.0 ± 8.50 a | 224.5 ± 4.95 b | 69.9 ± 0.28 a | 185.5 ± 20.51 a | 139.5 ± 9.19 a |

| 4% WPS | 67.9 ± 0.07 a | 943.5 ± 55.86 e | 73.4 ± 0.07 a | 412.0 ± 15.5 e | 349.0 ± 14.1 d | 309.5 ± 10.61 d | 73.8 ± 0.42 b | 594.5 ± 41.72 d | 345.0 ± 12.7 d |

| 3.8% WPS + 0.2% OF | 68.8 ± 0.00 b | 693.0 ± 21.2 c | 77.2 ± 0.92 c | 432.0 ± 2.83 e | 340.0 ± 0.00 d | 213.0 ± 4.24 b | 73.3 ± 1.48 b | 353.0 ± 21.21 b | 311.0 ± 4.24 c |

| 3.8% WPS + 0.2% AF | 68.8 ± 0.07 b | 781.0 ± 11.3 d | 76.1 ± 0.07 b,c | 382.0 ± 2.83 d | 283.5 ± 6.36 c | 282.5 ± 6.36 c | 73.2 ± 0.28 b | 497.5 ± 4.95 c | 238.5 ± 4.95 b |

| Sample | Ostwald–de Waele Model | |||||

|---|---|---|---|---|---|---|

| K (Pa∙sn) | n (-) | R2 | ||||

| 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | |

| 3% WPS | 1.02 ± 0.08 b | 4.70 ± 0.16 c | 0.73 ± 0.02 d | 0.45 ± 0.00 a | 0.992 | 0.9999 |

| 2.8% WPS + 0.2% OF | 0.19 ± 0.09 d | 2.87 ± 0.27 b | 0.99 ± 0.08 b | 0.49 ± 0.01 b | 0.988 | 1.0000 |

| 2.8% WPS + 0.2% AF | 0.02 ± 0.00 e | 1.26 ± 0.25 a | 1.27 ± 0.02 a | 0.53 ± 0.02 c | 0.994 | 1.0000 |

| 4% WPS | 1.55 ± 0.10 a | 6.94 ± 0.10 d | 0.73 ± 0.02 d | 0.45 ± 0.00 a | 0.988 | 0.9998 |

| 3.8% WPS + 0.2% OF | 0.85 ± 0.03 c | 4.87 ± 0.19 c | 0.83 ± 0.01 c | 0.48 ± 0.01 b | 0.989 | 0.9999 |

| 3.8% WPS + 0.2% AF | 0.24 ± 0.02 d | 3.08 ± 0.12 b | 1.00 ± 0.03 b | 0.49 ± 0.00 b | 0.989 | 0.9999 |

| Sample | Areas of the Hysteresis Loops (Pa/s) | ||

|---|---|---|---|

| Antithixotropy (A) | Thixotropy (T) | Total Area (A + T) | |

| 3% WPS | 163.0 b | 3.0 b | 166.0 b |

| 2.8% WPS + 0.2% OF | 46.1 a | 0.7 a | 46.8 a |

| 2.8% WPS + 0.2% AF | 167.2 b | 0.0 a | 167.2 b |

| 4% WPS | 203.2 c | 16.7 c | 219.9 d |

| 3.8% WPS + 0.2% OF | 150.1 b | 15.8 c | 165.9 b |

| 3.8% WPS + 0.2% AF | 198.7 c | 3.5 b | 202.2 d |

| Samples | Hardness [N] | ||

|---|---|---|---|

| After 1 Day of Storage H1 | After 7 Days of Storage H7 | H7/H1 | |

| 3% WPS | 0.145 ± 0.01 a | 0.263 ± 0.04 a | 1.81b ± 0.03 b |

| 2.8% WPS + 0.2% OF | 0.180 ± 0.00 c | 0.375 ± 0.02 b | 2.08 d ± 0.02 c |

| 2.8% WPS + 0.2% AF | 0.168 ± 0.01 b | 0.240 ± 0.01 a | 1.43 a ± 0.01 a |

| 4% WPS | 0.223 ± 0.01 d | 0.430 ± 0.04 c | 1.93 c ± 0.04 c |

| 3.8% WPS + 0.2%OF | 0.243 ± 0.01 e | 0.443 ± 0.03 c | 1.82 b ± 0.04 c |

| 3.8% WPS + 0.2% AF | 0.180 ± 0.01 c | 0.475 ± 0.06 c | 2.64 e ± 0.07 d |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczyk, G.; Krystyjan, M.; Jaworska, G. The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch. Polymers 2020, 12, 321. https://doi.org/10.3390/polym12020321

Adamczyk G, Krystyjan M, Jaworska G. The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch. Polymers. 2020; 12(2):321. https://doi.org/10.3390/polym12020321

Chicago/Turabian StyleAdamczyk, Greta, Magdalena Krystyjan, and Grażyna Jaworska. 2020. "The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch" Polymers 12, no. 2: 321. https://doi.org/10.3390/polym12020321

APA StyleAdamczyk, G., Krystyjan, M., & Jaworska, G. (2020). The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch. Polymers, 12(2), 321. https://doi.org/10.3390/polym12020321