Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity

Abstract

:1. Introduction

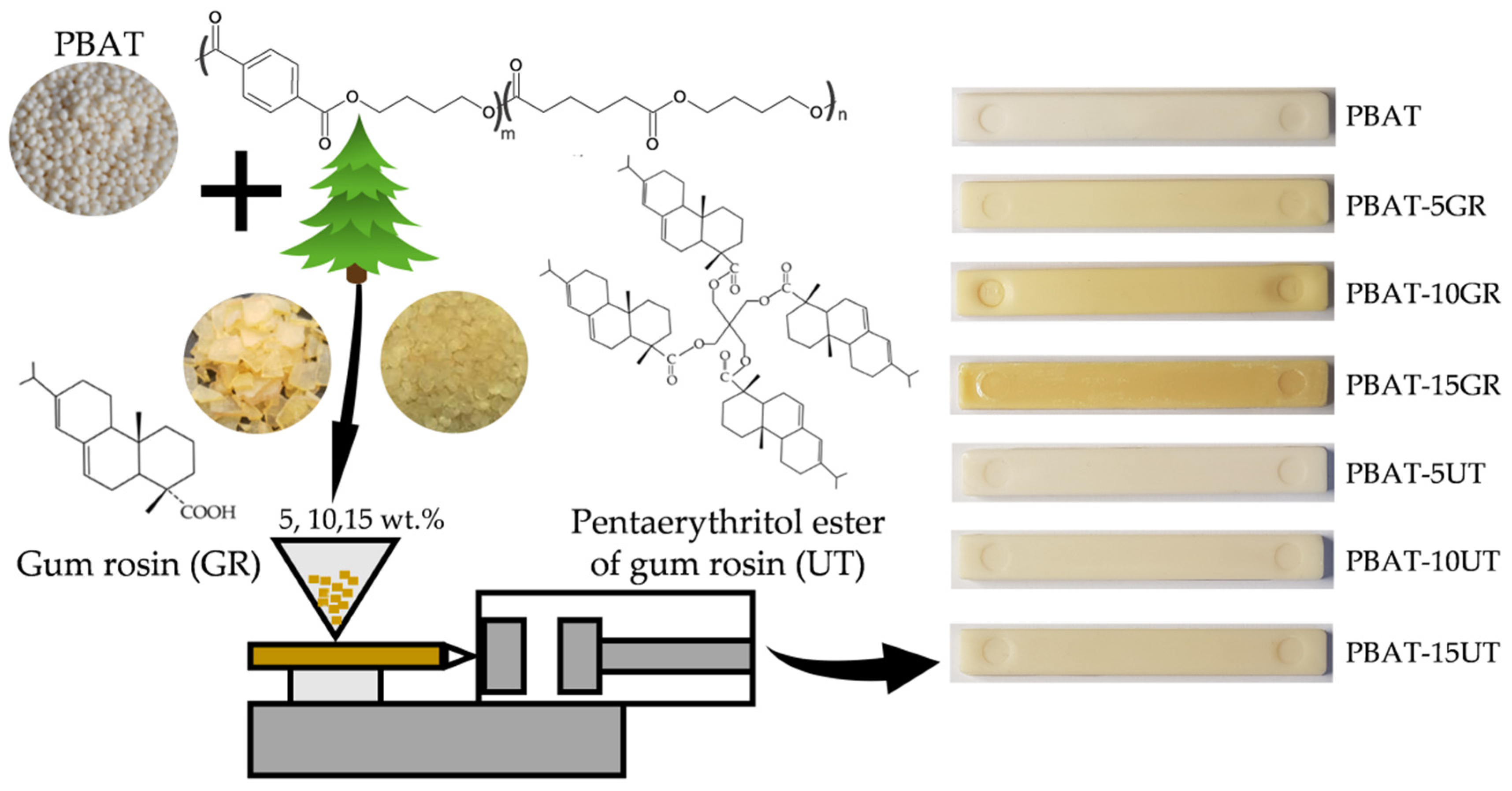

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Miscibility Prediction

2.2.2. PBAT-Resin Formulations Preparation

2.2.3. Mechanical Characterization

2.2.4. Microstructural Characterization

2.2.5. Thermal Characterization

2.2.6. Dynamic Mechanical Thermal Characterization

2.2.7. Wettability

2.2.8. Colour Characterization

2.2.9. Statistical Analyses

3. Results

3.1. Miscibility

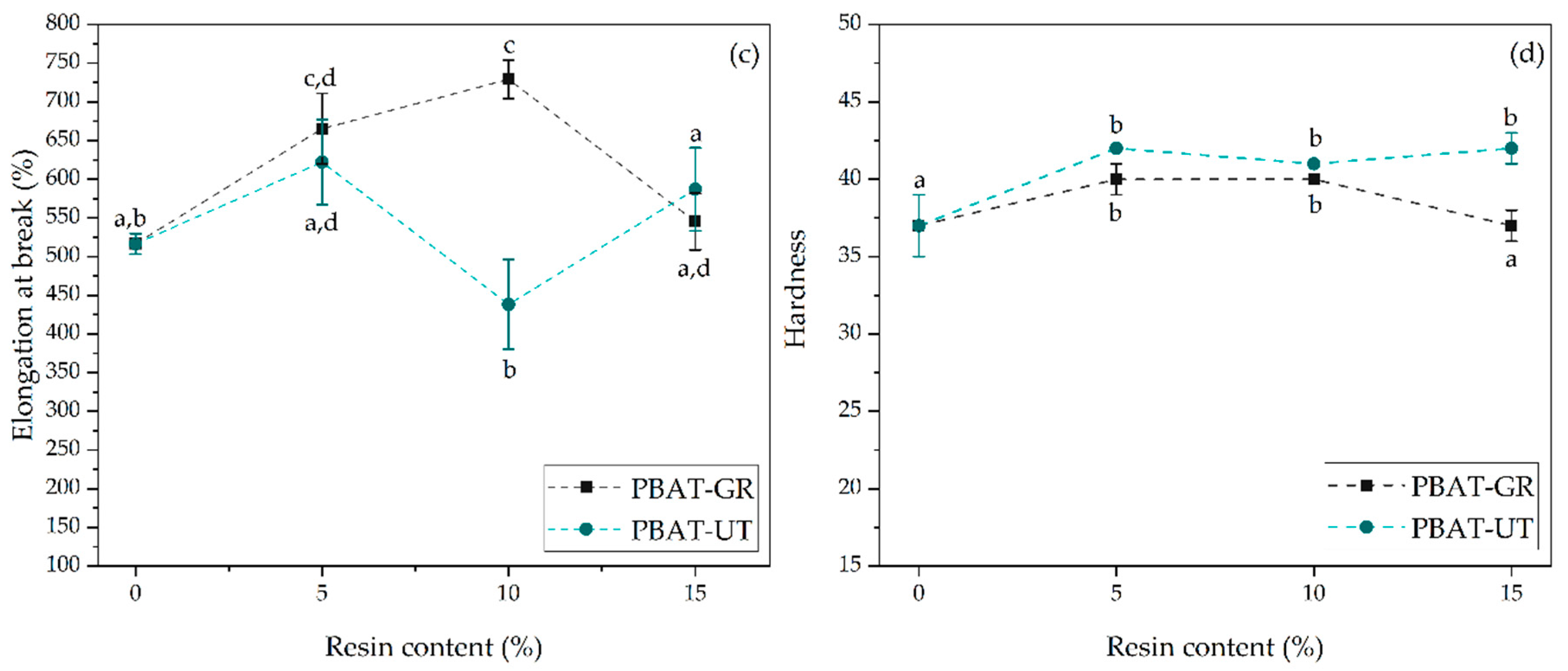

3.2. Mechanical Characterization

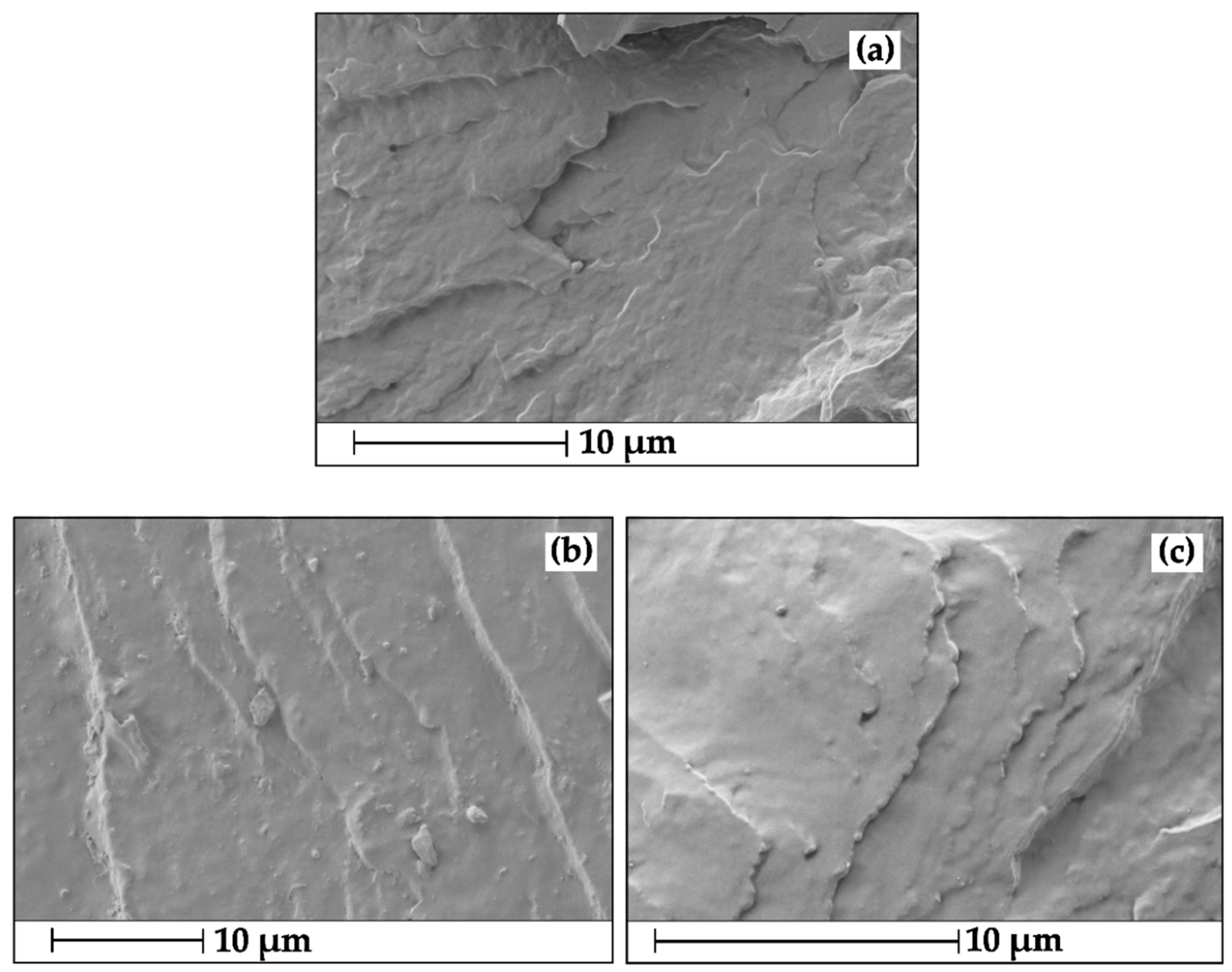

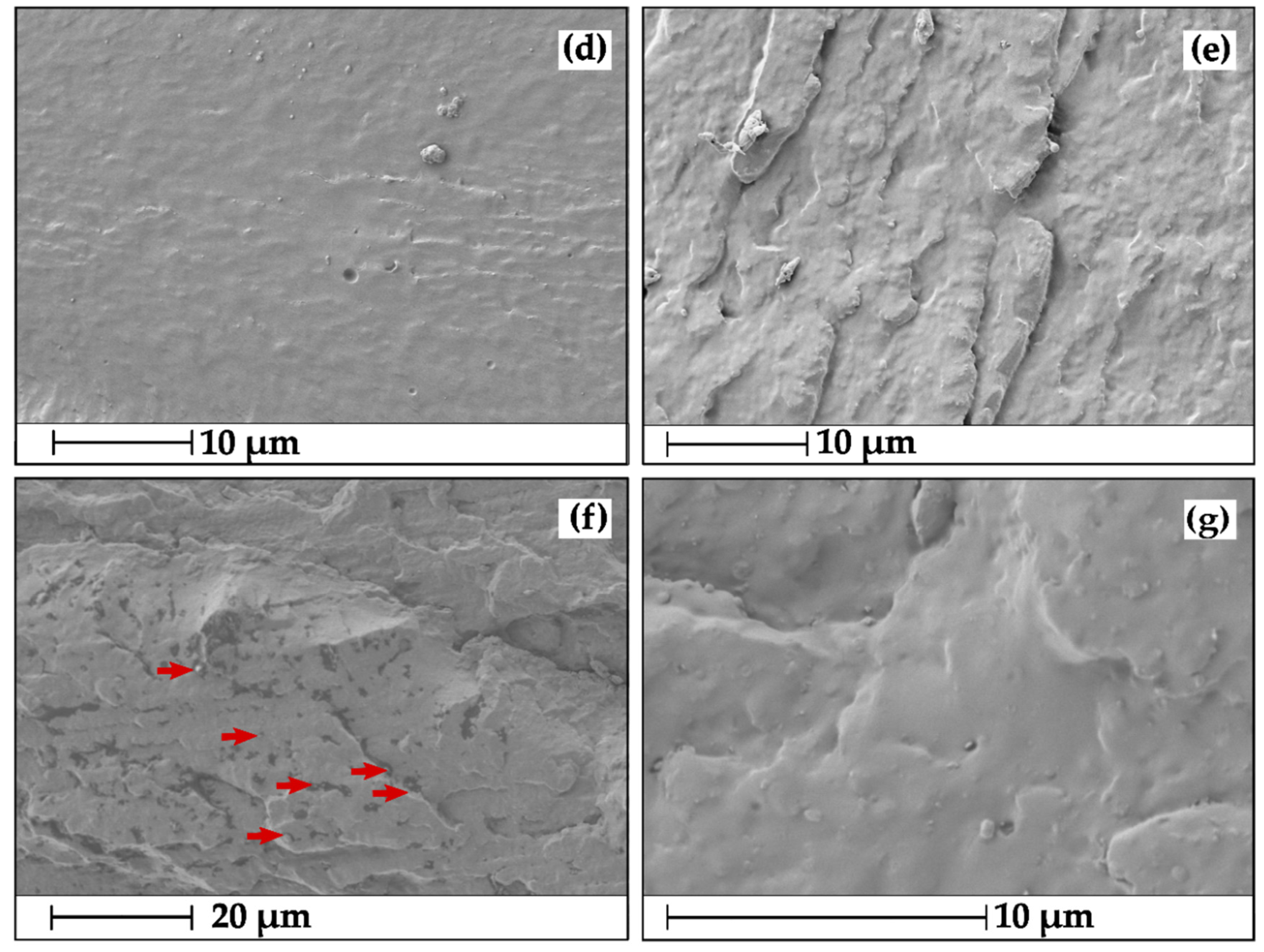

3.3. Microstructural Characterization

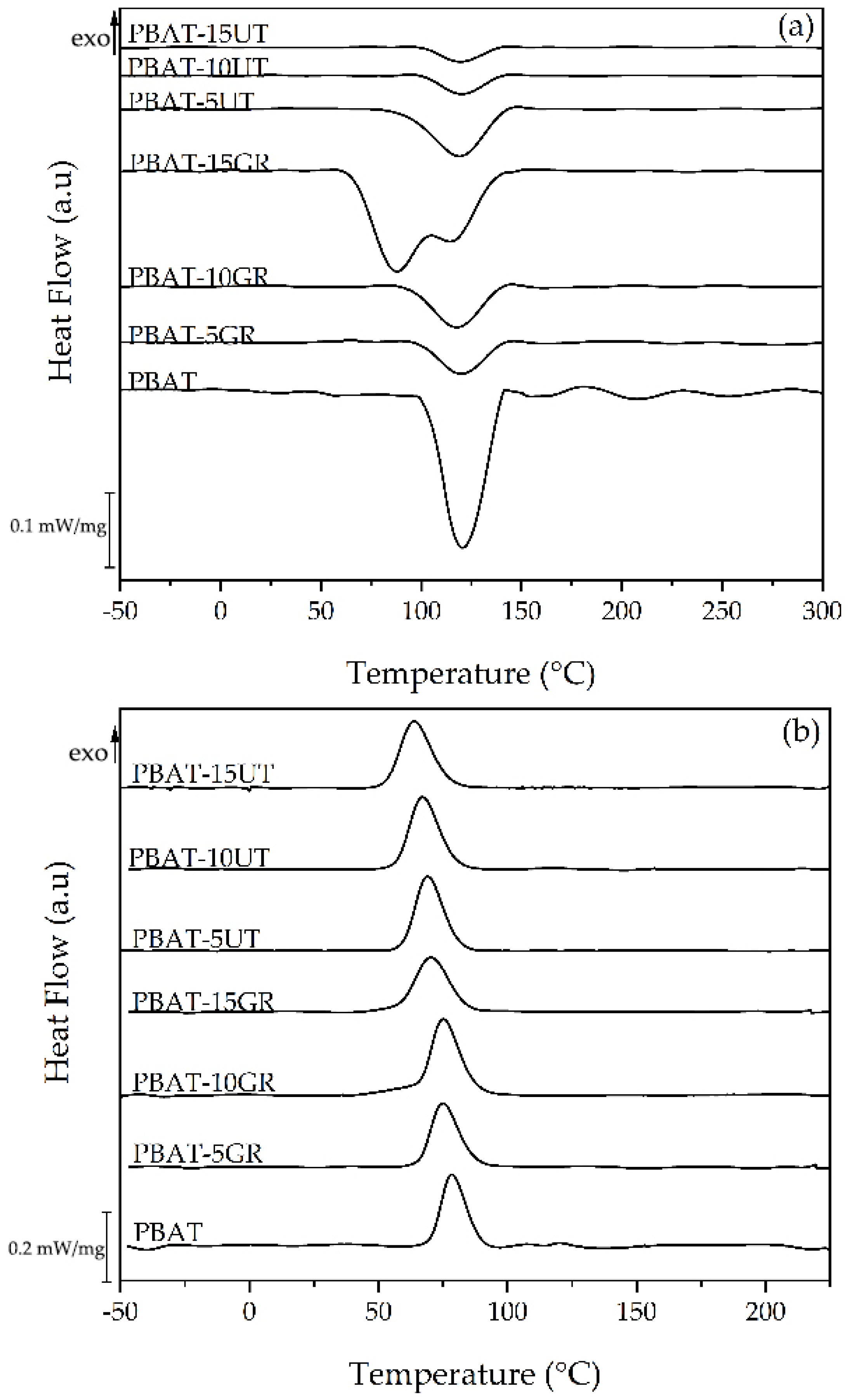

3.4. Thermal Characterization

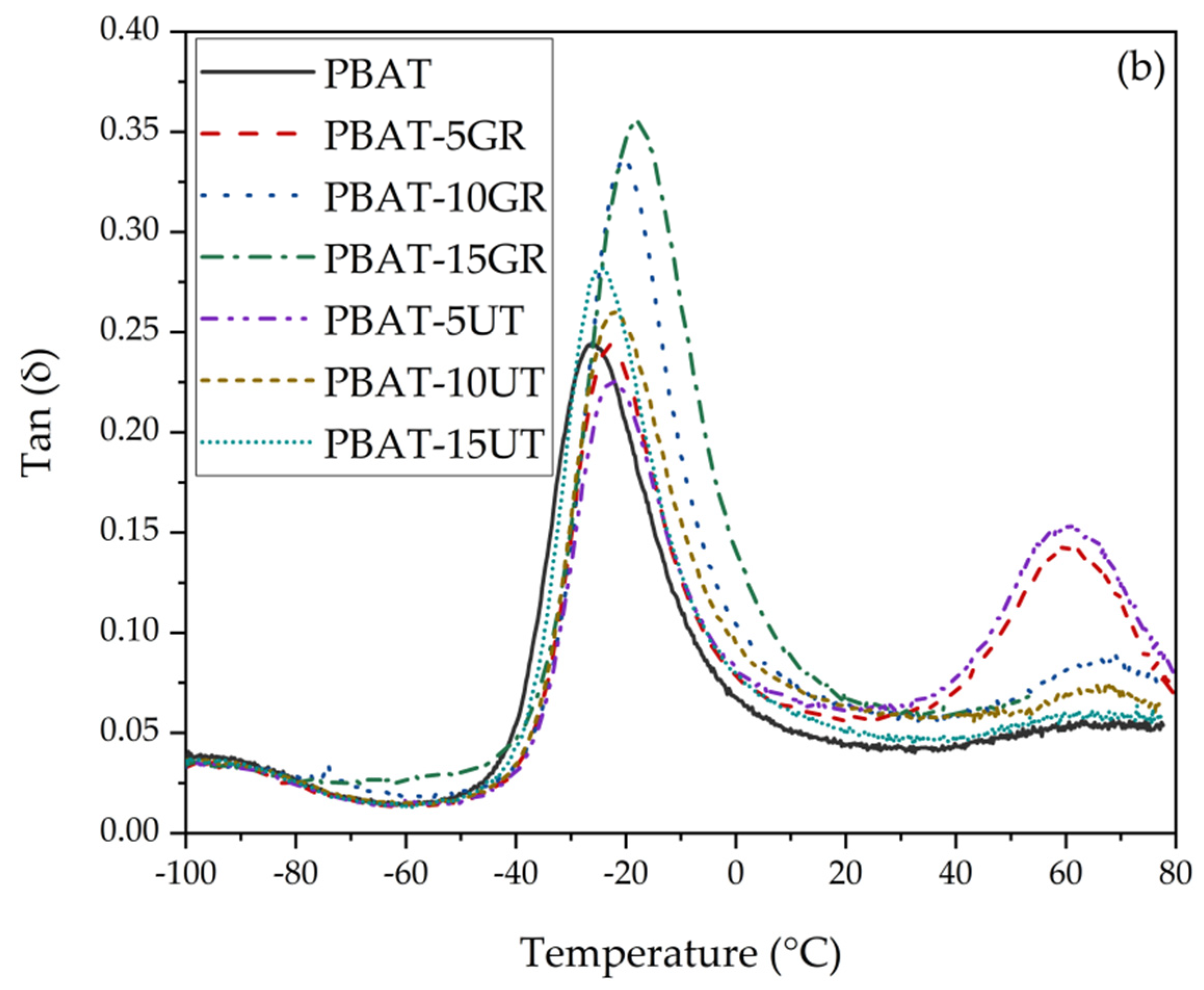

3.5. Dynamic Mechanical Thermal Characterization

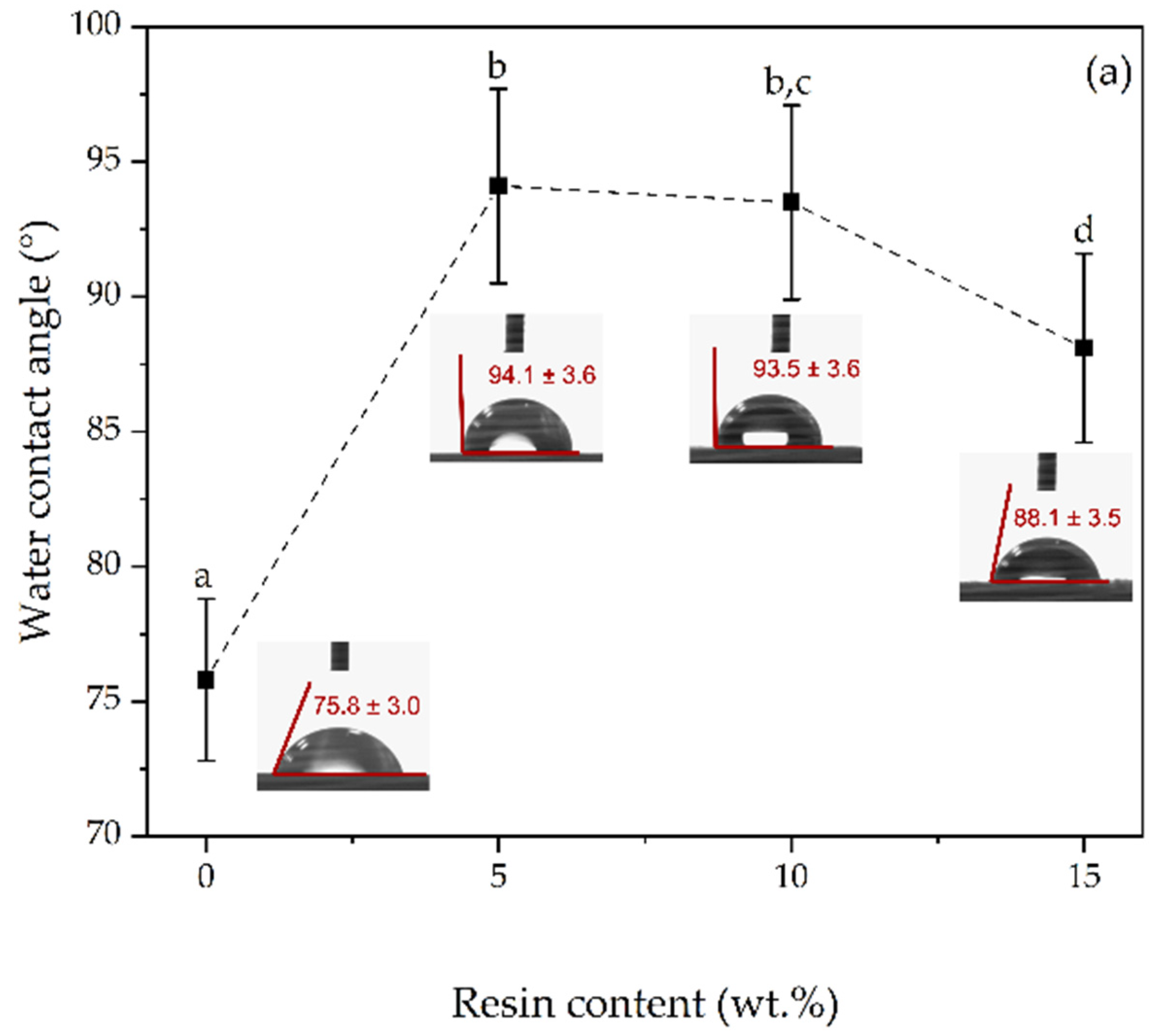

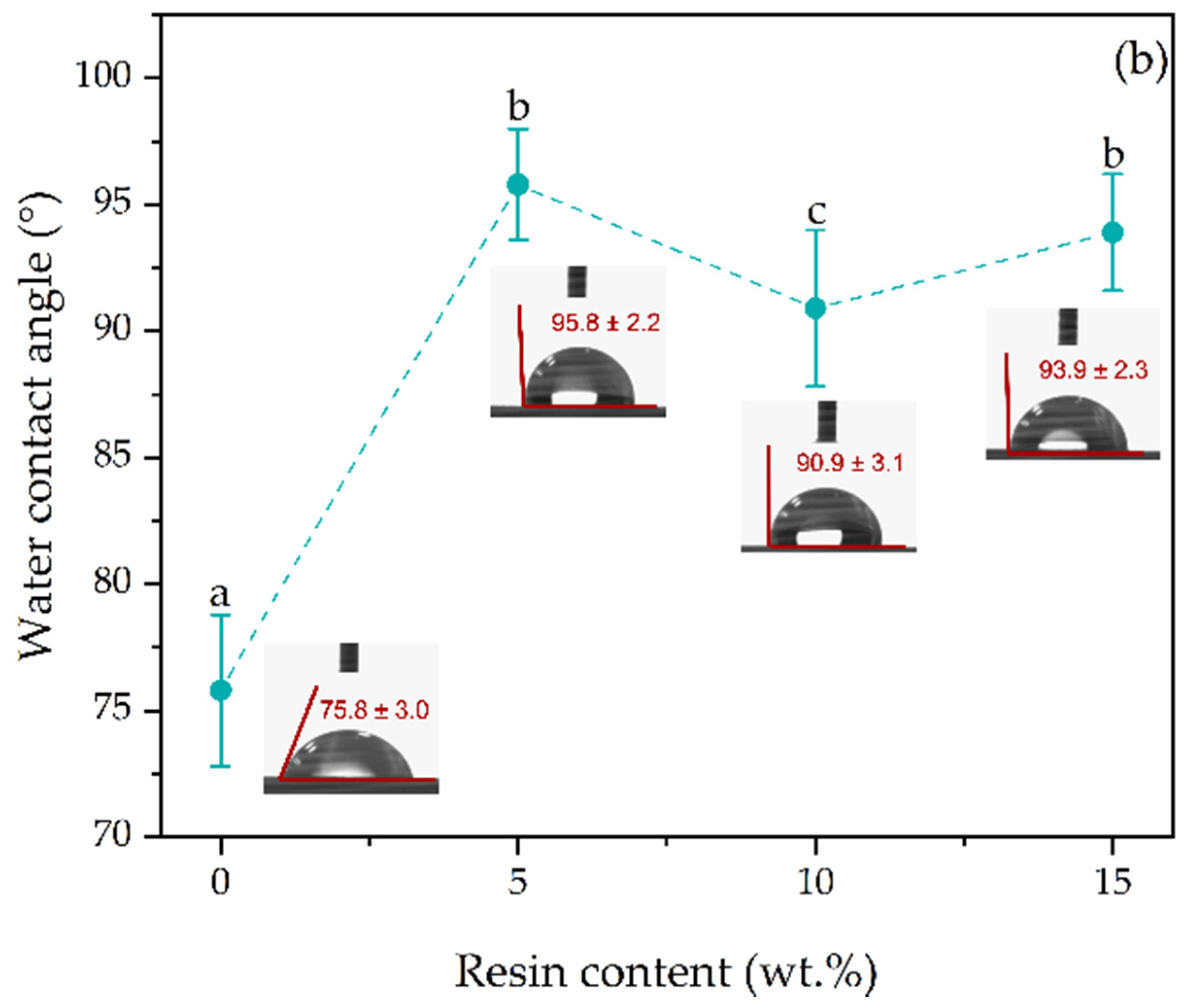

3.6. Wettability

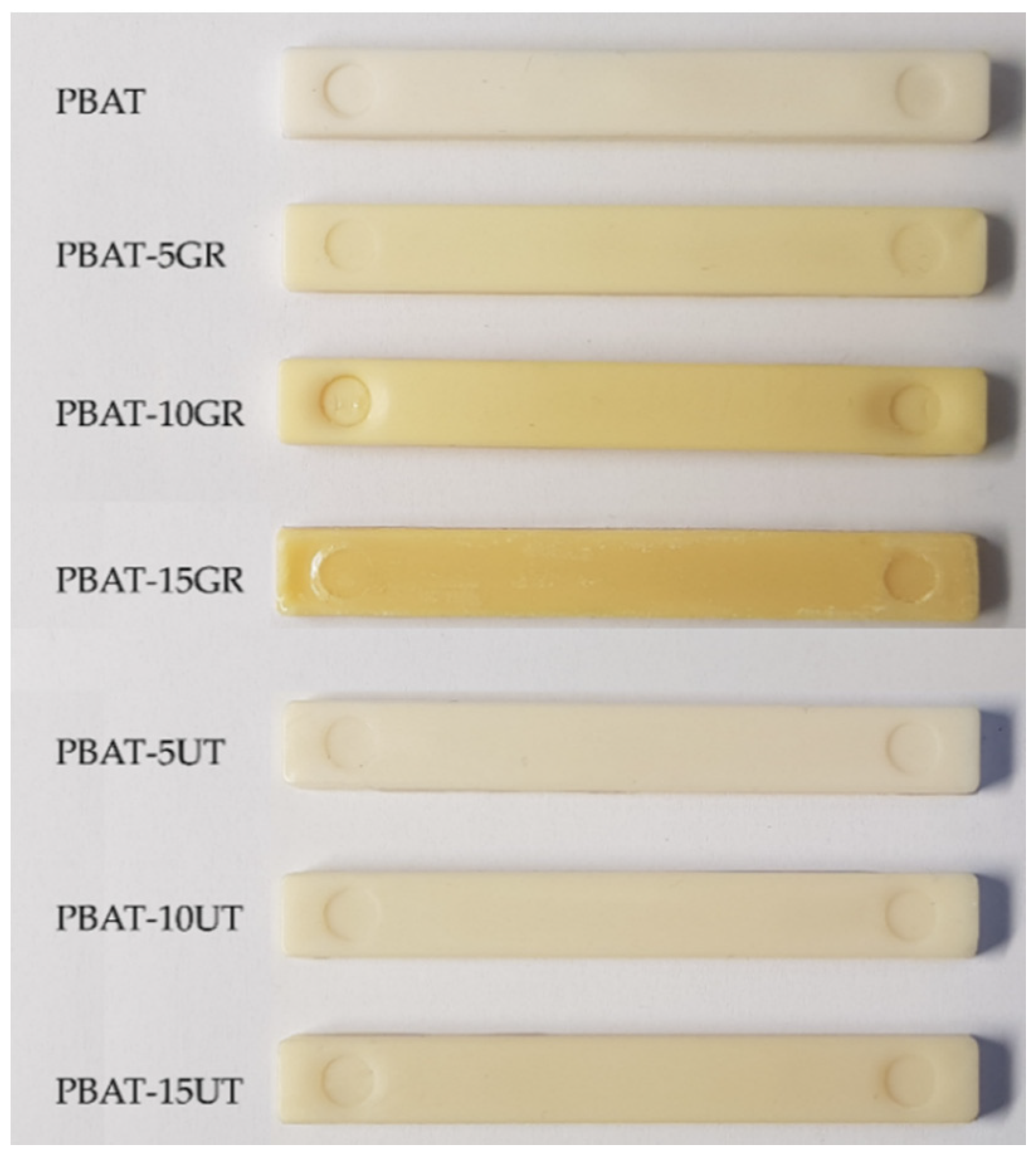

3.7. Colour Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ikada, Y.; Tsuji, H. Biodegradable Polyesters for Medical and Ecological Applications. Macromol. Rapid Commun. 2000, 21, 117–132. [Google Scholar] [CrossRef]

- Da Costa, J.P.; Santos, P.S.; Duarte, A.C.; Rocha-Santos, T. (Nano)plastics in the environment—Sources, fates and effects. Sci. Total Environ. 2016, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Aldas, M.; Valle, V.; Aguilar, J.; Pavon, C.; Santos, R.; Luna, M. Ionizing radiation as adjuvant for the abiotic degradation of plastic bags containing pro-oxidant additives. J. Appl. Polym. Sci. 2020, 138, e49664. [Google Scholar] [CrossRef]

- Aldas, M.; Paladines, A.; Valle, V.; Pazmiño, M.; Quiroz, F. Effect of the Prodegradant-Additive Plastics Incorporated on the Polyethylene Recycling. Int. J. Polym. Sci. 2018, 2018, 2474176. [Google Scholar] [CrossRef] [Green Version]

- Cacciotti, I.; Mori, S.; Cherubini, V.; Nanni, F. Eco-sustainable systems based on poly(lactic acid), diatomite and coffee grounds extract for food packaging. Int. J. Biol. Macromol. 2018, 112, 567–575. [Google Scholar] [CrossRef] [Green Version]

- Vahedikia, N.; Garavand, F.; Tajeddin, B.; Cacciotti, I.; Jafari, S.M.; Omidi, T.; Zahedi, Z. Biodegradable zein film composites reinforced with chitosan nanoparticles and cinnamon essential oil: Physical, mechanical, structural and antimicrobial attributes. Colloids Surf. B Biointerfaces 2019, 177, 25–32. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.; Aldas, M.; López-Martínez, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Pawlak, F.; Aldas, M.; López-Martínez, J.; Samper, M. Effect of Different Compatibilizers on Injection-Molded Green Fiber-Reinforced Polymers Based on Poly(lactic acid)-Maleinized Linseed Oil System and Sheep Wool. Polymers 2019, 11, 1514. [Google Scholar] [CrossRef] [Green Version]

- Auras, R.; Harte, B.R.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; De La Orden, M.; Urreaga, J.M.M. Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(lactic acid). Polymers 2020, 12, 1690. [Google Scholar] [CrossRef]

- Zia, K.M.; Noreen, A.; Zuber, M.; Tabasum, S.; Mujahid, M. Recent developments and future prospects on bio-based polyesters derived from renewable resources: A review. Int. J. Biol. Macromol. 2016, 82, 1028–1040. [Google Scholar] [CrossRef]

- Rezwan, K.; Chen, Q.Z.; Blaker, J.J.; Boccaccini, A.R. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 3413–3431. [Google Scholar] [CrossRef]

- Okada, M. Chemical syntheses of biodegradable polymers. Prog. Polym. Sci. 2002, 27, 87–133. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Aragón-Gutierrez, A.; Arrieta, M.P.; López-González, M.; Fernández-García, M.; López, D. Hybrid Biocomposites Based on Poly(Lactic Acid) and Silica Aerogel for Food Packaging Applications. Materials 2020, 13, 4910. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Lopez-Martinez, J.; Balart, R.; Strömberg, E.; Moriana, R. Reinforcing Capability of Cellulose Nanocrystals Obtained from Pine Cones in a Biodegradable Poly(3-Hydroxybutyrate)/Poly(ε-Caprolactone) (PHB/PCL) Thermoplastic Blend. Eur. Polym. J. 2018, 104, 10–18. [Google Scholar] [CrossRef]

- Li, F.; Xu, X.; Yu, J.; Cao, A. The morphological effects upon enzymatic degradation of poly(butylene succinate-co-butylene terephthalate)s (PBST). Polym. Degrad. Stab. 2007, 92, 1053–1060. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Burgos, N.; Peltzer, M.; López, J.; Peponi, L. Nanocellulose-Based Polymeric Blends for Food Packaging Applications. In Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcements; Elsevier: Amsterdam, The Netherlands, 2016; pp. 205–252. [Google Scholar]

- Tenn, N.; Follain, N.; Fatyeyeva, K.; Poncin-Epaillard, F.; Labrugère, C.; Marais, S. Impact of hydrophobic plasma treatments on the barrier properties of poly(lactic acid) films. RSC Adv. 2014, 4, 5626–5637. [Google Scholar] [CrossRef]

- Witt, U.; Müller, R.-J.; Augusta, J.; Widdecke, H.; Deckwer, W.-D. Synthesis, Properties and Biodegradability of Polyesters Based on 1,3-propanediol. Macromol. Chem. Phys. 1994, 195, 793–802. [Google Scholar] [CrossRef]

- Lee, S.H.; Lim, S.W.; Lee, K.H. Properties of potentially biodegradable copolyesters of (succinic acid–1,4-butanediol)/(dimethyl terephthalate–1,4-butanediol). Polym. Int. 1999, 48, 861–867. [Google Scholar] [CrossRef]

- Fukushima, K.; Wu, M.-H.; Bocchini, S.; Rasyida, A.; Yang, M.-C. PBAT based nanocomposites for medical and industrial applications. Mater. Sci. Eng. C 2012, 32, 1331–1351. [Google Scholar] [CrossRef] [PubMed]

- Bastarrachea, L.; Dhawan, S.; Sablani, S.S.; Mah, J.-H.; Kang, D.-H.; Zhang, J.; Tang, J. Biodegradable Poly(butylene adipate-co-terephthalate) Films Incorporated with Nisin: Characterization and Effectiveness against Listeria innocua. J. Food Sci. 2010, 75, E215–E224. [Google Scholar] [CrossRef] [PubMed]

- Sousa, F.M.; Costa, A.R.M.; Reul, L.T.A.; Cavalcanti, F.B.; Carvalho, L.H.; Almeida, T.G.; Canedo, E.L. Rheological and thermal characterization of PCL/PBAT blends. Polym. Bull. 2018, 76, 1573–1593. [Google Scholar] [CrossRef]

- Avérous, L. Biodegradable Multiphase Systems Based on Plasticized Starch: A Review. J. Macromol. Sci. Part C 2004, 44, 231–274. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134, 44498. [Google Scholar] [CrossRef]

- Park, H.Y.; Kim, S.S.; Kim, S.G.; Seo, K.H. Modification of Physical Properties of PBAT by Using TPS. Int. Proc. Chem. Biol. Environ. Eng. 2012, 46, 67–71. [Google Scholar]

- Aldas, M.; Pavon, C.; López-Martínez, J.; Arrieta, M.P. Pine Resin Derivatives as Sustainable Additives to Improve the Mechanical and Thermal Properties of Injected Moulded Thermoplastic Starch. Appl. Sci. 2020, 10, 2561. [Google Scholar] [CrossRef] [Green Version]

- Sharma, L.; Singh, C. Composite film developed from the blends of sesame protein isolate and gum rosin and their properties thereof. Polym. Compos. 2018, 39, 1480–1487. [Google Scholar] [CrossRef]

- Aldas, M.; Ferri, J.; Lopez-Martinez, J.; Samper, M.; Arrieta, M.P. Effect of pine resin derivatives on the structural, thermal, and mechanical properties of Mater-Bi type bioplastic. J. Appl. Polym. Sci. 2020, 137, 48236. [Google Scholar] [CrossRef]

- Narayanan, M.; Loganathan, S.; Valapa, R.B.; Thomas, S.; Varghese, T.O. UV protective poly(lactic acid)/rosin films for sustainable packaging. Int. J. Biol. Macromol. 2017, 99, 37–45. [Google Scholar] [CrossRef]

- Yao, K.; Tang, C. Controlled Polymerization of Next-Generation Renewable Monomers and Beyond. Macromolecules 2013, 46, 1689–1712. [Google Scholar] [CrossRef]

- Termentzi, A.; Fokialakis, N.; Skaltsounis, A.-L. Natural resins and bioactive natural products thereof as potential antimicrobial agents. Curr. Pharm. Des. 2011, 17, 1267–1290. [Google Scholar] [CrossRef] [PubMed]

- Savluchinske-Feio, S.; Curto, M.J.M.; Gigante, B.; Roseiro, J.C. Antimicrobial activity of resin acid derivatives. Appl. Microbiol. Biotechnol. 2006, 72, 430–436. [Google Scholar] [CrossRef] [PubMed]

- Aldas, M.F.; Arrieta, M.P.; Ferri Azor, J.M.; García-García, D.; Samper Madrigal, M.D.; López Martínez, J.; Mendes Ferreira, A.M. Improved Starch Based Biodegradable Polymers. WO Patent No. 2020156862, 6 August 2020. [Google Scholar]

- Huang, W.; Diao, K.; Tan, X.; Lei, F.; Jiang, J.; Goodman, B.A.; Ma, Y.; Liu, S. Mechanisms of Adsorption of Heavy Metal Cations from Waters by an Amino Bio-Based Resin Derived from Rosin. Polymers 2019, 11, 969. [Google Scholar] [CrossRef] [Green Version]

- Pavon, C.; Aldas, M.; López-Martínez, J.; Bou, S.F. New Materials for 3D-Printing Based on Polycaprolactone with Gum Rosin and Beeswax as Additives. Polymers 2020, 12, 334. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Samper, M.D.; Jiménez-López, M.; Aldas, M.; López, J. Combined effect of linseed oil and gum rosin as natural additives for PVC. Ind. Crop. Prod. 2017, 99, 196–204. [Google Scholar] [CrossRef]

- Liu, X.Q.; Huang, W.; Jiang, Y.H.; Zhu, J.; Zhang, C.Z. Preparation of a bio-based epoxy with comparable properties to those of petroleum-based counterparts. Express Polym. Lett. 2012, 6, 293–298. [Google Scholar] [CrossRef]

- Lascano, D.; Valcárcel, J.; Balart, R.; Quiles-carrillo, L. Fabricación de Materiales Compuestos de Alto Rendimiento Medioambiental Con Resina Epoxi de Origen Renovable y Núcleos Ligeros Permeables Para Infusión Asistida Por Vacío. Ingenius. Rev. Cienc. y Tecnol. 2020, 23, 62–73. [Google Scholar]

- Moustafa, H.; El Kissi, N.; Abou-Kandil, A.I.; Abdel-Aziz, M.S.; Dufresne, A. PLA/PBAT Bionanocomposites with Antimicrobial Natural Rosin for Green Packaging. ACS Appl. Mater. Interfaces 2017, 9, 20132–20141. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Ferri, J.M.; Dominici, F.; Boronat, T.; Sánchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- International Standards Organization. ISO 527-1:2012-Plastics—Determination of Tensile Properties—Part 1: General Principles; International Standards Organization: Geneva, Switzerland, 2012. [Google Scholar]

- International Standards Organization. ISO 527-2. Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; International Standards Organization: Geneva, Switzerland, 2012. [Google Scholar]

- Weatherall, I.L.; Coombs, B.D. Skin Color Measurements in Terms of CIELAB Color Space Values. J. Investig. Dermatol. 1992, 99, 468–473. [Google Scholar] [CrossRef] [Green Version]

- Elhamnia, M.; Motlagh, G.H. Predicting Droplet Size by Rheometry Analysis for PBAT/EVOH Blend. In Eco-friendly and Smart Polymer Systems; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2020; pp. 694–697. [Google Scholar]

- Dil, E.J.; Carreau, P.J.; Favis, B.D. Morphology, miscibility and continuity development in poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Polymers 2015, 68, 202–212. [Google Scholar] [CrossRef]

- De La Rosa-Ramírez, H.; Aldas, M.; Ferri, J.; López-Martínez, J.; Samper, M. Modification of poly (lactic acid) through the incorporation of gum rosin and gum rosin derivative: Mechanical performance and hydrophobicity. J. Appl. Polym. Sci. 2020, 137, e49346. [Google Scholar] [CrossRef]

- Aldas, M.; Rayón, E.; López-Martínez, J.; Arrieta, M.P. A Deeper Microscopic Study of the Interaction between Gum Rosin Derivatives and a Mater-Bi Type Bioplastic. Polymers 2020, 12, 226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Ai, X.; Pan, H.; Yang, J.; Gao, G.; Zhang, H.; Yang, H.; Dong, L. The morphological, mechanical, rheological, and thermal properties of PLA/PBAT blown films with chain extender. Polym. Adv. Technol. 2018, 29, 1706–1717. [Google Scholar] [CrossRef]

- Pan, H.; Ju, D.; Zhao, Y.; Wang, Z.; Yang, H.; Zhang, H.; Dong, L. Mechanical properties, hydrophobic properties and thermal stability of the biodegradable poly(butylene adipate-co-terephthalate)/maleated thermoplastic starch blown films. Fibers Polym. 2016, 17, 1540–1549. [Google Scholar] [CrossRef]

- Fresner, J.; Krenn, C. Theoretical minimum consumption calculation as starting point for cleaner production option identification as a new approach to benchmarking. J. Clean. Prod. 2018, 172, 1946–1956. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crop. Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Chang, R.; Rohindra, D.; Lata, R.; Kuboyama, K.; Ougizawa, T. Development of poly(ε-caprolactone)/pine resin blends: Study of thermal, mechanical, and antimicrobial properties. Polym. Eng. Sci. 2019, 59, E32–E41. [Google Scholar] [CrossRef]

- Zehetmeyer, G.; Meira, S.M.M.; Scheibel, J.M.; De Oliveira, R.V.B.; Brandelli, A.; Soares, R.M. Influence of melt processing on biodegradable nisin-PBAT films intended for active food packaging applications. J. Appl. Polym. Sci. 2015, 133, 43212. [Google Scholar] [CrossRef]

- Arrieta, M.P.; García, A.D.; Lopez, D.; Fiori, S.; Peponi, L. Antioxidant Bilayers Based on PHBV and Plasticized Electrospun PLA-PHB Fibers Encapsulating Catechin. Nanomaterials 2019, 9, 346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nayak, S.K. Biodegradable PBAT/Starch Nanocomposites. Polym. Technol. Eng. 2010, 49, 1406–1418. [Google Scholar] [CrossRef]

- Zhang, S.; He, Y.; Lin, Z.; Li, J.; Jiang, G. Effects of tartaric acid contents on phase homogeneity, morphology and properties of poly (butyleneadipate-co-terephthalate)/thermoplastic starch bio-composities. Polym. Test. 2019, 76, 385–395. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Hydrolytic degradation of biodegradable polyesters under simulated environmental conditions. J. Appl. Polym. Sci. 2015, 132, 42189. [Google Scholar] [CrossRef]

- Fourati, Y.; Tarrés, Q.; Mutjé, P.; Boufi, S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr. Polym. 2018, 199, 51–57. [Google Scholar] [CrossRef]

- Mohanty, S.N.; Nayak, S.K. Biodegradable Nanocomposites of Poly(butylene adipate-co-terephthalate) (PBAT) and Organically Modified Layered Silicates. J. Polym. Environ. 2012, 20, 195–207. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; López, J.; Jiménez, A. Combined Effect of Poly(hydroxybutyrate) and Plasticizers on Polylactic acid Properties for Film Intended for Food Packaging. J. Polym. Environ. 2014, 22, 460–470. [Google Scholar] [CrossRef]

- Hambleton, A.; Fabra, M.-J.; Debeaufort, F.; Dury-Brun, C.; Voilley, A. Interface and aroma barrier properties of iota-carrageenan emulsion–based films used for encapsulation of active food compounds. J. Food Eng. 2009, 93, 80–88. [Google Scholar] [CrossRef]

- Vogler, E.A. Structure and reactivity of water at biomaterial surfaces. Adv. Colloid Interface Sci. 1998, 74, 69–117. [Google Scholar] [CrossRef]

- Sifontes, Á.B.; Gutierrez, B.; Mónaco, A.; Yanez, A.; Díaz, Y.; Méndez, F.J.; Llovera, L.; Cañizales, E.; Brito, J.L. Preparation of functionalized porous nano-γ-Al2O3 powders employing colophony extract. Biotechnol. Rep. 2014, 4, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Garavand, F.; Cacciotti, I.; Vahedikia, N.; Rehman, A.; Tarhan, Ö.; Akbari-Alavijeh, S.; Shaddel, R.; Rashidinejad, A.; Nejatian, M.; Jafarzadeh, S.; et al. A comprehensive review on the nanocomposites loaded with chitosan nanoparticles for food packaging. Crit. Rev. Food Sci. Nutr. 2020, 1–34. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Magariño, S.; José, M.L.G.-S. Prediction of red and rosé wine CIELab parameters from simple absorbance measurements. J. Sci. Food Agric. 2002, 82, 1319–1324. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Peltzer, M.A.; López, J.; Garrigós, M.D.C.; Valente, A.J.; Jiménez, A. Functional properties of sodium and calcium caseinate antimicrobial active films containing carvacrol. J. Food Eng. 2014, 121, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Yadav, B.K.; Gidwani, B.; Vyas, A. Rosin: Recent advances and potential applications in novel drug delivery system. J. Bioact. Compat. Polym. 2015, 31, 111–126. [Google Scholar] [CrossRef]

- Cabaret, T.; Boulicaud, B.; Chatet, E.; Charrier, B. Study of rosin softening point through thermal treatment for a better understanding of maritime pine exudation. Holz als Roh- und Werkst. 2018, 76, 1453–1459. [Google Scholar] [CrossRef]

| DSC | TGA | DMA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Formulation | Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | T5% (°C) | Tmax1 (°C) | Tmax2 (°C) | Tg1 (°C) | Tg2 (°C) |

| PBAT | 78.0 | 15.23 | 120.3 | −23.41 | 356.7 | 408.8 | 530.8 | −26.0 | 68.0 |

| PBAT-5GR | 75.3 | 14.60 | 120.0 | −4.39 | 357.3 | 411.8 | 529.7 | −23.0 | 60.3 |

| PBAT-10GR | 75.7 | 14.24 | 117.3 | −7.93 | 367.6 | 412.9 | 552.4 | −20.4 | 67.3 |

| PBAT-15GR | 70.7 | 15.41 | 87.33 and 115.7 | −34.14 | 307.1 | 409.9 | 510.9 | −17.9 | 68.0 |

| PBAT-5UT | 69.0 | 14.92 | 119.0 | −7.60 | 364.7 | 413.7 | 527.6 | −22.1 | 60.3 |

| PBAT-10UT | 67.3 | 17.86 | 119.7 | −4.69 | 369.9 | 412.9 | 552.8 | −21.9 | 67.7 |

| PBAT-15UT | 64.1 | 15.50 | 119.0 | −6.46 | 371.4 | 412.8 | 558.9 | −24.5 | 67.8 |

| Formulation | L* | A* | B* | YI | ΔE |

|---|---|---|---|---|---|

| PBAT | 83.71 ± 0.7 a | −0.61 ± 0.20 a | 6.26 ± 0.49 a | 12.45 ± 1.07 a | - a |

| PBAT-5GR | 78.38 ± 0.3 b | 0.71 ± 0.28 b | 15.55 ± 0.58 b | 32.72 ± 1.25 b | 10.80 ± 0.45 b |

| PBAT-10GR | 76.78 ± 0.5 c | 1.26 ± 0.29 c | 20.85 ± 0.65 c | 43.39 ± 1.41 c | 16.27 ± 0.69 c |

| PBAT-15GR | 72.35 ± 0.7 d | 1.74 ± 0.14 d | 25.58 ± 0.29 d | 54.00 ± 0.68 d | 22.55 ± 0.49 d |

| PBAT-5UT | 81.28 ± 0.5 e | −0.70 ± 0.16 a | 9.15 ± 0.24 e | 18.50 ± 0.44 e | 3.82 ± 0.23 e |

| PBAT-10UT | 80.17 ± 0.5 f | −0.58 ± 0.17 a | 11.75 ± 0.42 f | 23.89 ± 0.90 f | 6.56 ± 0.33 f |

| PBAT-15UT | 78.81 ± 0.5 b | −0.74 ± 0.10 a | 12.21 ± 0.29 f | 24.97 ± 0.53 f | 7.73 ± 0.25 g |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavon, C.; Aldas, M.; Rosa-Ramírez, H.d.l.; López-Martínez, J.; Arrieta, M.P. Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity. Polymers 2020, 12, 2891. https://doi.org/10.3390/polym12122891

Pavon C, Aldas M, Rosa-Ramírez Hdl, López-Martínez J, Arrieta MP. Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity. Polymers. 2020; 12(12):2891. https://doi.org/10.3390/polym12122891

Chicago/Turabian StylePavon, Cristina, Miguel Aldas, Harrison de la Rosa-Ramírez, Juan López-Martínez, and Marina P. Arrieta. 2020. "Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity" Polymers 12, no. 12: 2891. https://doi.org/10.3390/polym12122891

APA StylePavon, C., Aldas, M., Rosa-Ramírez, H. d. l., López-Martínez, J., & Arrieta, M. P. (2020). Improvement of PBAT Processability and Mechanical Performance by Blending with Pine Resin Derivatives for Injection Moulding Rigid Packaging with Enhanced Hydrophobicity. Polymers, 12(12), 2891. https://doi.org/10.3390/polym12122891